Optimized Aluminum Reflector for Enhancement of UVC Cathodoluminescence Based-AlGaN Materials with Carbon Nanotube Field Emitters

Abstract

:1. Introduction

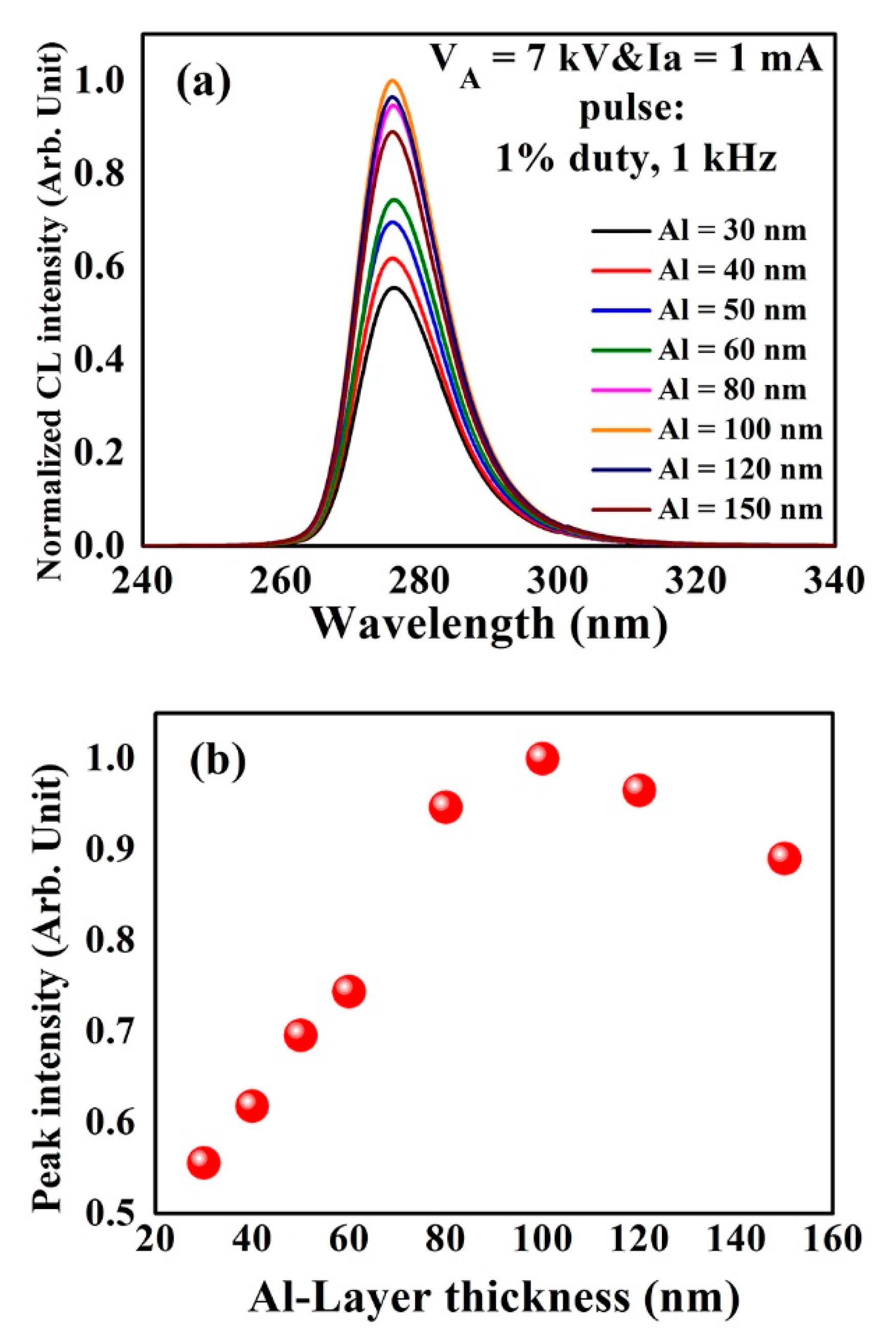

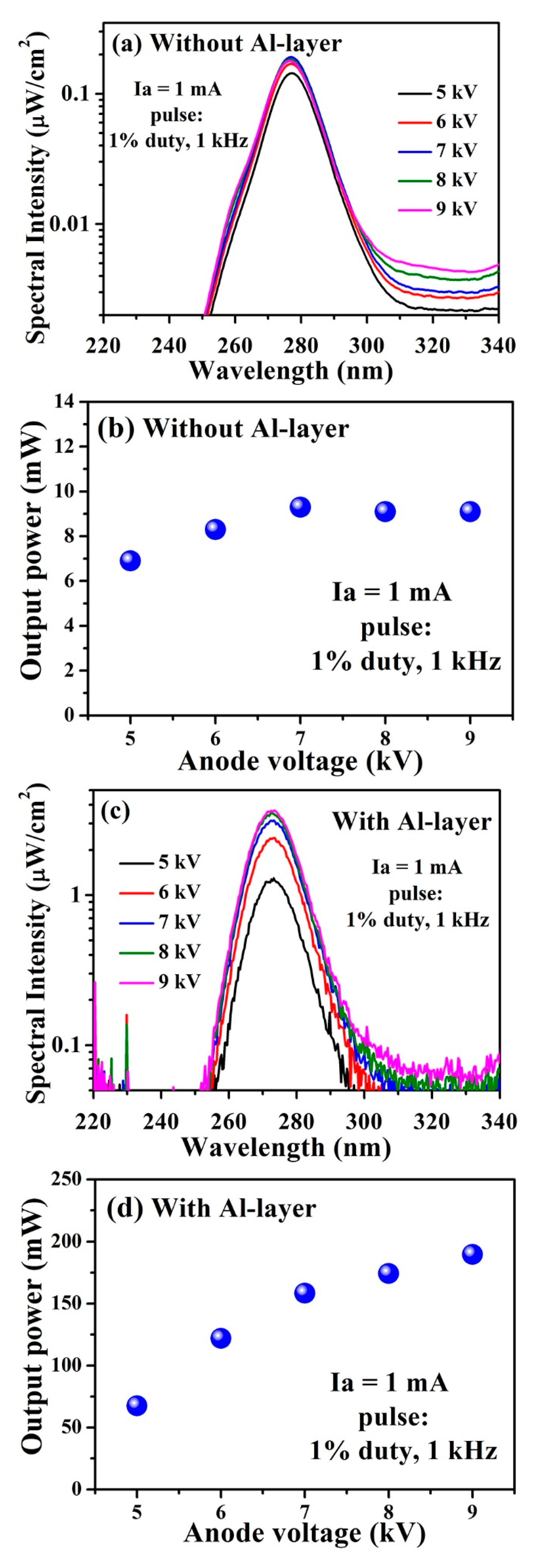

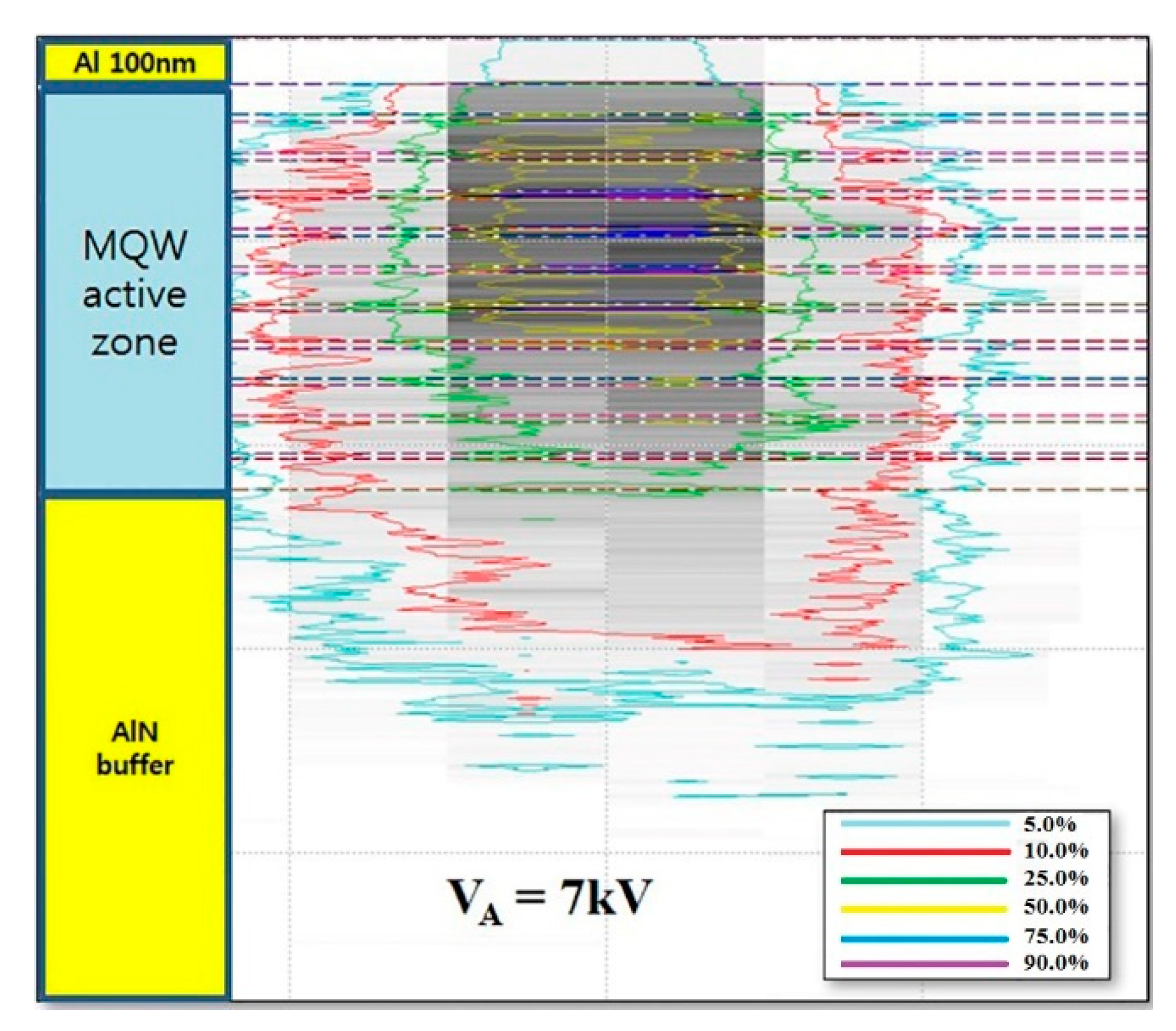

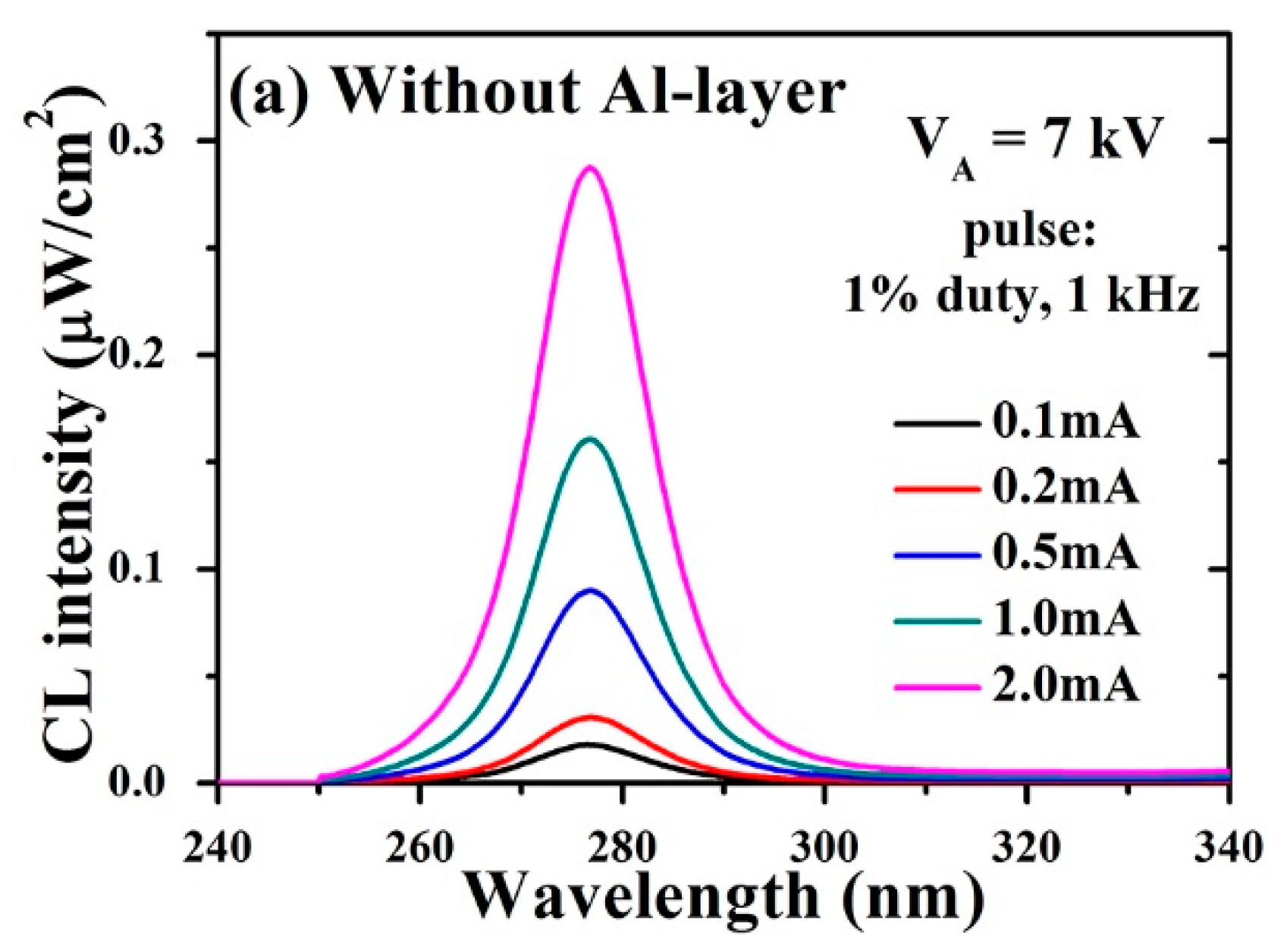

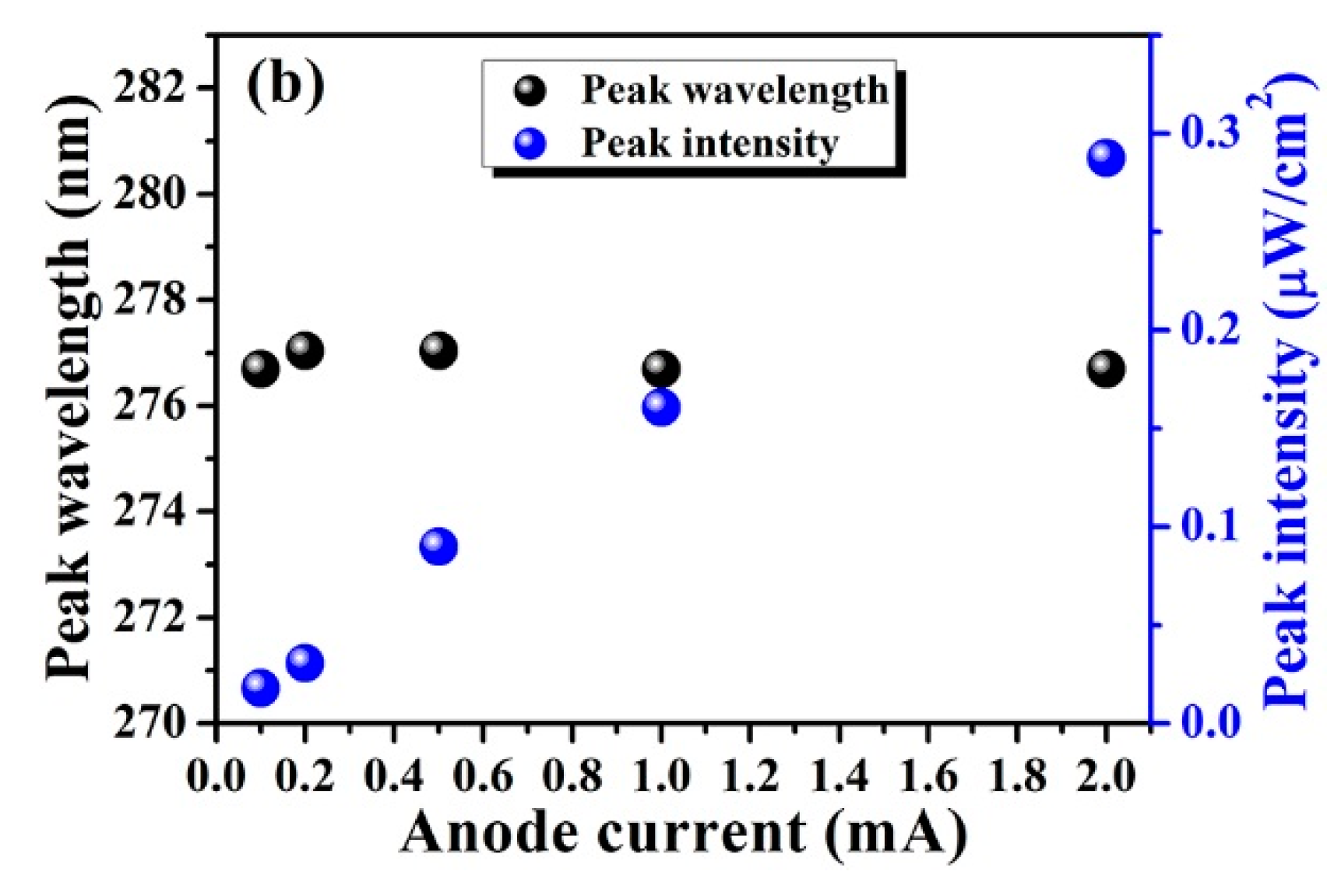

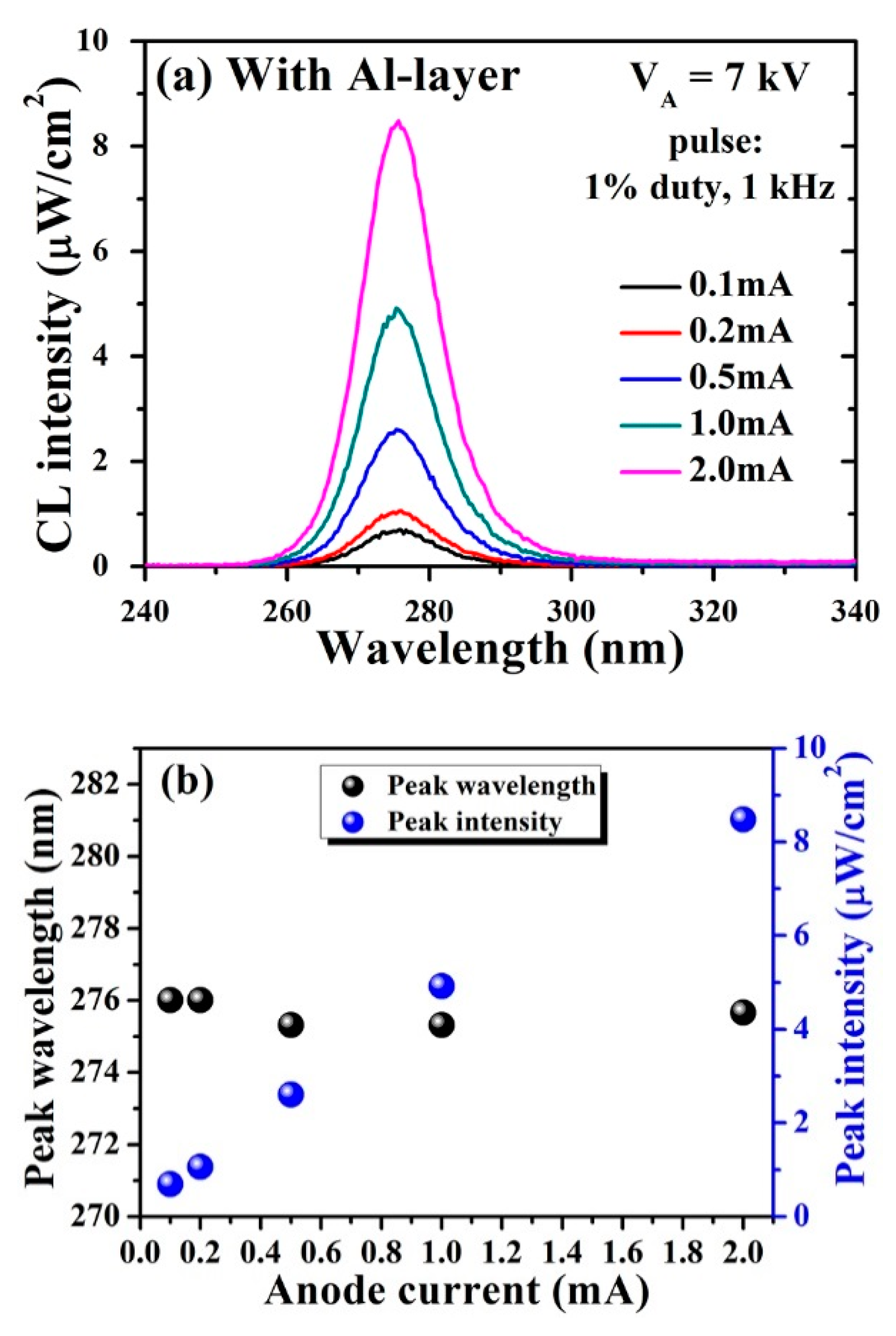

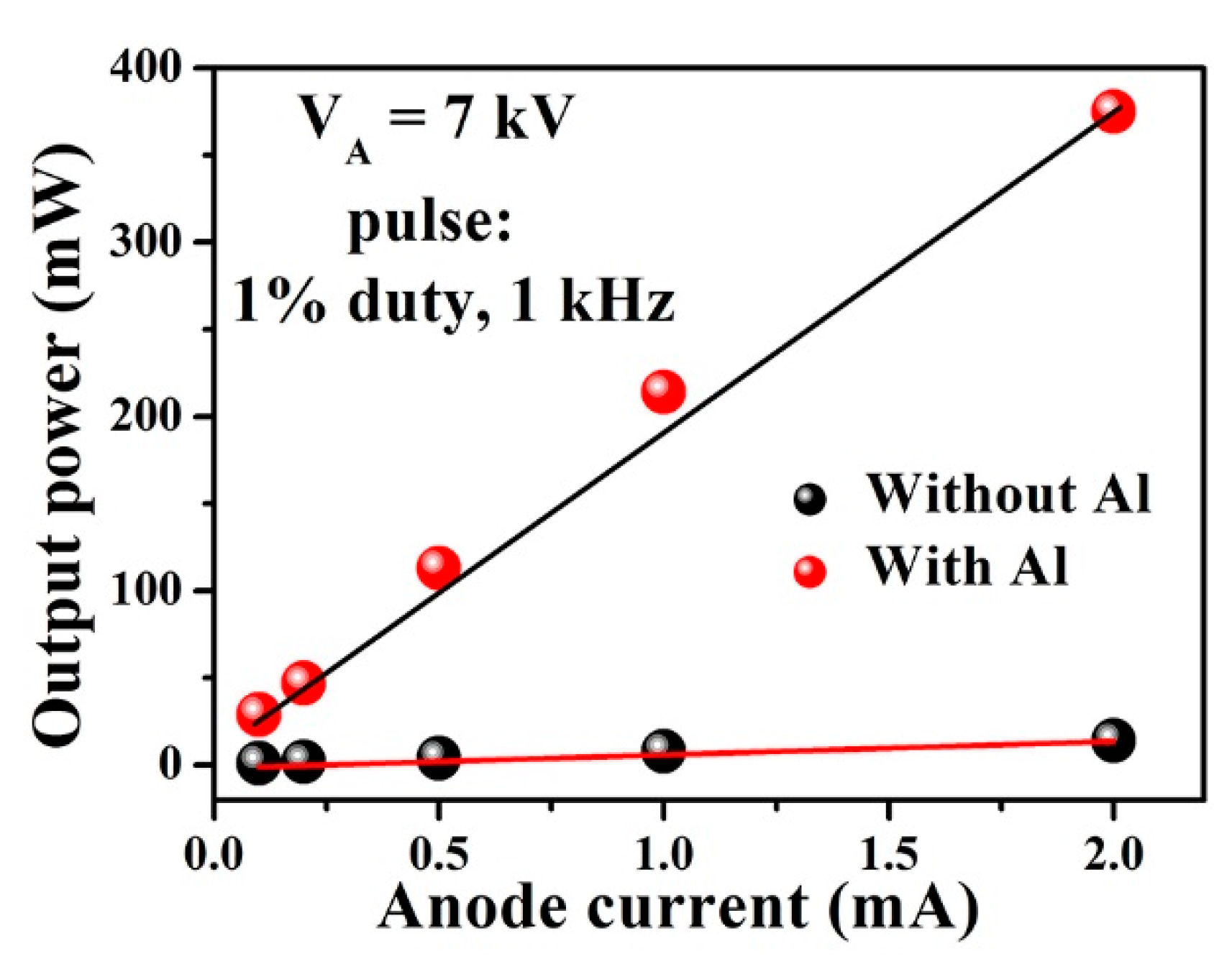

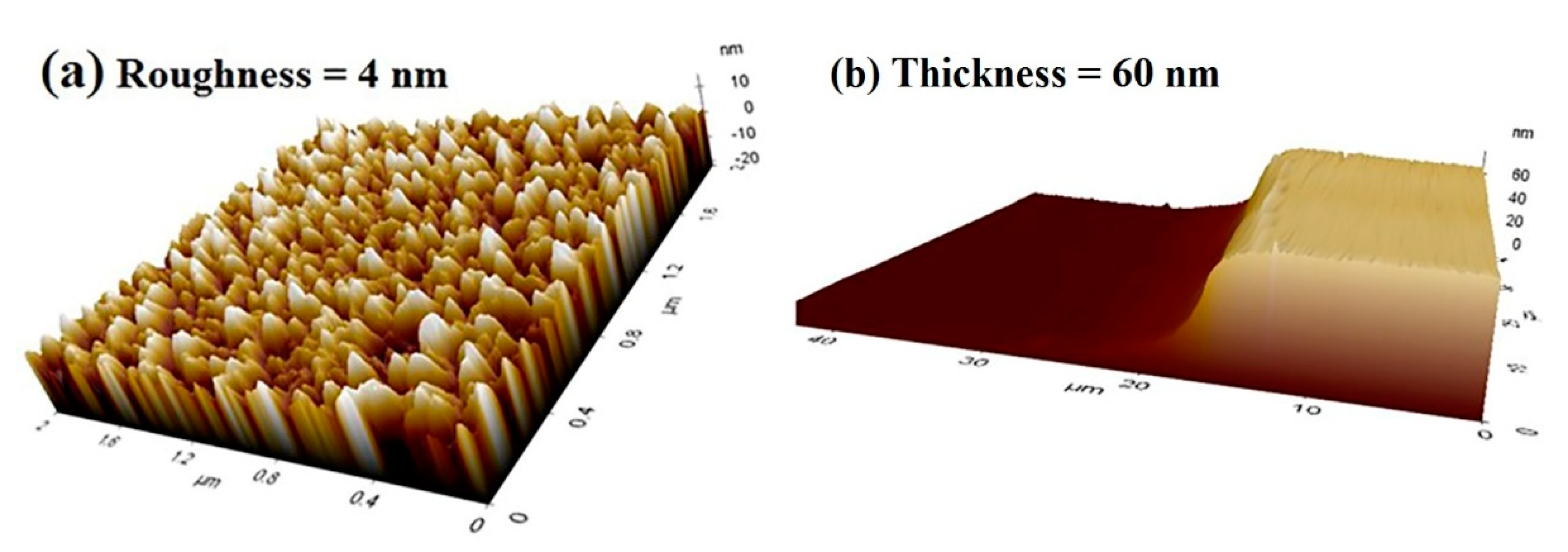

2. Results and Discussion

3. Materials and Methods

3.1. AlGaN Heterostructure Fabrication

3.2. Carbon Nanotubes Emitter Preparation

3.3. Design of the UVC–CNTs Device and CL Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Shatalov, M.; Yang, J.; Sun, W.; Kennedy, R.; Gaska, R.; Liu, K.; Shur, M.; Tamulaitis, G. Efficiency of light emission in high aluminum content AlGaN quantum wells. J. Appl. Phys. 2009, 105, 073103. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Moustakas, T.D.; Zhou, L.; Smith, D.J.; Hug, W. Deep ultraviolet emitting AlGaN quantum wells with high internal quantum efficiency. Appl. Phys. Lett. 2009, 94, 181907. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Nam, B.; Nakarmi, M.L.; Lin, J.Y.; Jiang, H.X. Band structure and fundamental optical transitions in wurtzite AlN. Appl. Phys. Lett. 2003, 83, 5163–5165. [Google Scholar] [CrossRef] [Green Version]

- Feneberg, M.; Romero, M.F.; Röppischer, M.; Cobet, C.; Esser, N.; Neuschl, B.; Thonke, K.; Bickermann, M.; Goldhahn, R. Anisotropic absorption and emission of bulk (1–100) AlN. Phys. Rev. B 2013, 87, 235209. [Google Scholar] [CrossRef] [Green Version]

- Banal, R.G.; Funato, M.; Kawakami, Y. Optical anisotropy in [0001]-oriented AlxGa1–xN/AlN quantum wells (x > 0.69). Phys. Rev. B 2009, 79, 121308. [Google Scholar] [CrossRef] [Green Version]

- Hirayama, H.; Fujikawa, S.; Noguchi, N.; Norimatsu, J.; Takano, T.; Tsubaki, K.; Kamata, N. 222–282 nm AlGaN and InAlGaN-based deep-UV LEDs fabricated on high-quality AlN on sapphire. Phys. Status Solidi A 2009, 206, 1176–1182. [Google Scholar] [CrossRef]

- Yoo, S.T.; Park, K.C. Sapphire Wafer for 226 nm Far UVC Generation with Carbon Nanotube-Based Cold Cathode Electron Beam (C-Beam) Irradiation. ACS Omega 2020, 5, 15601–15605. [Google Scholar] [CrossRef]

- Nakarmi, M.L.; Nepal, N.; Ugolini, C.; Altahtamouni, T.M.; Lin, J.Y.; Jiang, H.X. Correlation between optical and electrical properties of Mg-doped AlN epilayers. Appl. Phys. Lett. 2006, 89, 152120. [Google Scholar] [CrossRef]

- Banal, R.G.; Funato, M.; Kawakami, Y. Characteristic of high Al-content AlGaN/AlN quantum wells fabricated by modified migration enhanced epitaxy. Phys. Status Solidi C 2010, 7, 2111–2114. [Google Scholar] [CrossRef]

- Hirayama, H.; Tsukada, Y.; Maeda, T.; Kamata, N. Marked enhancement in the efficiency of deep-ultraviolet AlGaN light-emitting diodes by using a multi quantum-barrier electron blocking layer. Appl. Phys. Express 2010, 3, 031002. [Google Scholar] [CrossRef]

- Tawfik, W.Z.; Cho, S.O.; Ha, J.-S.; Ryu, S.-W.; Lee, J.K. Efficient Electrochemical Potentiostatic Activation Method for GaN-based Green Vertical-LEDs. ECS J. Solid State Sci. Technol. 2018, 7, Q47–Q51. [Google Scholar] [CrossRef]

- Lee, J.K.; Hyeon, G.Y.; Tawfik, W.Z.; Choi, H.S.; Ryu, S.-W.; Jeong, T.; Jung, E.; Kim, H. Electrochemical Removal of Hydrogen Atoms in Mg-doped GaN epitaxial layers. J. Appl. Phys. 2015, 117, 185702. [Google Scholar] [CrossRef]

- Taniyasu, Y.; Kasu, M.; Makimoto, T. An aluminium nitride light-emitting diode with a wavelength of 210 nanometres. Nature 2006, 441, 325–328. [Google Scholar] [CrossRef]

- Choi, H.S.; Kim, H.J.; Lee, J.J.; Seo, H.W.; Tawfik, W.Z.; Ha, J.-S.; Ryu, S.-W.; Jun, S.R.; Jeong, T.; Lee, J.K. Electrochemical Potentiostatic Activation for Improvement of Internal Quantum Efficiency of 385-nm Ultraviolet Light-Emitting Diodes. J. Appl. Surf. Sci. 2013, 283, 521–524. [Google Scholar] [CrossRef]

- Jo, M.S.; Seo, H.W.; Tawfik, W.Z.; Yang, S.B.; Lee, J.J.; Jeong, T.; Jeon, S.R.; Kim, J.Y.; Cui, H.; Park, S.H.; et al. Nano-Scale SiO2 Patterned n-Type GaN Substrate for 380nm Ultra Violet Light Emitting Diodes. J. Nanosci. Nanotechnol. 2014, 14, 6108–6111. [Google Scholar] [CrossRef]

- Tawfik, W.Z.; Bea, S.-J.; Jeong, T.; Lee, J.K. Effect of Residual Compressive Stress on Near-Ultraviolet InGaN/GaN Multi-Quantum Well Light-Emitting Diodes. J. Opt. Mater. 2014, 38, 131–136. [Google Scholar] [CrossRef]

- Tawfik, W.Z.; Hyeon, G.Y.; Lee, J.K. Stress-Induced Piezoelectric Field in GaN-based 450-nm Light-Emitting Diodes. J. Appl. Phys. 2014, 116, 164503. [Google Scholar] [CrossRef]

- Ryu, H.Y.; Choi, I.G.; Choi, H.S.; Shim, J.I. Investigation of Light Extraction Efficiency in AlGaN Deep-Ultraviolet Light-Emitting Diodes. Appl. Phys. Express 2013, 6, 062101. [Google Scholar] [CrossRef]

- Bao, X.; Sun, P.; Liu, S.; Ye, C.; Li, S.; Kang, J. Performance Improvements for AlGaN-Based Deep Ultraviolet Light-Emitting Diodes With the p-Type and Thickened Last Quantum Barrier. IEEE Photonics J. 2015, 7, 1400110. [Google Scholar] [CrossRef]

- Tabataba-Vakili, F.; Wunderer, T.; Kneissl, M.; Yang, Z.; Teepe, M.; Batres, M.; Feneberg, M.; Vancil, B.; Johnson, N.M. Dominance of radiative recombination from electron-beam-pumped deep-UV AlGaN multi-quantum-well heterostructures. Appl. Phys. Lett. 2016, 109, 181105. [Google Scholar] [CrossRef]

- Oto, T.; Banal, R.G.; Kataoka, K.; Funato, M.; Kawakami, Y. 100 mW deep-ultraviolet emission from aluminium-nitride-based quantum wells pumped by an electron beam. Nat. Photonics 2010, 4, 767–770. [Google Scholar] [CrossRef]

- Matsumoto, T.; Iwayama, S.; Saito, T.; Kawakami, Y.; Kubo, F.; Amano, H. Handheld deep ultraviolet emission device based on aluminum nitride quantum wells and graphene nanoneedle field emitters. Opt. Express 2012, 20, 24320–24329. [Google Scholar] [CrossRef] [PubMed]

- Ivanov, S.V.; Jmerik, V.N.; Nechaev, D.V.; Kozlovsky, V.I.; Tiberi, M.D. E-beam pumped mid-UV sources based on MBE-grown AlGaN MQW. Phys. Stat. Sol. A 2015, 212, 1011–1016. [Google Scholar] [CrossRef]

- Rong, X.; Wang, X.Q.; Ivanov, S.V.; Jiang, X.H.; Chen, G.; Wang, P.; Wang, W.Y.; He, C.G.; Wang, T.; Schulz, T.; et al. High-Output-Power Ultraviolet Light Source from Quasi–2D GaN Quantum Structure. Adv. Mater. 2016, 28, 7978–7983. [Google Scholar] [CrossRef] [PubMed]

- Jmerik, V.N.; Nechaev, D.V.; Toropov, A.A.; Evropeitsev, E.A.; Kozlovsky, V.I.; Martovitsky, V.P.; Rouvimov, S.; Ivanov, S.V. High-efficiency electron-beam-pumped sub-240-nm ultraviolet emitters based on ultra-thin GaN/AlN multiple quantum wells grown by plasma-assisted molecular-beam epitaxy on c-Al2O3. Appl. Phys. Express 2018, 11, 091003. [Google Scholar] [CrossRef]

- Tawfik, W.Z.; Kumar, C.M.M.; Park, J.; Shim, S.K.; Lee, H.; Lee, J.; Han, J.H.; Ryu, S.-W.; Lee, N.; Lee, J.K. Cathodoluminescence of a 2 inch ultraviolet-light-source tube based on the integration of AlGaN materials and carbon nanotube field emitters. J. Mater. Chem. C 2019, 7, 11540–11548. [Google Scholar] [CrossRef]

- Giubileo, F.; Bartolomeo, A.D.; Iemmo, L.; Luongo, G.; Urban, F. Field Emission from Carbon Nanostructures. Appl. Sci. 2018, 8, 526. [Google Scholar] [CrossRef] [Green Version]

- Lobo, N.; Rodriguez, H.; Knauer, A.; Hoppe, M.; Einfeldt, S.; Vogt, P.; Weyers, M.; Kneissl, M. Enhancement of light extraction in ultraviolet light-emitting diodes using nanopixel contact design with Al reflector. Appl. Phys. Lett. 2010, 96, 081109. [Google Scholar] [CrossRef]

- Liu, X.; Mou, Y.; Wang, H.; Liang, R.; Wang, X.; Peng, Y.; Chen, M. Enhanced light extraction of deep ultraviolet light-emitting diodes by using optimized aluminum reflector. Appl. Opt. 2018, 57, 7325. [Google Scholar] [CrossRef]

- Shim, S.K.; Tawfik, W.Z.; Kumar, C.M.M.; Liu, S.; Wang, X.; Lee, N.; Lee, J.K. Nanopatterned Sapphire Substrate to enhance the efficiency of AlGaN-based UVC Light Source Tube with CNTs electron-beam. J. Mater. Chem. C 2020, 8, 17336–17341. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohan, M.K.C.; Shim, S.K.; Lee, J.K.; Jang, N.; Lee, N.; Tawfik, W.Z. Optimized Aluminum Reflector for Enhancement of UVC Cathodoluminescence Based-AlGaN Materials with Carbon Nanotube Field Emitters. Molecules 2021, 26, 4025. https://doi.org/10.3390/molecules26134025

Mohan MKC, Shim SK, Lee JK, Jang N, Lee N, Tawfik WZ. Optimized Aluminum Reflector for Enhancement of UVC Cathodoluminescence Based-AlGaN Materials with Carbon Nanotube Field Emitters. Molecules. 2021; 26(13):4025. https://doi.org/10.3390/molecules26134025

Chicago/Turabian StyleMohan, Manoj Kumar Chandra, Sang Kyun Shim, June Key Lee, Nakwon Jang, Naesung Lee, and Wael Z. Tawfik. 2021. "Optimized Aluminum Reflector for Enhancement of UVC Cathodoluminescence Based-AlGaN Materials with Carbon Nanotube Field Emitters" Molecules 26, no. 13: 4025. https://doi.org/10.3390/molecules26134025

APA StyleMohan, M. K. C., Shim, S. K., Lee, J. K., Jang, N., Lee, N., & Tawfik, W. Z. (2021). Optimized Aluminum Reflector for Enhancement of UVC Cathodoluminescence Based-AlGaN Materials with Carbon Nanotube Field Emitters. Molecules, 26(13), 4025. https://doi.org/10.3390/molecules26134025