Optimization of the Production Factors of Boards Obtained from Arundo donax L. Fibers without Added Adhesives

Abstract

1. Introduction

2. Results and Discussion

2.1. Series 11 and 21: Comparison of Production Process with and without Final Heat Treatment (FHT)

2.2. Press Time Reduction (Series 22).

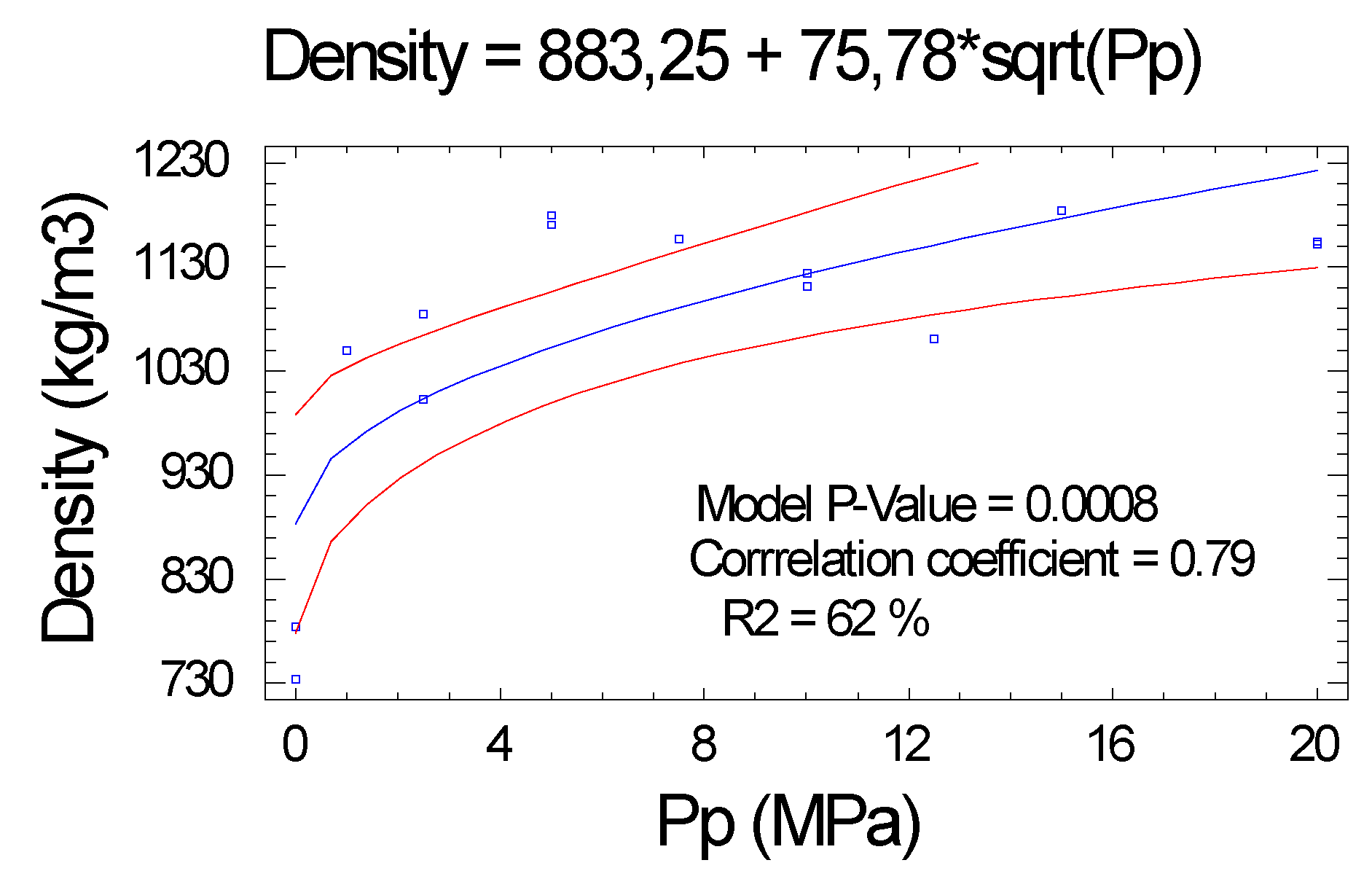

2.2.1. Density

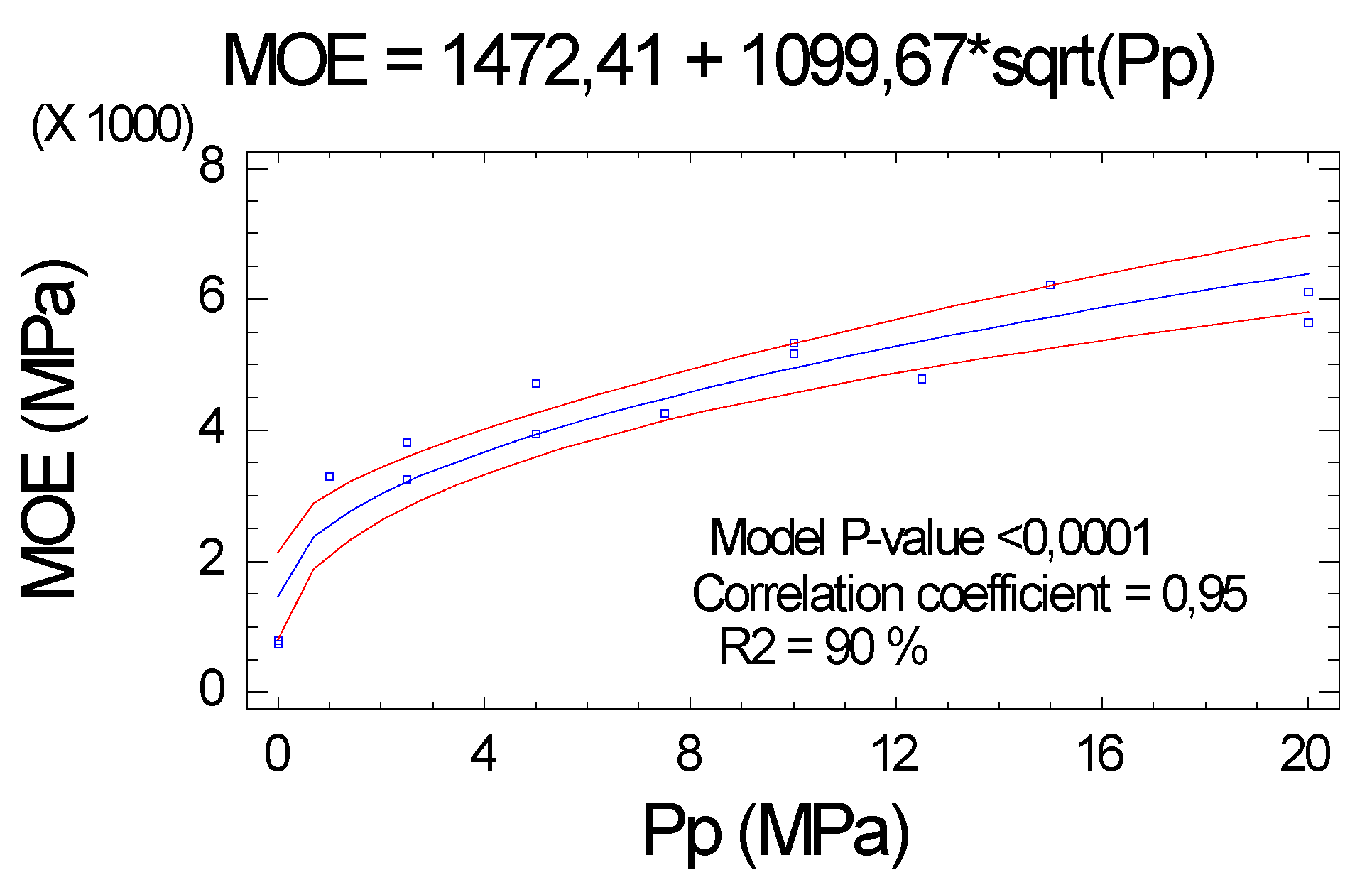

2.2.2. Modulus of Elasticity (MOE)

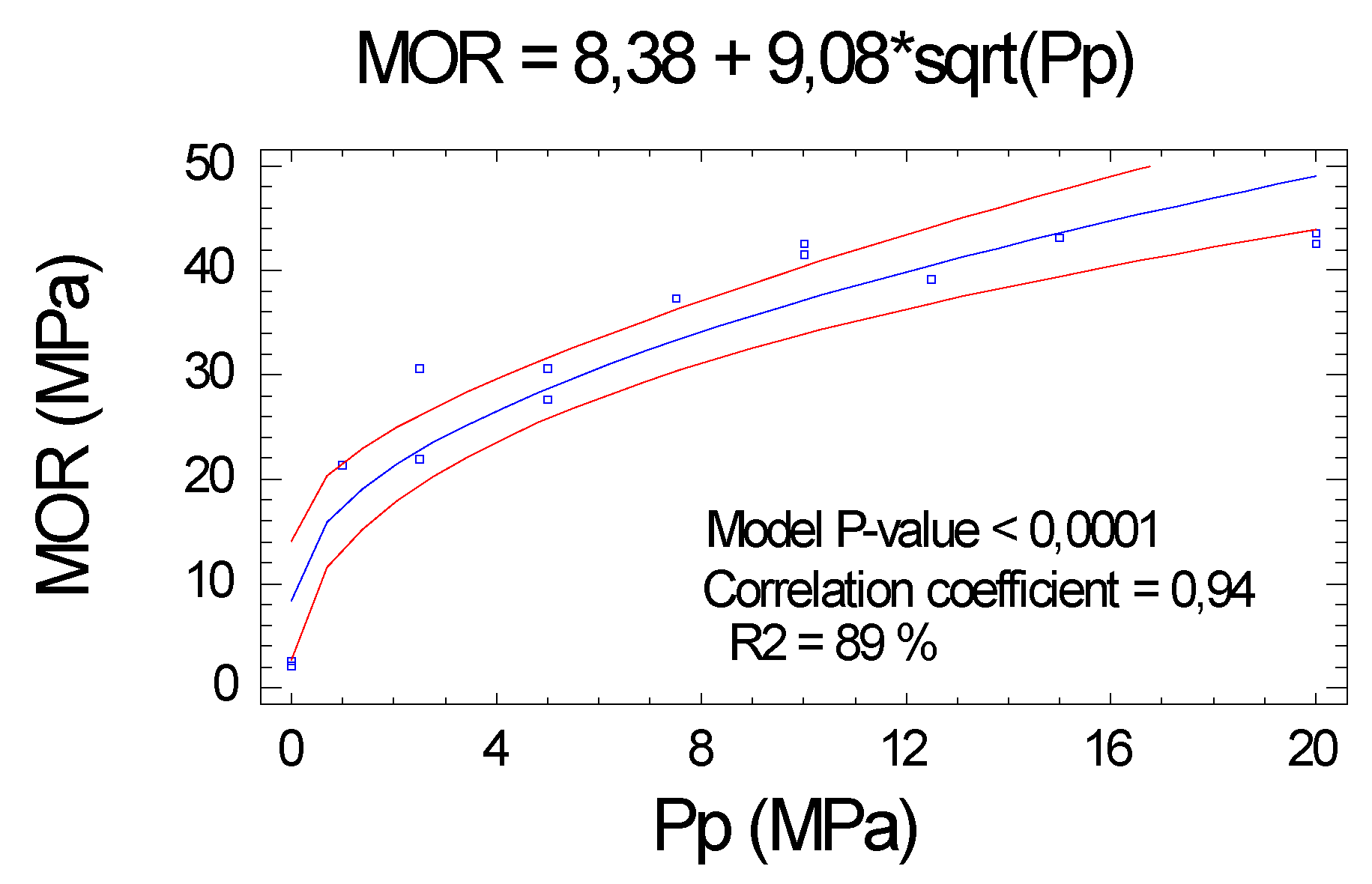

2.2.3. Modulus of Rupture (MOR)

2.2.4. Internal Bond (IB)

2.2.5. Thickness Swelling (TS)

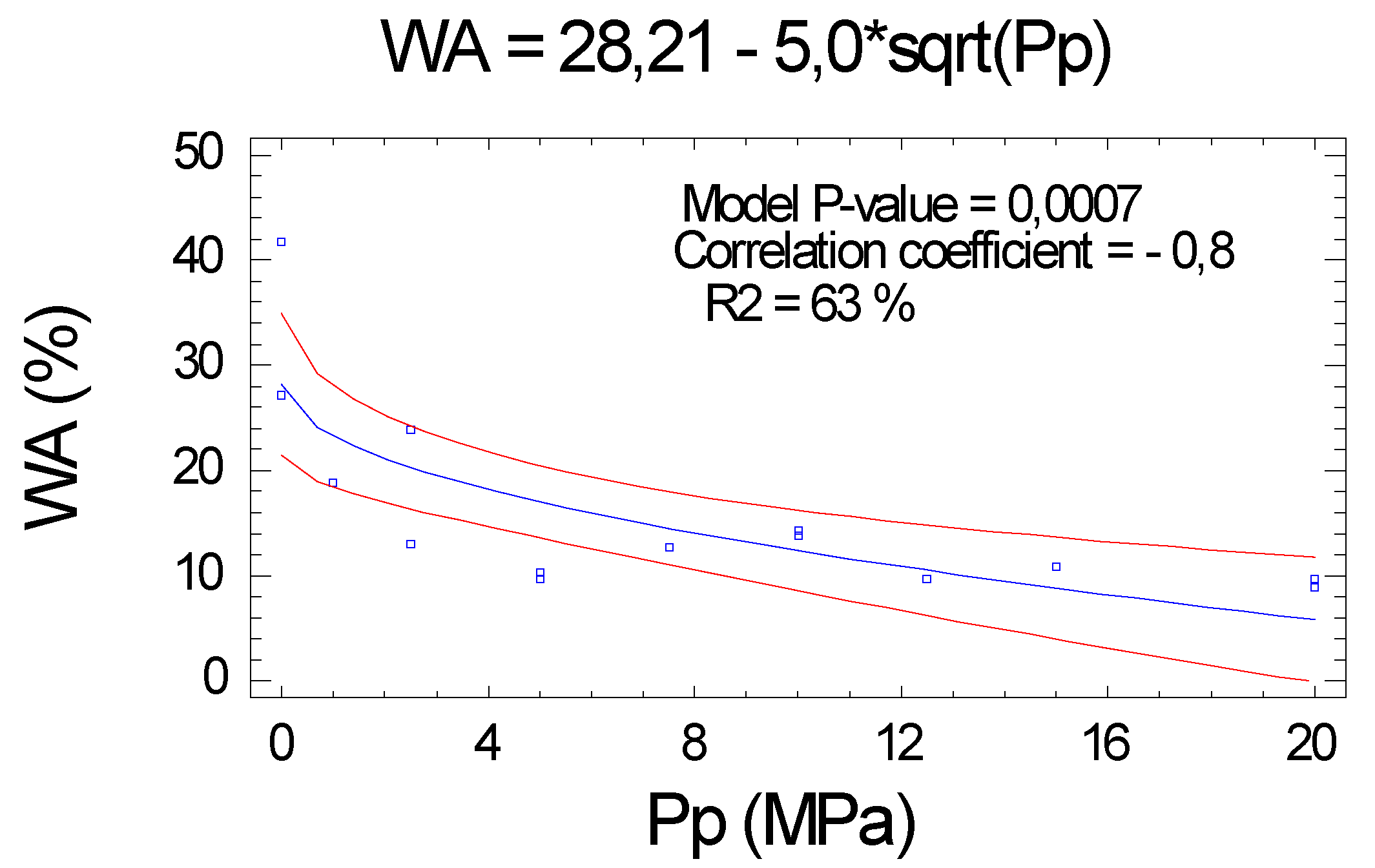

2.2.6. Water Absorption (WA)

2.3. Complementary Analyses: Comparison of Series 11 and 22 Boards and Series 21 and 22 Boards

2.3.1. Comparison between Series 11 and 22

2.3.2. Comparison between series 21 and 22.

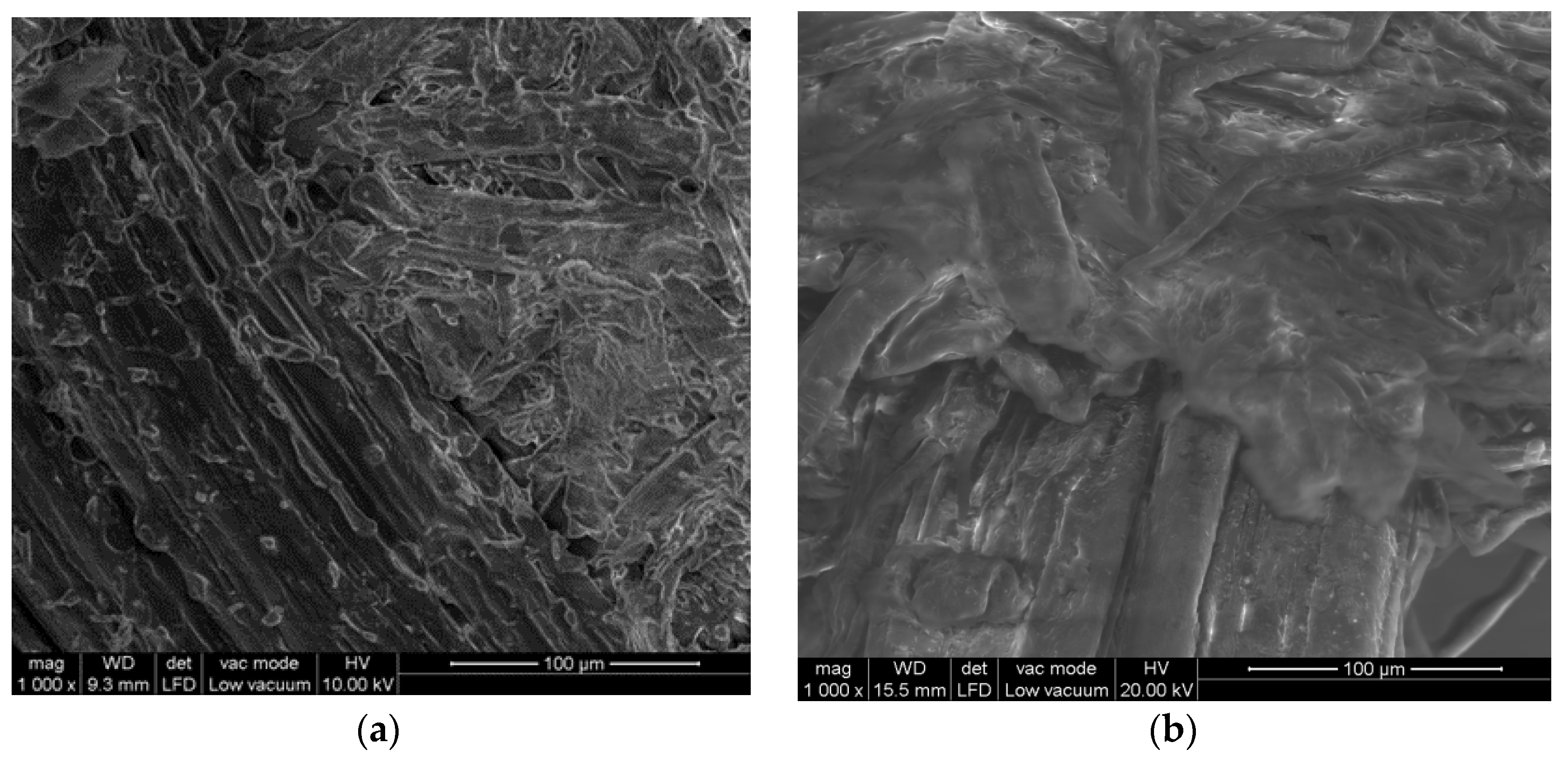

2.3.3. Microscopic Study of Boards made with Arundo donax L. L.

3. Materials and Methods

3.1. Materials

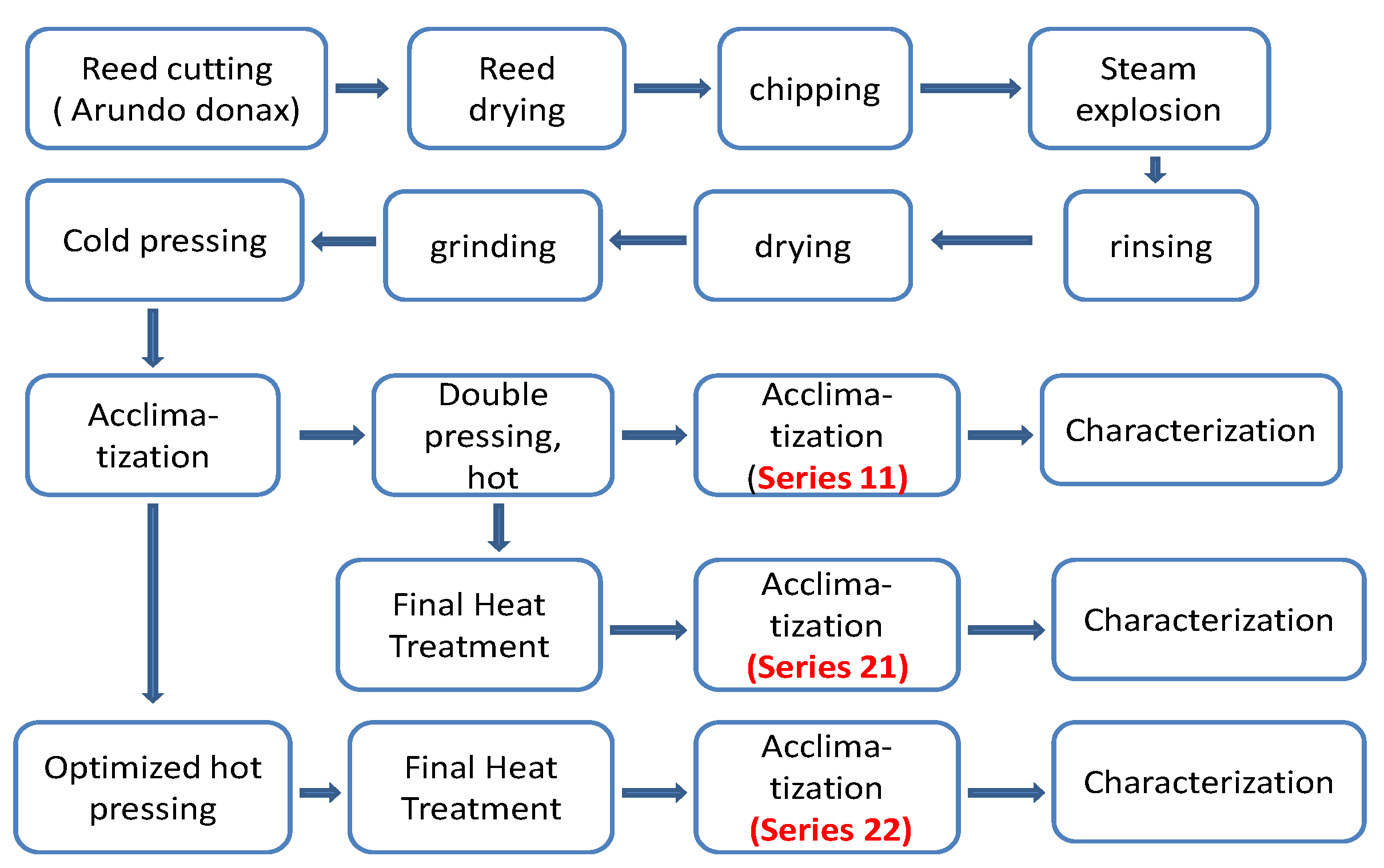

3.2. Panel Production Process

- Series 11: double hot pressing (see details below) and no final heat treatment.

- Series 21: double hot pressing with final heat treatment.

- Series 22: optimized hot pressing (see details below) with final heat treatment.

3.2.1. Steam Explosion (STEX)

3.2.2. Washing, Drying, and Grinding of Pretreated Material

3.2.3. Cold Pressing and Stabilization at Constant Temperature (T) and Relative Humidity (RH)

3.2.4. Hot Pressing

3.2.5. Final Heat Treatment (FHT)

3.3. Experimental Design

3.4. Characterization of the Boards

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| FHT | Final Heat Treatment |

| IB | Internal Bond, MPa |

| MOE | Modulus of Elasticity, MPa |

| MOR | Modulus of Rupture, MPa |

| Pp | Pressing Pressure, MPa |

| STEX | Steam Explosion |

| tp | Pressing Time, min |

| Tp | Pressing Temperature, °C |

| t_r | Pretreatment (Steam Explosion) Time, min |

| Tr | Pretreatment (Steam Explosion) Temperature, °C |

| TS | Thickness Swelling, % |

| WA | Water Absorption, % |

References

- Ramos, D.; Salvadó, J.; Fernando, F. High Mechanical Performance Boards Made from Fibers of Arundo donax L. without Added Adhesives. Bioresources 2017, 12, 5383–5394. [Google Scholar] [CrossRef]

- Monti, A.; Zegada-Lizarazu, W. Sixteen-Year Biomass Yield and Soil Carbon Storage of Giant Reed (Arundo donax L.) Grown Under Variable Nitrogen Fertilization Rates. BioEnergy Res. 2015, 9, 248–256. [Google Scholar] [CrossRef]

- Maceda-Veiga, A.; Basas, H.; de Sostoa, A.; Serra, A. Impacts of the invader giant reed (Arundo donax L.) on riparian habitats and ground arthopod communities. Biol. Invasions 2016, 18, 731–749. [Google Scholar] [CrossRef]

- Brundu, G. Plant invaders in European and Mediterranean inland waters: profiles, distribution, and threats. Hydrobiology 2014, 746, 61–79. [Google Scholar] [CrossRef]

- Fagnano, M.; Impagliazzo, A.; Mori, M.; Fiorentino, N. Agronomic and Environmental Impacts of Giant Reed (Arundo donax L.): Results from a Long-Term Field Experiment in Hilly Areas Subject to Soil Erosion. BioEnergy Res. 2014, 8, 415–422. [Google Scholar] [CrossRef]

- Fernando, A.L.; Boléo, S.; Barbosa, B.; Costa, J.; Duarte, M.; Monti, A. Perennial Grass Production Opportunities on Marginal Mediterranean Land. BioEnergy Res. 2015, 8, 1523–1537. [Google Scholar] [CrossRef]

- Monti, A.; Cosentino, S.L. Conclusive Results of the European Project OPTIMA: Optimization of Perennial Grasses for Biomass Production in the Mediterranean Area. BioEnergy Res. 2015, 8, 1459–1460. [Google Scholar] [CrossRef]

- Sanchez, E.; Scordia, D.; Lino, G.; Arias, C.; Cosentino, S.L.; Nogues, S. Salinity and Water Stress Effects on Biomass Production in Different Arundo donax L. Clones. BioEnergy Res. 2015, 8, 1461–1479. [Google Scholar] [CrossRef]

- Ceotto, E.; Castelli, F.; Moschella, A.; Diozzi, M.; Di Candilo, M. Cattle Slurry Fertilization to Giant Reed (Arundo donax L.): Biomass Yield and Nitrogen Use Efficiency. BioEnergy Res. 2015, 8, 1252–1262. [Google Scholar] [CrossRef]

- Soldatos, P. Economic Aspects of Bioenergy Production from Perennial Grasses in Marginal Lands of South Europe. BioEnergy Res. 2015, 8, 1562–1573. [Google Scholar] [CrossRef]

- Moya, R.; Rodríguez-Zúñiga, A.; Tenorio, C.; Valdez, J.; Valaert, J. Pellets Evaluation Made from Tropical-Climate Agricultural and Forestry Crops of Costa Rica with a Domestic Stove. Waste Biomass Valorizat. 2015, 6, 1037–1046. [Google Scholar] [CrossRef]

- El-Ramady, H.R.; Abdalla, N.; Alshaal, T.; El-Henawy, A.; Shams, M.S.; Faizy, S.E.-D.A.; Belal, E.-S.B.; Shehata, S.; Ragab, M.I.; Amer, M.M.; et al. Giant reed for selenium phytoremediation under changing climate. Environ. Chem. Lett. 2015, 13, 359–380. [Google Scholar] [CrossRef]

- Elhawat, N.; Alshaal, T.; Domokos-Szabolcsy, É.; El-Ramady, H.; Márton, L.; Czakó, M.; Kátai, J.; Balogh, P.; Sztrik, A.; Molnar, M.; et al. Phytoaccumulation potentials of two biotechnologically propagated ecotypes of Arundo donax in copper-contaminated synthetic wastewater. Environ. Sci. Pollut. Res. 2014, 21, 7773–7780. [Google Scholar] [CrossRef]

- Fedenko, J.R.; Erickson, J.E.; Woodard, K.R.; Sollenberger, L.E.; Vendramini, J.M.B.; Gilbert, R.A.; Helsel, Z.R.; Peter, G.F. Biomass Production and Composition of Perennial Grasses Grown for Bioenergy in a Subtropical Climate Across Florida, USA. BioEnergy Res. 2013, 6, 1082–1093. [Google Scholar] [CrossRef]

- Flores, J.; Pastor, J.; Gabarrón, A.M.; Blanes, F.J.G.; Rodríguez-Guisado, I.; Frutos, M. Arundo donax chipboard based on urea-formaldehyde resin using under 4mm particles size meets the standard criteria for indoor use. Ind. Crop. Prod. 2011, 34, 1538–1542. [Google Scholar] [CrossRef]

- Flores, J.; Pastor-Perez, J.-J.; Blanes, F.J.G.; Rodriguez-Guisado, I.; Frutos-Fernandez, M.-J. Full recovery of Arundo donax particleboard from swelling test without waterproofing additives. Bioresources 2012, 7, 5222–5235. [Google Scholar] [CrossRef]

- García-Ortuño, T.; Andréu-García, J.; Ferrández-García, M.; Ferrández-Villena, M.; Ferrandez-García, C. Evaluation of the physical and mechanical properties of particleboard made from giant reed (Arundo donax L.). BioResources 2011, 6, 477–486. [Google Scholar]

- Ramos, D. Producción de Tableros de fibras sin adición de adhesivos a partir de Arundo donax L. y bagazo de Saccharum Officinarum. Ph.D. Thesis, Rovira i Virgili University, Tarragona, Spain, 2012. [Google Scholar]

- Ramos, D.; El Mansouri, N.-E.; Ferrando, F.; Salvadó, J. All-lignocellulosic Fiberboard from Steam Exploded Arundo Donax L. Molecules 2018, 23, 2088. [Google Scholar] [CrossRef]

- Bernardini, J.; Licursi, D.; Anguillesi, I.; Cinelli, P.; Coltelli, M.-B.; Antonetti, C.; Galletti, A.M.R.; Lazzeri, A. Exploitation of Arundo donax L. Hydrolysis Residue for the Green Synthesis of Flexible Polyurethane Foams. Bioresources 2017, 12, 3630–3655. [Google Scholar] [CrossRef]

- Ventorino, V.; Robertiello, A.; Viscardi, S.; Ambrosanio, A.; Faraco, V.; Pepe, O. Bio-based Chemical Production from Arundo donax Feedstock Fermentation using Cosenzaea myxofaciens BPM1. Bioresources 2016, 11, 6566–6581. [Google Scholar] [CrossRef][Green Version]

- Aliberti, A.; Ventorino, V.; Robertiello, A.; Galasso, M.; Blaiotta, G.; Comite, E.; Faraco, V.; Pepe, O. Effect of Cellulase, Substrate Concentrations, and Configuration Processes on Cellulosic Ethanol Production from Pretreated Arundo donax. Bioresources 2017, 12, 5321–5342. [Google Scholar] [CrossRef][Green Version]

- Cristescu, C.; Karlsson, O. Changes in Content of Furfurals and Phenols in Self-Bonded Laminated Boards. Bioresources 2013, 8, 4056–4071. [Google Scholar] [CrossRef]

- Okuda, N.; Sato, M. Manufacture and mechanical properties of binderless boards from kenaf core. J. Wood Sci. 2004, 50, 53–61. [Google Scholar] [CrossRef]

- EN 323:1993. Wood-based panels—Determination of Density; AENOR: Madrid, Spain, 1994.

- EN 622-5: 2006. Fibreboards—Specifications—Part 5: Requirements for Dry Process Boards (MDF); AENOR: Madrid, Spain, 2007.

- Zhang, D.; Zhang, A.; Xue, L. A reiew of preparation of binderless fiberboards and its self-bonding mechanism. Wood Sci. Technol. 2015, 49, 661–679. [Google Scholar] [CrossRef]

- Overend, R.; Chornet, E. Fractionation of lignocellulosis by steam-aqueous pre-treatment. Phil. Trans. Royal Soc. London 1987, A321, 523–536. [Google Scholar]

- Zhuravlev, N.M. Classification and symbols for means of measuring linear and angular dimensions. Meas. Tech. 1977, 20, 1284–1286. [Google Scholar] [CrossRef]

- EN 310:1993. Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength; AENOR: Madrid, Spain, 1994.

- EN 319: 1993. Particleboards and Fibreboards. Determination of Tensile Strength Perpendicular to the Plane of the Board; AENOR: Madrid, Spain, 1994.

- EN 317: 1993. Particleboards and Fibreboards—Determination of Swelling in Thickness after Immersion in Water; AENOR: Madrid, Spain, 1994.

- EN 325: 1993. Wood-Based Panels. Determination of Dimensions of Test Pieces; AENOR: Madrid, Spain, 1994.

| Series | 11 and 21 | Hot Pressing | 2 × tp |

|---|---|---|---|

| Tr (°C) | 200 | tp (min) | 3.75 |

| t_r (min) | 9.5 | Tp (°C) | 205 |

| Severity | 8358 | Pp (MPa) | 5 |

| Washing | Yes | FHT Series 11 | No treatment |

| Cold pressing | 16 MPa | FHT Series 21 | 5 h/165 °C |

| Factor | Series | Mean | Standard Deviation | Difference (11–21) | Limits (LSD) +/− |

|---|---|---|---|---|---|

| Density * (kg/m3) | 11 | 1180 | 28 | −33.2 ** | 32.21 |

| 21 | 1213 | 32 | |||

| MOE (MPa) | 11 | 6249 | 505 | 1014 * | 481.52 |

| 21 | 5234 | 385 | |||

| MOR (MPa) | 11 | 40.38 | 3.87 | 9.21 * | 4.08 |

| 21 | 31.17 | 3.73 | |||

| IB (MPa) | 11 | 1.46 | 0.51 | −1.03 * | 0.64 |

| 21 | 2.50 | 0.67 | |||

| TS (%) | 11 | 11.11 | 2.53 | 5.61 * | 3.07 |

| 21 | 5.50 | 3.15 | |||

| WA (%) | 11 | 21.2 | 2.82 | 12.05 * | 2.54 |

| 21 | 9.15 | 1.80 |

| Series | 22 | Hot Pressing | 2′ at 1 MPa + tp at Pp |

|---|---|---|---|

| Tr (°C) | 200 | tp (s) | 30 except blank (0) |

| t_r (min) | 9.5 | Tp (°C) | 205 |

| Severity | 8358 | Pp (MPa) | variable |

| Washing | Yes | FHT | 5 h/165 °C |

| Cold pressing | dry |

| Board | Pp | MOE | MOR | IB | Density | TS | WA |

|---|---|---|---|---|---|---|---|

| MPa | >3000 MPa | >29 MPa | >0.7 MPa | >800 kg/m3 | <35% | <30% | |

| 1 (blank) | 0 | 740 | 2.072 | 0.51 | 734 | 26.34 | 41.77 |

| 2 | 1 | 3296 | 21.36 | 2.28 | 1050 | 10.22 | 18.82 |

| 3 | 2.5 | 3817 | 30.63 | 2.10 | 1084 | 6.25 | 13.04 |

| 4 | 5 | 4711 | 30.63 | 2.72 | 1179 | 7.64 | 9.68 |

| 5 | 7.5 | 4251 | 37.27 | 3.05 | 1157 | 8.03 | 12.64 |

| 6 | 10 | 5323 | 42.59 | 3.46 | 1124 | 7.07 | 14.29 |

| 7 | 12.5 | 4792 | 39.13 | 3.25 | 1061 | 6.02 | 9.68 |

| 8 | 15 | 6222 | 43.09 | 3.21 | 1184 | 5.84 | 10.87 |

| 9 | 20 | 6106 | 43.61 | 2.95 | 1152 | 3.96 | 8.99 |

| 10 | 0 | 795 | 2.55 | 0.43 | 784 | 18.30 | 27.17 |

| 11 | 25 | 3254 | 21.94 | 2.46 | 1003 | 12.80 | 23.81 |

| 12 | 5 | 3950 | 27.64 | 3.75 | 1086 | 11.13 | 10.34 |

| 13 | 10 | 5167 | 41.57 | 3.62 | 1111 | 9.62 | 13.79 |

| 14 | 20 | 5634 | 42.6 | 3.76 | 1154 | 3.81 | 9.78 |

| Series | Density * | MOE * | MOR * | IB * | TS * | WA * |

|---|---|---|---|---|---|---|

| Specifications UNE EN 622-5: 2006 | >800 kg/m3 | >3000 MPa | >29 MPa | >0.7 MPa | <35% | <30% |

| 11 | 1180 | 6249 | 40.4 | 1.5 | 11.1 | 21.2 |

| 21 | 1213 | 5234 | 31.2 | 2.5 | 5.5 | 9.1 |

| 22 | 1133 | 4331 | 29.1 | 3.2 | 9.4 | 10.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramos, D.; Ferrando, F.; Farriol, X.; Salvadó, J. Optimization of the Production Factors of Boards Obtained from Arundo donax L. Fibers without Added Adhesives. Molecules 2020, 25, 1660. https://doi.org/10.3390/molecules25071660

Ramos D, Ferrando F, Farriol X, Salvadó J. Optimization of the Production Factors of Boards Obtained from Arundo donax L. Fibers without Added Adhesives. Molecules. 2020; 25(7):1660. https://doi.org/10.3390/molecules25071660

Chicago/Turabian StyleRamos, Diego, Francesc Ferrando, Xavier Farriol, and Joan Salvadó. 2020. "Optimization of the Production Factors of Boards Obtained from Arundo donax L. Fibers without Added Adhesives" Molecules 25, no. 7: 1660. https://doi.org/10.3390/molecules25071660

APA StyleRamos, D., Ferrando, F., Farriol, X., & Salvadó, J. (2020). Optimization of the Production Factors of Boards Obtained from Arundo donax L. Fibers without Added Adhesives. Molecules, 25(7), 1660. https://doi.org/10.3390/molecules25071660