One-Part Plastic Formable Inorganic Coating Obtain from Alkali-Activated Slag /Starch(CMS) Hybrid Composites

Abstract

1. Introduction

2. Results and Discussion

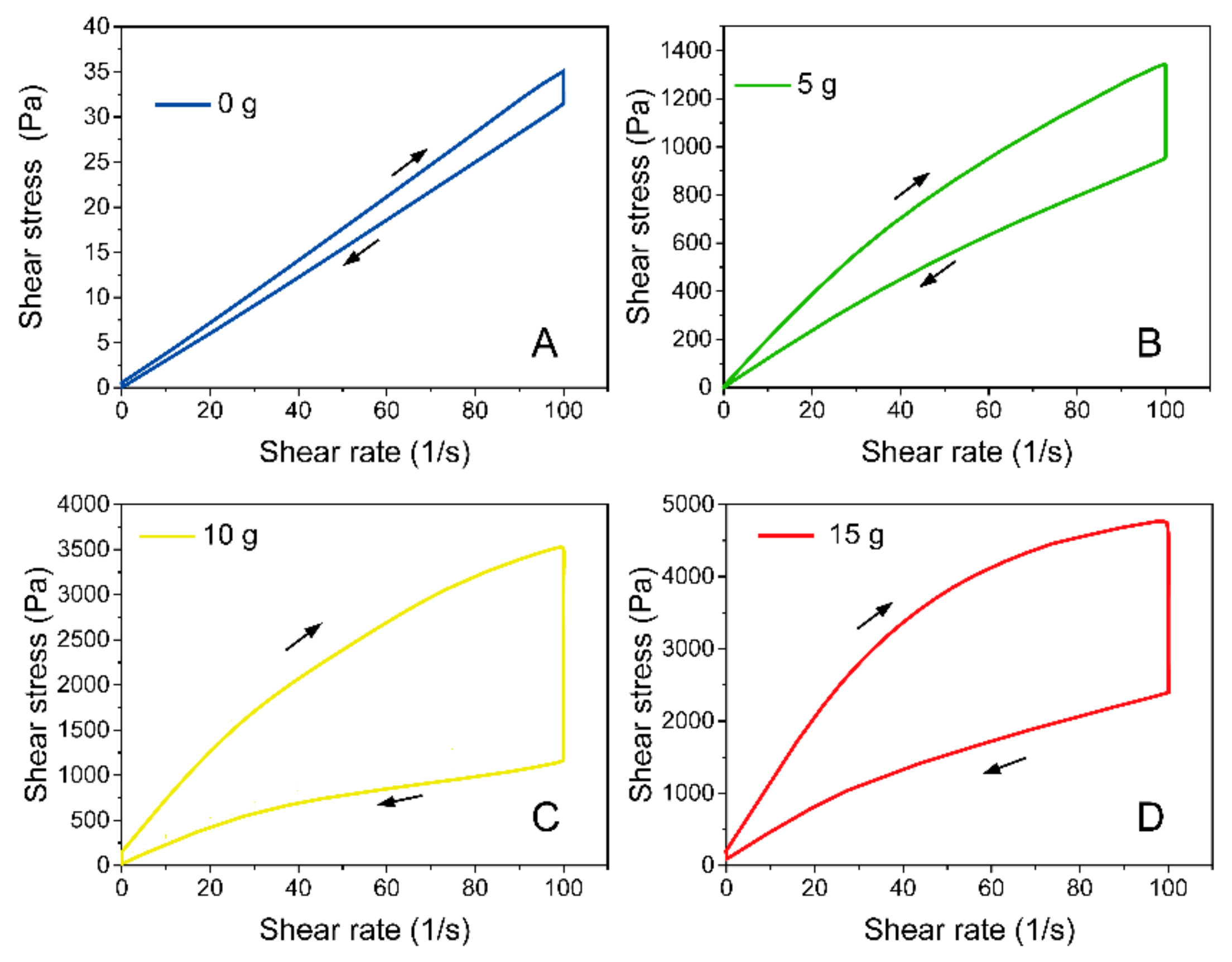

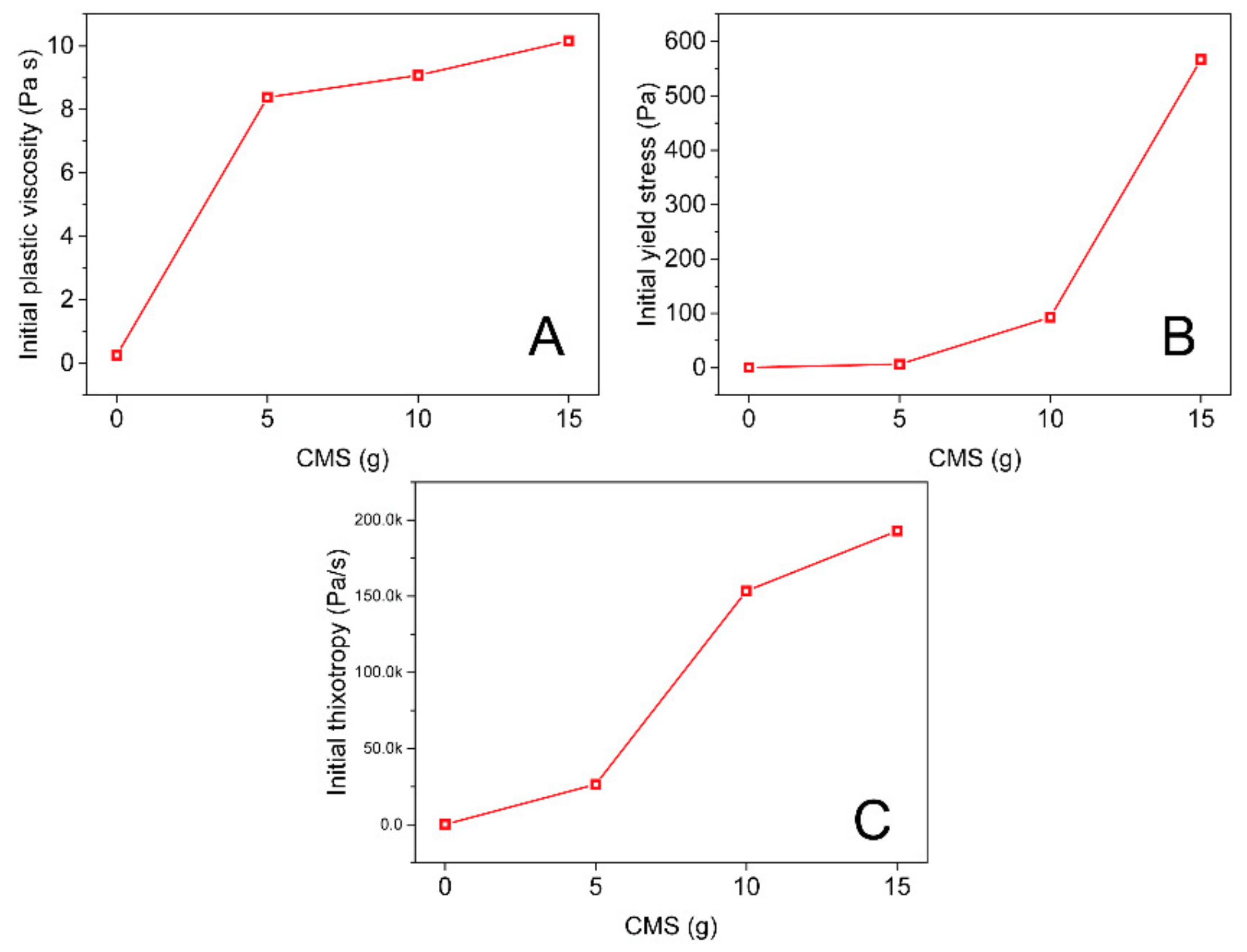

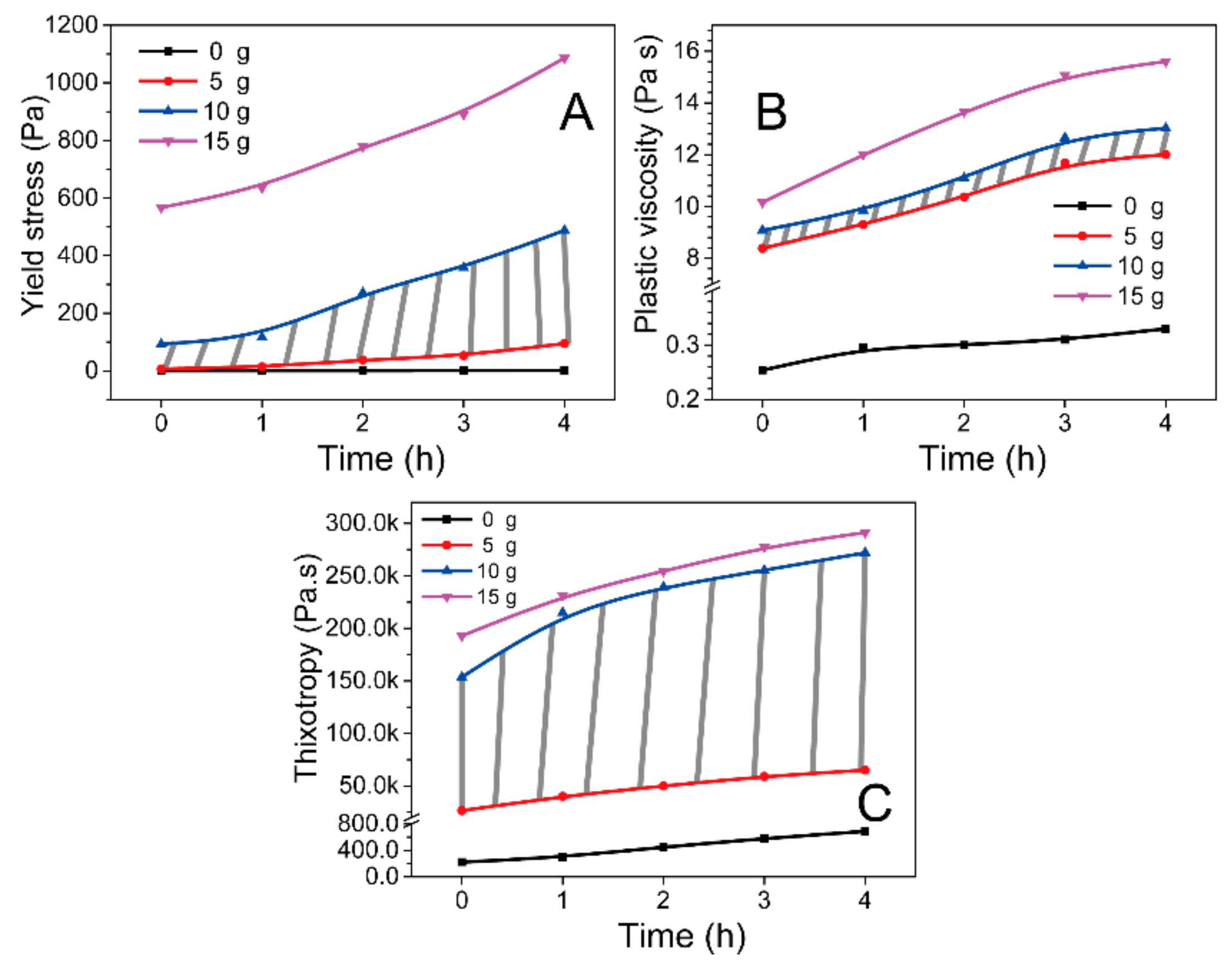

2.1. Rheology and Workability

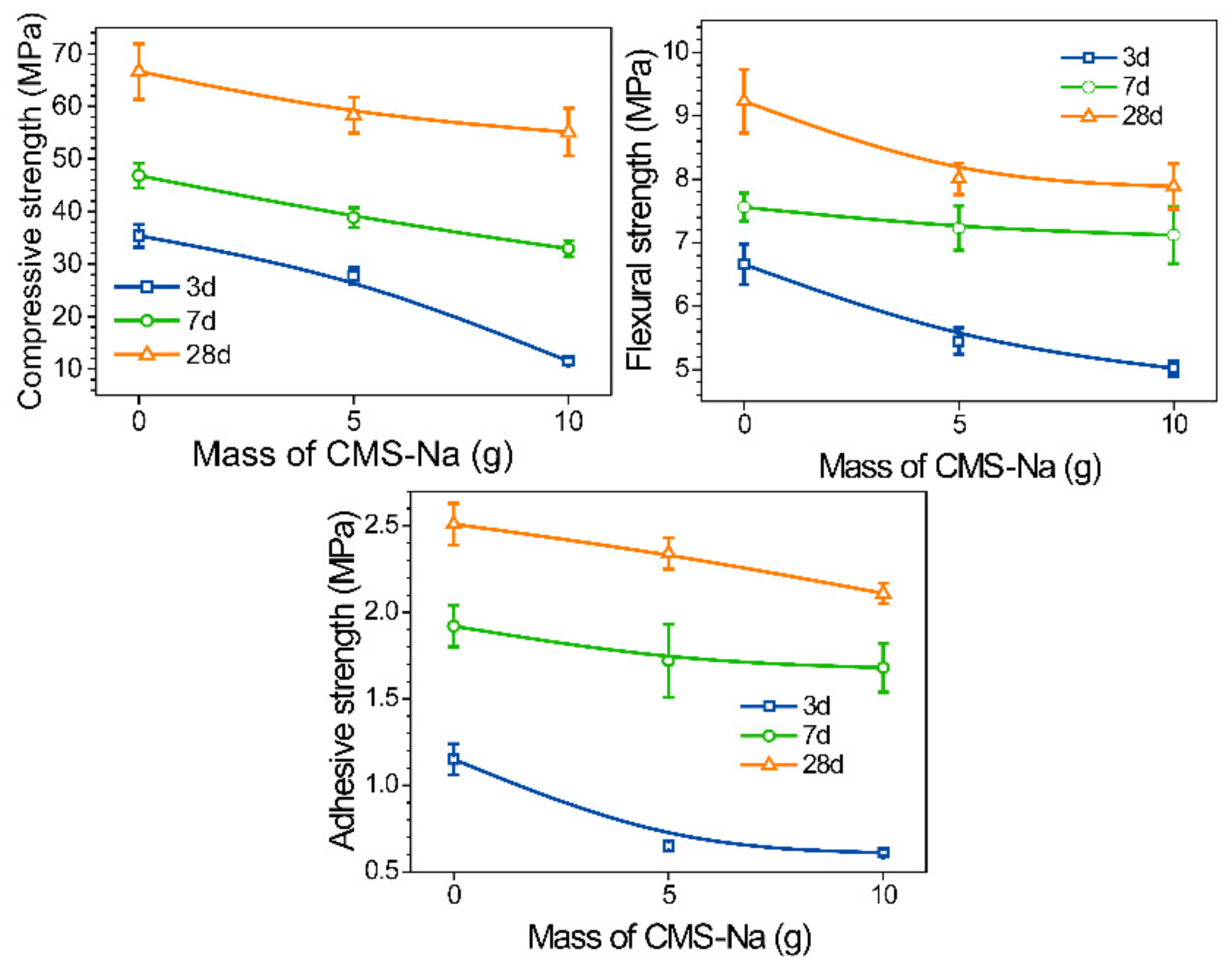

2.2. Mechanical Strength

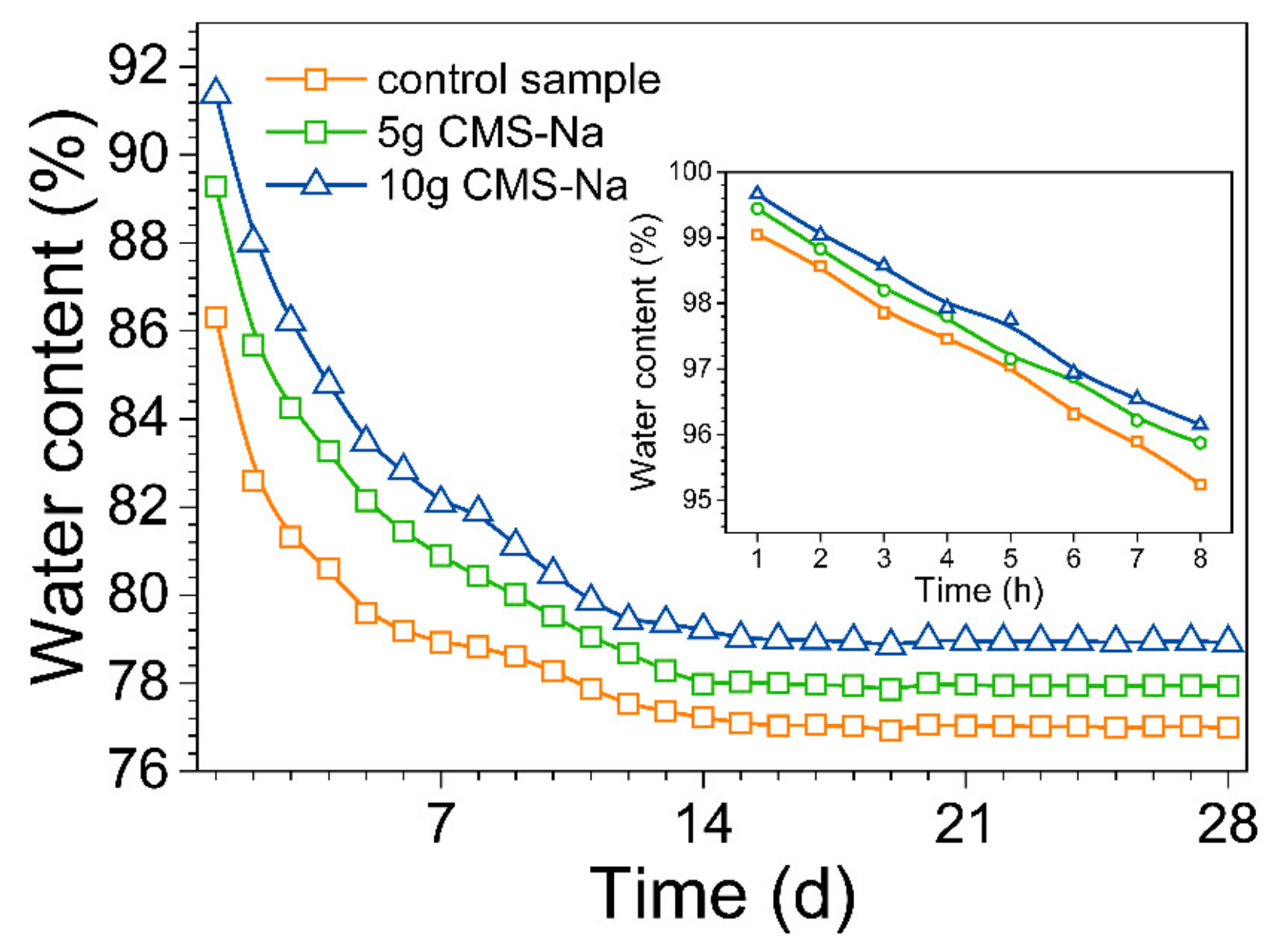

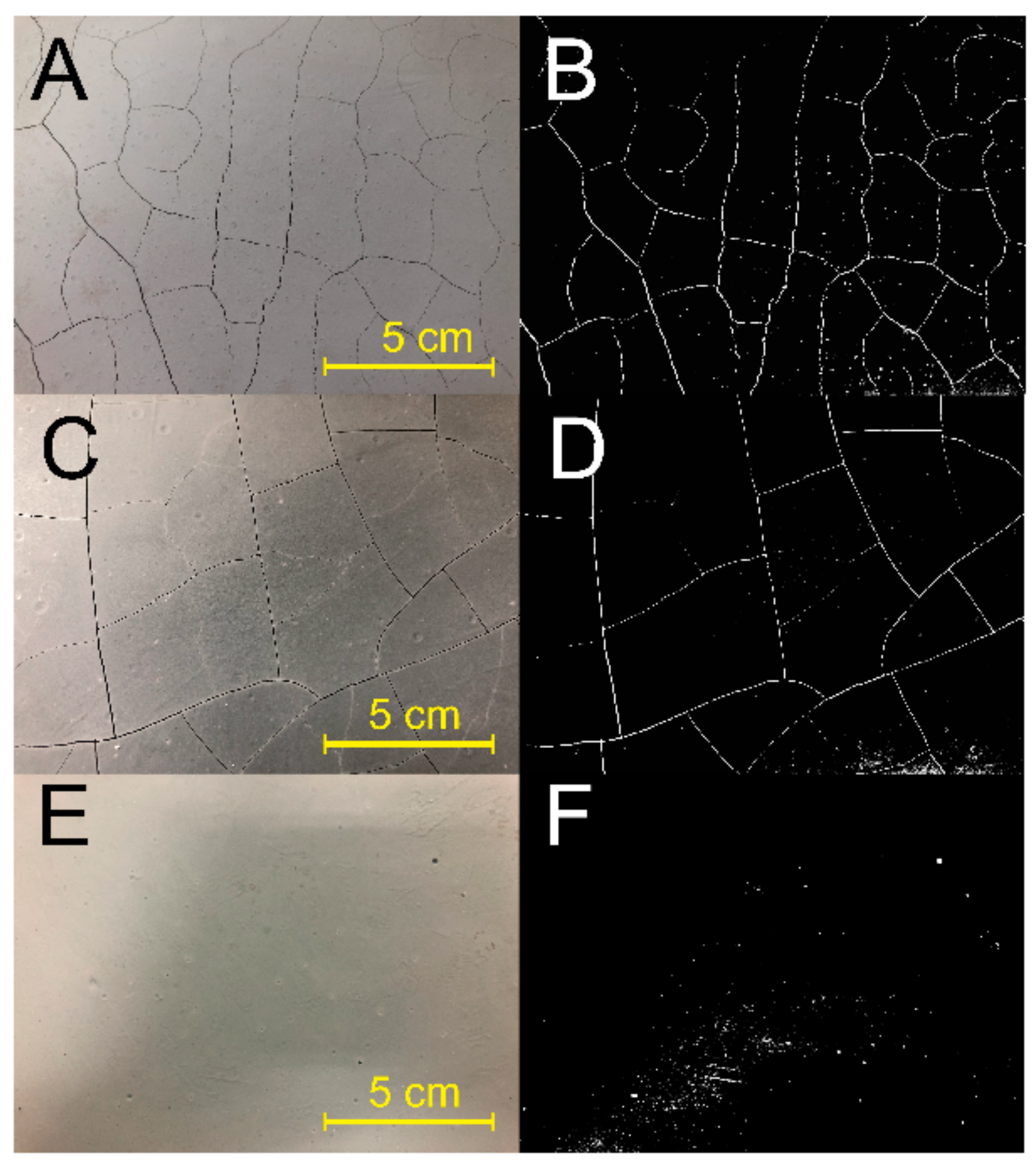

2.3. Water Retention, Shrinkage, and Cracking

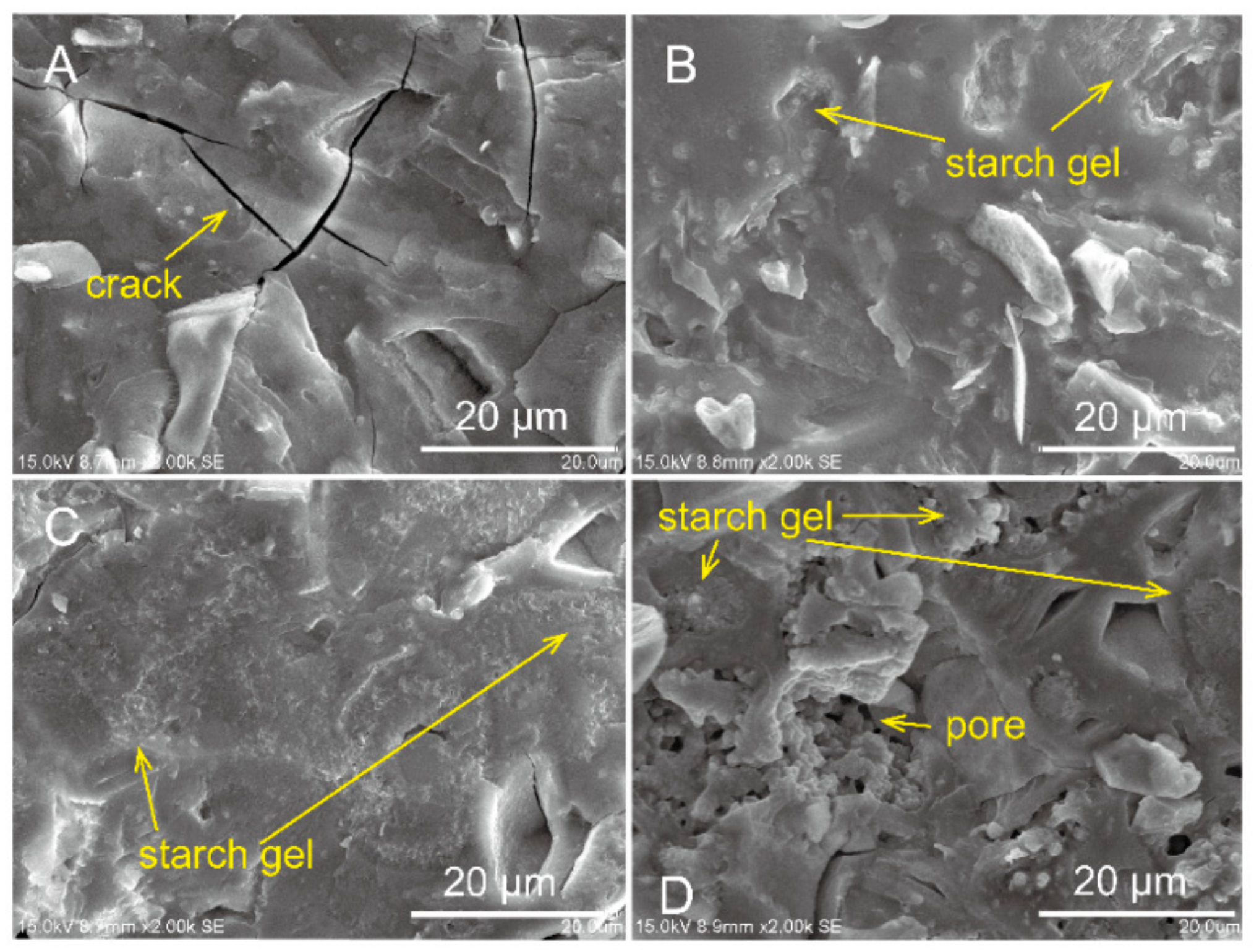

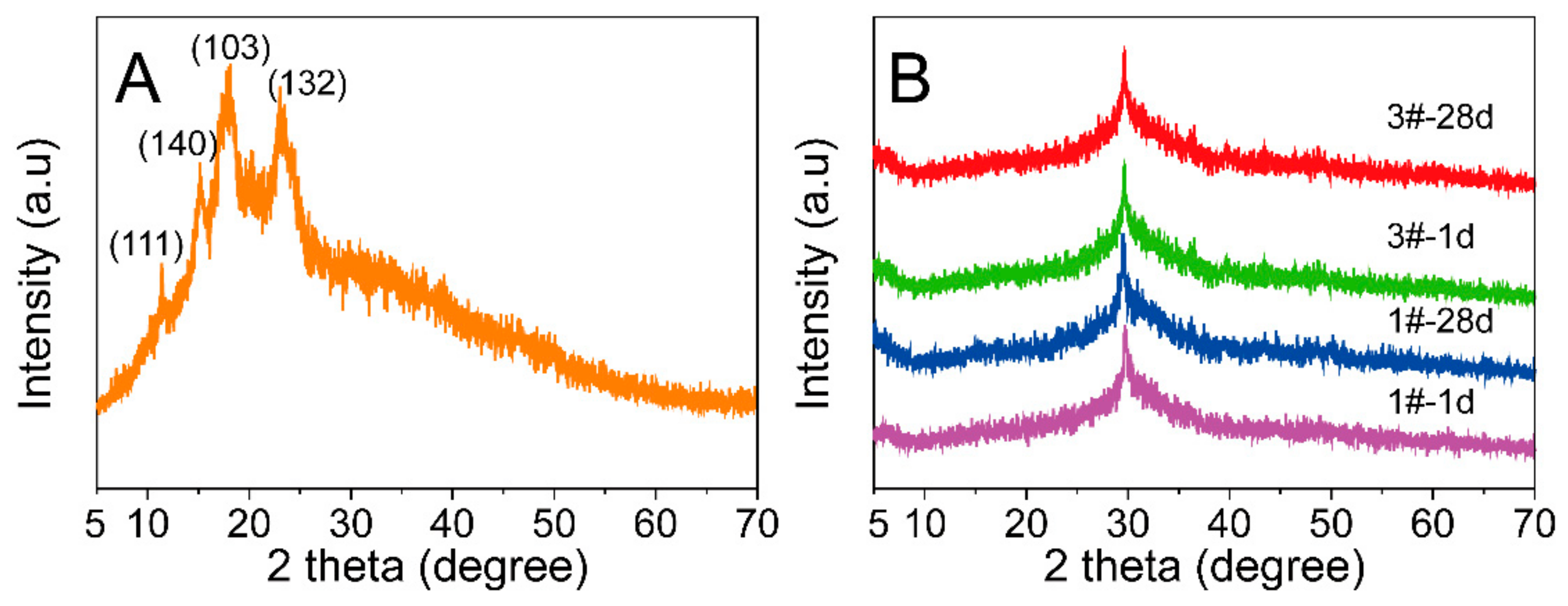

2.4. Microstructure Analysis

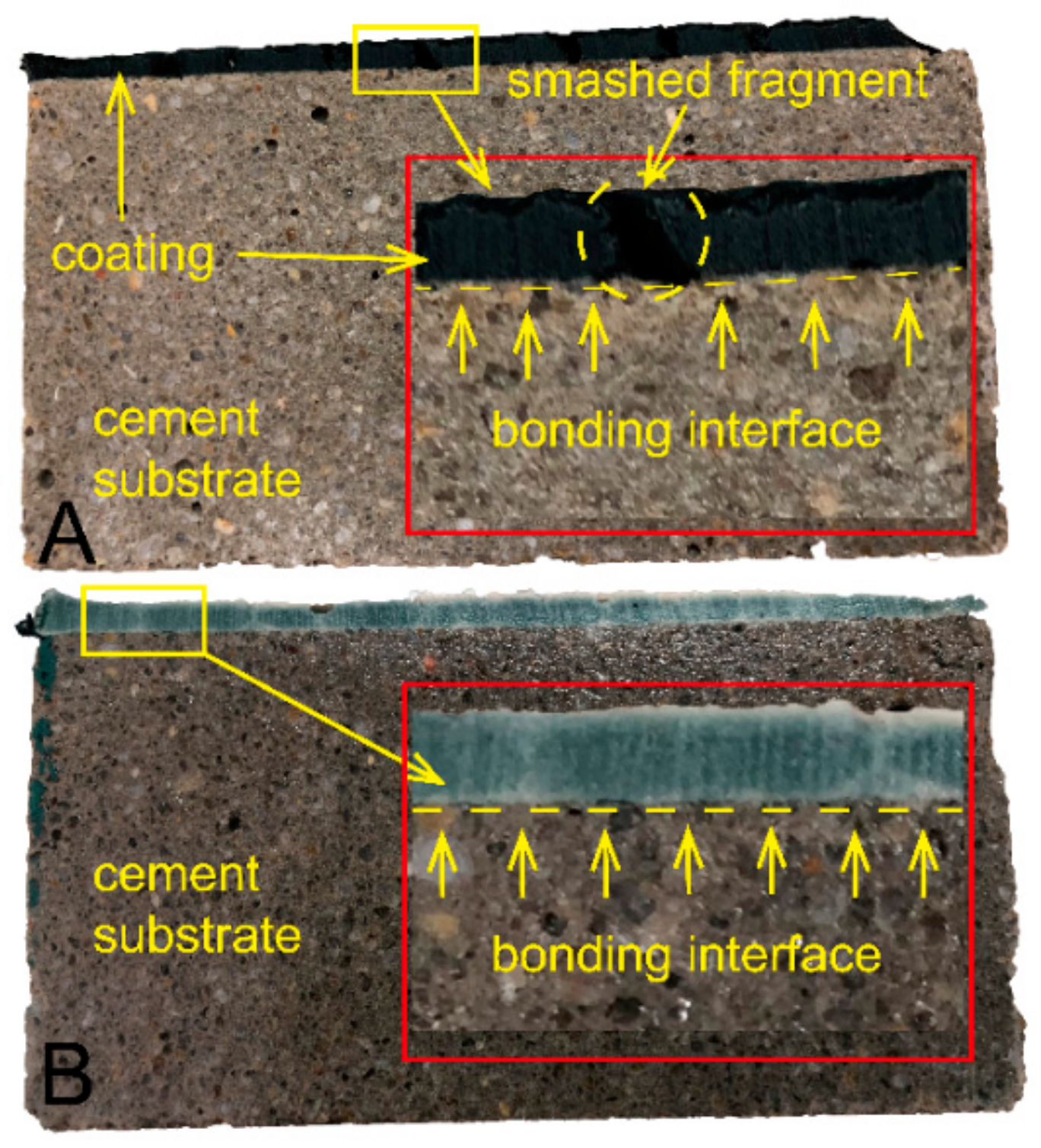

2.5. Applicable Test of Coating

3. Materials and Methods

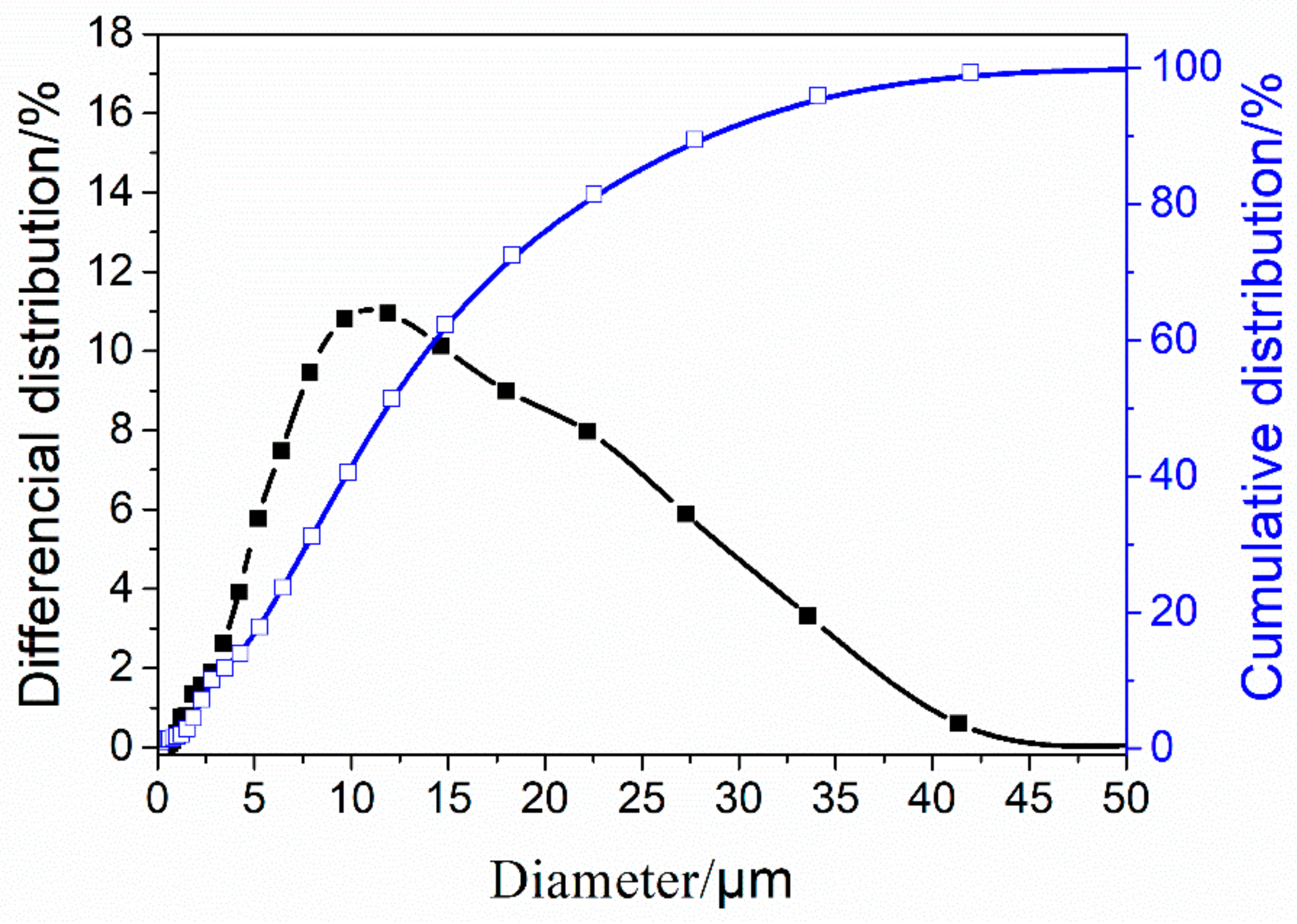

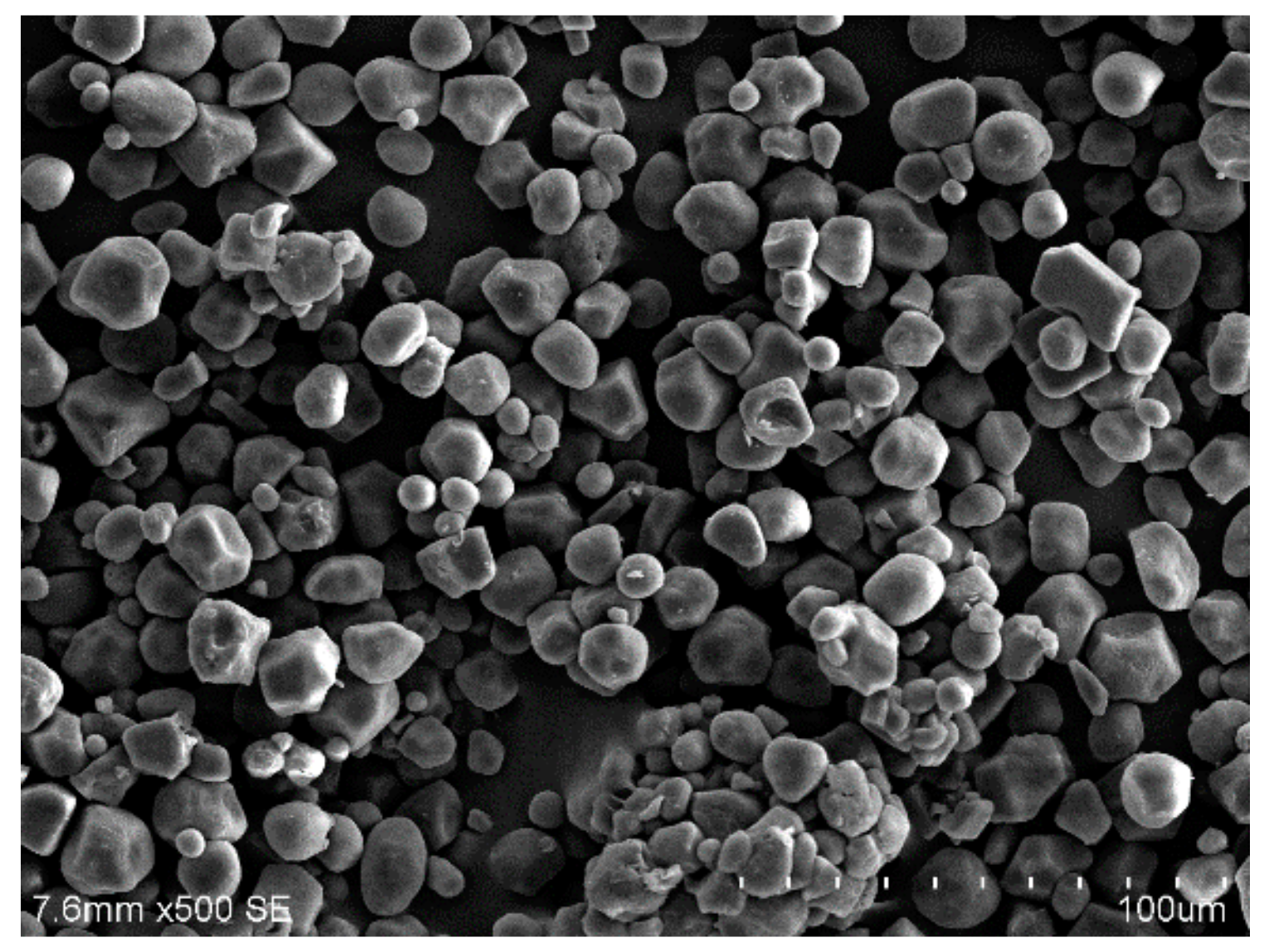

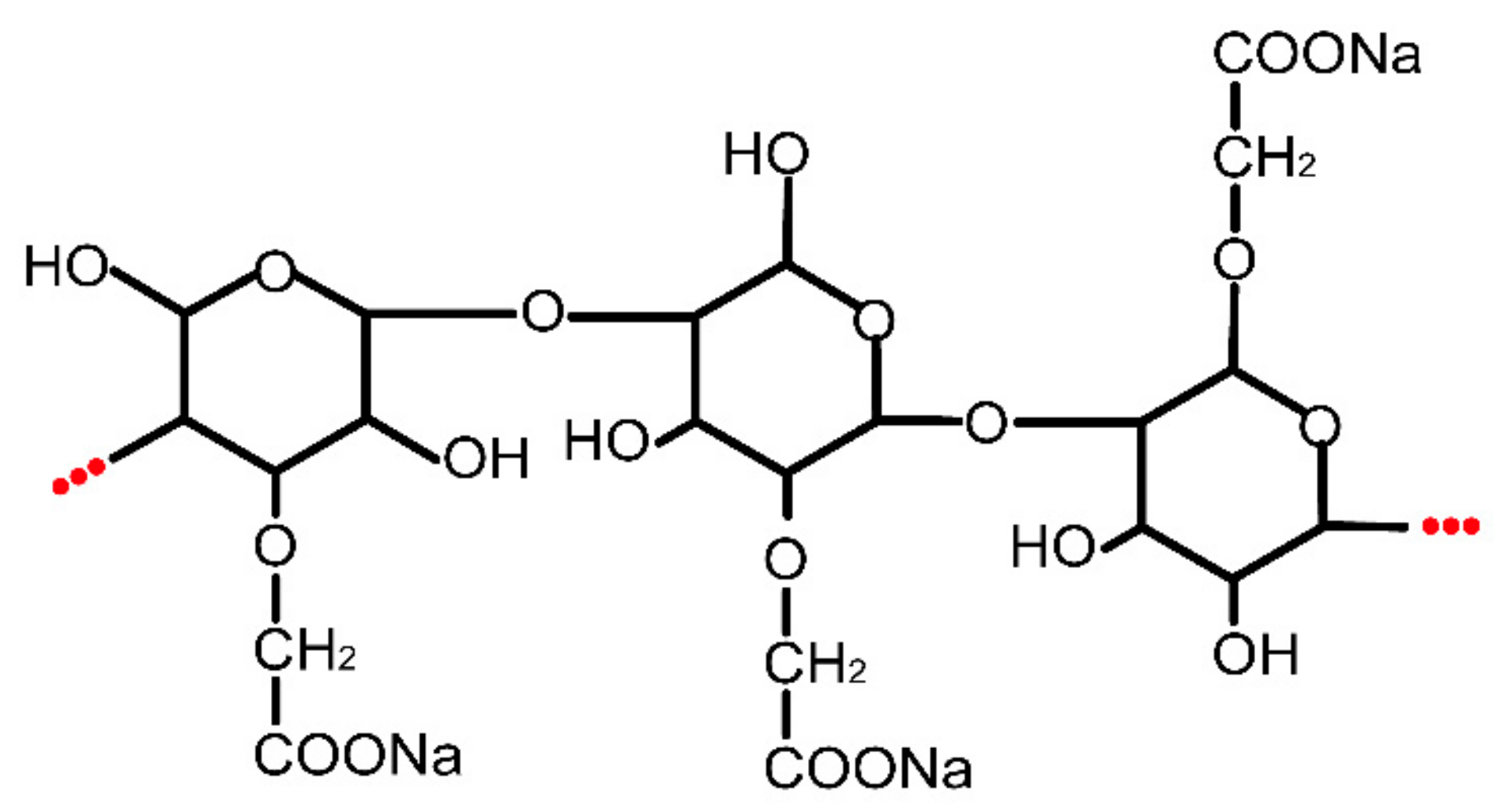

3.1. Materials

3.2. Sample Preparations

3.3. Experimental Procedures

3.3.1. Rheology and Workability

3.3.2. Mechanical Strength

3.3.3. Water Retention, Shrinkage and Cracking

3.3.4. Microstructure Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, L.-Y.; Cui, L.-Y.; Zeng, R.-C.; Li, S.-Q.; Chen, X.-B.; Zheng, Y.; Kannan, M.B. Advances in functionalized polymer coatings on biodegradable magnesium alloys – A review. Acta Biomater. 2018, 79, 23–36. [Google Scholar] [CrossRef] [PubMed]

- Yang J, X.L.-L.; Wang, L.; Zhang, Z.-B.; Liu, F. Study on new inorganic coating for outdoor. J. Nanjing Univ. Sci. Technol. Nat. Sci. Ed. 2008, 30, 78–82. [Google Scholar]

- Wang, Y.X.; Zhang, S. Toward hard yet tough ceramic coatings. Surf. Coat. Technol. 2014, 258, 1–16. [Google Scholar] [CrossRef]

- Munafò, P.; Goffredo, G.B.; Quagliarini, E. TiO2-based nanocoatings for preserving architectural stone surfaces: An overview. Constr. Build. Mater. 2015, 84, 201–218. [Google Scholar] [CrossRef]

- Zhan, Y.; Zhang, J.; Wan, X.; Long, Z.; He, S.; He, Y. Epoxy composites coating with Fe3O4 decorated graphene oxide: Modified bio-inspired surface chemistry, synergistic effect and improved anti-corrosion performance. Surf. Coat. Technol. 2018, 436, 756–767. [Google Scholar] [CrossRef]

- Shao, H.; Wang, W.; Zhang, H.; Wang, A.; Chen, X.; Huang, Y. Nano-TiO2 decorated carbon coating on the separator to physically and chemically suppress the shuttle effect for lithium-sulfur battery. J. Power Sources 2018, 378, 537–545. [Google Scholar] [CrossRef]

- Zvonkina, I.J.; Soucek, M.D. Inorganic–organic hybrid coatings: common and new approaches. Curr. Opin. Chem. Eng. 2016, 11, 123–127. [Google Scholar] [CrossRef]

- Yuan, M.-r.; Lu, J.-t.; Kong, G. Effect of SiO2:Na2O molar ratio of sodium silicate on the corrosion resistance of silicate conversion coatings. Surf. Coat. Technol. 2010, 204, 1229–1235. [Google Scholar] [CrossRef]

- Mu, S.; Liu, J.; Lin, W.; Wang, Y.; Liu, J.; Shi, L.; Jiang, Q. Property and microstructure of aluminosilicate inorganic coating for concrete: Role of water to solid ratio. Constr. Build. Mater. 2017, 148, 846–856. [Google Scholar] [CrossRef]

- Glassen, D. The reaction of zinc oxide and zinc dust with sodium silicate solution. J. Appl. Chem. Biot. 1978, 6, 799–810. [Google Scholar]

- Li, Y.; Zeng, G.; Yang, G.; Wu, Q.; Zhang, H.; Li, W.; Qian, Y. Synthesis, characterization and properties of ATO/potassium silicate film prepared by twice spray pyrolysis. J. Alloy Compd. 2019, 772, 240–246. [Google Scholar] [CrossRef]

- Wang, Y.M.; Feng, W.; Xing, Y.R.; Ge, Y.L.; Guo, L.X.; Ouyang, J.H.; Jia, D.C.; Zhou, Y. Degradation and structure evolution in corrosive LiOH solution of microarc oxidation coated Zircaloy-4 alloy in silicate and phosphate electrolytes. Appl. Surf. Sci. 2018, 431, 2–12. [Google Scholar] [CrossRef]

- Li, M.; Hong, Y.; Yu, H.; Qu, S.; Wang, P. A novel high solar reflective coating based on potassium silicate for track slab in high-speed railway. Constr. Build. Mater. 2019, 225, 900–908. [Google Scholar] [CrossRef]

- Pham, L.T.; Hatzignatiou, D.G. Rheological evaluation of a sodium silicate gel system for water management in mature, naturally-fractured oilfields. J. Petrol Sci. Eng. 2016, 138, 218–233. [Google Scholar] [CrossRef]

- Zhou Xirong, T.S.; Zhou, W. Application and preparation of new inorganic paints. Shandong Ceram. 2004, 27, 17–20. [Google Scholar]

- Liew, Y.-M.; Heah, C.-Y.; Li, L.-y.; Jaya, N.A.; Abdullah, M.M.A.B.; Tan, S.J.; Hussin, K. Formation of one-part-mixing geopolymers and geopolymer ceramics from geopolymer powder. Constr. Build. Mater. 2017, 156, 9–18. [Google Scholar] [CrossRef]

- Ma, L.; Zhao, Y.; Gong, J. Restrained early-age shrinkage cracking properties of high-performance concrete containing fly ash and ground granulated blast-furnace slag. Constr. Build. Mater. 2018, 191, 1–12. [Google Scholar] [CrossRef]

- Sufian Badar, M.; Kupwade-Patil, K.; Bernal, S.A.; Provis, J.L.; Allouche, E.N. Corrosion of steel bars induced by accelerated carbonation in low and high calcium fly ash geopolymer concretes. Constr. Build. Mater. 2014, 61, 79–89. [Google Scholar] [CrossRef]

- Yang, T.; Zhu, H.; Zhang, Z. Influence of fly ash on the pore structure and shrinkage characteristics of metakaolin-based geopolymer pastes and mortars. Constr. Build. Mater. 2017, 153, 284–293. [Google Scholar] [CrossRef]

- Kondepudi, K.; Subramaniam, K.V.L. Rheological characterization of low-calcium fly ash suspensions in alkaline silicate colloidal solutions for geopolymer concrete production. J. Clean. Prod. 2019, 234, 690–701. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, D.-w.; Li, L.; Wang, J.-x.; Shao, N.-n.; Wang, D.-m. Microstructure and phase evolution of alkali-activated steel slag during early age. Constr. Build. Mater. 2019, 204, 158–165. [Google Scholar] [CrossRef]

- Zhang, D.-W.; Wang, D.-m.; Liu, Z.; Xie, F.-z. Rheology, agglomerate structure, and particle shape of fresh geopolymer pastes with different NaOH activators content. Constr. Build. Mater. 2018, 187, 674–680. [Google Scholar] [CrossRef]

- Lv, X.; Wang, K.; He, Y.; Cui, X. A green drying powder inorganic coating based on geopolymer technology. Constr. Build. Mater. 2019, 214, 441–448. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Salem, H.A. Effect of water addition, plasticizer and alkaline solution constitution on fly ash based geopolymer concrete performance. Constr. Build. Mater. 2016, 121, 694–703. [Google Scholar] [CrossRef]

- Roussel, N.; Lemaître, A.; Flatt, R.J.; Coussot, P. Steady state flow of cement suspensions: A micromechanical state of the art. Cement Concrete Res. 2010, 40, 77–84. [Google Scholar] [CrossRef]

- Abd El-Rehim, H.A.; Hegazy, E.-S.A.; Diaa, D.A. Radiation synthesis of eco-friendly water reducing sulfonated starch/acrylic acid hydrogel designed for cement industry. Radiat. Phys. Chem. 2013, 85, 139–146. [Google Scholar] [CrossRef]

- Yang, T.; Zhu, H.; Zhang, Z.; Gao, X.; Zhang, C.; Wu, Q. Effect of fly ash microsphere on the rheology and microstructure of alkali-activated fly ash/slag pastes. Cement Concrete Res. 2018, 109, 198–207. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Li, S.; Xu, D.L.; Wang, B.Q.; Xu, G.M.; Yang, D.F.; Wang, N.; Liu, H.C.; Wang, Y.C. A novel method for preparation of organic resins reinforced geopolymer composites. J. Mater. Sci. 2010, 45, 1189–1192. [Google Scholar] [CrossRef]

- Zhang, S.; Gong, K.; Lu, J. Novel modification method for inorganic geopolymer by using water soluble organic polymers. Mater. Lett. 2004, 58, 1292–1296. [Google Scholar] [CrossRef]

- Chen, X.; Zhu, G.; Zhou, M.; Wang, J.; Chen, Q. Effect of Organic Polymers on the Properties of Slag-based Geopolymers. Constr. Build. Mater. 2018, 167, 216–224. [Google Scholar] [CrossRef]

- Wu, Y.; Lu, B.; Bai, T.; Wang, H.; Du, F.; Zhang, Y.; Cai, L.; Jiang, C.; Wang, W. Geopolymer, green alkali activated cementitious material: Synthesis, applications and challenges. Constr. Build. Mater. 2019, 224, 930–949. [Google Scholar] [CrossRef]

- Zhang, Z.; Yao, X.; Wang, H. Potential application of geopolymers as protection coatings for marine concrete III. Field experiment. Appl. Clay Sci. 2012, 67–68, 57–60. [Google Scholar] [CrossRef]

- Kaczmarska, K.; Grabowska, B.; Spychaj, T.; Zdanowicz, M.; Sitarz, M.; Bobrowski, A.; Cukrowicz, S. Effect of microwave treatment on structure of binders based on sodium carboxymethyl starch: FT-IR, FT-Raman and XRD investigations. Spectrochim. Acta Part A 2018, 199, 387–393. [Google Scholar] [CrossRef] [PubMed]

Sample Availability: Samples of the compounds are not available from the authors. |

| Composition | CaO | SiO2 | Al2O3 | MgO | SO3 | TiO2 | MnO | Fe2O3 | K2O | Na2O | LOIa |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Content | 47.39 | 29.73 | 11.89 | 5.99 | 1.79 | 0.95 | 0.65 | 0.49 | 0.47 | 0.30 | 0.35 |

| No. | Slag (g) | Water Glass (g) | CMS (g) | Distill Water (g) | CMS (%) |

|---|---|---|---|---|---|

| 1# | 50.00 | 15.00 | 0.00 | 26.00 | 0.00 |

| 2# | 45.00 | 15.00 | 5.00 | 26.00 | 7.70 |

| 3# | 40.00 | 15.00 | 10.00 | 26.00 | 15.40 |

| 4# | 35.00 | 15.00 | 15.00 | 26.00 | 23.10 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, X.; Qin, Y.; Lin, Z.; Tian, Z.; Cui, X. One-Part Plastic Formable Inorganic Coating Obtain from Alkali-Activated Slag /Starch(CMS) Hybrid Composites. Molecules 2020, 25, 844. https://doi.org/10.3390/molecules25040844

Lv X, Qin Y, Lin Z, Tian Z, Cui X. One-Part Plastic Formable Inorganic Coating Obtain from Alkali-Activated Slag /Starch(CMS) Hybrid Composites. Molecules. 2020; 25(4):844. https://doi.org/10.3390/molecules25040844

Chicago/Turabian StyleLv, Xuesen, Yao Qin, Zhaoxu Lin, Zhenkun Tian, and Xuemin Cui. 2020. "One-Part Plastic Formable Inorganic Coating Obtain from Alkali-Activated Slag /Starch(CMS) Hybrid Composites" Molecules 25, no. 4: 844. https://doi.org/10.3390/molecules25040844

APA StyleLv, X., Qin, Y., Lin, Z., Tian, Z., & Cui, X. (2020). One-Part Plastic Formable Inorganic Coating Obtain from Alkali-Activated Slag /Starch(CMS) Hybrid Composites. Molecules, 25(4), 844. https://doi.org/10.3390/molecules25040844