Fine Modulation of the Catalytic Properties of Rhizomucor miehei Lipase Driven by Different Immobilization Strategies for the Selective Hydrolysis of Fish Oil

Abstract

1. Introduction

2. Result and discussion

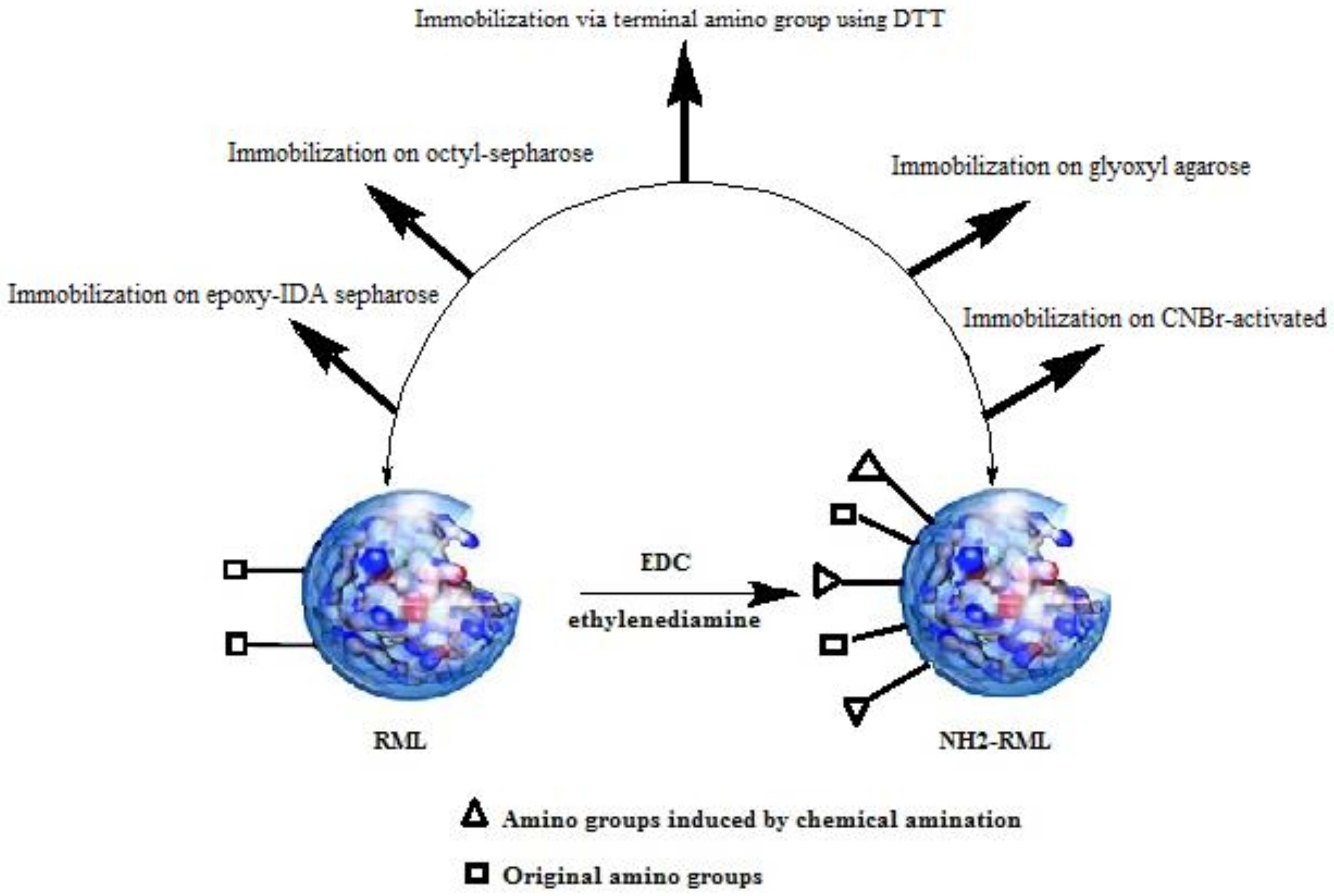

2.1. Immobilization of RML and Aminated RML on Different Supports

2.2. Thermal Stability of the Immobilized Derivatives

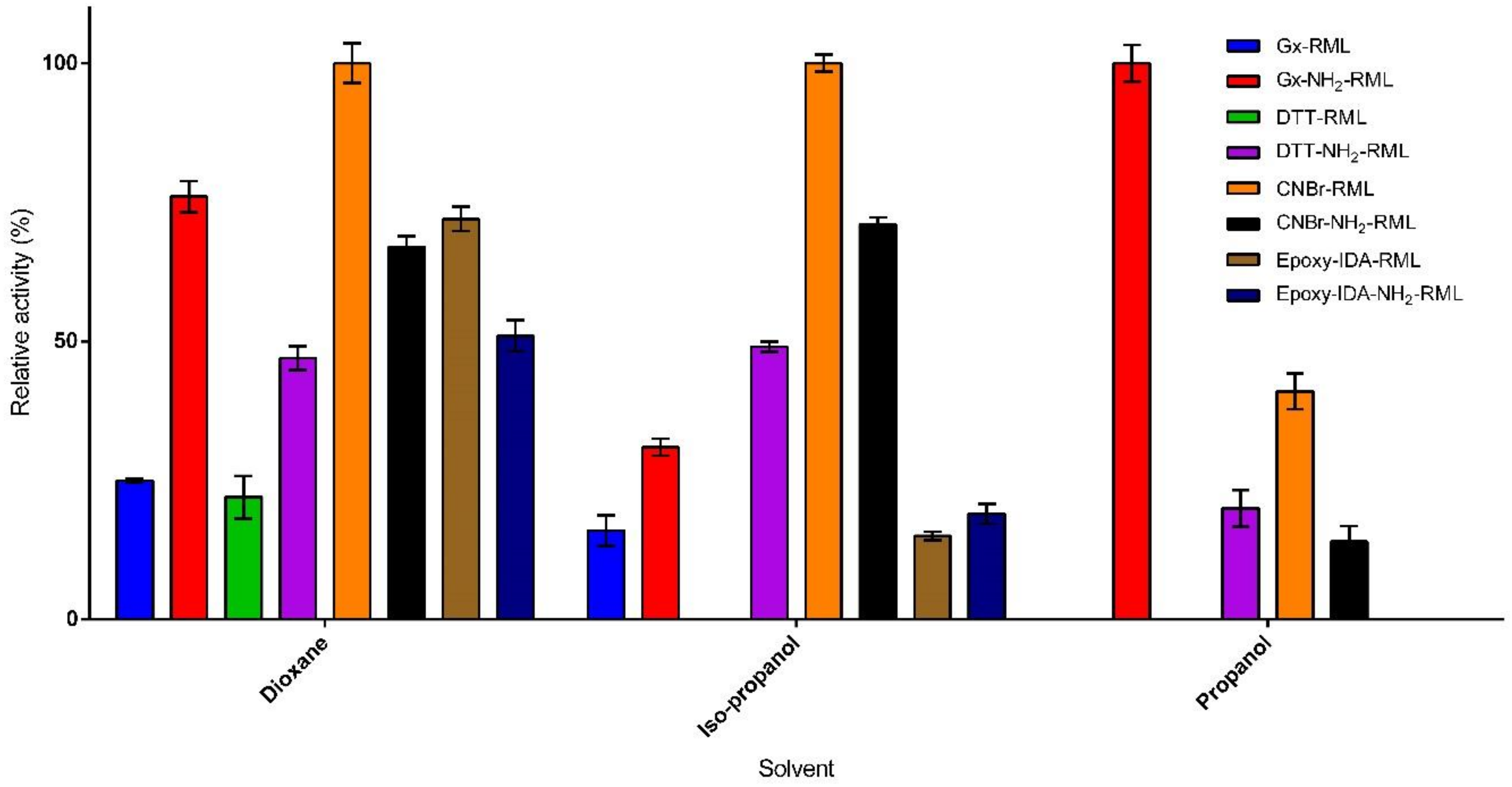

2.3. Stability of RML Derivatives in the Presence of Organic Solvents

2.4. Fish Oil Hydrolysis

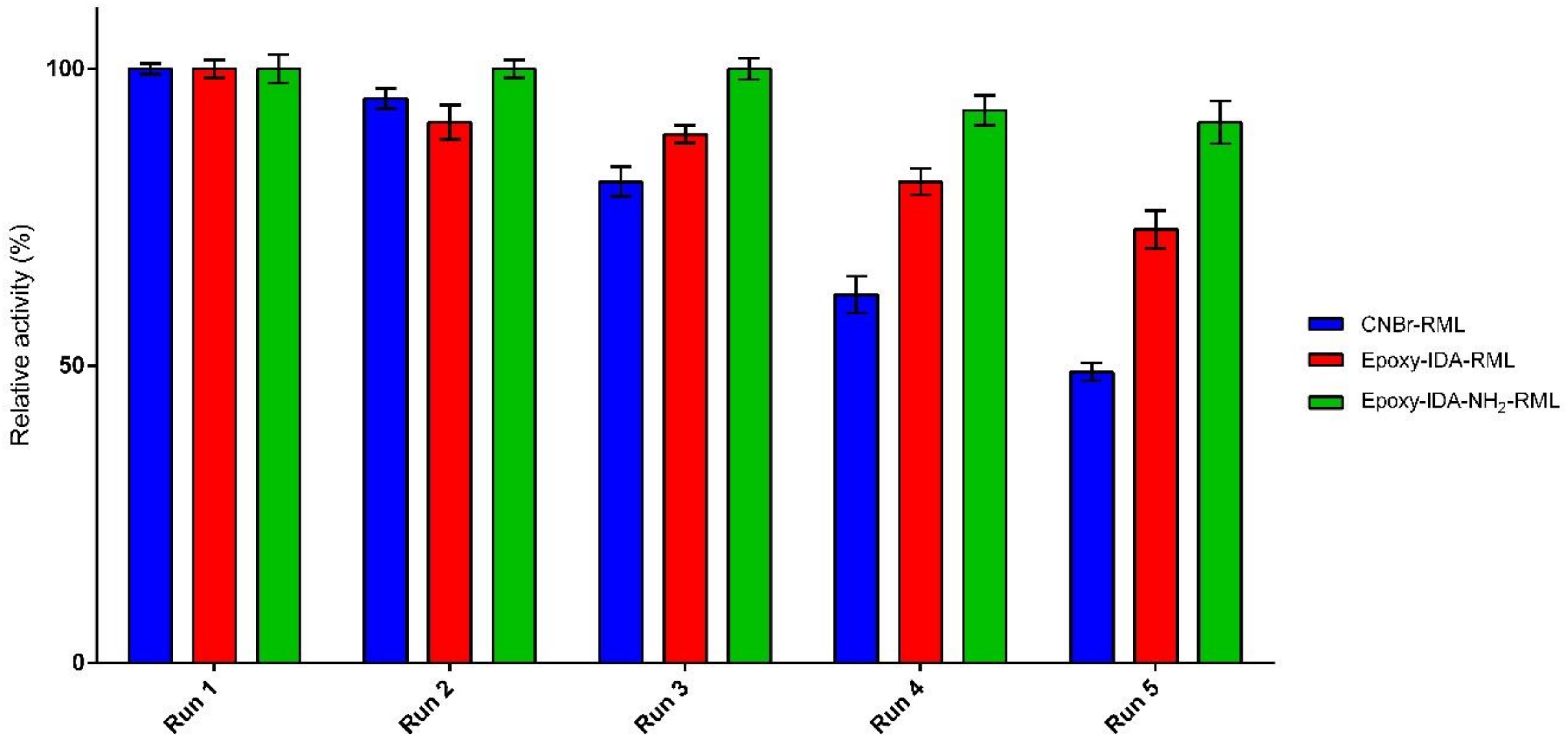

2.5. Recyclability of the Selected Biocatalysts in Fish Oil Hydrolysis

3. Materials and Methods

3.1. Materials

3.2. Methodology

3.2.1. Purification of RML

3.2.2. Chemical Amination of Immobilized RML

3.2.3. Desorption of the Aminated and Non-Aminated RML from Octyl-Sepharose

3.2.4. Immobilization of RML and NH2-RML on Cyanogen Bromide-Activated Support

3.2.5. Immobilization of RML on Glyoxyl Agarose

3.2.6. Immobilization of Aminated RML on Glyoxyl Agarose

3.2.7. Immobilization of Aminated RML via Terminal Amino Group Using DTT

3.2.8. Preparation of Epoxy Support

3.2.9. Preparation of the Heterofunctional Support

3.2.10. Introducing Nickel Cations to the Surface of the Heterofunctional Support

3.2.11. Orientation and Immobilization of RML and NH2-RML on the Heterofunctional Support

3.2.12. Enzymatic Activity Assay

3.2.13. Determination of the Amount of Protein Bonded to the Carriers

3.2.14. Thermal Inactivation of the Immobilized Preparations

3.2.15. Co-solvent Stability of the Immobilized Preparations

3.2.16. Hydrolysis of Fish Oil

3.2.17. Recyclability of Immobilized Derivatives

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jamison, D.T.; Breman, J.G.; Measham, A.R.; Alleyne, G.; Claeson, M.; Evans, D.B.; Jha, P.; Mills, A.; Musgrove, P. Disease Control Priorities in Developing Countries; The World Bank: Washington, DC, USA, 2006; pp. 1–50. [Google Scholar]

- Navarini, L.; Afeltra, A.; Afflitto, G.G.; Margiotta, D.P.E. Polyunsaturated fatty acids: Any role in rheumatoid arthritis? Lipids Health Dis. 2017, 16, 197. [Google Scholar] [CrossRef]

- Mehta, L.R.; Dworkin, R.H.; Schwid, S.R. Polyunsaturated fatty acids and their potential therapeutic role in multiple sclerosis. Nat. Rev. Neurol. 2009, 5, 82–92. [Google Scholar] [CrossRef] [PubMed]

- Demaison, L.; Moreau, D. Dietary n-3 polyunsaturated fatty acids and coronary heart disease-related mortality: A possible mechanism of action. Cell. Mol. Life Sci. CMLS 2002, 59, 463–477. [Google Scholar] [CrossRef] [PubMed]

- Coletta, J.M.; Bell, S.J.; Roman, A.S. Omega-3 fatty acids and pregnancy. Rev. Obstet. Gynecol. 2010, 3, 163–171. [Google Scholar] [PubMed]

- Zivkovic, A.M.; Telis, N.; German, J.B.; Hammock, B.D. Dietary omega-3 fatty acids aid in the modulation of inflammation and metabolic health. Calif. Agric. 2011, 65, 106–111. [Google Scholar] [CrossRef]

- Dovale-Rosabal, G.; Rodriguez, A.; Contreras, E.; Ortiz-Viedma, J.; Munoz, M.; Trigo, M.; Aubourg, S.P.; Espinosa, A. Concentration of EPA and DHA from Refined Salmon Oil by Optimizing the Urea(-)Fatty Acid Adduction Reaction Conditions Using Response Surface Methodology. Molecules 2019, 24, 1642. [Google Scholar] [CrossRef] [PubMed]

- Rubio-Rodríguez, N.; Beltrán, S.; Jaime, I.; de Diego, S.M.; Sanz, M.T.; Carballido, J.R. Production of omega-3 polyunsaturated fatty acid concentrates: A review. Innov. Food Sci. Emerg. Technol. 2010, 11, 1–12. [Google Scholar] [CrossRef]

- Mehrasbi, M.R.; Mohammadi, J.; Peyda, M.; Mohammadi, M. Covalent immobilization of Candida antarctica lipase on core-shell magnetic nanoparticles for production of biodiesel from waste cooking oil. Renew. Energy 2017, 101, 593–602. [Google Scholar] [CrossRef]

- Mohammadi, M.; Habibi, Z.; Gandomkar, S.; Yousefi, M. A novel approach for bioconjugation of Rhizomucor miehei lipase (RML) onto amine-functionalized supports; Application for enantioselective resolution of rac-ibuprofen. Int. J. Biol. Macromol. 2018, 117, 523–531. [Google Scholar] [CrossRef]

- Gonçalves Filho, D.; Silva, A.G.; Guidini, C.Z. Lipases: Sources, immobilization methods, and industrial applications. Appl. Microbiol. Biotechnol. 2019, 103, 7399–7423. [Google Scholar] [CrossRef]

- Filice, M.; Guisan, J.M.; Terreni, M.; Palomo, J.M. Regioselective monodeprotection of peracetylated carbohydrates. Nat. Protoc. 2012, 7, 1783–1796. [Google Scholar] [CrossRef] [PubMed]

- Palomo, J.M.; Filice, M. New emerging bio-catalysts design in biotransformations. Biotechnol Adv. 2015, 33, 605–613. [Google Scholar] [CrossRef] [PubMed]

- Filice, M.; Romero, O.; Gutierrez-Fernandez, J.; de Las Rivas, B.; Hermoso, J.A.; Palomo, J.M. Synthesis of a heterogeneous artificial metallolipase with chimeric catalytic activity. Chem. Commun. (Camb.) 2015, 51, 9324–9327. [Google Scholar] [CrossRef] [PubMed]

- Filice, M.; Romero, O.; Aires, A.; Guisan, J.M.; Rumbero, A.; Palomo, J.M. Preparation of an Immobilized Lipase-Palladium Artificial Metalloenzyme as Catalyst in the Heck Reaction: Role of the Solid Phase. Adv. Synth. Catal. 2015, 357, 2687–2696. [Google Scholar] [CrossRef]

- Ashjari, M.; Mohammadi, M.; Badri, R. Selective concentration of eicosapentaenoic acid and docosahexaenoic acid from fish oil with immobilized/stabilized preparations of Rhizopus oryzae lipase. J. Mol. Catal. B Enzym. 2015, 122, 147–155. [Google Scholar] [CrossRef]

- Filice, M.; Marciello, M.; Betancor, L.; Carrascosa, A.V.; Guisan, J.M.; Fernandez-Lorente, G. Hydrolysis of fish oil by hyperactivated rhizomucor miehei lipase immobilized by multipoint anion exchange. Biotechnol. Prog. 2011, 27, 961–968. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, M.; Habibi, Z.; Dezvarei, S.; Yousefi, M.; Samadi, S.; Ashjari, M. Improvement of the stability and selectivity of Rhizomucor miehei lipase immobilized on silica nanoparticles: Selective hydrolysis of fish oil using immobilized preparations. Process. Biochem. 2014, 49, 1314–1323. [Google Scholar] [CrossRef]

- Mohammadi, M.; Habibi, Z.; Dezvarei, S.; Yousefi, M.; Ashjari, M. Selective enrichment of polyunsaturated fatty acids by hydrolysis of fish oil using immobilized and stabilized Rhizomucor miehei lipase preparations. Food Bioprod. Process. 2015, 94, 414–421. [Google Scholar] [CrossRef]

- Palomo, J.M.; Filice, M.; Romero, O.; Guisan, J.M. Improving lipase activity by immobilization and post-immobilization strategies. Methods Mol. Biol. 2013, 1051, 255–273. [Google Scholar]

- Viñambres, M.; Filice, M.; Marciello, M. Modulation of the catalytic properties of lipase B from Candida antarctica by immobilization on tailor-made magnetic iron oxide nanoparticles: The key role of nanocarrier surface engineering. Polymers 2018, 10, 615. [Google Scholar] [CrossRef]

- Rodrigues, R.C.; Virgen-Ortíz, J.J.; dos Santos, J.C.; Berenguer-Murcia, Á.; Alcantara, A.R.; Barbosa, O.; Ortiz, C.; Fernandez-Lafuente, R. Immobilization of lipases on hydrophobic supports: Immobilization mechanism, advantages, problems, and solutions. Biotechnol. Adv. 2019, 37, 746–770. [Google Scholar] [CrossRef] [PubMed]

- Palomo, J.M. Lipases enantioselectivity alteration by immobilization techniques. Curr. Bioact. Compd. 2008, 4, 126–138. [Google Scholar] [CrossRef]

- Orrego, A.H.; Ghobadi, R.; Moreno-Perez, S.; Mendoza, A.J.; Fernandez-Lorente, G.; Guisan, J.M.; Rocha-Martin, J. Stabilization of Immobilized Lipases by Intense Intramolecular Cross-Linking of Their Surfaces by Using Aldehyde-Dextran Polymers. Int. J. Mol. Sci. 2018, 19, 553. [Google Scholar] [CrossRef] [PubMed]

- Marciello, M.; Bolivar, J.M.; Filice, M.; Mateo, C.; Guisan, J.M. Preparation of Lipase-Coated, Stabilized, Hydrophobic Magnetic Particles for Reversible Conjugation of Biomacromolecules. Biomacromolecules 2013, 14, 602–607. [Google Scholar] [CrossRef]

- Habibi, Z.; Mohammadi, M.; Yousefi, M. Enzymatic hydrolysis of racemic ibuprofen esters using Rhizomucor miehei lipase immobilized on different supports. Process. Biochem. 2013, 48, 669–676. [Google Scholar] [CrossRef]

- Bassan, J.; de Souza Bezerra, T.; Peixoto, G.; da Cruz, C.; Galán, J.; Vaz, A.; Garrido, S.; Filice, M.; Monti, R. Immobilization of trypsin in lignocellulosic waste material to produce peptides with bioactive potential from whey protein. Materials 2016, 9, 357. [Google Scholar] [CrossRef]

- Bolivar, J.M.; López-Gallego, F.; Godoy, C.; Rodrigues, D.S.; Rodrigues, R.C.; Batalla, P.; Rocha-Martín, J.; Mateo, C.; Giordano, R.L.; Guisán, J.M. The presence of thiolated compounds allows the immobilization of enzymes on glyoxyl agarose at mild pH values: New strategies of stabilization by multipoint covalent attachment. Enzym. Microb. Technol. 2009, 45, 477–483. [Google Scholar] [CrossRef]

- Ghattas, N.; Filice, M.; Abidi, F.; Guisán, J.M.; Salah, A.B. Purification and improvement of the functional properties of Rhizopus oryzae lipase using immobilization techniques. J. Mol. Catal. B Enzym. 2014, 110, 111–116. [Google Scholar] [CrossRef]

- Guisán, J.M. Aldehyde-agarose gels as activated supports for immobilization-stabilization of enzymes. Enzym. Microb. Technol. 1988, 10, 375–382. [Google Scholar] [CrossRef]

- Klibanov, A.M. Improving enzymes by using them in organic solvents. Nature 2001, 409, 241–246. [Google Scholar] [CrossRef]

- Li, Z.; Chen, H.; Su, J.; Wang, W.; Chen, H.; Yang, B.; Wang, Y. Highly Efficient and Enzyme-Recoverable Method for Enzymatic Concentrating Omega-3 Fatty Acids Generated by Hydrolysis of Fish Oil in a Substrate-Constituted Three-Liquid-Phase System. J. Agric. Food Chem. 2019, 67, 2570–2580. [Google Scholar] [CrossRef] [PubMed]

- Garmroodi, M.; Mohammadi, M.; Ramazani, A.; Ashjari, M.; Mohammadi, J.; Sabour, B.; Yousefi, M. Covalent binding of hyper-activated Rhizomucor miehei lipase (RML) on hetero-functionalized siliceous supports. Int J. Biol. Macromol. 2016, 86, 208–215. [Google Scholar] [CrossRef] [PubMed]

- Bradford, M.M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 1976, 72, 248–254. [Google Scholar] [CrossRef]

- Fernandez-Lorente, G.; Godoy, C.A.; Mendes, A.A.; Lopez-Gallego, F.; Grazu, V.; de las Rivas, B.; Palomo, J.M.; Hermoso, J.; Fernandez-Lafuente, R.; Guisan, J.M. Solid-phase chemical amination of a lipase from Bacillus thermocatenulatus to improve its stabilization via covalent immobilization on highly activated glyoxyl-agarose. Biomacromolecules 2008, 9, 25532561. [Google Scholar] [CrossRef]

- Armisén, P.; Mateo, C.; Cortés, E.; Barredo, J.L.; Salto, F.; Diez, B.; Rodés, L.; Garcia, J.L.; Fernández-Lafuente, R.; Guisán, J.M. Selective adsorption of poly-His tagged glutaryl acylase on tailor-made metal chelate supports. J. Chromatogr. A 1999, 848, 61–70. [Google Scholar] [CrossRef]

- Fernández-Lorente, G.; Betancor, L.; Carrascosa, A.V.; Guisán, J.M. Release of omega-3 fatty acids by the hydrolysis of fish oil catalyzed by lipases immobilized on hydrophobic supports. J. Am. Oil Chem. Soc. 2011, 88, 1173–1178. [Google Scholar] [CrossRef]

Sample Availability: Samples of the RML-immobilized compounds are available from the authors. |

| Enzyme Derivative | Immobilization Yield (%) a | Specific Activity UI/mg Lipase b |

|---|---|---|

| Epoxy-IDA-RML | 43 | 0.6 |

| Epoxy-IDA-NH2-RML | 73 | 1.1 |

| CNBr-RML | 88 | 1.9 |

| CNBr- NH2-RML | 54 | 1.6 |

| Gx-RML | 47 | 0.6 |

| Gx-NH2-RML | 80 | 0.5 |

| Gx-DTT-NH2-RML | 59 | 0.8 |

| Gx-DTT-RML | 11 | 0.2 |

| Biocatalysts | pH 7, 25 °C | pH 5, 25 °C | ||

|---|---|---|---|---|

| Catalytic Efficiency a | Selectivity b | Catalytic Efficiency | Selectivity | |

| Gx-RML | 0.07 | 3.6 | 0.01 | 6.7 |

| Gx-NH2-RML | 0.02 | 2.7 | 0.01 | 3.8 |

| CNBr-RML | 0.5 | 3.9 | 0.16 | 11.2 |

| CNBr-NH2-RML | 0.07 | 8.8 | 0.04 | 11.0 |

| DTT-RML | 0.01 | 2.9 | 0.01 | 3.7 |

| DTT-NH2-RML | 0.04 | 6.6 | 0.01 | 2.8 |

| Epoxy-IDA-RML | 0.09 | 18.1 | 0.08 | 7.0 |

| Epoxy-IDA-NH2-RML | 1.7 | 6.8 | 1.1 | 22.1 |

| Biocatalysts | Catalytic Efficiency | Selectivity |

|---|---|---|

| CNBr-RML | 0.12 | 10.6 |

| Epoxy-IDA-RML | 0.04 | 22.1 |

| Epoxy-IDA-NH2-RML | 0.09 | 32.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yousefi, M.; Marciello, M.; Guisan, J.M.; Fernandez-Lorente, G.; Mohammadi, M.; Filice, M. Fine Modulation of the Catalytic Properties of Rhizomucor miehei Lipase Driven by Different Immobilization Strategies for the Selective Hydrolysis of Fish Oil. Molecules 2020, 25, 545. https://doi.org/10.3390/molecules25030545

Yousefi M, Marciello M, Guisan JM, Fernandez-Lorente G, Mohammadi M, Filice M. Fine Modulation of the Catalytic Properties of Rhizomucor miehei Lipase Driven by Different Immobilization Strategies for the Selective Hydrolysis of Fish Oil. Molecules. 2020; 25(3):545. https://doi.org/10.3390/molecules25030545

Chicago/Turabian StyleYousefi, Maryam, Marzia Marciello, Jose Manuel Guisan, Gloria Fernandez-Lorente, Mehdi Mohammadi, and Marco Filice. 2020. "Fine Modulation of the Catalytic Properties of Rhizomucor miehei Lipase Driven by Different Immobilization Strategies for the Selective Hydrolysis of Fish Oil" Molecules 25, no. 3: 545. https://doi.org/10.3390/molecules25030545

APA StyleYousefi, M., Marciello, M., Guisan, J. M., Fernandez-Lorente, G., Mohammadi, M., & Filice, M. (2020). Fine Modulation of the Catalytic Properties of Rhizomucor miehei Lipase Driven by Different Immobilization Strategies for the Selective Hydrolysis of Fish Oil. Molecules, 25(3), 545. https://doi.org/10.3390/molecules25030545