Aroma Characteristics of Lavender Extract and Essential Oil from Lavandula angustifolia Mill.

Abstract

1. Introduction

2. Results and Discussion

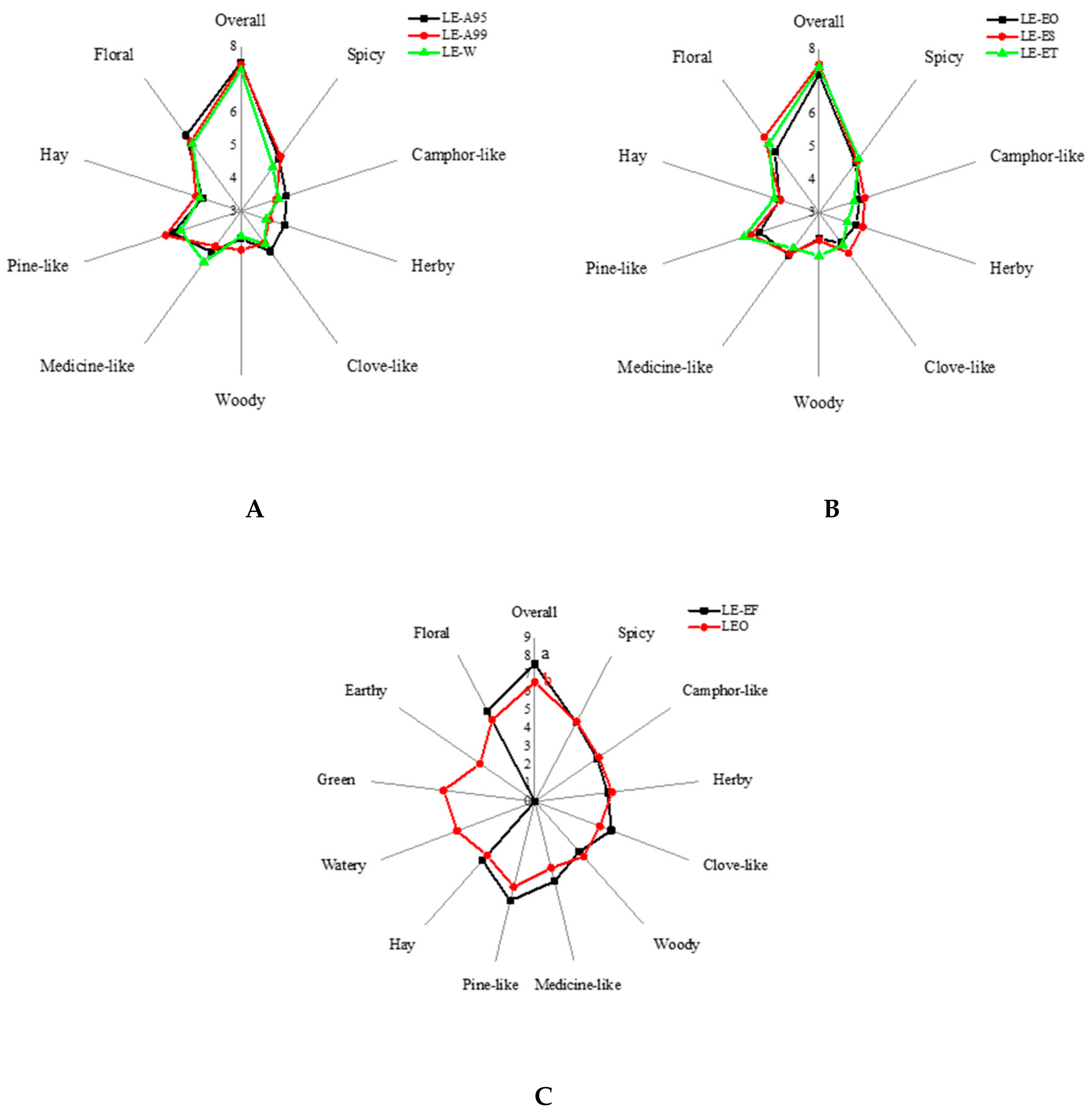

2.1. Odor Property of Lavender Extracts

2.1.1. Effect of Extraction Solvent on the Volatile Compositions of LEs

2.1.2. Effect of Extraction Solvent on the Odor Characteristics of LEs

2.1.3. Effect of Extraction Times on the Volatile Compositions of LEs

2.1.4. Effect of Extraction Times on the Odor Characteristic of LEs

2.1.5. Verification Experiments on the Preparation of LEs

2.2. Odor Property of Lavender Essential Oil

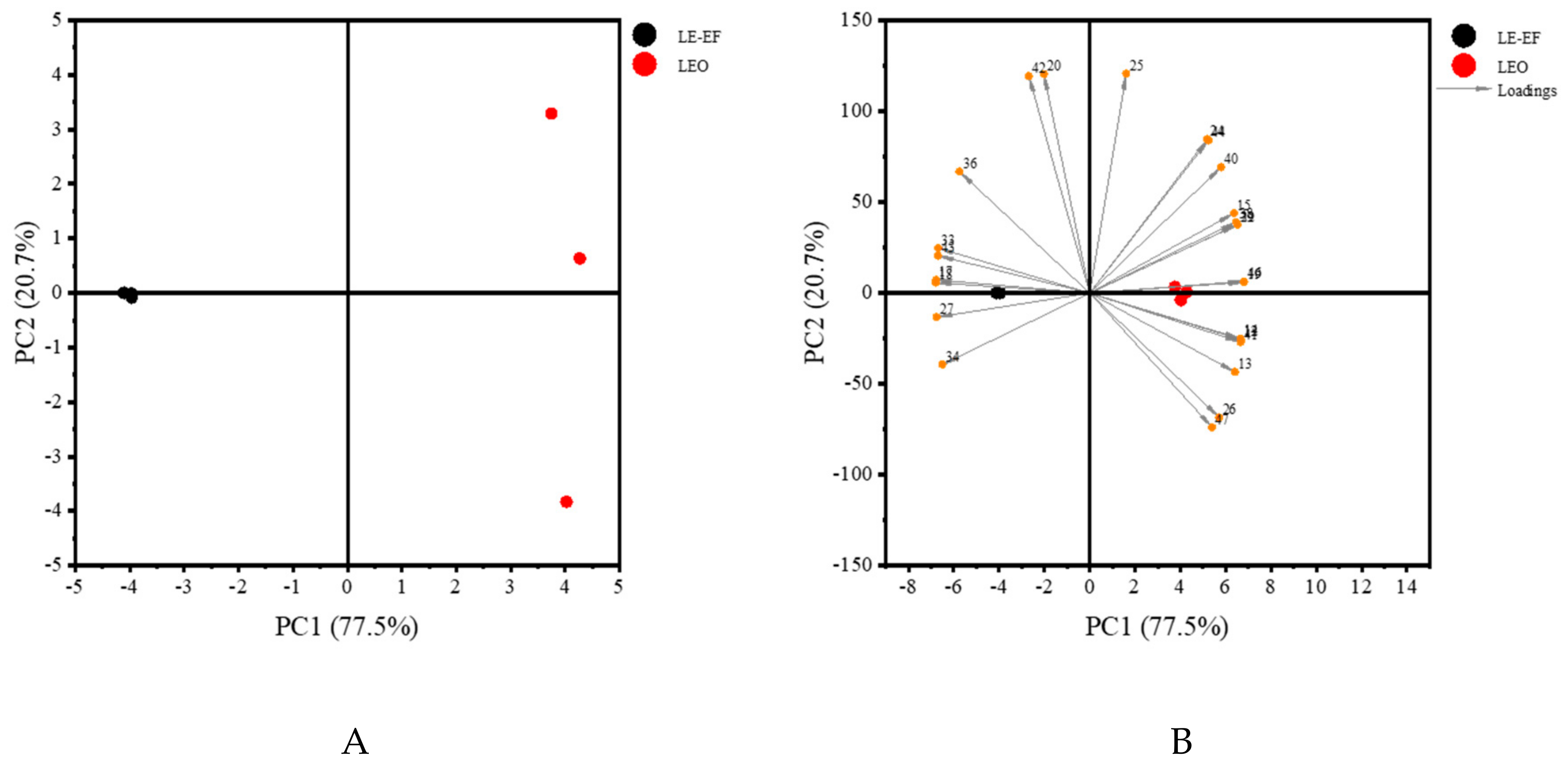

2.3. Principal Component Analysis

3. Materials and Methods

3.1. Reagents and Materials

3.2. Essential Oil Isolation

3.3. Lavender Extracts Preparation with Different Extraction Solvents

3.4. Lavender Extract Preparation with Different Extraction Times

3.5. Sensory Evaluation

3.6. Determination of Volatile Compounds in Lavender Extracts

3.7. Determination of Volatile Compounds in Lavender Essential Oil

3.8. The Analysis of Volatile Compositions

3.9. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dong, G.; Bai, X.; Aimila, A.; Aisa, H.A.; Maiwulanjiang, M. Study on lavender essential oil chemical compositions by GC-MS and improved pGC. Molecules 2020, 25, 3166. [Google Scholar] [CrossRef] [PubMed]

- Romeo, F.V.; De Luca, S.; Piscopo, A.; Poiana, M. Antimicrobial effect of some essential oils. J. Essent. Oil Res. 2008, 20, 373–379. [Google Scholar] [CrossRef]

- Carrasco, A.; Martinez-Gutierrez, R.; Tomas, V.; Tudela, J. Lavandula angustifolia and Lavandula latifolia essential oils from Spain: Aromatic profile and bioactivities. Planta Med. 2016, 82, 163–170. [Google Scholar] [PubMed]

- Giovannini, D.; Gismondi, A.; Basso, A.; Canuti, L.; Braglia, R.; Canini, A.; Mariani, F.; Cappelli, G. Lavandula angustifolia Mill. essential oil exerts antibacterial and anti-inflammatory effect in macrophage mediated immune response to Staphylococcus aureus. Immunol. Investig. 2016, 45, 11–28. [Google Scholar] [CrossRef] [PubMed]

- Sharifi-Rad, J.; Sureda, A.; Tenore, G.C.; Daglia, M.; Sharifi-Rad, M.; Valussi, M.; Tundis, R.; Sharifi-Rad, M.; Loizzo, M.R.; Ademiluyi, A.O.; et al. Biological activities of essential oils: From plant chemoecology to traditional healing systems. Molecules 2017, 22, 70. [Google Scholar] [CrossRef]

- Lee, K.-G.; Shibamoto, T. Determination of antioxidant potential of volatile extracts_isolated from various herbs and spices. J. Agr. Food Chem. 2002, 50, 4947–4952. [Google Scholar] [CrossRef]

- Woronuk, G.; Demissie, Z.; Rheault, M.; Mahmoud, S. Biosynthesis and therapeutic properties of Lavandula essential oil constituents. Planta Med. 2011, 77, 7–15. [Google Scholar] [CrossRef]

- Lin, P.W.-K.; Chan, W.-C.; Ng, B.F.-L.; Lam, L.C.-W. Efficacy of aromatherapy (Lavandula angustifolia) as an intervention for agitated behaviours in Chinese older persons with dementia: A cross-over randomized trial. Int. J. Geriatr. Psychiatry 2007, 22, 405–410. [Google Scholar] [CrossRef]

- Lubbe, A.; Verpoorte, R. Cultivation of medicinal and aromatic plants for specialty industrial materials. Ind. Crop. Prod. 2011, 34, 785–801. [Google Scholar] [CrossRef]

- Buljat, A.M.; Jurina, T.; Tušek, A.J.; Valinger, D.; Kljusurić, J.G.; Benković, M. Applicability of foam mat drying process for production of instant cocoa powder enriched with lavender extract. Food Technol. Biotechnol. 2019, 57, 159–170. [Google Scholar] [CrossRef]

- Détár, E.; Németh, É.Z.; Gosztola, B.; Demján, I.; Pluhár, Z. Effects of variety and growth year on the essential oil properties of lavender (Lavandula angustifolia Mill.) and lavandin (Lavandula x intermedia Emeric ex Loisel.). Biochem. Syst. Ecol. 2020, 90, 104020. [Google Scholar] [CrossRef]

- Mieriņa, I.; Jakaite, L.; Kristone, S.; Adere, L.; Jure, M. Extracts of peppermint, chamomile and lavender as antioxidants. Key Eng. Mater. 2018, 762, 31–35. [Google Scholar] [CrossRef]

- Guo, X. Optimization of extraction, antioxidant activities and beverage application of extract from leaves of Moringa oleifera Lam. Food Res. Develop. 2019, 40, 145–150, (in Chinese with English abstract). [Google Scholar]

- Cai, M.; Guo, X.; Liang, H.; Sun, P. Microwave-assisted extraction and antioxidant activity of star anise oil from Illicium verum Hook.f. Int. J. Food Sci. Technol. 2013, 48, 2324–2330. [Google Scholar]

- Guo, X.; Ho, C.-T.; Schwab, W.; Song, C.; Wan, X. Aroma compositions of large-leaf yellow tea and potential effect of theanine on volatile formation in tea. Food Chem. 2019, 280, 73–82. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Guo, X.; Yang, Y.; Xie, Y.; Ju, F.; Guo, W. Characterization of the aromatic profile in “zijuan” and “pu-erh” green teas by headspace solid-phase microextraction coupled with GC-O and GC-MS. Anal. Methods 2016, 8, 4727–4735. [Google Scholar] [CrossRef]

- Tamura, H.; Boonburung, S.; Yoshizawa, T.; Varayanond, W. The Volatile constituents in the peel and pulp of a green Thai mango, Khieo Sawoei Cultivar (Mangifera indica L). Food Sci. Technol. Res. 2001, 7, 72–77. [Google Scholar] [CrossRef]

- Pino, J.A.; Mesa, J. Contribution of volatile compounds to mango (Mangifera indica L.) aroma. Flavour Fragr. J. 2006, 21, 207–213. [Google Scholar] [CrossRef]

- Du, X.; Finn, C.E.; Qian, M.C. Volatile composition and odour-activity value of thornless ‘Black Diamond’ and ‘Marion’ blackberries. Food Chem. 2010, 119, 1127–1134. [Google Scholar] [CrossRef]

- Wang, D.; Yoshimura, T.; Kubota, K.; Kobayashi, A. Analysis of glycosidically bound aroma precursors in tea leaves. 1. Qualitative and quantitative analyses of glycosides with aglycons as aroma compounds. J. Agric. Food Chem. 2000, 48, 5411–5418. [Google Scholar] [CrossRef]

- Djenane, D.; Aïder, M.; Yangüela, J.; Idir, L.; Gómez, D.; Roncalés, P. Antioxidant and antibacterial effects of Lavandula and Mentha essential oils in minced beef inoculated with E. coli O157:H7 and S. aureus during storage at abuse refrigeration temperature. Meat Sci. 2012, 92, 667–674. [Google Scholar] [CrossRef] [PubMed]

- Amoore, J.E.; Hautala, E. Odor as an aid to chemical safety: Odor thresholds compared with threshold limit values and volatilities for 214 industrial chemicals in air and water dilution. J. Appl. Toxicol. 1983, 3, 272–290. [Google Scholar] [CrossRef] [PubMed]

- Yano, T.; Kanetake, T.; Saita, M.; Noda, K. Effects of l-menthol and dl-camphor on the penetration and hydrolysis of methyl salicylate in hairless mouse skin. J. Pharmacobiodyn 1991, 14, 663–669. [Google Scholar] [CrossRef] [PubMed]

- ISO 3515: 2002. Oil of lavender (Lavandula angustifolia Mill.). Available online: https://www.iso.org/standard/36253.html (accessed on 24 November 2020).

- Sowbhagya, H.B. Chemistry, technology, and nutraceutical functions of cumin (Cuminum cyminum L): An overview. Crit. Rev. Food Sci. Nutr. 2013, 53, 1–10. [Google Scholar] [CrossRef]

- Sakauchi, H.; Kiyota, H.; Oritani, T.; Kuwahara, S.; Takigawa, S.-Y. Enzymatic Resolution and Odor Description of Both Enantiomers of Lavandulol, a Fragrance of Lavender Oil. Chem. Biodivers. 2005, 2, 1183–1186. [Google Scholar] [CrossRef]

- Jindal, G.; Sunoj, R.B. Revisiting sesquiterpene biosynthetic pathways leading to santalene and its analogues: A comprehensive mechanistic study. Org. Biomol. Chem. 2012, 10, 7996–8006. [Google Scholar] [CrossRef]

- Lin, J.; Zhang, P.; Pan, Z.; Xu, H.; Luo, Y.; Wang, X. Discrimination of oolong tea (Camellia sinensis) varieties based on feature extraction and selection from aromatic profiles analysed by HS-SPME/GC-MS. Food Chem. 2013, 141, 259–265. [Google Scholar] [CrossRef]

- Kashima, Y.; Miyazawa, M. Chemical composition and aroma evaluation of essential oils from Evolvulus alsinoides L. Chem. Biodivers. 2014, 11, 396–407. [Google Scholar] [CrossRef]

- Ali, A.; Tabanca, N.; Demirci, B.; Blythe, E.K. Chemical Composition and Biological Activity of Four Salvia Essential Oils and Individual Compounds against Two Species of Mosquitoes. J. Agric. Food Chem. 2015, 63, 447–456. [Google Scholar] [CrossRef]

- Usano-Alemany, J.; Palá-Paúl, J.; Rodríguez, M.S.C.; Herraiz-Peñalver, D. Chemical description and essential oil yield variability of different accessions of Salvia lavandulifolia. Nat. Prod. Commun. 2014, 9, 273–276. [Google Scholar]

- Sebai, H.; Selmi, S.; Rtibi, K.; Souli, A.; Gharbi, N.; Sakly, M. Lavender (Lavandula stoechas L.) essential oils attenuate hyperglycemia and protect against oxidative stress in alloxan-induced diabetic rats. Lipids Health Dis. 2013, 12, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Lapczynski, A.; Foxenberg, R.J.; Bhatia, S.P.; Letizia, C.S.; Api, A.M. Fragrance material review on nerol. Food Chem. Toxicol. 2008, 46, S241–S244. [Google Scholar] [CrossRef] [PubMed]

- Iwasa, M.; Iwasaki, T.; Ono, T.; Miyazawa, M. Chemical composition and major odor-active compounds of essential oil from PINELLIA TUBER (dried rhizome of Pinellia ternata) as crude drug. J. Oleo Sci. 2014, 63, 127–135. [Google Scholar] [CrossRef] [PubMed]

- Wüst, M.; Reindl, J.; Fuchs, S.; Beck, T.; Mosandl, A. Structure elucidation, enantioselective analysis, and biogenesis of nerol oxide in Pelargonium species. J. Agr. Food Chem. 1999, 47, 3145–3150. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Ho, C.T.; Wan, X.; Zhu, H.; Liu, Q.; Wen, Z. Changes of volatile compounds and odor profiles in Wuyi rock tea during processing. Food Chem. 2021, 341, 128230. [Google Scholar] [CrossRef]

- Guo, X. Analysis of volatile compositions in six edible fragrant plants by GC-MS/GC-O technology. Trans. Chinese Soc. Agric. Eng. 2019, 35, 299–307, (in Chinese with English abstract). [Google Scholar]

- Guo, X. Analysis on flower volatile components of Cinnamomum camphora var. linaloolifera. J. Plant Resour. Environ. 2020, 29. in press. (in Chinese with English abstract). [Google Scholar]

Sample Availability: Samples of the compounds are available from the authors upon reasonable request. |

| No. | RT | RI | Volatile Compounds | Relative Content (%) | ID * | ||

|---|---|---|---|---|---|---|---|

| LE-A95 | LE-A99 | LE-W | |||||

| 1 | 2.44 | 666 | Acetic acid | 0.22 ± 0.01 | 0.71 ± 0.00 | 0.59 ± 0.02 | MS, RI, S |

| 2 | 9.35 | 979 | 1-Octen-3-ol | 0.05 ± 0.00 | nd | nd | MS, RI, S |

| 3 | 9.66 | 988 | β-Myrcene | 0.89 ± 0.00 | 0.63 ± 0.02 | 0.56 ± 0.02 | MS, RI, S |

| 4 | 11.39 | 996 | Hexyl acetate | 0.53 ± 0.03 | 0.18 ± 0.00 | 0.12 ± 0.00 | MS, RI, S |

| 5 | 12.19 | 1018 | Limonene | 0.15 ± 0.01 | 0.07 ± 0.00 | 0.06 ± 0.00 | MS, RI, S |

| 6 | 13.37 | 1022 | 1,8-Cineole | 2.25 ± 0.10 | 1.26 ± 0.00 | 0.58 ± 0.04 | MS, RI |

| 7 | 19.52 | 1048 | (E)-β-Ocimene | 0.86 ± 0.00 | 0.25 ± 0.01 | 0.19 ± 0.01 | MS, RI, S |

| 8 | 20.04 | 1052 | (Z)-β-Ocimene | 0.71 ± 0.02 | 0.38 ± 0.01 | 0.32 ± 0.02 | MS, RI, S |

| 9 | 21.46 | 1081 | Linalool oxide Ⅱ ((E)-furanoid) | 1.13 ± 0.01 | 1.08 ± 0.05 | 0.51 ± 0.01 | MS, RI, S |

| 10 | 22.72 | 1098 | Linalool oxide Ⅰ ((Z)-furanoid) | 0.92 ± 0.04 | 0.90 ± 0.04 | 0.39 ± 0.01 | MS, RI, S |

| 11 | 23.75 | 1111 | 1-Octen-3-yl acetate | 3.93 ± 0.16 | 2.72 ± 0.04 | 1.95 ± 0.03 | MS, RI |

| 12 | 23.83 | 1120 | Camphol | 0.28 ± 0.02 | 0.44 ± 0.02 | 0.48 ± 0.02 | MS, RI, S |

| 13 | 24.40 | 1145 | Camphor | 0.15 ± 0.00 | 0.27 ± 0.00 | 0.20 ± 0.00 | MS, RI |

| 14 | 24.96 | 1159 | Cryptone | 0.48 ± 0.00 | 0.71 ± 0.02 | 0.71 ± 0.05 | MS, RI |

| 15 | 26.03 | 1159 | Terpinen-4-ol | 0.16 ± 0.00 | 0.24 ± 0.01 | 0.28 ± 0.01 | MS, RI |

| 16 | 29.68 | 1163 | Linalool | 12.51 ± 0.72 | 11.63 ± 0.29 | 7.72 ± 0.41 | MS, RI, S |

| 17 | 30.16 | 1165 | (3E,5Z)-1,3,5-Undecatriene | 0.33 ± 0.02 | 0.13 ± 0.01 | 0.10 ± 0.00 | MS, RI |

| 18 | 30.18 | 1166 | Linalyl acetate | 46.62 ± 0.45 | 47.22 ± 1.01 | 47.00 ± 1.14 | MS, RI |

| 19 | 30.59 | 1170 | Lavandulol | 0.61 ± 0.03 | 0.91 ± 0.03 | 1.11 ± 0.05 | MS, RI |

| 20 | 30.89 | 1192 | Hexyl butanoate | 0.68 ± 0.03 | 0.51 ± 0.01 | 0.42 ± 0.01 | MS, RI |

| 21 | 31.10 | 1238 | Carvone | 0.07 ± 0.00 | 0.09 ± 0.00 | 0.14 ± 0.00 | MS, RI |

| 22 | 31.92 | 1247 | Cumaldehyde | 0.35 ± 0.01 | 0.39 ± 0.00 | 0.46 ± 0.02 | MS, RI |

| 23 | 32.91 | 1268 | Lavandulyl acetate | 11.88 ± 0.14 | 11.10 ± 0.36 | 10.32 ± 0.11 | MS, RI |

| 24 | 34.86 | 1289 | Bornyl acetate | 0.34 ± 0.00 | 0.47 ± 0.03 | 0.40 ± 0.02 | MS, RI |

| 25 | 35.90 | 1348 | Copaene | 0.16 ± 0.01 | 0.15 ± 0.01 | 0.10 ± 0.01 | MS, RI, S |

| 26 | 36.63 | 1363 | Neryl acetate | 0.30 ± 0.02 | 0.26 ± 0.01 | 0.26 ± 0.01 | MS, RI, S |

| 27 | 37.02 | 1383 | Geranyl acetate | 0.57 ± 0.03 | 0.45 ± 0.01 | 0.44 ± 0.01 | MS, RI, S |

| 28 | 37.32 | 1433 | trans-α-Bergamotene | 0.54 ± 0.02 | 0.47 ± 0.00 | 0.54 ± 0.01 | MS, RI |

| 29 | 38.60 | 1442 | (E)-β-Caryophyllene | 6.67 ± 0.14 | 4.7 ± 0.14 | 5.02 ± 0.07 | MS, RI, S |

| 30 | 39.18 | 1469 | (E)-β-Farnesene | 1.37 ± 0.06 | 1.37 ± 0.08 | 1.85 ± 0.11 | MS, RI, S |

| 31 | 40.85 | 1477 | Coumarin | 0.13 ± 0.01 | 0.14 ± 0.00 | 0.24 ± 0.01 | MS, RI, S |

| 32 | 41.18 | 1484 | Germacrene D | 0.31 ± 0.02 | 0.30 ± 0.01 | 0.13 ± 0.00 | MS, RI |

| 33 | 50.78 | 1593 | Caryophyllene oxide | 0.25 ± 0.00 | 0.29 ± 0.01 | 0.41 ± 0.02 | MS, RI |

| No. | RT | RI | Volatile Compounds | Relative Content (%) | ID * | |||

|---|---|---|---|---|---|---|---|---|

| LE-EO | LE-ES | LE-ET | LE-EF | |||||

| 1 | 2.44 | 666 | Acetic acid | 0.48 ± 0.03 | 0.22 ± 0.01 | 0.67 ± 0.03 | 0.28 ± 0.01 | MS, RI, S |

| 2 | 9.35 | 979 | 1-Octen-3-ol | nd | 0.05 ± 0.00 | nd | 0.15 ± 0 | MS, RI, S |

| 3 | 9.66 | 988 | β-Myrcene | 0.60 ± 0.00 | 0.89 ± 0.00 | 0.65 ± 0.02 | 0.83 ± 0.02 | MS, RI, S |

| 4 | 11.39 | 996 | Hexyl acetate | 0.12 ± 0.01 | 0.53 ± 0.03 | 0.19 ± 0.01 | 0.01 ± 0 | MS, RI, S |

| 5 | 12.19 | 1018 | Limonene | 0.06 ± 0.00 | 0.15 ± 0.01 | 0.07 ± 0.01 | 0.09 ± 0 | MS, RI, S |

| 6 | 13.37 | 1022 | 1,8-Cineole | 0.45 ± 0.02 | 2.25 ± 0.10 | 1.27 ± 0.02 | 0.18 ± 0 | MS, RI |

| 7 | 19.52 | 1048 | (E)-β-Ocimene | 0.20 ± 0.01 | 0.86 ± 0.00 | 0.25 ± 0.00 | 0.28 ± 0.01 | MS, RI, S |

| 8 | 20.04 | 1052 | (Z)-β-Ocimene | 0.35 ± 0.00 | 0.71 ± 0.02 | 0.41 ± 0.03 | 0.48 ± 0.01 | MS, RI, S |

| 9 | 21.46 | 1081 | Linalool oxide Ⅱ ((E)-furanoid) | 1.24 ± 0.04 | 1.13 ± 0.01 | 1.23 ± 0.09 | 1.2 ± 0.06 | MS, RI, S |

| 10 | 22.72 | 1098 | Linalool oxide Ⅰ ((Z)-furanoid) | 1.00 ± 0.09 | 0.92 ± 0.04 | 0.91 ± 0.01 | 0.9 ± 0.03 | MS, RI, S |

| 11 | 23.75 | 1111 | 1-Octen-3-yl acetate | 2.00 ± 0.06 | 3.93 ± 0.16 | 2.68 ± 0.04 | 1.31 ± 0 | MS, RI |

| 12 | 23.83 | 1120 | Camphol | 0.71 ± 0.02 | 0.28 ± 0.02 | 0.43 ± 0.01 | 0.74 ± 0 | MS, RI, S |

| 13 | 24.40 | 1145 | Camphor | 0.24 ± 0.02 | 0.15 ± 0.00 | 0.27 ± 0.00 | 0.13 ± 0 | MS, RI |

| 14 | 24.96 | 1159 | Cryptone | 0.80 ± 0.03 | 0.48 ± 0.00 | 0.73 ± 0.03 | 0.81 ± 0.03 | MS, RI |

| 15 | 26.03 | 1159 | Terpinen-4-ol | 0.35 ± 0.02 | 0.16 ± 0.00 | 0.22 ± 0.02 | 0.39 ± 0 | MS, RI |

| 16 | 29.68 | 1163 | Linalool | 14.58 ± 0.18 | 7.72 ± 0.41 | 11.87 ± 0.34 | 16.82 ± 0.31 | MS, RI, S |

| 17 | 30.16 | 1165 | (3E,5Z)-1,3,5-Undecatriene | nd | 0.33 ± 0.02 | 0.13 ± 0.00 | nd | MS, RI |

| 18 | 30.18 | 1166 | Linalyl acetate | 47.28 ± 0.35 | 46.62 ± 0.45 | 47.08 ± 0.19 | 46.76 ± 0.37 | MS, RI |

| 19 | 30.59 | 1170 | Lavandulol | 1.50 ± 0.06 | 0.61 ± 0.03 | 0.86 ± 0.04 | 1.54 ± 0.01 | MS, RI |

| 20 | 30.89 | 1192 | Hexyl butanoate | 0.48 ± 0.02 | 0.68 ± 0.03 | 0.52 ± 0.01 | 0.37 ± 0.01 | MS, RI |

| 21 | 31.10 | 1238 | Carvone | 0.17 ± 0.02 | 0.07 ± 0.00 | 0.09 ± 0.01 | 0.19 ± 0 | MS, RI |

| 22 | 31.92 | 1247 | Cumaldehyde | 0.63 ± 0.00 | 0.35 ± 0.01 | 0.38 ± 0.01 | 0.63 ± 0.01 | MS, RI |

| 23 | 32.91 | 1268 | Lavandulyl acetate | 13.46 ± 0.09 | 11.88 ± 0.14 | 12.05 ± 0.82 | 14.21 ± 0.28 | MS, RI |

| 24 | 34.86 | 1289 | Bornyl acetate | 0.46 ± 0.03 | 0.34 ± 0.00 | 0.45 ± 0.03 | 0.5 ± 0.01 | MS, RI |

| 25 | 35.90 | 1348 | Copaene | 0.07 ± 0.00 | 0.16 ± 0.01 | 0.15 ± 0.00 | nd | MS, RI, S |

| 26 | 36.63 | 1363 | Neryl acetate | 0.33 ± 0.01 | 0.30 ± 0.02 | 0.25 ± 0.01 | 0.41 ± 0.02 | MS, RI, S |

| 27 | 37.02 | 1383 | Geranyl acetate | 0.49 ± 0.04 | 0.57 ± 0.03 | 0.44 ± 0.01 | 0.68 ± 0.01 | MS, RI, S |

| 28 | 37.11 | 1402 | α-Santalene | 0.96 ± 0.08 | nd | nd | 0.5 ± 0.01 | MS, RI |

| 29 | 37.32 | 1433 | trans-α-Bergamotene | 0.32 ± 0.01 | 0.54 ± 0.02 | 0.50 ± 0.04 | 0.24 ± 0.01 | MS, RI |

| 30 | 38.60 | 1442 | (E)-β-Caryophyllene | 3.34 ± 0.15 | 6.67 ± 0.14 | 4.33 ± 0.37 | 2.34 ± 0.01 | MS, RI, S |

| 31 | 39.18 | 1469 | (E)-β-Farnesene | 1.24 ± 0.02 | 1.37 ± 0.06 | 1.31 ± 0.05 | 1.13 ± 0.01 | MS, RI, S |

| 32 | 40.85 | 1477 | Coumarin | 0.27 ± 0.02 | 0.13 ± 0.01 | 0.14 ± 0.00 | 0.17 ± 0.01 | MS, RI, S |

| 33 | 41.18 | 1484 | Germacrene D | 0.30 ± 0.01 | 0.31 ± 0.02 | 0.29 ± 0.02 | 0.09 ± 0 | MS, RI |

| 34 | 50.78 | 1593 | Caryophyllene oxide | 0.50 ± 0.04 | 0.25 ± 0.00 | 0.28 ± 0.02 | 0.63 ± 0 | MS, RI |

| No. | RT | RI | Volatile Compounds | LEO (%) | ID * |

|---|---|---|---|---|---|

| 1 | 2.56 | 748 | 3-Methyl-2-butenal | 0.01 ± 0.00 | MS, RI, S |

| 2 | 3.49 | 852 | 1-Hexanol | 0.05 ± 0.00 | MS, RI, S |

| 3 | 4.54 | 929 | α-Thujene | 0.10 ± 0.06 | MS, RI |

| 4 | 4.65 | 931 | α-Pinene | 0.28 ± 0.04 | MS, RI, S |

| 5 | 4.95 | 958 | Camphene | 0.33 ± 0.09 | MS, RI, S |

| 6 | 5.46 | 963 | 1-Octen-3-ol | 0.47 ± 0.08 | MS, RI, S |

| 7 | 5.65 | 989 | 3-Octanone | 0.28 ± 0.18 | MS, RI |

| 8 | 5.74 | 990 | β-Pinene | 0.70 ± 0.05 | MS, RI, S |

| 9 | 6.23 | 1003 | 3-Carene | 0.78 ± 0.06 | MS, RI |

| 10 | 6.47 | 1011 | p-Cymene | 0.13 ± 0.03 | MS, RI, S |

| 11 | 6.54 | 1015 | o-Cymene | 0.35 ± 0.01 | MS, RI, S |

| 12 | 6.65 | 1018 | Limonene | 0.95 ± 0.18 | MS, RI, S |

| 13 | 6.73 | 1022 | 1,8-Cineole | 1.02 ± 0.27 | MS, RI |

| 14 | 6.85 | 1034 | (E)-β-Ocimene | 4.38 ± 0.91 | MS, RI, S |

| 15 | 7.13 | 1036 | (Z)-β-Ocimene | 1.71 ± 0.37 | MS, RI, S |

| 16 | 7.44 | 1047 | γ-Terpinene | 0.09 ± 0.04 | MS, RI, S |

| 17 | 8.21 | 1081 | Linalool oxide Ⅱ ((E)-furanoid) | 0.22 ± 0.07 | MS, RI, S |

| 18 | 7.83 | 1098 | Linalool oxide Ⅰ ((Z)-furanoid) | 0.28 ± 0.03 | MS, RI, S |

| 19 | 8.68 | 1103 | Linalool | 29.01 ± 0.33 | MS, RI, S |

| 20 | 8.79 | 1106 | 1-Octen-3-yl acetate | 1.25 ± 0.18 | MS, RI |

| 21 | 9.15 | 1118 | allo-Ocimene | 0.33 ± 0.09 | MS, RI |

| 22 | 9.53 | 1121 | Camphor | 0.38 ± 0.03 | MS, RI |

| 23 | 9.68 | 1137 | Nerol oxide | 0.02 ± 0.01 | MS, RI |

| 24 | 9.98 | 1161 | Camphol | 1.65 ± 0.66 | MS, RI |

| 25 | 10.00 | 1162 | Lavandulol | 1.72 ± 0.71 | MS, RI, S |

| 26 | 10.20 | 1167 | Terpinen-4-ol | 2.24 ± 1.05 | MS, RI |

| 27 | 10.39 | 1170 | Cryptone | 0.31 ± 0.04 | MS, RI |

| 28 | 10.54 | 1172 | α-Terpineol | 2.03 ± 0.22 | MS, RI, S |

| 29 | 10.81 | 1196 | Eucarvone | 0.08 ± 0.05 | MS, RI |

| 30 | 10.99 | 1226 | (Z)-Carveol | 0.03 ± 0.00 | MS, RI |

| 31 | 11.15 | 1237 | Nerol | 0.40 ± 0.08 | MS, RI |

| 32 | 11.37 | 1239 | α-Methylbenzenepropanal | 0.23 ± 0.03 | MS, RI |

| 33 | 11.44 | 1240 | Carvone | 0.04 ± 0.03 | MS, RI |

| 34 | 11.68 | 1251 | Linalyl acetate | 27.33 ± 5.05 | MS, RI, S |

| 35 | 12.02 | 1280 | Phellandral | 0.04 ± 0.01 | MS, RI |

| 36 | 12.25 | 1294 | Lavandulyl acetate | 7.00 ± 3.86 | MS, RI |

| 37 | 12.31 | 1295 | Cuminol | 0.04 ± 0.01 | MS, RI |

| 38 | 13.33 | 1367 | Neryl acetate | 0.60 ± 0.06 | MS, RI |

| 39 | 13.63 | 1383 | Geranyl acetate | 1.23 ± 0.15 | MS, RI, S |

| 40 | 14.21 | 1418 | α-Santalene | 0.77 ± 0.15 | MS, RI |

| 41 | 14.26 | 1421 | (E)-β-Caryophyllene | 3.67 ± 0.26 | MS, RI, S |

| 42 | 14.41 | 1427 | trans-α-Bergamotene | 0.22 ± 0.05 | MS, RI |

| 43 | 14.46 | 1428 | Coumarin | 0.08 ± 0.02 | MS, RI, S |

| 44 | 14.64 | 1455 | (E)-β-Farnesene | 1.66 ± 0.38 | MS, RI, S |

| 45 | 14.73 | 1456 | α-Humulene | 0.20 ± 0.00 | MS, RI |

| 46 | 15.09 | 1482 | Germacrene D | 0.80 ± 0.02 | MS, RI |

| 47 | 16.44 | 1561 | Caryophyllene oxide | 0.72 ± 0.06 | MS, RI |

| 48 | 17.06 | 1589 | epi-Bicyclosesquiphellandrene | 0.29 ± 0.12 | MS, RI |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Wang, P. Aroma Characteristics of Lavender Extract and Essential Oil from Lavandula angustifolia Mill. Molecules 2020, 25, 5541. https://doi.org/10.3390/molecules25235541

Guo X, Wang P. Aroma Characteristics of Lavender Extract and Essential Oil from Lavandula angustifolia Mill. Molecules. 2020; 25(23):5541. https://doi.org/10.3390/molecules25235541

Chicago/Turabian StyleGuo, Xiangyang, and Pu Wang. 2020. "Aroma Characteristics of Lavender Extract and Essential Oil from Lavandula angustifolia Mill." Molecules 25, no. 23: 5541. https://doi.org/10.3390/molecules25235541

APA StyleGuo, X., & Wang, P. (2020). Aroma Characteristics of Lavender Extract and Essential Oil from Lavandula angustifolia Mill. Molecules, 25(23), 5541. https://doi.org/10.3390/molecules25235541