Influence of Pear Variety and Drying Methods on the Quality of Dried Fruit

Abstract

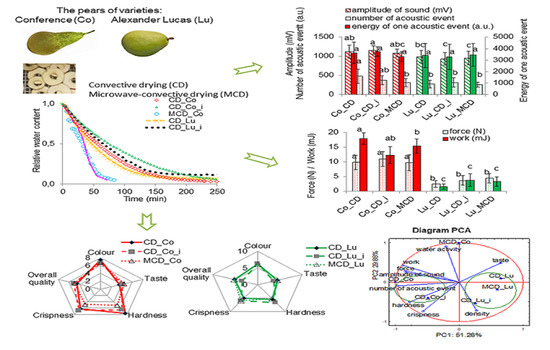

1. Introduction

2. Results and Discussion

2.1. Drying Kinetics, Water Activity and Density Analysis

2.2. Color Analysis

2.3. Acoustic and Mechanical Properties

2.4. Sensory Properties

2.5. A Complex Evaluation of the Dried Fruit Texture

3. Materials and Methods

3.1. Materials

3.2. Drying Methods

3.3. Density and Water Activity

3.4. Color Measurements

3.5. Acoustic and Mechanical Properties

3.6. Sensory Properties

3.7. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Co | Pear of the “Conference” variety |

| Lu | Pear of the “Alexander Lucas” variety |

| CD | Convective drying method |

| MCD | Microwave-convective drying method |

| CA | Citric acid |

| i | Immersion in CA |

| C* | Chroma |

| ΔE | Chroma |

| h* | Hue angle |

| YI | Yellowness index |

References

- Alonzo-Macías, M.; Montejano-Gaitán, G.; Allaf, K. Impact of drying processes on strawberry (fragaria var. Camarosa) texture: Identification of crispy and crunchy features by instrumental measurement. J. Texture Stud. 2014, 45, 246–259. [Google Scholar] [CrossRef]

- Andreani, P.; de Moraes, J.O.; Murta, B.H.P.; Link, J.V.; Tribuzi, G.; Laurindo, J.B.; Paul, S.; Carciofi, B.A.M. Spectrum crispness sensory scale correlation with instrumental acoustic high-sampling rate and mechanical analyses. Food Res. Internat. 2020, 129, 108886. [Google Scholar] [CrossRef] [PubMed]

- Saeleaw, M.; Schleining, G. A review. Crispness in dry foods and quality measurements based on acoustic-mechanical destructive techniques. J. Food Eng. 2011, 105, 387–399. [Google Scholar] [CrossRef]

- Kiczorowska, B.; Kiczorowski, P. Comparison of basic chemical and mineral composition in edible parts of chosen pear cultivars produced in Podkarpackie Province. Acta Sci. Pol. Hortorum Cultus 2011, 10, 153–169. [Google Scholar]

- Öztekin, Y.B.; Sacilik, K. Drying characteristics of “Ankara” pear slices. Ital. J. Food Sci. 2020, 32, 251–264. [Google Scholar]

- Juhaimi, F.A.; Uslu, N.; Özcan, M.M.; Fadil, E.; Babiker, E.; Ghafoorn, K. Effect of drying on antioxidant activity, total phenol and mineral contents of pear fruits. J. Food Saf. Food Qual. 2016, 67, 113–148. [Google Scholar]

- González-Martínez, C.M.; Xue, K.; Chiralt, A. Effect of the osmotic pre-treatment on the convective air arying kinetics of pear var. Blanquilla. Int. J. Food Prop. 2006, 9, 541–549. [Google Scholar] [CrossRef]

- Doymaz, I. Experimental study on drying of pear slices in a convective dryer. Int. J. Food Sci. Tech. 2013, 48, 1909–1915. [Google Scholar] [CrossRef]

- Da Costa Ribeiro, A.S.; Aguiar-Oliveira, E.; Maldonado, R.R. Optimization of osmotic dehydration of pear followed by conventional drying and their sensory quality. LWT-Food Sci. Technol. 2016, 72, 407–415. [Google Scholar] [CrossRef]

- Guiné, R.P.F. Influence of drying method on density and porosity of pears. Food Bioprod. Process. 2006, 84, 179–185. [Google Scholar] [CrossRef]

- Guiné, R.P.F.; Barroca, M.J.; Gonçalves, F.J.; Alves, M.; Oliveira, S.; Correia, P.M.R. Effect of drying on total phenolic compounds, antioxidant activity, and kinetics decay in pears. Int. J. Fruit Sci. 2015, 15, 173–186. [Google Scholar] [CrossRef]

- Santos, S.C.; Guiné, R.P.; Barros, A.I. Influence of drying on the properties of pears of the Rocha variety (Pyrus communis L.). Int. J. Food Eng. 2013, 9, 197–207. [Google Scholar] [CrossRef]

- Silva, V.; Figueiredo, A.R.; Costa, J.J.; Guiné, R.P.F. Experimental and mathematical study of the discontinuous drying kinetics of pears. J. Food Eng. 2014, 134, 30–36. [Google Scholar] [CrossRef]

- Djendoubi Mrad, N.; Boudhrioua, N.; Kechaou, N.; Courtois, F.; Bonazzi, C. Influence of air drying temperature on kinetics physicochemical properties, total phenolic content an ascorbic acid of pears. Food Bioprod. Process. 2012, 90, 433–441. [Google Scholar] [CrossRef]

- Djendoubi Mrad, N.; Boudhriuoa Mihoubi, N.; Kechaou, N.; Courtois, F.; Bonazzi, C. Effect of osmo-dehydration conditions on the quality attributes of pears. J Food Process Technol. 2013, 4, 256. [Google Scholar] [CrossRef]

- Kolniak-Ostek, J. Chemical composition and antioxidant capacity of different anatomical parts of pear (Pyrus communis L.). Food Chem. 2016, 203, 491–497. [Google Scholar] [CrossRef]

- Morais, R.M.S.C.; Morais, A.M.M.B.; Dammak, I.; Bonilla, J.; Sobral, P.J.A.; Laguerre, J.C.; Afonso, M.J.; Ramalhosa, E.C.D. Review Article Functional Dehydrated Foods for Health Preservation. J. Food Qual. 2018, 3, 1–29. [Google Scholar] [CrossRef]

- Raponi, F.; Moscetti, R.; Monarca, D.; Colantoni, A.; Massantini, R. Monitoring and optimization of the process of drying fruits and vegetables using computer vision: A Review. Sustainability 2017, 9, 2009. [Google Scholar] [CrossRef]

- Deng, L.-Z.; Mujumdar, A.S.; Zhang, Q.; Yang, X.-H.; Wang, J.; Zheng, Z.-A.; Gao, Z.-J.; Xiao, H.-W. Chemical and physical pretreatments of fruits and vegetables: Effects on drying characteristics and quality attributes—A comprehensive review. Crit. Rev. Food Sci. Nutr. 2017, 1408–1432. [Google Scholar] [CrossRef]

- Kumar, C.; Karim, M.A. Microwave-convective drying of food materials: A critical review. Crit. Rev. Food Sci. Nutr. 2019, 59, 379–394. [Google Scholar] [CrossRef]

- Aral, S.; Beşe, A.V. Convective drying of hawthorn fruit (Crataegus spp.): Effect of experimental parameters on drying kinetics, colour, shrinkage, and rehydration capacity. Food Chem. 2016, 210, 577–584. [Google Scholar] [CrossRef]

- Celejewska, K.; Mieszczakowska-Frąc, M.; Konopacka, D.; Krupa, T. The influence of ultrasound and cultivar selection on the biocompounds and physicochemical characteristics of dried blueberry (Vaccinium corymbosum L.) snacks. J. Food Sci. 2018, 83, 2305–2316. [Google Scholar] [CrossRef]

- Li, K.; Zhang, M.; Mujumdar, A.S.; Chitrakar, B. Recent developments in physical field-based drying techniques for fruits and vegetables, Dry Technol. 2019, 37, 1954–1973. [CrossRef]

- Ferreira, D.; Da Silva, J.A.L.; Pinto, G.; Santos, C.; Delgadillo, I.; Coimbra, M.A. Effect of sun-drying on microstructure and texture of S. Bartolomeu pears (Pyrus communis L.). Eur. Food Res. Tech. 2008, 226, 1545–1552. [Google Scholar] [CrossRef]

- Figiel, A.; Michalska, A. Overall quality of fruits and vegetables products affected by the drying processes with the assistance of vacuum-microwaves. Int. J. Mol. Sci. 2017, 18, 71. [Google Scholar] [CrossRef]

- Amiripour, M.; Habibi-Najafi, M.B.; Mohebbi, M.; Emadi, B. Optimization of osmo-vacuum drying of pear (Pyrus communis L.) using response surface methodology. J Food Meas. Charact. 2015, 9, 269–280. [Google Scholar] [CrossRef]

- Antal, T.; Tarek-Tilistyák, J.; Cziáky, Z.; Sinka, L. Comparison of drying and quality characteristics of pear (Pyrus communis L.) using mid-infrared-freeze drying and single stage of freeze drying. Int. J. Food Eng. 2017, 13, 125–146. [Google Scholar] [CrossRef]

- Dujmić, F.; Brnčić, M.; Karlović, S.; Bosiljkov, T.; Ježek, D.; Tripalo, B.; Mofardin, I. Ultrasound-assisted infrared drying of pear slices: Textural issues. J. Food Process. Eng. 2013, 36, 397–406. [Google Scholar] [CrossRef]

- Duan, X.; Liu, W.C.; Ren, G.Y.; Yang, X. Effects of different drying methods on the physical characteristics and flavor of dried hawthorns (Crataegus spp.). Dry Technol. 2017, 35, 1412–1421. [Google Scholar] [CrossRef]

- Aboonajmi, M.; Jahangiri, M.; Hassan-Beygi, S.R. A review on application of acoustic analysis in quality evaluation of agro-food products. J. Food Process. Preserv. 2015, 39, 3175–3188. [Google Scholar] [CrossRef]

- Zdunek, A. Application of Acoustic Emission for Quality Evaluation of Fruits and Vegetables, in Acoustic Emission: Research and Applications; Sikorski, W., Ed.; In Tech: Rijeka, Croatia, 2013. [Google Scholar]

- Marzec, A.; Kowalska, H.; Zadrożna, M. Analysis of instrumental and sensory texture attributes of microwave–convective dried apples. J. Texture Stud. 2010, 41, 417–439. [Google Scholar] [CrossRef]

- Zheng, Y.; Pierce, A.; Wagner, W.L.; Scheller, H.V.; Mohnen, D.; Tsuda, A.; Ackermann, M.; Steven, J.; Mentzer, S.J. Analysis of pectin biopolymer phase states using acoustic emissions. Carbohyd. Polym. 2020, 227, 1–6. [Google Scholar] [CrossRef]

- Lewicki, P.P.; Marzec, A.; Ranachowski, Z. Acoustic properties of foods. Chapter 24. In Food Properties Handbook, 2nd ed.; Rahman, M.S., Ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2009; pp. 811–841. [Google Scholar]

- Di Scala, K.; Crapiste, G. Drying kinetics and quality changes during drying of red pepper. LWT-Food Sci. Technol. 2008, 41, 789–795. [Google Scholar] [CrossRef]

- Guiné, R.P.F.; Almiro, J.; Castro, A.M. Pear drying process analysis: Drying rates and evolution of water and sugar concentrations in space and time. Dry Technol. 2002, 20, 1515–1526. [Google Scholar] [CrossRef]

- Lüle, F.; Koyuncu, T. Convective and microwave drying characteristics of sorbus fruits (Sorbus domestica L.). Procedia.-Soc. Behav. Sci. 2015, 195, 2634–2643. [Google Scholar] [CrossRef][Green Version]

- Doymaz, I. Convective drying kinetics of strawberry. Chem. Eng. Process. 2008, 47, 914–919. [Google Scholar] [CrossRef]

- Doymaz, I. Effect of citric acid and blanching pre-treatments on drying and rehydration of Amasya red apples. Food Bioprod. Process. 2010, 8, 124–132. [Google Scholar] [CrossRef]

- Gawkowska, D.; Cybulska, J.; Zdunek, A. Structure-Related Gelling of Pectins and Linking with Other Natural Compounds: A Review. Polymers 2018, 10, 762. [Google Scholar] [CrossRef]

- Djendoubi Mrad, N.; Bonazzi, C.; Boudhrioua, N.; Kechaou, N.; Courtois, F. Moisture sorption isotherms, thermodynamic properties, and glass transition of pears and apples. Dry Technol. 2012, 30, 1397–1406. [Google Scholar] [CrossRef]

- Krokida, M.K.; Maroulis, Z.B. Effect of drying method on shrinkage and porosity. Dry Technol. 2007, 15, 2441–2458. [Google Scholar] [CrossRef]

- Bonazzi, C.; Dumoulin, E. Modern drying technology Volume 3. In Product Quality and Formulation, 1st ed.; Tsotsas, E., Mujumdar, A.S., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2011. [Google Scholar]

- Nassiri, S.M.; Heydari, M.M. Shrinkage of pear fruit Cuber Turing drying in a cabinet dryer. In Proceedings of the Agriculture, Engineering for Healthier Life, International Conference of Agricultural Engineering, Valencia, Spain, 8–12 July 2010. [Google Scholar]

- Link, J.V.; Tribuzi, G.; Laurindo, J.B. Improving quality of dried fruits: A comparison between conductive multi-flash and traditional drying methods. LWT-Food Sci. Technol. 2017, 84, 717–725. [Google Scholar] [CrossRef]

- La Fuente, C.I.A.; Lopes, C.C. HTST puffing in order to produce crispy banana—The effect of the step-down treatment prior to air-drying HTST puffing in order to produce crispy banana. LWT-Food Sci. Technol. 2018, 92, 324–329. [Google Scholar]

- Ciurzyńska, A.; Marzec, A.; Mieszkowska, A.; Lenart, A. Structure influence on mechanical and acoustic properties of freeze-dried gels obtained with the use of hydrocolloids. J. Texture Stud. 2017, 48, 131–142. [Google Scholar] [CrossRef]

- Duizer, L. A review of acoustic research for studying the sensory perception of crisp, crunchy and crackly textures. Trends Food Sci. Technol. 2001, 12, 17–24. [Google Scholar] [CrossRef]

- ISO 4121. Sensory Analysis-Methodology-Evaluation of food products by methods using scales; Polish Committee for Standardization: Warsaw, Poland, 2003. [Google Scholar]

| Sample | Moisture (g/g) | Water Activity | Drying Time | Apparent Density (g/cm3) | Particle Density (g/cm3) | Porosity (%) |

|---|---|---|---|---|---|---|

| CD_Co | 2.25 ± 0.40 c | 0.171 ±0.001 e | 250 | 1.198 ± 0.051 a | 1.129 ± 0.032 | 5.7 ± 0.7 a,b |

| CD_Co_i | 0.83 ± 0.25 a | 0.139 ± 0.005 c | 267 | 1.317 ± 0.029 e | 1.235 ± 0.182 | 6.1 ± 0.7 b |

| MCD_Co | 2.75 ± 0.12 d | 0.222 ± 0.005 f | 80 | 1.236 ± 0.050 b | 1.113 ± 0.105 | 10.0 ± 0.5 a |

| CD_Lu | 1.55 ± 0.05 b | 0.147 ± 0.008 b,c | 298 | 1.267 ± 0.017 c | 1.161 ± 0.551 | 8.2 ± 0.5 c |

| CD_Lu_i | 0.85 ± 0.15 a | 0.152 ± 0.009 d | 300 | 1.400 ± 0.022 e | 1.227 ± 0.125 | 12.3 ± 0.7 d |

| MCD_Lu | 1.35 ± 0.10 b | 0.145 ± 0.006 b | 85 | 1.359 ± 0.021 d | 1.176 ± 0.095 | 13.1 ± 0.1 d |

| Level of Significance | ||||||

| Variety | <0.001 * | <0.001 * | - | 0.015 * | <0.001 * | <0.001 * |

| The method of drying | <0.001 * | <0.001 * | - | 0.062 | 0.110 | <0.001 * |

| Variety X method drying | <0.001 * | <0.001 * | - | 0.400 | 0.001 * | 0.008 * |

| L* | a* | b* | C* | h* | ΔE | YI | |

|---|---|---|---|---|---|---|---|

| Co_fresh | 71.05 ± 1.01 x | −1.74 ± 0.05 y | 14.97 ± 0.47 x | 15.08 ± 0.59 x | 96.61 ± 0.69 y | - | 15.80 ± 0.91 |

| CD_Co | 68.66 ± 1.03 a,b | 6.92± 1.02 b,c | 36.73 ± 1.24 a | 37.38 ± 1.41 c | 79.39± 1.17 b | 23.55 ± 1.63 b | 76.45 ± 3.73 c |

| CD_Co_i | 67.08 ± 1.51 a | 9.31± 2.53 c | 33.57 ± 1.10 b | 34.89 ± 1.41 b,c | 74.61 ± 3.93 a | 24.06 ± 3.27 b | 71.49 ± 5.68 b,c |

| MCD_Co | 72.64 ± 0.76 c | 2.68 ± 0.72 a | 33.31 ± 1.11 b | 33.42 ± 1.16 a,b | 85.47 ± 1.08 c | 18.94 ± 1.2 2 a | 65.51 ± 6.77 a,b |

| Lu_fresh | 72.97 ± 1.05 x | −1.22 ± 1.23 x | 8.08 ± 0.49 y | 8.17 ± 0.59 y | 98.58 ± 0.28 x | - | 30.10 ± 0.78 |

| CD_Lu | 69.03 ± 0.31 a,b | 5.47 ± 0.36 a,b | 30.83 ± 0.85 a | 31.31 ± 0.87 a | 79.98± 0.53 b | 24.04 ± 0.87 b | 63.80 ± 1.77 a,b |

| CD_Lu_i | 70.60 ± 2.20 b,c | 5.01 ± 1.81 a,b | 30.68 ± 1.81 a | 31.11 ± 2.09 a | 80.88 ± 2.67 b | 23.64 ± 2.49 b | 62.19 ± 5.68 a |

| MCD_Lu | 69.52 ± 3.28 a,b,c | 5.43 ± 2.25 a,b | 30.09 ± 1.88 a | 30.61 ± 2.28 a | 79.98 ± 3.39 b | 23.41 ± 2.92 b | 62.04 ± 6.75 a |

| Level of Significance | |||||||

| Variety | 0.529 | 0.941 | <0.001 * | <0.001 * | 0.474 | 0.049 * | 0.003 * |

| Drying of method | 0.028 * | 0.009 * | 0.150 | 0.072 | 0.012 * | 0.024 * | 0.041 * |

| Variety X method drying | 0.015 * | 0.006 * | 0.486 | 0.234 | 0.007 * | 0.052 | 0.095 |

Sample Availability: Samples are available from the authors. | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marzec, A.; Kowalska, H.; Kowalska, J.; Domian, E.; Lenart, A. Influence of Pear Variety and Drying Methods on the Quality of Dried Fruit. Molecules 2020, 25, 5146. https://doi.org/10.3390/molecules25215146

Marzec A, Kowalska H, Kowalska J, Domian E, Lenart A. Influence of Pear Variety and Drying Methods on the Quality of Dried Fruit. Molecules. 2020; 25(21):5146. https://doi.org/10.3390/molecules25215146

Chicago/Turabian StyleMarzec, Agata, Hanna Kowalska, Jolanta Kowalska, Ewa Domian, and Andrzej Lenart. 2020. "Influence of Pear Variety and Drying Methods on the Quality of Dried Fruit" Molecules 25, no. 21: 5146. https://doi.org/10.3390/molecules25215146

APA StyleMarzec, A., Kowalska, H., Kowalska, J., Domian, E., & Lenart, A. (2020). Influence of Pear Variety and Drying Methods on the Quality of Dried Fruit. Molecules, 25(21), 5146. https://doi.org/10.3390/molecules25215146