The Study of Electrical and Electrochemical Properties of Magnesium Ion Conducting CS: PVA Based Polymer Blend Electrolytes: Role of Lattice Energy of Magnesium Salts on EDLC Performance

Abstract

1. Introduction

2. Experimental

2.1. Materials and Polymer Electrolyte Preparation

2.2. Fabrication of the EDLC

2.3. Electrical and Electrochemical Characterization

2.3.1. Impedance and Electrical Study

2.3.2. Transference Number Analysis (TNM)

2.3.3. Linear Sweep Voltammetry (LSV)

2.3.4. Cyclic Voltammetry (CV) of the EDLC

3. Results and Discussion

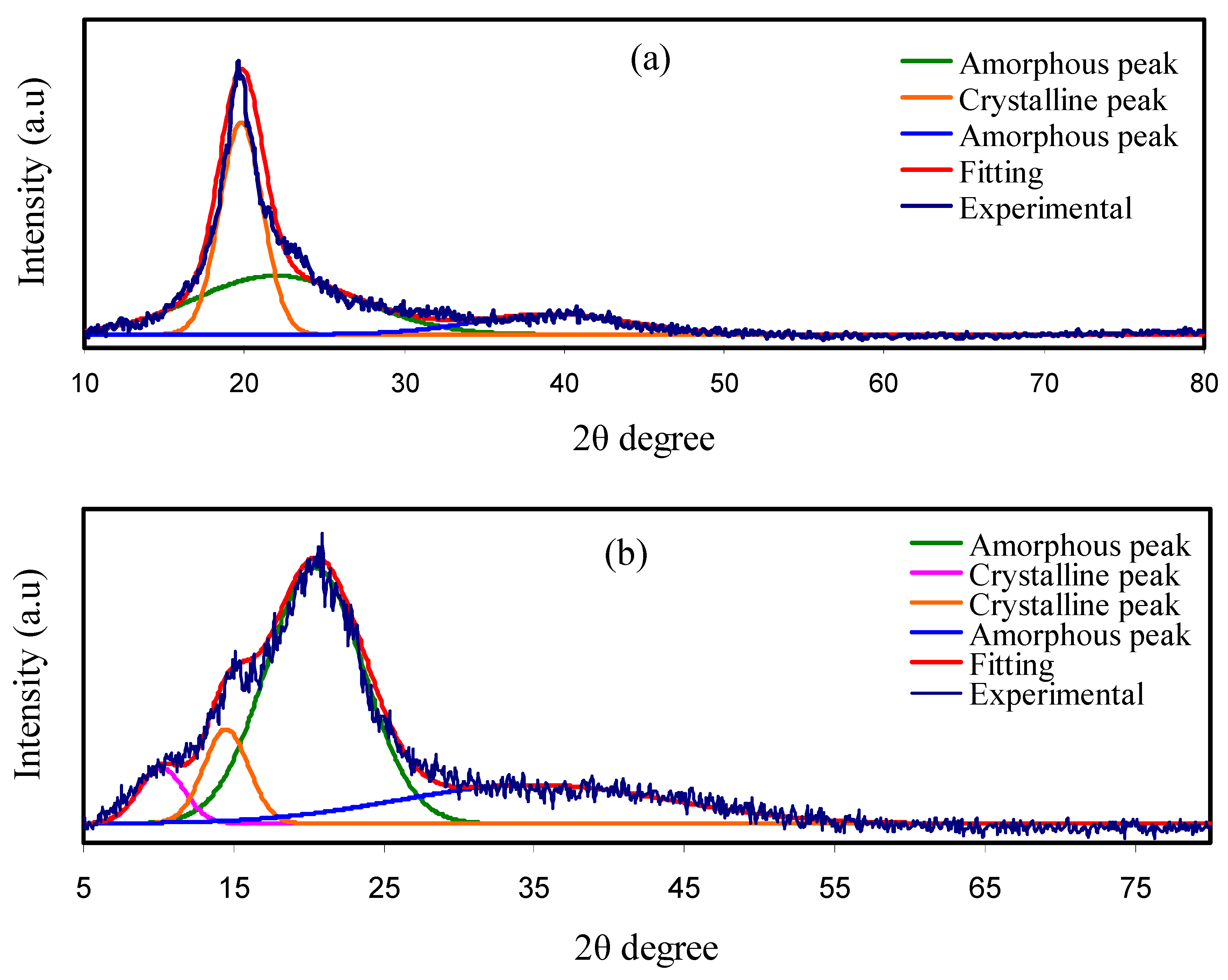

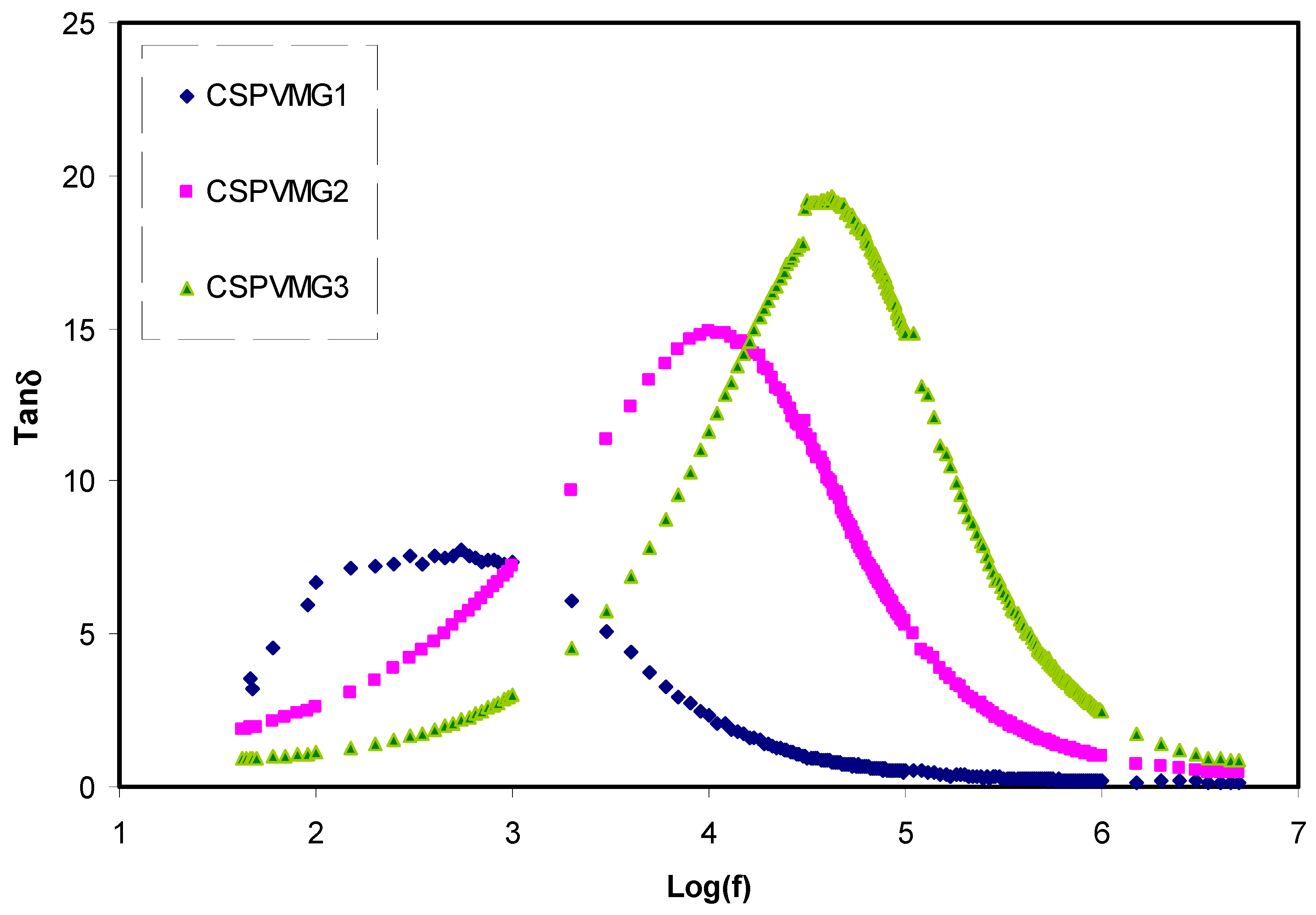

3.1. XRD Analysis

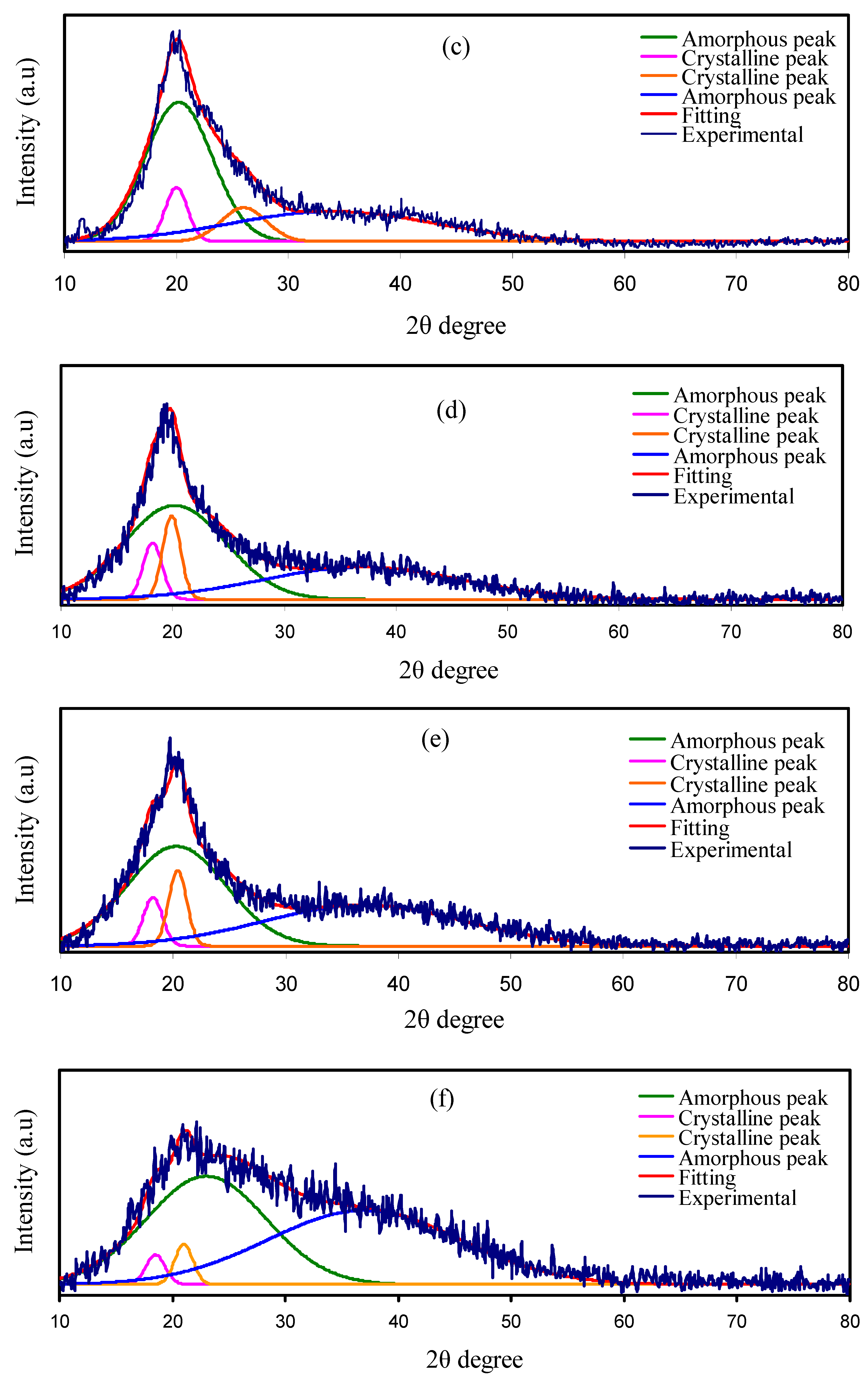

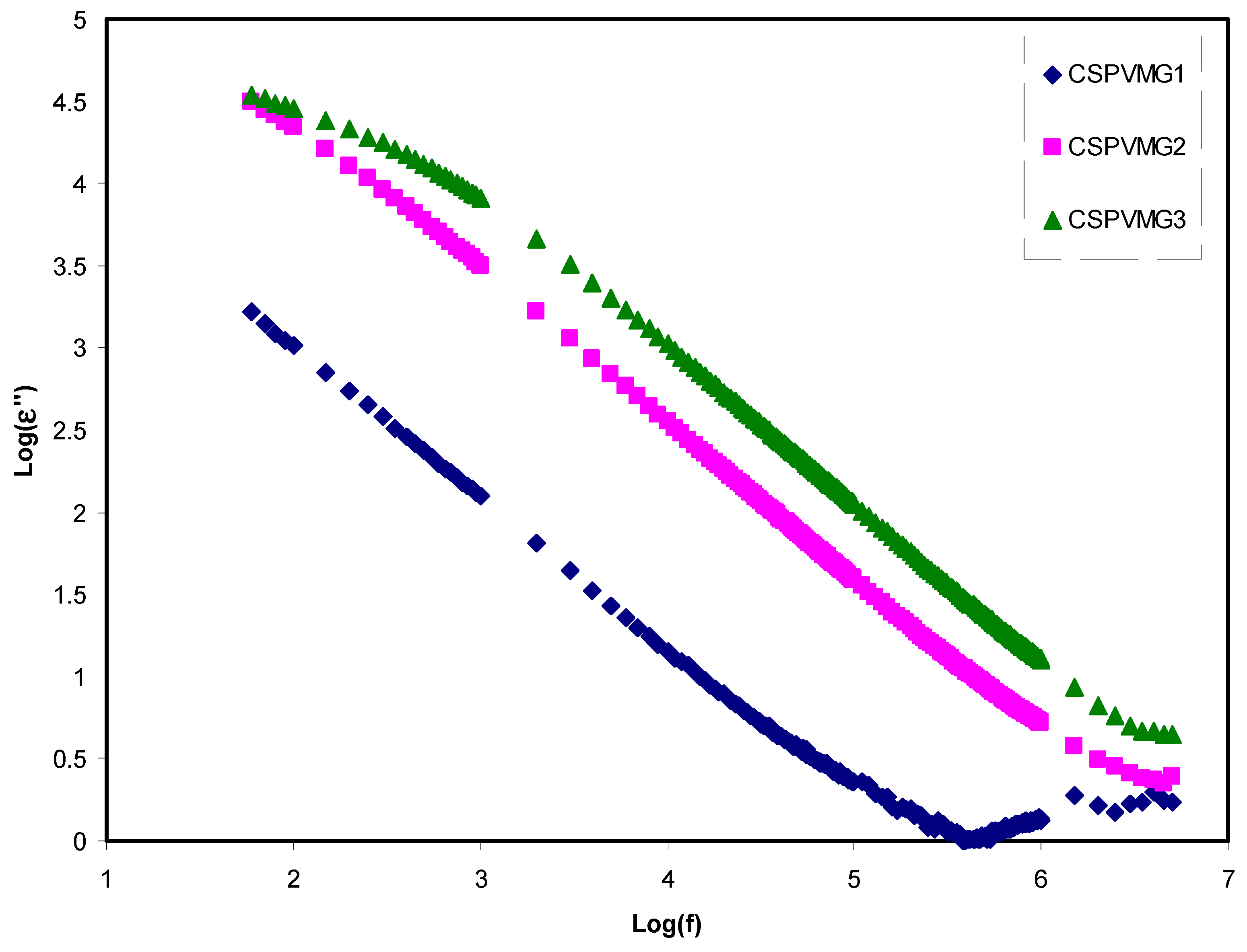

3.2. Dielectric Properties

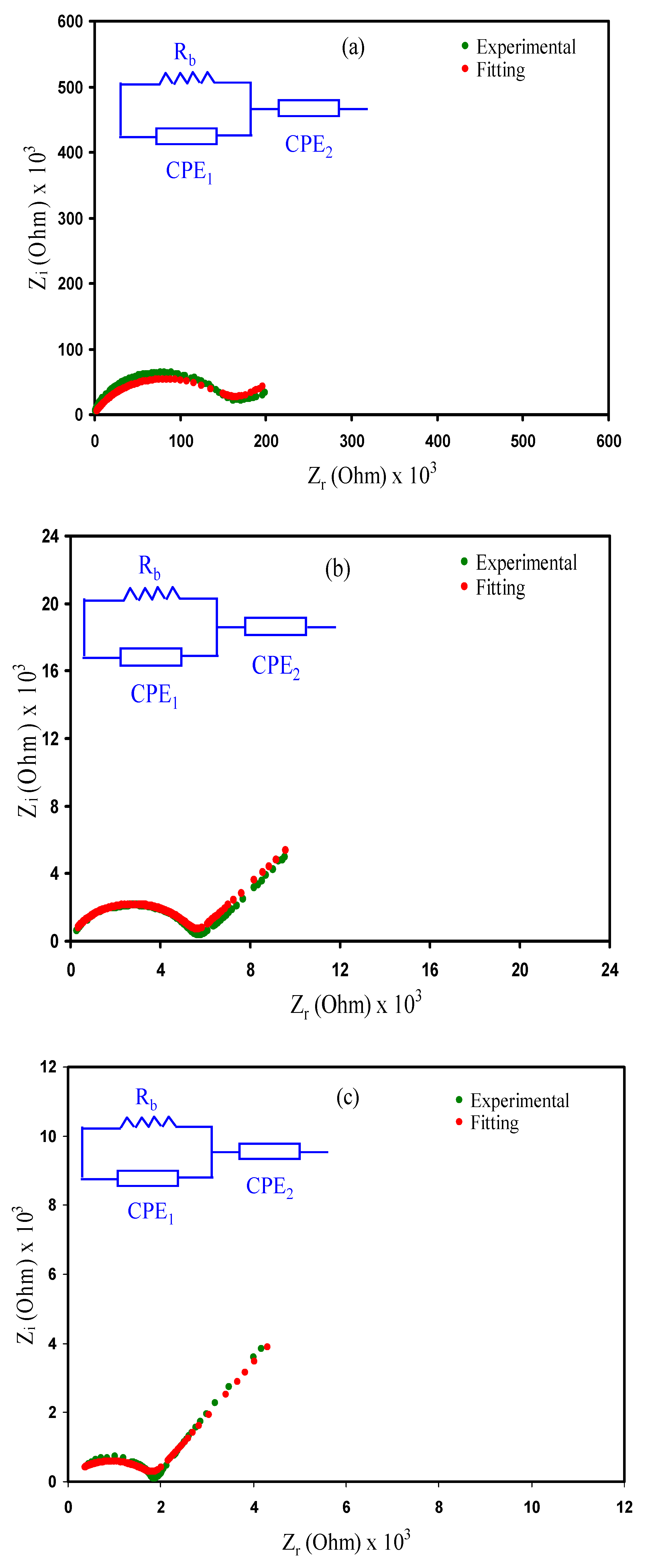

3.3. Impedance Analysis

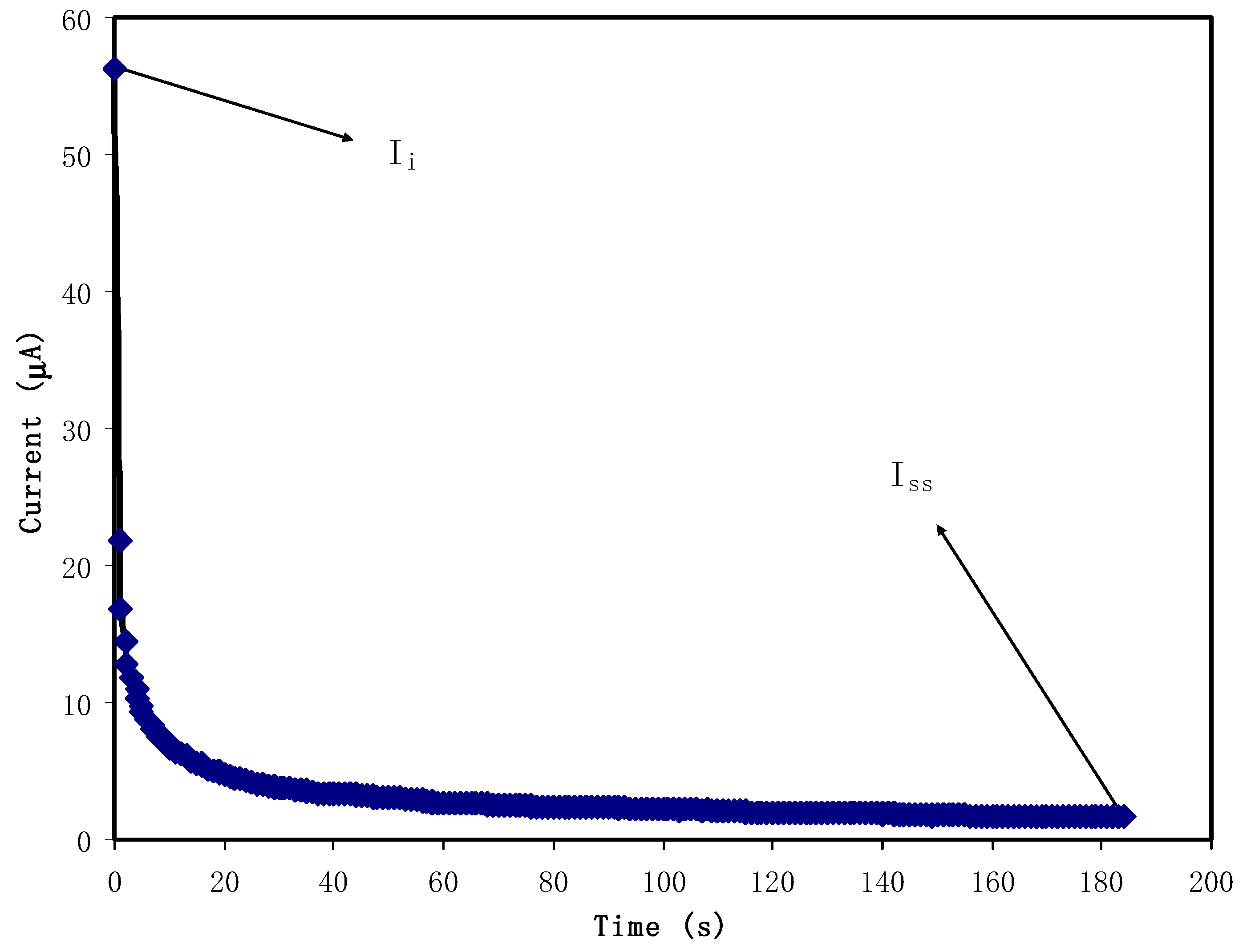

3.4. Transfer Number Measurement (TNM) Study

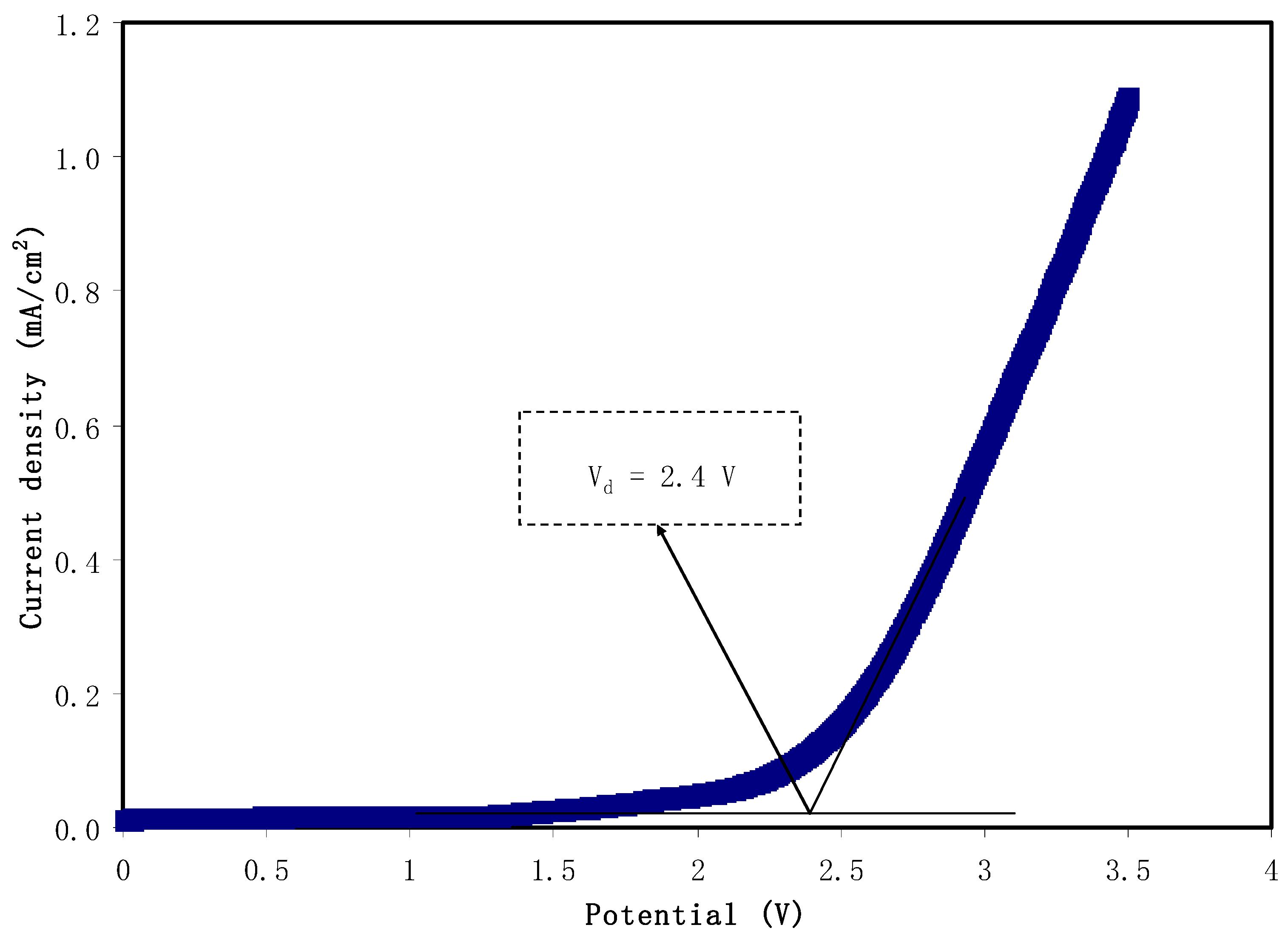

3.5. Linear Sweep Voltammetry (LSV)

3.6. Cyclic Voltammetry (CV)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sudhakar, Y.; Selvakumar, M.; Bhat, D.K. An introduction of Biopolymer Electrolytes. In Biopolymer Electrolytes; Elsevier BV: Oxford, UK, 2018; pp. 1–34. [Google Scholar]

- Zainol, N.; Osman, Z.; Othman, L.; Isa, K.M. Transport and Morphological Properties of Gel Polymer Electrolytes Containing Mg (CF3SO3)2. Adv. Mater. Res. 2013, 686, 137–144. [Google Scholar] [CrossRef]

- Isa, K.B.M. Magnesium ion-based gel polymer electrolytes: Ionic conduction and infrared spectroscopy studies. Int. J. Electrochem. Sci. 2013, 8, 3602–3614. [Google Scholar]

- Buraidah, M.; Shah, S.; Teo, L.; Chowdhury, F.I.; Careem, M.; Albinsson, I.; Mellander, B.-E.; Arof, A.K. High efficient dye sensitized solar cells using phthaloylchitosan based gel polymer electrolytes. Electrochim. Acta 2017, 245, 846–853. [Google Scholar] [CrossRef]

- Riess, I. Polymeric mixed ionic electronic conductors. Solid State Ionics 2000, 136, 1119–1130. [Google Scholar] [CrossRef]

- Parameswaran, V.; Nallamuthu, N.; Devendran, P.; Nagarajan, E.; Manikandan, A. Electrical conductivity studies on Ammonium bromide incorporated with Zwitterionic polymer blend electrolyte for battery application. Phys. B Condens. Matter 2017, 515, 89–98. [Google Scholar] [CrossRef]

- Abu Bakar, N.Y.; Muhamaruesa, N.H.M.; Aniskari, N.A.B.; Isa, M.I.N. Electrical Studies of Carboxy Methycellulose-Chitosan Blend Biopolymer Doped Dodecyltrimethyl Ammonium Bromide Solid Electrolytes. Am. J. Appl. Sci. 2015, 12, 40–46. [Google Scholar] [CrossRef]

- Liew, C.-W.; Ramesh, S.; Arof, A. Investigation of ionic liquid-doped ion conducting polymer electrolytes for carbon-based electric double layer capacitors (EDLCs). Mater. Des. 2016, 92, 829–835. [Google Scholar] [CrossRef]

- Shukur, M.; Hamsan, M.; Kadir, M. Investigation of plasticized ionic conductor based on chitosan and ammonium bromide for EDLC application. Mater. Today Proc. 2019, 17, 490–498. [Google Scholar] [CrossRef]

- Aziz, S.B.; Abdullah, R.M.; Kadir, M.; Ahmed, H.M. Non suitability of silver ion conducting polymer electrolytes based on chitosan mediated by barium titanate (BaTiO3) for electrochemical device applications. Electrochim. Acta 2019, 296, 494–507. [Google Scholar] [CrossRef]

- Aziz, S.B.; Hamsan, M.H.; Kadir, M.F.Z.; Woo, H.J. Design of Polymer Blends Based on Chitosan: POZ with Improved Dielectric Constant for Application in Polymer Electrolytes and Flexible Electronics. Adv. Polym. Technol. 2020, 2020, 1–10. [Google Scholar] [CrossRef]

- Stepniak, I.; Galiński, M.; Nowacki, K.; Wysokowski, M.; Jakubowska, P.; Bazhenov, V.V.; Leisegang, T.; Ehrlich, H.; Jesionowski, T. A novel chitosan/sponge chitin origin material as a membrane for supercapacitors—Preparation and characterization. RSC Adv. 2016, 6, 4007–4013. [Google Scholar] [CrossRef]

- Marf, A.S.; Abdullah, R.M.; Aziz, S.B. Structural, Morphological, Electrical and Electrochemical Properties of PVA: CS-Based Proton-Conducting Polymer Blend Electrolytes. Membranes 2020, 10, 71. [Google Scholar] [CrossRef] [PubMed]

- Sundaramahalingam, K.; Muthuvinayagam, M.; Nallamuthu, N.; Vanitha, D.; Vahini, M. Investigations on lithium acetate-doped PVA/PVP solid polymer blend electrolytes. Polym. Bull. 2019, 76, 5577–5602. [Google Scholar] [CrossRef]

- Saroj, A.; Krishnamoorthi, S.; Singh, R. Structural, thermal and electrical transport behaviour of polymer electrolytes based on PVA and imidazolium based ionic liquid. J. Non-Crystalline Solids 2017, 473, 87–95. [Google Scholar] [CrossRef]

- Yusof, Y.M.; Illias, H.A.; Kadir, M. Incorporation of NH4Br in PVA-chitosan blend-based polymer electrolyte and its effect on the conductivity and other electrical properties. Ionics 2014, 20, 1235–1245. [Google Scholar] [CrossRef]

- Buraidah, M.; Arof, A.K. Characterization of chitosan/PVA blended electrolyte doped with NH4I. J. Non-Crystalline Solids 2011, 357, 3261–3266. [Google Scholar] [CrossRef]

- Kadir, M.F.Z.; Arof, A.K. Application of PVA–chitosan blend polymer electrolyte membrane in electrical double layer capacitor. Mater. Res. Innov. 2011, 15, s217–s220. [Google Scholar] [CrossRef]

- Gong, S.-D.; Huang, Y.; Cao, H.-J.; Lin, Y.-H.; Li, Y.; Tang, S.-H.; Wang, M.-S.; Li, X. A green and environment-friendly gel polymer electrolyte with higher performances based on the natural matrix of lignin. J. Power Sources 2016, 307, 624–633. [Google Scholar] [CrossRef]

- Yusof, Y.M.; Shukur, M.F.; A Illias, H.; Kadir, M.F.Z. Conductivity and electrical properties of corn starch–chitosan blend biopolymer electrolyte incorporated with ammonium iodide. Phys. Scr. 2014, 89, 1–10. [Google Scholar] [CrossRef]

- Maheshwaran, C.; Kanchan, D.; Gohel, K.; Mishra, K.; Kumar, D. Effect of Mg (CF3SO3)2 concentration on structural and electrochemical properties of ionic liquid incorporated polymer electrolyte membranes. J. Solid State Electrochem. 2020, 24, 655–665. [Google Scholar] [CrossRef]

- Sarangika, H.N.M.; Rathnayake, R.R.D.V.; Dissanayake, M.A.K.L.; Senadeera, G.; Pitawala, H.M.J.C. Polyethylene oxide and ionic liquid-based solid polymer electrolyte for rechargeable magnesium batteries. Ionics 2016, 23, 2829–2835. [Google Scholar] [CrossRef]

- Syahidah, S.; Majid, S. Ionic liquid-based polymer gel electrolytes for symmetrical solid-state electrical double layer capacitor operated at different operating voltages. Electrochim. Acta 2015, 175, 184–192. [Google Scholar] [CrossRef]

- Guan, K.H.; Farhana, N.K.; Omar, F.S.; Saidi, N.M.; Bashir, S.; Ramesh, S.; Ramesh, K. Influence of tetraglyme towards magnesium salt dissociation in solid polymer electrolyte for electric double layer capacitor. J. Polym. Res. 2020, 27, 1–9. [Google Scholar] [CrossRef]

- Lee, D.K.; Allcock, H.R. The effects of cations and anions on the ionic conductivity of poly[bis(2-(2-methoxyethoxy)ethoxy)phosphazene] doped with lithium and magnesium salts of trifluoromethanesulfonate and bis(trifluoromethanesulfonyl)imidate. Solid State Ionics 2010, 181, 1721–1726. [Google Scholar] [CrossRef]

- Shukur, M.F.; Ithnin, R.; Kadir, M. Ionic conductivity and dielectric properties of potato starch-magnesium acetate biopolymer electrolytes: The effect of glycerol and 1-butyl-3-methylimidazolium chloride. Ionics 2016, 22, 1113–1123. [Google Scholar] [CrossRef]

- Mattos, R.I.; Raphaël, E.; Majid, S.R.; Arof, A.K.; Pawlicka, A. Enhancement of Electrical Conductivity in Plasticized Chitosan Based Membranes. Mol. Cryst. Liq. Cryst. 2012, 554, 150–159. [Google Scholar] [CrossRef]

- Inagaki, M.; Konno, H.; Tanaike, O. Carbon materials for electrochemical capacitors. J. Power Sources 2010, 195, 7880–7903. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, X.; Chen, Y.; Yu, P.; Wang, C.; Ma, Y. Enhanced capacitance and rate capability of graphene/polypyrrole composite as electrode material for supercapacitors. J. Power Sources 2011, 196, 5990–5996. [Google Scholar] [CrossRef]

- Pell, W.G.; Conway, B.E. Peculiarities and requirements of asymmetric capacitor devices based on combination of capacitor and battery-type electrodes. J. Power Sources 2004, 136, 334–345. [Google Scholar] [CrossRef]

- Subramanian, V.; Zhu, H.; Wei, B. Nanostructured manganese oxides and their composites with carbon nanotubes as electrode materials for energy storage devices. Pure Appl. Chem. 2008, 80, 2327–2343. [Google Scholar] [CrossRef]

- Shukur, M.F.; Ithnin, R.; Illias, H.; Kadir, M. Proton conducting polymer electrolyte based on plasticized chitosan–PEO blend and application in electrochemical devices. Opt. Mater. 2013, 35, 1834–1841. [Google Scholar] [CrossRef]

- Kadir, M.; Majid, S.; Arof, A.K. Plasticized chitosan–PVA blend polymer electrolyte based proton battery. Electrochim. Acta 2010, 55, 1475–1482. [Google Scholar] [CrossRef]

- Wang, H.; Lin, J.; Shen, Z.X. Polyaniline (PANi) based electrode materials for energy storage and conversion. J. Sci. Adv. Mater. Devices 2016, 1, 225–255. [Google Scholar] [CrossRef]

- Iro, Z.S. A Brief Review on Electrode Materials for Supercapacitor. Int. J. Electrochem. Sci. 2016, 11, 10628–10643. [Google Scholar] [CrossRef]

- Aziz, S.B. Study of Dielectric Properties and Ion Transport Parameters in Chitosan-Barium Nitrate Based Solid Polymer Electrolytes. Int. J. Electrochem. Sci. 2019, 14, 11580–11595. [Google Scholar] [CrossRef]

- Brza, M.; Aziz, S.B.; Anuar, H.; Ali, F.; Hamsan, M.; Kadir, M. Metal Framework as a Novel Approach for the Fabrication of Electric Double Layer Capacitor Device with High Energy Density Using Plasticized Poly(vinyl alcohol): Ammonium Thiocyanate Based Polymer Electrolyte. Arab. J. Chem. 2020. [Google Scholar] [CrossRef]

- Salleh, N.S.; Aziz, S.B.; Aspanut, Z.; Kadir, M. Electrical impedance and conduction mechanism analysis of biopolymer electrolytes based on methyl cellulose doped with ammonium iodide. Ionics 2016, 22, 2157–2167. [Google Scholar] [CrossRef]

- Cholant, C.M.; Rodrigues, M.P.; Peres, L.L.; Balboni, R.D.C.; Krüger, L.U.; Placido, D.N.; Flores, W.H.; Gündel, A.; Pawlicka, A.; Avellaneda, C.O. Study of the conductivity of solid polymeric electrolyte based on PVA/GA blend with addition of acetic acid. J. Solid State Electrochem. 2020, 1–9. [Google Scholar] [CrossRef]

- Hemalatha, R.; Alagar, M.; Selvasekarapandian, S.; Sundaresan, B.; Moniha, V.; Boopathi, G.; Selvin, P.C. Preparation and characterization of proton-conducting polymer electrolyte based on PVA, amino acid proline, and NH4Cl and its applications to electrochemical devices. Ionics 2018, 25, 141–154. [Google Scholar] [CrossRef]

- Aziz, S.B.; Abdullah, O.G.; Rasheed, M.A.; Ahmed, H.M. Effect of High Salt Concentration (HSC) on Structural, Morphological, and Electrical Characteristics of Chitosan Based Solid Polymer Electrolytes. Polymers 2017, 9, 187. [Google Scholar] [CrossRef]

- Liu, J.; Khanam, Z.; Muchakayala, R.; Song, S. Fabrication and characterization of Zn-ion-conducting solid polymer electrolyte films based on PVdF-HFP/Zn(Tf)2 complex system. J. Mater. Sci. Mater. Electron. 2020, 31, 6160–6173. [Google Scholar] [CrossRef]

- Hadi, J.M. Electrochemical Impedance study of Proton Conducting Polymer Electrolytes based on PVC Doped with Thiocyanate and Plasticized with Glycerol. Int. J. Electrochem. Sci. 2020, 4671–4683. [Google Scholar] [CrossRef]

- Aziz, S.B.; Abidin, Z.H.Z. Ion-transport study in nanocomposite solid polymer electrolytes based on chitosan: Electrical and dielectric analysis. J. Appl. Polym. Sci. 2014, 132, 1–10. [Google Scholar] [CrossRef]

- Ramesh, S.; Ng, H.M.; Shanti, R.; Ramesh, K. Studies on the Influence of Titania Content on the Properties of Poly(vinyl chloride)—Poly (acrylonitrile)-Based Polymer Electrolytes. Polym. Technol. Eng. 2013, 52, 1474–1481. [Google Scholar] [CrossRef]

- Machappa, T.; Prasad, M.A. AC conductivity and dielectric behavior of polyaniline/sodium metavenadate (PANI/NaVO3) composites. Phys. B Condens. Matter 2009, 404, 4168–4172. [Google Scholar] [CrossRef]

- Khiar, A.; Puteh, R.; Arof, A.K. Conductivity studies of a chitosan-based polymer electrolyte. Phys. B Condens. Matter 2006, 373, 23–27. [Google Scholar] [CrossRef]

- Klein, R.J.; Zhang, S.; Dou, S.; Jones, B.H.; Colby, R.H.; Runt, J. Modeling electrode polarization in dielectric spectroscopy: Ion mobility and mobile ion concentration of single-ion polymer electrolytes. J. Chem. Phys. 2006, 124, 144903. [Google Scholar] [CrossRef]

- Bhargav, P.B.; Sarada, B.A.; Sharma, A.K.; Rao, V.V.R.N. Electrical Conduction and Dielectric Relaxation Phenomena of PVA Based Polymer Electrolyte Films. J. Macromol. Sci. Part A 2009, 47, 131–137. [Google Scholar] [CrossRef]

- Basha, S.K.S.; Sundari, G.S.; Kumar, K.V.; Rao, M.C. Preparation and dielectric properties of PVP-based polymer electrolyte films for solid-state battery application. Polym. Bull. 2017, 75, 925–945. [Google Scholar] [CrossRef]

- Aziz, S.B.; Abidin, Z.H.Z. Electrical and morphological analysis of chitosan: AgTf solid electrolyte. Mater. Chem. Phys. 2014, 144, 280–286. [Google Scholar] [CrossRef]

- Woo, H.; Majid, S.; Arof, A.K. Dielectric properties and morphology of polymer electrolyte based on poly(ɛ-caprolactone) and ammonium thiocyanate. Mater. Chem. Phys. 2012, 134, 755–761. [Google Scholar] [CrossRef]

- Chopra, S.; Sharma, S.; Goel, T.; Mendiratta, R. Structural, dielectric and pyroelectric studies of Pb1−XCaXTiO3 thin films. Solid State Commun. 2003, 127, 299–304. [Google Scholar] [CrossRef]

- Aziz, S.B.; Karim, W.O.; Ghareeb, H.O. The deficiency of chitosan: AgNO3 polymer electrolyte incorporated with titanium dioxide filler for device fabrication and membrane separation technology. J. Mater. Res. Technol. 2020, 9, 4692–4705. [Google Scholar] [CrossRef]

- Pradhan, D.K.; Choudhary, R.N.P.; Samantaray, B.K. Studies of dielectric relaxation and AC conductivity behavior of plasticized polymer nanocomposite electrolytes. Int. J. Electrochem. Sci. 2008, 3, 597–608. [Google Scholar]

- Aziz, S.B.; Hamsan, M.; Brza, M.; Kadir, M.; Muzakir, S.; Abdulwahid, R.T. Effect of glycerol on EDLC characteristics of chitosan:methylcellulose polymer blend electrolytes. J. Mater. Res. Technol. 2020, 9, 8355–8366. [Google Scholar] [CrossRef]

- Asnawi, A.S.F.M.; Aziz, S.B.; Nofal, M.M.; Hamsan, M.H.; Brza, M.A.; Yusof, Y.M.; Abdulwahid, R.T.; Muzakir, S.K.; Kadir, M. Glycerolized Li+ Ion Conducting Chitosan-Based Polymer Electrolyte for Energy Storage EDLC Device Applications with Relatively High Energy Density. Polymers 2020, 12, 1433. [Google Scholar] [CrossRef]

- Asnawi, A.S.F.M.; Aziz, S.B.; Nofal, M.M.; Yusof, Y.M.; Brevik, I.; Hamsan, M.H.; Brza, M.A.; Abdulwahid, R.T.; Kadir, M. Metal Complex as a Novel Approach to Enhance the Amorphous Phase and Improve the EDLC Performance of Plasticized Proton Conducting Chitosan-Based Polymer Electrolyte. Membranes 2020, 10, 132. [Google Scholar] [CrossRef]

- Mustafa, M.S.; Ghareeb, H.O.; Aziz, S.B.; Brza, M.A.; Al-Zangana, S.; Hadi, J.M.; Kadir, M.F.Z. Electrochemical Characteristics of Glycerolized PEO-Based Polymer Electrolytes. Membranes 2020, 10, 116. [Google Scholar] [CrossRef]

- Hadi, J.M.; Aziz, S.B.; Mustafa, M.S.; Hamsan, M.H.; Abdulwahid, R.T.; Kadir, M.F.; Ghareeb, H.O. Role of nano-capacitor on dielectric constant enhancement in PEO:NH4SCN:xCeO2 polymer nano-composites: Electrical and electrochemical properties. J. Mater. Res. Technol. 2020, 9, 9283–9294. [Google Scholar] [CrossRef]

- Manjunatha, H.; Damle, R.; Pravin, K.; Kumaraswamy, G.N. Modification in the transport and morphological properties of solid polymer electrolyte system by low-energy ion irradiation. Ionics 2018, 24, 3027–3037. [Google Scholar] [CrossRef]

- Aziz, S.B.; Abdullah, R.M.; Rasheed, M.A.; Ahmed, H.M. Role of Ion Dissociation on DC Conductivity and Silver Nanoparticle Formation in PVA: AgNt Based Polymer Electrolytes: Deep Insights to Ion Transport Mechanism. Polymers 2017, 9, 338. [Google Scholar] [CrossRef] [PubMed]

- Osman, Z.; Zainol, N.; Samin, S.; Chong, W.; Isa, K.M.; Othman, L.; Supa’At, I.; Sonsudin, F. Electrochemical Impedance Spectroscopy Studies of Magnesium-Based Polymethylmethacrylate Gel Polymer Electroytes. Electrochim. Acta 2014, 131, 148–153. [Google Scholar] [CrossRef]

- Aziz, S.B.; Hamsan, M.H.; Kadir, M.F.Z.; Karim, W.O.; Abdullah, R.M. Development of Polymer Blend Electrolyte Membranes Based on Chitosan: Dextran with High Ion Transport Properties for EDLC Application. Int. J. Mol. Sci. 2019, 20, 3369. [Google Scholar] [CrossRef]

- Saadiah, M.; Nagao, Y.; Samsudin, A.S. Proton (H+) transport properties of CMC–PVA blended polymer solid electrolyte doped with NH4NO3. Int. J. Hydrog. Energy 2020, 45, 14880–14896. [Google Scholar] [CrossRef]

- Aziz, N.; Majid, S.; Arof, A.K. Synthesis and characterizations of phthaloyl chitosan-based polymer electrolytes. J. Non-Cryst. Solids 2012, 358, 1581–1590. [Google Scholar] [CrossRef]

- Aziz, S.B.; Brza, M.; Mishra, K.; Hamsan, M.; Karim, W.O.; Abdullah, R.M.; Kadir, M.; Abdulwahid, R.T. Fabrication of high performance energy storage EDLC device from proton conducting methylcellulose: Dextran polymer blend electrolytes. J. Mater. Res. Technol. 2020, 9, 1137–1150. [Google Scholar] [CrossRef]

- Swaminathan, A.; Ravi, R.; Sasikumar, M.; Dasaiah, M.; Hirankumar, G.; Ayyasamy, S. Preparation and characterization of PVA/PAM/NH4SCN polymer film by ultrasound-assisted solution casting method for application in electric double layer capacitor. Ionics 2020, 1–16. [Google Scholar] [CrossRef]

- Sudhakar, Y.; Selvakumar, M. Lithium perchlorate doped plasticized chitosan and starch blend as biodegradable polymer electrolyte for supercapacitors. Electrochim. Acta 2012, 78, 398–405. [Google Scholar] [CrossRef]

- Aziz, S.B.; Brza, M.; Mohamed, P.A.; Kadir, M.; Hamsan, M.; Abdulwahid, R.T.; Woo, H. Increase of metallic silver nanoparticles in Chitosan:AgNt based polymer electrolytes incorporated with alumina filler. Results Phys. 2019, 13, 102326. [Google Scholar] [CrossRef]

- Polu, A.R.; Kumar, R. Preparation and characterization of PEG–Mg(CH3COO)2–CeO2 composite polymer electrolytes for battery application. Bull. Mater. Sci. 2014, 37, 309–314. [Google Scholar] [CrossRef]

- Priya, S.S.; Karthika, M.; Selvasekarapandian, S.; Manjuladevi, R. Preparation and characterization of polymer electrolyte based on biopolymer I-Carrageenan with magnesium nitrate. Solid State Ionics 2018, 327, 136–149. [Google Scholar] [CrossRef]

- Polu, A.R.; Kumar, R. Ionic Conductivity and Discharge Characteristic Studies of PVA-Mg(CH3COO)2 Solid Polymer Electrolytes. Int. J. Polym. Mater. 2013, 62, 76–80. [Google Scholar] [CrossRef]

- Jo, N.J.; Kim, N.Y.; Kang, S.Y.; Ryu, K.S. The influence of the cations of salts on the electrochemical stability of a solidpolymer electrolyte based on segmented poly (ether urethane). Phys. Scr. 2010, 2010, 014035. [Google Scholar] [CrossRef]

- Zainol, N.H.; Halizan, M.Z.M.; Chong, W.G.; Osman, Z. Ionic Transport and Electrochemical Properties of PMMA-Based Gel Polymer Electrolytes for Magnesium Batteries. Adv. Mater. Res. 2014, 1024, 348–351. [Google Scholar] [CrossRef]

- Kiruthika, S.; Malathi, M.; Selvasekarapandian, S.; Tamilarasan, K.; Maheshwari, T. Conducting biopolymer electrolyte based on pectin with magnesium chloride salt for magnesium battery application. Polym. Bull. 2019, 1–19. [Google Scholar] [CrossRef]

- Hamsan, H.; Aziz, S.B.; Kadir, M.; Brza, M.; Karim, W.O. The study of EDLC device fabricated from plasticized magnesium ion conducting chitosan based polymer electrolyte. Polym. Test. 2020, 106714, 106714. [Google Scholar] [CrossRef]

- Hamsan, M.; Aziz, S.B.; Nofal, M.M.; Brza, M.; Abdulwahid, R.T.; Hadi, J.M.; Karim, W.O.; Kadir, M. Characteristics of EDLC device fabricated from plasticized chitosan:MgCl2 based polymer electrolyte. J. Mater. Res. Technol. 2020, 9, 10635–10646. [Google Scholar] [CrossRef]

- Pal, B.; Yang, S.; Ramesh, S.; Thangadurai, V.; Josed, R. Electrolyte selection for supercapacitive devices: A critical review. Nanoscale Adv. 2019, 1, 3807–3835. [Google Scholar] [CrossRef]

- Deng, J.; Li, J.; Xiao, Z.; Song, S.; Li, L. Studies on Possible Ion-Confinement in Nanopore for Enhanced Supercapacitor Performance in 4V EMIBF4 Ionic Liquids. Nanomaterial 2019, 9, 1664. [Google Scholar] [CrossRef]

- Chong, M.Y.; Numan, A.; Liew, C.-W.; Ng, H.; Ramesh, K.; Ramesh, S. Enhancing the performance of green solid-state electric double-layer capacitor incorporated with fumed silica nanoparticles. J. Phys. Chem. Solids 2018, 117, 194–203. [Google Scholar] [CrossRef]

- De Farias, R.F.; Kaya, S. Lattice Energies for Groups 1 and 2 Halides from Absolute Hardness. Cumhur. Sci. J. 2018, 39, 192–195. [Google Scholar] [CrossRef]

- Diebler, H.; Eigen, M.; Ilgenfritz, G.; Maass, G.; Winkler, R. Kinetics and mechanism of reactions of main group metal ions with biological carriers. Pure Appl. Chem. 1969, 20, 93–116. [Google Scholar] [CrossRef]

- Brza, M.A.; Aziz, S.B.; Nofal, M.M.; Saeed, S.R.; Al-Zangana, S.; Karim, W.O.; Hussen, S.A.; Abdulwahid, R.T.; Kadir, M. Drawbacks of Low Lattice Energy Ammonium Salts for Ion-Conducting Polymer Electrolyte Preparation: Structural, Morphological and Electrical Characteristics of CS:PEO:NH4BF4-Based Polymer Blend Electrolytes. Polymers 2020, 12, 1885. [Google Scholar] [CrossRef] [PubMed]

- Aziz, S.B.; Brza, M.; Saed, S.R.; Hamsan, M.; Kadir, M. Ion association as a main shortcoming in polymer blend electrolytes based on CS:PS incorporated with various amounts of ammonium tetrafluoroborate. J. Mater. Res. Technol. 2020, 9, 5410–5421. [Google Scholar] [CrossRef]

- Liew, C.-W.; Ramesh, S.; Arof, A.K. Enhanced capacitance of EDLCs (electrical double layer capacitors) based on ionic liquid-added polymer electrolytes. Energy 2016, 109, 546–556. [Google Scholar] [CrossRef]

- Teoh, K.H.; Lim, C.-S.; Liew, C.-W.; Ramesh, S. Electric double-layer capacitors with corn starch-based biopolymer electrolytes incorporating silica as filler. Ionics 2015, 21, 2061–2068. [Google Scholar] [CrossRef]

- Chong, M.Y.; Numan, A.; Liew, C.-W.; Ramesh, K.; Ramesh, S. Comparison of the performance of copper oxide and yttrium oxide nanoparticle based hydroxylethyl cellulose electrolytes for supercapacitors. J. Appl. Polym. Sci. 2016, 134. [Google Scholar] [CrossRef]

- Nadiah, N.; Omar, F.S.; Numan, A.; Mahipal, Y.K.; Ramesh, S.; Ramesh, K. Influence of acrylic acid on ethylene carbonate/dimethyl carbonate based liquid electrolyte and its supercapacitor application. Int. J. Hydrog. Energy 2017, 42, 30683–30690. [Google Scholar] [CrossRef]

- Fattah, N.F.A.; Ng, H.M.; Mahipal, Y.K.; Numan, A.; Ramesh, S.; Ramesh, K. An Approach to Solid-State Electrical Double Layer Capacitors Fabricated with Graphene Oxide-Doped, Ionic Liquid-Based Solid Copolymer Electrolytes. Materials 2016, 9, 450. [Google Scholar] [CrossRef]

- Aziz, S.B.; Hadi, J.M.; Dannoun, E.M.A.; Abdulwahid, R.T.; Saeed, S.R.; Marf, A.S.; Karim, W.O.; Kadir, M. The Study of Plasticized Amorphous Biopolymer Blend Electrolytes Based on Polyvinyl Alcohol (PVA): Chitosan with High Ion Conductivity for Energy Storage Electrical Double-Layer Capacitors (EDLC) Device Application. Polymers 2020, 12, 1938. [Google Scholar] [CrossRef]

- Francis, K.A.; Liew, C.-W.; Ramesh, S.; Ramesh, K. Effect of ionic liquid 1-butyl-3-methylimidazolium bromide on ionic conductivity of poly(ethyl methacrylate) based polymer electrolytes. Mater. Express 2016, 6, 252–258. [Google Scholar] [CrossRef]

- Farah, N.; Ng, H.; Numan, A.; Liew, C.-W.; Latip, N.; Ramesh, K.; Ramesh, S. Solid polymer electrolytes based on poly (vinyl alcohol) incorporated with sodium salt and ionic liquid for electrical double layer capacitor. Mater. Sci. Eng. B 2019, 251, 114468. [Google Scholar] [CrossRef]

Sample Availability: Not available. |

| Sample Designation | PVA (g) | CS (g) | Mg (CF3SO3)2 (g) | Glycerol (g) | Glycerol W.t.% |

|---|---|---|---|---|---|

| CSPVMG1 | 0.5 | 0.5 | 0.666 | 0.271 | 14 |

| CSPVMG2 | 0.5 | 0.5 | 0.666 | 0.647 | 28 |

| CSPVMG3 | 0.5 | 0.5 | 0.666 | 1.206 | 42 |

| Sample Designation | Degree of Crystallinity (%) |

|---|---|

| Pure PVA | 41.68 |

| Pure CS | 15.97 |

| CS:PVA | 15 |

| CSPVMG1 | 13.87 |

| CSPVMG2 | 11.26 |

| CSPVMG3 | 4.55 |

| Sample Designation | Rb | σdc (S cm−1) |

|---|---|---|

| CSPVMG1 | 1.5 × 105 | 1.286 × 10−7 |

| CSPVMG2 | 5.6 × 103 | 3.446 × 10−6 |

| CSPVMG3 | 1.9 × 103 | 1.016 × 10−5 |

| Sample Designation | K1 (F−1) | K2 (F−1) | C1 (F) | C2 (F) |

|---|---|---|---|---|

| CSPVMG1 | 6.0 × 108 | 8.0 × 105 | 1.67 × 10−9 | 1.25 × 10−6 |

| CSPVMG2 | 5.0 × 108 | 1.9 × 105 | 2.0 × 10−9 | 5.26 × 10−6 |

| CSPVMG3 | 5.0 × 107 | 1.8 × 105 | 2.0 × 10−8 | 5.56 × 10−6 |

| Scan rate (mV/s) | Area | M (g) | V2 − V1 (V) | Ccyc (F/g) |

|---|---|---|---|---|

| 100 | 3.24 × 10−3 | 2.43 × 10−3 | 0.9 | 7.41 |

| 50 | 3.13 × 10−3 | 2.43 × 10−3 | 0.9 | 14.31 |

| 20 | 2.21 × 10−3 | 2.43 × 10−3 | 0.9 | 25.26 |

| 10 | 1.43 × 10−3 | 2.43 × 10−3 | 0.9 | 32.69 |

| Ammonium Salts | Cation | Anion | Cation Radius (pm) [83] | Anion Radius (pm) [83] | Lattice Energy (KJ/moL) |

|---|---|---|---|---|---|

| Mg(CF3SO3)2 | Mg+2 | CF3SO3− | 72 | 256 [70] | 1967.51 |

| Mg(NO3)2 | Mg+2 | NO3− | 72 | 185 | 2429.51 |

| MgCl2 | Mg+2 | Cl− | 72 | 167 | 2582.13 |

| Mg(CH3COO)2 | Mg+2 | CH3COO− | 72 | 162 | 2627.64 |

| System | Ccyc(F/g) | Scan Rate (mV/s) | Reference |

|---|---|---|---|

| PVA-CH3COONH4 | 0.14 | 10 | [85] |

| Starch-LiClO4 | 8.70 | 10 | [86] |

| HEC-Mg(CF3SO3)2 | 21.40 | 5 | [87] |

| EC-DMC-LiTFSI | 24.00 | 5 | [88] |

| P(VdF-HFP)-EMI-BTI | 29.60 | 3 | [89] |

| PEMA-Mg(CF3SO3)2 | 1.99 | 10 | [90] |

| PVA-CS-NH4SCN-glycerol | 25.05 | 10 | [91] |

| PEMA-Mg(CF3SO3)2-BmImBr | 7.34 | 10 | [92] |

| PVA-NaCF3SO3 | 14.78 | 3 | [93] |

| CS-PVA-Mg(CF3SO3)2:glycerol | 32.69 | 10 | This work |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aziz, S.B.; Brza, M.A.; Dannoun, E.M.A.; Hamsan, M.H.; Hadi, J.M.; Kadir, M.F.Z.; Abdulwahid, R.T. The Study of Electrical and Electrochemical Properties of Magnesium Ion Conducting CS: PVA Based Polymer Blend Electrolytes: Role of Lattice Energy of Magnesium Salts on EDLC Performance. Molecules 2020, 25, 4503. https://doi.org/10.3390/molecules25194503

Aziz SB, Brza MA, Dannoun EMA, Hamsan MH, Hadi JM, Kadir MFZ, Abdulwahid RT. The Study of Electrical and Electrochemical Properties of Magnesium Ion Conducting CS: PVA Based Polymer Blend Electrolytes: Role of Lattice Energy of Magnesium Salts on EDLC Performance. Molecules. 2020; 25(19):4503. https://doi.org/10.3390/molecules25194503

Chicago/Turabian StyleAziz, Shujahadeen B., Mohamad A. Brza, Elham M. A. Dannoun, Muhamad H. Hamsan, Jihad M. Hadi, Mohd F. Z. Kadir, and Rebar T. Abdulwahid. 2020. "The Study of Electrical and Electrochemical Properties of Magnesium Ion Conducting CS: PVA Based Polymer Blend Electrolytes: Role of Lattice Energy of Magnesium Salts on EDLC Performance" Molecules 25, no. 19: 4503. https://doi.org/10.3390/molecules25194503

APA StyleAziz, S. B., Brza, M. A., Dannoun, E. M. A., Hamsan, M. H., Hadi, J. M., Kadir, M. F. Z., & Abdulwahid, R. T. (2020). The Study of Electrical and Electrochemical Properties of Magnesium Ion Conducting CS: PVA Based Polymer Blend Electrolytes: Role of Lattice Energy of Magnesium Salts on EDLC Performance. Molecules, 25(19), 4503. https://doi.org/10.3390/molecules25194503