Mechanical and Hydrothermal Aging Behaviour of Polyhydroxybutyrate-Co-Valerate (PHBV) Composites Reinforced by Natural Fibres

Abstract

1. Introduction

2. Results and Discussion

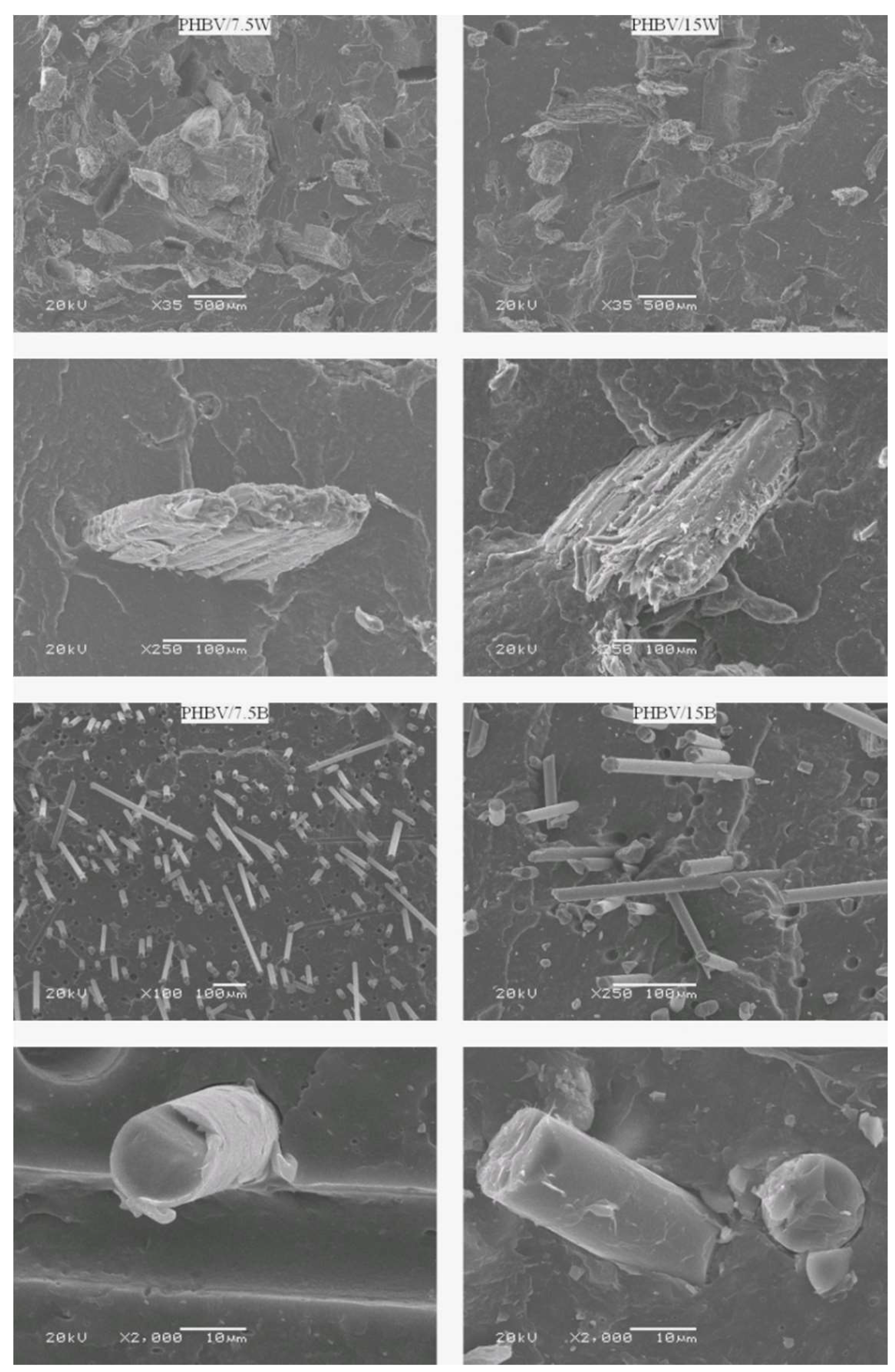

2.1. Fractographic Analysis

2.2. Coefficient of Thermal Expansion (CTE)

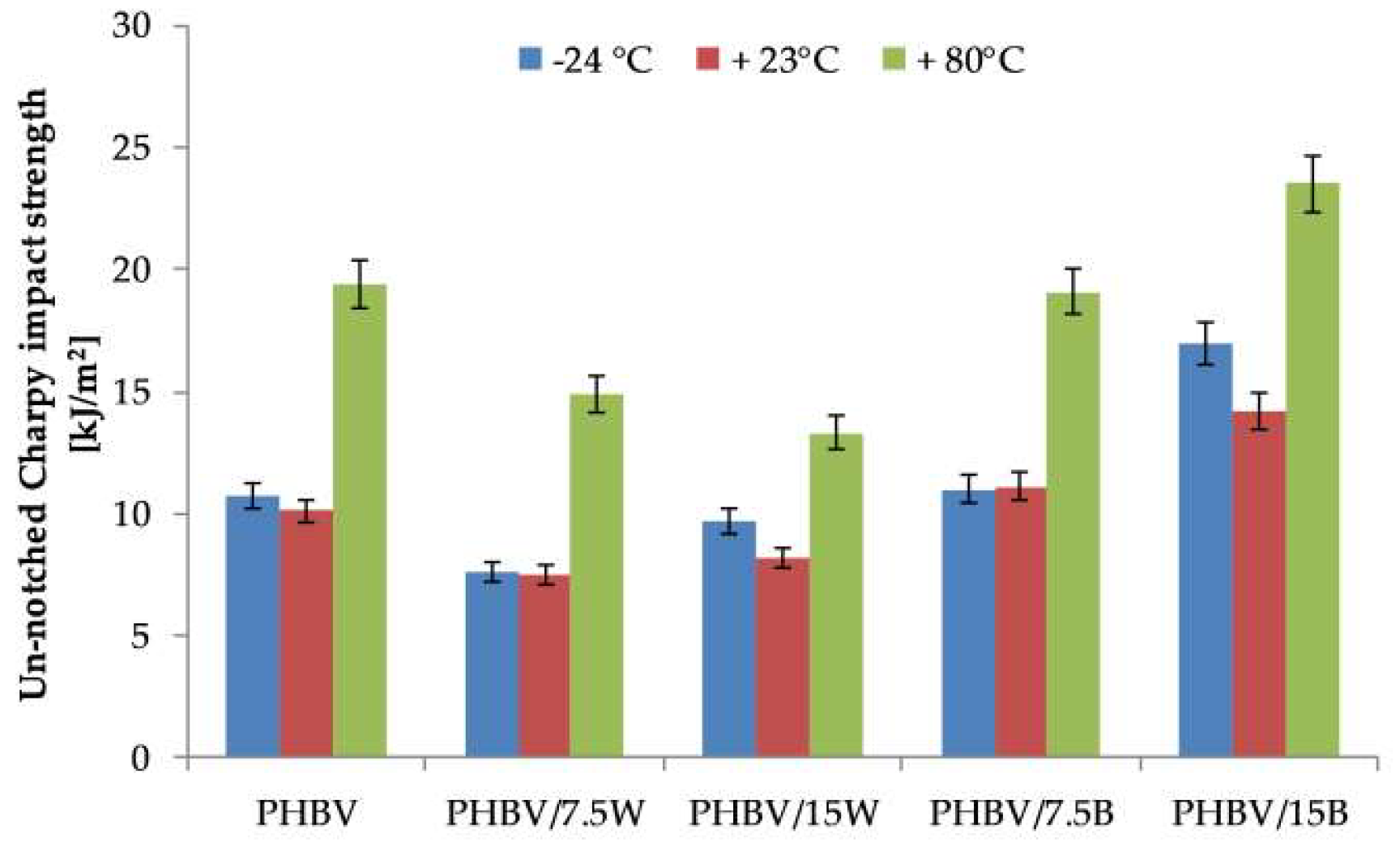

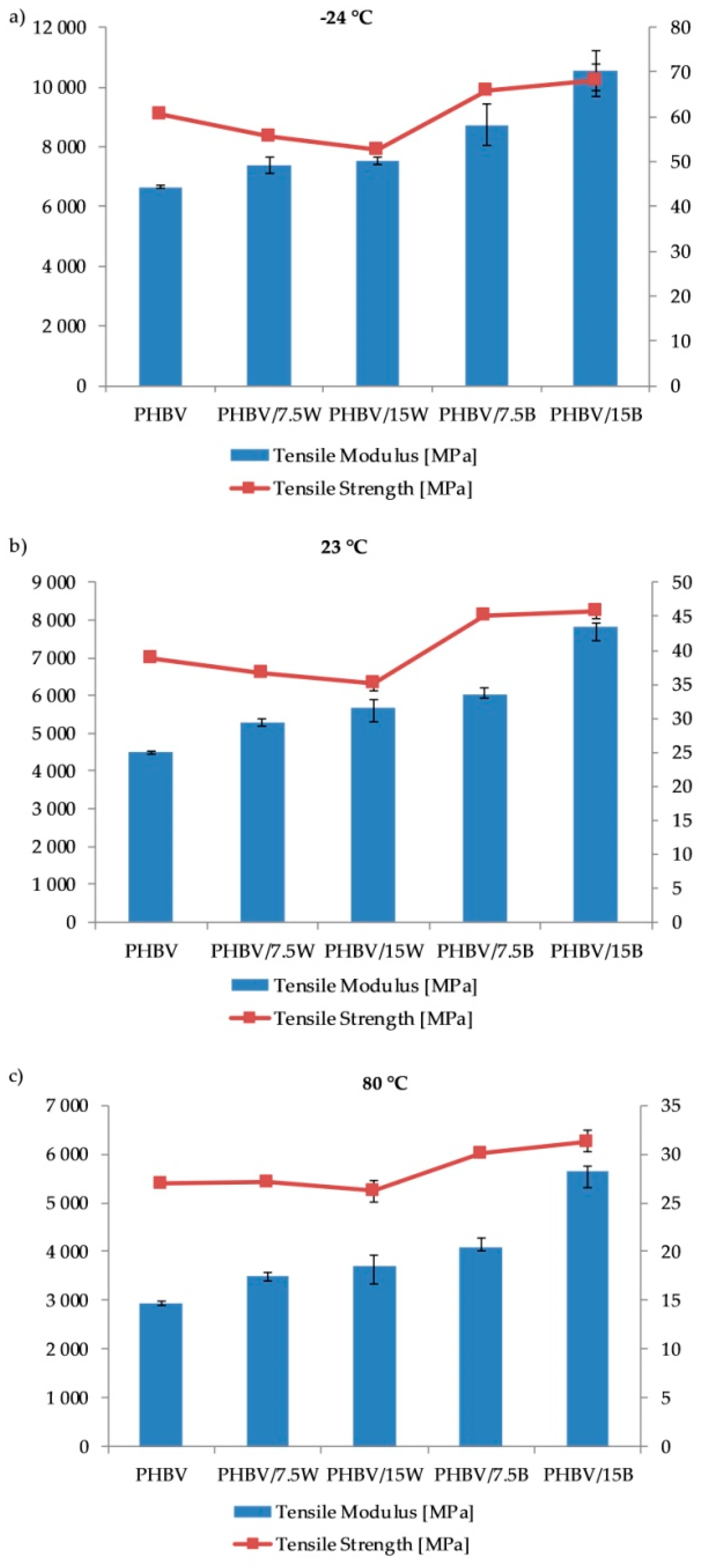

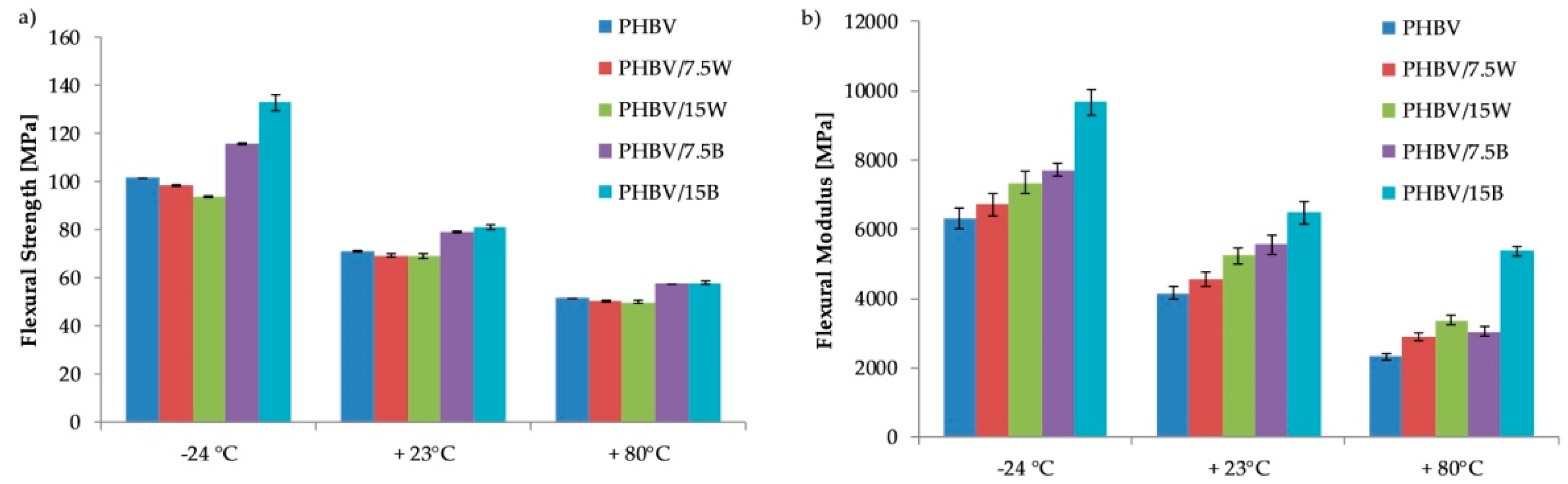

2.3. Mechanical Tests

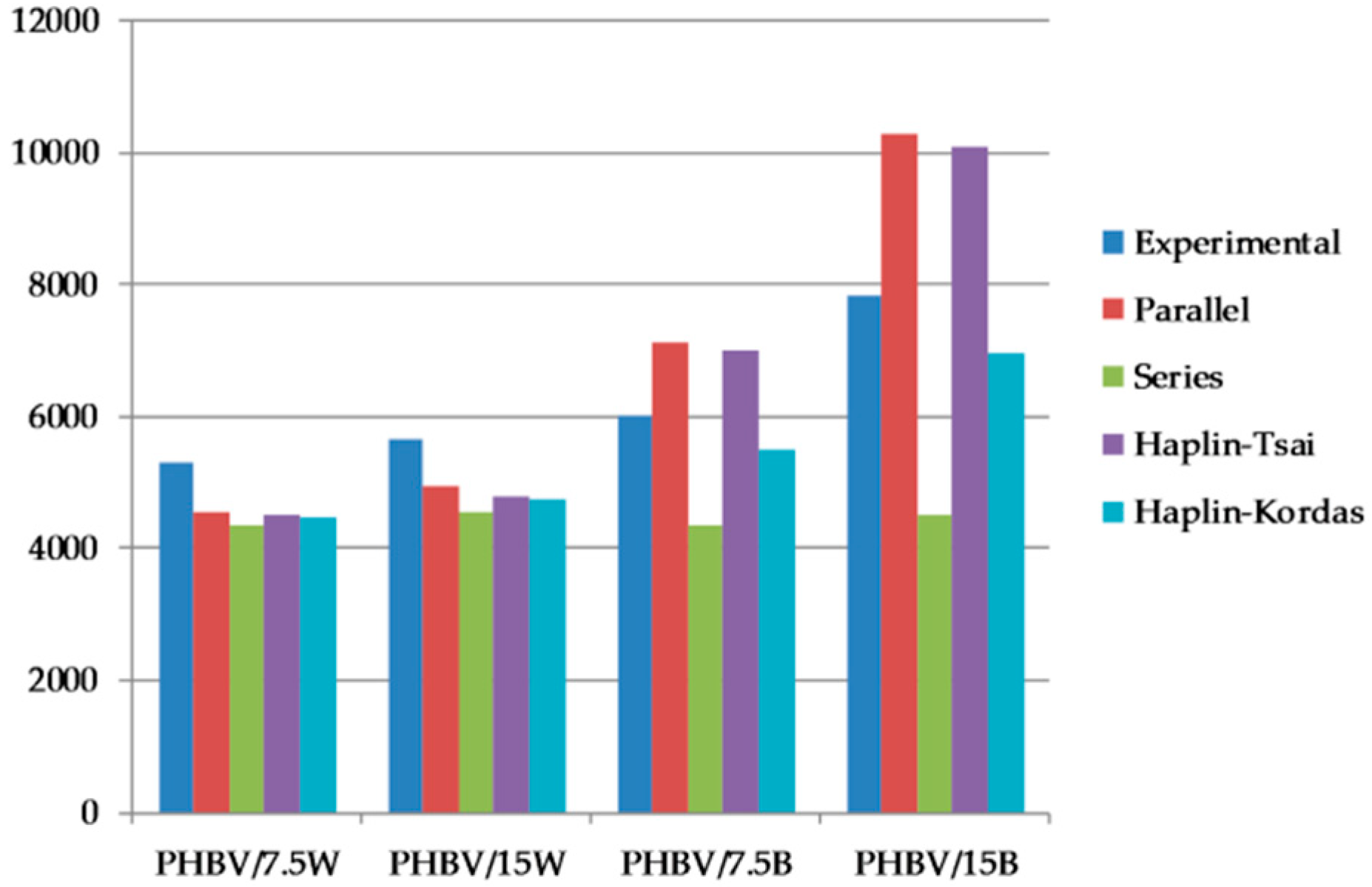

2.4. Micromechanical Analysis

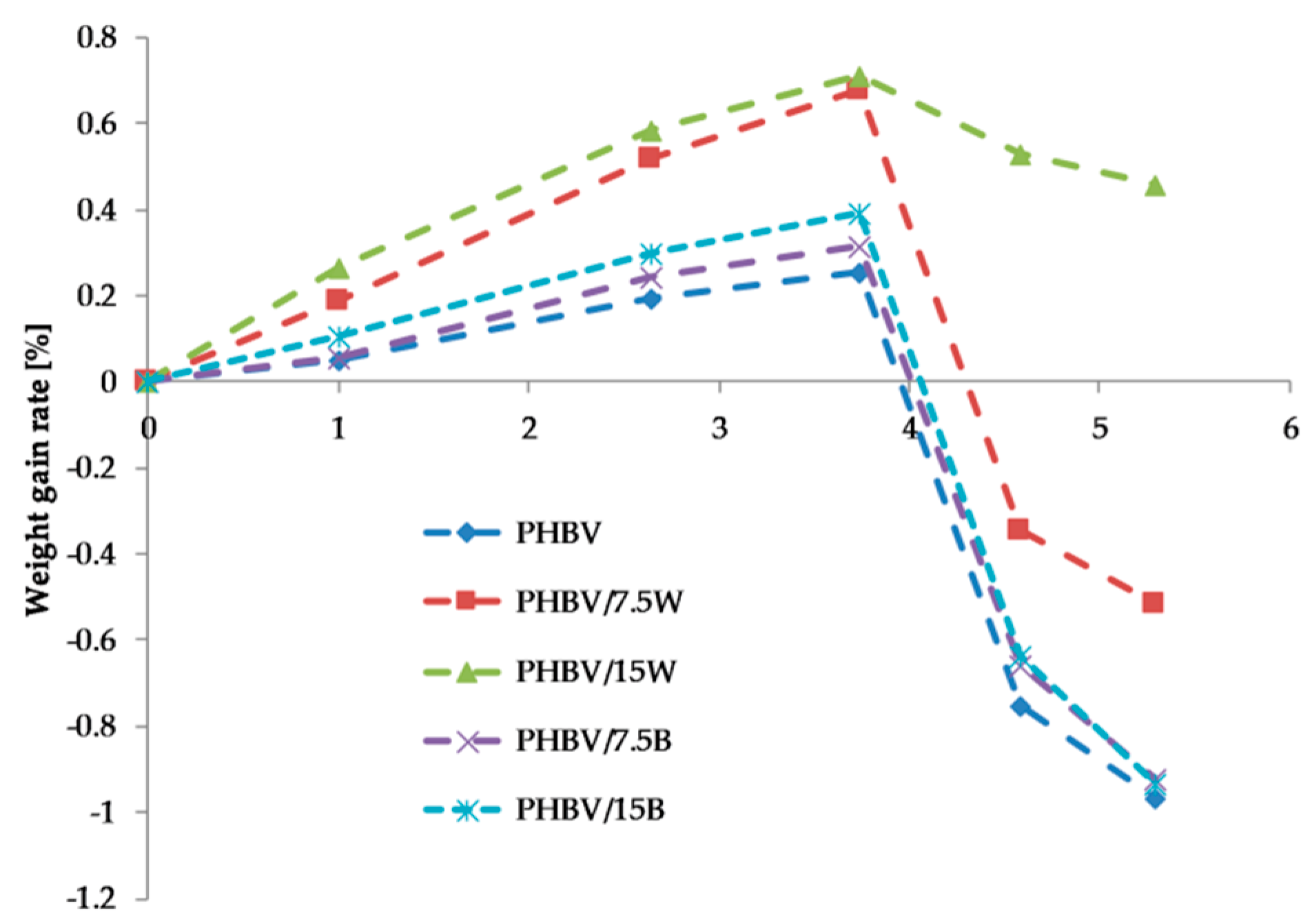

2.5. Hydrothermal Aging

3. Materials and Methods

3.1. Materials

Preparations of Biocomposites

3.2. Methods of Testing

3.2.1. Fractographic Observations

3.2.2. Coefficient of Thermal Expansion

3.2.3. Tensile, Bending and Impact Test

3.2.4. Micromechanical Models

3.2.5. Hydrothermal Aging

4. Conclusions

- (1)

- Addition of BF increased all tested properties, regardless of the test temperature. The improvement at +24 °C for tensile strength was 18%, modulus of elasticity 74%, impact strength 40%, flexural strength was 30% and flexural modulus over 50%. In the case of elevated temperatures, the highest differences were obtained between neat PHBV and BF composites, where the increase for Young modulus was about 100%.

- (2)

- The addition of WFs results in a quantity proportional to the increase in modulus of elasticity with a slight approximately 10% decrease in strength.

- (3)

- The addition of the fibers to PHBV effectively improved the thermal stability, as the fibre content increased, the values of CTE decreased. The highest over 40% decrease was recorded for composites with 15 wt% of BF.

- (4)

- Additionally, the addition of fibers resulted in an increase in water absorption compared to neat polymer. The water absorption increased for the highest degree of saturation from 0.25% (PHBV) to 0.71% (PHBV/15W). Composites with WF had a higher tendency to absorb water and together with the content of fibers increased the capacity of water uptake, regardless of the type of fibre. In the case of non-absorbable BF, this was poor fiber/matrix adhesion. The water diffusion, with a Fick`s law behavior for the composites, increased with the content of fibers and it`s the highest for composites with 15 wt% of WF –4.68 × 10−18 m2/s.

- (5)

- After two weeks of biodegradation in saline at 40 °C, a slight decrease of about 10% in strength properties of the tested materials was observed. These studies confirm that biodegradable PHBV-based composites filled with natural fillers can be successfully used as a material for long-life products.

- (6)

- Regarding the mechanical properties, all biocomposites are characterized by higher stiffness that unmodified the polymer. Further work will concern the increase of adhesion of the fibers to the matrix, which will significantly improve the test results.

Author Contributions

Funding

Conflicts of Interest

References

- Bledzki, A.K.; Jaszkiewicz, A. Mechanical performance of biocomposites based on PLA and PHBV reinforced with natural fibres—A comparative study to PP. Compos. Sci. Technol. 2010. [Google Scholar] [CrossRef]

- Kuciel, S.; Mazur, K.; Jakubowska, P. Novel biorenewable composites based on poly (3-hydroxybutyrate-co-3-hydroxyvalerate) with natural fillers. J. Polym. Env. 2019. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable bio-composites from renewable resources: Opportunities and challenges in the green materials world. J. Polym. Env. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Benini, K.C.C.C.; Ornaghi Júnior, H.L.; Bianchi, O.; de Magalhães, W.F.; Henriques, F.F.; Windmoller, D.; Voorwald, H.J.C.; Cioffi, M.O.H. Novel biodegradable composites based on PHBV: Effect of nanocellulose incorporation on the non-isothermal crystallization kinetic and structural parameters. Polym. Compos. 2018, 40, 3156–3165. [Google Scholar] [CrossRef]

- Keller, A. Compounding and mechanical properties of biodegradable hemp fibre composites. Compos. Sci. Technol. 2003, 63, 1307–1316. [Google Scholar] [CrossRef]

- Rivera-Briso, A.L.; Serrano-Aroca, Á. Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate): Enhancement strategies for advanced applications. Polymers 2018, 10, 732. [Google Scholar] [CrossRef]

- Avella, M.; Bogoeva-Gaceva, G.; Buzarovska, A.; Errico, M.E.; Gentile, G.; Grozdanov, A. Poly(3-hydroxybutyrate-co-3-hydroxyvalerate)-based biocomposites reinforced with kenaf fibers. J. Appl. Polym. Sci. 2007, 104, 3192–3200. [Google Scholar] [CrossRef]

- Kuciel, S.; Liber-Kneć, A. Biocomposites based on PHB filled with wood or kenaf fibers. Polim. Polym. 2011, 56, 218–223. [Google Scholar] [CrossRef]

- Liber-Kneć, A.; Kuźniar, P.; Kuciel, S. Accelerated fatigue testing of biodegradable composites with flax fibers. J. Polym. Env. 2015. [Google Scholar] [CrossRef]

- Srubar, W.V.; Pilla, S.; Wright, Z.C.; Ryan, C.A.; Greene, J.P.; Frank, C.W.; Billington, S.L. Mechanisms and impact of fiber-matrix compatibilization techniques on the material characterization of PHBV/oak wood flour engineered biobased composites. Compos. Sci. Technol. 2012, 72, 708–715. [Google Scholar] [CrossRef]

- Hassaini, L.; Kaci, M.; Benhamida, A.; Bruzaud, S.; Pillin, I.; Grohens, Y. The effects of PHBV-g-MA compatibilizer on morphology and properties of poly(3-hydroxybutyrate-Co-3-hydroxyvalerate)/olive husk flour composites. J. Adhes. Sci. Technol. 2016, 30, 2061–2080. [Google Scholar] [CrossRef]

- Andrew, J.; Ramesh, C. Residual strength and damage characterization of unidirectional glass–basalt hybrid/epoxy cai laminates. Arab. J. Sci. Eng. 2015, 40, 1695–1705. [Google Scholar] [CrossRef]

- Czigány, T.; Kovács, J.G.; Tábi, T. Basalt fiber reinforced poly (lactic acid) composites for engineering applications. In Proceedings of the ICCM International Conferences on Composite Materials, Montreal, Canada; 2013; pp. 4377–4384. [Google Scholar]

- Ying, Z.; Wu, D.; Zhang, M.; Qiu, Y. Polylactide/basalt fiber composites with tailorable mechanical properties: Effect of surface treatment of fibers and annealing. Compos. Struct. 2017, 176, 1020–1027. [Google Scholar] [CrossRef]

- Ferreira, F.; Pinheiro, I.; de Souza, S.; Mei, L.; Lona, L. Polymer composites reinforced with natural fibers and nanocellulose in the automotive industry: A short review. J. Compos. Sci. 2019, 3, 51. [Google Scholar] [CrossRef]

- Huang, R.; Zhang, Y.; Xu, X.; Zhou, D.; Wu, Q. Effect of hybrid mineral and bamboo fillers on thermal expansion behavior of bamboo fiber and recycled polypropylene-polyethylene composites. BioResources 2012, 7, 4563–4574. [Google Scholar] [CrossRef]

- Nishino, T.; Matsuda, I.; Hirao, K. All-cellulose composite. Macromolecules 2004, 37, 7683–7687. [Google Scholar] [CrossRef]

- Bauer, F.; Kempf, M.; Weiland, F.; Middendorf, P. Structure-property relationships of basalt fibers for high performance applications. Compos. Part B Eng. 2018, 145, 121–128. [Google Scholar] [CrossRef]

- Liu, W.J.; Yang, H.L.; Wang, Z.; Dong, L.S.; Liu, J.J. Effect of Nucleating Agents on the Crystallization of Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate). J. Appl. Polym. Sci. 2002, 86, 2145–2152. [Google Scholar] [CrossRef]

- Singh, S.; Mohanty, A.K. Wood fiber reinforced bacterial bioplastic composites: Fabrication and performance evaluation. Compos. Sci. Technol. 2007, 67, 1753–1763. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S. A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Spiridon, I.; Darie, R.N.; Kangas, H. Influence of fiber modifications on PLA/fiber composites. Behavior to accelerated weathering. Compos. Part B Eng. 2016, 92, 19–27. [Google Scholar] [CrossRef]

- Yatigala, N.S.; Bajwa, D.S.; Bajwa, S.G. Compatibilization improves physico-mechanical properties of biodegradable biobased polymer composites. Compos. Part A Appl. Sci. Manuf. 2018, 107, 315–325. [Google Scholar] [CrossRef]

- Altun, Y.; Doǧan, M.; Bayramli, E. Effect of alkaline treatment and pre-impregnation on mechanical and water absorbtion properties of pine wood flour containing poly (lactic acid) based green-composites. J. Polym. Env. 2013, 21, 850–856. [Google Scholar] [CrossRef]

- Gunning, M.A.; Geever, L.M.; Killion, J.A.; Lyons, J.G.; Higginbotham, C.L. Mechanical and biodegradation performance of short natural fibre polyhydroxybutyrate composites. Polym. Test. 2013, 32, 1603–1611. [Google Scholar]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Kuciel, S.; Romańska, P. Hybrid composites of polylactide with basalt and carbon fibers and their thermal treatment. Materials 2018. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Mohanty, A.K.; Sugie, T.; Takai, Y.; Hamada, H. Renewable resource based biocomposites from natural fiber and polyhydroxybutyrate-co-valerate (PHBV) bioplastic. Compos. Part A Appl. Sci. Manuf. 2008, 39, 875–886. [Google Scholar] [CrossRef]

- Jonoobi, M.; Harun, J.; Mathew, A.P.; Oksman, K. Mechanical properties of cellulose nanofiber (CNF) reinforced polylactic acid (PLA) prepared by twin screw extrusion. Compos. Sci. Technol. 2010, 70, 1742–1747. [Google Scholar] [CrossRef]

- Tan, B.; Thomas, N.L. A review of the water barrier properties of polymer/clay and polymer/graphene nanocomposites. J. Memb. Sci. 2016, 514, 595–612. [Google Scholar] [CrossRef]

- Jiang, N.; Yu, T.; Li, Y. Effect of hydrothermal aging on injection molded short jute fiber reinforced poly(lactic acid) (pla) composites. J. Polym. Env. 2018, 26, 3176–3186. [Google Scholar] [CrossRef]

- Ventura, H.; Claramunt, J.; Rodríguez-Pérez, M.A.; Ardanuy, M. Effects of hydrothermal aging on the water uptake and tensile properties of PHB/flax fabric biocomposites. Polym. Degrad. Stab. 2017, 142, 129–138. [Google Scholar] [CrossRef]

- Voigt, W. Ueber die Beziehung zwischen den beiden Elasticitätsconstanten isotroper Körper. Ann. Phys. 1889, 274, 573–587. [Google Scholar] [CrossRef]

- Reuss, A. Berechnung der Fließgrenze von Mischkristallen auf Grund der Plastizitätsbedingung für Einkristalle. Zamm-J. Appl. Math. Mech./Z. Für Angew. Math. Und Mech. 1929, 9, 49–58. [Google Scholar] [CrossRef]

- Affdl, J.C.H.; Kardos, J.L. The halpin-tsai equations: A review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar] [CrossRef]

- Fick, A. Ueber Diffusion. Ann. Phys. 1855, 94, 59–86. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are available from the authors. |

| Sample | Coefficient of Thermal Expansion |

|---|---|

| PHBV | 72.473 × 10−6/°C |

| PHBV/7.5W | 59.923 × 10−6/°C |

| PHBV/15W | 53.513 × 10−6/°C |

| PHBV/7.5B | 48.533 × 10−6/°C |

| PHBV/15B | 42.343 × 10−6/°C |

| Composites | h [m] | Mm [%] | Dx [×10−18 m2/s] |

|---|---|---|---|

| PHBV | 0.004 | 0.25 | 1.26 |

| PHBV/7.5W | 0.004 | 0.68 | 3.03 |

| PHBV/15W | 0.004 | 0.71 | 4.69 |

| PHBV/7.5B | 0.004 | 0.32 | 1.76 |

| PHBV/15B | 0.004 | 0.39 | 2.06 |

| Components | Length (l) [mm] | Diameter (d) [μm] | Density [g/cm3] | Young Modulus (E) [GPa] |

|---|---|---|---|---|

| Matrix | - | - | 1.25 | 4.2 |

| Wood fibre | 0.3 | 150 | 1.52 | 10 |

| Basalt fibre | 4 | 17 | 2.67 | 84 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mazur, K.; Kuciel, S. Mechanical and Hydrothermal Aging Behaviour of Polyhydroxybutyrate-Co-Valerate (PHBV) Composites Reinforced by Natural Fibres. Molecules 2019, 24, 3538. https://doi.org/10.3390/molecules24193538

Mazur K, Kuciel S. Mechanical and Hydrothermal Aging Behaviour of Polyhydroxybutyrate-Co-Valerate (PHBV) Composites Reinforced by Natural Fibres. Molecules. 2019; 24(19):3538. https://doi.org/10.3390/molecules24193538

Chicago/Turabian StyleMazur, Karolina, and Stanisław Kuciel. 2019. "Mechanical and Hydrothermal Aging Behaviour of Polyhydroxybutyrate-Co-Valerate (PHBV) Composites Reinforced by Natural Fibres" Molecules 24, no. 19: 3538. https://doi.org/10.3390/molecules24193538

APA StyleMazur, K., & Kuciel, S. (2019). Mechanical and Hydrothermal Aging Behaviour of Polyhydroxybutyrate-Co-Valerate (PHBV) Composites Reinforced by Natural Fibres. Molecules, 24(19), 3538. https://doi.org/10.3390/molecules24193538