1. Introduction

Sensors are required in both hard and soft robotics [

1]. Hard robotics deals with rigid structural materials actuated by mechatronic definitions with powered controllers and computers, while soft robotics predominantly utilizes soft materials involving elastomers, thin, flexible sheets, liquids, etc. Rubber is suitable as a soft material because it is highly elastic and compressible. Polydimethylsiloxane (PDMS), for example, is currently much used as a silicone rubber (Q) [

2]. Q is also tractable and is a major commercial material in molding. Many studies have been carried out and many propositions have been made regarding functionalizing sensory systems in robotics. In hard robotics, sensors are ordinarily installed in or on the materials. In contrast, in soft robotics, variegated sensors with electrodes [

3], such as Hall Effect sensors [

4], pressure sensors [

5], etc., are embedded in the soft material [

6].

However, material that has sensors installed or embedded becomes fragile due to large tensile or compressive motion in both hard and soft robotics. In addition, in the case of soft robotics, sensing intelligence is often provided in the soft material, which utilizes rubber that is conductive due to a compounding filler such as carbon black [

7] or magnetic powder [

2]. The addition of such a filler into a material such as Q makes the material mechanically harder.

We can propose biological mimicry as another way to resolve the above inconvenience for both wide and soft motion and for both hard and soft robotics. Sensors are indispensable to obtain information about force, temperature, and so on, and a robot particularly requires the sensors’ haptic intelligence and structured sensing systems. Current robots either have an outer body of rigid plastic or have no outer body to cover the bare machinery, with the result that the robot would not necessarily be familiar with human society. Therefore, it is desirable to be able to embed sensors in an outer body that envelopes the machinery. The use of tactile rubber with sensibility fulfills this prerequisite because this type of rubber also has large elasticity and compressibility, like human skin [

8].

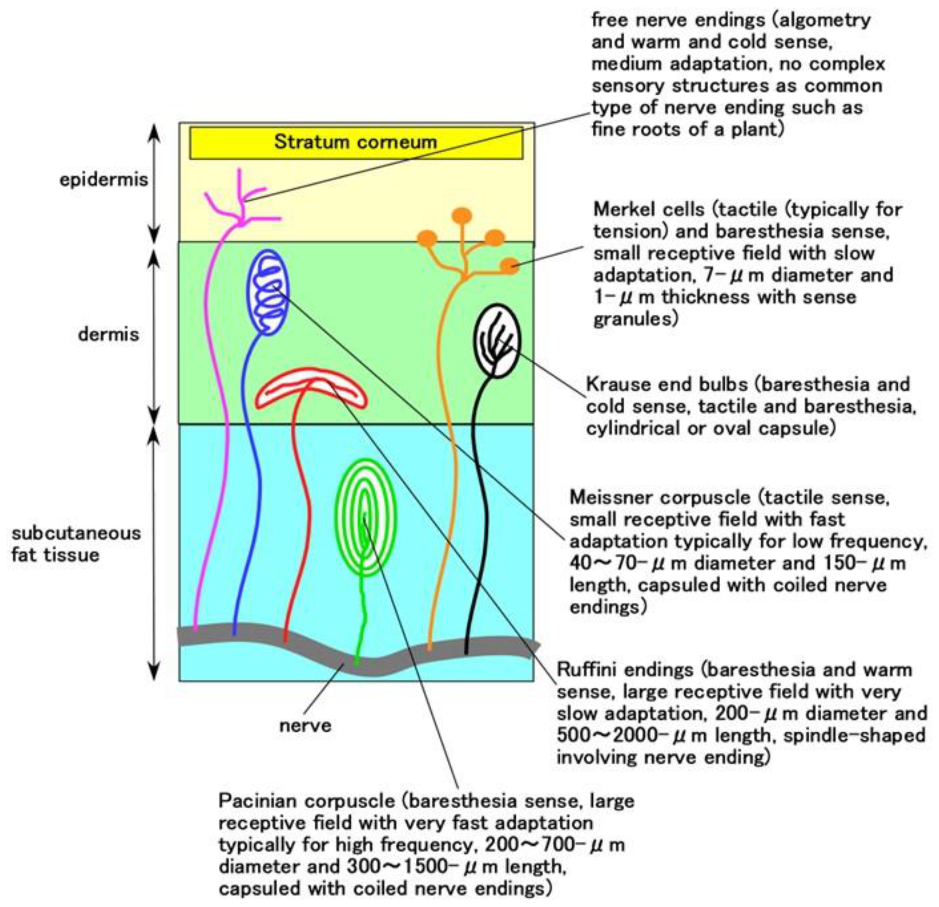

Regarding biological mimicry, we can utilize a mimetic organ of perceptual cells in the human body. Perceptual cells are categorized into several types based on configuration and sensory intelligence. Configuration is based on the shape of the nerve endings of the receptor, for example, Meissner corpuscles, Pacinian corpuscles, Merkel cells, Ruffini endings, etc., and receptors include mechanoreceptors, thermoreceptors, etc. Until recently, they have been investigated with an eye to simulating them by replicating or mimicking their intelligence using mechanical or electronic devices with the application of stimuli [

9,

10,

11]. The devices are not embedded in artificial skin such as rubber, but rather are externally structured gadgets with machinery and electric circuits to demonstrate mechanoreception or thermoreception. In addition, for the purpose of creating a humanoid with skin inspired by stimuli, electrical circuits with electrodes that are flexible and stretchable to deal with mechanical stress/strain have been utilized in thin film [

12,

13]; this corresponds to wearable devices installed on a human body involving the arm or hand. Although the demonstrated mechanoreceptors and thermoreceptors have been simulated as haptic sensors, they have been so large that they have not been a cell-like fabric in a human body at a μm-scale. To date, there have not been studies on the morphological fabrication of cutaneous receptors and human skin tissue using artificial materials. Therefore, the production of artificial skin embedded with artificial cutaneous receptors utilizing a rubber is a fascinating and invaluable subject.

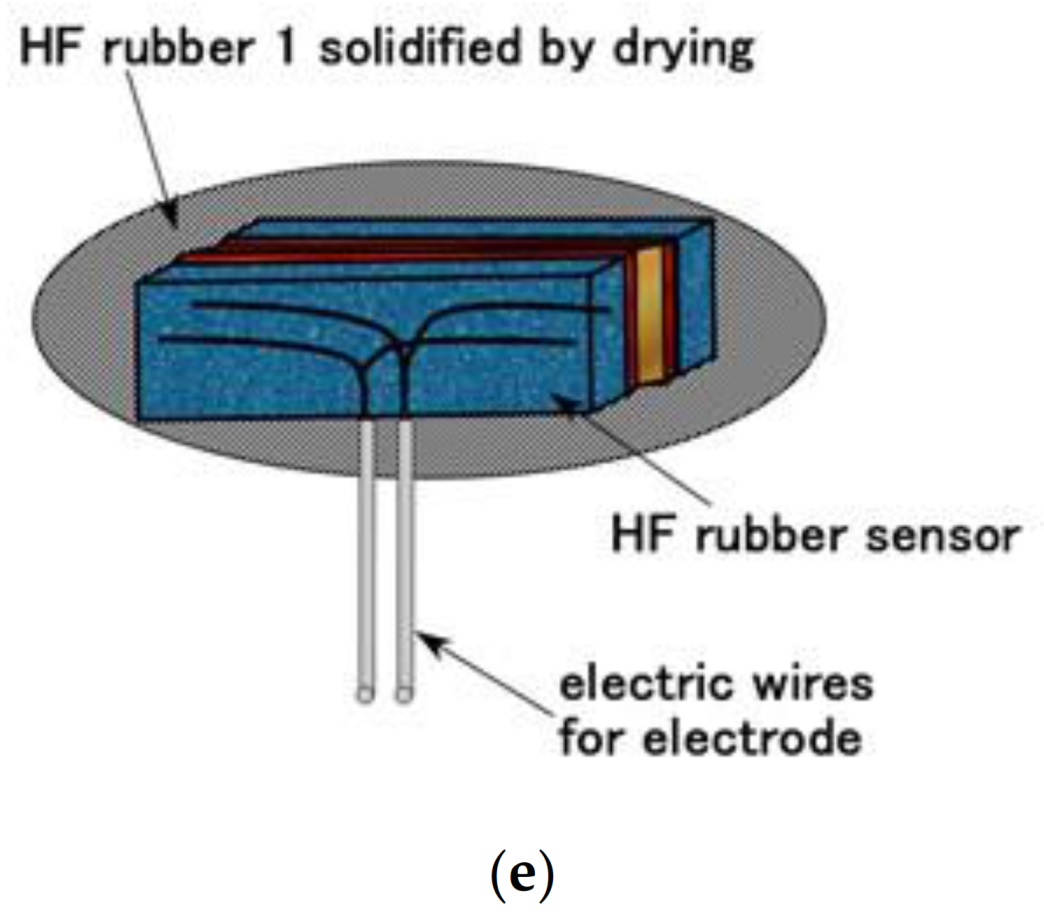

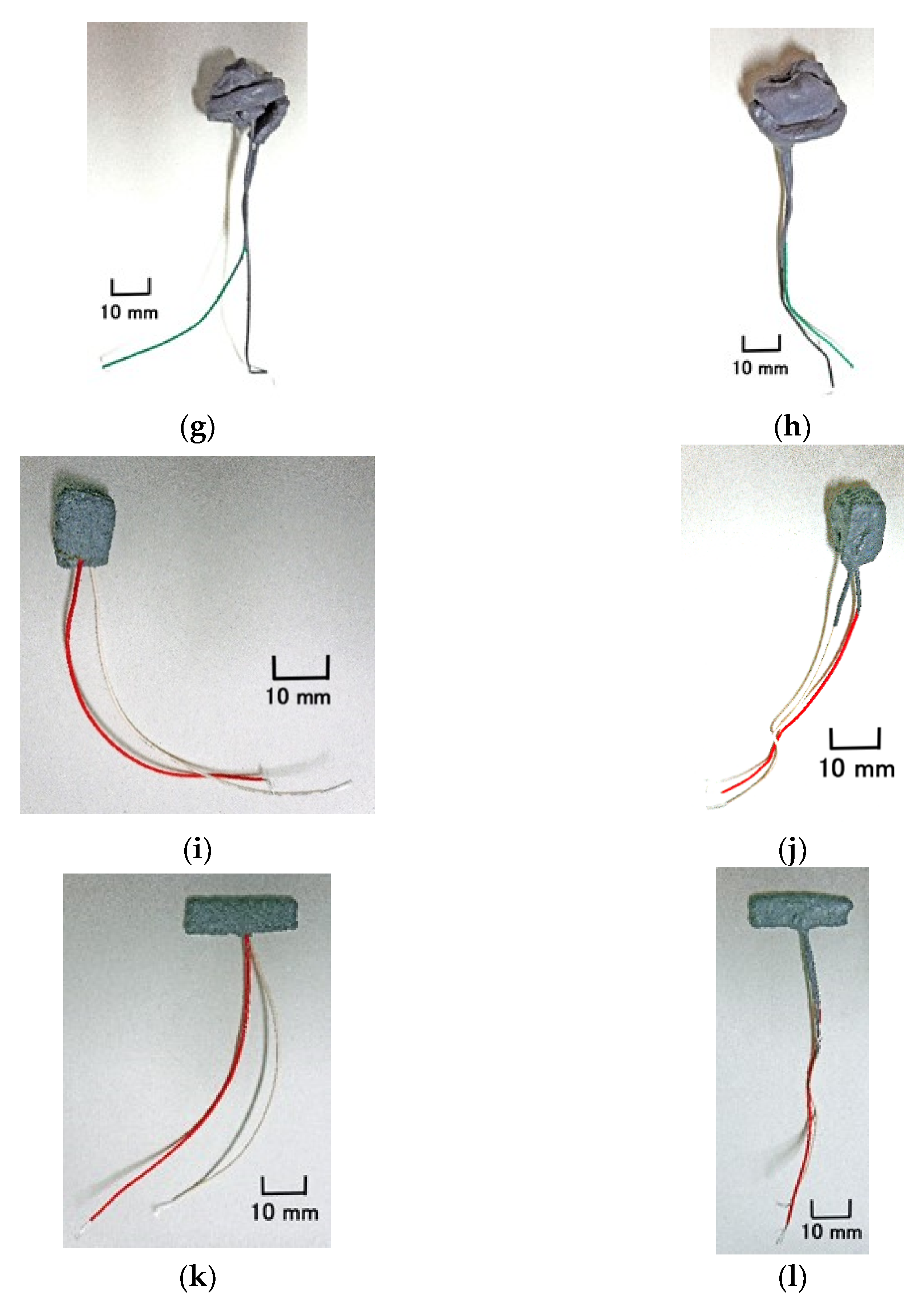

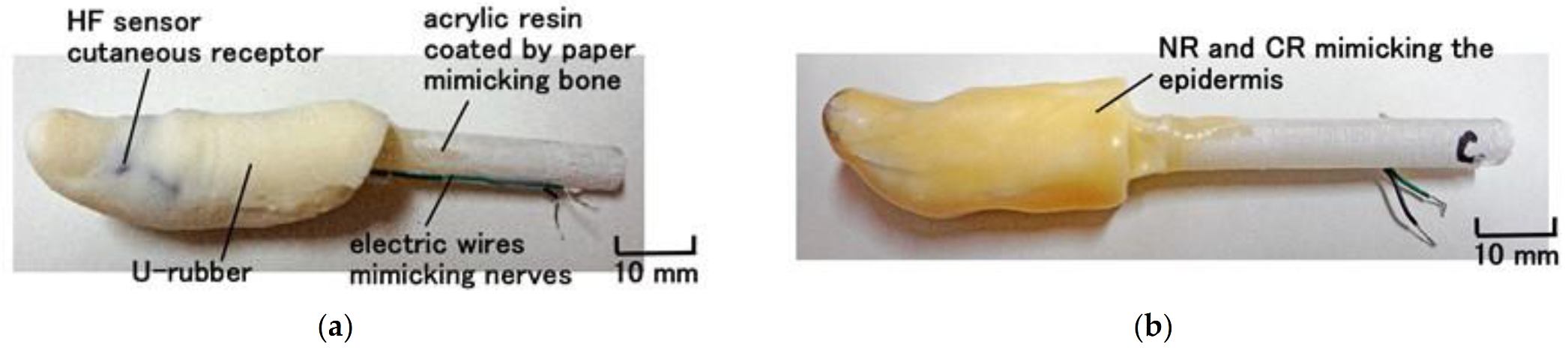

Therefore, in the present study, we fabricated artificial cutaneous receptors embedded in artificial rubber skin mimicking human skin tissue. We propose a fabrication technique using rubber involving magnetic responsive fluid for cutaneous receptors mimicking human perceptual cells and a body part, the finger, with the rubber sensor embedded in urethane rubber (U). In general, the issues of the mixture of any rubbers and magnetic responsive fluid have not been conducted until recent except for our serial investigations, because the physical mechanism is elucidated and complicated.

However, the issues are significant for the development of the production of magnetic rubber. Therefore, the mixture of U-rubber and magnetic responsive fluid such as the present study is invaluable. Our proposed fabrication technique also includes the utilization of our previously proposed technique of adhesion of electric wires onto the rubber sensor and the rubber for the purpose of avoiding electric wires’ desorption from the sensor by large elongation or deformation of the body. The key issue of the present paper is the preliminary work of trying the fabrication of the mimic organ. Then, as a first step, we presented the viability of the fabrication of a finger involving simulated cutaneous receptors for both mechanical and thermal sensing: forcing, thermo and shearing sensibility, which are demonstrated as typical cases in our daily life: touching a body, touching a hot or cold water in washing a face or bathing, or robbing a rough body surface.

2. Hybrid Fluid (HF)

In order to take advantage of the defense against deterioration of non-diene rubber, diene and non-diene rubbers are combined using polyvinyl alcohol (PVA) [

14]. Diene rubbers such as natural rubber (NR) and chloroprene rubber (CR) are soluble in water, while non-diene rubbers such as Q are soluble in kerosene. In particular, Q is soluble in silicone oil with PDMS. Therefore, rubber latex combined with NR (Ulacol; Rejitex Co., Ltd., Atsugi, Japan), CR (671A; Showa Denko Co., Ltd., Tokyo, Japan) and Q can be soluble in water, kerosene or silicone oil. For the possible combination of rubber and magnetic responsive fluid such as magnetic fluid (MF), the magnetic responsive fluid may include water, kerosene, or silicone oil. Where MF is both expensive and inconvenient as it must be purchased from a company, it cannot be easily produced in laboratory and its constituents are obscure because of a confidential engineering patent. Therefore, there is a new magnetic responsive fluid that replaces MF consists of magnetic particles and surfactant, which is simulated MF whose Fe

3O

4 is coated by a surfactant.

In the present study, we propose a cutting-edge magnetic responsive fluid, HF (hybrid fluid). HF consists of Fe

3O

4 (Fujifilm Wako Chemicals Co., Ltd., Osaka, Japan) and Fe (M300, about 50-μm particles; Kyowa Pure Chemical Co., Ltd., Tokyo, Japan) particles in the solution mixed with water, kerosene, or silicone oil (KF96 with 1-cSt viscosity with PDMS; Shin-Etsu Chemical Co., Ltd., Tokyo, Japan) with a surfactant of sodium hexadecyl sulfate aqueous solution (Fujifilm Wako Chemicals Co. Ltd., Osaka, Japan). Where KF96 contains PDMS, M300 should be compounded because the mixed fluid has little response to a magnetic field when we used only Fe

3O

4. The purpose of using the surfactant is to optimize the combination of diene and non-diene rubbers, as shown in our previous study [

15]. HF can be produced as follows. First, sodium hexadecyl sulfate is combined with water at a weight ratio of 1:10. This sodium hexadecyl sulfate aqueous solution was compounded with Fe

3O

4 and M300 using an agitator. Next, the mixture was agitated for about 1 h with water, kerosene, KF96 and PVA. The use of a high-speed agitator or the mixing under vacuum optimizes dispersion enough to avoid the separated state of the mixed liquids. We should pay attention of degassing from the liquids since the liquids inflate by the agitating. If we do not use the vacuum pump during agitating, the liquids must be vacuumed intermittently in the interval of agitating. The constituents of HF are 3 g water, 3 g kerosene, 3 g KF96 (1cSt), 21 g PVA, 3 g Fe

3O

4, 3 g M300, 4 g sodium hexadecyl sulfate aqueous solution, and they are optimum in terms of miscibility with Q, NR, and CR.

When a magnetic field is applied, many needle-like magnetic clusters are created, such as our proposed magnetic compound fluid (MCF) as one of magnetic responsive fluid that is tackled in the issues of the mixture of any rubbers and magnetic responsive fluid. MCF is an intelligent colloidal fluid that is responsive to a magnetic field and is constructed by 1-μm ordered metal particles such as Ni, Fe, Cu, etc. and 10-nm ordered sphere magnetite (Fe

3O

4) particles in a solvent such as water, kerosene, silicone oil, etc., since MCF is made by compounding metal particles and MF. Regarding the combination of metal particles into a rubber, there have been many investigations on the combination of particles such as carbon, metal, etc. in the rubbers of NR [

16], CR [

17], nitrile rubber (NBR) [

18], styrene-butadiene rubber (SBR) [

19], Q [

20,

21], and on the combination of NR and SBR [

22,

23,

24,

25], NR and NBR [

25], NR and ethylene-propylene rubber (EPM or EPDM) [

26]. However, there are few reports of combining magnetic responsive fluid into a rubber except for the rubber involved MCF or HF of our serial investigation.

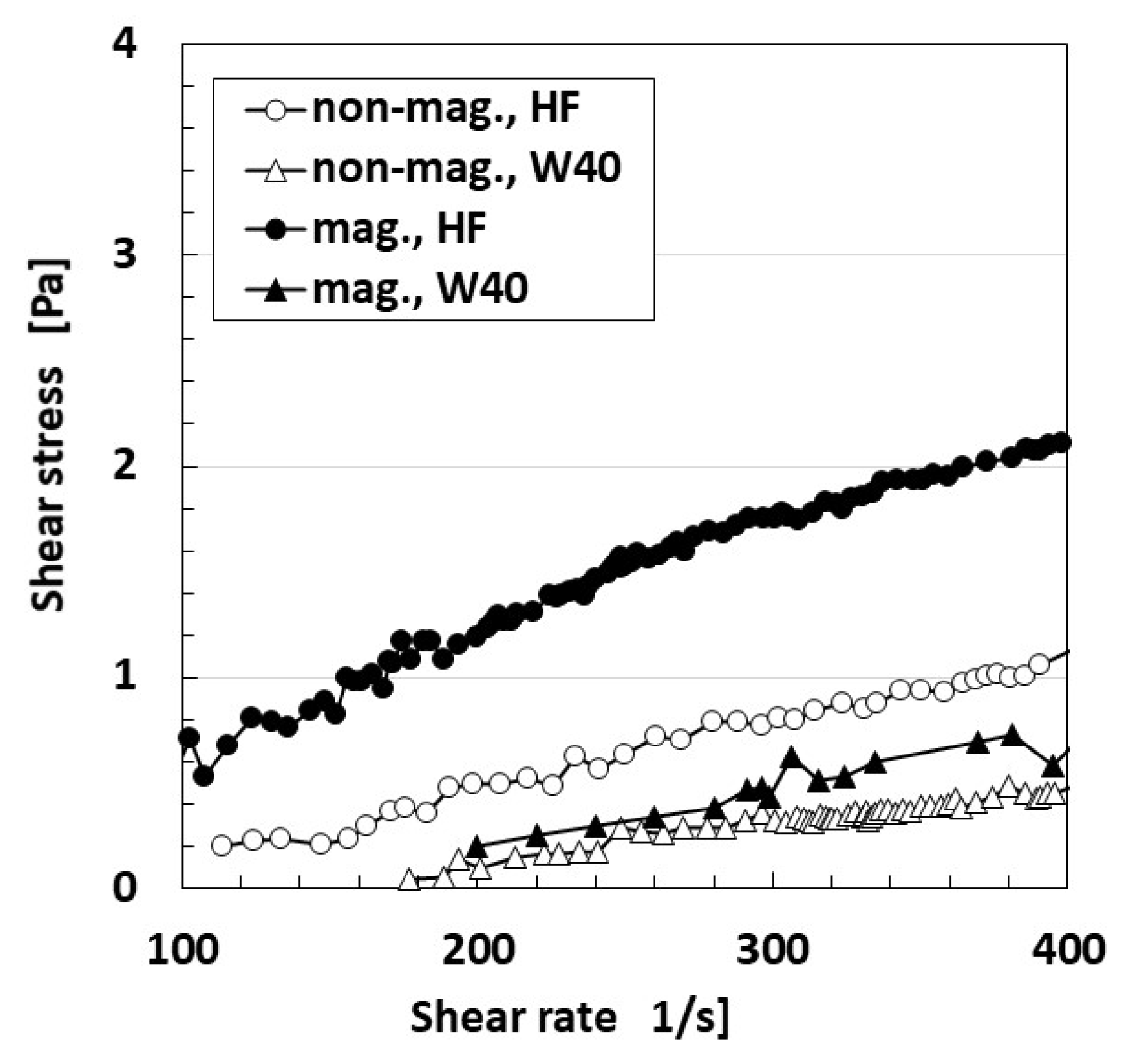

The relationship between shear rate and shear stress is shown in

Figure 1. W40 in the figure indicates a water-based MF with 40 wt% Fe

3O

4 (W40; Taiho Industry Co., Ltd., Takatsuki, Japan), for comparison with the HF, which replaces MF. For measurement, we used a plate-plate type rotational viscometer in order to achieve uniform distribution of the magnetic field over the rotational plate with a 40-mm diameter throughout. Torque applied on the plate was measured by torque meter (SS-005, Ono Sokki, Co. Ltd., Yokohama, Japan) under a rotational speed of the plate applied by DC motor (Vexta, BXM460-GFH2, Oriental Motor, Co. Ltd., Tokyo, Japan). The distance between the plates was 1 mm. 39-mT magnetic field was applied by a permanent magnet. Given this result, when no magnetic field was used, HF has almost the same quantitative ordered viscosity of MF, which also has the same ordered viscosity (water, kerosene, KF96). Under the application of a magnetic field, the viscosity of HF is multiplied several times, which is the same tendency seen with MF. However, the viscosity does not become greater than that of other magnetic responsive fluids, such as MRF. In general, the fluid polymerized by emulsifier has a comparatively low viscosity. HF is guessed to have a similar peculiarity.

Figure 2 shows the magnetization of HF compared to MF measured by a vibrating sample magnetometer (VSM, TM-VSM1015-CRO-T, Tamakawa Co. Ltd., Sendai, Japan). The saturation magnetization of the HF specimens is several times larger than that of MF. However, it is not larger than that of other magnetic responsive fluids; MRF, for example, is the same regarding viscosity.

HF is coordinate with MF because its viscosity and magnetization are equivalent to those of MF based on the results shown in

Figure 1 and

Figure 2.

When utilizing HF in rubber, it is important to estimate the piezoelectricity and piezoresistivity of the electrolytically polymerized rubber. By another comparison of the piezoelectricity of electrolytically polymerized HF rubber using M300 and Ni (µm-order and pimple-like shapes on the surface; No. 123; Yamaishi), the spontaneous voltage using Ni is larger than that of M300. Detailed results of behavior, viscosity, magnetization of HF, as well as the optimal material in piezoelectricity and piezoelectricity are presented in another paper [

27]. In addition, we adopted the utilization of Ni, as shown in the following section on the production of HF rubber sensors. Conveniently, the use of an outer power supply connected to a sensor in order to obtain an electrical signal from the sensor by the application of an electric field is dispensable. Because the use of an outer power supply is bulky and heavy, or the use of electric wires is obstructive for the operation of a robot. Therefore, the measurement of the spontaneous generating voltage in piezoelectricity is tractable on the operation.

4. Mechanical and Thermal Sensing

We investigated the characteristics of the produced thumb with HF sensors mimicking cutaneous receptors by using a simple experimental apparatus. For the way to estimate the sensibility of a mimetic organ of perceptual cells in a human body, we adopted the ordinary measurement of voltage from the fabricated organ for the application of any forcing and heating. Because the present fabricate is a novel haptic sensor, the predefined parameters estimated the electrical signal from the novel haptic sensor had not been stipulated. Until recently, there have not been studies on the fabrication of a mimetic organ of perceptual cells in a human body. The measurement of the data, such as the voltage for the application of any forcing and heating, is the latest issue in the field of fusion of engineering and medical science so that it might be developed for the future. On the other hand, the key issue of the paper is the preliminary work of trying the fabrication of the mimic organ. Therefore, in the present paper, at the primary level of the measurement, the voltage for the application of any forcing and heating is employed.

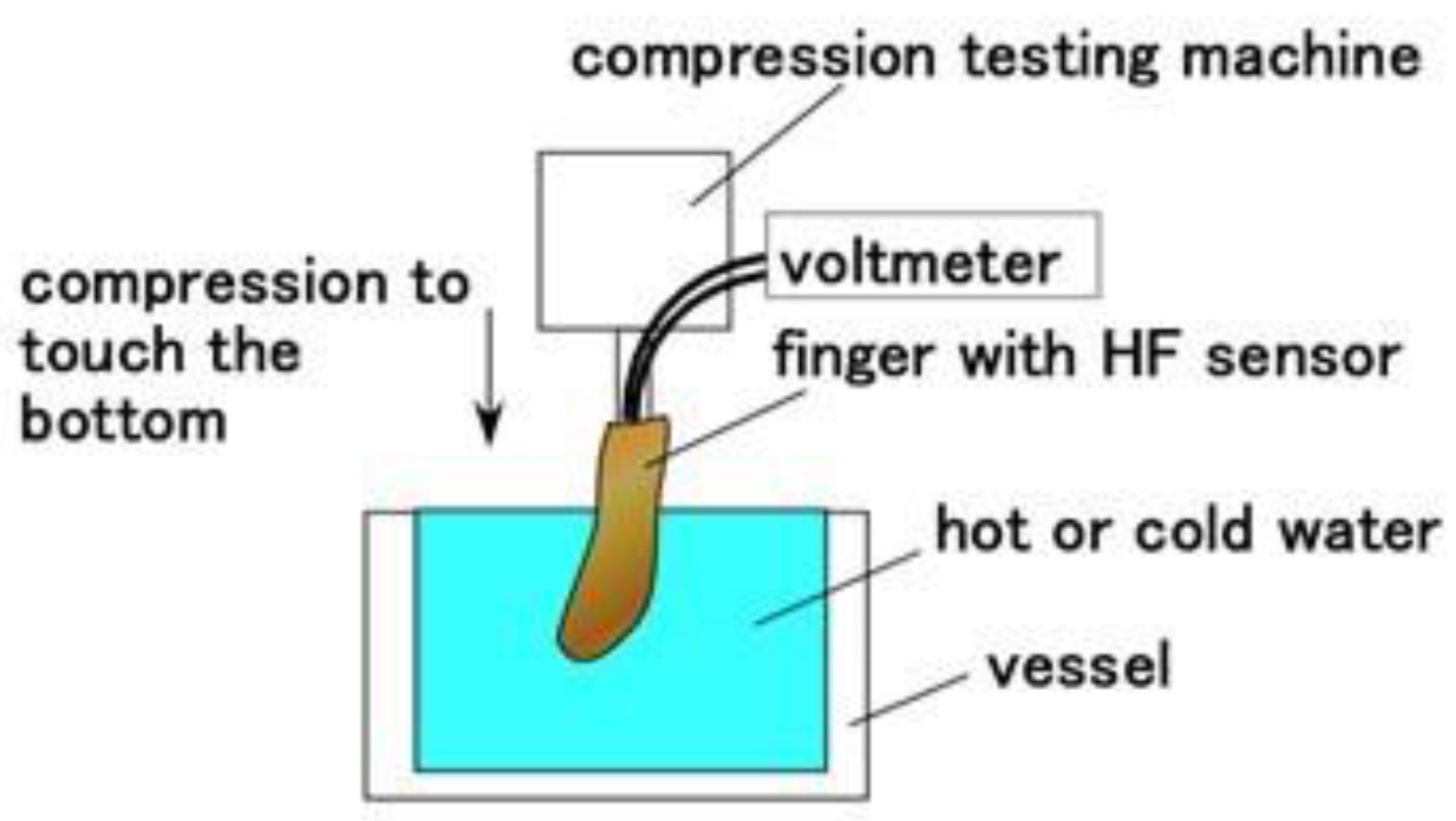

At first, as shown in

Figure 14, we investigated the response to the application of normal force and thermal body by using the same normal force experiment (NFE) apparatus [

34]. The finger was moved to touch hot or cold water, continuing to touch the bottom of the vessel. The up and down motion in the water was repeated five times by a compression testing machine (SL-6002; IMADA-SS Co., Ltd., Toyohasi, Japan) at a velocity of 300-mm/min. The voltage from the sensor was measured by a voltage meter (PC710, Sanwa Electric Instrument Co. Ltd., Tokyo, Japan). The finger can bend very softly, as shown in

Figure 15.

Figure 16 shows the results at each HF sensor cutaneous receptors (Types A–E). The instant that the finger touches the water is indicated in each case. Regarding thermal response,

Figure 16b–d show that the HF sensor is sharply responsive to the thermal input. In the case of the Type-B sensor, the thermal response is conspicuous. There is no thermal response in Types A and E. This sharp response in a human is so effective that the human can perceive the thermal input instantly upon touching with shouting. Therefore, the goal of the present simulation is the perception of a healthy human. The fabrication of the HF sensor, both in its materials and in its multi-layer structure, contributes to its ability to receive thermal input.

Regarding the response to force, the change in voltage in Type-B is larger than that of any of the other types. An instantaneous decrease in voltage appears occasionally during the application of compression. This is due to the behavior of the ions in the HF rubber: the voltage increases with decreasing distance between ions; however, the voltage becomes zero when the ions reach contact. The same tendency has been confirmed in MCF rubber [

35]. The change in voltage in Types C and D is small, however, and essentially remains constant. In contrast, Types A and E are very small and increase or decrease as a slow wave. We hypothesize that the fabrication of the HF sensor with many electric wires as in Type B, or with multi-layer structures as in Types B, C and D, contributes to the ability of the sensor to receive input about force.

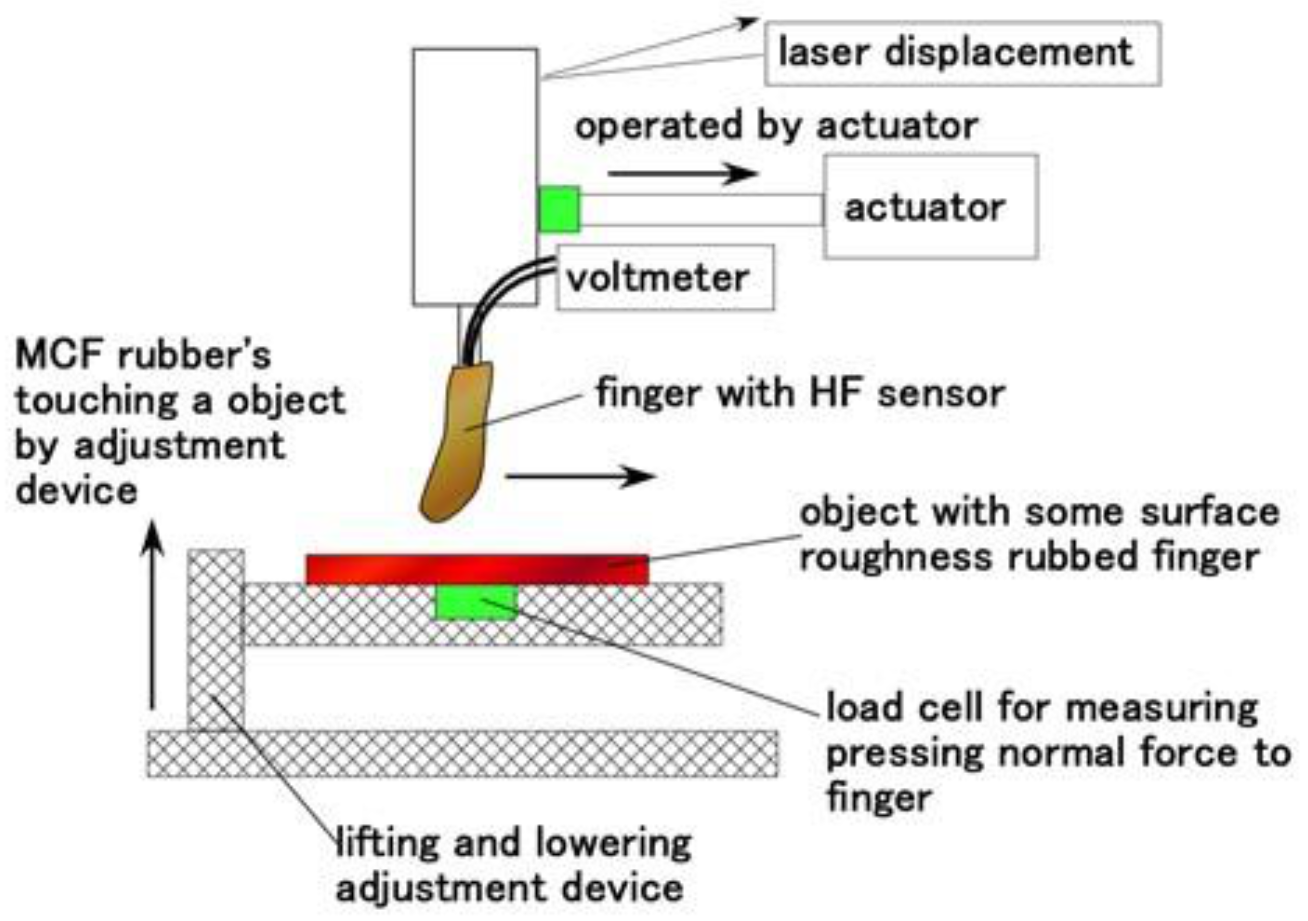

Next, as shown in

Figure 17, we investigated the response to the application of shear force by using the same shear force experiment (SFE) apparatus [

34]. The finger came into contact with a rubbed object and installed on an actuator with 50-mm/min sweeping speed, 50-mm sweeping distance and around 0.02-N normal force, was swept parallel to the object with some surface roughness by adjusting a constant height interval by adjustment device. The object is of two types: alternate surface roughness using a few sandpapers and a body concave and convex. The normal force on the finger was measured by a load cell, and the total distance by a laser displacement.

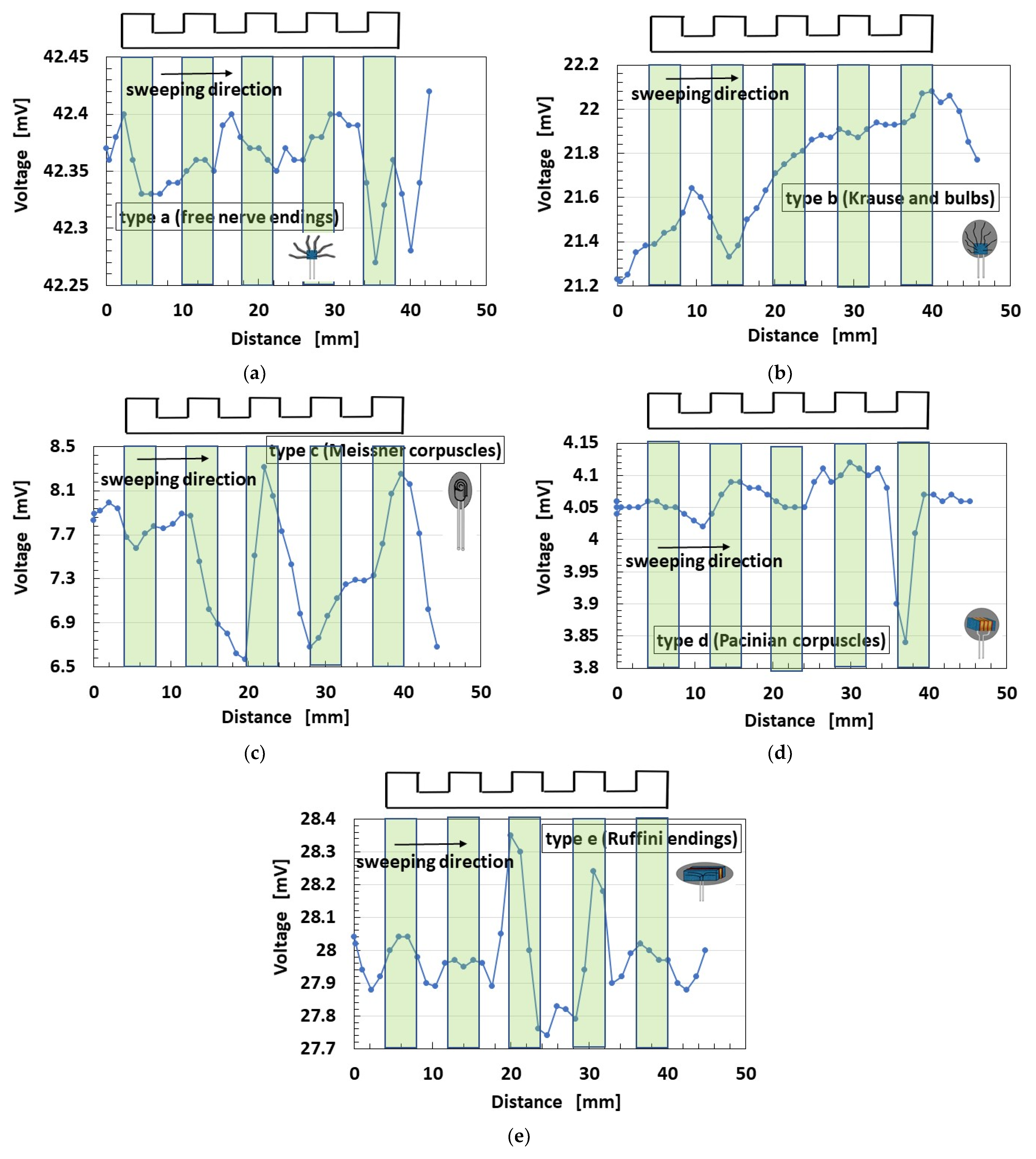

Figure 18 shows the spontaneous voltage by stroking alternate sandpapers with a surface roughness of #40 (the arithmetic average height

Ra = 41.11 μm, root mean square height

Rq = 48.91 μm, the difference of height between maximum and minimum

Ry = 170.3 μm), #60 (

Ra = 30.91 μm,

Rq = 36.38 μm,

Ry = 139.4 μm), #80 (

Ra = 24.11 μm,

Rq = 28.6 μm,

Ry = 103.9 μm) sandwiched by a sleek acrylic resin surface between them (

Ra = 0.03 μm,

Rq = 0.03 μm,

Ry = 0.2 μm). The surface roughness was measured by a surface roughness measuring device (SJ-400, Mitutoyo, Co. Ltd., Kawasaki, Japan). The white areas of

Figure 18 are the one of acrylic resin. The figure also indicates that the sweeping direction is from the left to right side, shown by arrow.

The changes in voltage in Types B and C are larger than any other types. However, Type E is the most responsive to the surface roughness of sandpapers, although the change in voltage is small. The cause is guessed that type E can be responsive to a shear motion because the lateral length of sensor is long.

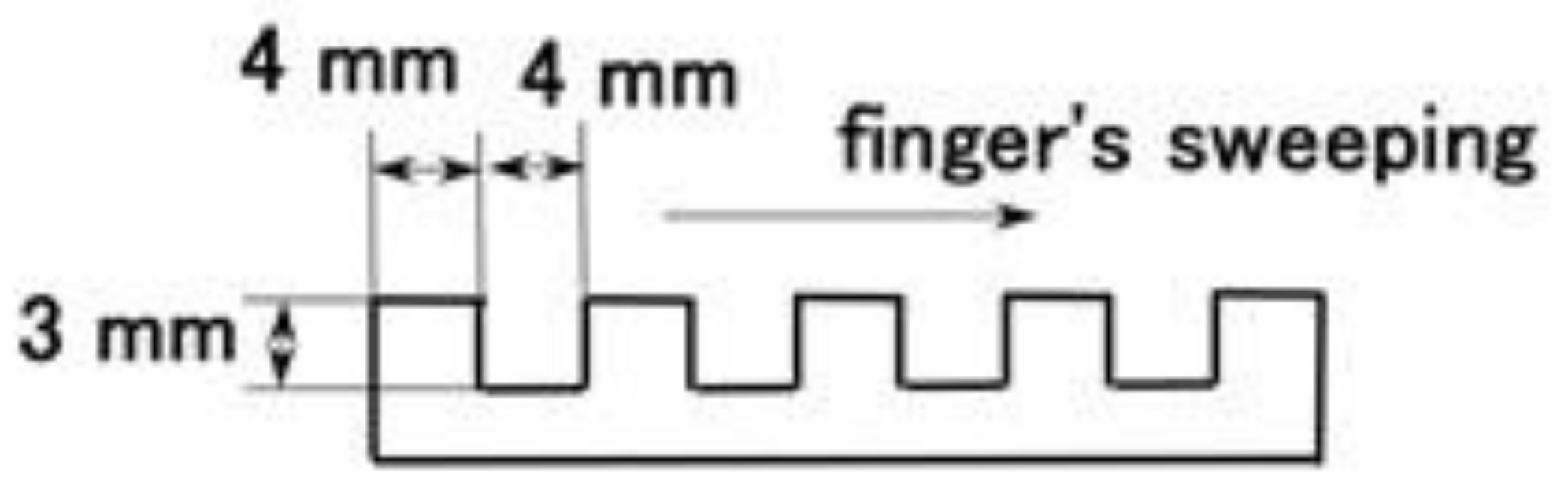

Figure 19 shows the spontaneous voltage by stroking a concave and convex body. The detail dimension is shown in

Figure 20. The figure indicates that the position of the concave and convex body corresponds to the change in voltage and that the sweeping direction is from left to right side shown by arrow.

As shown in

Figure 18, the changes in voltage in Types B and C are larger than any other type. However, Type E is the most responsive to the surface roughness of convex parts, although the change in voltage is small. This denotes that type E can be responsive to a shear motion because the lateral length of sensor is long.

The measured data of voltage have the accuracy of 0.001 mV by our used instrument. Therefore, the change in the voltage has significant difference. The measured data of voltage could be obtained quantitatively and qualitatively repeatedly. Based on the accuracy, our fabricated mimicked perceptual cells present three peculiarities: the change of the voltage by forcing or seeping the groove is large, as shown in

Figure 16b and

Figure 18a–c, except for thermo-sensibility; the change of the voltage by them is small and the voltage changes around a large value, as shown in

Figure 16a,e,

Figure 18e and

Figure 19a,b,e; the change of the voltage by them is small and the voltage changes around a large small value, as shown in

Figure 16c,d,

Figure 18d and

Figure 19c,d, except for thermo-sensibility. The cause of these three peculiarities is due to the structured style of the fabricate.

Our experimental results are not completely similar to previous results in the dermatology field on cutaneous receptors. The cause of this can be could be due to the fact that there is room for improvement on the fabrication and the location of cutaneous receptors contrary to our proposed fabrication and arrangement in the present study. In addition, the effect of the size of the fabricated cutaneous receptors could be due to their very small size, or the interactions of the complicated systems among cutaneous receptors under the operation of plural variegated cutaneous receptors, etc. However, in the present study, the purpose of the proposition of the fabrication of cutaneous receptors embedded in a body for robotics was achieved. The experimental data presented here is an example of the results obtained under various experimental conditions, such as response to vibration, electromagnetic waves, etc. Further results obtained under other experimental conditions will be addressed in other reports.

5. Conclusions

Our novel magnetic responsive fluid, HF, is so useful in the production of conductive soft rubber using electrolytic polymerization that it can be mixed with both diene and non-diene rubbers. HF consists of a combination of water, kerosene, KF96 and PVA. The viscosity and the magnetization of HF are equivalent to those of other magnetic responsive fluids, MF. For the production of the rubber sensor by the combination of HF and rubber, the piezoelectric characteristics of compounded rubber with HF indicate that the Ni compound is optimal. The cause is the convenience that using an external power supply and electric wires is dispensable for the operation of the robot installed a haptic sensor made of HF rubber.

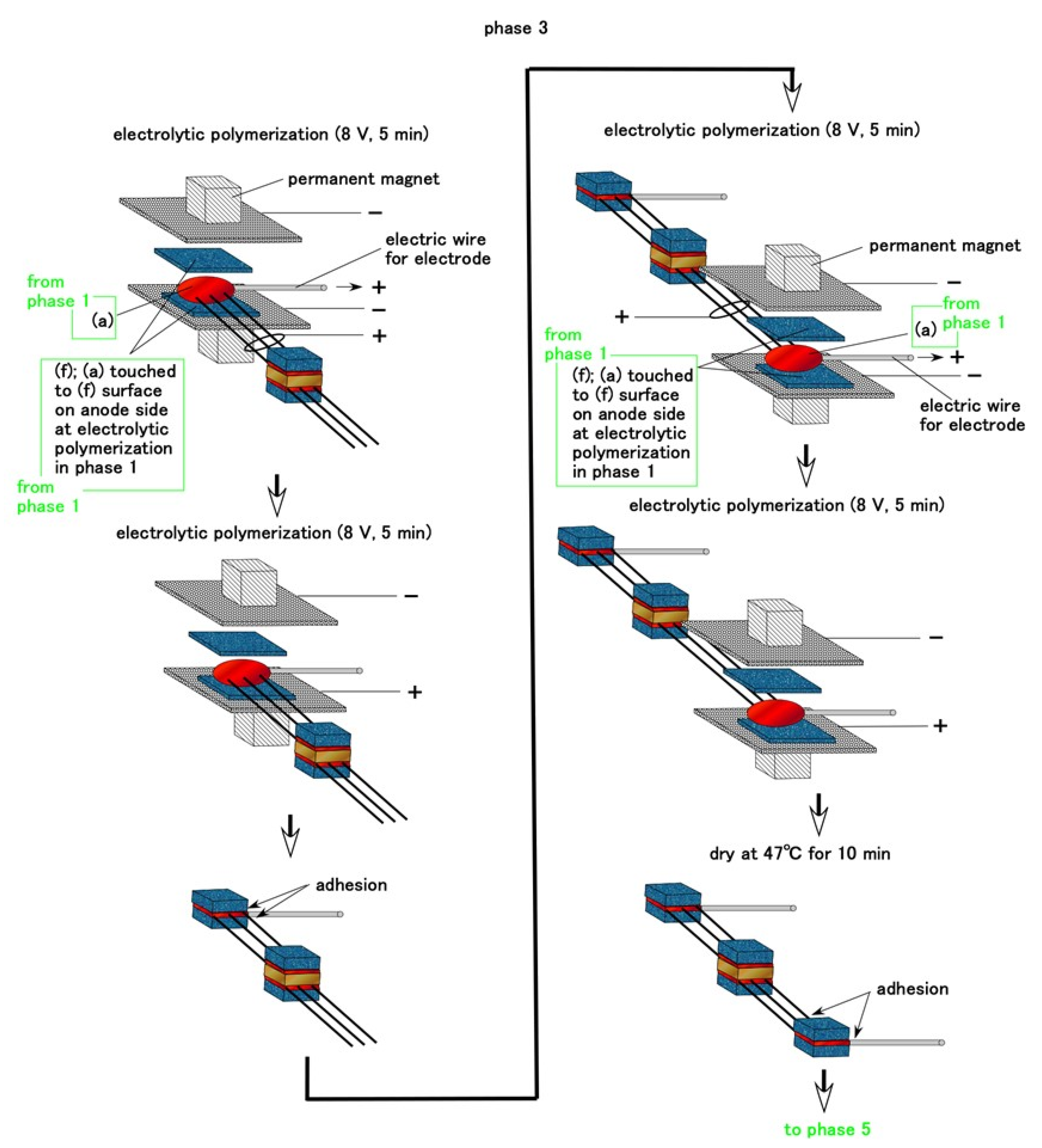

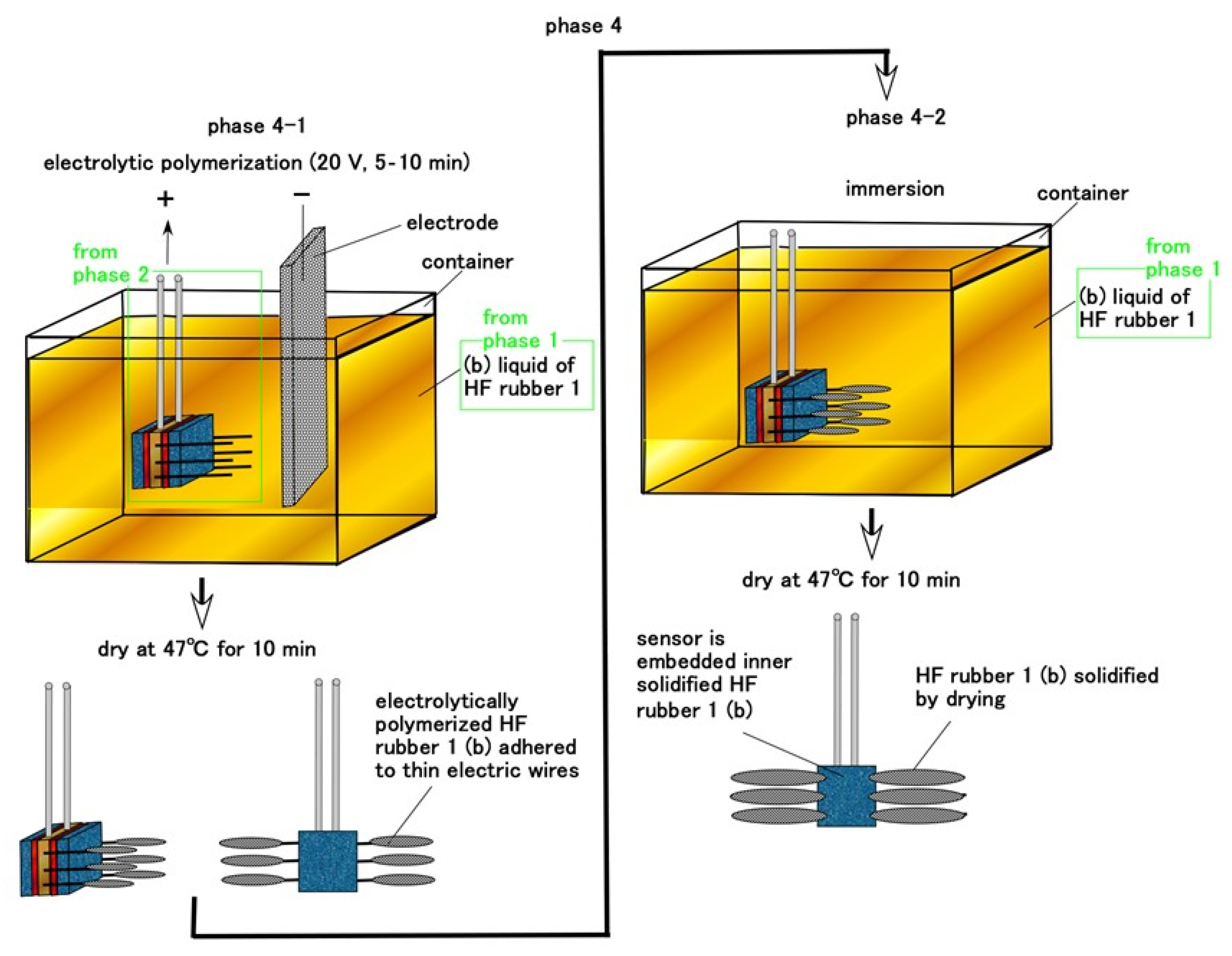

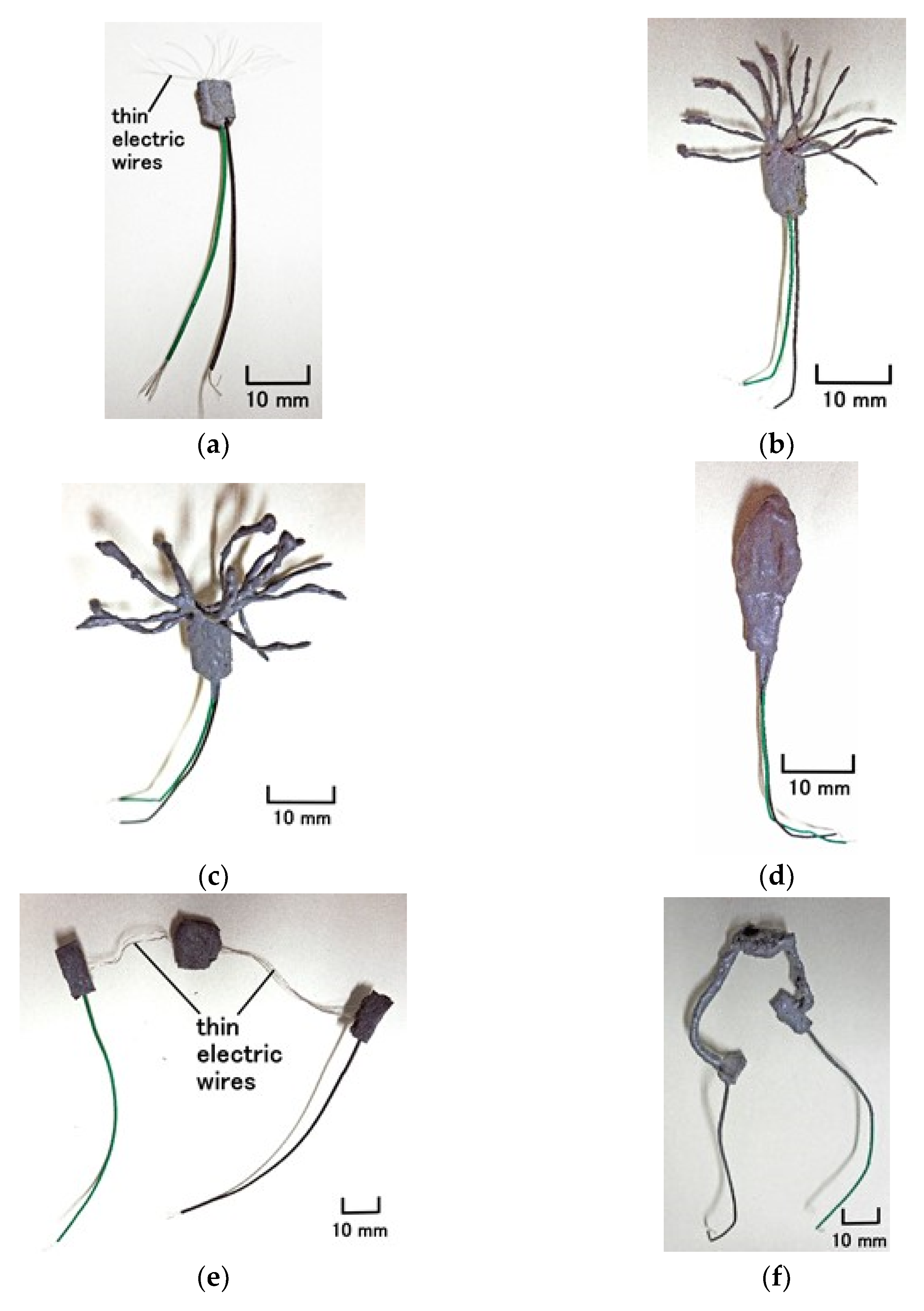

By utilizing our previously proposed novel techniques for rubber vulcanization and adhesion between rubber and metal by electrolytic polymerization, we addressed five cutaneous receptors: free nerve endings, Krause and bulbs, Meissner corpuscles, Pacinian corpuscles and Ruffini endings. In addition, we proposed a fabrication technique for a thumb with HF rubber sensors embedded in U-rubber. The technique of adhesion of electric wires onto the HF rubber sensor and the rubber was utilized and effective to avoid electric wires’ desorption from the sensor by large elongation or deformation of the body. In an experiment involving the finger touching cold or hot water to test sensing by mechanoreceptors or thermoreceptors in the mimicked human tissue, we found that the spontaneous voltage generated from the finger for mechanical and thermal sensing depends on its fabric. For thermal sensibility, the Type-B HF sensor mimicked Krause and bulbs, the Type-C HF sensor mimicked Meissner corpuscles, and the Type-D HF sensor mimicked Pacinian corpuscles type have the most thermal responsive in any other cutaneous receptors: 10-mV ordered large changing voltage for Type B, 1-mV ordered changing voltage for Type C, 0.1-mV ordered changing voltage for Type D. For pressing sensibility, the Type-B HF sensor mimicked Krause and bulbs is the most responsive to the pressure with 10-mV ordered large changing voltage. The other cutaneous receptors have responsive to the pressure with 0.1-mV ordered small changing voltage. For shearing sensibility, the Type-E HF sensor mimicked Ruffini endings is the most responsive to the surface roughness with 0.1-mV ordered small changing voltage in any other cutaneous receptors.

There are points that do not align with previous results known in the dermatology field on cutaneous receptors. This situation is not typical just for the present study. In general, many current varied mimicked materials in soft robotics do not yet reach the actual biological phenomena. Therefore, we must continue to investigate and elucidate the phenomena and simulate the actual biological phenomena. In addition, the response time of the voltage created from our fabricated sensor is also such a significant issue that it should be investigated. However, based on the results presented here, the fabrication of a finger involving simulated cutaneous receptors appears viable, though further experimental investigation is needed for more detail. The technique used in the present fabrication is suitable and helpful for the production of artificial cutaneous receptors embedded in artificial rubber skin mimicking human skin and installed in a humanoid or human-like robot in the future.