Abstract

There is a lack of awareness and knowledge among the Malaysian construction industry about waste management reduction. Numerous nations worldwide have understood and have incorporated the concept of the 3R (reduce, reuse, and recycle) in waste management, and it has worked out well. This study investigated construction waste issues and developed a model for sustainable reduction by applying 3R using a partial least squares structural equation modeling PLS-SEM in Malaysia. The research methodology adopted the quantitative and qualitative approaches by sending a survey questionnaire to the relevant stakeholders to obtain their views or perceptions and interviewing an expert in the related field about waste reduction in the Malaysian construction industry. Three hundred thirty questionnaires were collected within six months of submission. The significant factors are determined using mean ranking for the reduce, reuse and recycle elements. Based on the results, the exploratory power of the study model is considered sustainable with R2 values of 0.83%. At the same time, the results of relationships between improving factors, policy-related factors, construction waste generated, and sustainable construction waste reduction were significant. Also, the findings revealed that the top factors for waste generation on reducing, reusing, and recycling are lack of design and documentation, and lack of guidance for effective construction waste-collecting. The paper will explore different and dynamic practices, such as recycling, reuse of construction waste management cost reduction, enabling stakeholders and managers to estimate and quantify the actual size of CWM costs and benefits for sustainable development goals.

1. Introduction

The development of the economy in every nation depends on construction projects undertaken through several types of contract. The economy is mainly based on resources, which results in a significant amount of Waste that may violate the sustainable development goals set out in Paris in 2015 [1]. Over 23,000 tonnes of waste are created each day in Malaysia [2]. The problems that construction and demolition waste encounter can largely depend on the project lifecycle. Meadows and Randers [3] reported that construction sites has inappropriate raw material use, poor waste management practices, and a lack of awareness of the importance of waste minimization in the local area. It also contributes to excessive waste production and becomes an increasing problem for clients due to increased costs of this waste. Still, the issue of waste management continues to persist. More than 6 million tonnes of waste were generated from 2018, of which a quarter was produced in the Klang Valley alone [4]. It is estimated that 33% of construction waste directly resulted from the designer’s inability to use waste minimization measures during the design phase [5]. However, waste management costs are often relatively higher than the benefits that the organization would gain more attention being given to it [6]. There is a lack of awareness and knowledge among the Malaysian construction industry about waste management issues [7]. Waste reduction by 3R is one of the most efficient construction industry steps towards sustainable waste management [7]. When reuse and recycling practices are applied to the large amount of construction waste generated at the sites, such practices lead to achieving sustainable development goals and, often, new product development [8].

Construction materials and building operations account for roughly half of overall carbon dioxide (CO2) emissions [9]. According to a recent study, the construction industry exploited 30–40% of natural resources in developing countries [9]. As a result, successfully managing waste by incorporating environmental, social, and economic issues into long-term waste management strategies has become a significant challenge worldwide [10]. Furthermore, The rapid rate of urbanization is responsible not only for the increased use of non-renewable resources but also for the development of significant amounts of C&D waste, as well as the associated environmental concern [11]. More than 6 million tonnes of waste were created in Malaysia, with a quarter of that made in the country’s most prosperous region, the Klang Valley [4]. It is estimated that about 33% of construction waste results from designers’ failure to use waste management measures (WMM) throughout the design process [12]. Only 10% of construction waste is recycled. As a result, in Malaysia, disposing of construction waste remains a major challenge.

The 3R is considered a promising approach that would extend the life of landfills while reducing natural resource exploration. Recycling building wastes can help to recycle natural resources and minimize the cost of waste treatment before disposal, in addition to the environmental benefits of reducing the demand on land for waste disposal [13]. As a result, the general public, companies, developers, contractors, architects, and engineers must be enlightened on waste reduction and the value of recycling construction waste. To guide the construction industry in the right direction in a sustainable way, all relevant parties should ensure that waste is reduced by completing waste material reduction, reuse, and recycling. In other aspects, sustainability consists of a particular investment of advantages and costs of implementation planning, plus a cost-effective redistribution of capital available over time throughout waste management planning [14]. Esa [15] stated that implementing a construction and demolition waste management program begins with the planning and designing stage. The main purpose is to keep costs down in new construction projects, especially when they suffer from ineffective coordination, design errors, lack of activity planning, and bad procurement practices [16]. In due course, optimal planning of construction waste management policy demands deliberation over several issues, ranging from economic developments on emissions, health, and promotion of waste recycling to planning matters such as waste facilities and waste distribution networks to services. The previous study indicates inadequate methods and applications for minimizing construction waste during the construction and procurement phase [17,18]. Nevertheless, it is noticeable that there is a lack of focus on managing waste at the design phase based on an assessment carried out by [18]. The effectiveness of enhancement opportunities in construction can be tackled by embracing waste identification or reduction methods in the flow operations in parallel with value-adding techniques by developing new management tools and appropriate training programs [19].

The generation of waste from construction projects has had a significant impact on the environment, particularly when it comes to illegal dumping. The rising frequency of illegal dumping activities from Malaysian construction projects indicates that the country’s construction waste management has to be addressed. Nonetheless, there is no clear definition of a comprehensive criterion for construction waste management, particularly in developing nations. As a result, more research on Malaysia’s construction waste management is required [20]. The construction industry is highly unfriendly to the environment [21]. In terms of natural resource exploration, irreversible environmental transformation, and the accumulation of pollutants in the atmosphere, this industry contributes significantly to the environmental crisis [22]. During construction, waste is generated due to site clearing, material damage, material use, material non-use, excess procurement, and human errors. Moreover, statistics show that building and demolition projects account for 10–30% of overall trash [11]. Consequently, the primary objective was to develop a model for achieving sustainable construction waste reduction using PLS-SEM. By doing so, it could minimize the amount of waste generated during the construction processes.

2. Background of the Study

2.1. Overview of Construction and Demolition Waste Management in Malaysia and throughout the World

Based on the research goal, a categorization of C&DW management literature should be constructed to answer two key questions: the elements that affect C&DW management and the offered model for effective C&DW management to achieve sustainability. This study responds to C&DW definitions and generation questions, followed by a review of the research subjects of earlier studies in C&DW management, which paints a clear picture of previous C&DW management research techniques. Based on this study’s research gap, the research questions and objectives are stated in depth at this phase. During the last few decades, industry and scholars worldwide have been increasingly aware of C&DW problems. Despite various efforts over the previous few years, it is estimated that the construction industry is still in its infancy and requires maturation to contribute to reducing environmental burdens [23] effectively. Many countries throughout the world are grappling with how to efficiently and effectively mitigate C&DW generation. Since the 1980s, significant study has been devoted to C&DW minimization to reduce the negative impacts of C&DW on building structures [23].

Researchers must have a thorough understanding of previous C&DW management studies and the C&DW management frameworks produced by other researchers. For example, Kabirifar [24] created a framework to improve C&DW management in Portugal, considering the project life cycle and stakeholders. Lu and Yuan [25] presented another framework in which research boundaries for C&DW management were described; this framework covers the amount, origins, and impacts of C&DW management, as well as C&DW reduction, reuse, and recycle strategies, C&DW tools, humans’ role, performance, and regulatory environment.

Furthermore, Kabirifar [26] created a framework for C&DW environmental management practices in Europe. The author conducted a study to evaluate the effectiveness of C&DW management at three levels: national, regional, and project. At the national level, the effectiveness of techniques in the Malaysian construction industry, for example, was investigated [27]. Villoria Sáez [28] offered a framework for evaluating C&DW efficacy in another study. C&DW management has been studied from a hierarchical perspective, including C&DW reduction strategy; for example, the waste reduction strategy was deemed the most effective waste minimization strategy [25]. However, since some C&DW will be generated in the future, C&DW reuse and recycling should be implemented as feasible waste management methods to reduce waste to landfills. The term ”C&DW reuse” refers to the practice of reusing the same building material for several purposes, even in various functions. If the generated waste cannot be reused, the materials should be transformed into new materials through recycling [24]. In addition, several scholars have investigated other elements that affect C&DW management. Identifying building activities that can accommodate reused construction materials [29], having waste targets for all linked trades [30], and having recycling targets for each construction project are just a few examples [31]. Specific places for cutting and storage of material [32], reuse material scraps [33], waste sorting, reusing, and recycling [34], and making sub-contractors responsible for waste disposal [35]. Although the variables listed above for C&DW management have addressed key essential themes related to C&DW management from both a hierarchical and influencing perspective, previous research has uncovered and categorized these elements in a structured manner. Then, to manage C&DW successfully, practical C&DW contributing elements should be found and classified, and these aspects should be linked with contributing factors to the C&DW management hierarchy.

2.2. Waste Reduction Hierarchy on 3R (Reduce, Reuse and Recycle)

The 3Rs principle of reducing, reusing, and recycling in a hierarchical order, classifying WM strategies as desirable. The 3Rs are intended to be a hierarchy, arranged from low to high in ascending order of their adverse environmental impacts [36]. This section discusses reducing, recycling, and reusing based on their hierarchical order and can be considered.

The summary of 3R factors used from previous research in construction waste management is shown in Table 1. We sought an idea from a professional with at least 20 years of working experience in construction management and who has participated in many construction projects in which he experienced construction first-hand information.

Table 1.

Causes of 3R (reduce, reuse and recycle) application in building construction projects.

3. Methodology

A conceptual model is the first step in developing a research strategy. In addition, the conceptual model can be a supportive method by identifying a relevant literature review used to form intermediate theories (hypotheses) that can be checked through the empirical evidence [73]. The conceptual modeling method is divided into three stages: (1) identifying the model’s constructs, (2) identifying these constructs, and (3) describing the relationships between these constructs [74,75,76].

This study carried on an in-depth evaluation of reports based on Scopus, Science Direct, Sage, Wiley Library, Emerald-based journal articles, and conference proceedings published on the subject matter to identify the model’s constructs [77,78]. Previous research has only used measurement tools that can only measure a 3R error [79,80]. However, in this study, there is a greater awareness of the need to improve construction waste management 3R, and Malaysia’s current CWM treatment condition is dire. Therefore, a survey was used to discover a new set of sustainable construction waste reduction factors, specifically in Malaysia [81]. The first part of the questionnaire gives a brief introduction to the survey—part two of the survey used a questionnaire to gather demographic information. The third part of the assessment included a semi-structured interview with an expert to obtain his opinion about the research’s identified factors. The questionnaire utilized in this study was developed through focus groups with residential construction professionals, consultants, and other construction experts. Sampling is a process or technique for drawing a characteristic group of individuals or cases from a specific population [82]. For this study, a stratified random sampling technique and simple random sampling technique have been adopted. The sample size for this study has been determined based on Krejcie [83] table. The table indicates that for the population size of 950, the sample size should be 274 as the minimum. Following that, a validation process was carried out on four residential projects in Kuala Lumpur and the Perak Table 2 was used to establish the 3R of waste generated on-site, which was over 60% for high-rise construction and less than 25% for housing project sites. Table 2 depicts a high-level summary of the project under investigation.

Table 2.

Overview of the project investigated.

3.1. Pilot Study

To ensure the validity of the data, we conducted a pilot study and evaluated the reliability of the data before distributing the questionnaire survey. Respondents’ clarity and relevance were reviewed by an industry-experienced professor and some academics lectures of Malaysia’s public and private university’s construction industry. Following the recommendation of [84,85], a minimum Cronbach’s alpha achieved acceptable values of 0.882 and 0.815, respectively. The value of the variables under the construction waste generation factors was 0.889. The Cronbach Alpha values obtained indicate an excellent internal consistency for the scale. A study sample should be between 150 and 300 for the study’s EFA research [86,87].

Nonetheless [88], as previously reported, the researchers disagree about the size of a factor analysis sample, but the assumption is that a larger sample should be used. When it comes to the number of variables [89,90,91], statistical theory holds that working with 20–50 variables is more effective than individual factors because various factors fail to return the correct results variables exceeds that range. According to a study, reducing the number of variables is possible if the sample size is large enough [92]. For this study, the sample size was 330, which was considered a valid representation of the population as a whole within appropriate ranges [92,93,94].

3.2. Main Survey Design

The questionnaire survey was developed to collect data about Malaysia’s sustainable construction waste reduction. First, a conceptual model is used to lay the groundwork for a research strategy. Then, a conceptual framework is used to investigate the topic literature to produce intermediate theories (hypotheses) that can be subjected to scientific investigation [95,96]. A questionnaire was created to gather cross-sections of all existing literature to undergo a comprehensive review. For the questionnaire, three main categories were chosen: contractors, consultants, and clients. Architects, electrical engineers, quantity surveyors, structural and mechanical engineers fall under these categories. The majority (32.0%) and 26.2% of survey respondents, respectively, have between 10 and 15 years and 15–20 years of industry experience. Just 7.5% of respondents have less than five years of experience [97].

However, this segment gives the results of the characteristics of respondents of this study. These findings show that the respondents possessed the required expertise and information to comment on the 3Rs (reduce, reuse, and recycle) for sustainable construction waste reduction, which led to them obtaining a significant amount of trust in their input and the validity of the findings. In addition, the results indicate that site engineers accounted for the majority (43.5%) of the participants’ employment, followed by construction engineers (24.3%). For Bachelors (BSc), Masters (MS), and PhD degrees, the respondents’ academic qualifications were 81%, 53%, and 35% [97], respectively. As shown in Table 3.

Table 3.

Survey responds.

3.3. Assessing Goodness-of-Fit (GoF)

The goodness of fit provides a global criterion for assessing the overall quality of the (PLS-SEM) model. However, unlike the covariance-based structural equation modeling (SEM), there is no generally accepted goodness of fit measure to evaluate PLS models. However, ref. [98] proposed a global criterion of the goodness of fit called the “GoF” index.

It can be determined using the formula below:

Choshin and Ghaffari [99] succumbed to a law of thumb for examining GoF. It is considered small, medium, and large if the values are 0.1, 0.25, and 0.36. Accordingly, the GoF of the structural research model is calculated as shown.

Based on Behl [100] the model GoF of 0.39 is considered significant. Therefore, the research model fitted very well. The structural model is, consequently, good.

4. Results and Discussion

The survey data were analyzed using a combination of SPSS, Microsoft Excel, and partial structural equation modeling (PLS-SEM) software to determine the causal relationship between the exogenous (independent) constructs and the endogenous (dependent) construct. This study included measurement of individual item reliability, and these models have Cronbach’s alpha, convergence, discriminant validity, path coefficients, coefficient of determination (R2), effect size (f2), system predictive relevance (Q2), and goodness-of-fit (GoF), PLS-SEM moderation results, and correlation. Out of 481 questionnaires, 330 were returned, resulting in an overall response rate of 69% of the sample size within 6 months of submission. This is deemed to be satisfactory for questionnaires compared to other related surveys in engineering and construction management. The findings of the Cronbach alpha for the main constructs are presented as follows. The field data indicated that (construction waste generation factors), (improving factors) achieved acceptable values of 0.882 and 0.815, respectively; the variables under the (sustainable construction waste generation) have a value of 0.889. The Cronbach’s alpha values indicate an excellent internal consistency for the scale with the sample values above 0.7 considered acceptable [101]. In this study, hypotheses would contribute immensely to the established knowledge of the study’s subject matter for kinds of material and what amount are waste, and how much is produced and classified as waste are explained in the following section.

4.1. The Amount Types of Construction Waste Generated

Many scholars lament the difficulties in obtaining reliable data on the amounts of construction waste generated, owing to the difficulty in determining the waste’s precise quantity and composition. However, studies disclose some statistics and facts, such as that many contractors have waste percentage guidelines that they use when estimating bills of quantities. These proportions mainly depend on their labor force experience [102]. However, the contractor will likely engage with several subcontractors on various projects, and the subcontractors’ labor will be motivated to complete the work as quickly as possible. As a result, waste levels will most likely differ from those anticipated [103]. Saunders and Wynn in the United Kingdom found that a waste level of roughly 10% is acceptable [104]. However, according to Harper, the typical waste allowance is 5% of the net measurements [105]. As a result, after a careful examination of different estimation approaches, estimates for construction waste for a Malaysian residential project have been completed.

4.1.1. Built-Up Projects Assessment

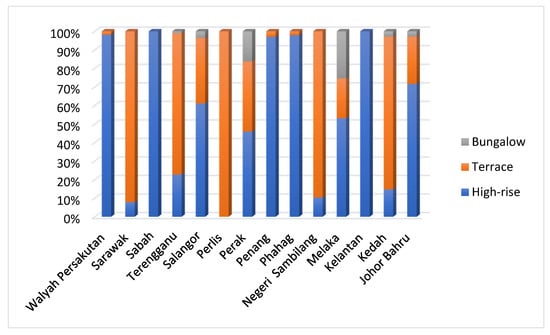

This study is the first step in estimating the waste generated by residential construction projects in Malaysia. According to the overall findings, the built-up area of the entire project (179 projects) under evaluation was around 7,895,147.461m2 throughout all states and across the three project categories based on the findings: high-rise, terrace, and bungalow. The high-rise project accounts for 41% of the total project, while the terrace and bungalow projects account for 51% and 8%, respectively. Furthermore, it reveals that most of these projects were located in Selangor (25%) and Johor Bahru (15%), respectively, and were located across the 12 states. Figure 1 depicts the summary of all the project locations and build-up areas under investigation.

Figure 1.

Build-up area (m2).

4.1.2. Estimated Waste for a Residential Project

The waste indicator approach was introduced to estimate the construction waste generated, defined as the quantity of construction waste generated in a unit of volume or weight per m2 of gross floor area or area of activity [106]. Moreover, the estimated waste generated rate from Malaysian residential projects was determined by calculating the total gross floor area of the project’s WGR of Singapore (30.2 kg/m2 [64,65] and Thailand (21.38 kg/m2) for residential construction.

Moreover, the approximate waste generated rate from Malaysia residential project was determined by calculating the total GFA of the project (7,895,147.461 m2) as adopted by numerous researchers [107,108,109]. This can be calculated as Equation (3).

EWG = GFA × WGR

EWG is the total expected waste generated by the project (m2), GFA denotes the gross floor area per m2 (based on CIDB data), and WGR indicates the waste rate generated per m2.

EWG = 25.79 kg/m2 × 7,895,147.461 m2 = 203,616 tons

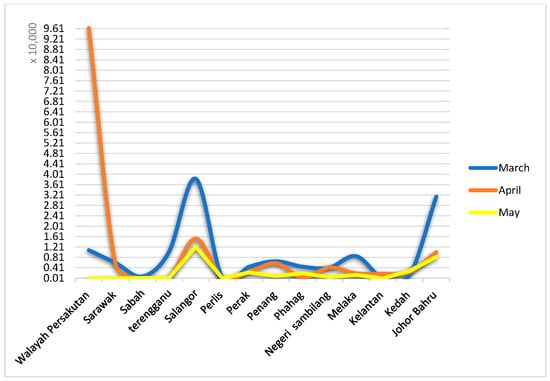

Consequently, based on the findings throughout the research period, from March to May 2018, the total estimated wastes accumulated by Malaysian residential buildings were 203,615 tonnes, as illustrated in Figure 2.

Figure 2.

Waste generated in tonnes.

4.1.3. Mean Ranking for Waste Minimization Strategies

Following this finding, the respondent ranked 10 waste minimization strategies, with the reuse, reduction, and recycling of waste material on-site receiving the highest mean of 0.908, consistent with numerous writers [110]. Suppose improved material handling management is adopted on construction sites. In that case, the amount of waste that needs to be disposed of should be considerably decreased [111]. As a result, the respondent agrees that proper storage and material handling at a building site with a mean score of 0.874 will significantly reduce waste. A mean of 0.857 was followed by a list of recovered, reused, reduced, and recycled waste products. Poon, et al. [53], discovered that many materials are lost on construction sites due to poor material control. Due to improper storage and handling, this material wastage is not isolated on building sites since many resources can be spared. The respondent ranked the following factors as the least important: issuing waste segregation guidelines (mean = 0.829); and minimizing design changes (mean = 0.752), which is not surprising given that this factor was identified by Faniran and Cabanas as one of the major sources of waste generation [112]. Mean = 0.749 for analyzing site waste to be generated, 0.728 for minimizing waste at the source of origin, and 0.723 for organizing waste management meetings and training construction personnel; and designating waste disposal ranks last in the waste minimization strategies, with a mean score of 0.689, as shown in Table 4.

Table 4.

Ranking for waste minimization strategies.

According to the findings of this study, approximately 4–6% of the concrete used will be lost to waste. Dry concrete was separated from other waste in some projects and repurposed to provide aggregate for road sub-bases. Wooden boards are used for falsework and formwork for concrete constructions and the erection of site boundaries and bamboo scaffolding. Some wooden boards were reused on the work site multiple times until the boards’ quality degenerated, so they could no longer be used. Wood boards should be reused at least five times, resulting in a waste rate of about 20% [113].

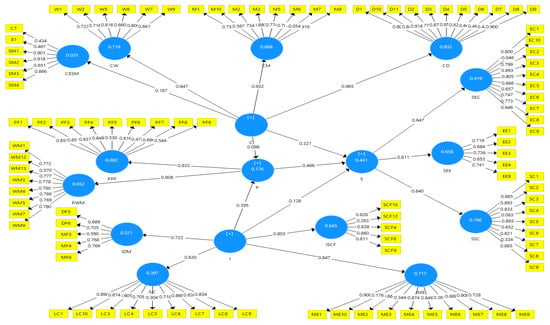

4.2. Structure Equation Modeling PLS-SEM

The two-stage evaluation criteria in PLS-SEM modeling include assessing the structural model after evaluation of the measurement model. The measuring model must meet all the quality evaluation requirements before running the structural model [114]. Accordingly, the structural model is run after confirming the reliability and validity of the measurement models. The structural model established the causal relationships between the measurement models in the structural model [70]. The interrelationships identified are meant to address the research questions and test the research hypotheses. Results showed that all outer loads were related to the information phase of 3R (reduce, reuse, and recycle) for sustainable construction waste reduction from the initial measurement model because the loading factor was less than 0.5. The majority of these loads did not influence the related construct. All the models were examined using the model report with cr = 0.70 and, as a result, were proven to be accurate and valid [115,116].

4.2.1. Measurement Model

The factor loadings, cross-loadings, Alpha, Rho_A C.R value in structural equation model (PLS-SEM), and the average variance extracted (AVE) were used to discover any problem with an item and evaluate a framework for achieving sustainable construction waste reduction the application of 3R. All items loaded effectively on their related constructs in the analysis were above 0.5 as the recommended threshold measures [117]. As displayed in Table 4, Table 5 and Table 6, all the items packed on factor loadings, cross-loadings, Alpha, Rho_A C.R, and AVE are in a lower range of 0.5278 upper range 0.9244. According to Bhandari and Naudeer [118], the AVE must be at least 0.5 for convergence constructs. However, both AVE interpretations are 0.5, with is the lowest acceptable value. This gave a relatively satisfactory result with adequate item loadings, composite reliability, higher-order constructs (HOC), as well as lower-order constructs (LOCs) such as Alpha Rho A, C.R, and AVE. As far as the individual items go, there are sufficient grounds to prove the indicators. The entire modified final model AVEs are above the recommended minimum of 0.5. The table shows that the minimum factor loading is above 0.6 and is significant (t-stat > 1.96; p-value < 0.005). The factors for improving waste management for sustainable development with applying 3R practical are 0.579, 0.761, 0.508, 0.736, 0.627, 0.564, 0.522, 0.717, 0.503, 0.591, 0.320, 0.551 and 0.563, respectively. Table 5 illustrates the final model for significant variables for sustainable construction waste reduction. The study used PLS-SEM, including various new methodological innovations to the current body. Previous literature mainly centered on the conceptualization and assessment of CWM in general.

Table 5.

Measurement model.

Table 6.

Discriminant validity using Fornell.

Assessment of Discriminant Validity

Discriminant validity is the degree of measurement of the model compared with other model constructs of the study. Voorhees, et al. [77,78] introduced criteria for evaluating validity. The idea that the variance items share with their measurement model is more significant than they associate in the research with other measurement models. Therefore, the AVE square root, which is the average correlation between the measurement models’ indicator variables, should be greater than the correlation between the construct and any other structural model constructs. Since the square root of the correlation coefficient of each outer model is significantly higher than the square root of the AVE of each outer model [119,120]. Table 6 shows discriminant validity using heterotrait-monotrait (HTMT).

The HTMT ratio, Fornell used to assess the measurement models’ discriminant validity as presented in Table 6, respectively. The assessment of discriminant validity using the HTMT ratio shown in the result indicates that the highest HTMT rate among the measurement models is 0.965 between C and CD. The highest value is below the recommended maximum conservative value of 0.85 [79]. This outcome shows that discriminant validity was achieved using the HTMT ratio criterion.

4.2.2. Assessment of Structural Model (Path Analysis)

The second-order constructs for their lower-order constructs are often recognized as the relative importance of construction waste generation. The factor with high path coefficients displays the relative strength of each element on the specific construct base on the developed model for achieving sustainability. Table 7 below demonstrates the necessary items on second-order constructs for their lower-order constructs for the relative strength for their particular construct.

Table 7.

Second-order constructs for their lower order constructs.

This study is the first stage of estimating the second-order constructs on their lower-order constructs for relative strength for their particular construct by anticipated waste generated base on 3R in Malaysia. The estimated wastes generated from Malaysian projects under the constructs of C -> CD with high path coefficients of 0.965 and T statistics of 219.955 have p-values of 0.000, which is very significant as shown in Table 7. Thus, the result revealed that I -> ISCF is the second factor leading to tremendous growth. They improve for waste generation with path coefficients of 0.803, 30.982 as t statistics and p- values of 0.000, as illustrated in Table 7.

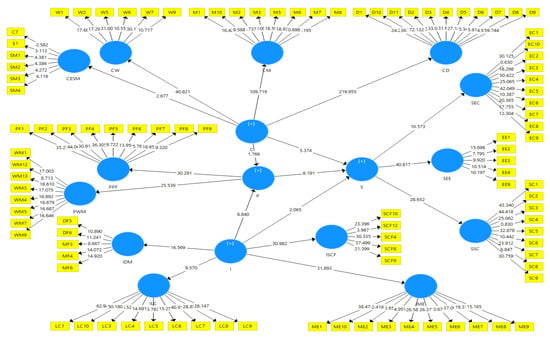

The PLS-SEM research model on achieving sustainable construction waste reduction was used to investigate the impact of 3R (reduce, reuse, and recycle). The model is presented in (Figure 3 and Figure 4). After reviewing the Bootstrapping approach, it was discovered that the hypothesis was of significance to the model. Bootstrapping is a random re-sampling of the original dataset used, in addition to the re-sampling process to generate new samples of the same size as the original dataset. The first approach tests the data set to determine correct path coefficients’ statistical significance. It serves to determine whether the calculated path coefficients are accurate [121,122]. As seen in Figure 3, the pathway significance, pathway coefficients (β), and p-values (the P-value for the standardized pathway coefficient), as well as R2 for each endogenous construct, were all tested. The result of the bootstrapping method showcases the p-values for every possible path. According to these results, the effect of 3R for sustainable construction waste reduction was positive and significant (β = 0.743, p < 0.001).

Figure 3.

Study model.

Figure 4.

Model t-statistics and bootstrapping.

Impact of CDW Generation, Improving Factors, and Policy-Related Factors on Sustainable Construction Waste

A group of constructs agreed by respondents achieves the objectives/hypothesis of this study in a model using Smart-PLS 20 software [123]. The constructs presented in Table 8 identify the significant relationship of each group in improving design-out waste for sustainable development goals. Present causes for waste generation and policy-related factors significantly affect sustainable construction waste, as illustrated in Table 8.

Table 8.

Effects of C, I, and P on S.

Assessment of R2 (Coefficient of Determination)

The determination coefficient (R2) measures how the exogenous constructs describe or predict the endogenous construct. It measures the inner model predictive accuracy by stating the model percentage of construct variance [124]. Although there is no generally acceptable level of R2 value, an R2 value of 0.2 is considered high in the construction waste management area. The R2 of the endogenous construct of the study is shown in Table 9. The R2 level of the endogenous constructs.

Table 9.

R2 assessment.

The results show that sustainable construction waste reduction R2 value is 0.841 and adjusted R square 0.835, respectively, with the main endogenous construct, CD having the highest value. Thus, based on the evaluation criteria, the R2 values in this study are within the acceptable moderate levels. However, the study is exploratory; its R2 values can be considered high [125].

Predictive Relevance (Q2) of the Structural Model

Q2 assessed using the predictive relevance of Stone-Geisser (Q2), which tested that all indicators’ data points are predicted accurately in the outer model of endogenous constructs [126]. This quality evaluation criterion required the cross-validated redundancy (Q2) value to be a positive integer above 0 to have sufficient predictive relevance [127]. According to the above submission, the study’s final model was evaluated to determine the cross-validated redundancy (Q2) using the blindfolding procedure with the aid of Smart-PLS 3 software [128]. This indicates the cross-validated redundancy of the models of the current waste practices and the factors for improving waste management. All the endogenous constructs have Q2 values greater than 0. The Q2 indicated that all the research models have good predictive relevance [129]. Therefore, the model is good.

4.3. Discussion

A comparative study was very useful because each instance served as a guideline or structure for understanding the others. The waste-generated rates from the three projects under evaluation are explained. The construction waste generated from various building materials is shown in Figure 1 and Figure 2. Furthermore, with an overall mean of 0.908, the data analysis suggests that the participants have a high level of agreement. The results indicate that a greater percentage of respondents believed that their criteria were a significant sign for efficient waste reduction, reuse, and recycling. The 5% trimmed-mean is tested once more to see if the data set’s extreme values have changed the mean [130].

In this study, the mean (6.6714) and the 5% trimmed mean (7.9603) are quite close, showing that extreme values did not affect the data’s analysis. Because of the requirement to complete construction work in Malaysia, the construction industry produces much waste. As a result, mitigating the environmental impact is a major concern in a construction project’s implementation. It is also an essential aspect of the commitment to addressing global sustainability issues. Construction waste like demolition waste, which is mostly combined, can cause sorting, transforming, and disposal obstacles.

Furthermore, since these activities require many personnel, sorting and crushing might demand a high price in the recycling strategy. The predicted weight of waste generated per day for construction on the site was modified according to the data collection and analysis. For example, less than 1 tonne produces 43%, 1–5 tonnes produce 55%, and more than 5 tonnes produce only 3%. This signifies that a lot of waste is produced without regard for the project’s environmental impact. In contrast to the high-rise building, which generated a lot of construction waste but had a very high rate of reducing, reusable, and recyclability, the mass housing (semi-detached and bungalow) had a level of reduction, reuse, and recycling of about 16% to 32% from projects three and four, respectively. It was found that concrete and aggregate generated the most waste in projects one and two, accounting for approximately 71% and 72% of total waste generated, respectively. This was because the two projects created less wood waste, as illustrated in Figure 1. However, the most significant proportion of waste came from wood in projects 2 and 3, accounting for around 87% and 82%, respectively. Moreover, all the three constructs that have a significant impact on sustainable construction waste are discussed in the following sections: identify the impact of construction waste generation on sustainability; identify the impact of improving factors on sustainable construction waste management; and identify the impact of policy-related factors on sustainability.

5. Conclusions and Implications

Based on the results and discussion above, this study investigated the modeling of 3R (reduce, reuse and recycle) for sustainable construction waste reduction. A questionnaire was used to analyze the perspective and comprehension of Malaysian construction industry experts regarding construction waste management. The majority of respondents believed that 20% of the construction trash generated at their site might be repurposed in their project while the minority of respondents reported that more than 50% of the waste produced on-site could be repurposed. Furthermore, the results revealed that the amount of waste generated at a construction site in Malaysia is an estimated average of 5 tonnes per day. The construction waste generated from high-rise building construction was calculated to be 4.4 tons/day. However, it was estimated to be 2.47 tons/day for housing projects, which was in line with the predicted amount.

On the other hand, the results of SEM-PLS indicated that the exploratory power of the study model is considered sustainable with R2 values 0.83%. At the same time, the results of relationships between improving factors, policy-related factors, construction waste generated, and sustainable construction waste reduction were significant. Therefore, the results of this study demonstrated that all hypotheses were supported.

Regarding its theoretical contribution, this study will extend the body of knowledge regarding construction waste management strategies. This paper contributes to the literature to be a foundation for future researchers interested in construction waste management strategies. The results may also be helpful to many construction companies, particularly those in developing countries where there is a lot of construction waste with low awareness. Practically, the results will be beneficial to many construction companies, particularly those in developing countries where construction waste awareness is low. Furthermore, they can assist small and medium construction companies to use technologies for practical and efficient training toward sustainable development goals. Finally, this study has established a basis for improved specifications that could be critical for evaluating and removing waste. Construction waste prevention is significant, leading to the avoidance of design errors contributing to waste generation. The construction waste is identified chiefly through processes that involve conventional construction.

A study limitation is insufficient data on the amount of C&D waste reuse and recycling in Malaysia. However, the results revealed numerous concerns and problems contributing to the low percentage of reuse and recycling waste. Contamination, waste quality, collecting and transportation challenges, and difficulty sorting, converting, and disposing waste are the most pressing concerns. The model predicts waste generation, the 3R-produced waste, CO2, and waste assessment model for residential buildings. These elements of the CDW management model may guide how to handle construction waste more sustainably. Future researchers need to address the international standards in the construction industry, waste management, and construction demolition waste.

Author Contributions

Conceptualization and Investigation, M.M.; writing—original draft preparation M.M.; supervision and quality control, project leader, N.S. and N.A.Z.; Data collection, M.M. and N.S. Analysis of the literature, M.M.; N.S. and N.A.Z. software and data analysis, M.M.; A.-B.A.A.-M., visualization, M.M.; N.S. and N.A.Z. writing—review and editing, N.S., A.E., E.F.R., N.A.Z., A.H., A.D.R., M.B.I. and A.-B.A.A.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data supporting and used in this study findings are available from the corresponding author upon reasonable request.

Acknowledgments

The authors would like to express their gratitude to the postgraduate studies UTP for providing financial support for the Graduate Assistantship Scheme. The use of research facilities provided by Universiti Teknologi PETRONAS UTP Malaysia is acknowledged.

Conflicts of Interest

The authors declare that they have no established conflicting financial interests or personal relationships that may seem to have influenced the research presented in this paper.

Abbreviations

| average variance extracted | AVE |

| coefficient | Rho_A C.R |

| Improving factors | I |

| effect size | (f2) |

| Policy related factors (P) | P |

| carbon dioxide | (CO2) |

| construction and demolition | C&D |

| waste management measures | (WMM) |

| construction and demolition waste | C&DW |

| waste management | WM |

| Construction waste management | CWM |

| Specifications for building works | (SBW) |

| Construction industry development board | (CIDB). |

| Exploratory Factor Analysis | (EFA) |

| Bachelors (BSc), Masters (MS), and Doctorate Degree (PhD) | (BSc), (MS) and (PhD) |

| coefficient of determination | (R2) |

| system predictive relevance | (Q2) |

| goodness-of-fit | (GoF) |

| lower-order constructs | (LOCs) |

| Heterotrait-Monotrait ratio | (HTMT) |

| Construction waste generated | (C) |

| Sustainable construction waste Reduction | (S) |

| A partial least squares structural equation modelling | (PLS-SEM) |

| Reduce, reuse and recycle | 3R |

References

- Hickel, J. The contradiction of the sustainable development goals: Growth versus ecology on a finite planet. Sustain. Dev. 2019, 27, 873–884. [Google Scholar] [CrossRef]

- Johari, A.; Alkali, H.; Hashim, H.; Ahmed, S.I.; Mat, R. Municipal solid waste management and potential revenue from recycling in Malaysia. Mod. Appl. Sci. 2014, 8, 37. [Google Scholar] [CrossRef]

- Meadows, D.; Randers, J. The Limits to Growth: The 30-Year Update; Routledge: Milton Park, Miltonm, UK, 2012. [Google Scholar]

- Cheam, W.-Y.; Lau, L.-S.; Wei, C.-Y. Factors influencing the residence’s intention to adopt solar photovoltaic technology: A case study from Klang Valley, Malaysia. Clean Energy 2021, 5, 464–473. [Google Scholar] [CrossRef]

- Arslan, H.; Coşgun, N.; Salgin, B. Construction and Demolition Waste Management in Turkey. In Waste Management: An Integrated Vision; IntechOpen: London, UK, 2012; pp. 313–332. [Google Scholar]

- Starovoytova, D.; Namango, S. Solid waste management at university campus (Part 4/10): Perceptions, attitudes, and practices of students and vendors. J. Environ. Earth Sci. 2018, 8, 2224–3216. [Google Scholar]

- Mitra, S.; Datta, P.P. Adoption of green supply chain management practices and their impact on performance: An exploratory study of Indian manufacturing firms. Int. J. Prod. Res. 2014, 52, 2085–2107. [Google Scholar] [CrossRef]

- Schroeder, P.; Anggraeni, K.; Weber, U. The Relevance of Circular Economy Practices to the Sustainable Development Goals. J. Ind. Ecol. 2018, 23, 77–95. [Google Scholar] [CrossRef]

- Neo, S.M.; Choong, W.W.; Bin Ahamad, R. Differential environmental psychological factors in determining low carbon behaviour among urban and suburban residents through responsible environmental behaviour model. Sustain. Cities Soc. 2017, 31, 225–233. [Google Scholar] [CrossRef]

- Badgie, D.; Samah, M.A.A.; Manaf, L.A.; Muda, A.B. Assessment of Municipal Solid Waste Composition in Malaysia: Management, Practice, and Challenges. Pol. J. Environ. Stud. 2012, 21, 539–547. [Google Scholar]

- Islam, R.; Nazifa, T.H.; Yuniarto, A.; Uddin, A.S.; Salmiati, S.; Shahid, S. An empirical study of construction and demolition waste generation and implication of recycling. Waste Manag. 2019, 95, 10–21. [Google Scholar] [CrossRef] [PubMed]

- Ikechukwu, A.F.; Shabangu, C. Strength and durability performance of masonry bricks produced with crushed glass and melted PET plastics. Case Stud. Constr. Mater. 2021, 14, e00542. [Google Scholar]

- Sarkodie, S.A.; Owusu, P.A. Global assessment of environment, health and economic impact of the novel coronavirus (COVID-19). Environ. Dev. Sustain. 2020, 23, 5005–5015. [Google Scholar] [CrossRef] [PubMed]

- Babashamsi, P.; Yusoff, N.I.M.; Ceylan, H.; Nor, N.G.M.; Jenatabadi, H.S. Sustainable Development Factors in Pavement Life-Cycle: Highway/Airport Review. Sustainability 2016, 8, 248. [Google Scholar] [CrossRef]

- Esa, M.R.; Halog, A.; Rigamonti, L. Strategies for minimizing construction and demolition wastes in Malaysia. Resour. Conserv. Recycl. 2017, 120, 219–229. [Google Scholar] [CrossRef]

- Arayici, Y.; Egbu, C.O.; Coates, S.P. Building information modelling (BIM) implementation and remote construction projects: Issues, challenges, and critiques. J. Inf. Technol. Constr. 2012, 17, 75–92. [Google Scholar]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.C.; Tam, V.W. A conceptual foundation for effective construction and demolition waste management. Clean. Eng. Technol. 2020, 1, 100019. [Google Scholar] [CrossRef]

- Won, J.; Cheng, J.C.; Lee, G. Quantification of construction waste prevented by BIM-based design validation: Case studies in South Korea. Waste Manag. 2016, 49, 170–180. [Google Scholar] [CrossRef]

- Fewings, P.; Henjewele, C. Construction Project Management: An Integrated Approach; Routledge: Milton Park, Milton, UK, 2019. [Google Scholar]

- Mah, C.M.; Fujiwara, T.; Ho, C.S. Life cycle assessment and life cycle costing toward eco-efficiency concrete waste management in Malaysia. J. Clean. Prod. 2018, 172, 3415–3427. [Google Scholar] [CrossRef]

- Ametepey, S.; Aigbavboa, C.; Ansah, K. Barriers to Successful Implementation of Sustainable Construction in the Ghanaian Construction Industry. Procedia Manuf. 2015, 3, 1682–1689. [Google Scholar] [CrossRef]

- Hessing, M.; Summerville, T. Canadian Natural Resource and Environmental Policy: Political Economy and Public Policy; UBC Press: Vancouver, BC, Canada, 2014. [Google Scholar]

- Boyd, C.E.; D’Abramo, L.R.; Glencross, B.D.; Huyben, D.C.; Juarez, L.M.; Lockwood, G.S.; McNevin, A.A.; Tacon, A.G.J.; Teletchea, F.; Tomasso, J.R., Jr.; et al. Achieving sustainable aquaculture: Historical and current perspectives and future needs and challenges. J. World Aquac. Soc. 2020, 51, 578–633. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Lu, W.; Yuan, H. A framework for understanding waste management studies in construction. Waste Manag. 2011, 31, 1252–1260. [Google Scholar] [CrossRef] [PubMed]

- Kabirifar, K.; Mojtahedi, M.; Wang, C. A Systematic Review of Construction and Demolition Waste Management in Australia: Current Practices and Challenges. Recycling 2021, 6, 34. [Google Scholar] [CrossRef]

- Khalfan, M.M.; Maqsood, T. Current state of off-site manufacturing in Australian and Chinese residential construction. J. Constr. Eng. 2014, 2014, 164863. [Google Scholar] [CrossRef]

- Sáez, P.V.; Merino, M.D.R.; Porras-Amores, C.; Astorqui, J.S.C.; Pericot, N.G. Analysis of Best Practices to Prevent and Manage the Waste Generated in Building Rehabilitation Works. Sustainability 2019, 11, 2796. [Google Scholar] [CrossRef]

- Danso, H. Engineering, Identification of key indicators for sustainable construction materials. Adv. Mater. Sci. Eng. 2018, 2018, 6916258. [Google Scholar] [CrossRef]

- Tlusty, M.F.; Rhyne, A.L.; Kaufman, L.; Hutchins, M.; Reid, G.M.; Andrews, C.; Boyle, P.; Hemdal, J.; McGilvray, F.; Dowd, S. Opportunities for Public Aquariums to Increase the Sustainability of the Aquatic Animal Trade. Zoo Biol. 2012, 32, 1–12. [Google Scholar] [CrossRef]

- Karlsson, I.; Rootzén, J.; Johnsson, F. Reaching net-zero carbon emissions in construction supply chains—Analysis of a Swedish road construction project. Renew. Sustain. Energy Rev. 2019, 120, 109651. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, H.C.; Lee, J.Y. Highly Reversible Lithium Storage in Porous SnO2 Nanotubes with Coaxially Grown Carbon Nanotube Overlayers. Adv. Mater. 2006, 18, 645–649. [Google Scholar] [CrossRef]

- Klemeš, J.J.; Fan, Y.V.; Jiang, P. Plastics: Friends or foes? The circularity and plastic waste footprint. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 43, 1549–1565. [Google Scholar] [CrossRef]

- Adeniran, A.; Nubi, A.; Adelopo, A. Solid waste generation and characterization in the University of Lagos for a sustainable waste management. Waste Manag. 2017, 67, 3–10. [Google Scholar] [CrossRef] [PubMed]

- Ogunmakinde, O.E.; Sher, W.; Maund, K. An Assessment of Material Waste Disposal Methods in the Nigerian Construction Industry. Recycling 2019, 4, 13. [Google Scholar] [CrossRef]

- Nduneseokwu, C.K.; Qu, Y.; Appolloni, A. Factors Influencing Consumers’ Intentions to Participate in a Formal E-Waste Collection System: A Case Study of Onitsha, Nigeria. Sustainability 2017, 9, 881. [Google Scholar] [CrossRef]

- Dalsgaard, P.; Halskov, K. Reflective design documentation. In Proceedings of the Designing Interactive Systems Conference, Newcastle, UK, 11–15 June 2012. [Google Scholar]

- Chybiński, M.; Kurzawa, Z.; Polus, Ł. Problems with Buildings Lacking Basic Design Documentation. Procedia Eng. 2017, 195, 24–31. [Google Scholar] [CrossRef]

- Silver, D. Haste or Waste? Peer pressure and productivity in the emergency department. Rev. Econ. Stud. 2021, 88, 1385–1417. [Google Scholar] [CrossRef]

- Granado, M.P.P.; Suhogusoff, Y.V.M.; Santos, L.R.O.; Yamaji, F.M.; De Conti, A.C. Effects of pressure densification on strength and properties of cassava waste briquettes. Renew. Energy 2020, 167, 306–312. [Google Scholar] [CrossRef]

- Rajendran, P.; Gomez, C.P. Implementing BIM for waste minimisation in the construction industry: A literature review. In Proceedings of the 2nd International Conference on Management, Kuala Lumpur, Malaysia, 11–12 June 2012. [Google Scholar]

- Lundesjö, G. Consolidation centres construction logistics. In Urban Logistics: Management, Policy and Innovation in a Rapidly Changing Environment; Kogan Page, Limited: London, UK, 2018; p. 210. [Google Scholar]

- Sahoo, P.; Jana, D.K.; Pramanik, S.; Panigrahi, G. A novel reduction method for type-2 uncertain normal critical values and its applications on 4D profit transportation problem involving damageable and substitute items. Int. J. Appl. Comput. Math. 2021, 7, 123. [Google Scholar] [CrossRef]

- Singh, G.; Singh, A. Solving fixed-charge transportation problem using a modified particle swarm optimization algorithm. Int. J. Syst. Assur. Eng. Manag. 2021, 1–14. [Google Scholar] [CrossRef]

- Negash, Y.T.; Hassan, A.M.; Tseng, M.-L.; Wu, K.-J.; Ali, M.H. Sustainable construction and demolition waste management in Somaliland: Regulatory barriers lead to technical and environmental barriers. J. Clean. Prod. 2021, 297, 126717. [Google Scholar] [CrossRef]

- Vignesh, K.; Rajadesingu, S.; Arunachalam, K.D. Challenges, issues, and problems with zero-waste tools. In Concepts of Advanced Zero Waste Tools; Elsevier: Amsterdam, The Netherlands, 2021; pp. 69–90. [Google Scholar]

- Rubinov, V.; Fetisov, V. Problems of a Modern Approach to the Technological Process of Waste Management. In Proceedings of the 2021 Wave Electronics and Its Application in Information and Telecommunication Systems (WECONF), St. Petersburg, Russia, May 31–June 4 2021. [Google Scholar]

- Daoud, A.O.; Othman, A.A.; Robinson, H.; Bayati, A. Exploring the relationship between materials procurement and waste minimization in the construction industry: The case of Egypt. In Proceedings of the International Conference on Sustainability, Green Buildings, Environmental Engineering & Renewable Energy (SGER 2018), Kuala Lumpur, Malaysia, 27 January 2018. [Google Scholar]

- Nagapan, S.; Rahman, I.A.; Asmi, A. A review of construction waste cause factors. In Proceedings of the Asian Conference on Real Estate: Sustainable Growth Managing Challenges (ACRE), Johor Bahru, Malaysia, 3–5 October 2011. [Google Scholar]

- Osmani, M.; Villoria-Sáez, P. Current and Emerging Construction Waste Management Status, Trends and Approaches. In Waste; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Crawford, R.H.; Mathur, D.; Gerritsen, R. Barriers to Improving the Environmental Performance of Construction Waste Management in Remote Communities. Procedia Eng. 2017, 196, 830–837. [Google Scholar] [CrossRef]

- Aldana, J.C.; Serpell, A. Methodology for the preparation of construction project waste management plans based on innovation and productive thinking processes: A case study in Chile. J. Constr. 2016, 15, 32–41. [Google Scholar] [CrossRef]

- de Magalhães, R.F.; Danilevicz, Â.D.M.F.; Saurin, T.A. Reducing construction waste: A study of urban infrastructure projects. Waste Manag. 2017, 67, 265–277. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Poon, C.S.; Yu, A.T.W.; Jaillon, L.C. Reducing building waste at construction sites in Hong Kong. Constr. Manag. Econ. 2004, 22, 461–470. [Google Scholar] [CrossRef]

- Farrow, R.L. ManTech Journal. Achieving A Breakthrough. Volume 7/Number 3. 1982; Army Materials and Mechanics Research Center: Watertown, MA, USA, 1982. [Google Scholar]

- Sundström, M. Connecting Social Science and Information Technology: Democratic Privacy in the Information Age. Lund University: Lund, Sweden, 2001. [Google Scholar]

- Ferguson, J. Managing and Minimizing Construction Waste: A Practical Guide; Thomas Telford: Westerkirk, UK, 1995. [Google Scholar]

- Dainty, A.R.J.; Brooke, R.J. Towards improved construction waste minimisation: A need for improved supply chain integration? Struct. Surv. 2004, 22, 20–29. [Google Scholar] [CrossRef]

- Muthu, S.S. Advances in Textile Waste Water Treatments; Springer Nature: Basingstoke, UK, 2021. [Google Scholar]

- König, H.; Kohler, N.; Kreißig, J.; Lützkendorf, T. A Life Cycle Approach to Buildings; Walter de Gruyter: Berlin, Germany, 2012. [Google Scholar]

- Hasmori, M.F.; Zin, A.F.M.; Nagapan, S.; Deraman, R.; Abas, N.; Yunus, R.; Klufallah, M. The on-site waste minimization practices for construction waste. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Chennai, India, 16–17 September 2020; IOP Publishing: Bristol, UK, 2020. [Google Scholar]

- Ajayi, S.O.; Oyedele, L.O.; Bilal, M.; Akinade, O.; Alaka, H.A.; Owolabi, H.A. Critical management practices influencing on-site waste minimization in construction projects. Waste Manag. 2016, 59, 330–339. [Google Scholar] [CrossRef]

- Al-Moghany, S.S. Managing and Minimizing Construction Waste in Gaza Strip; Islamic University of Gaza-Palestine: Gaza, Palestine, 2006. [Google Scholar]

- Holdren, J.P.; Fetter, S. Contribution of Activation Products to Fusion Accident Risk: Part II. Effects Of Alternative Materials And Designs. Nucl. Technol.-Fusion 1983, 4, 599–619. [Google Scholar] [CrossRef]

- Adewuyi, T.O.; Odesola, I.A. Factors affecting material waste on construction sites in Nigeria. J. Eng. Technol. 2015, 6, 82–99. [Google Scholar]

- Wilson, R.E. Educational Specifications. In AIA School Plant; American Institute Of Architects: Washington, DC, USA, 1955; p. 18. [Google Scholar]

- Polat, G.; Damci, A.; Turkoglu, H.; Gurgun, A.P. Identification of Root Causes of Construction and Demolition (C&D) Waste: The Case of Turkey. Procedia Eng. 2017, 196, 948–955. [Google Scholar] [CrossRef]

- Aparcana Robles, S.R.; Hinostroza, M.L. Guidebook for the Development of Nationally Appropriate Mitigation Actions on Sustainable Municipal Waste Management. 2015. Available online: https://core.ac.uk/download/pdf/43252112.pdf (accessed on 1 September 2021).

- Begum, R.A.; Siwar, C.; Pereira, J.J.; Jaafar, A.H. A benefit–cost analysis on the economic feasibility of construction waste minimisation: The case of Malaysia. Resour. Conserv. Recycl. 2006, 48, 86–98. [Google Scholar] [CrossRef]

- Bao, Z.; Lee, W.M.; Lu, W. Implementing on-site construction waste recycling in Hong Kong: Barriers and facilitators. Sci. Total Environ. 2020, 747, 141091. [Google Scholar] [CrossRef] [PubMed]

- Bishop, B.; Johnson, K.; King, E.; Lotts, C.; Miller, S.; Wurtz, M. Environmental Assessment of Proposed Mixed-Use Business Park on an Enchanced Use Lease at Grand Forks Air Force Base, North Dakota; Air Force Civil Engineer Center Joint Base: San Antonio, TX, USA, 2014. [Google Scholar]

- LoBiondo-Wood, G.; Faan, P.R.; Haber, J.; Faan, P.R. Nursing Research E-Book: Methods and Critical Appraisal for Evidence-Based Practice; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Jarvis, C.B.; MacKenzie, S.B.; Podsakoff, P.M. A Critical Review of Construct Indicators and Measurement Model Misspecification in Marketing and Consumer Research. J. Consum. Res. 2003, 30, 199–218. [Google Scholar] [CrossRef]

- Al-Mekhlafi, A.-B.A.; Isha, A.S.N.; Chileshe, N.; Abdulrab, M.; Kineber, A.F.; Ajmal, M. Impact of Safety Culture Implementation on Driving Performance among Oil and Gas Tanker Drivers: A Partial Least Squares Structural Equation Modelling (PLS-SEM) Approach. Sustainability 2021, 13, 8886. [Google Scholar] [CrossRef]

- Al-Mekhlafi, A.-B.; Isha, A.; Chileshe, N.; Abdulrab, M.; Saeed, A.; Kineber, A. Modelling the Relationship between the Nature of Work Factors and Driving Performance Mediating by Role of Fatigue. Int. J. Environ. Res. Public Health 2021, 18, 6752. [Google Scholar] [CrossRef]

- Al-Mekhlafi, A.B.A.; Isha, A.S.N.; Naji, G.M.A. The relationship between fatigue and driving performance: A review and directions for future research. J. Crit. Rev. 2020, 7, 134–141. [Google Scholar]

- Al-Mekhlafi, A.B.A.; Isha, A.S.N.; Sabir, A.A.; Naji, G.M.A.; Ajmal, M.; Al-Harasi, A.H. Fatigue Assessment of Oil and Gas Tanker Drivers: Psychomotor Vigilance Test (PVT-192). Solid State Technol. 2020, 63, 4256–4262. [Google Scholar]

- Yang, G.-L.; Fukuyama, H.; Song, Y.-Y. Measuring the inefficiency of Chinese research universities based on a two-stage network DEA model. J. Inf. 2018, 12, 10–30. [Google Scholar] [CrossRef]

- Kineber, A.F.; Othman, I.; Oke, A.E.; Buniya, M.K. Value Management Activities in Building Projects in Developing Countries. in Advances in Civil Engineering Materials. In Proceedings of the International Conference on Architecture and Civil Engineering (ICACE2020), Kuala Lumpur, Malaysia, 4–5 January 2021; Springer: Singapore, 2021. [Google Scholar]

- Siti–Nabiha, A.K.; George, R.A.; Wahid, N.A.; Amran, A.; Mahadi, R.; Abustan, I. The Development of a Green Practice Index for the Malaysian Hotel Industry. Issues Soc. Environ. Account. 2014, 8, 23. [Google Scholar] [CrossRef]

- Ritchie, J.; Lewis, J.; Elam, R.G. Selecting Samples. In Qualitative Research Practice: A Guide for Social Science Students and Researchers; Sage: Los Angeles, CA, USA, 2013. [Google Scholar]

- Krejcie, R.V.; Morgan, D.W. Determining Sample Size for Research Activities. Educ. Psychol. Meas. 1970, 30, 607–610. [Google Scholar] [CrossRef]

- Jaso-Sánchez, M.A. Evaluation of Research Collaboration in the Mexican Phyto-Pharmaceutical Sector; The University of Manchester: Manchester, UK, 2007. [Google Scholar]

- Kineber, A.; Othman, I.; Oke, A.; Chileshe, N.; Buniya, M. Identifying and Assessing Sustainable Value Management Implementation Activities in Developing Countries: The Case of Egypt. Sustainability 2020, 12, 9143. [Google Scholar] [CrossRef]

- Kyriazos, T.A. Applied Psychometrics: Sample Size and Sample Power Considerations in Factor Analysis (EFA, CFA) and SEM in General. Psychology 2018, 9, 2207–2230. [Google Scholar] [CrossRef]

- Kineber, A.F.; Othman, I.; Oke, A.E.; Chileshe, N.; Buniya, M.K. Impact of Value Management on Building Projects Success: Structural Equation Modeling Approach. J. Constr. Eng. Manag. 2021, 147, 04021011. [Google Scholar] [CrossRef]

- Ferreira-Valente, A.; Costa, P.; Elorduy, M.; Virumbrales, M.; Costa, M.J.; Palés, J.; Ferreira-Valente, M.A. Psychometric properties of the Spanish version of the Jefferson Scale of Empathy: Making sense of the total score through a second order confirmatory factor analysis. BMC Med. Educ. 2016, 16, 242. [Google Scholar] [CrossRef]

- Morgan, J.N.; Sonquist, J.A. Problems in the analysis of survey data, and a proposal. J. Am. Stat. Assoc. 1963, 58, 415–434. [Google Scholar] [CrossRef]

- Ajmal, M.; Isha, A.S.N.; Nordin, S.M.; Kanwal, N.; Al-Mekhlafi, A.B.A.; Naji, G.M.A. A Conceptual Framework for the Determinants of Organizational Agility: Does Safety Commitment Matters? Solid State Technol. 2020, 63, 4112–4119. [Google Scholar]

- Ajmal, M.; Isha, A.S.N.; Nordin, S.M.; Sabir, A.A.; Munir, A.; Al-Mekhlafi, A.B.A.; Naji, G.M.A. Safety Management Paradigms: COVID-19 Employee Well-Being Impact on Occupational Health and Safety Performance. J. Hunan Univ. Nat. Sci. 2021, 48, 128–142. [Google Scholar]

- Mason, M. Sample size and saturation in PhD studies using qualitative interviews. In Forum Qualitative Sozialforschung/Forum: Qualitative Social Research; Institute for Qualitative Research and Center for Digital Systems (Free University of Berlin): Berlin, Germany, 2010; Volume 11. [Google Scholar]

- Naji, G.M.A.; Isha, A.S.N.; Al-Mekhlafi, A.B.A.; Sharafaddin, O.; Ajmal, M. Implementation of leading and lagging indicators to improve safety performance in the upstream oil and gas industry. J. Crit. Rev. 2020, 7, 265–269. [Google Scholar]

- Naji, G.M.A.; Isha, A.S.N.; Alzoraiki, M.; Al-Mekhlafi, A.B.A.; Sharafaddin, O.; Saleem, M.S. Impact Of Safety Culture and Psychosocial Hazard on Safety Performance Among Upstream Employees in Malaysia at Oil And Gas Industry. Solid State Technol. 2020, 63, 4120–4126. [Google Scholar]

- Robinaugh, D.J.; Hoekstra, R.H.A.; Toner, E.; Borsboom, D. The network approach to psychopathology: A review of the literature 2008–2018 and an agenda for future research. Psychol. Med. 2019, 50, 353–366. [Google Scholar] [CrossRef] [PubMed]

- Kineber, A.F.; Othman, I.; Oke, A.E.; Chileshe, N.; Zayed, T. Exploring the value management critical success factors for sustainable residential building—A structural equation modelling approach. J. Clean. Prod. 2021, 293, 126115. [Google Scholar] [CrossRef]

- Reichmann, S.; Klebel, T.; Hasani-Mavriqi, I.; Ross-Hellauer, T.J.S.S. Between administration and research: Understanding data management practices in a mid-sized technical university. SocArXiv 2020, 1. [Google Scholar]

- Wong, K.K.K. Partial least squares structural equation modeling (PLS-SEM) techniques using SmartPLS. Mark. Bull. 2013, 24, 1–32. [Google Scholar]

- Choshin, M.; Ghaffari, A. An investigation of the impact of effective factors on the success of e-commerce in small-and medium-sized companies. Comput. Hum. Behav. 2017, 66, 67–74. [Google Scholar] [CrossRef]

- Behl, A. Antecedents to firm performance and competitiveness using the lens of big data analytics: A cross-cultural study. Manag. Decis. 2020. [Google Scholar] [CrossRef]

- Malta, J.S.; Silveira, L.P.; Drummond, P.L.D.M.; Costa, N.L.; dos Santos, R.M.M.; Reis, I.A.; Reis, A.M.M.; de Pádua, C.A.M. Validity and reliability of the QLQ-MY20 module for assessing the health-related quality of life in Brazilians with multiple myeloma. Curr. Med. Res. Opin. 2021, 37, 1163–1169. [Google Scholar] [CrossRef] [PubMed]

- Perez, M.V.; Navarro, P.X.S.; Morillas, A.V.; Valdemar, R.M.E.; Araiza, J.P.H.L. Waste management and environmental impact of absorbent hygiene products: A review. Waste Manag. Res. 2020, 39, 767–783. [Google Scholar] [CrossRef] [PubMed]

- Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.C.; Tam, V.W. Effective construction and demolition waste management assessment through waste management hierarchy; a case of Australian large construction companies. J. Clean. Prod. 2021, 312, 127790. [Google Scholar] [CrossRef]

- Slorach, P.C.; Jeswani, H.K.; Cuéllar-Franca, R.; Azapagic, A. Environmental and economic implications of recovering resources from food waste in a circular economy. Sci. Total Environ. 2019, 693, 133516. [Google Scholar] [CrossRef]

- Wu, H.; Duan, H.; Zheng, L.; Wang, J.; Niu, Y.; Zhang, G. Demolition waste generation and recycling potentials in a rapidly developing flagship megacity of South China: Prospective scenarios and implications. Constr. Build. Mater. 2016, 113, 1007–1016. [Google Scholar] [CrossRef]

- Subramaniam, S.; Nagapan, S.; Kupusamy, K.; Manian, H.; Daud, Z. Investigate How Construction Waste Generation Rate is Different for Every Types of Project in Peninsular Malaysia Using Site Visit Method. Int. J. Integr. Eng. 2018, 10, 150–156. [Google Scholar] [CrossRef][Green Version]

- Umar, U.A.; Shafiq, N.; Isa, M.H. Investigation of construction wastes generated in the Malaysian residential sector. Waste Manag. Res. 2018, 36, 1157–1165. [Google Scholar] [CrossRef]

- Maniam, H.; Nagapan, S.; Abdullah, A.H.; Subramaniam, S.; Sohu, S. A Comparative Study of Construction Waste Generation Rate Based on Different Construction Methods on Construction Project in Malaysia. Eng. Technol. Appl. Sci. Res. 2018, 8, 3488–3491. [Google Scholar] [CrossRef]

- Jin, R.; Li, B.; Zhou, T.; Wanatowski, D.; Piroozfar, P. An empirical study of perceptions towards construction and demolition waste recycling and reuse in China. Resour. Conserv. Recycl. 2017, 126, 86–98. [Google Scholar] [CrossRef]

- Hiete, M.; Stengel, J.; Ludwig, J.; Schultmann, F. Matching construction and demolition waste supply to recycling demand: A regional management chain model. Build. Res. Inf. 2011, 39, 333–351. [Google Scholar] [CrossRef]

- Ribić, B.; Voća, N.; Ilakovac, B. Concept of sustainable waste management in the city of Zagreb: Towards the implementation of circular economy approach. J. Air Waste Manag. Assoc. 2017, 67, 241–259. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.H.; Song, H.B. Analysis of the global warming potential for wood waste recycling systems. J. Clean. Prod. 2014, 69, 199–207. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 2014, 43, 115–135. [Google Scholar] [CrossRef]

- Laato, S.; Islam, A.N.; Farooq, A.; Dhir, A. Unusual purchasing behavior during the early stages of the COVID-19 pandemic: The stimulus-organism-response approach. J. Retail. Consum. Serv. 2020, 57, 102224. [Google Scholar] [CrossRef]

- Abu Aisheh, Y.I.; Tayeh, B.A.; Alaloul, W.S.; Almalki, A. Health and safety improvement in construction projects: A lean construction approach. Int. J. Occup. Saf. Ergon. 2021, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Narayan, D.; Cassidy, M.F. A dimensional approach to measuring social capital: Development and validation of a social capital inventory. Curr. Sociol. 2001, 49, 59–102. [Google Scholar] [CrossRef]

- Bhandari, S.; Naudeer, S. Improving efficiency and value in health care Intravenous iron management for anaemia associated with chronic kidney disease: Linking treatment to an outpatient clinic, optimizing service provision and patient choice. J. Eval. Clin. Pract. 2008, 14, 996–1001. [Google Scholar] [CrossRef] [PubMed]

- Afthanorhan, W.M.A.B.W. A comparison of partial least square structural equation modeling (PLS-SEM) and covariance based structural equation modeling (CB-SEM) for confirmatory factor analysis. Int. J. Eng. Sci. Innov. Technol. 2013, 2, 198–205. [Google Scholar]

- Purwanto, A. Partial Least Squares Structural Squation Modeling (PLS-SEM) Analysis for Social and Management Research: A Literature Review. J. Ind. Eng. Manag. Res. 2021, 2, 114–123. [Google Scholar]

- Chytrý, M.; Tichý, L.; Holt, J.; Botta-Dukát, Z. Determination of diagnostic species with statistical fidelity measures. J. Veg. Sci. 2002, 13, 79–90. [Google Scholar] [CrossRef]

- Dijkstra, T.K.; Henseler, J. Consistent partial least squares path modeling. MIS Q. 2015, 39, 297–316. [Google Scholar] [CrossRef]

- Al-Maroof, R.S.; Salloum, S.A. An Integrated Model of Continuous Intention to Use of Google Classroom. In Recent Advances in Intelligent Systems and Smart Applications; Springer: Berlin/Heidelberg, Germany, 2021; pp. 311–335. [Google Scholar]

- Hair, J.F., Jr.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M. A Primer on Partial Least Squares Structural Equation Modeling (PLS-SEM); Sage Publications: Kowloon, Hong Kong, 2021. [Google Scholar]

- Chakrabarti, S.; Makhija, M. Exploratory study on variables impacting display advertising spend of leading advertisers in the USA. J. Mark. Commun. 2021, 27, 176–206. [Google Scholar] [CrossRef]

- Chin, W.; Cheah, J.-H.; Liu, Y.; Ting, H.; Lim, X.-J.; Cham, T.H. Demystifying the role of causal-predictive modeling using partial least squares structural equation modeling in information systems research. Ind. Manag. Data Syst. 2020, 120, 2161–2209. [Google Scholar] [CrossRef]

- Roldán, J.L.; Sánchez-Franco, M.J. Variance-based structural equation modeling: Guidelines for using partial least squares in information systems research. In Research Methodologies, Innovations and Philosophies in Software Systems Engineering and Information Systems; IGI Global: Hershey, PA, USA, 2012; pp. 193–221. [Google Scholar]

- Yahaya, M. Partial Least Square Structural Equation Modeling (PLS-SEM): A Note For Beginners; Sokoto, Nigeria. 2019. Available online: https://www.researchgate.net/publication/339433516_Partial_Least_Square_Structural_Equation_Modeling_PLS-SEM_A_NOTE_FOR_BEGINNERS (accessed on 1 September 2021).

- Sharma, P.N.; Shmueli, G.; Sarstedt, M.; Danks, N.; Ray, S. Prediction-Oriented Model Selection in Partial Least Squares Path Modeling. Decis. Sci. 2018, 52, 567–607. [Google Scholar] [CrossRef]

- Umar, U.A.; Shafiq, N.; Ahmad, F.A. A case study on the effective implementation of the reuse and recycling of construction & demolition waste management practices in Malaysia. Ain Shams Eng. J. 2020, 12, 283–291. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).