The characterisation of the composites was accomplished to evaluate the tensile properties and determine the variation of these properties with temperature and wt.% of reinforcements.

3.2. Results of Tensile tests

- ➢

Ultimate Tensile Strength (UTS)

The comparative evaluation of the ultimate tensile strength of the composite specimens for different compositions of the reinforcements and heat treatment temperatures is given in

Figure 9,

Figure 10,

Figure 11 and

Figure 12. From the graph (

Figure 9), it is evident that the ultimate tensile strength of the composites increases with the increase in the wt.% of fly ash due to inoculation accelerated by the thermal exposure of the composites in the post-treatment condition up to a temperature of 160 °C, as ascertained by the findings of the Kumar et al. [

36], who reported the findings related to the influence of fly ash reinforcements on the tensile strength of Al/3Cu/8.5Si and drew similar inferences of increase in the strength with the increase in wt.% of fly ash attributed to close packing of the reinforcements in the matrix. However, the increase in the thermal exposure temperature to 200 °C leads to a slight decrease in the ultimate tensile strength which can be attributed to the agglomeration of the reinforcements at certain regions in the matrix at an elevated temperature of exposure, as reported in the findings of Kok et al. [

37] about the effect of thermal exposure on the Al

2O

3 particle dispersions in the matrix; the Al

2O

3 particles dispersed in the matrix phase and exposed to a temperature of 150 °C had better strength characteristics, as compared to those aluminium composites with Al

2O

3 particle dispersions in the matrix subjected to a temperature above 150 °C which is in line with the findings of the present work.

Further, the contour and 3D surface plots (

Figure 9) depict that the inoculation brought about by the fly ash reinforcements will enhance the strength of the composites, due to the strong bonding and inherent coring of the reinforcements with the matrix brought about by the thermal exposure. The inferences are based on those of Gireesh et al. [

38], who reported an increase of the tensile strength of the Al 6061 reinforced with SiC and Al

2O

3 by 8.5%, while an increase in yield strength by 36.8% mainly due to the adhesive bonding between the matrix and reinforcements attributed to uniform mixing and distribution of the reinforcements.

Santhosh et al. [

39] reported the findings of tensile characterisation of aluminium AA 5083/SiC/fly ash composites and compared the results with the base alloy. They distinctly identified the need to fabricate high-performance hybrid aluminium composites and reported that the mechanical properties particularly the tensile strength improves up to a certain extent, i.e., 3 to 5 wt.% of SiC; however, beyond this range, the tensile strength showed a decreasing trend. This is addressed by the present research, wherein the tensile strengths show continuous improvement because of the controlled dispersion of the SiC reinforcements alongside fly ash in the matrix and the T6 thermal treatment, due to which the solute elements precipitate in the Al solid solution, facilitating strong bonding the matrix and the reinforcements. The trend observed with respect to the increase in the tensile characteristics from the present work substantiates the need for thermal treatment for the improvement in the characteristics of the composites owing to better bonding and interstitial strengthening.

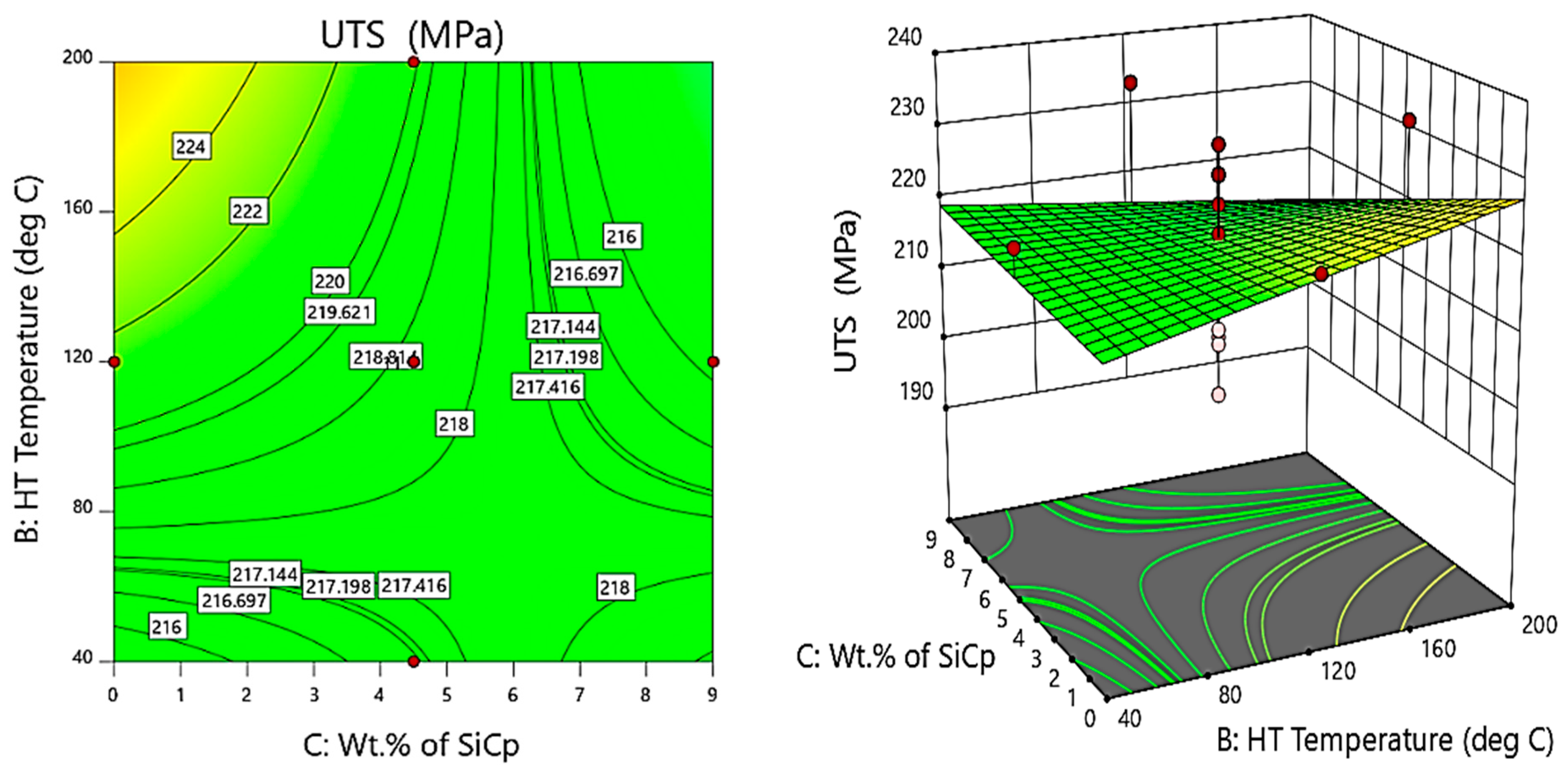

The influence of heat treatment on the strength of these composites is of significant importance to enhance the characteristics of the composites for real-time engineering applications. In this regard, the contour plots and surface plots help us to understand the influence of heat treatment on the ultimate tensile strength of the composite materials. The contour and 3D surface plots in

Figure 11 give the variation of the ultimate tensile strength (MPa) with heat treatment and wt.% of SiC. From the 3 D surface and contour plots, it is evident that the ultimate tensile strength is maximum for composite specimens with 9 wt.% of SiC, exposed to a treatment temperature of 160 °C, i.e., the specimens after successful heat treatment, especially after T6-grade treatment and thermal exposure for a duration of 24 h in oven conditions at 160 °C, will form strong bonds with enhanced toughness, owing to micro coring and granular segregations.

Further,

Figure 12 shows the contour and 3D surface plots for the variation of the ultimate tensile strength (MPa) with heat treatment and wt.% of fly ash. From the plots, it is evident that the ultimate tensile strength is maximum for composite specimens with 6 wt.% of fly ash, exposed to a treatment temperature of 160 °C, i.e., the composite specimens after successful heat treatment, especially after T6-grade treatment and thermal exposure at a temperature of 160 °C, will form strong bonds between the Al atoms and the silicates present in the fly ash. It is, therefore, evident from the graphs that the ultimate tensile strength is dependent on the wt.% of fly ash and the heat treatment temperature [

39].

The findings are in line with the research outcomes of Tiwari et al. [

40], who studied the influence of heat treatment on mechanical characteristics of aluminium–fly ash composites. Their findings indicate that the varying wt.% of fly ash and heat treatment of the composite specimens enhance the mechanical properties attributed to them through modification of the crystalline structure of the composites, followed by the varying wt.% and size of the fly ash particles. The investigations carried out by Chen et al. [

41] on the influence of heat treatment on the microstructure and mechanical properties of TiB

2 reinforced Al 2024 composites provided a fundamental basis for the thermal exposure of the composites, and the results reveal that the addition of TiB

2 results in significant grain refinement with the random orientation of θ-Al

2Cu phases.

- ➢

Yield Strength

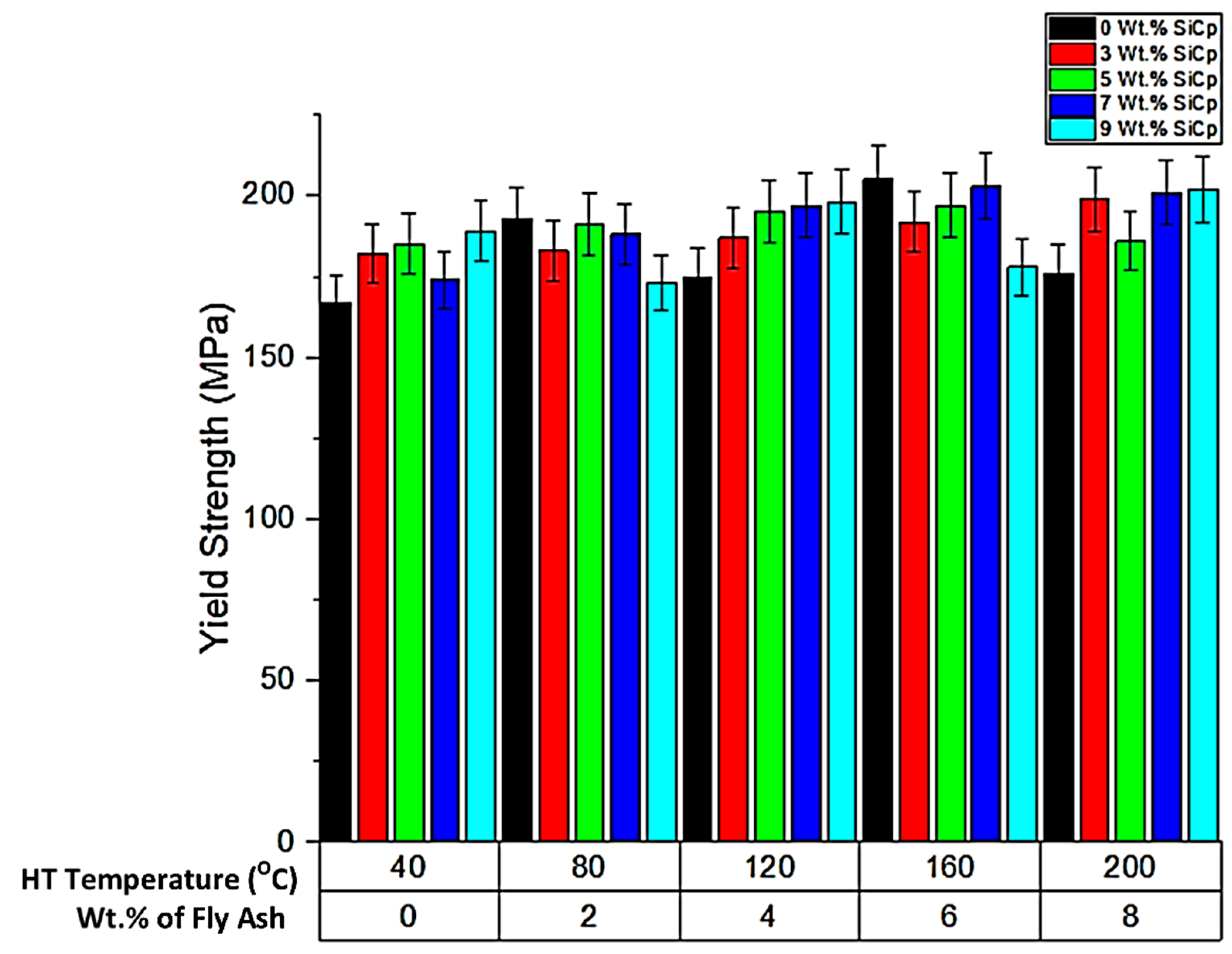

The comparative evaluation of the yield strength of the composite specimens for different heat treatment temperatures and composition of reinforcements is presented in

Figure 13,

Figure 14,

Figure 15 and

Figure 16. From the graph, it is evident that the yield strength of the composites increases with the inoculation, resulting in grain packing and bonding between the atoms and thereby increasing the yield strength which is further facilitated by the thermal exposure of 160 °C, attributed to the increase in the stiffness of the material; however, beyond 160 °C, there will be a slight reduction in the yield strength. The findings are supported by the research of Santhosh et al. [

39], wherein the inclusion of fly ash brought about the inoculation in the matrix, thereby leading to coherent bonding and interstitial micro coring. The process of inoculation is further accelerated in the present work due to the homogenisation of the fly ash particles in the matrix phase brought about by uniform stirring and post-treatment thermal exposure. Subrahmanyam et al. [

42] carried out the inoculation of aluminium alloy using agricultural waste rice husk ash. The researchers reported that the mechanical characteristics of MMCs performed exceptionally better with the inclusion of RHA in aluminium alloy. The microstructure of the composites fabricated by them with 8% RHA particles exhibited exceptional mechanical characteristics and uniformly distributed particulates.

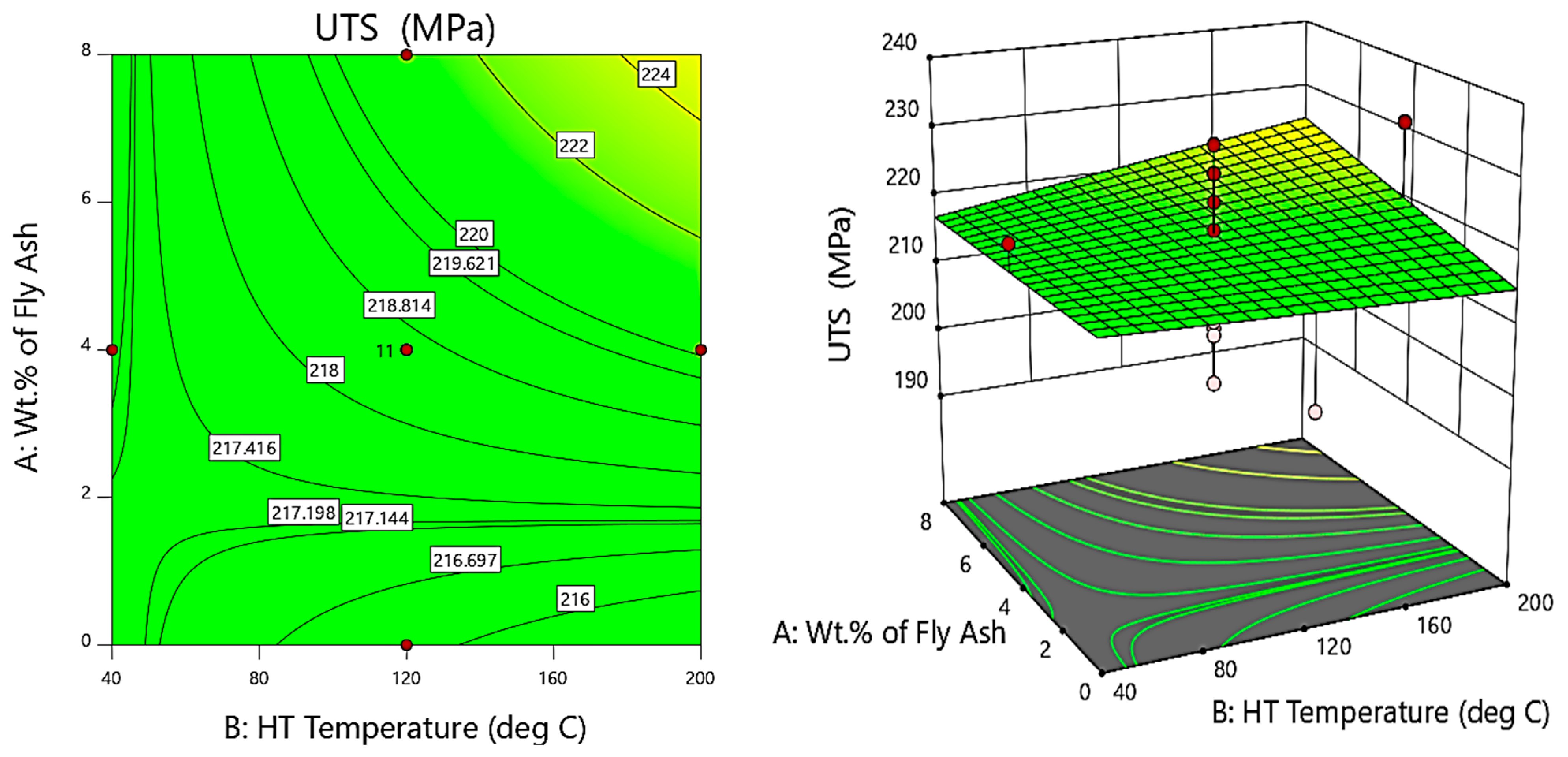

Further, the contour and 3D surface plots (

Figure 14,

Figure 15 and

Figure 16) are considered for the variation of yield strength (YS) with the weight percentage of SiC and fly ash and the heat treatment (HT) temperature. It is clearly evident from the contour and surface plots that the composites synthesised with 6 wt.% of fly ash, 9 wt.% of SiC, and exposed to a temperature of 160 °C have a major influence on maximising the yield strength of the AA 5083/SiC/fly ash composites.

From the contour and 3D surface plots for variation of YS with varying wt.% of reinforcements at different heat treatment temperatures, it is clearly evident that the reinforcements and heat treatment increases the yield strength of the composites, attributed to Orowan strengthening facilitated by precipitation hardening. Shin et al. [

43] identified the microstructural evolution and strengthening mechanisms in Al/SiC composites en route the liquid pressing process, subsequently followed by the heat treatment process, which helps in increasing the strength due to solution heat treatment and artificial ageing, especially due to the formation of Mg

2Si precipitates attributed to precipitation hardening.

- ➢

% Elongation

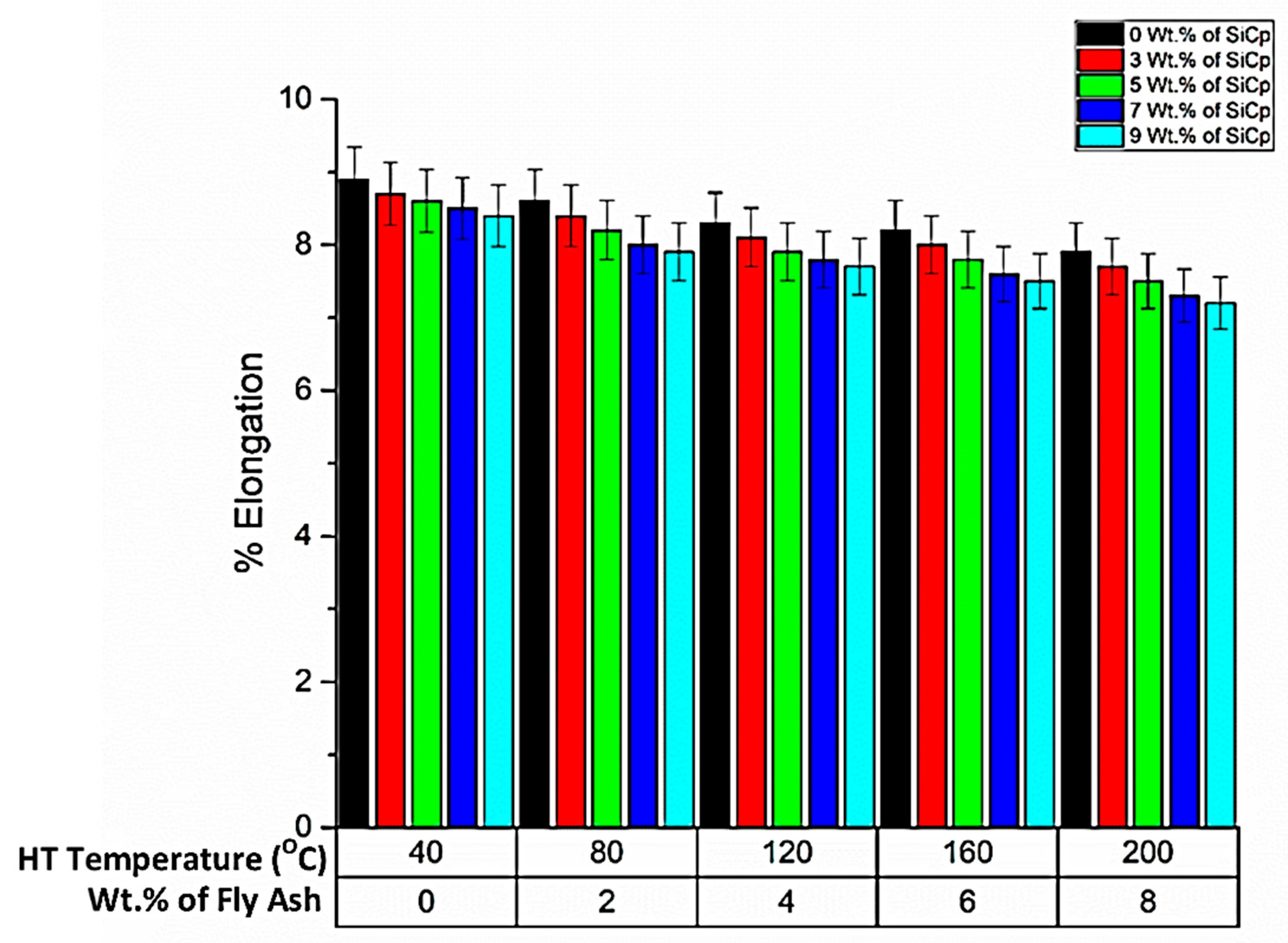

% Elongation is an important attribute for determining the ductility of the composites; specifically, it gives an overview of the length up to which the material elongates in the plastic zone before fracturing. The bar chart in

Figure 17 lists the % elongation that the composites undergo before failure. The % elongation of the base alloy (AA 5083) specimens are relatively higher than the composites, attributed mainly due to the lack of stiffness and the lack of the ability to absorb the applied loads in the plastic zone before failure; however, the percentage elongation decreases with the increase in the reinforcements, especially the SiC reinforcements, which are hard ceramic particles that increase the hardness and strength, causing embrittlement in the composite phase. Similarly, fly ash particles and heat treatment also lead to strong bonding between the Al-C compounds, with the reaction between the atoms accelerated by the inoculation of the Si atoms from the fly ash in the Al matrix. Further, the formation of Al-Si-C bonds along with the Mg atoms along the periphery of the compounds leads to the strengthening of the composites and an increase in the stiffness of the composites, with increased embrittlement between the atoms.

The comparative evaluation of the % elongation of the composite specimens for different heat treatment temperatures is interpreted from the graph (

Figure 17). From the graph, it is evident that the % elongation of the composites decreases with the increase in the wt.% of SiC and fly ash and the heat treatment temperature, mainly attributed to the coherent bonding and interstitial micro coring and increase in the stiffness of the material. This is also supported by the inferences of Florián-Algarín et al. [

44], who concluded that, as the strength increases, the elongation decreases; this is due to the fact that the increase in strength, especially the increase in ultimate tensile strength, yields in increased strength, and Young’s modulus significantly increases the stiffness of the material, thereby decreasing the tenacity related to the % elongation (ductility). However, at the thermal exposure temperature of 160 °C, there is a slight increase in the % elongation, due to the critical softening of the material occurring consequent to the thermal deformation, beyond which the % elongation decreases due to embrittlement accelerated by the strain hardening, as noted in the works of Lu et al. [

45] on the influence of hard ceramic reinforcements in enhancing the mechanical strength of the composite materials. They studied the impact of reinforcements in enhancing the damping characteristics of the composite materials, especially attributed to the synthesis of composites in controlled environments.

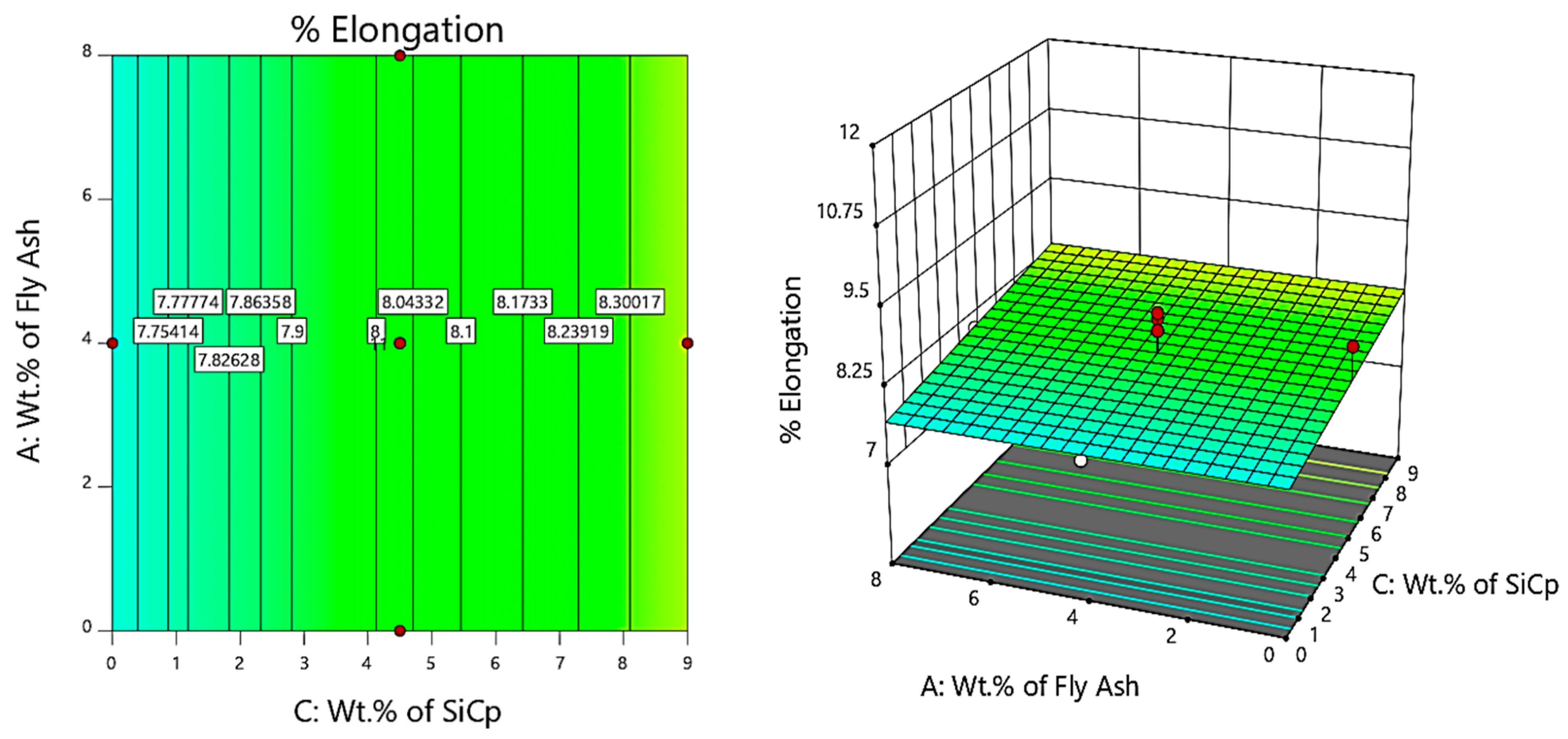

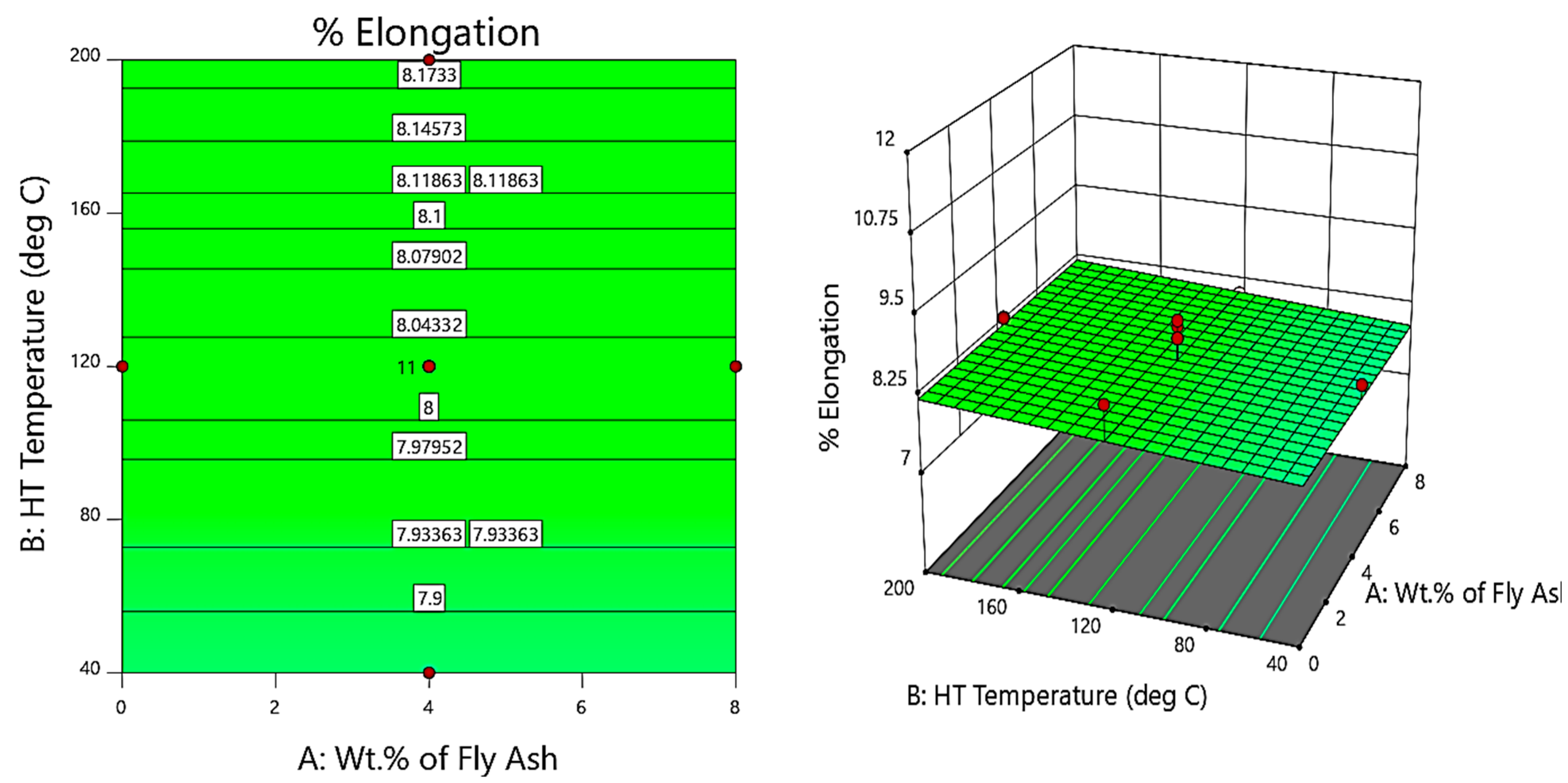

Further, the contour and 3D surface plots (

Figure 18,

Figure 19 and

Figure 20) depict that the inclusion of the reinforcements reduces the ductility of the composites due to the strong bonding facilitated by the inclusion of reinforcements that leads to the process of precipitation hardening, accelerated by the heat treatment, i.e., as the temperature of thermal exposure increases, the hardness and strength of the composites increase due to micro coring and interstitial bonding, while the ductility decreases due to embrittlement and crack initiation and rapid propagation along the 45° plane. Although the ductility decreases with heat treatment up to 160 °C, the % elongation at 160 °C slightly increases with the slightest improvement in ductility, due to thermomechanical softening and easy deformation [

46].

From the contour and 3D surface plots for variation of % elongation with varying wt.% of reinforcements at different heat treatment temperatures, it is clearly evident that the reinforcements and heat treatment decreases the % elongation of the composites, thereby reducing the ductility of the composites attributed to strain hardening and embrittlement. The findings are in line with the results reported by Gan et al. [

47]. The researchers studied the processing of composite materials and analysed the effect of particulates on the ductility of the composites developed; they indicated the decrease in ductility with the agglomeration of the hard ceramic particulates and suggested the friction processing of composites as one of the methodologies of fabrication of composites for better mechanical properties.

- ➢

Optimisation Studies for Ultimate Tensile Strength (UTS)

Optimisation studies by Taguchi methods were carried out to find the optimised wt.% of fly ash and SiC and the temperature of the exposure for maximising the UTS of the composite specimens fabricated en route stir casting. Additionally, the optimisation results give us an overview of the influence of the reinforcements and heat treatment on the ultimate tensile strength of the composites developed.

Table 6 and

Table 7 provide the response tables for S/N ratios and means, while

Figure 21 and

Figure 22 show the main-effect plots for S/N ratios and means for the UTS.

From the response tables and main-effect plots for S/N Ratios and means, it is evident that the wt.% of SiC has a major influence on the UTS, followed by the wt.% of fly ash and heat treatment temperature. Among these factors, level 4 (6 wt.%) for fly ash and level 4 (160 °C) for HT temperature are found to be the optimised set of parameters for maximising the UTS, while the inclusion of silicon carbide in the increments of 2 wt.% is found to outrightly improve the UTS, beginning from 3 wt.% up to the maximum limit of 9 wt.% chosen for the present work.

Parasuraman et al. [

48] studied the optimisation of machinability of AA 7075/TiB

2 composites; the parametric studies helped optimise the cutting forces and surface roughness during the drilling of composites, and the methodology adopted by the authors are in line with the statistical studies carried out in the present work to optimise the process parameters for stir casting the composites, subsequently followed by post-treatment to obtain maximum strength.

Park et al. [

49] reported the interface and synthetic reaction between the atoms and subatomic packings in the matrix and their effect on the characteristics of the composite materials developed. It has been observed, from their studies, that the interface reaction is accelerated by the grain growth epitaxy due to the atomic reagents in the form of material inoculants, which leads to improved tensile strength in the composites.