Versatile Strip Seed Drill: A 2-Wheel Tractor-Based Option for Smallholders to Implement Conservation Agriculture in Asia and Africa

Abstract

:1. Introduction

| Country | Total 2WT and Power Tiller Number |

|---|---|

| Thailand | 2,644,982 |

| Philippines | 1,526,557 |

| Bangladesh | 700,000 |

| Vietnam | 325,000 |

| Myanmar | 199,668 |

| Indonesia | 192,905 |

| Cambodia | 151,701 |

| Sri Lanka | 130,000 |

| India | 117,200 |

| Afghanistan | 20,000 |

| Nepal | 9123 |

| Bhutan | 5000 |

| Timor-Leste | 1000 |

| Total: | 6,023,136 |

2. Material and Methods

2.1. Construction of VSSD

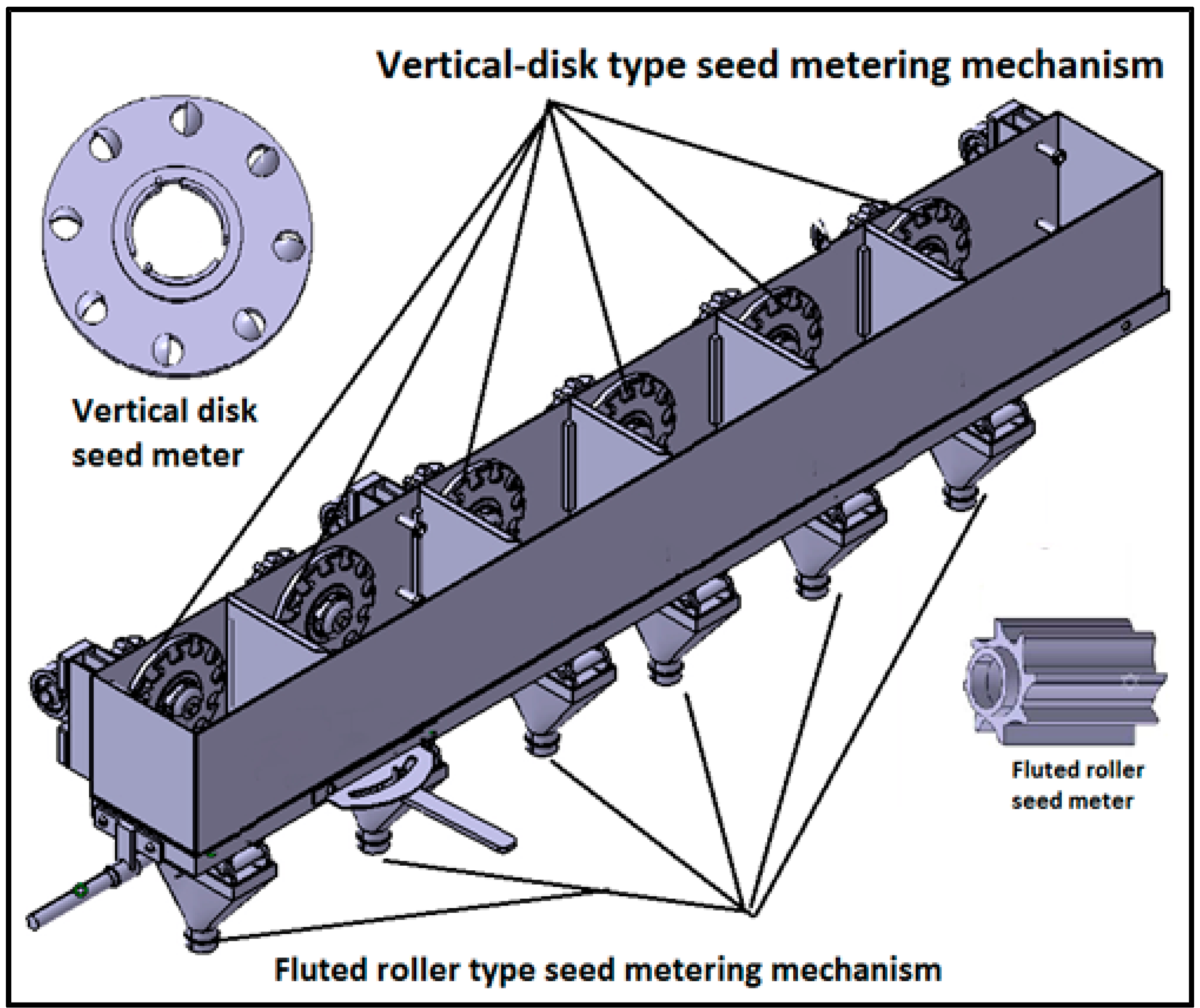

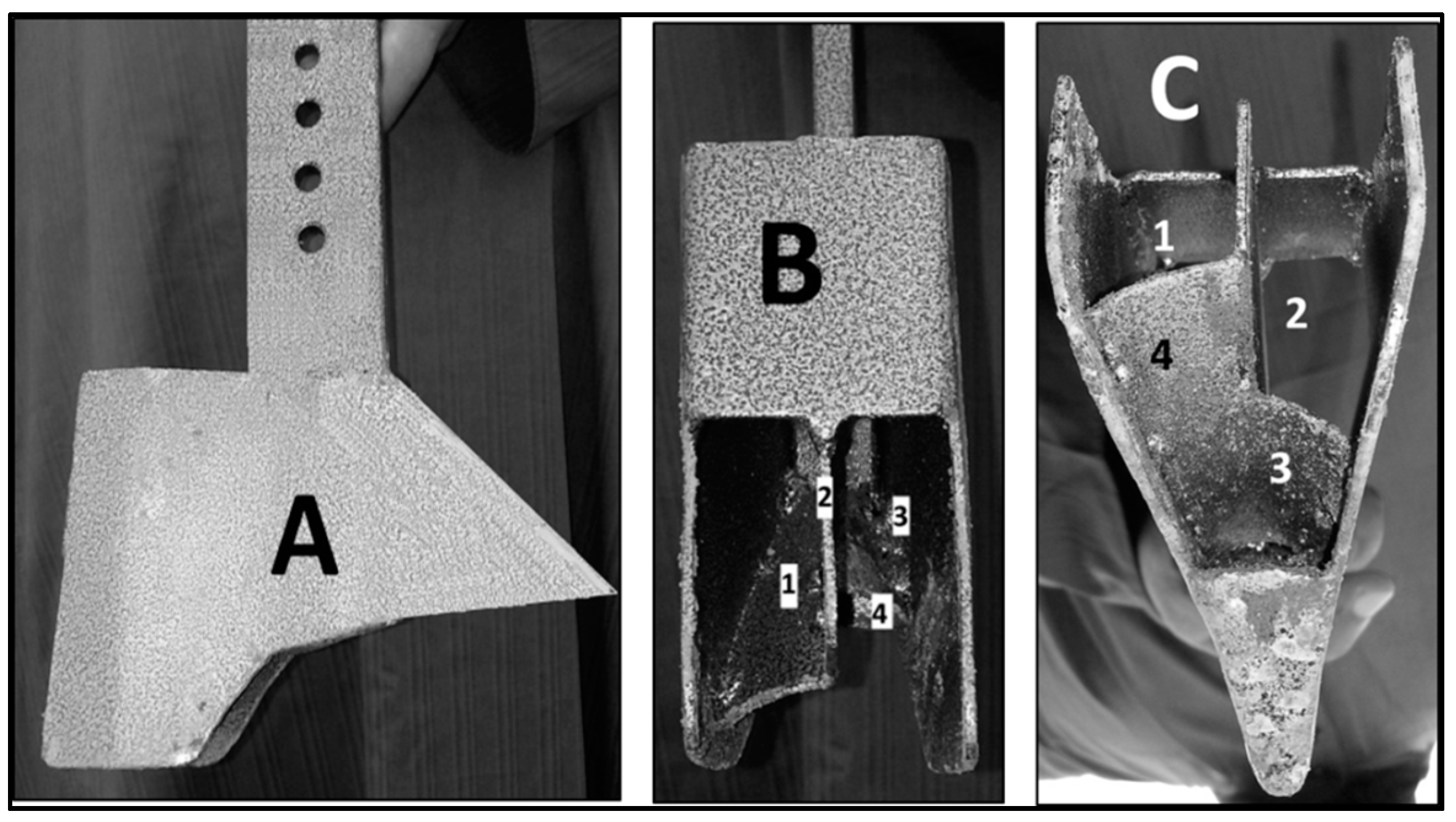

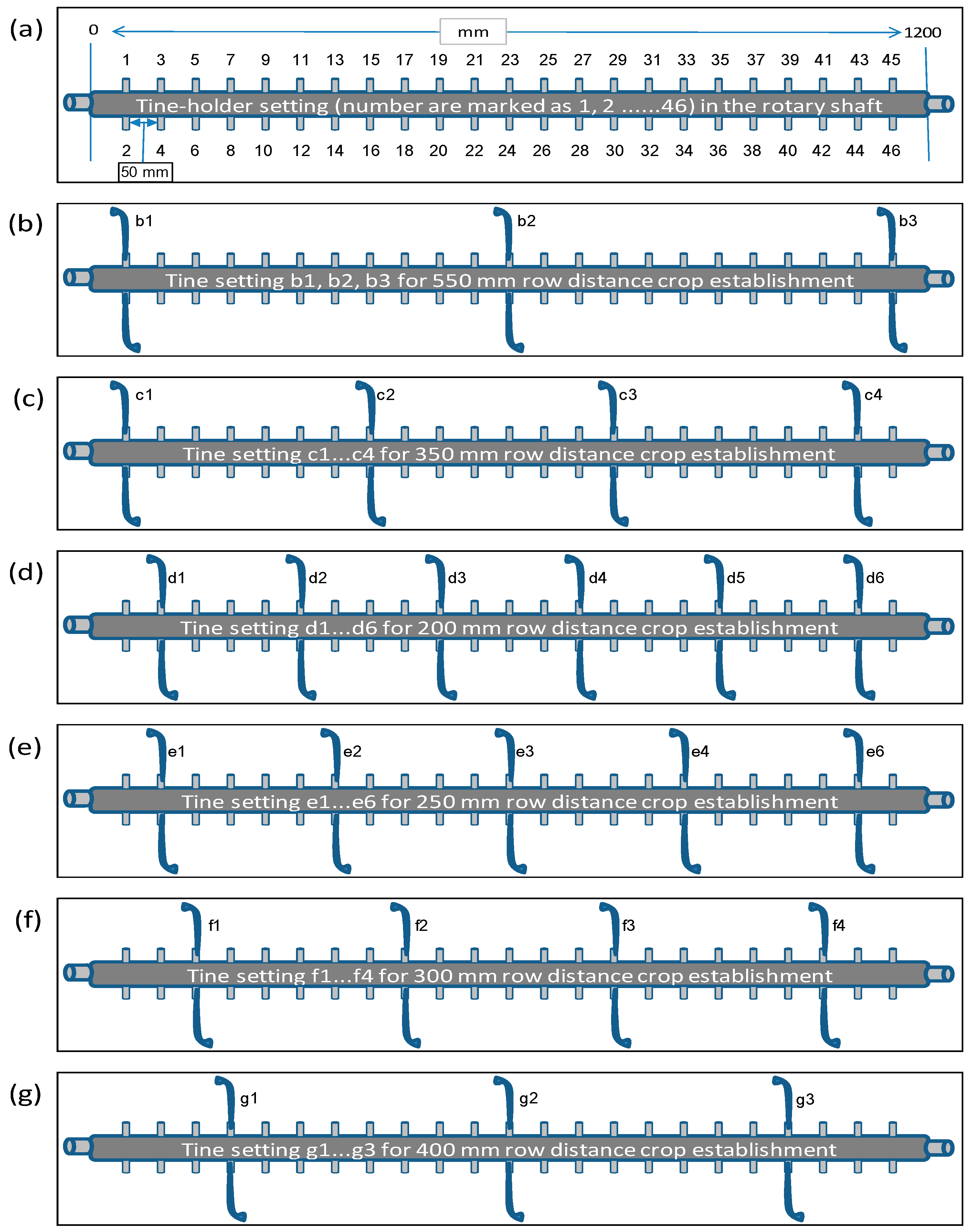

2.2. Versatile Strip Seed Drill Design

2.3. Initial Testing of VSSD

2.4. Seed Calibration

| Crop | Seed Rate (kg·ha−1) | Seeding Depth (mm) | Type of Seed Meter Used | Number of Rows Planted in Each Pass | Effective Field Capacity (ha·h−1) | Fuel Consumption (L·ha−1) | Plant Population m−2 (15 Days after Establishment) |

|---|---|---|---|---|---|---|---|

| Wheat (n = 3) | 120 | 20–40 | 8 flutes | 6 | 0.18 (2nd gear) | 4.97 (±0.46) | 137 (±19) |

| Rice (n = 3) | 27 | 30–60 | Vertical disk | 6 | 0.13 (1st gear) | 6.08 (±0.52) | 78 ± 11 (24 hills) |

| Chickpea (n = 5) | 30 | 30–50 | 8 flutes | 5 | 0.18 (2nd gear) | 4.42 (±0.39) | 58 ± 6 |

| Lentil (n = 4) | 34 | 20–40 | 8 flutes | 5 | 0.17 (2nd gear) | 4.79 (±0.42) | 169 ± 23 |

| Maize (n = 6) | 18 | 30–50 | Vertical disk | 3 | 0.13 (1st gear) | 4.47 (±0.35) | 9 ± 2 |

2.5. Soil Types and Agro-Ecology of Initial Field Trials of VSSD

2.6. Field Evaluation of VSSD

2.6.1. Initial Field Trials of VSSD

2.6.2. Multi-Locational on-Farm Evaluation Trials

- SP = Locally hired VSSD was used in dry land to open 20- to 50-mm deep and 40- to 50-mm wide planting strips; seed and fertilizers were placed in rows, either by a vertical-type seed meters for spaced planting (1 seed of maize and 3–4 seeds of rice per hill) or a fluted roller-type seed meter for high density seeding (for wheat, mustard, jute, and lentil) in a single pass operation.

- CT = Land preparation for crop establishment was done by locally hired 2WT using 2 to 4 full rotary tillage passes in dry land followed by 1 to 2 leveling operations. The tillage depth of CT was 45–55 mm. The seed and fertilizers were hand broadcast prior to final soil tillage and leveling.

| Treatments | Grain Yield (Mg·ha−1) (n = 6) | |||

|---|---|---|---|---|

| Wheat (2013-14) | Wheat (2014-15) | Mustard (2014-15) | Lentil (2014-15) | |

| SP | 3.13 | 3.50 | 1.44a | 0.88a |

| CT | 2.95 | 3.34 | 1.27b | 0.74b |

| Level of significant | NS | NS | ** | ** |

| CV | 8.9 | 5.2 | 6.3 | 6.4 |

2.6.3. VSSD Contract Planted Fields

2.6.4. VSSD for Establishing Unpuddled Rice Seedling Transplanting

2.7. Data Collection

2.7.1. Data on Initial Field Trials of VSSD

2.7.2. Multi-Locational on-Farm Evaluation Trials

2.7.3. VSSD Contract Planted Fields

| Treatments | Grain Yield (Mg·ha−1) | ||||

|---|---|---|---|---|---|

| Wheat (2013-14) (n = 8) | Wheat (2014-15) (n = 10) | Mustard (2014-15) (n = 10) | Lentil (2014-15) (n = 10) | Unpuddled Rice (2015) (n = 5) | |

| SP | 3.31a | 3.73a | 1.30 | 0.89a | 5.02a |

| CT | 2.96b | 3.40b | 1.18 | 0.75b | 4.74b |

| Level of significant | ** | ** | NS | ** | * |

| CV | 6.5 | 5.3 | 13.7 | 12.7 | 3.8 |

2.8. Data Analysis

2.8.1. Initial Field Trials of VSSD

2.8.2. Multi-Locational on-Farm Evaluation Trials and Contracted VSSD Planting

3. Results and Discussion

3.1. Effective Field Capacity of VSSD for Seed Sowing

3.2. Fuel Consumption of VSSD

3.3. Performance of VSSD for Crop Establishment

3.4. On-Farm Multi-Locational Evaluation Trials of VSSD for Crop Cultivation

3.4.1. Wheat

3.4.2. Mustard

3.4.3. Lentil

3.5. Performance of VSSD in Contracted Farmers’ Fields

3.5.1. Wheat

3.5.2. Mustard

3.5.3. Lentil

3.5.4. Unpuddled (No-Till) Rice Seedling Transplanting

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mrema, G.C.; Baker, D.; Kahan, D. Agricultural Management Marketing and Finance Occasional Paper 22. Agricultural Mechanization in Sub-Saharan Africa: Time for a New Look; FAO: Rome, Italy, 2008; p. 56. [Google Scholar]

- Baker, C.J.; Saxton, K.E.; Ritchie, W.R. No-Tillage Seeding: Science and Practice; CAB International: Wallingford, UK, 1996; p. 258. [Google Scholar]

- Meisner, C.A. Report of an on-Farm Survey of the Greater Sylhet Region: Wheat Growers’ Practices, Perceptions, and Their Implications; Monograph No. 16; Bangladesh Agricultural Research Institute, Wheat Research Center: Nashipur, Bangladesh, 2001. [Google Scholar]

- Justice, S.E.; Haque, M.E.; Meisner, C.A.; Hossain, I.; Sah, G.; Tripathi, J.; Rashid, M.H. Giving South Asia farmers a choice: A single drill for reduced and strip till crops for 2-wheel tractors. In Proceedings of the 2004 CIGR International Conference, Beijing, China, 11–14 October 2004; Wang, Z., Gao, H., Eds.; China Agricultural Science And Technology Press: Beijing, China, 2004; pp. 230–237. [Google Scholar]

- Sims, B.; Kienzle, J. Mechanization of conservation agriculture for smallholders: Issues and options for sustainable intensification. Environments 2015, 2, 139–166. [Google Scholar] [CrossRef]

- Baudron, F.; Sims, B.; Justice, S.; Kahan, D.G.; Rose, R.; Mkomwa, M.; Kaumbutho, P.; Sariah, J.; Nazare, R.; Moges, G.; et al. Re-examining appropriate mechanization in Eastern and Southern Africa: Two-wheel tractors, conservation agriculture, and private sector involvement. Food Secur. 2015, 7, 889–904. [Google Scholar] [CrossRef]

- Haque, M.E.; Bell, R.W. Development of machinery for smallholders in South and South East Asia. In Presented in Workshop on Modern Conservation Farming Systems and CIMMYT Science Week, Lanzhou, China, 1–4 July 2015.

- Pagliai, M.; Vignozzi, N.; Pellegrini, S. Soil structure and the effect of management practices. Soil Tillage Res. 2004, 79, 131–143. [Google Scholar] [CrossRef]

- Hobbs, P.R. Conservation agriculture: What is it and why is it important for future sustainable food production? J. Agric. Sci. 2007, 145, 127–137. [Google Scholar] [CrossRef]

- Kassam, A. Overview of the current status of conservation agriculture globally and challenges with designing and adapting CA to the circumstances of the smallholders. In Proceedings of the Conference on Conservation Agriculture for Smallholders in Asia and Africa, Mymensingh, Bangladesh, 7–11 December 2014; Vance, W.H., Bell, R.W., Haque, M.E., Eds.; 2014; pp. 2–4, Published as e-Proceedings. Available online: http://researchrepository.murdoch.edu.au/26081/ (accessed on 17 November 2015). [Google Scholar]

- Haque, M.E.; Bell, R.W. Versatile strip tillage planter: An option for 2-wheel tractor-based smallholders’ conservation agriculture in Asia and Africa. In Proceedings of the 1st African Congress of Conservation Agriculture, Lusaka, Zambia, 18–21 March 2014; African Tillage Network, Ed.; African Conservation Tillage (ACT) Network, KARI: Nairobi, Keniya, 2014; pp. 216–219. [Google Scholar]

- Haque, M.E.; Rahman, S.N.; Bell, R.W. Smallholders’ minimum tillage planter adoption in Bangladesh: A successful case of private sector involvement for technology commercialization. In Proceedings of the 1st CIGR Inter-regional Conference on Land and Water; Challenges for Sustainable Development, Bari, Valenzano, Italy, 10–14 September 2013; Lamaddalena, N., Todorovic, M., Pereira, L.S., Eds.; CIHEAM-Institute of Agronomy Mediterranean Bari: Valenzano, Italy, 2013; pp. 68–69. [Google Scholar]

- Haque, M.E.; Bell, R.W.; Islam, A.K.M.S.; Sayre, K.; Hossain, M.M. Versatile multi-crop planter for two-wheel tractors: An innovative option for smallholders. In Proceedings of the 5th World Congress of Conservation Agriculture Incorporating 3rd Farming Systems Design Conference, Brisbane, Australia, 26–29 September 2011; Gilkes, R.J., Prakongkep, N., Eds.; pp. 102–103.

- Hunt, D. Farm Power and Machinery Management, Laboratory Manual and Work Book; Iowa State University Press: Ames, IA, USA, 1973. [Google Scholar]

- Food and Agriculture Organization of the United Nations; United Nations Development Programme. Land Resources Appraisal of Bangladesh for Agricultural Development; Report to: Agro Ecological Regions of Bangladesh; Food and Agriculture Organization of the United Nations, Via delle Terme di Caracarla: Rome, Italy, 1988. [Google Scholar]

- Salahin, N.; Jahiruddin, M.; Islam, M.R.; Bell, R.W.; Haque, M.E.; Alam, M.K. Effects of minimum tillage practices and crop residue retention on soil properties and crop yields under a rice-based cropping system. In Proceedings of the Conference on Conservation Agriculture for Smallholders in Asia and Africa, Bangladesh Agricultural University, Mymensingh, Bangladesh, 7–11 December 2014; Vance, W.H., Bell, R.W., Haque, M.E., Eds.; Published as e-Proceedings. pp. 133–134. Available online: http://researchrepository.murdoch.edu.au/26081/ (accessed on 17 November 2015).

- Anonymous. About the District, West Singhbhum. 2015. Available online: http://chaibasa.nic.in/Aboutthedist.html (accessed on 18 November 2015).

- Haque, M.E.; Bell, R.W.; Islam, M.A.; Rahman, M.A. Minimum tillage unpuddled transplanting: An alternative crop establishment strategy for rice in conservation agriculture cropping systems. Field Crop. Res. 2016, 185, 31–39. [Google Scholar] [CrossRef]

- Islam, A.K.M.S.; Hossain, M.M.; Saleque, M.A.; Rahman, M.A.; Karmakar, B.; Haque, M.E. Effect of minimum tillage on soil properties, crop growth and yield of Aman rice in drought prone Northwest Bangladesh. Bangladesh Agron. J. 2012, 15, 43–51. [Google Scholar]

- So, H.B.; Kirchhof, G.; Bakker, R.; Smith, G.D. Low input tillage/cropping systems for limited resource areas. Soil Tillage Res. 2001, 61, 109–123. [Google Scholar] [CrossRef]

- Roy, K.C.; Haque, M.E.; Justice, S.E.; Hossain, M.I.; Meisner, C.A. Development of Tillage Machinery for Conservation Agriculture in Bangladesh. Agric. Mech. Asia Africa Lat. Am. 2009, 40, 58–64. [Google Scholar]

- Johansen, C.J.; Haque, M.E.; Bell, R.W.; Thierfelder, C.; Esdaile, R.J. Conservation agriculture for small holder rainfed farming: Opportunities and constraints of new mechanized seeding systems. Field Crop. Res. 2012, 132, 18–32. [Google Scholar] [CrossRef]

- Miah, M.M.A.; Haque, M.E.; Baksh, M.; Hossain, M.I. Economic analysis of power tiller operated seeder operation at farm level. J. Agric. Eng. 2010, 38, 19–24. [Google Scholar]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haque, M.E.; Bell, R.W.; Kassam, A.; Mia, M.N.N. Versatile Strip Seed Drill: A 2-Wheel Tractor-Based Option for Smallholders to Implement Conservation Agriculture in Asia and Africa. Environments 2016, 3, 1. https://doi.org/10.3390/environments3010001

Haque ME, Bell RW, Kassam A, Mia MNN. Versatile Strip Seed Drill: A 2-Wheel Tractor-Based Option for Smallholders to Implement Conservation Agriculture in Asia and Africa. Environments. 2016; 3(1):1. https://doi.org/10.3390/environments3010001

Chicago/Turabian StyleHaque, Md. Enamul, Richard W. Bell, Amir Kassam, and Md. Nur Nobi Mia. 2016. "Versatile Strip Seed Drill: A 2-Wheel Tractor-Based Option for Smallholders to Implement Conservation Agriculture in Asia and Africa" Environments 3, no. 1: 1. https://doi.org/10.3390/environments3010001