3D Printing of Polyamide to Fabricate a Non-Metal Clasp Removable Partial Denture via Fused Filament Fabrication: A Case Report

Abstract

:1. Introduction

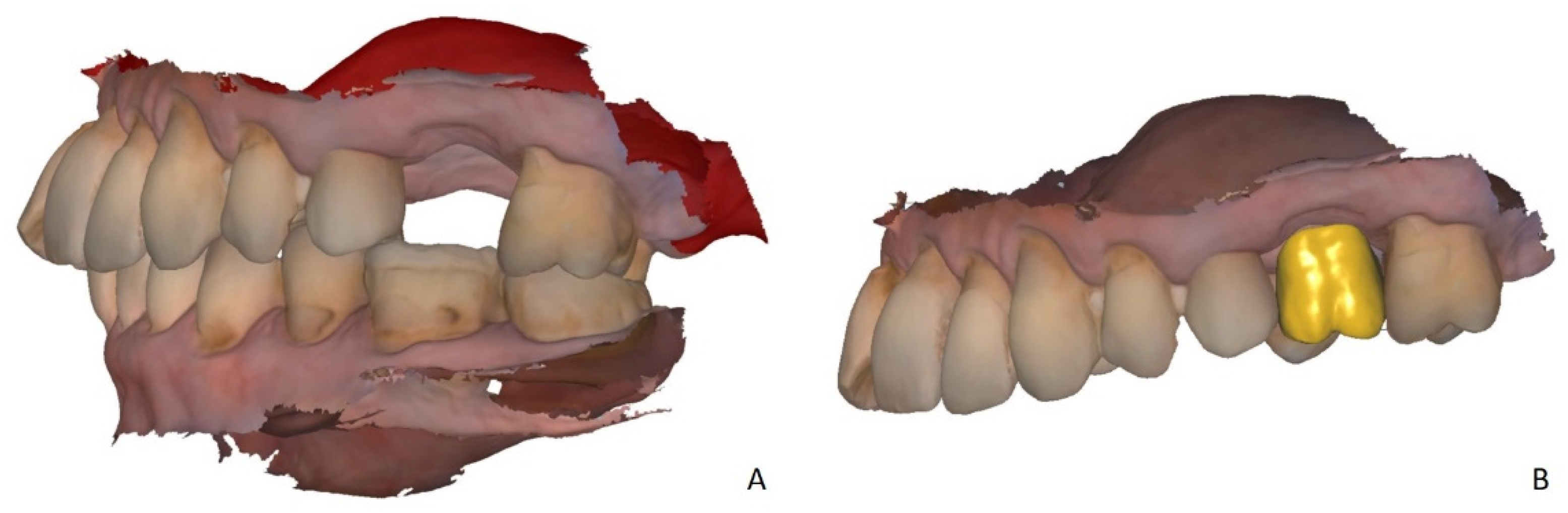

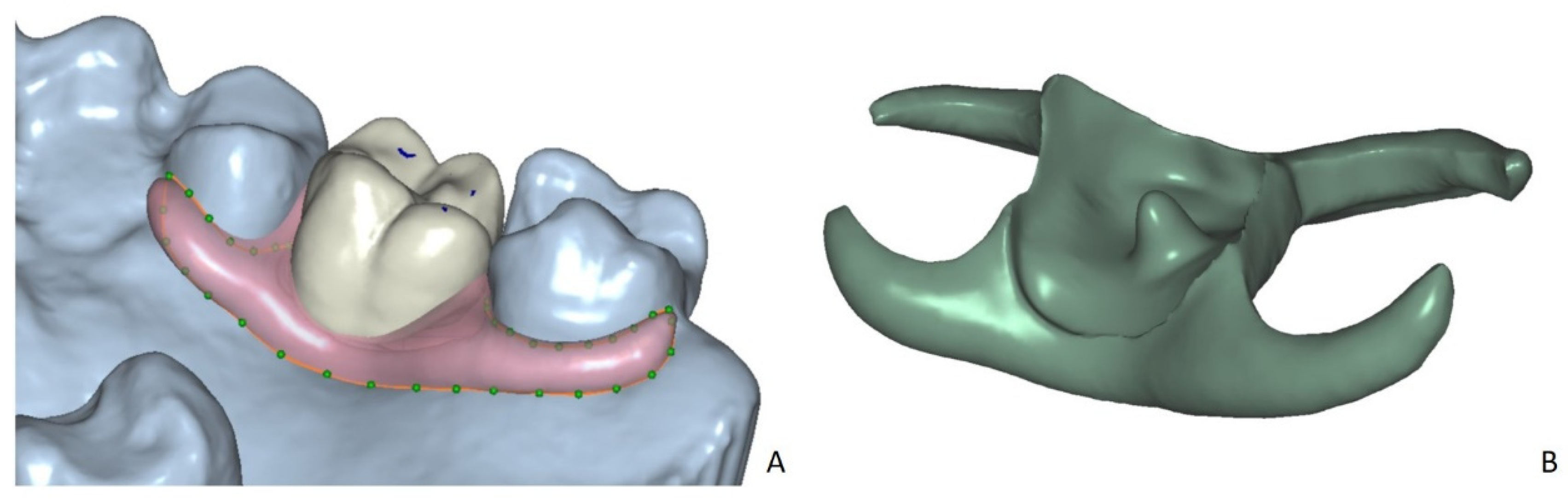

2. Case Report

3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Campbell, S.D.; Cooper, L.; Craddock, H.; Hyde, T.P.; Nattress, B.; Pavitt, S.H.; Seymour, D.W. Removable Partial dentures: The clinical need for innovation. J. Prosthet. Dent. 2017, 118, 273–280. [Google Scholar] [CrossRef] [Green Version]

- Jones, J.D.; Turkyilmaz, I.; Garcia, L.T. Removable partial dentures—Treatment now and for the future. Tex. Dent. J. 2010, 127, 365–372. [Google Scholar] [PubMed]

- Fueki, K.; Ohkubo, C.; Yatabe, M.; Arakawa, I.; Arita, M.; Ino, S.; Kanamori, T.; Kawai, Y.; Kawara, M.; Komiyama, O.; et al. Clinical application of removable partial dentures using thermoplastic resin-part I: Definition and indication of non-metal clasp dentures. J. Prosthodont. Res. 2014, 58, 3–10. [Google Scholar] [CrossRef] [Green Version]

- Fueki, K.; Ohkubo, C.; Yatabe, M.; Arakawa, I.; Arita, M.; Ino, S.; Kanamori, T.; Kawai, Y.; Kawara, M.; Komiyama, O.; et al. Clinical application of removable partial dentures using thermoplastic resin. Part II: Material properties and clinical features of non-metal clasp dentures. J. Prosthodont. Res. 2014, 58, 71–84. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Soygun, K.; Bolayir, G.; Boztug, A. Mechanical and thermal properties of polyamide versus reinforced PMMA denture base materials. J. Adv. Prosthodont. 2013, 5, 153–160. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, S.Y.; Kim, K.S.; Lee, J.Y.; Shin, S.W. Physical properties and color stability of injection-molded thermoplastic denture base resins. J. Adv. Prosthodont. 2019, 11, 32–40. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stafford, G.D.; Huggett, R.; MacGregor, A.R.; Graham, J. The use of nylon as a denture-base material. J. Dent. 1986, 14, 18–22. [Google Scholar] [CrossRef]

- Matthews, E.; Smith, D.C. Nylon as a denture base material. Br. Dent. J. 1955, 98, 231–237. [Google Scholar]

- Tribst, J.P.M.; Dal Piva, A.M.O.; Borges, A.L.S.; Araújo, R.M.; da Silva, J.M.F.; Bottino, M.A.; Kleverlaan, C.J.; de Jager, N. Effect of different materials and undercut on the removal force and stress distribution in circumferential clasps during direct retainer action in removable partial dentures. Dent. Mater. 2020, 36, 179–186. [Google Scholar] [CrossRef]

- Virard, F.; Venet, L.; Richert, R.; Pfeffer, D.; Viguié, G.; Bienfait, A.; Farges, J.C.; Ducret, M. Manufacturing of an immediate removable partial denture with an intraoral scanner and CAD-CAM technology: A case report. BMC Oral Health 2018, 18, 120. [Google Scholar] [CrossRef]

- Unkovskiy, A.; Wahl, E.; Zander, A.T.; Huettig, F.; Spintzyk, S. Intraoral scanning to fabricate complete dentures with functional borders: A proof-of-concept case report. BMC Oral Health 2019, 19, 46. [Google Scholar] [CrossRef] [Green Version]

- Hamanaka, I.; Isshi, K.; Takahashi, Y. Fabrication of a non-metal clasp denture supported by an intraoral scanner and CAD-CAM. J. Prosthet. Dent. 2018, 120, 9–12. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, Y.; Hamanaka, I.; Isshi, K. CAD/CAM-Fabricated Nonmetal Clasp Denture: In Vitro Pilot Study. Int. J. Prosthodont. 2017, 30, 277–279. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Lee, D.; Young Lee, S.; Yang, H.; Park, S.W.; Lim, H.P.; Yun, K.D.; Park, C. Denture flask fabrication using fused deposition modeling three-dimensional printing. J. Prosthodont. Res. 2020, 64, 231–234. [Google Scholar] [CrossRef] [PubMed]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khorsandi, D.; Fahimipour, A.; Abasian, P.; Saber, S.S.; Seyedi, M.; Ghanavati, S.; Ahmad, A.; De Stephanis, A.A.; Taghavinezhaddilami, F.; Leonova, A.; et al. 3D and 4D printing in dentistry and maxillofacial surgery: Printing techniques, materials, and applications. Acta Biomater. 2021, 122, 26–49. [Google Scholar] [CrossRef]

- Cuan-Urquizo, E.; Barocio, E.; Tejada-Ortigoza, V.; Pipes, R.B.; Rodriguez, C.A.; Roman-Flores, A. Characterization of the Mechanical Properties of FFF Structures and Materials: A Review on the Experimental, Computational and Theoretical Approaches. Materials 2019, 12, 895. [Google Scholar] [CrossRef] [Green Version]

- Abdullah, A.M.; Rahim, T.; Hamad, W.; Mohamad, D.; Akil, H.M.; Rajion, Z.A. Mechanical and cytotoxicity properties of hybrid ceramics filled polyamide 12 filament feedstock for craniofacial bone reconstruction via fused deposition modelling. Dent. Mater. 2018, 34, e309–e316. [Google Scholar] [CrossRef]

- Kashapov, R.; Korobkina, A.; Platonov, E.; Saleeva, G. The method of manufacture of nylon dental partially removable prosthesis using additive technologies. IOP. Conf. Ser. Mater. Sci. Eng. 2014, 69. [Google Scholar] [CrossRef] [Green Version]

- Marchan, S.; Bishop, A.K.; Smith, W.; Seerattan, P.; Hinds, D. A Comparative Assessment of the Surface Roughness of Thermoplastic Denture Base Resins Following Adjustment and Re-Polishing. Open J. Stomatol. 2017, 7, 250–263. [Google Scholar] [CrossRef] [Green Version]

- Kraemer Fernandez, P.; Unkovskiy, A.; Benkendorff, V.; Klink, A.; Spintzyk, S. Surface Characteristics of Milled and 3D Printed Denture Base Materials Following Polishing and Coating: An In-Vitro Study. Materials 2020, 13, 3305. [Google Scholar] [CrossRef] [PubMed]

- Petropolis, C.; Kozan, D.; Sigurdson, L. Accuracy of medical models made by consumer-grade fused deposition modelling printers. Plast. Surg. 2015, 23, 91–94. [Google Scholar] [CrossRef] [Green Version]

- Li, R.; Yuan, S.; Zhang, W.; Zheng, H.; Zhu, W.; Li, B.; Zhou, M.; Wing-Keung Law, A.; Zhou, K. 3D Printing of Mixed Matrix Films Based on Metal-Organic Frameworks and Thermoplastic Polyamide 12 by Selective Laser Sintering for Water Applications. ACS. Appl. Mater. Interfaces 2019, 11, 40564–40574. [Google Scholar] [CrossRef]

- Wieckiewicz, M.; Opitz, V.; Richter, G.; Boening, K.W. Physical properties of polyamide-12 versus PMMA denture base material. Biomed. Res. Int. 2014, 2014, 150298. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ucar, Y.; Akova, T.; Aysan, I. Mechanical properties of polyamide versus different PMMA denture base materials. J. Prosthodont. 2012, 21, 173–176. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spintzyk, S.; Schmunk, R.; Kraemer Fernandez, P.; Huettig, F.; Unkovskiy, A. 3D Printing of Polyamide to Fabricate a Non-Metal Clasp Removable Partial Denture via Fused Filament Fabrication: A Case Report. Int. J. Environ. Res. Public Health 2021, 18, 8241. https://doi.org/10.3390/ijerph18168241

Spintzyk S, Schmunk R, Kraemer Fernandez P, Huettig F, Unkovskiy A. 3D Printing of Polyamide to Fabricate a Non-Metal Clasp Removable Partial Denture via Fused Filament Fabrication: A Case Report. International Journal of Environmental Research and Public Health. 2021; 18(16):8241. https://doi.org/10.3390/ijerph18168241

Chicago/Turabian StyleSpintzyk, Sebastian, Roman Schmunk, Pablo Kraemer Fernandez, Fabian Huettig, and Alexey Unkovskiy. 2021. "3D Printing of Polyamide to Fabricate a Non-Metal Clasp Removable Partial Denture via Fused Filament Fabrication: A Case Report" International Journal of Environmental Research and Public Health 18, no. 16: 8241. https://doi.org/10.3390/ijerph18168241

APA StyleSpintzyk, S., Schmunk, R., Kraemer Fernandez, P., Huettig, F., & Unkovskiy, A. (2021). 3D Printing of Polyamide to Fabricate a Non-Metal Clasp Removable Partial Denture via Fused Filament Fabrication: A Case Report. International Journal of Environmental Research and Public Health, 18(16), 8241. https://doi.org/10.3390/ijerph18168241