A New Thermal-Solar Field Configuration: The Rotatory Fresnel Collector or Sundial

Abstract

:1. Introduction

1.1. Solar Thermal Power Plant Structure Literature Review

- The concentrator, or mirror field: Rays from the sun are reflected onto a focal zone; in the focal zone, radiation reaches much higher intensities than the maximum value of the direct solar radiation, which will be around 1 kW/m2 in very good atmospheric conditions [1]. The named “concentration factor” is the value that characterizes the optical performance of the concentrator. There are several concentrator morphologies, which can achieve different values of radiation concentration. A piece of advice stemming from exergy analysis points out that the concentration factor should be as low as required for producing the thermal map desired in the receiver [25,26]. In this sense, Fresnel or trough collectors with small aperture systems can achieve concentration features that are enough for some applications [27]. In some systems curved and modified shapes are sufficient to reach adequate concentration/temperatures [28]. Photovoltaics gives another point of view, i.e., that the use of azimuthal tracking systems [29] can create new possibilities for solar thermal tracking systems, hence resulting in new concentrator possibilities.

- The receiver is a tube or a bundle of tubes that can have very different geometries, where a high fraction of the concentrated radiation is captured and transformed into thermal energy and is used by the heat carrier fluid that flows inside the tube or tubes to increase its enthalpy. The size of the receiver and its shape, as well as the flow pattern in its tubes, are critical elements of the design (to reduce thermal losses, above all) [30]. The suitable material temperature is the main restrictive factor of the receiver’s performance. It is worth noting that operating temperature increases thermal losses from the receiver. This is another limiting effect [31].

- Heat carrier fluid piping: the usual solar thermal power plant is very large, because of the low intensity of the solar resource, which conveys very long pipes for connecting all the systems [32]. Pressure drops along circuit pipes can reach very high values, which involves very high values of pumping power (which eventually can become even higher than the plant’s electric power, creating a curious problem) [33].

- Thermal energy storage (TES) is another relevant system but is not mandatory at all. It can contribute to attaining the best results from these plants [34]. There is a large variety of configurations and materials for building these systems [35], but molten salts seem to be the most suitable for current investments, although they present important disadvantages, such as the risk of solidifying at relatively high temperatures. It goes without saying that charging and discharging the storage implies some loss of thermal energy, as well as a decrease in temperature.

- Block of power (BOP): The heat carrier fluid piping drives the main part of the collected thermal energy to the BOP, where it is delivered to a thermodynamic cycle [36]. The most popular one nowadays is the standard steam Rankine cycle, although some proposals have been made to use the Joule–Brayton cycle [37] or the hybrid Rankine–Brayton cycle [38]. It is also worth remembering that the cycle efficiency increases with the temperature of the hot focus (which is the hottest flow of the heat carrier fluid) [39].

- -

- Safety;

- -

- Low cost of electricity;

- -

- Operational reliability;

- -

- Generation flexibility and regulation.

- -

- Robustness, avoiding weak parts.

- -

- Reduced weight. This is likely the main route to a low cost. Note that a standard 50-MW solar plant with trough collectors and a small solar multiple [19] (about 1.1) has more than 5000 tons of steel, 4000 tons of glass, and 13,000 tons of concrete [15,16]. Some innovative proposals suggest using epoxy resins instead of steel and substituting aluminum foils for glass mirrors, although reflectivity is poorer in this case. Of course, some alternatives present a higher potential for reducing weight. In this context, it is worth noting that PV costs have undergone an important decline in the last decade, due to weight reductions. In poly-c Si cells, grams per watt have decreased from 10 to less than four [42]. The change has been even more dramatic in CdTe thin films, with a negligible weight (as compared to the production cost) and a final cell cost of 1 USD/W (from more than 5 USD/W 5 years ago) [43].

- -

- Higher efficiency in thermal-to-electric power conversion, which implies going to a higher T in the BOP, as well as in the final section of the solar field [44].

- -

- Reduced water consumption. Solar radiation reaches its highest values in very dry places, where water is very expensive or does not exist at all. Note that in very hot places with air temperatures over 40 °C and relative humidity below 25%, cooling with an evaporative tower can consume 1 kg of water per kWh, which is something that is absolutely out of scope. Dry cooling methods must be considered, which is also a promising line of research [45].

- -

- Simplified operation and maintenance, particularly in relation to cleaning. Reflectivity decreases a lot with dirtiness and lower transparency values. Efficient cleaning methods are necessary, and they depend greatly on the geometry of the mirrors and the receiver. This fact also affects water consumption, which must be minimized. Dirtiness can become the worst enemy of concentrating solar power [46].

1.2. The Chosen Structure for the Solar Field: Linear Fresnel Reflector

- -

- General solar field layout (Section 2).

- -

- Detailed analysis of the concentration by means of curved mirrors (Section 3).

- -

- Application of new solar field layout and concentration by means of curved mirrors in the Sundial system (Section 4).

- -

- Economic analysis (Section 5).

- -

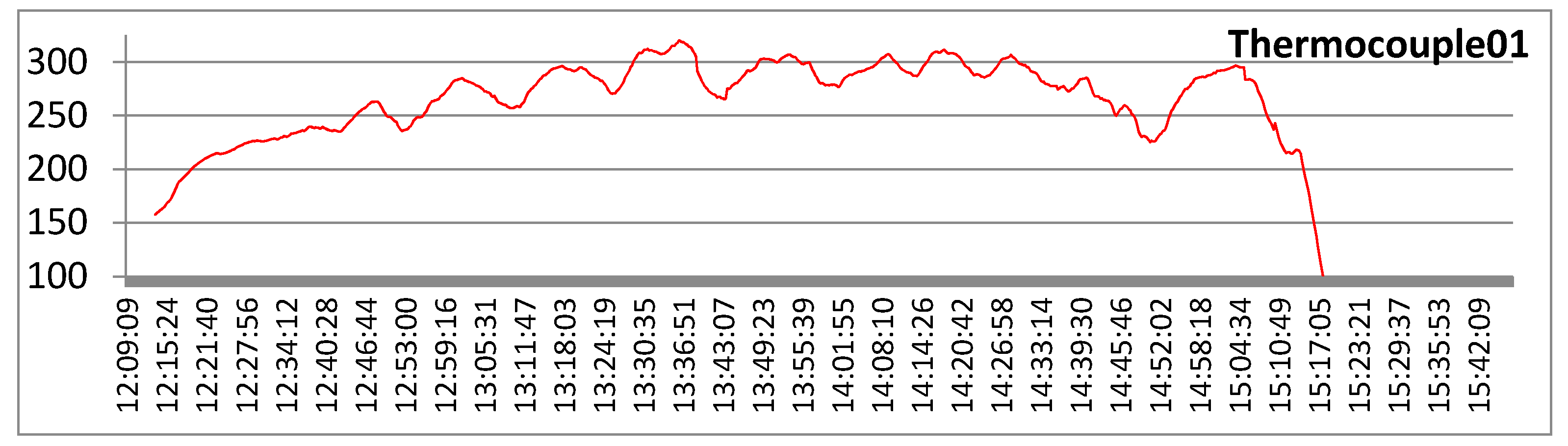

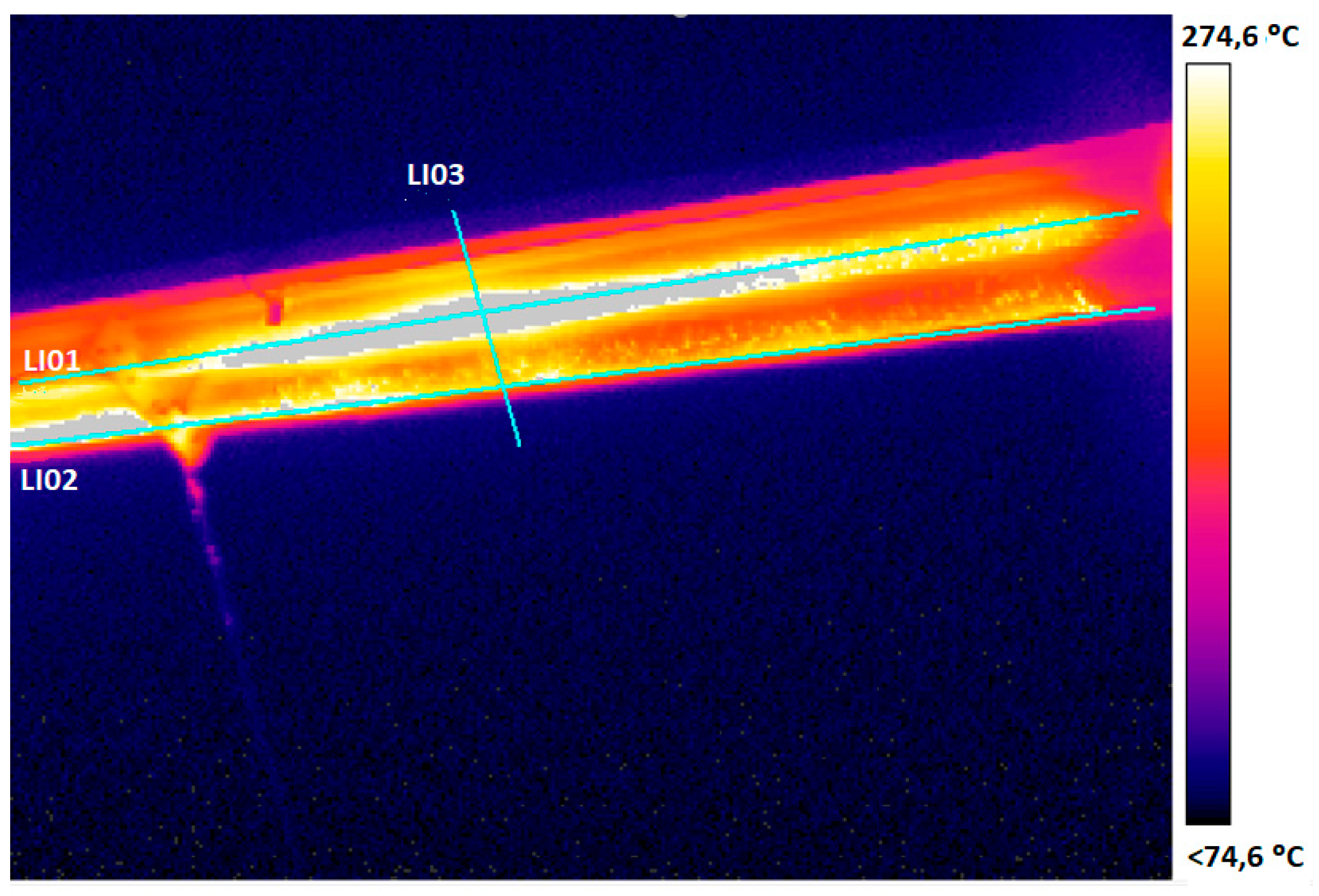

- Experimental results (Section 6).

- -

- Conclusions and work in process (prototype in Tecnogetafe [21]).

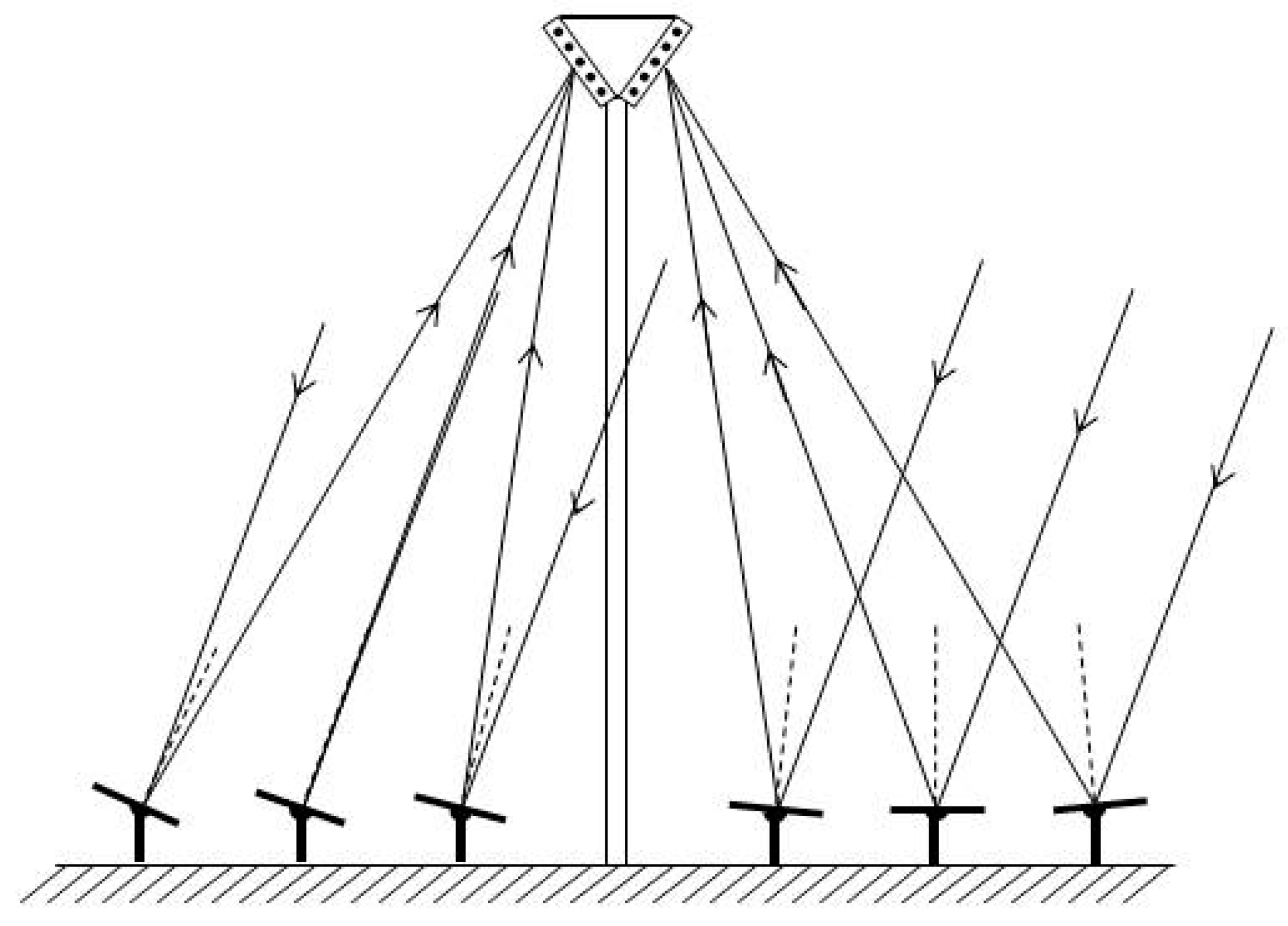

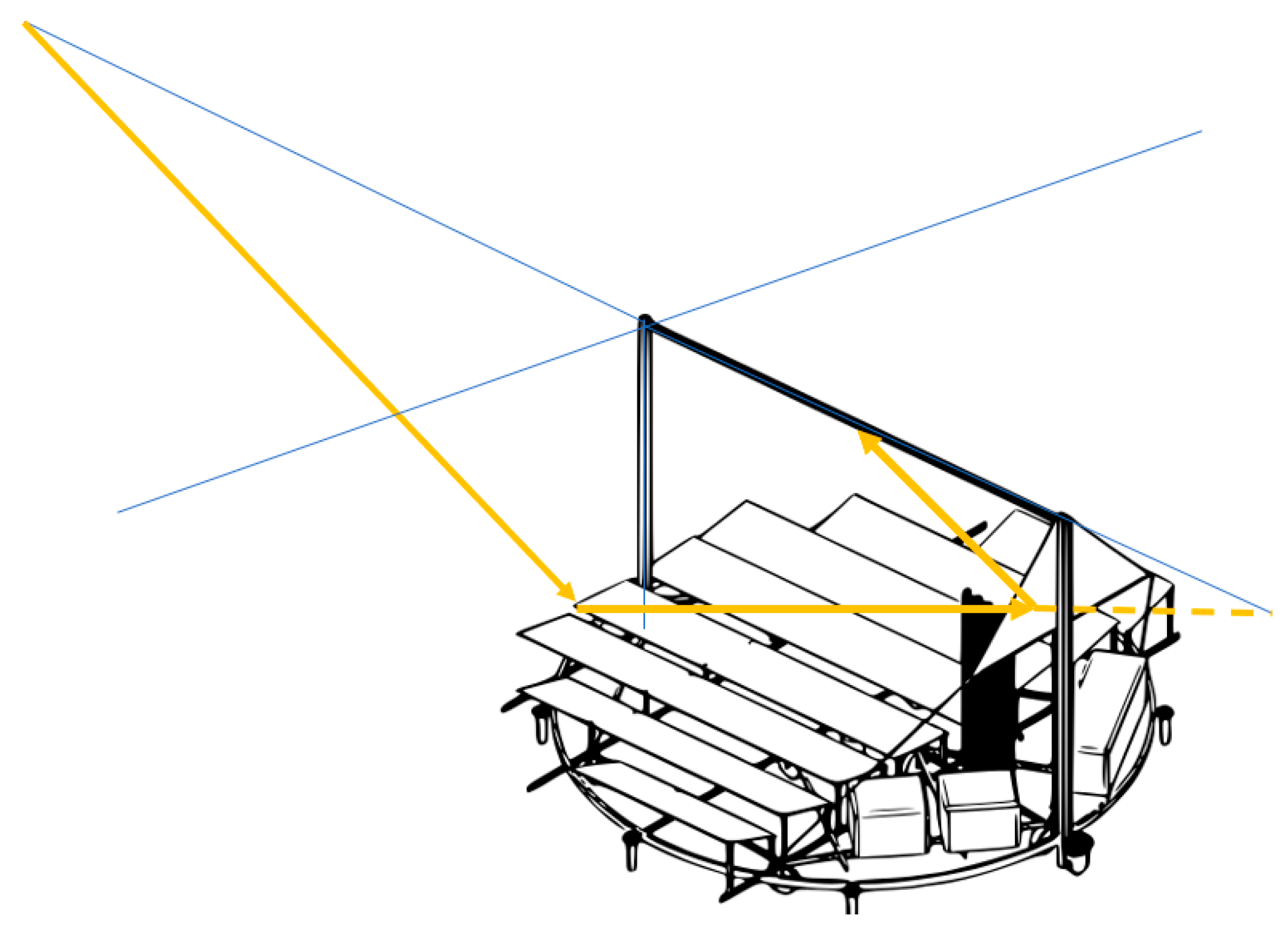

2. A New Concept of a Solar Field. The Rotatory Fresnel Collector or Sundial

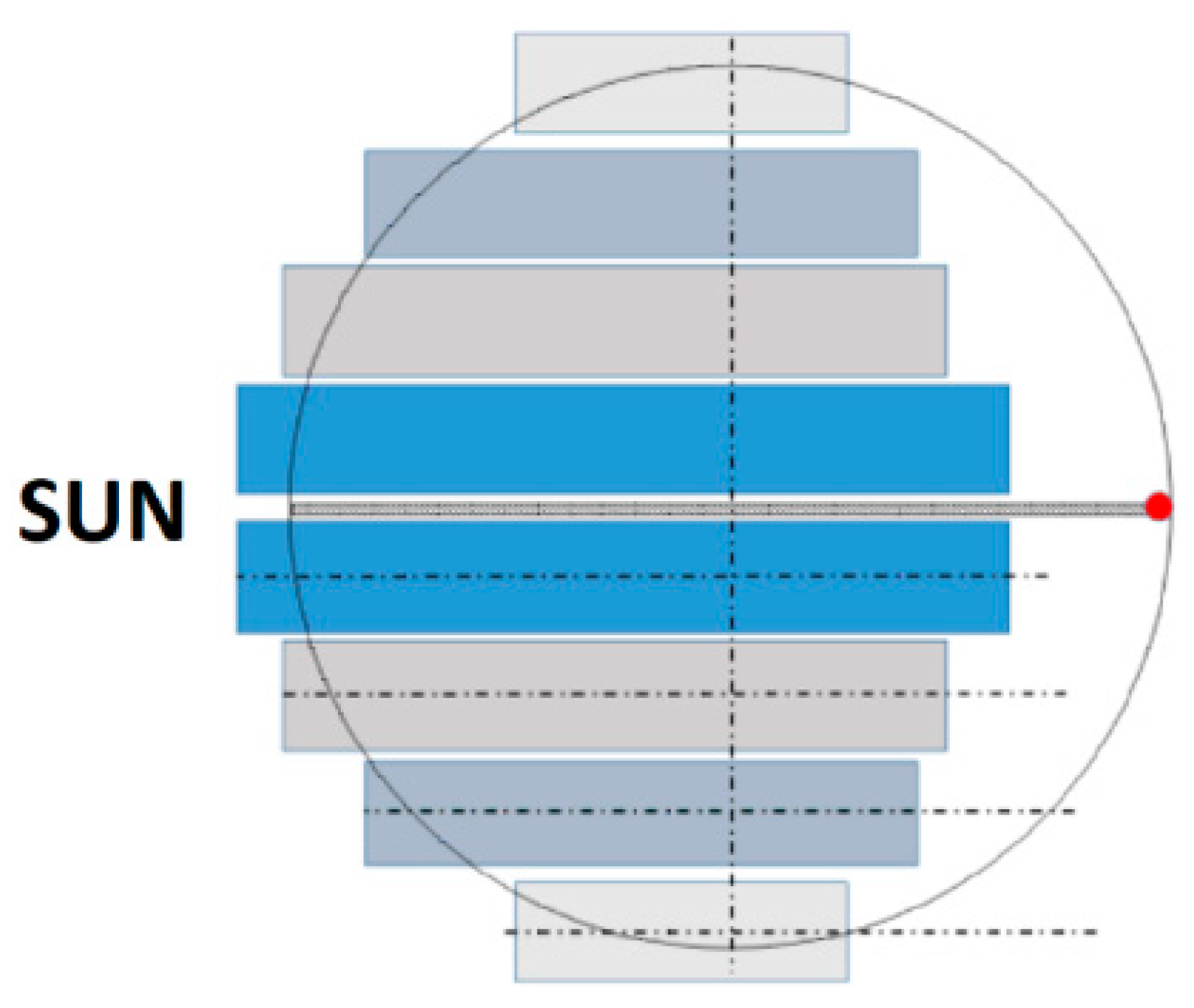

2.1. The New Concept

- -

- The absorber position corresponds to the intersection of the narrow bundle of mirror focal lines.

- -

- Considering the platform as the reference system means that the only change will be the zenithal angle of the sun, which will always be in the symmetry plane.

- -

- The incidence longitudinal angle has to be taken into account because it produces end losses in the opposite side to that of the sun’s position. Those losses can be reduced by tilting the mirrors towards the sun, but this is not sufficient for avoiding those losses. It is necessary to include some vertical mirrors close to the back end of the symmetry plane.

2.2. Coherent Integration of Elements to Oobtain an Optimum Configuration

- -

- The platform size does not have strict limitations, other than the tilting angle.

- -

- A trade-off is needed between the benefits of tilting the mirrors and increasing the platform size in order to obtain the optimum configuration.

- -

- A conical configuration would ensure that the vertical axis is kept fixed.

- -

- However, the accuracy required for the sun tracking is attained with commercial wheels for scaffoldings and other industrial applications. Those wheels (40 cm in diameter) withstand 500 kg with a width narrower than 20 cm, which means that the pressure on the wheel trail can exceed 50 N/cm2, and a suitably resistant round track is needed to that end.

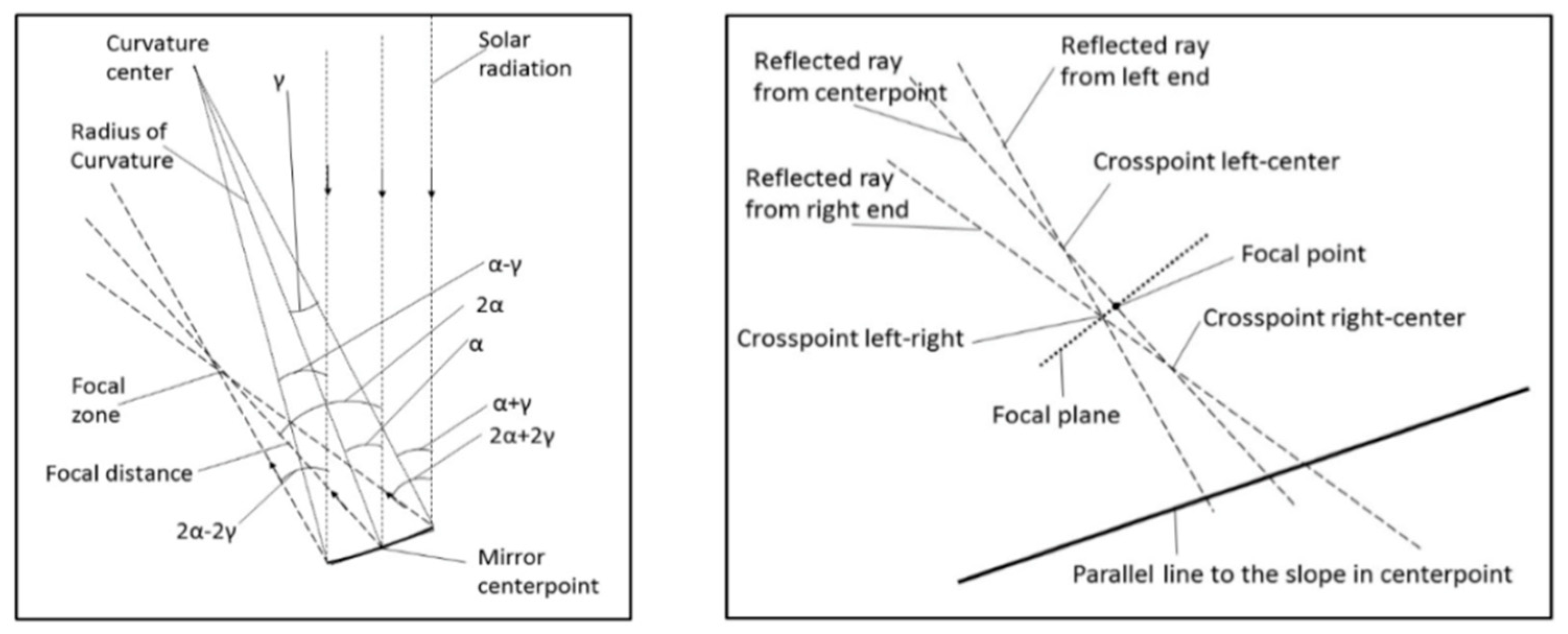

3. Solar Concentration Capacity with Flat Mirrors

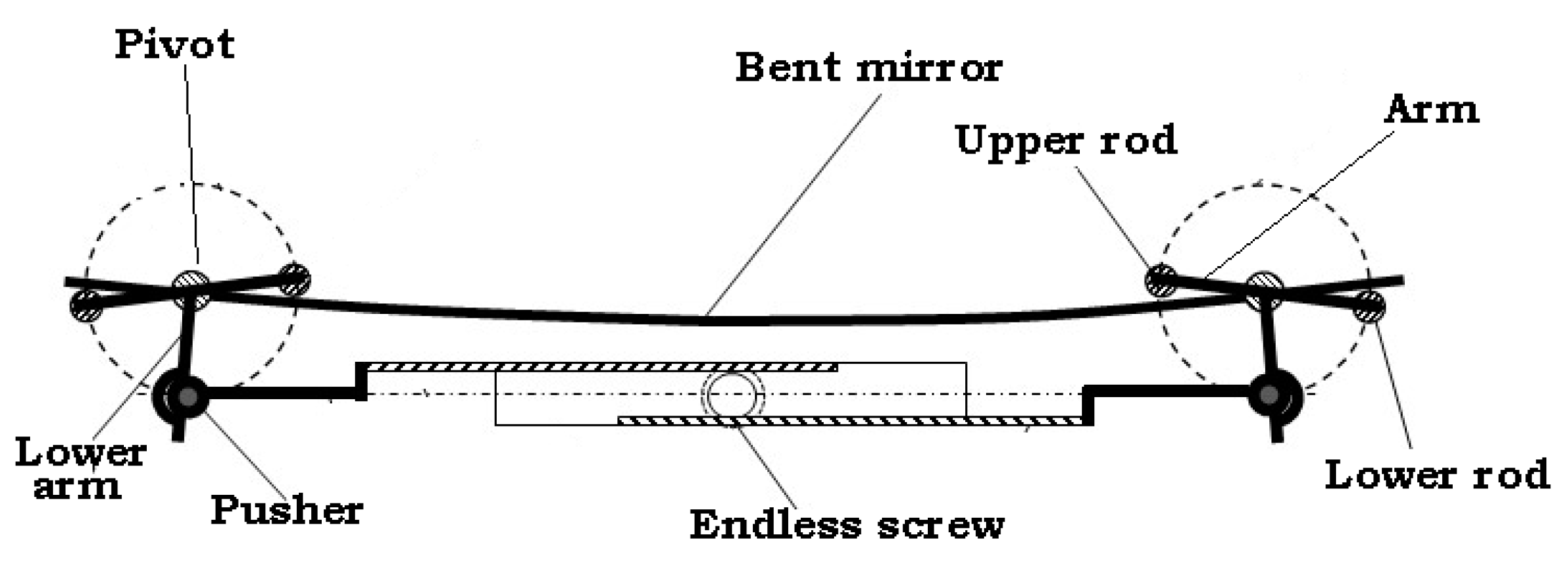

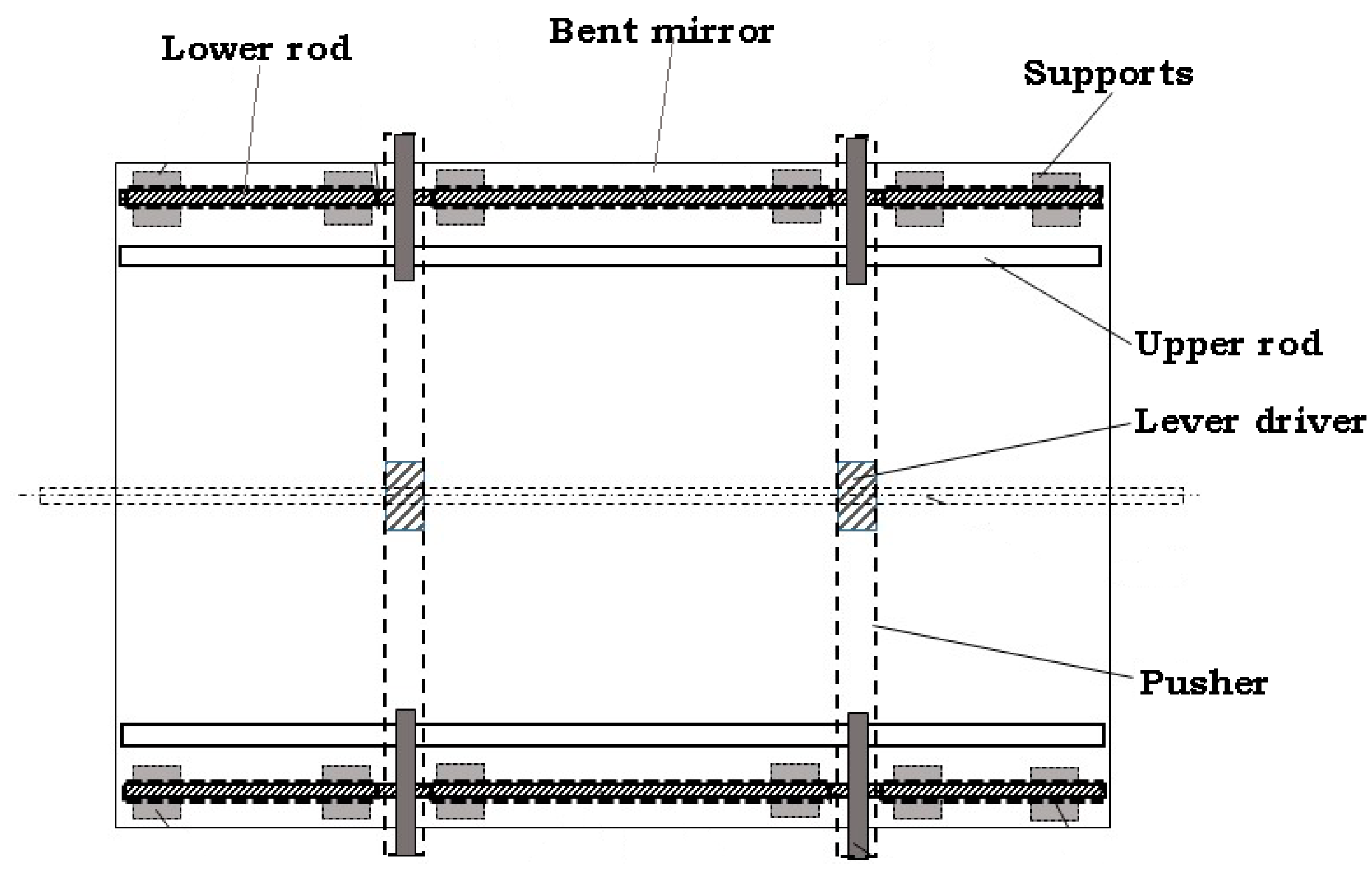

3.1. Bending Flat Mirrors

- -

- -

- There are two rods, one at each side, above and below the glass of the mirror; they are rotated until reaching the slope predicted by the former analysis. Both rods are pushed by a radial arm turning around a pivot. Once the mirror has obtained its corrected curved shape, the pusher is kept fixed.

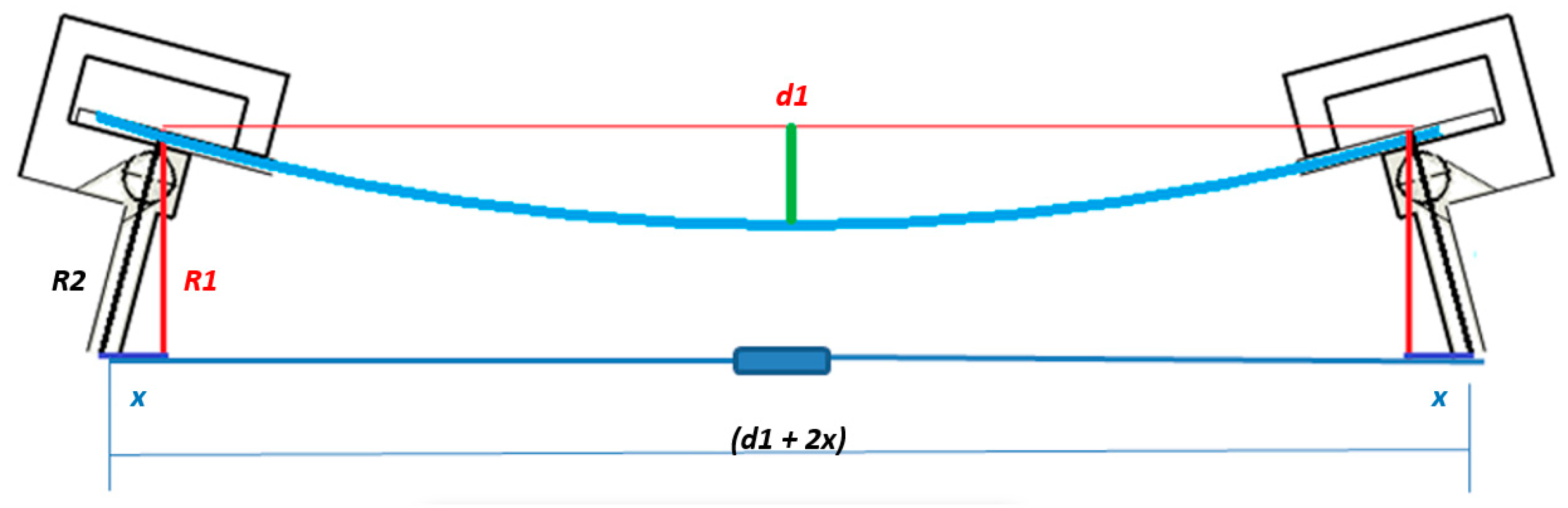

3.1.1. Transversal Deformation

3.1.2. Radius of Curvature

3.1.3. Longitudinal Deformation

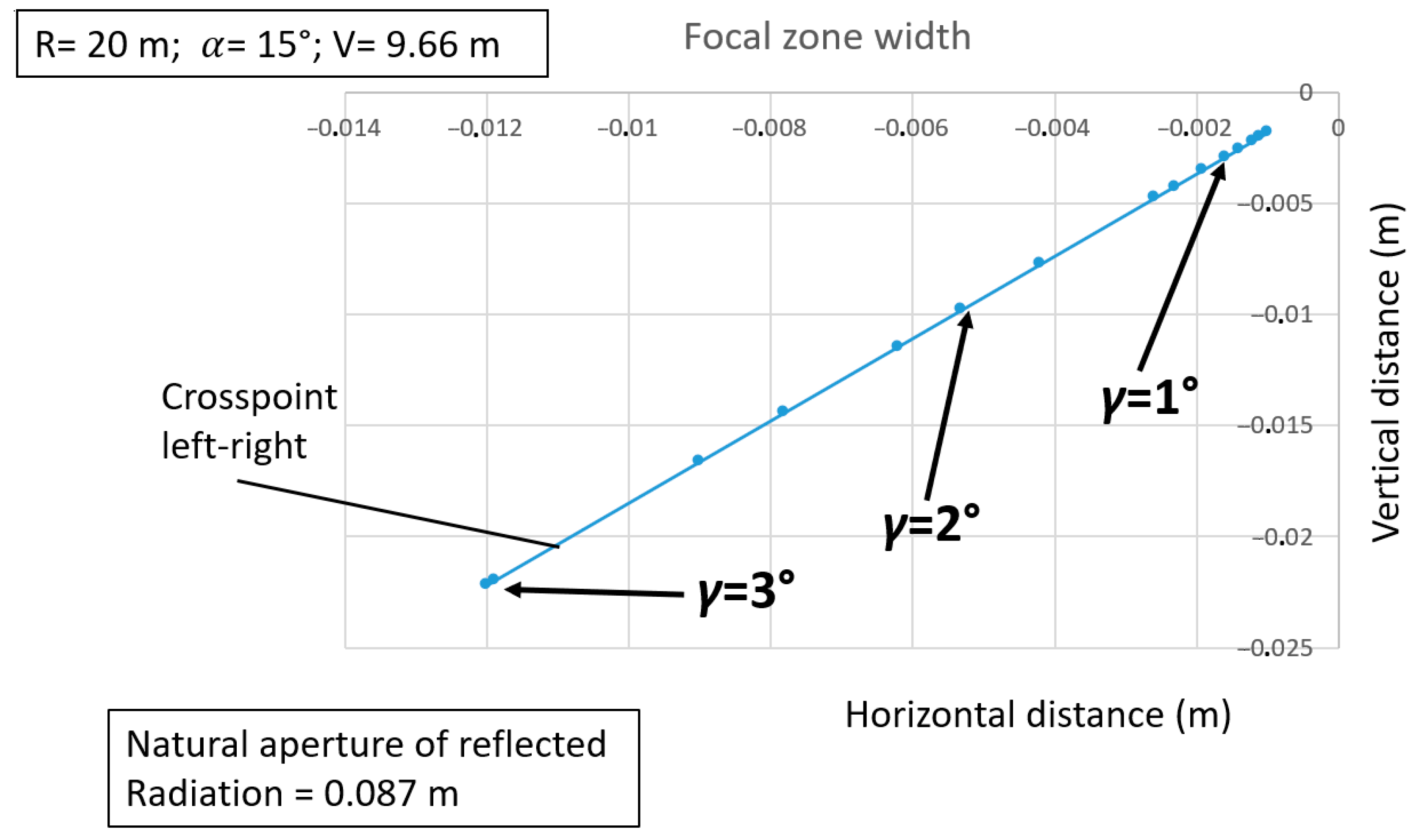

3.2. Concentration with Flat Bent Mirrors

4. Application Example: Sundial

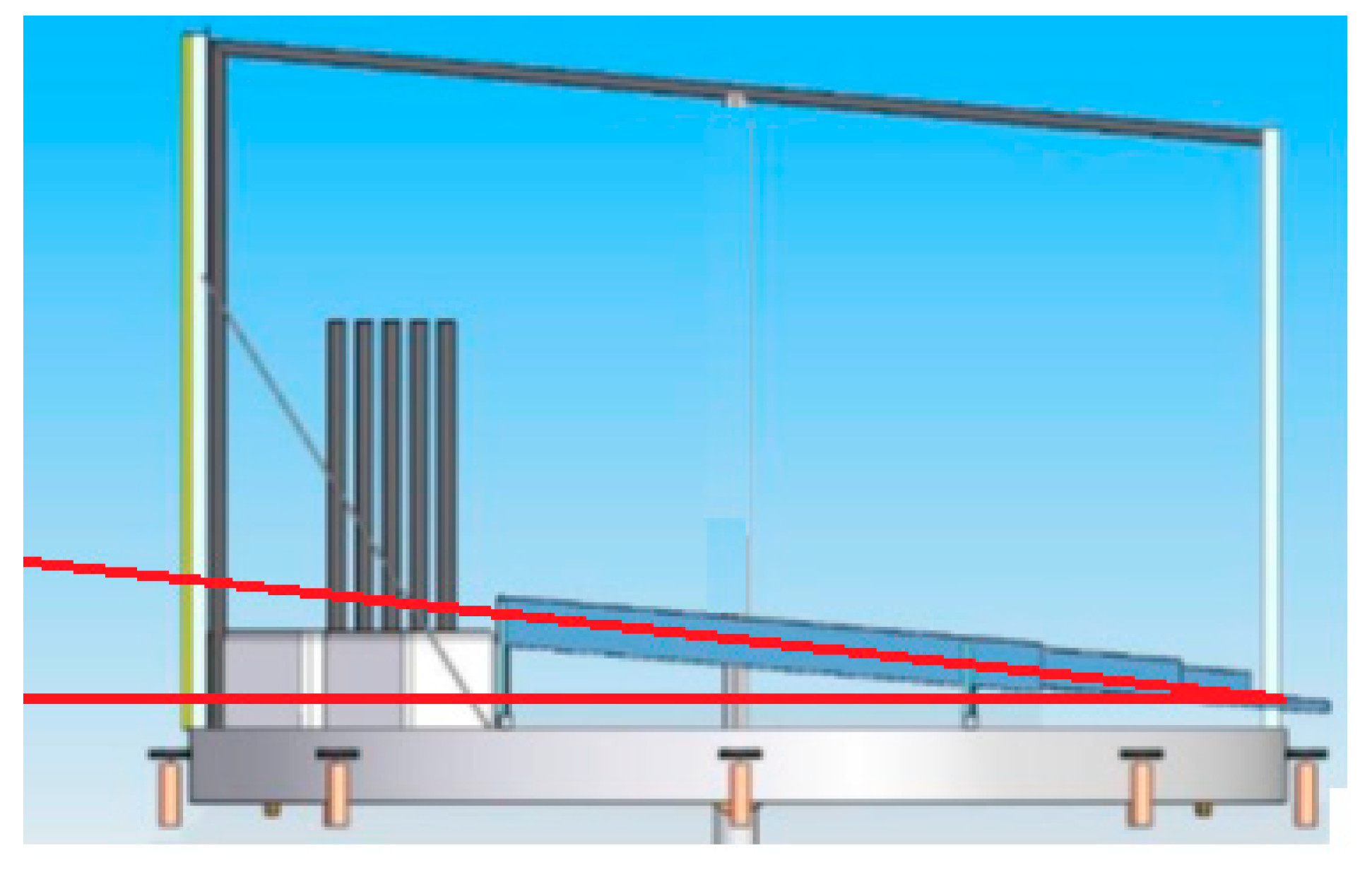

4.1. Solar Field Layout

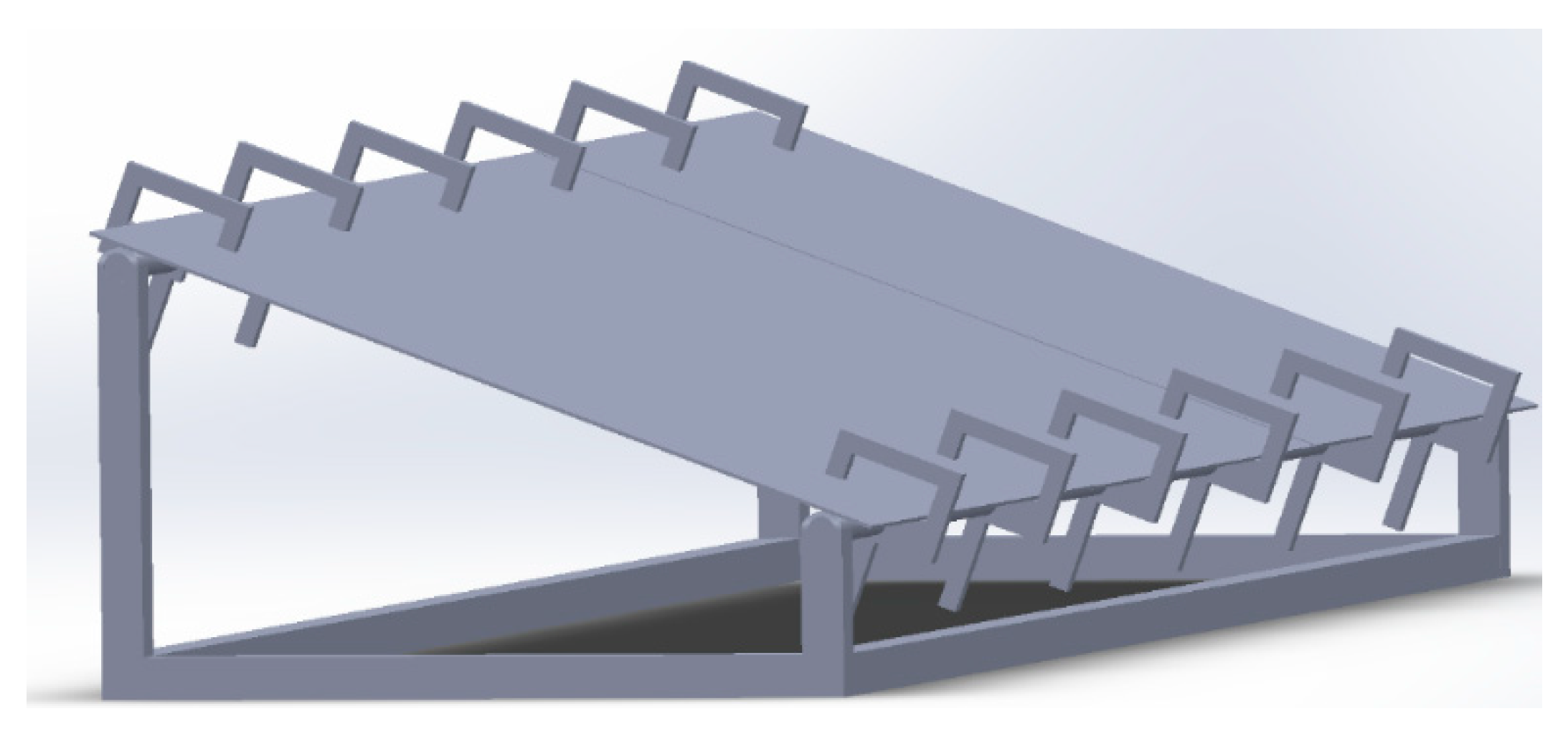

4.2. Mirror Support Structure

4.3. Mirror Bending System—Model Design

4.4. End Losses Solution

5. RFC Component Description and Costs

- Industrial materials and components (high level of maturity and low prices);

- Avoiding complex assemblies and very specialized operations;

- Reducing the required weight of the main materials.

5.1. Platform Base and Traction System Cost

5.2. Mechanical Parts Except Base and Traction System

5.3. Comparison with Common Parabolic Trough

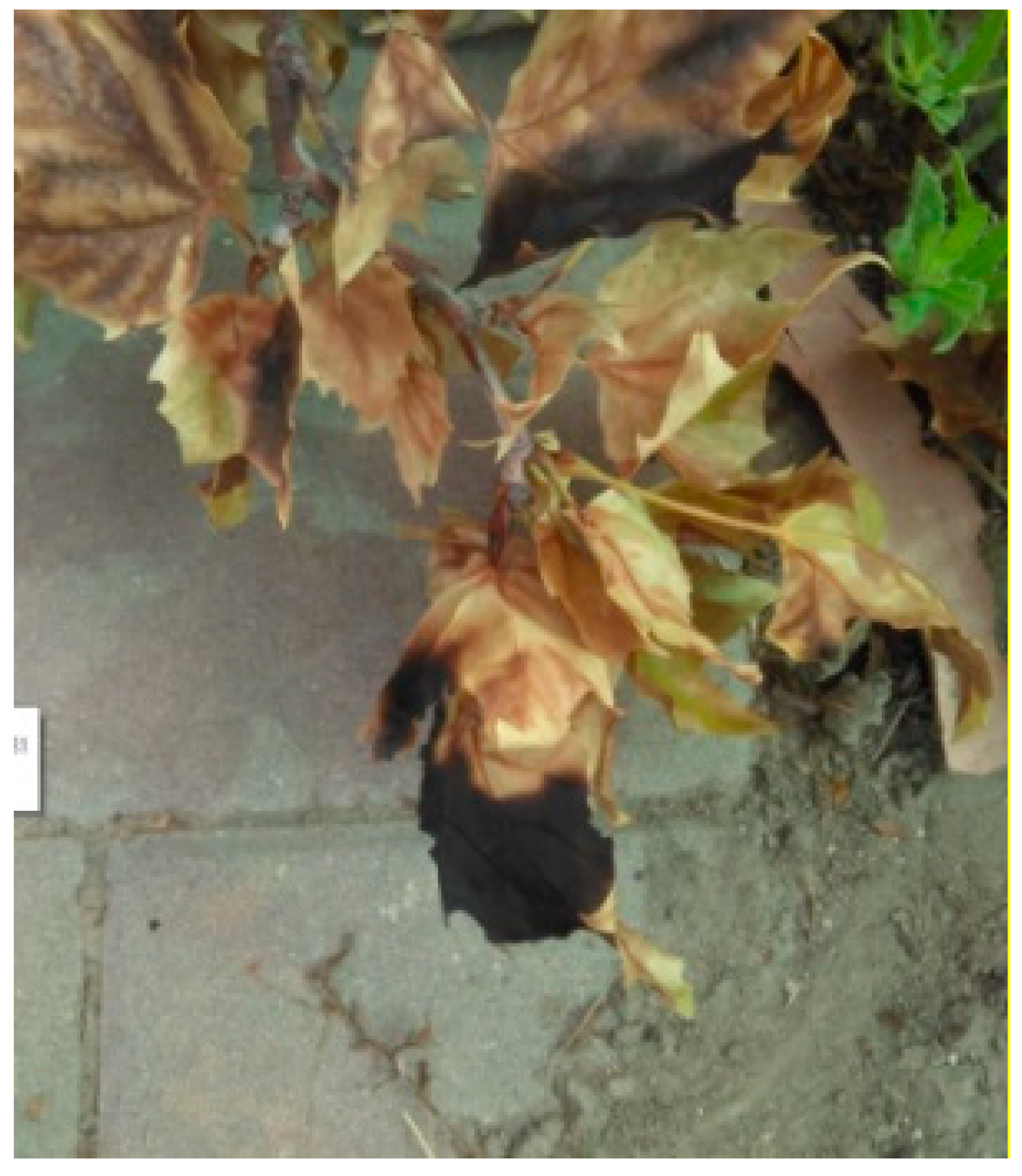

6. Results and Discussion

7. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Meteorological Organization. Available online: https://public.wmo.int/en/sun’s-impact-earth (accessed on 16 June 2021).

- Muneer, T. Solar Radiation and Daylight Models (with Software Available from Companion Web Site); Elsevier Butterworth-Heinemann: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Castells, X.E. El Modelo Energético Español; Ediciones Díaz de Santos: Madrid, Spain, 2012. [Google Scholar]

- Muradov, N.Z.; Veziroğlu, T.N. Green path from fossil-based to hydrogen economy: An overview of carbon-neutral technologies. Int. J. Hydrogen Energy 2008, 33, 6804–6839. [Google Scholar] [CrossRef]

- Abbas, R.; Montes, M.J.; Piera, M.; Martínez-Val, J.M. Solar radiation concentration features in linear fresnel reflector arrays. Energy Convers. Manag. 2012, 54, 133–144. [Google Scholar] [CrossRef]

- Luque, A.L.; Viacheslav, A. Concentrator Photovoltaics; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Benoit, H.; Spreafico, L.; Gauthier, D.; Flamant, G. Review of heat transfer fluids in tube-receivers used in concentrating solar thermal systems: Properties and heat transfer coefficients. Renew. Sustain. Energy Rev. 2016, 55, 298–315. [Google Scholar] [CrossRef]

- Shigenari, H.; Shuhei, S.; Ichita, K. Solar Thermal Receiver and Solar Thermal Electric Generation System. U.S. Patent 12/708, 17 June 2013. [Google Scholar]

- Clements, B. Energy Subsidy Reform: Lessons and Implications; International Monetary Fund: Washington, DC, USA, 2013. [Google Scholar]

- Forrester, J. The value of CSP with thermal energy storage in providing grid stability. Energy Procedia 2014, 49, 1632–1641. [Google Scholar] [CrossRef] [Green Version]

- Sangster, A. Massive energy storage systems enable secure electricity supply from renewables. J. Mod. Power Syst. Clean Energy 2016, 4, 659–667. [Google Scholar] [CrossRef] [Green Version]

- Vukosavic, S.N. Grid-Side Converters Control and Design: Interfacing Between the AC Grid and Renewable Power Sources; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Shivakumar, A.; Pye, S.; Anjo, J.; Miller, M.; Rouelle, P.; Densing, M.; Kober, T. Smart energy solutions in the EU: State of play and measuring progress. Energy Strategy Rev. 2018, 20, 133–149. [Google Scholar] [CrossRef]

- Vadari, M. Electric System Operations: Evolving to the Modern Grid; Artech House: Boston, FL, USA, 2013. [Google Scholar]

- TAseri, K.; Sharma, C.; Kandpal, T.C. Estimating capital cost of parabolic trough collector based concentrating solar power plants for financial appraisal: Approaches and a case study for india. Renew. Energy 2020, 156, 1117–1131. [Google Scholar]

- Fundación de la Energía de la Comunidad; de Madrid and Madrid (Comunidad Autónoma) Consejería de Economía, y Hacienda. Guía técnica de la energía solar termoeléctrica. Madrid, Madrid Fundación de la Energía de la Comunidad de Madrid Consejería de Economía y Hacienda. 2012. Available online: https://www.fenercom.com/publicacion/guia-tecnica-de-la-energia-solar-termoelectrica-2012/ (accessed on 16 June 2021).

- Sait, H.H.; Martinez-Val, J.; Abbas, R.; Munoz-Anton, J. Fresnel-based modular solar fields for performance/cost optimization in solar thermal power plants: A comparison with parabolic trough collectors. Appl. Energy 2015, 141, 175–189. [Google Scholar] [CrossRef] [Green Version]

- Kolios, A.J.; Paganini, S.; Proia, S. Development of thermodynamic cycles for concentrated solar power plants. Int. J. Sustain. Energy 2013, 32, 296–314. [Google Scholar] [CrossRef]

- Duffy, A. Renewable Energy and Energy Efficiency: Assessment of Projects and Policies; Wiley Blackwell: West Sussex, UK, 2015. [Google Scholar]

- Reddy, V.S.; Kaushik, S.C.; Ranjan, K.R.; Tyagi, S.K. State-of-the-art of solar thermal power plants—A review. Renew. Sustain. Energy Rev. 2013, 27, 258–273. [Google Scholar] [CrossRef]

- Tecnogetafe. Tecnogetafe. Available online: https://www.tecnogetafe.es/en/ (accessed on 18 June 2021).

- Wang, Z. Design of Solar Thermal Power Plants; Academic Press: London, UK, 2019. [Google Scholar]

- Padilla, R.V.; Fontalvo, A.; Demirkaya, G.; Martinez, A.; Quiroga, A.G. Exergy analysis of parabolic trough solar receiver. Appl. Therm. Eng. 2014, 67, 579–586. [Google Scholar] [CrossRef]

- Tsatsaronis, G. Definitions and nomenclature in exergy analysis and exergoeconomics. Energy 2007, 32, 249–253. [Google Scholar] [CrossRef]

- Montes, M.J.; Barbero, R.; Abbas, R.; Rovira, A. Performance model and thermal comparison of different alternatives for the fresnel single-tube receiver. Appl. Therm. Eng. 2016, 104, 162–175. [Google Scholar] [CrossRef]

- Muñoz, J.; Martinez-Val, J.; Ramos, A. Thermal regimes in solar-thermal linear collectors. Sol. Energy 2011, 85, 857–870. [Google Scholar] [CrossRef]

- Ituna-Yudonago, J.; Galindo-Luna, Y.; García-Valladares, O.; Brown, R.B.Y.; Shankar, R.; Ibarra-Bahena, J. Review of solar-thermal collectors powered autoclave for the sterilization of medical equipment. Alex. Eng. J. 2021, 60, 5401–5417. [Google Scholar] [CrossRef]

- Wu, G.; Yang, Q.; Zhang, Y.; Fang, H.; Feng, C.; Zheng, H. Energy and optical analysis of photovoltaic thermal integrated with rotary linear curved fresnel lens inside a chinese solar greenhouse. Energy 2020, 197, 117215. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, S.; Gehlot, A.; Pachauri, R. An imperative role of sun trackers in photovoltaic technology: A review. Renew. Sust. Energ Rev. 2018, 82, 3263–3278. [Google Scholar] [CrossRef]

- Dabiri, S.; Khodabandeh, E.; Poorfar, A.; Mashayekhi, R.; Toghraie, D.; Zade, S. Parametric investigation of thermal characteristic in trapezoidal cavity receiver for a linear fresnel solar collector concentrator. Energy 2018, 153, 17–26. [Google Scholar] [CrossRef]

- López-Martín, R.; Vicente, G.S.; Morales, A.; Valenzuela, L. Radiant emittance calculated by heat transfer analysis of a PTC receiver tested with vacuum versus measurement of an absorber sample using spectrophotometer. AIP Conf. Proc. 2019, 2126, 120010. [Google Scholar]

- Bai, Y.; Bai, Q. Chapter 14—Heat Transfer and Thermal Insulation; Elsevier Inc.: Paris, France, 2010. [Google Scholar] [CrossRef]

- Ranganayakulu, C.; Seetharamu, K.N. Compact Heat Exchangers Wiley; Wiley: Bangalore, India, 2018; pp. 45–100. [Google Scholar]

- Boukelia, T.E.; Mecibah, M.S.; Kumar, B.N.; Reddy, K.S. Investigation of solar parabolic trough power plants with and without integrated TES (thermal energy storage) and FBS (fuel backup system) using thermic oil and solar salt. Energy 2015, 88, 292–303. [Google Scholar] [CrossRef]

- Cabeza, L.F. Advances in Thermal Energy Storage Systems: Methods and Applications; Woodhead Publishing: Cambridge, UK, 2015. [Google Scholar]

- Wu, C. Thermodynamics and Heat Powered Cycles a Cognitive Engineering Approach; Nova Science Publishers: New York, NY, USA, 2007. [Google Scholar]

- Padilla, R.; Too, Y.; Benito, R.; Stein, W. Exergetic analysis of supercritical CO2 brayton cycles integrated with. solar central receivers. Appl. Energy 2015, 148, 348–365. [Google Scholar] [CrossRef]

- Muñoz, M.; Rovira, A.; Sánchez, C.; Montes, M.J. Off-design analysis of a hybrid rankine-brayton cycle used as the power block of a solar thermal power plant. Energy 2017, 134, 369–381. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Solar Energy Engineering: Processes and Systems, 2nd ed.; Elsevier/Academic Press: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Prinsloo, G.; Dobson, R. Solar Tracking, Sun Tracking, Sun Tracker, Solar Tracker, Follow Sun, Sun Position. 2015. Available online: https://www.researchgate.net/publication/263128579_Solar_Tracking_Sun_Tracking_Sun_Tracker_Solar_Tracker_Follow_Sun_Sun_Position (accessed on 16 June 2021).

- Patterson, B.D.; Mo, F.; Borgschulte, A.; Hillestad, M.; Joos, F.; Kristiansen, T.; Sunde, S.; van Bokhoven, J.A. Renewable CO2 Recycling and Synthetic Fuel Production in a Marine Environment. Proc. Natl. Acad. Sci. USA 2019, 116, 12212–12219. [Google Scholar] [CrossRef] [Green Version]

- Polysilicon Market Outlook 2020—Research and Markets; Business Wire: New York, NY, USA, 2017.

- Horowitz, K.A.W.; Fu, R.; Silverman, T.; Woodhouse, M.; Sun, X.; Alam, M.A. An Analysis of the Cost and Performance of Photovoltaic Systems as a Function of Module Area; National Renewable Energy Lab.: Golden, CO, USA, 2017. [Google Scholar]

- Greaves, C. The direct conversion of heat into electricity. thermoelectric conversion and thermionic conversion. Phys. Educ. 1968, 3, 330–338. [Google Scholar] [CrossRef]

- Espargilliere, H.; del Campo, L.; Echegut, P.; Py, X.; Muselli, M.; Rochier, D. Applicability of CSP solar fields to the dry cooling of related thermodynamic cycles. Appl. Therm. Eng. 2017, 127, 319–329. [Google Scholar] [CrossRef]

- Ontology Systems: OSS/BSS Data Misalignment is Causing Havoc for CSPs; New Industry Research Highlights Just How Much Dirty Data Is Killing CSP Efficiency, Causing Revenue Leakage and Disrupting Both Customer Experience And Service Management. M2 Presswire. 2010. Available online: https://www.proquest.com/docview/288258396 (accessed on 16 June 2021).

- Abbas, R.; Montes, M.J.; Rovira, A.; Martínez-Val, J.M. Parabolic trough collector or linear fresnel collector? A comparison of optical features including thermal quality based on commercial solutions. Sol. Energy 2016, 124, 198–215. [Google Scholar] [CrossRef]

- Kusgen, F.; Kueser, D. Fresnel CSP: A startling technology for solar generation. Power Eng. Int. 2009, 17, 44. [Google Scholar]

- Martinez-Val Penalosa, J.M.; Abbas Camara, R.; Amengual Matas, R.; Montes Pita, M.J.; Rovira De Antonio, A. Sistema de Espejos Transversales en los Extremos de un Concentrador Longitudinal de la Radiación Solar. 2014. Available online: https://worldwide.espacenet.com/publicationDetails/biblio?FT=D&date=20140930&DB=EPODOC&locale=&CC=ES&NR=2449167B2&KC=B2&ND=1 (accessed on 16 June 2021).

- Martinez-Val Penalosa, J.M.; Muñoz Anton, J.; Camara, R.A.; Carrete, M.P.; Rovira De Antonio, A.J.; Montes Pita, M.J. Dispositivo Rotatorio Horizontal de Concentración de la Radiación Solar. 2016. Available online: https://worldwide.espacenet.com/publicationDetails/biblio?FT=D&date=20151021&DB=EPODOC&CC=ES&NR=2537607B2# (accessed on 16 June 2021).

- Martinez-Val Penalosa, J.M.; Muñoz Anton, J.; Cámara, R.A.; Carrete, M.P.; Pita, M.J.M.; Rovira De Antonio, A.J. Dispositivo Rotatorio de Seguimiento del Azimut Solar. 2015. Available online: https://worldwide.espacenet.com/publicationDetails/biblio?FT=D&date=20150728&DB=EPODOC&CC=ES&NR=1138715Y# (accessed on 16 June 2021).

- Martinez-Val Penalosa, J.M.; Muñoz Anton, J.; Cámara, R.A.; Carrete, M.P.; Rovira, A.; Pita, M.J.M. Dispositivo Para Combar Placas Planas y Procedimiento de Uso. 2017. Available online: https://worldwide.espacenet.com/publicationDetails/biblio?FT=D&date=20170905&DB=EPODOC&CC=ES&NR=2596294B2# (accessed on 16 June 2021).

- Martinez-Val Penalosa, J.M.; Muñoz Anton, J.; Cámara, R.A.; Carrete, M.P.; Pita, M.J.M.; Rovira De Antonio, A.J. Dispositivo Rotatorio Horizontal de Concentración de la Radiación Solar. 2015. Available online: https://worldwide.espacenet.com/publicationDetails/biblio?FT=D&date=20151021&DB=EPODOC&CC=ES&NR=2537607B2# (accessed on 16 June 2021).

- Muñoz-Antón, J.; Martínez-Val, J.M.; González-Portillo, L.F.; Cano, J.; Millán, J.S. Experimental facility for a new thermal-solar field configuration: The rotatory fresnel collector or sundial. AIP Conf. Proc. 2019, 2126, 060007. [Google Scholar]

- Nogueras, J.C. Thermo-Economic Optimization of Solar Thermal Devices by Coherent Integration of Technologies. Energy Power Eng. 2020, 12, 671–707. [Google Scholar] [CrossRef]

- Rovira, A.; Martínez-Val, J.M.; Valdés, M. Thermoeconomic coherence: A methodology for the analysis and optimisation of thermal systems. Entropy 2016, 18, 250. Available online: https://search.proquest.com/docview/1803832133 (accessed on 12 June 2021). [CrossRef] [Green Version]

- Fundación Fomento Innovación Industrial. Fundación Para el Fomento de la Innovación Industrial. Available online: http://www.f2i2.net/ (accessed on 18 June 2021).

- Bosch Rexroth. Bosch Rexroth. Available online: https://www.boschrexroth.com/es/es/ (accessed on 1 March 2021).

- Bellos, E.; Tzivanidis, C.; Moghimi, M.A. Reducing the optical end losses of a linear fresnel reflector using novel techniques. Sol Energy 2019, 186, 247–256. [Google Scholar] [CrossRef]

- Yang, M.; Zhu, Y.; Taylor, R.A. End losses minimization of linear fresnel reflectors with a simple, two-axis mechanical tracking system. Energy Convers. Manag. 2018, 161, 284–293. [Google Scholar] [CrossRef]

- Cristaleria Madrid. Available online: https://www.cristaleriamadrid.es/ (accessed on 12 April 2021).

- Garrido, S.G. Ingeniería de Centrales termosolares CCP; Renovetec: Madrid, Spain, 2011. [Google Scholar]

- Martínez-Val, J.M.; Abbas, R.; Montes, M.J.; Rovira, A.; Muñoz-Antón, J.; Valdés, M.; Villagrá, M.R. A new thermal-solar plant configuration with vertical axis. In Proceedings of the SolarPACES, Abu Dhabi, United Arab Emirates, 11–14 October 2016. [Google Scholar]

| Description | Value |

|---|---|

| Thermal power | 30 kW |

| Basis diameter | 8 m |

| Aperture area | 20.25 m2 |

| Receiver diameter | 140 mm |

| Working fluid | Air |

| Working pressure | Atmospheric pressure |

| Working temperatures | Up to 325 °C |

| Receiver absorptivity/emissivity | 80 |

| Description | Project Total Budget | Prototype Total Budget |

|---|---|---|

| Sundial cost | 47,547 EUR | 33,255 EUR |

| Civil work cost | 18,209 EUR | 17,773 EUR |

| Total cost | 65,756 EUR | 51,028 EUR |

| Description | Cost |

|---|---|

| Elements of the platform base and traction and rolling system. (Total) | 15,027 EUR |

| Platform (Figure 19) | 6391 EUR |

| Centering device | 649 EUR |

| Central support and auxiliary devices | 1500 EUR |

| Traction (Figure 20) | 4635 EUR |

| Others | 1852 EUR |

| Description | Cost (EUR) |

|---|---|

| Mechanical elements (not including the platform base and traction system) (Total) | 19,041.00 EUR |

| Steel tubes (Figure 21) | 9695.00 EUR |

| Bracing | 1027.00 EUR |

| Heat exchangers | 0.00 EUR |

| Mirror field (Figure 22) | 5746.00 EUR |

| Joints | 456.00 EUR |

| Reflector cover over receiver | 749.00 EUR |

| Electrical installation | 1368.00 EUR |

| Description | Cost | % of Total Cost |

|---|---|---|

| Engineering | 12,496,000.00 EUR | 6.40% |

| Solar field | 64,408,006.00 EUR | 33.00% |

| Civil work/BOP | 7,980,000.00 EUR | 4.09% |

| HTF system | 9,680,000.00 EUR | 4.96% |

| Steam generation | 4,800,000.00 EUR | 2.46% |

| AV cycle | 10,340,000.00 EUR | 5.30% |

| Turbo group | 15,000,000.00 EUR | 7.69% |

| BOP | 6,100,000.00 EUR | 3.13% |

| Electric system | 7,500,000.00 EUR | 3.84% |

| Control system | 5,000,000.00 EUR | 2.56% |

| Mechanical assembly | 44,974,080.00 EUR | 23.04% |

| Start-up | 6,900,000.00 EUR | 3.54% |

| Total | 195,178,086.00 EUR | 100.00% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cano-Nogueras, J.; Muñoz-Antón, J.; Martinez-Val, J.M. A New Thermal-Solar Field Configuration: The Rotatory Fresnel Collector or Sundial. Energies 2021, 14, 4139. https://doi.org/10.3390/en14144139

Cano-Nogueras J, Muñoz-Antón J, Martinez-Val JM. A New Thermal-Solar Field Configuration: The Rotatory Fresnel Collector or Sundial. Energies. 2021; 14(14):4139. https://doi.org/10.3390/en14144139

Chicago/Turabian StyleCano-Nogueras, Javier, Javier Muñoz-Antón, and José M. Martinez-Val. 2021. "A New Thermal-Solar Field Configuration: The Rotatory Fresnel Collector or Sundial" Energies 14, no. 14: 4139. https://doi.org/10.3390/en14144139

APA StyleCano-Nogueras, J., Muñoz-Antón, J., & Martinez-Val, J. M. (2021). A New Thermal-Solar Field Configuration: The Rotatory Fresnel Collector or Sundial. Energies, 14(14), 4139. https://doi.org/10.3390/en14144139