Static Behaviors and Applications of Buckling Monitoring Members with Rigid Ends

Abstract

1. Introduction

2. Experimental Study

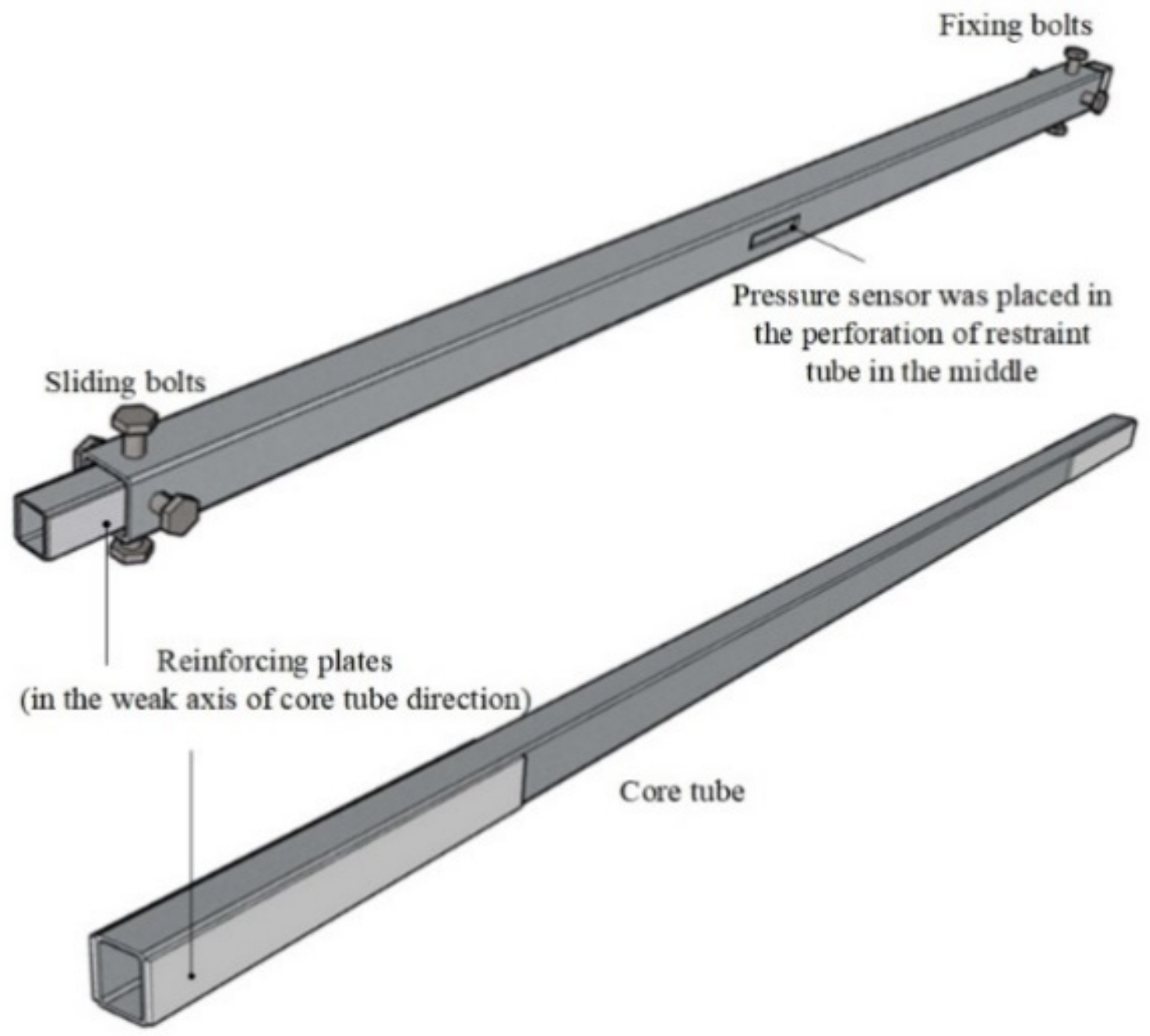

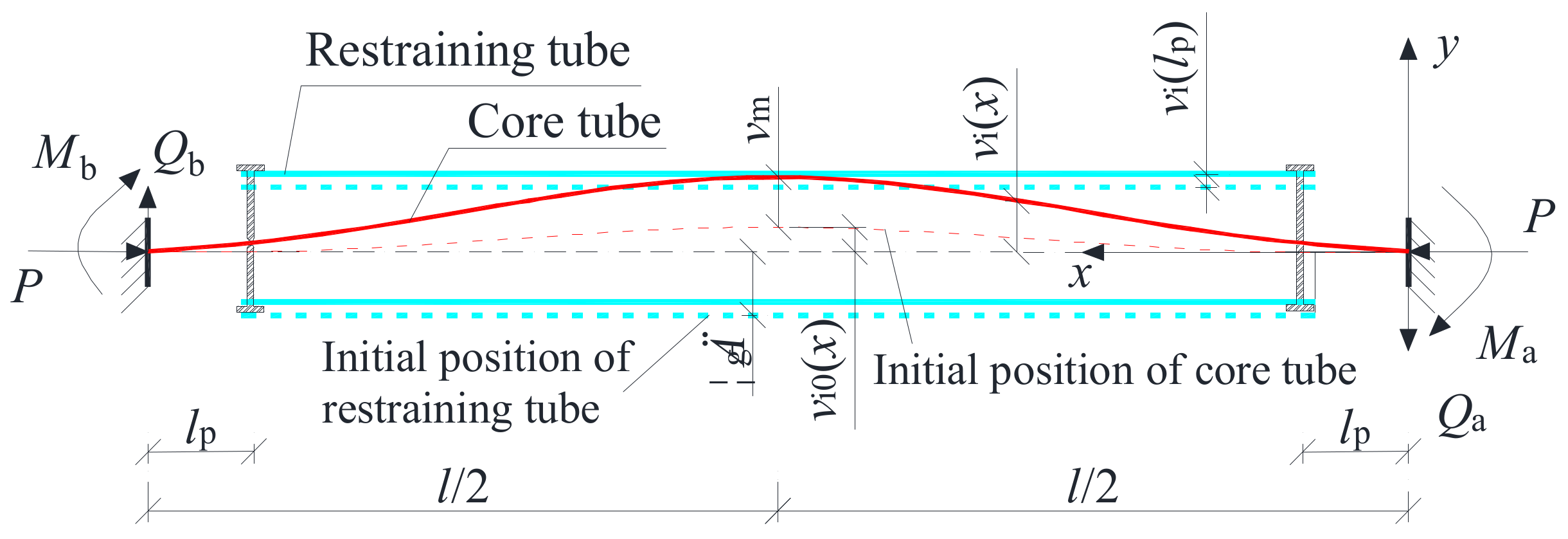

2.1. Configuration of the Buckling Monitoring Member

2.2. Details of the Specimen

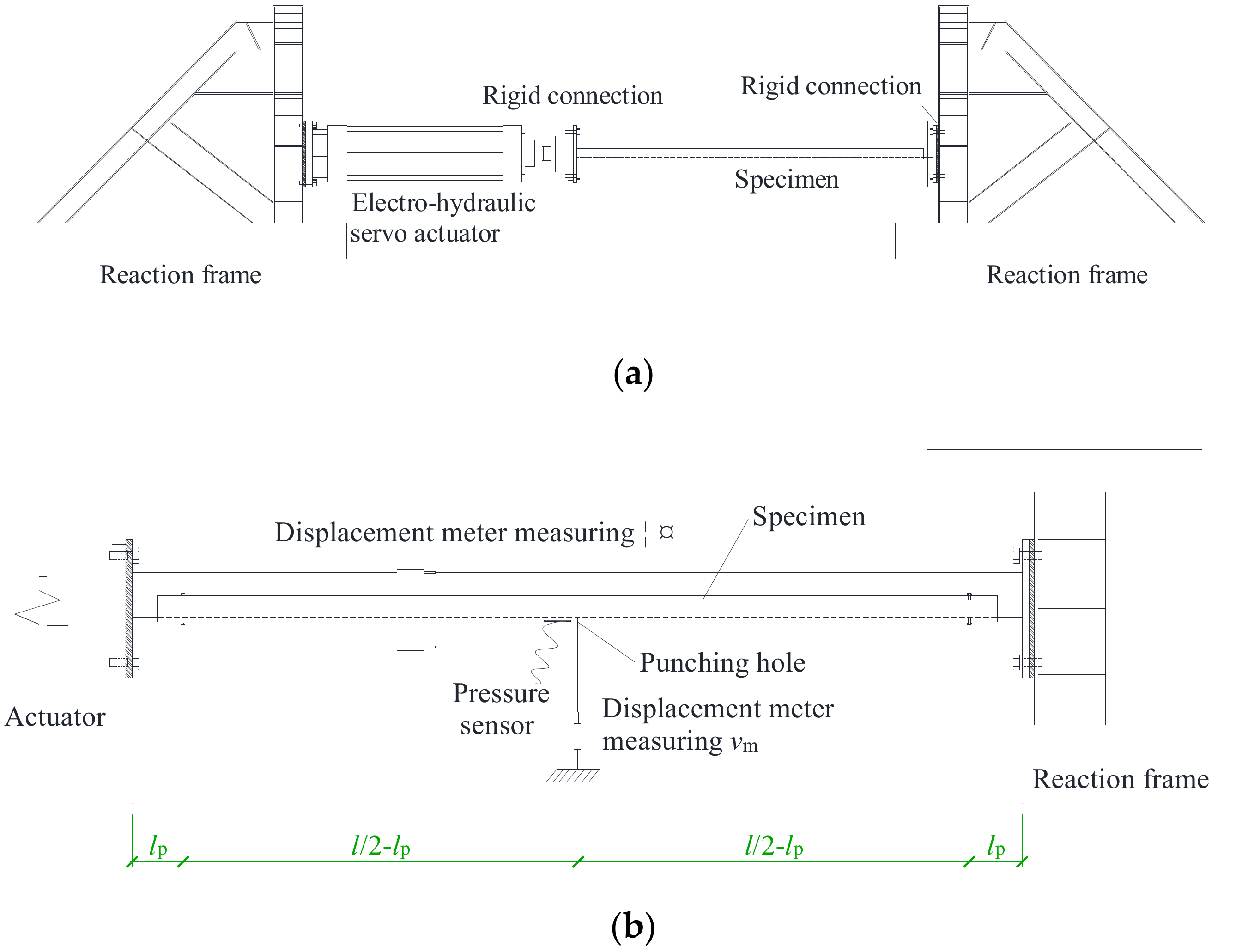

2.3. Loading and Measurement System

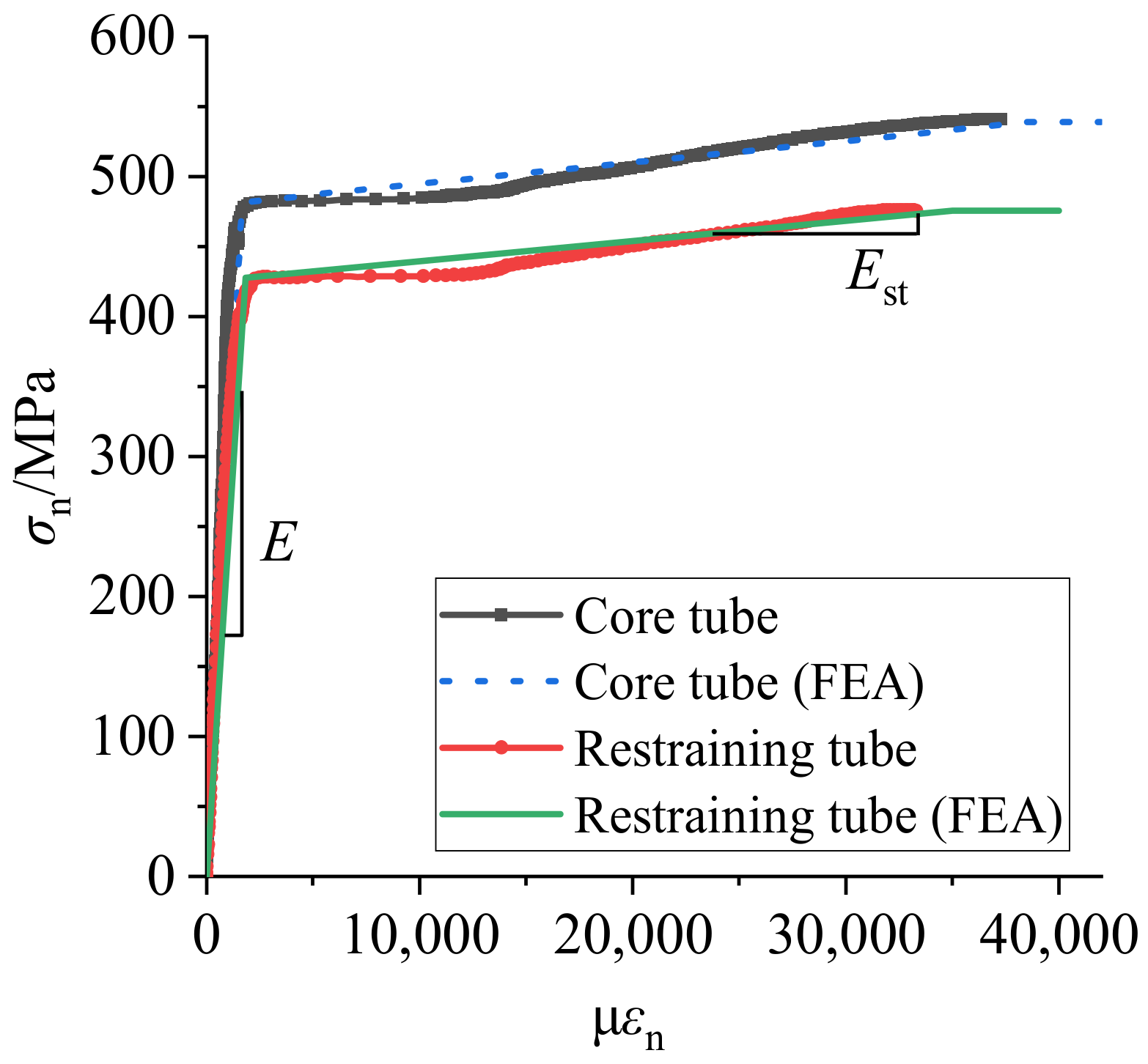

2.4. Material Properties

2.5. Experimental Curves and Failure Mode

3. Finite Element Analysis

3.1. Finite Element Model

3.2. Material, Geometric and Contact Nonlinearity

3.3. FEA Analysis Results and Their Comparison with Experimental Results

4. Parametric Studies

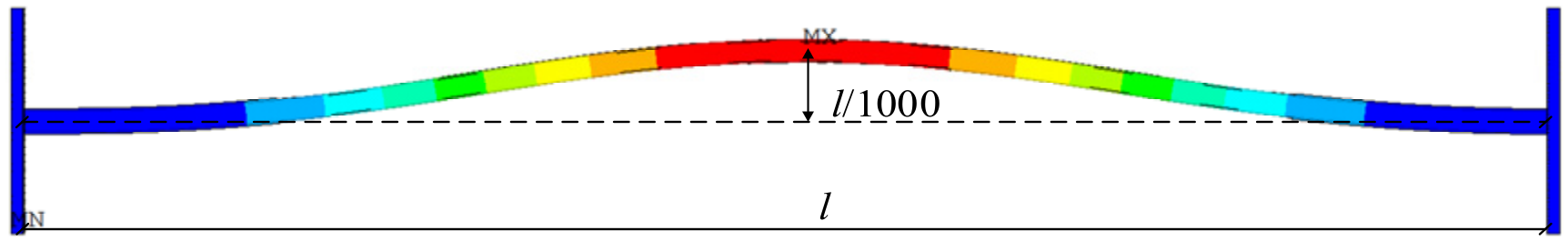

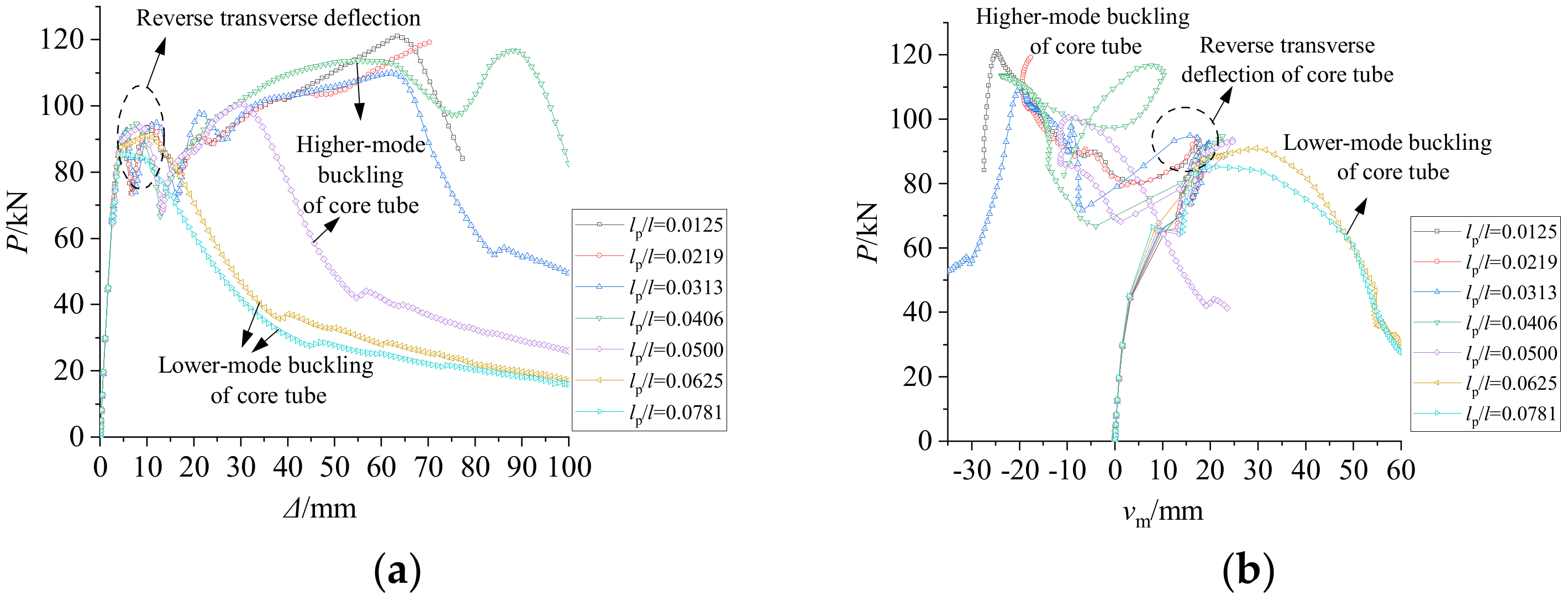

4.1. Effect of the Core Protrusion Length

4.2. Effect of the Flexural Rigidity Ratio

4.3. Effect of Core Slenderness Ratio

4.4. Effect of the Gap between Core Tube and Restraining Tube

5. Two Typical Failure Modes

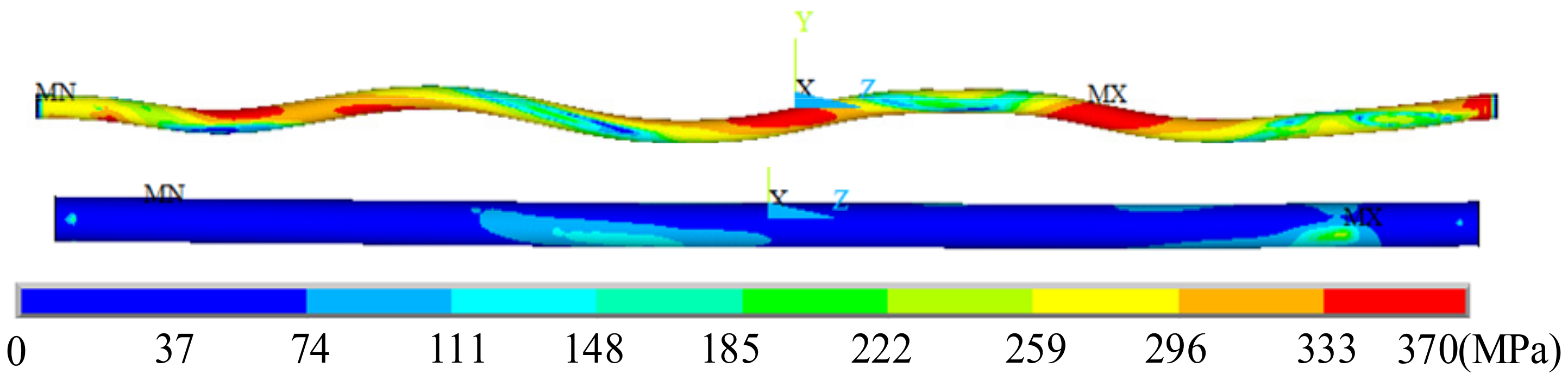

5.1. Global Buckling of Core Tube

5.2. Local Buckling of Core Tube

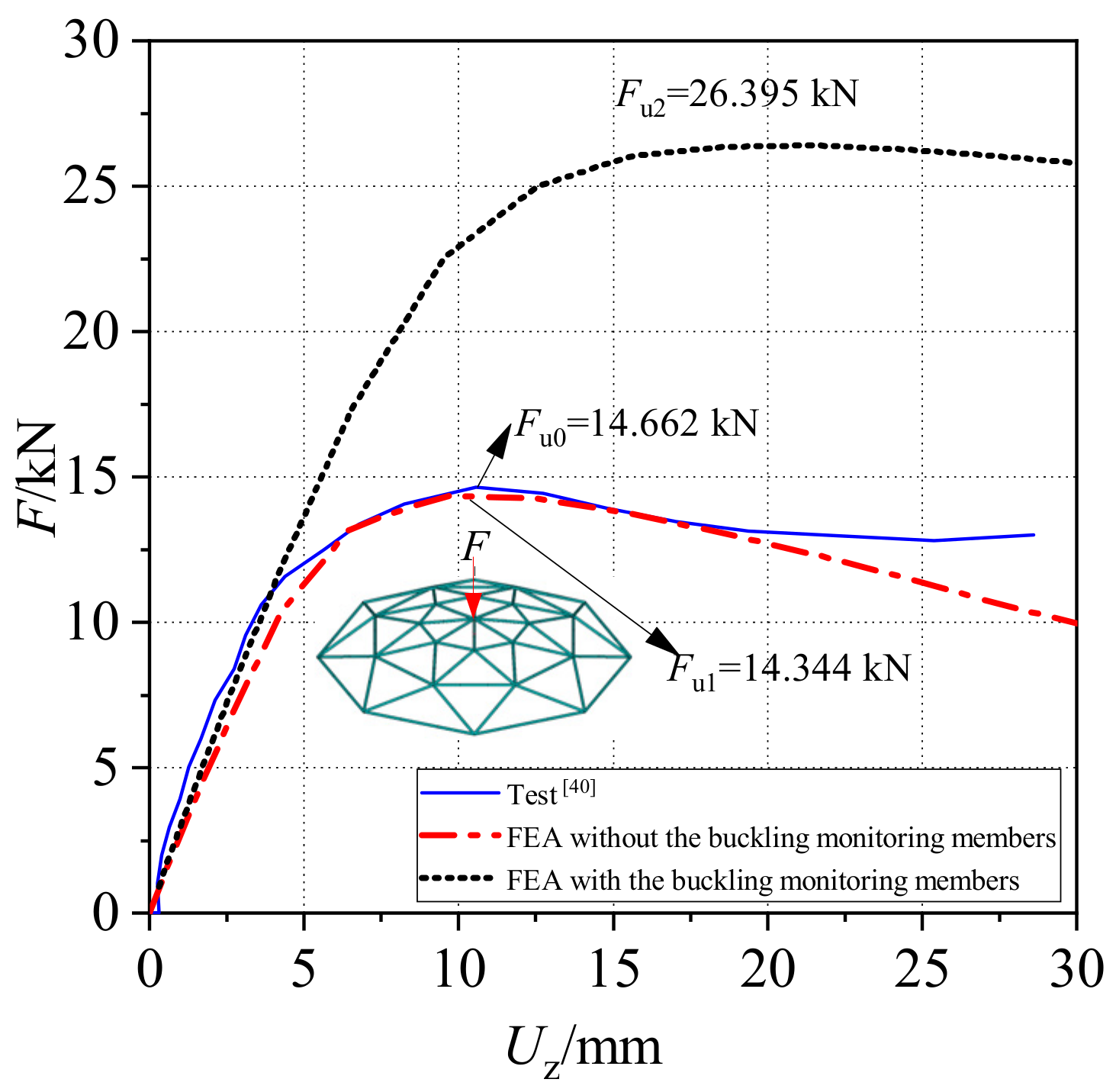

6. Application Example

7. Conclusions

- The deflection calculation formulas of core tube and restraining tube were deduced with the equilibrium differential equation, and the deduced calculation formula of gap indicated that δg was significantly affected by δ0 and λi.

- The test results show that the ultimate bearing capacity of core tube improved due to the restraint from the restraining tube. The contact states were successfully sensed by the pressure sensor. The finite element model was verified by comparing the experimental results and FEA results, and it can be used to simulate the buckling monitoring members.

- The core protrusion length lp determines the control range of the restraining tube to the core tube. The smaller the core protrusion, the more likely global buckling will occur. The core slenderness ratio λi is a sensitive parameter influencing the failure mode and the mechanical behaviors of the buckling monitoring members. Local buckling of core tube is apt to occur when the core tube is slender. The larger the flexural rigidity ratio, the more likely the global buckling occurs. Pu is obviously affected by β. The gap δg determines the alert moment for contact, but it has no effect on the failure mode.

- For the buckling monitoring members with global and local buckling, the stress distribution and deformation in different contact states are presented, revealing that the reason for the lower ultimate bearing capacity of the buckling monitoring members with local buckling was the insufficient support to the core tube. The reason that reverse deflection began to appear was full-section plasticity of the core tube. lp/l < 0.0625, β ≥ 8.349, λi < 156.787 are proposed for the buckling monitoring members to have the higher ultimate bearing capacity and superior ductility.

- The buckling monitoring members can effectively enhance the bearing capacity and increase the post-ultimate bearing capacity of reticulated shell, and it also can raise the alert of buckling of the compression members with its contact sensor. It is considered as a positive supplement for structural health monitoring system to monitor the structural capacity.

- Potential future research works should focus on the theoretical studies on the mechanical behaviors of the buckling monitoring members. Moreover, testing should be conducted to verify the effect of the buckling monitoring members on the spatial structures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jung, H.M.; Yamada, M. Buckling of rigidly-jointed single-layer latticed domes with square network: Theoretical and experimental study. In Proceedings of the Third Summer Colloquium on Shell and Spatial Structures, Taegu, Korea, August 1990; pp. 625–636. [Google Scholar]

- Qatu, M.S.; Asadi, E.; Wang, W. Review of recent literature on static analyses of composite shells: 2000–2010. Open J. Compos. Mater. 2012, 2, 61–86. [Google Scholar] [CrossRef]

- Matsushita, F.; Matsue, Y.; Ueki, T.; Kato, S. Study of the elasto–plastic buckling of single-layer domes. In Space Structures, 4th ed.; Thomas Telford: London, UK, 1993; Volume 1, pp. 67–175. [Google Scholar]

- Yamashita, T.; Kato, S. Elastic buckling characteristics of two-way grid shells of single layer and its application in design to evaluate the non-linear behavior and ultimate strength. J. Constr. Steel Res. 2001, 57, 1289–1308. [Google Scholar] [CrossRef]

- Gioncu, V. Buckling of reticulated shells: State-of-the-art. Int. J. Space Struct. 1995, 10, 1–46. [Google Scholar] [CrossRef]

- Abedi, K.; Parke, G. Progressive collapse of single-layer braced domes. Int. J. Space Struct. 1996, 11, 291–306. [Google Scholar] [CrossRef]

- Cynthia, P.; Delatte, N. Collapse of the Quebec bridge. J. Perform. Constr. Facil. 2006, 20, 84–91. [Google Scholar]

- Martin, R.; Delatte, N.J. Another look at hartford civic center Coliseum collapse. J. Perform. Constr. Facil. 2001, 15, 31–36. [Google Scholar] [CrossRef][Green Version]

- Gan, W.S. Earthquake Response of Stella Braces and Braced Steel Frames. Ph.D. Thesis, California Institute of Technology, Pasadena, CA, USA, 1997. [Google Scholar]

- Sabelli, R.; Mahin, S.; Chang, C. Seismic demands on steel braced frame buildings with buckling-restrained braces. Eng. Struct. 2003, 25, 655–666. [Google Scholar] [CrossRef]

- Lopez, W.A.; Gwie, D.S.; Lauck, T.W.; Saunders, C. Structural design and experimental verification of a buckling-restrained braced frame system. Eng. J. AISC 2004, 41, 177–186. [Google Scholar]

- Tremblay, R.; Bolduc, P.; Neville, R.; DeVall, R. Seismic testing and performance of buckling-restrained bracing systems. Can. J. Civ. Eng. 2006, 33, 183–198. [Google Scholar] [CrossRef]

- Piedrafita, D.; Maimí, P.; Cahís, X. A constitutive model for a novel modular all-steel buckling restrained brace. Eng. Struct. 2015, 100, 326–331. [Google Scholar] [CrossRef]

- Della Corte, G.; D’Aniello, M.; Landolfo, R. Field testing of all-steel buckling-restrained braces applied to a damaged reinforced concrete building. J. Struct. Eng. 2015, 141, D4014004. [Google Scholar] [CrossRef]

- Hoveidae, N.; Tremblay, R.; Rafezy, B.; Davaran, A. Numerical investigation of seismic behavior of short-core all-steel buckling restrained braces. J. Constr. Steel Res. 2015, 114, 89–99. [Google Scholar] [CrossRef]

- Momenzadeh, S.; Seker, O.; Faytarouni, M. Seismic performance of all-steel buckling-controlled braces with various cross-sections. J. Constr. Steel Res. 2017, 139, 44–61. [Google Scholar] [CrossRef]

- Torkamani, H.; Maalek, H.S. Conceptual numerical investigation of all-steel Tube-in-Tube buckling restrained braces. J. Constr. Steel Res. 2017, 139, 220–235. [Google Scholar] [CrossRef]

- Sridhara, B.N. Sleeved column as a basic compression member. In Proceedings of the 4th International Conference on Steel, Structures & Space Frames, Singapore, 5–8 May 1990; pp. 181–188. [Google Scholar]

- Prasad, B. Experimental investigation of Sleeved Column. In Proceedings of the 33rd Structures, Structural Dynamics and Materials Conference, Dallas, TX, USA, 13–15 April 1992. [Google Scholar]

- Zhang, C.H.; Deng, C.G. Theoretical study of sleeved compression members considering the core protrusion. Struct. Eng. Mech. 2018, 66, 783–792. [Google Scholar]

- Zhang, C.; Deng, C. Static behaviors of buckling-monitoring members. Eng. Struct. 2019, 178, 55–69. [Google Scholar] [CrossRef]

- Shen, B. Theoretical and Experimental Investigations on the Static Stability of Sleeved Compression Members. Ph.D. Thesis, Tongji University, Shanghai, China, 2007. [Google Scholar]

- Abdeljaber, O.; Avci, O.; Kiranyaz, S.; Gabbouj, M. Real-time vibration-based structural damage detection using one-dimensional convolutional neural networks. J. Sound Vib. 2017, 388, 154–170. [Google Scholar] [CrossRef]

- Cigada, A.; Moschioni, G.; Vanali, M.; Caprioli, A. The measurement network of the San Siro Meazza stadium in Milan: Origin and implementation of a new data acquisition strategy for structural health monitoring. Exp. Tech. 2010, 34, 70–81. [Google Scholar] [CrossRef]

- Mansouri, M.; Avci, O.; Nounou, H. Iterated square root unscented Kalman filter for nonlinear states and parameters estimation: Three DOF damped system. J. Civ. Struct. Health Monit. 2015, 5, 493–508. [Google Scholar] [CrossRef]

- Gao, Z.; Chen, M.Z.Q.; Zhang, D. Special Issue on “Advances in Condition Monitoring, Optimization and Control for Complex Industrial Processes”. Processes 2021, 9, 664. [Google Scholar] [CrossRef]

- Li, N.; Shi, H.; Song, B.; Tao, Y. Temporal-Spatial Neighborhood Enhanced Sparse Autoencoder for Nonlinear Dynamic Process Monitoring. Processes 2020, 8, 1079. [Google Scholar] [CrossRef]

- Park, Y.J.; Fan, S.K.S.; Hsu, C.Y. A Review on Fault Detection and Process Diagnostics in Industrial Processes. Processes 2020, 8, 1123. [Google Scholar] [CrossRef]

- Anton, S.R.; Inman, D.J.; Park, G. Reference-free damage detection using instantaneous baseline measurements. AIAA J. 2009, 47, 1952–1964. [Google Scholar] [CrossRef]

- Bhalla, S.; Soh, C.K. Structural health monitoring by piezo-impedance transducers. II: Applications. J. Aerosp. Eng. 2004, 17, 166–175. [Google Scholar] [CrossRef]

- Wu, T.H.; Deng, C.G.; Shen, B. Buckling control and application of axial compression steel member. J. Southeast Univ. 2009, 39, 53–57. [Google Scholar]

- Hu, L.; Shen, B.; Ma, K.J. A mechanical model and experimental investigations for axially compressed sleeved column. J. Constr. Steel Res. 2013, 89, 107–120. [Google Scholar] [CrossRef]

- See, T.; McConnel, R.E. Large displacement elastic buckling of space structures. J. Struct. Eng. 1986, 112, 1052–1069. [Google Scholar] [CrossRef]

- Fathelbab, F.A. The Effect of Joints on the Stability of Shallow Single Layer Lattice Domes. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 1987. [Google Scholar]

- EI-Sheikh, A.I. Numerical analysis of space trusses with flexible member-end joints. Int. J. Space Struct. 1993, 8, 189–197. [Google Scholar] [CrossRef]

- Shibata, R.; Kato, S.; Yamada, S. Experimental study on the ultimate strength of single-layer reticular domes. In Proceedings of the Fourth International Conference on Space Structures, Guildford, UK, 5–10 September 1993; pp. 387–395. [Google Scholar]

- GB 50017-2017. Standard for Design of Steel Structures; China Architecture Industry Press: Beijing, China, 2017. [Google Scholar]

- Papp, F. Buckling assessment of steel members through overall imperfection method. Eng. Struct. 2016, 106, 124–136. [Google Scholar] [CrossRef]

- JGJ 7-2010. Technical Specification for Space Frame Structures; China Architecture Industry Press: Beijing, China, 2010. [Google Scholar]

- Luo, Y.F.; Shen, Z.Y.; Hu, X.R. Experiment research on the elastoplastic stability of single layer. J. Civ. Eng. 1995, 4, 33–40. [Google Scholar]

| Core Tube | Restraining Tube | l (m) | lp (mm) | le (m) | λi | δg (mm) | β | Nu (kN) | Pc (kN) |

|---|---|---|---|---|---|---|---|---|---|

| □50.327 × 39.96 × 2.725 | □70.387 × 70.387 × 4.7 | 2.4 | 70 | 2.26 | 76.45 | 10.66 | 7.84 | 137.16 | 165.61 |

| Member | E/MPa | fy/MPa | Est/MPa | fu/MPa |

|---|---|---|---|---|

| Core tube | 2.105 × 105 | 481.83 | 2.484 × 103 | 539.00 |

| Restraining tube | 2.060 × 105 | 427.54 | 2.326 × 103 | 475.98 |

| Member | Core Tube | Restraining Tube | L (mm) | lp (mm) | λi | δg (mm) | β/kN | Nu/kN |

|---|---|---|---|---|---|---|---|---|

| MSM-S | ϕ19 × 2 | ϕ32 × 4 | 368.22 | 23 | 39.69 | 2.5 | 8.994 | 24.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ying, W.; Deng, C.; Zhang, C. Static Behaviors and Applications of Buckling Monitoring Members with Rigid Ends. Processes 2021, 9, 836. https://doi.org/10.3390/pr9050836

Ying W, Deng C, Zhang C. Static Behaviors and Applications of Buckling Monitoring Members with Rigid Ends. Processes. 2021; 9(5):836. https://doi.org/10.3390/pr9050836

Chicago/Turabian StyleYing, Wudang, Changgen Deng, and Chenhui Zhang. 2021. "Static Behaviors and Applications of Buckling Monitoring Members with Rigid Ends" Processes 9, no. 5: 836. https://doi.org/10.3390/pr9050836

APA StyleYing, W., Deng, C., & Zhang, C. (2021). Static Behaviors and Applications of Buckling Monitoring Members with Rigid Ends. Processes, 9(5), 836. https://doi.org/10.3390/pr9050836