Influence of the Fly Ash Material Inoculants on the Tensile and Impact Characteristics of the Aluminum AA 5083/7.5SiC Composites

Abstract

1. Introduction

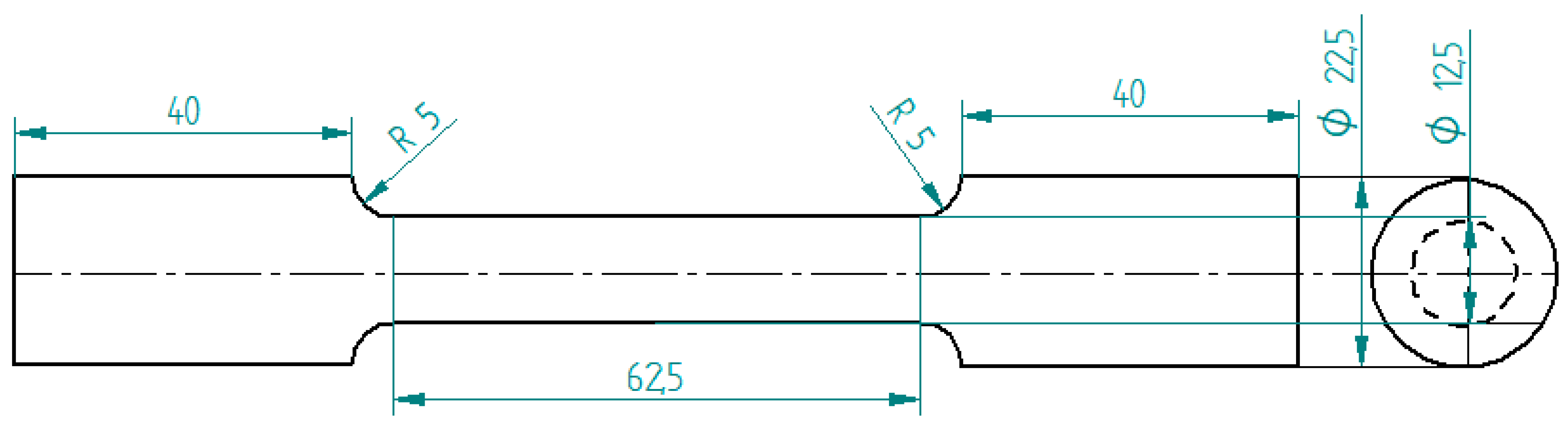

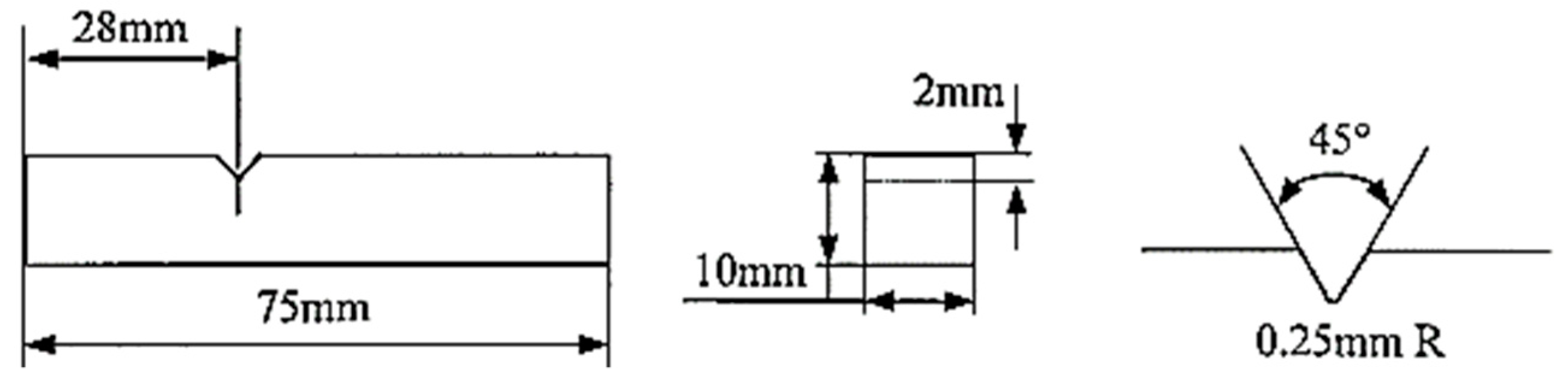

2. Materials and Methods

3. Results and Discussions

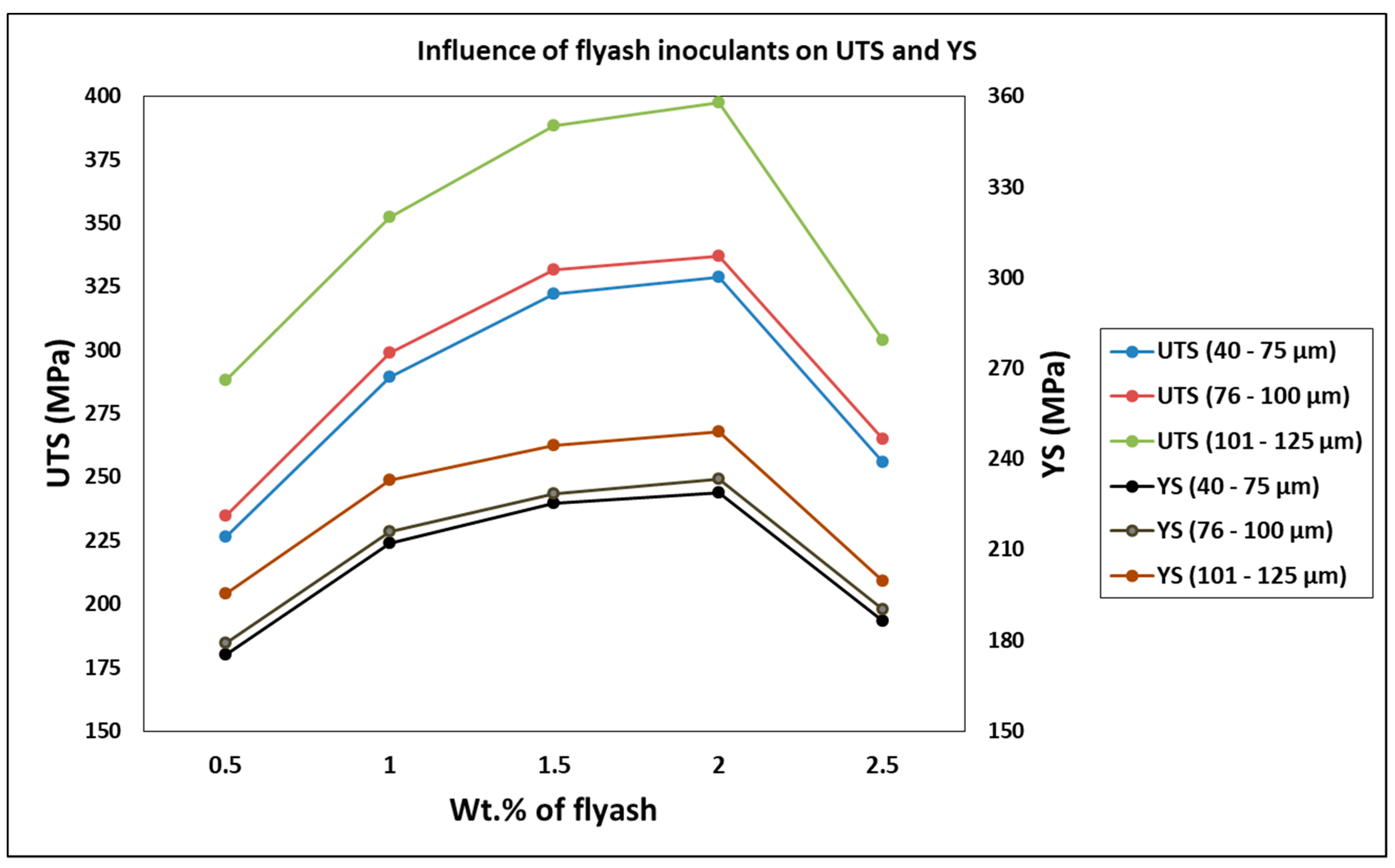

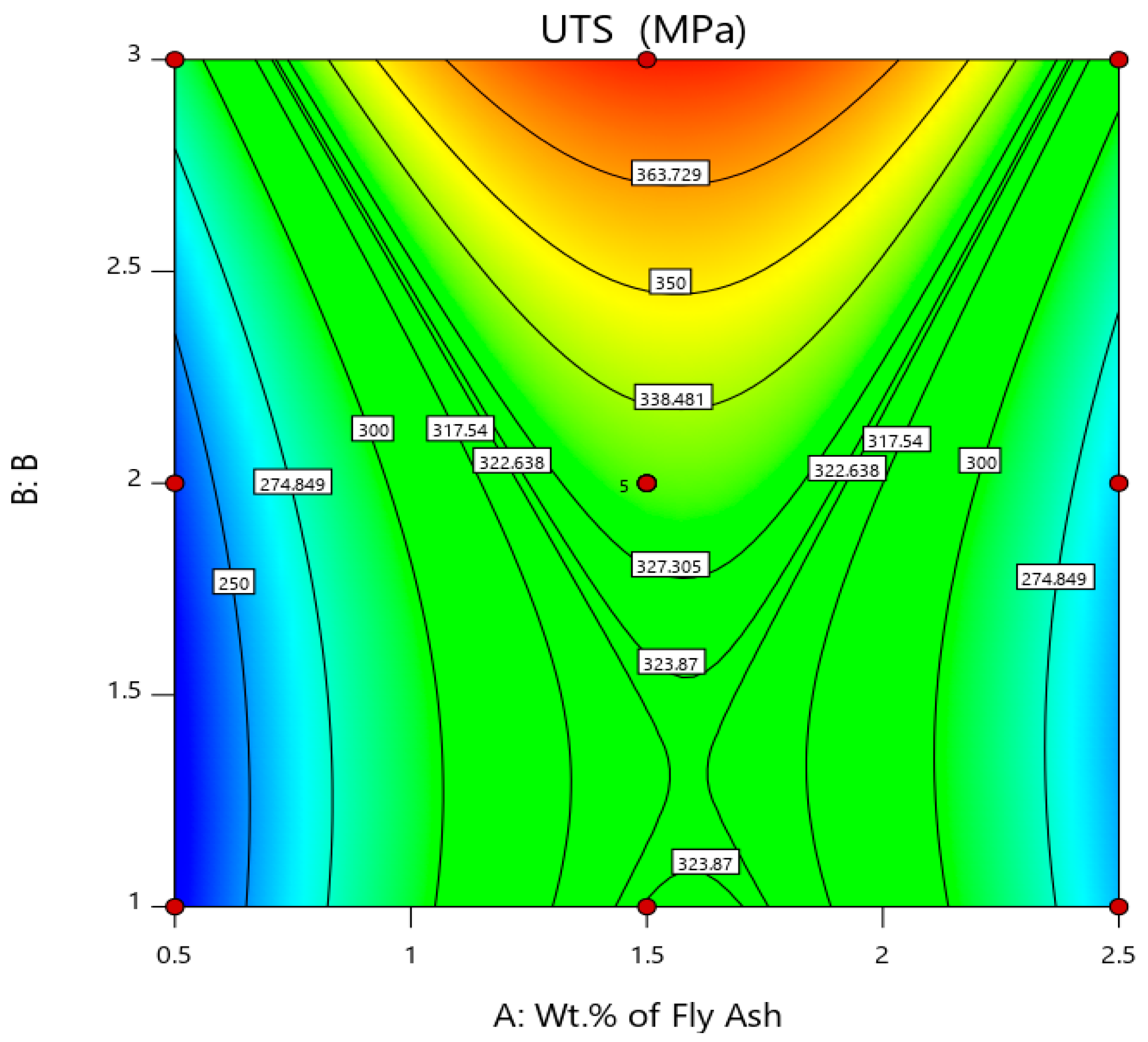

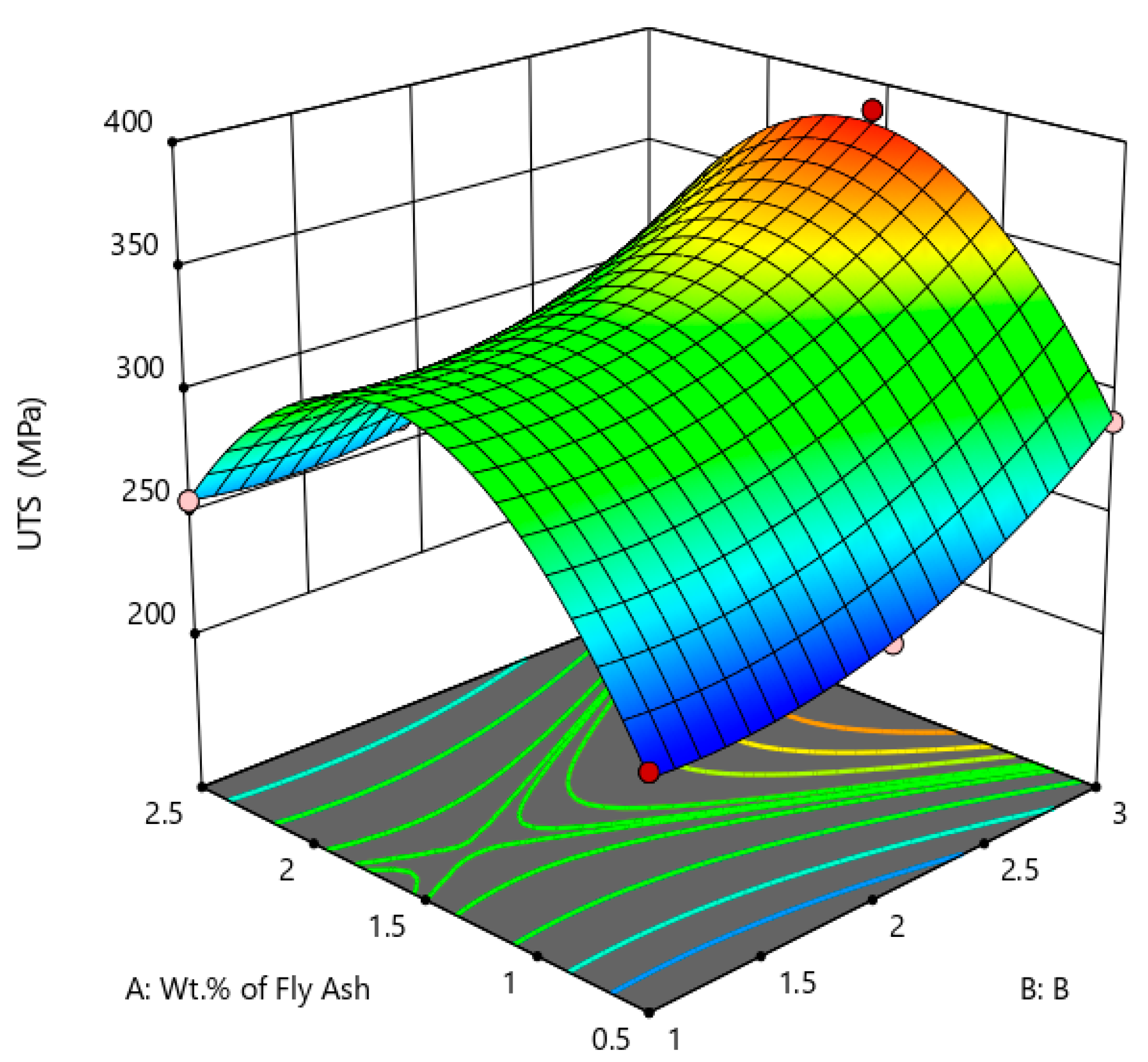

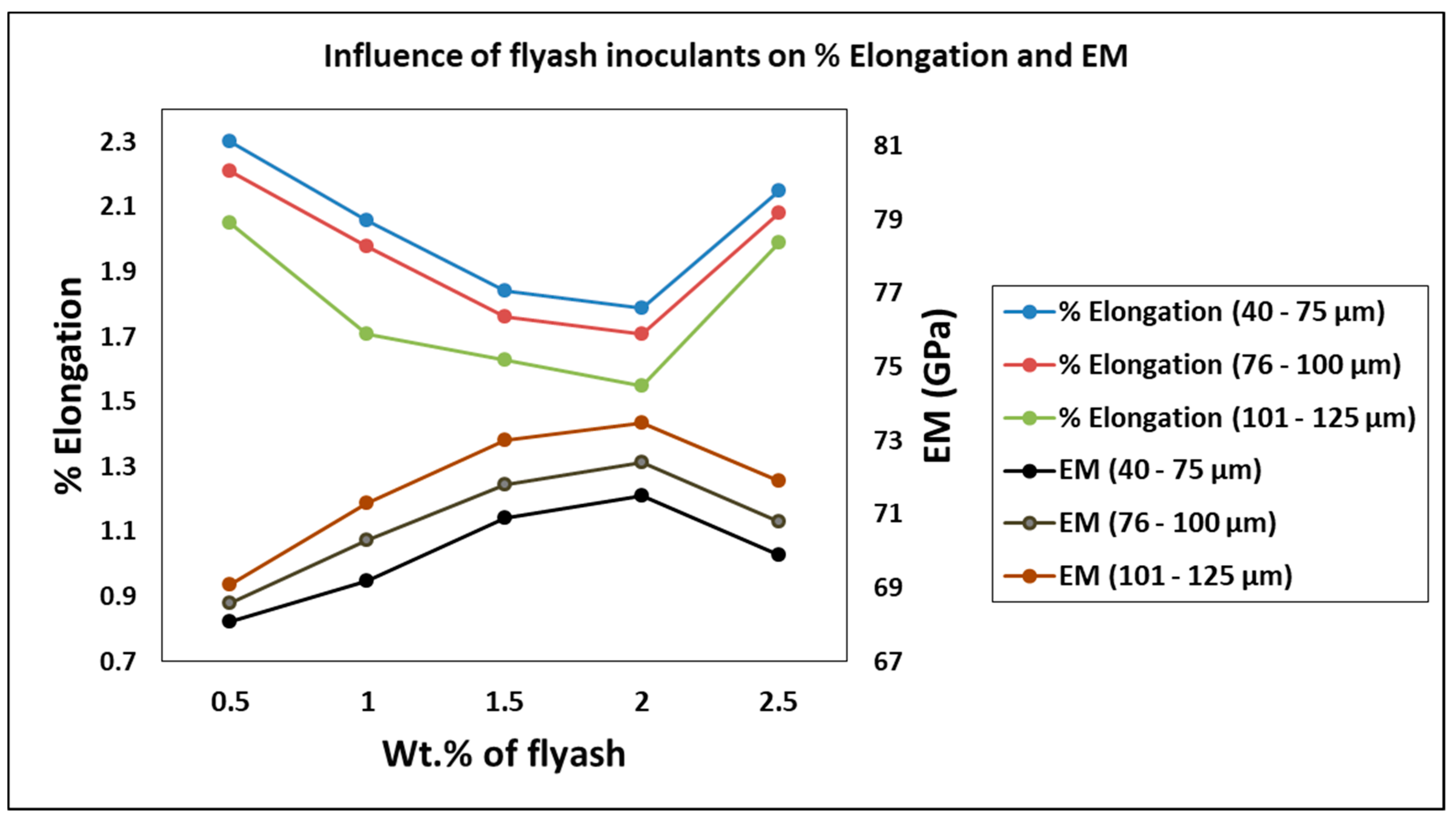

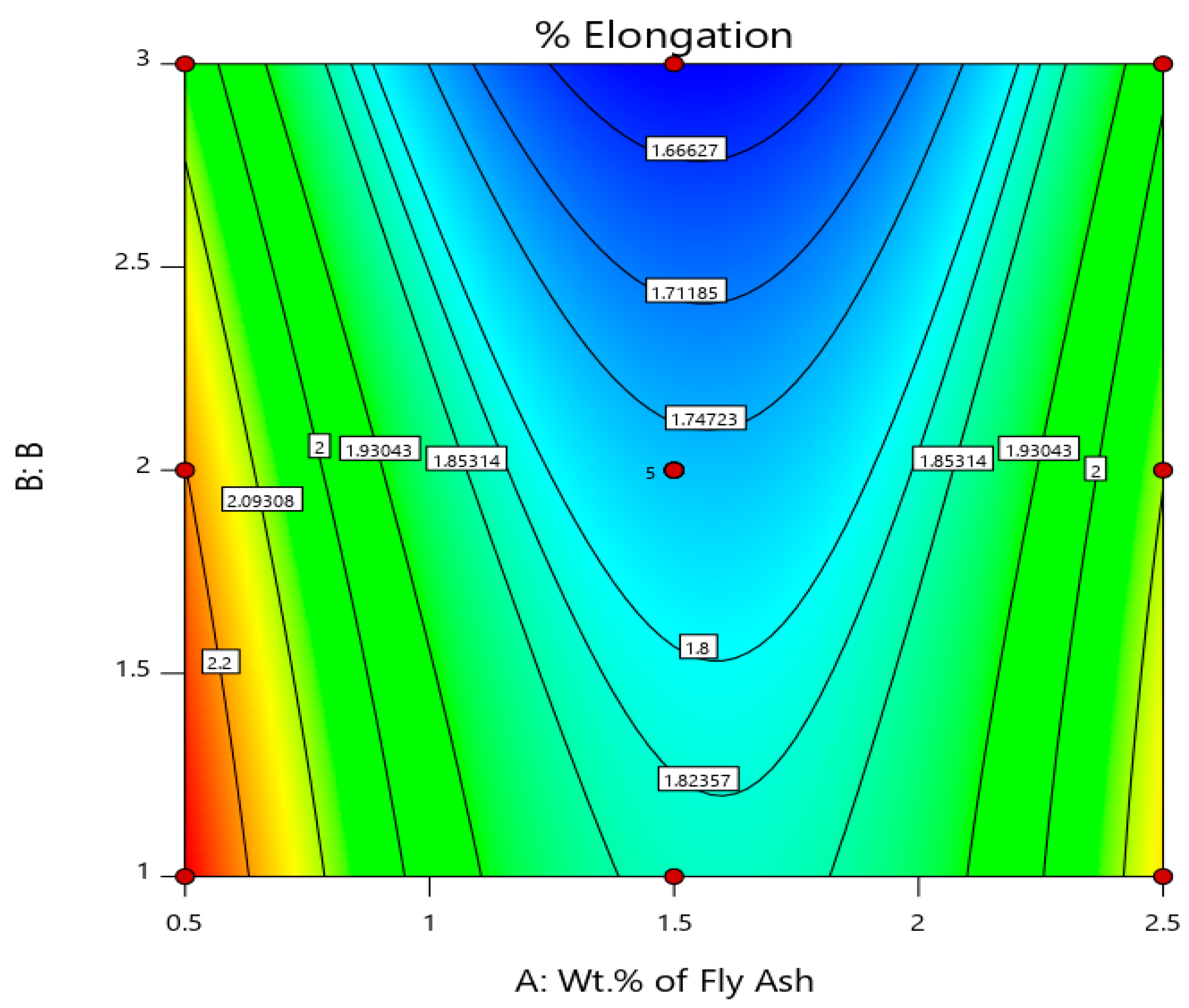

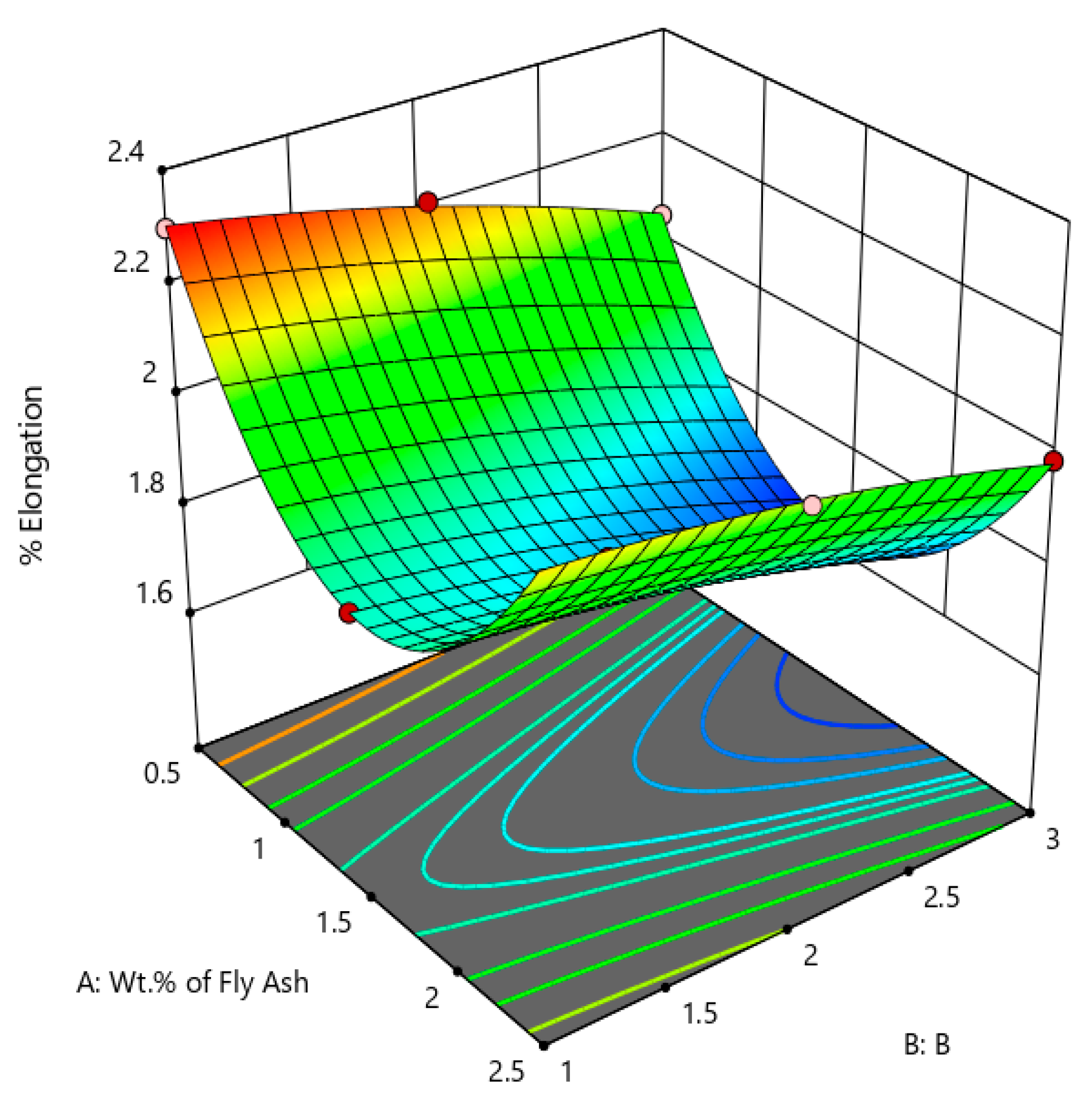

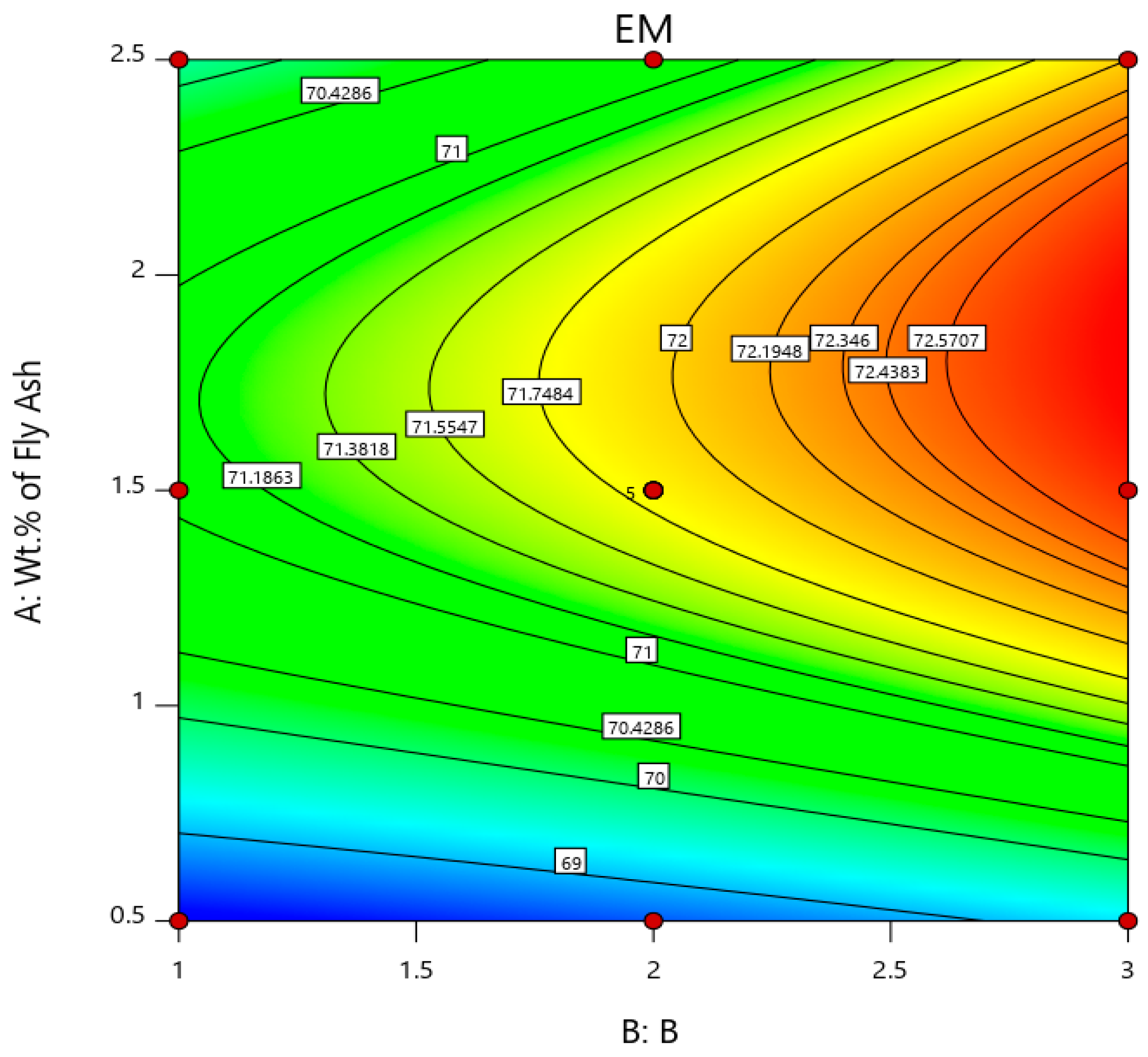

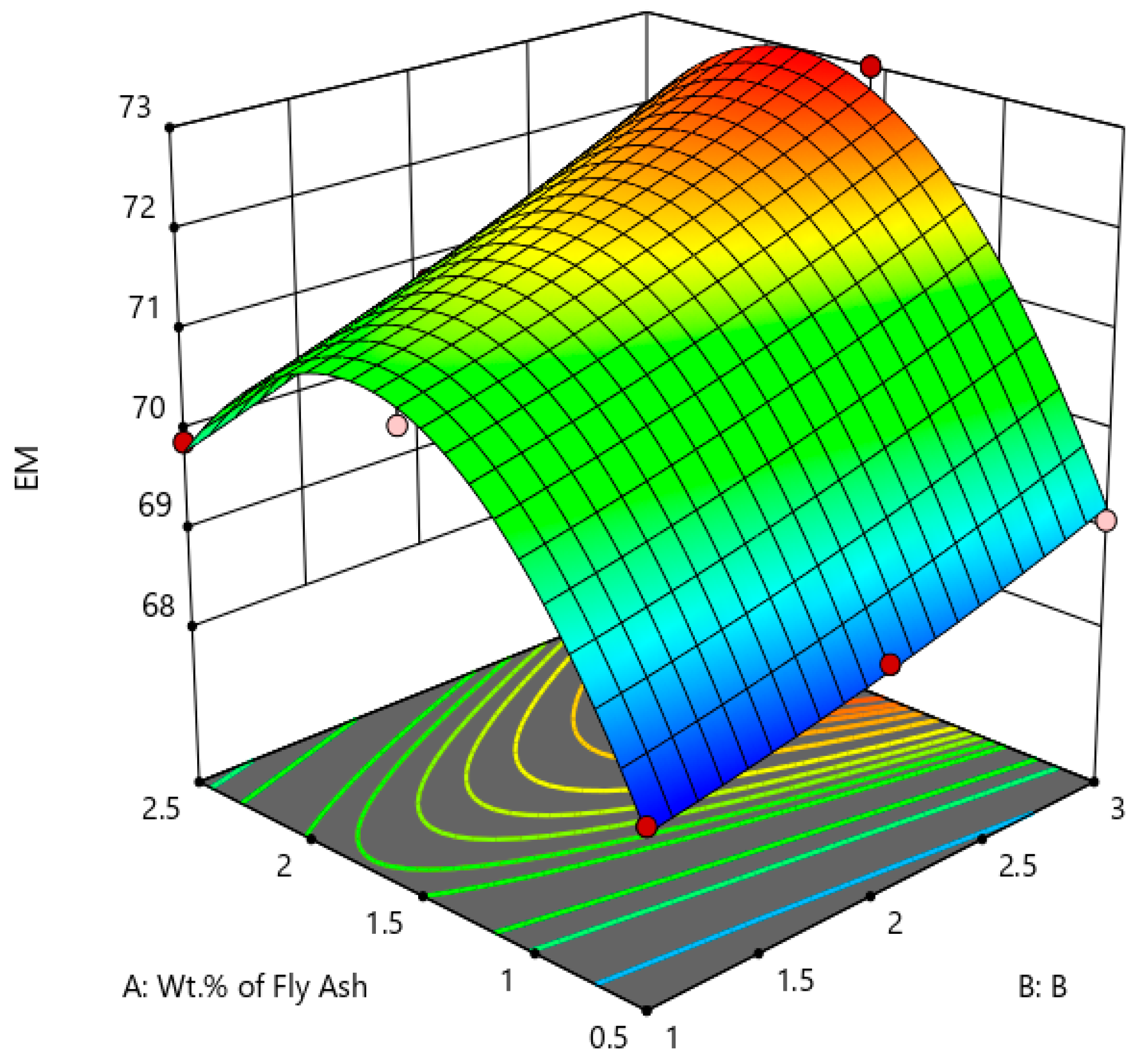

3.1. Influence of Inoculation of Fly Ash on Tensile Characteristics

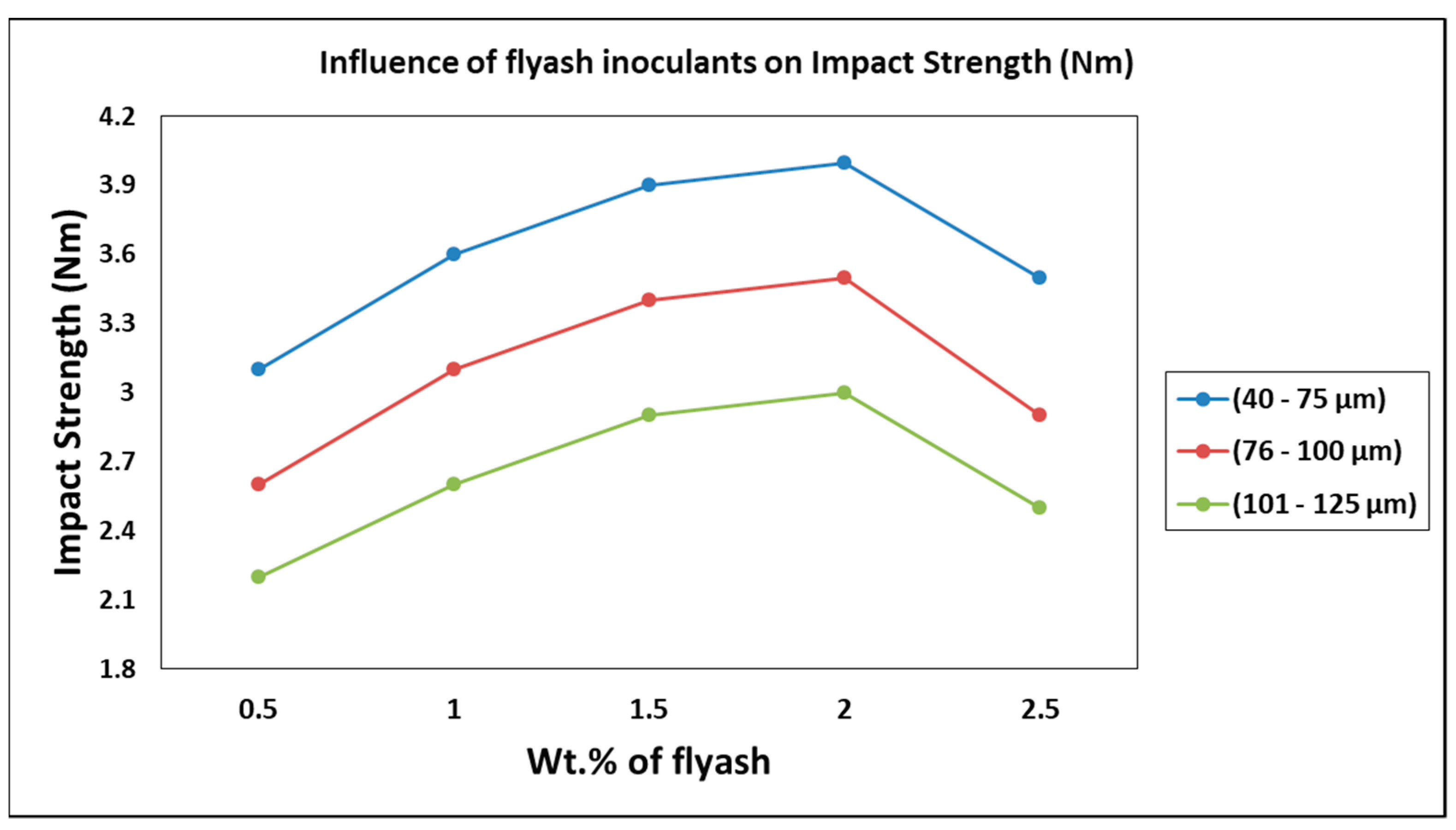

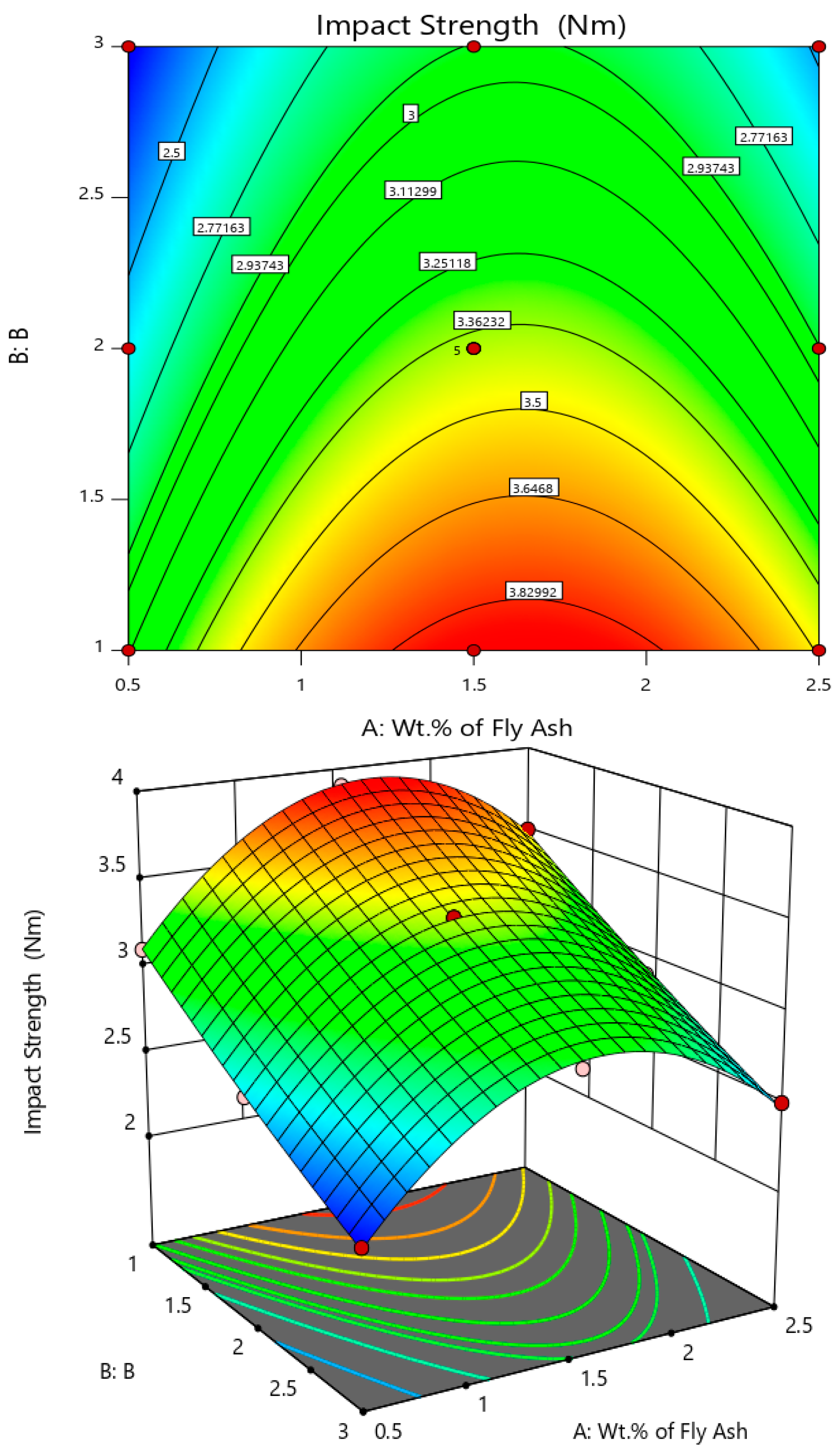

3.2. Influence of Inoculation of Fly Ash on Impact Strength

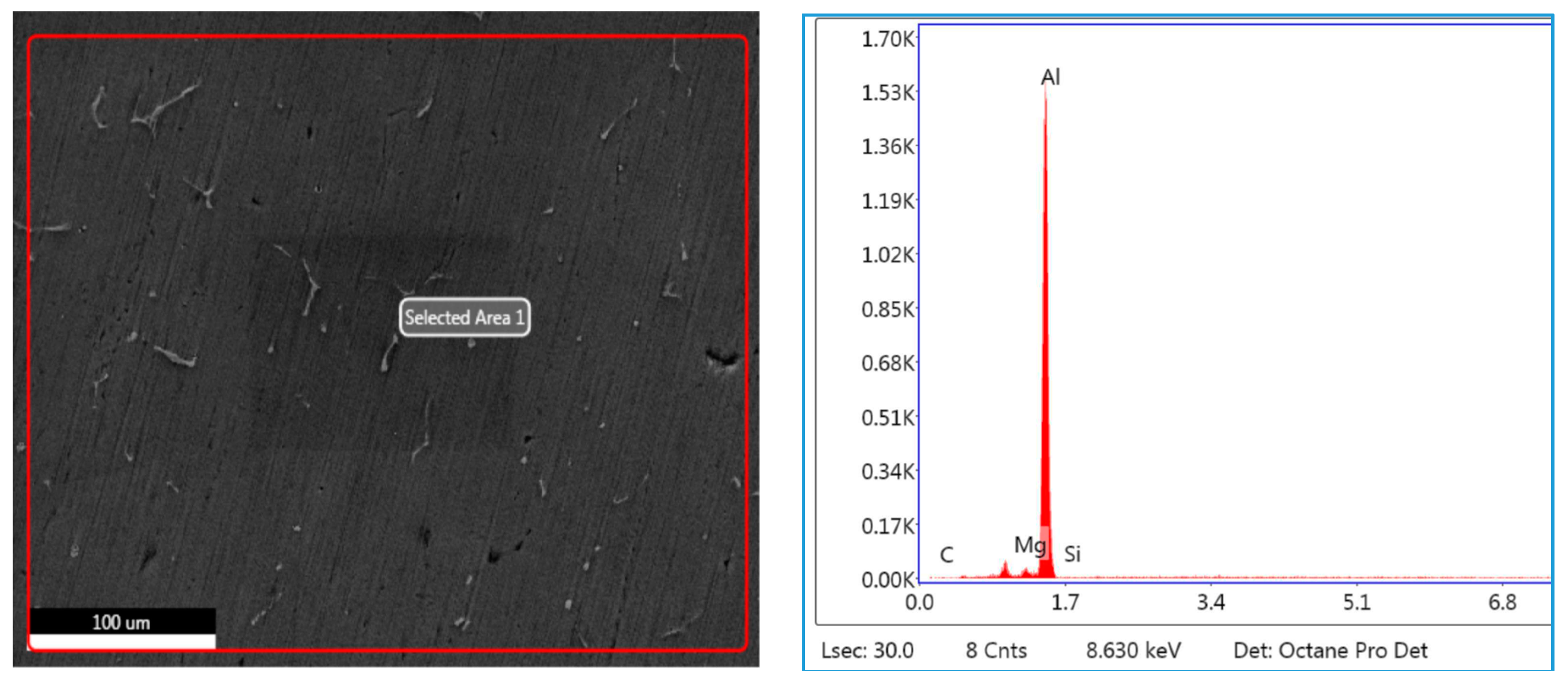

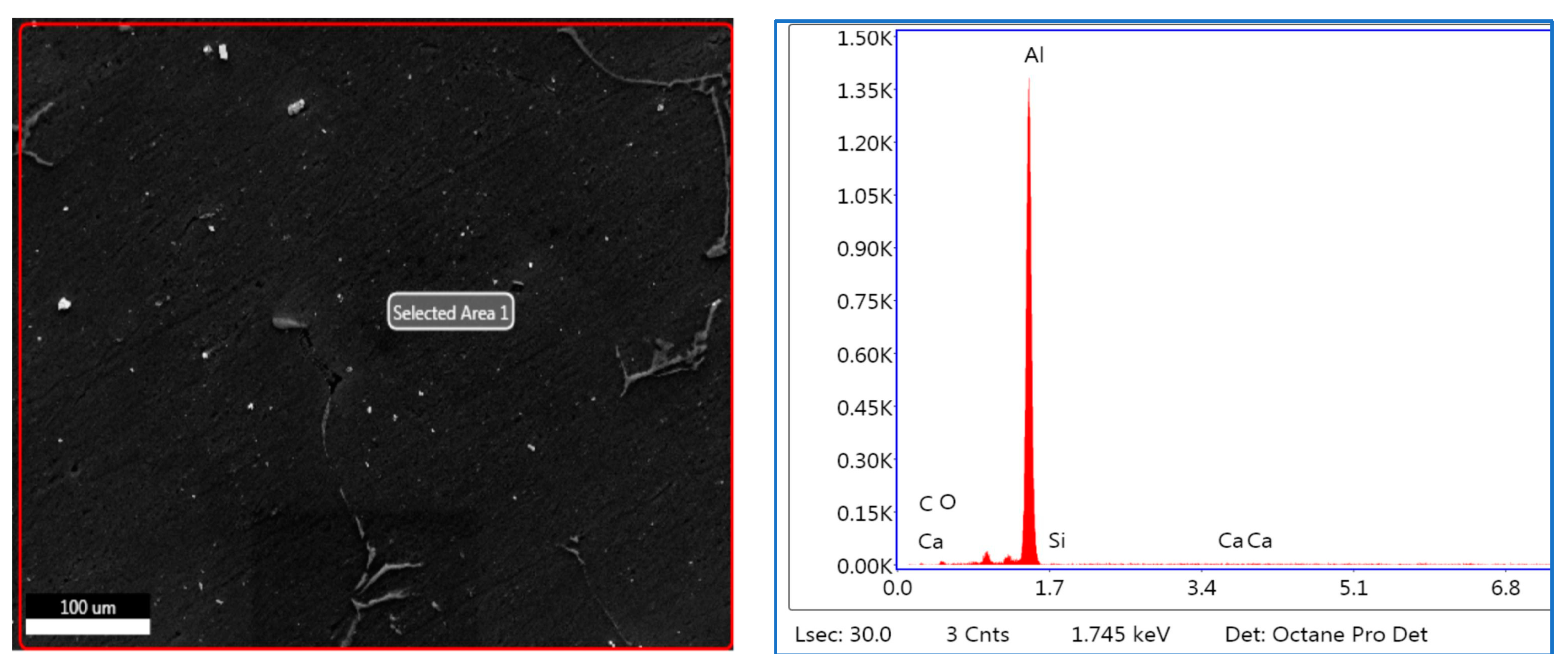

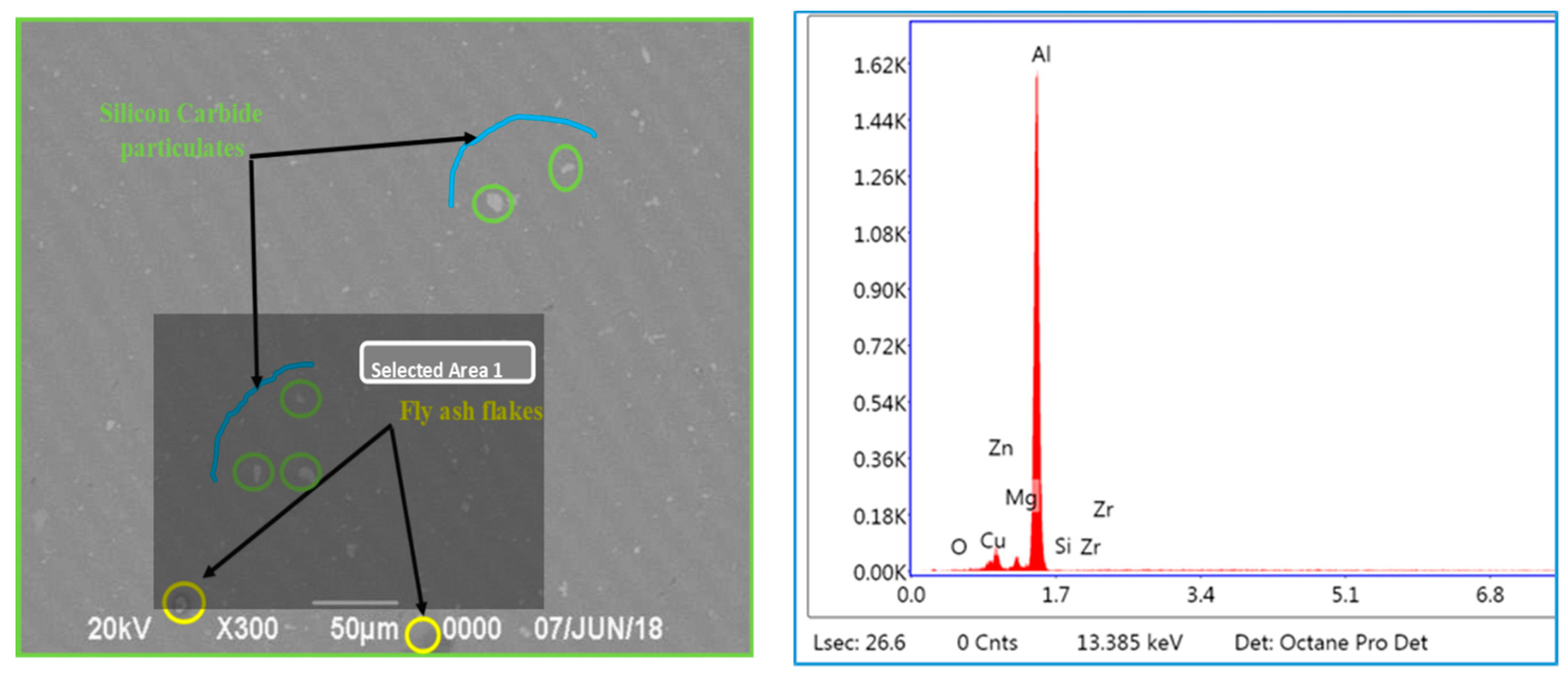

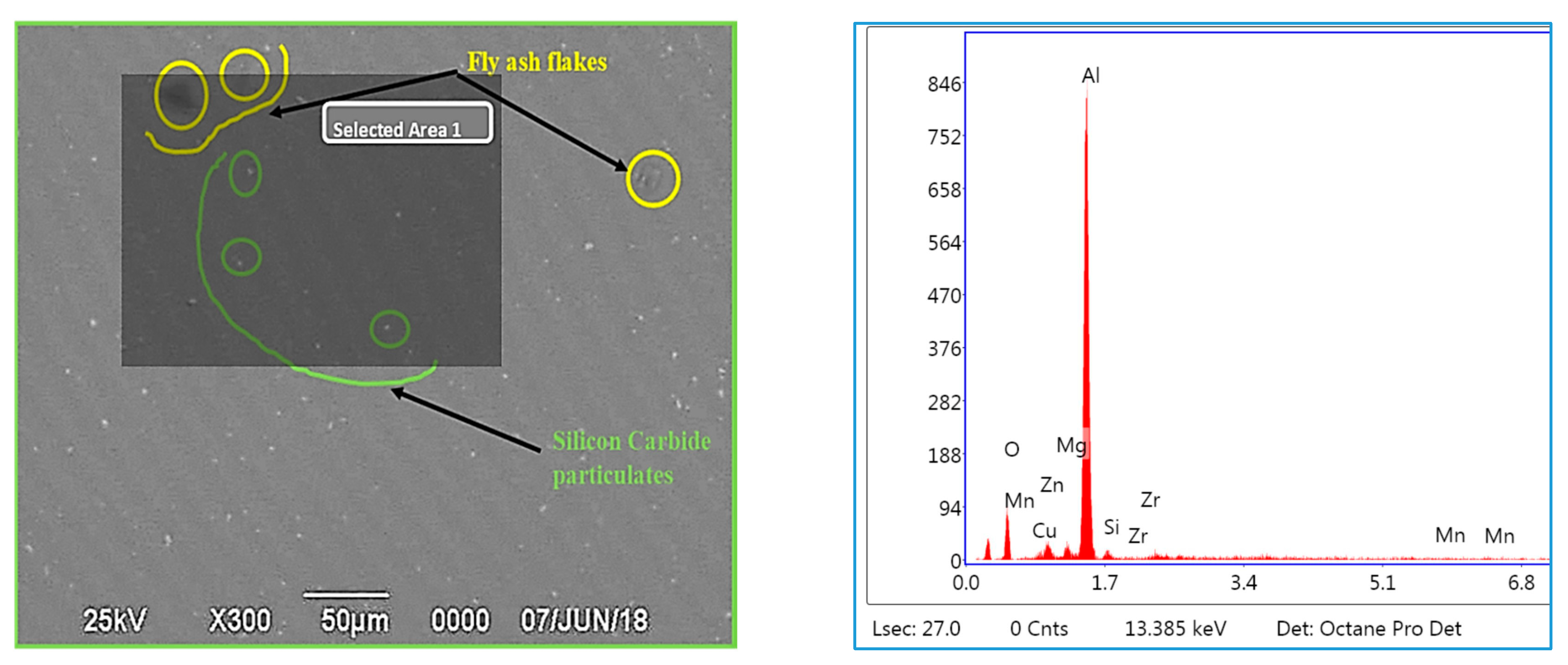

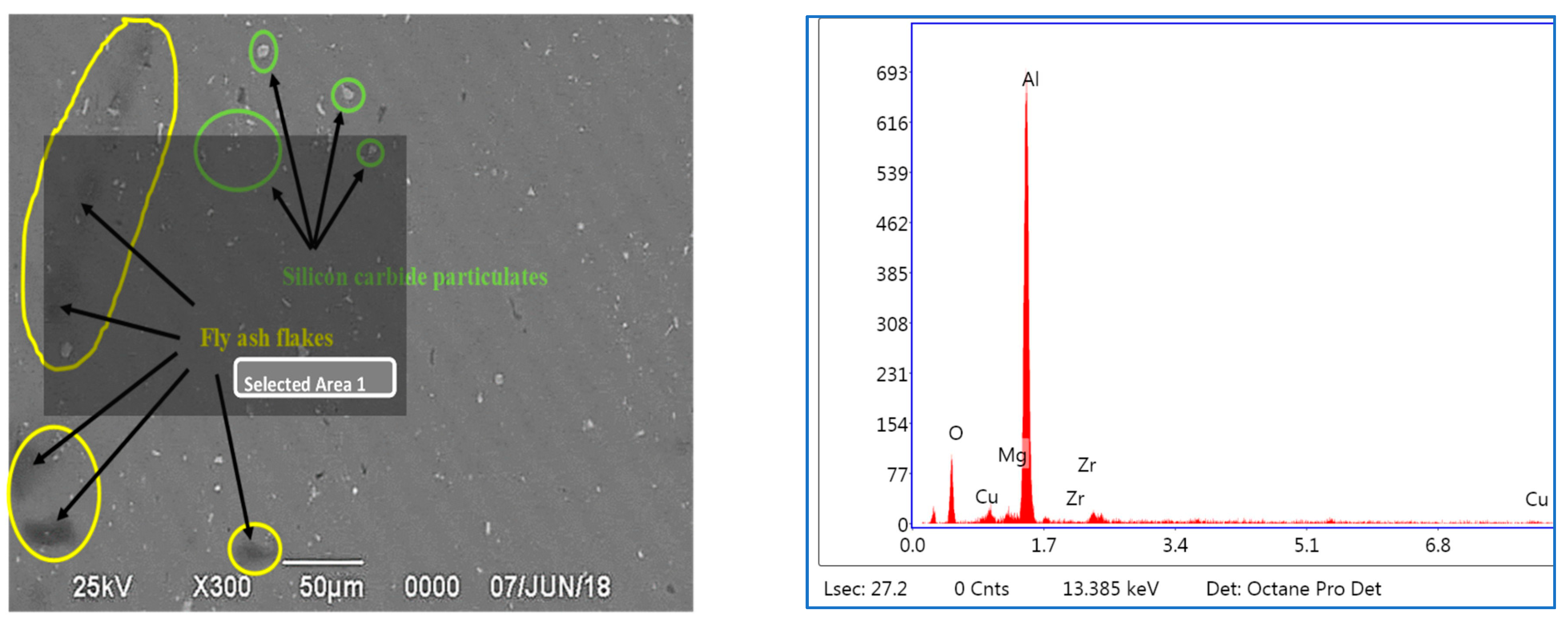

3.3. EDS Studies Characterizing the Inoculation of Fly Ash

3.3.1. EDS of 40–75 μm, 2 wt. % Fly Ash Inoculants in AA 5083/7.5SiC

3.3.2. EDS of 76–100 μm, 2 wt. % Fly Ash Inoculants in AA 5083/7.5SiC

3.3.3. EDS of 101–125 μm, 2 wt. % Fly Ash Inoculants in AA 5083/7.5SiC

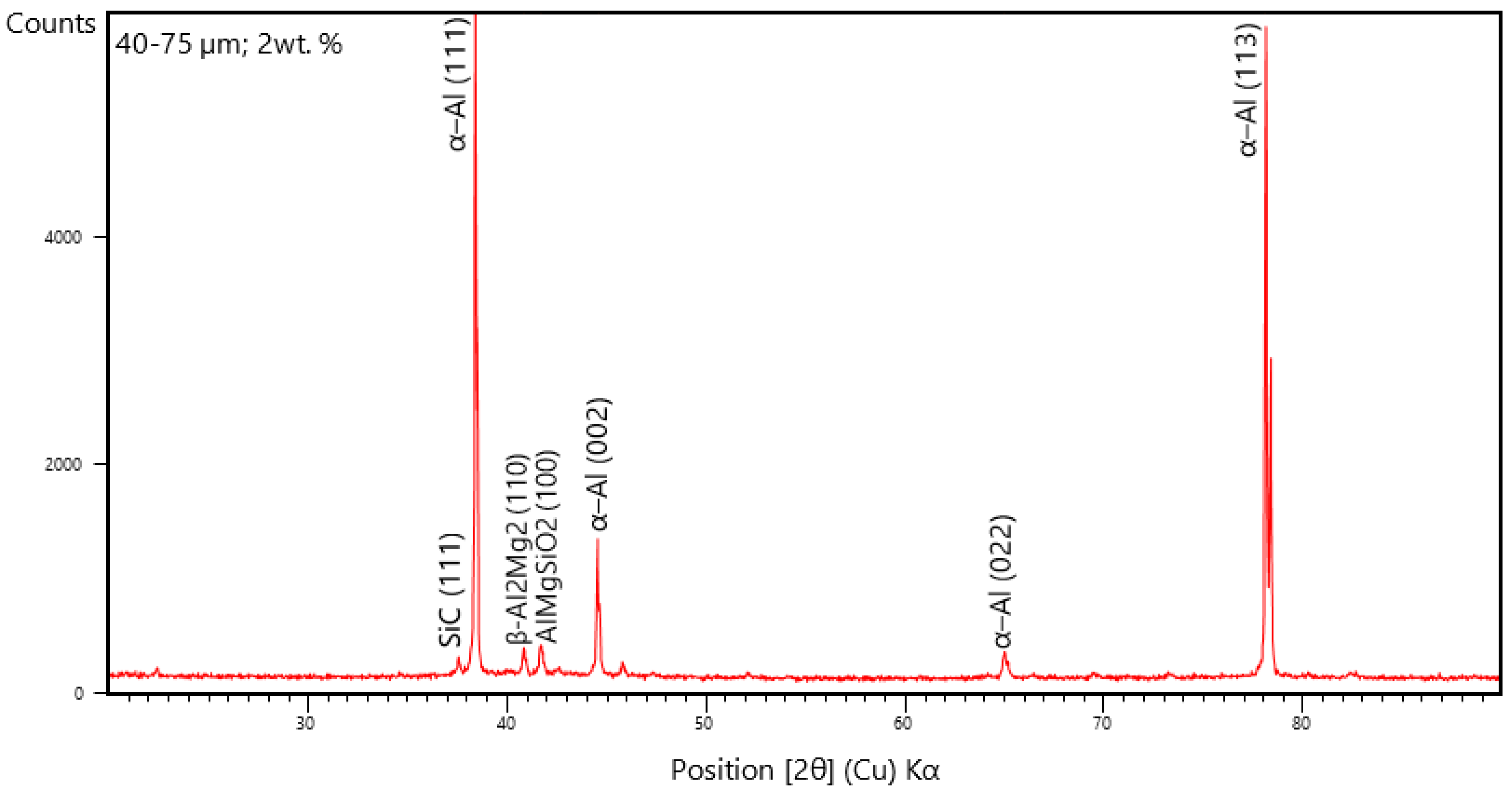

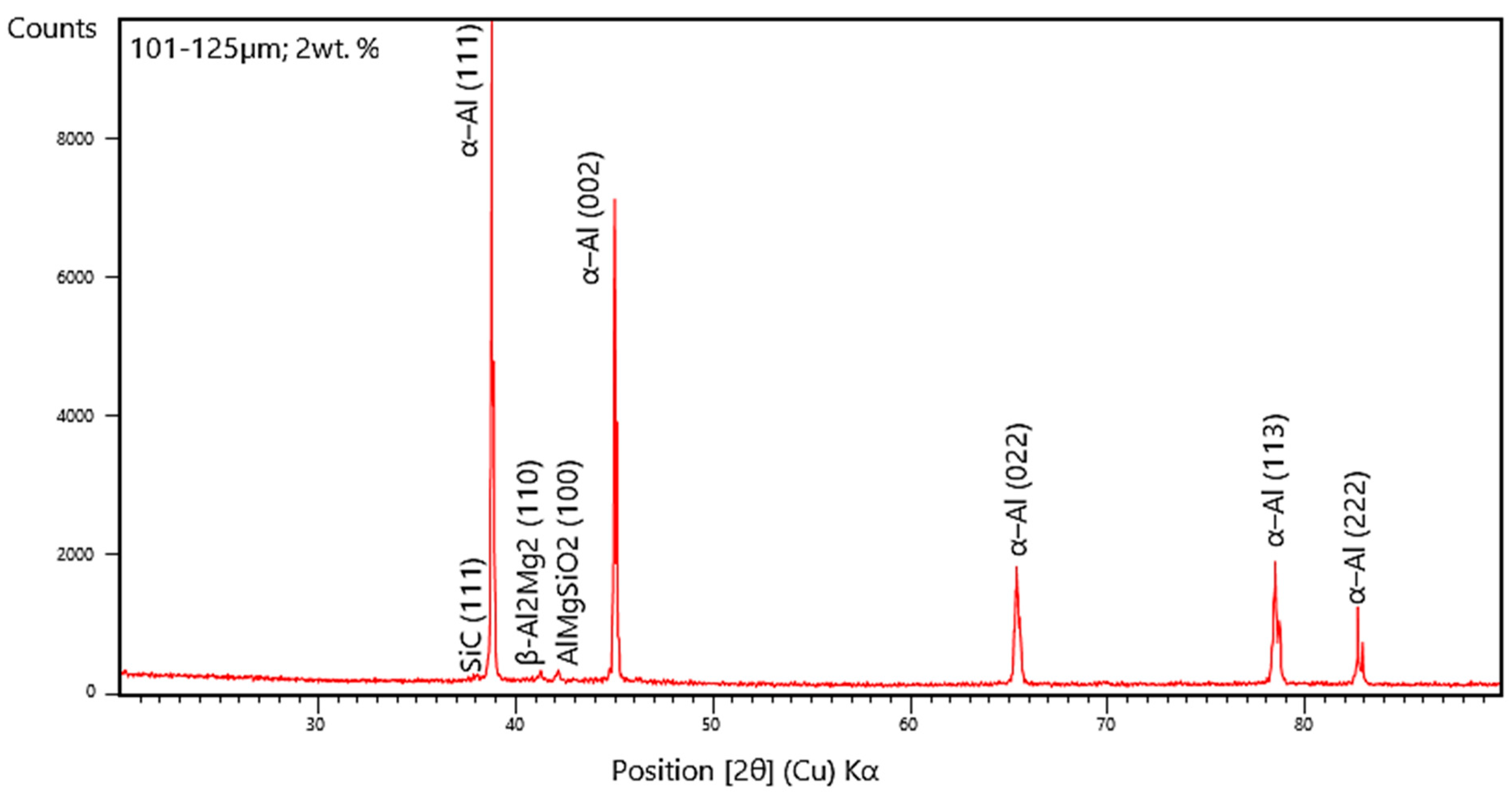

3.4. X-ray Diffraction Studies

3.5. Microstructural Studies and EDS Point Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kempaiah, U.N.; Santhosh, N.; Kumar, D.H.; Chelgeri, A.H.; Vishnu, P.; Raorane, S. Characterization of High performance Al 5083/SiCP/Fly ash hybrid metal matrix composite for advanced Aerospace Applications. Int. J. Adv. Innov. Res. 2015, 3, 334–341. [Google Scholar]

- Gowda, A.C.; Girish, D.P.; Santhosh, N.; Kumar, A. Study of Wear Characteristics of Aluminium/B4C/CNT Hybrid Composites under the Influence of Controlled Factors. Nano Trends A J. Nanotechnol. Its Appl. 2016, 18, 21–32. [Google Scholar]

- Santhosh, N.; Kempaiah, U.N.; Venkateswaran, S. Vibration Mechanics of Hybrid Al 5083/SiCp/Fly Ash Composite Plates for its Use in Dynamic Structures. J. Exp. Appl. Mech. 2017, 8, 11–18. [Google Scholar]

- Santhosh, N.; Kempaiah, U.N.; Sajjan, G.; Gowda, A.C. Fatigue behaviour of Silicon Carbide and fly ash Dispersion Strengthened High Performance Hybrid Al 5083 Metal Matrix Composites. J. Miner. Mater. Charact. Eng. 2017, 5, 78892. [Google Scholar] [CrossRef]

- Santhosh, N.; Kempaiah, U.N.; Sunil, G.S.; Reddy, H.N. Novel Aluminium–SiCp–Fly Ash Hybrid Metal Matrix Composites: Synthesis and Properties. J. Aerosp. Eng. Technol. 2017, 7, 26–33. [Google Scholar]

- Santhosh, N.; Kempaiah, U.N.; Gowda, A.C. Corrosion Characterization of Silicon Carbide and Fly Ash Particulates Dispersion Strengthened Aluminium 5083 Composites. J. Catal. Catal. 2017, 4, 9–21. [Google Scholar]

- Santhosh, N.; Kempaiah, U.N. Influence of Ceramic Particulate Reinforcements on Fly Ash Dispersion Strengthened Composites for Aircraft Structures. J. Aerosp. Eng. Technol. (JOAET) 2017, 7, 38–45. [Google Scholar]

- Santhosh, N.; Kempaiah, U.N. Vibration Characterization of SiCp and Fly Ash Dispersion Strengthened Aluminium 5083 Composites. J. Aerosp. Eng. Technol. (JOAET) 2017, 7, 61–72. [Google Scholar]

- Santhosh, N. Gufran Mohammed Khan, Ankur Dubey, Smit Patel, Aditya Phookan, Fabrication and Characterization of Tensile Properties of Aluminum 5083/Silicon Carbide/Fly Ash Composites for Advanced Engineering Applications. J. Polym. Compos. 2018, 6, 6–9. [Google Scholar]

- Santhosh, N.; Kempaiah, U.N.; Bhanupratap, R. Critically Damped Composite plates for Structural applications in Smart Cities. In Proceedings of the International Conference on Development of Smart Cities, Interface, Governance & Technology, Dr Ambedkar Institute of Technology, Bangalore, Karnataka, India, 9–10 September 2016. [Google Scholar]

- Sadashiva, M.; Shivanand, H.K.; Rajesh, M.; Santhosh, N. Corrosion Behavior of Friction Stir Welded Al 6061 Hybrid Metal Matrix Composite Plates. In Proceedings of the International Conference on Advances in Mechanical Engineering Sciences (ICAMES-17), PESCE, Mandya, Karnataka, India, 21–22 April 2017. [Google Scholar]

- Santhosh, N.; Kempaiah, U.N.; Gowda, A.C.; Rao, S. Gurumoorthy Hebbar, Evaluation of Corrosion Mechanics of Silicon Carbide and Fly Ash Reinforced Hybrid Aluminium Metal Matrix Composites. In Proceedings of the International Conference-10-on Emerging Research in Civil, Aeronautical & Mechanical Engineering, ERCAM 2017, Nitte Meenakshi Institute of Technology, Bengaluru, India, 21 July 2017; pp. 214–218. [Google Scholar]

- Ramesha, K.; Sudershanan, P.D.; Santhosh, N. Mechanical and Thermal characterization of Friction Stir weld joints of Al–Mg alloy. In Proceedings of the International Conference on Emerging Trends in Mechanical Engineering (ETME), Mandya, Karnataka state, India, 27–28 December 2017, IJRAME. ISSN 2321–3051. [Google Scholar]

- Santhosh, N.; Kempaiah, U.N. Effect of heat treatment and reinforcements on mechanical properties of aerospace grade Aluminium composites at elevated temperatures. In Proceedings of the 2nd International Conference on Recent Research Emerging Trends in Mechanical & Civil Engineering, (ICRRETMCE-2018), REVA University, Bangalore, Karnataka state, India, 13–14 July 2018. [Google Scholar]

- Santhosh, N.; Kempaiah, U.N. Effect of silicon carbide and fly ash on characteristics of Aluminium matrix composites for improved dynamic performance. In Proceedings of the Advanced Ceramics and Nano materials for sustainable development (ACeND-2018), CHRIST (Deemed to be University), Bangalore, Karnataka state, India, 19–21 September 2018. [Google Scholar]

- Ramesha, K.; Santhosh, N.; Sudersanan, P.D. Friction stir welding of dissimilar metal joints of 3103–H18 Aluminium Alloy and AZ63A-T6 Magnesium Alloy. In Proceedings of the Advanced Ceramics and Nano materials for sustainable development (ACeND-2018), CHRIST (Deemed to be University), Bangalore, Karnataka state, India, 19–21 September 2018. [Google Scholar]

- Santhosh, N.; Srinivasa, M.R.; Rammohan, Y.S.; Sadashiva, M. Enhancement of Hardness of Graphene Reinforced Aluminium Composites with Shock Waves. In Proceedings of the 3rd International Conference on Recent Emerging Trends in Materials and Mechanical Engineering, REVA University, Bangalore, India, 12–13 July 2019. [Google Scholar]

- Yellappa, M.; Puneet, U.; Krishnareddy, G.V.; Giriswamy, B.G.; Satyamurthy, N. Fabrication and Characterization of Aluminium-Fly Ash Composite Using Stir Casting Method. Int. J. Mech. Eng. Robot. Res. 2014, 3, 331–332. [Google Scholar]

- Reddy, B.R.; Srinivas, C. Fabrication and Characterization of Silicon Carbide and Fly Ash Reinforced Aluminium Metal Matrix Hybrid Composites. Mater. Today Proc. 2018, 5, 8374–8381. [Google Scholar] [CrossRef]

- Shaikh, M.B.N.; Arif, S.; Siddiqui, M.A. Fabrication and characterization of aluminium hybrid composites reinforced with fly ash and silicon carbide through powder metallurgy. Mater. Res. Express 2018, 5, 046506. [Google Scholar] [CrossRef]

- Lu, H.; Wang, X.; Zhang, T.; Cheng, Z.; Fang, Q. Design, Fabrication, and Properties of High Damping Metal Matrix Composites—A Review. Materials 2009, 2, 958–977. [Google Scholar] [CrossRef]

- Manojkumar, M.; Shanmuga Prakash, R. Wear Characteristics of Hybrid Al 6063 Matrix Composites Reinforced with Graphite and Fly Ash Particulates. Appl. Mech. Mater. 2016, 403, 20. [Google Scholar] [CrossRef]

- Yadeem, J.M.; Krishna, G. Design, Fabrication, Characterization and 414 Deformation Studies of Fly ash/SiC Reinforced AA2024 Composites. Int. J. Mech. Ind. Technol. 2015, 3, 258–268. [Google Scholar]

- Rohatgi, P.K.; Weiss, D.; Gupta, N. Applications of fly ash in synthesizing low-cost MMCs for automotive and other applications. Miner. Met. Mater. Soc. 2006, 58, 71–76. [Google Scholar] [CrossRef]

- Malaki, M.; Xu, W.; Kasar, A.K.; Menezes, P.L.; Dieringa, H.; Varma, R.S.; Gupta, M. Advanced Metal Matrix Nanocomposites. Metal 2019, 9, 330. [Google Scholar] [CrossRef]

- Anilkumar, H.C.; Hebbar, H.; Ravishankar, K. Mechanical properties of fly ash reinforced aluminium alloy (Al6061) composites. Int. J. Mech. Mater. Eng. 2011, 6, 41–45. [Google Scholar]

- Juang, S.H.; Xue, C.S. Investigation of mechanical properties and microstructures of aluminum-fly ash composite processed by friction stirring. Mater. Sci. Eng. A 2015, 640, 314–319. [Google Scholar] [CrossRef]

- Kök, M.; Özdin, K. Wear resistance of aluminium alloy and its composites reinforced by Al2O3 particles. J. Mater. Process Technol. 2007, 183, 301–309. [Google Scholar] [CrossRef]

- Kumar, K.R.; Mohanasundaram, K.M.; Subramanian, R.; Anandavel, B. Influence of fly ash particles on tensile and impact behaviour of aluminium (Al/3Cu/8.5Si) metal matrix composites. Sci. Eng. Compos. Mater. 2014, 21, 181–189. [Google Scholar] [CrossRef]

- Park, J.S.; Kim, J.M. Interface Reactions and Synthetic Reaction of Composite Systems. Materials 2010, 3, 264–295. [Google Scholar] [CrossRef]

- Gan, Y.X.; Solomon, D.; Reinbolt, M. Friction Stir Processing of Particle Reinforced Composite Materials. Materials 2010, 3, 329–350. [Google Scholar] [CrossRef]

- Srivatsan, T.S.; Al-Hajri, M. The fatigue and final fracture of SiC particulate reinforced 7034 aluminium matrix composites. Compos. Eng.-Part B 2002, 33, 391–404. [Google Scholar] [CrossRef]

- Sahin, Y.; Murphy, S. Wear performance of aluminium alloy composites containing unidirectionally-oriented silicon carbide coated boron fibres. Wear 1996, 197, 248–254. [Google Scholar] [CrossRef]

- Singla, M.; Dwivedi, D.D.; Singh, L.; Chawla, V. Development of aluminium based silicon carbide particulate metal matrix composite. J. Miner. Mater. Charact. Eng. 2009, 8, 455–467. [Google Scholar] [CrossRef]

- Hayrettin, A.; Tolga, K.; Ercan, C.; Huseyin, C. Wear behaviour of Al/(Al2O3p+SiCp) hybrid composites. Tribol. Int. 2006, 39, 213–220. [Google Scholar] [CrossRef]

- Levashov, E.; Kurbatkina, V.; Alexandr, Z. Improved Mechanical and Tribological Properties of Metal-Matrix Composites Dispersion-Strengthened by Nanoparticles. Materials 2010, 3, 97–109. [Google Scholar] [CrossRef]

- Boopathi, M.M.; Arulshri, K.; Iyandurai, N. Evaluation of Mechanical Properties of Aluminium Alloy 2024 Reinforced with Silicon Carbide and Fly Ash Hybrid Metal Matrix Composites. Am. J. Appl. Sci. 2013, 10, 219–229. [Google Scholar] [CrossRef]

- Rao, J.B.; Rao, D.V.; Prasad, K.S.; Bhargava, N.R.M.R. Dry sliding wear behaviour of fly ash particles reinforced AA 2024 composites. Mater. Sci. Pol. 2012, 30, 204–211. [Google Scholar] [CrossRef]

- Mahendra, K.V.; Radhakrishna, K. Fabrication of Al-4.5% Cu alloy with fly ash metal matrix composites and its characterization. Mater. Sci. Pol. 2007, 25, 57–68. [Google Scholar]

- Chaluvaraju, B.V.; Afzal, A.; Vinnik, D.A.; Kaladgi, A.R.; Alamri, S.; Tirth, V. Mechanical and Corrosion Studies of Friction Stir Welded Nano Al2O3 Reinforced Al-Mg Matrix Composites: RSM-ANN Modelling Approach. Symmetry 2021, 13, 537. [Google Scholar] [CrossRef]

| Chemical Analysis (Composition) | Class C Flyash wt. % | ASTM C-618 |

|---|---|---|

| SiO2 | 48.2 | - |

| Al2O3 | 18.4 | - |

| Fe2O3 | 3.7 | - |

| SiO2 + Al2O3 + Fe2O3 | 70.3 | 50 (MIN%) |

| CaO | 19.6 | - |

| f-CaO | 5.2 | - |

| CaO + f-CaO | 24.8 | 20 (MIN%) |

| MgO | 1.1 | - |

| SO3 | 1.7 | 5 (MAX%) |

| LOI | - | 6 (MAX%) |

| MOISTURE | - | 3 (MAX%) |

| Elements in the Alloy | % Present in the Alloy |

|---|---|

| Cu | 0.15 |

| Zn | 0.20 |

| Ti | 0.20 |

| Cr | 0.1 |

| Mg | 4.5 |

| Si | 0.45 |

| Fe | 0.45 |

| Mn | 0.7 |

| Al | Remainder |

| Element | Weight% | Atomic% | Net Int. | Error% | Kratio |

|---|---|---|---|---|---|

| AlK | 96.37 | 94.34 | 722.24 | 1.99 | 0.9181 |

| Element | Weight% | Atomic% | Net Int. | Error% | Kratio |

|---|---|---|---|---|---|

| AlK | 90.00 | 82.52 | 654.39 | 2.06 | 0.8451 |

| Element | Weight% | Atomic% | Net Int. | Error% | Kratio |

|---|---|---|---|---|---|

| AlK | 93.37 | 91.29 | 722.55 | 2.39 | 0.8519 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagaraja, S.; Nagegowda, K.U.; Kumar V, A.; Alamri, S.; Afzal, A.; Thakur, D.; Kaladgi, A.R.; Panchal, S.; Saleel C, A. Influence of the Fly Ash Material Inoculants on the Tensile and Impact Characteristics of the Aluminum AA 5083/7.5SiC Composites. Materials 2021, 14, 2452. https://doi.org/10.3390/ma14092452

Nagaraja S, Nagegowda KU, Kumar V A, Alamri S, Afzal A, Thakur D, Kaladgi AR, Panchal S, Saleel C A. Influence of the Fly Ash Material Inoculants on the Tensile and Impact Characteristics of the Aluminum AA 5083/7.5SiC Composites. Materials. 2021; 14(9):2452. https://doi.org/10.3390/ma14092452

Chicago/Turabian StyleNagaraja, Santhosh, Kempaiah Ujjaini Nagegowda, Anand Kumar V, Sagr Alamri, Asif Afzal, Deepak Thakur, Abdul Razak Kaladgi, Satyam Panchal, and Ahamed Saleel C. 2021. "Influence of the Fly Ash Material Inoculants on the Tensile and Impact Characteristics of the Aluminum AA 5083/7.5SiC Composites" Materials 14, no. 9: 2452. https://doi.org/10.3390/ma14092452

APA StyleNagaraja, S., Nagegowda, K. U., Kumar V, A., Alamri, S., Afzal, A., Thakur, D., Kaladgi, A. R., Panchal, S., & Saleel C, A. (2021). Influence of the Fly Ash Material Inoculants on the Tensile and Impact Characteristics of the Aluminum AA 5083/7.5SiC Composites. Materials, 14(9), 2452. https://doi.org/10.3390/ma14092452