Order–Disorder-Type Transitions Through a Multifractal Procedure in Cu-Zn-Al Alloys—Experimental and Theoretical Design

Abstract

1. Introduction

- Ms (Martensite start)—the temperature at which the martensitic transformation initiates during cooling.

- Mf (Martensite finish)—the temperature at which the transformation to martensite completes.

- As (Austenite start)—the temperature at which the reverse transformation begins upon heating.

- Af (Austenite finish)—the temperature at which the material fully reverts to austenite.

- Shape Memory Effect (SME): This effect involves the recovery of a previously induced deformation (introduced below As) upon heating the material above Af, due to the reversible nature of the phase transformation.

- Superelasticity (SE): Also referred to as pseudoelasticity, this occurs at temperatures above Af and is characterized by a stress-induced martensitic transformation during loading, followed by an austenitic reversion during unloading.

2. Experimental Design

2.1. Materials and Methods

- Pellet size: Influences the microstructural configuration, with implications for phase transformation dynamics.

- Sample thickness: Affects the material’s thermal response and mechanical performance, thereby impacting shape recovery efficiency.

- Chemical composition determination: Optimal ratios were defined to achieve the desired thermal and mechanical performance.

- Load calculation and preparation: Precise quantities of each component were weighed to ensure compositional accuracy.

- Melting: Controlled melting was carried out to maintain homogeneity and minimize contamination.

- Alloying: Metals were combined to yield a uniform alloy composition.

- Casting: The alloy was cast under regulated cooling conditions to avoid defects and maintain structural integrity. The casting was carried out in a vacuum induction furnace under an inert argon atmosphere. The molds were preheated, in order to reduce thermal shock and allow for better control of cooling gradients. This step was critical in reducing the formation of cracks and segregation zones.

- Low production costs, making them suitable for mass manufacturing (while shape memory alloys are generally considered to be costly, Cu-Zn-Al variants have a lower production cost compared to Ni-Ti variants, due to more available and less expensive constituent elements);

- High thermal conductivity, supporting rapid heat transfer;

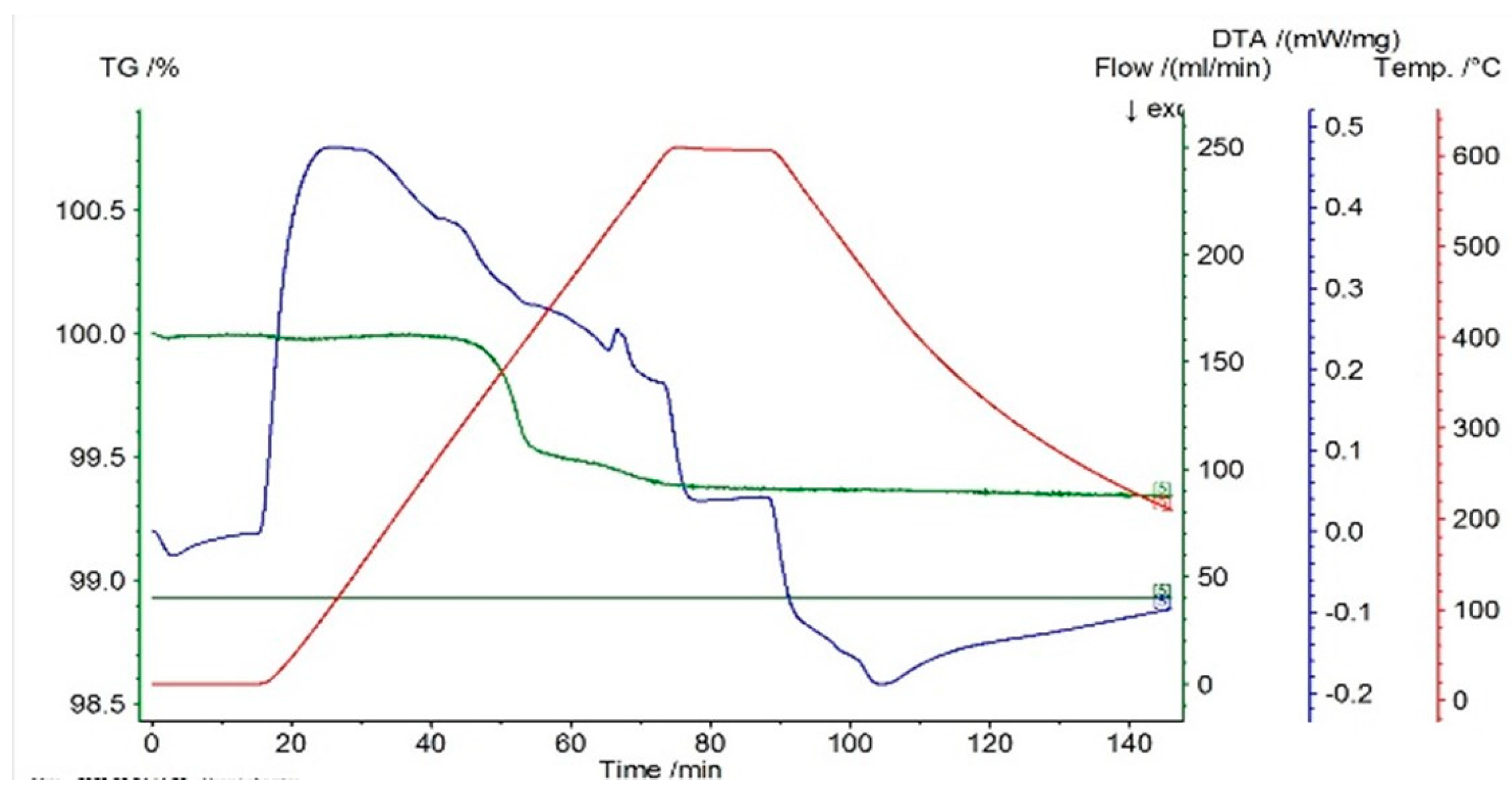

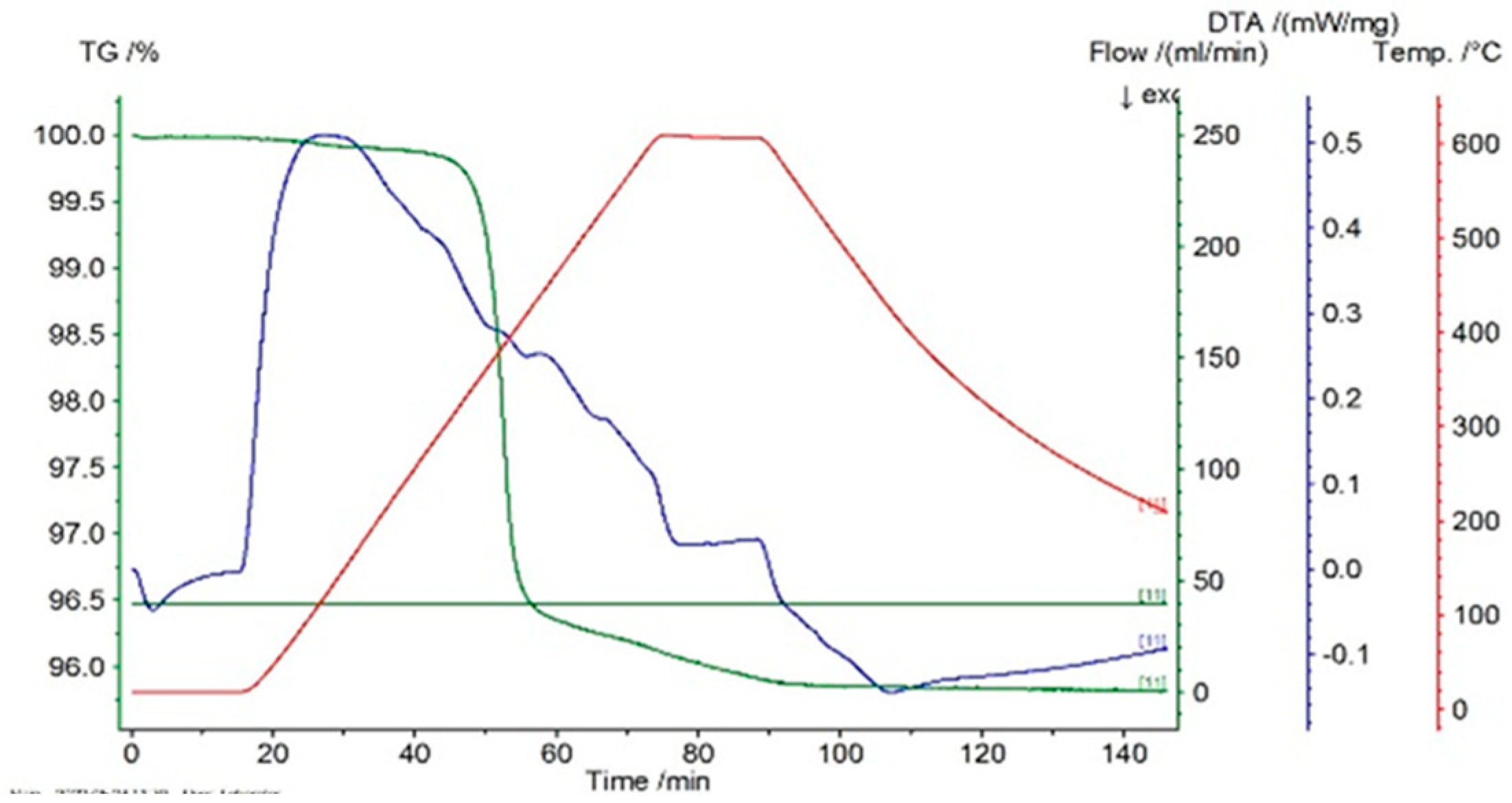

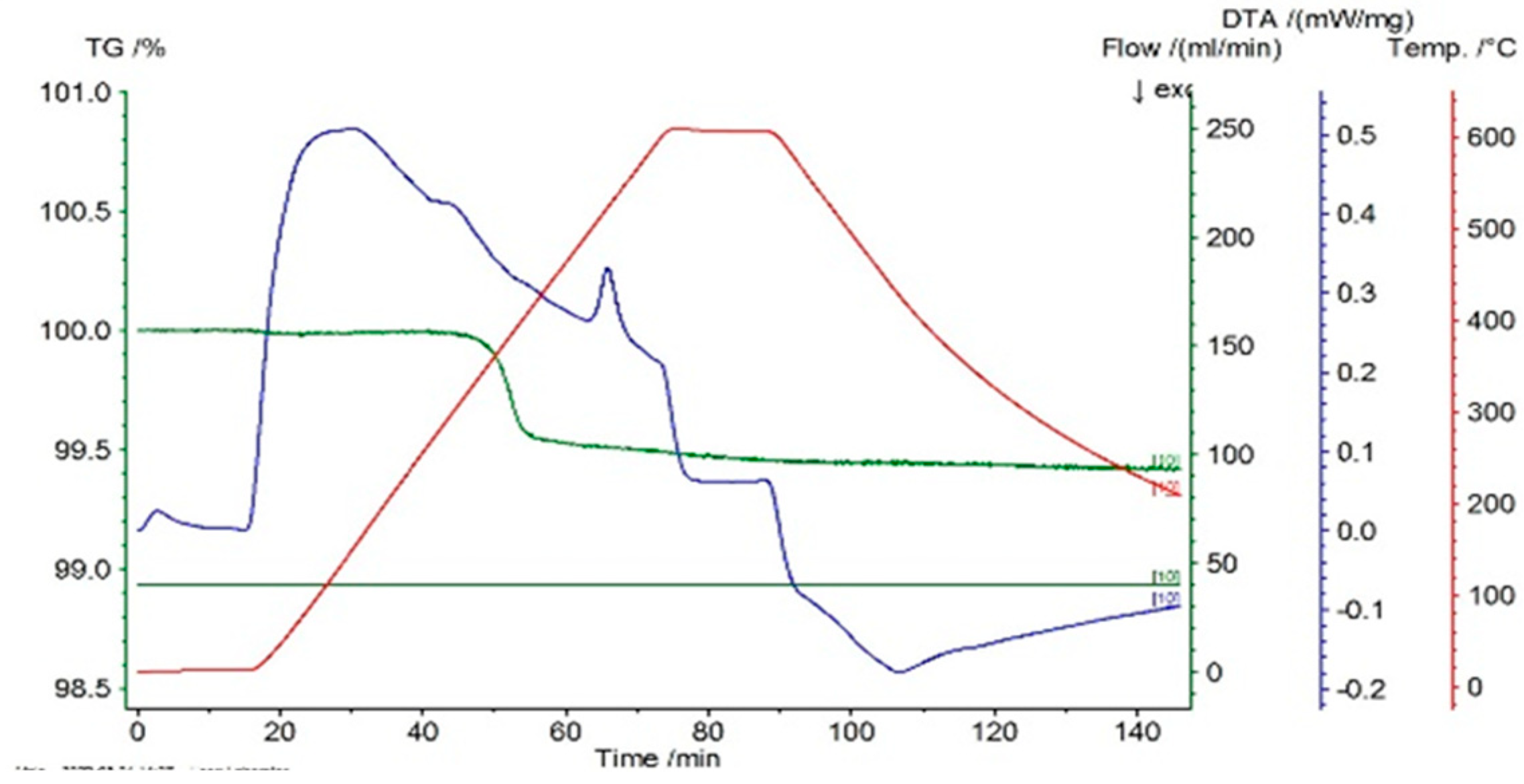

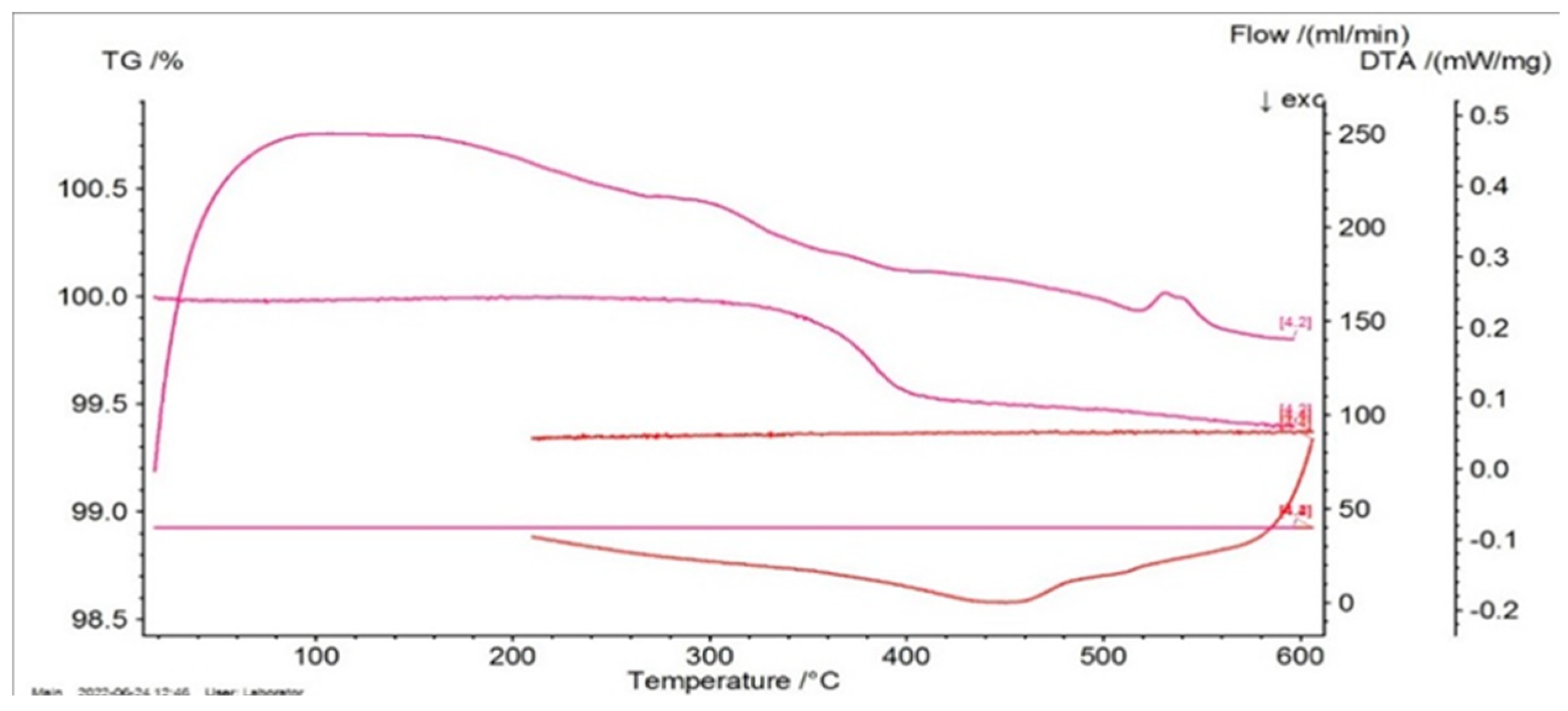

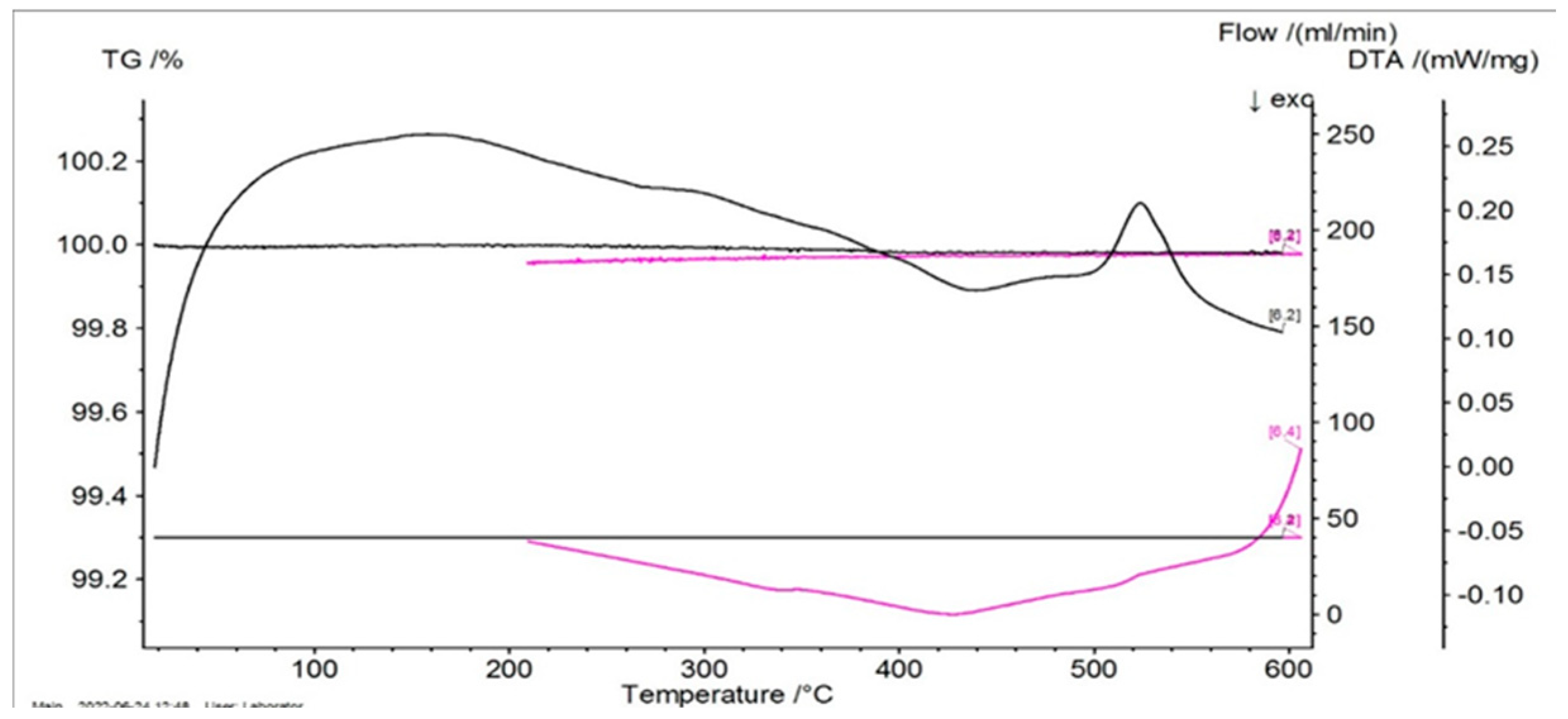

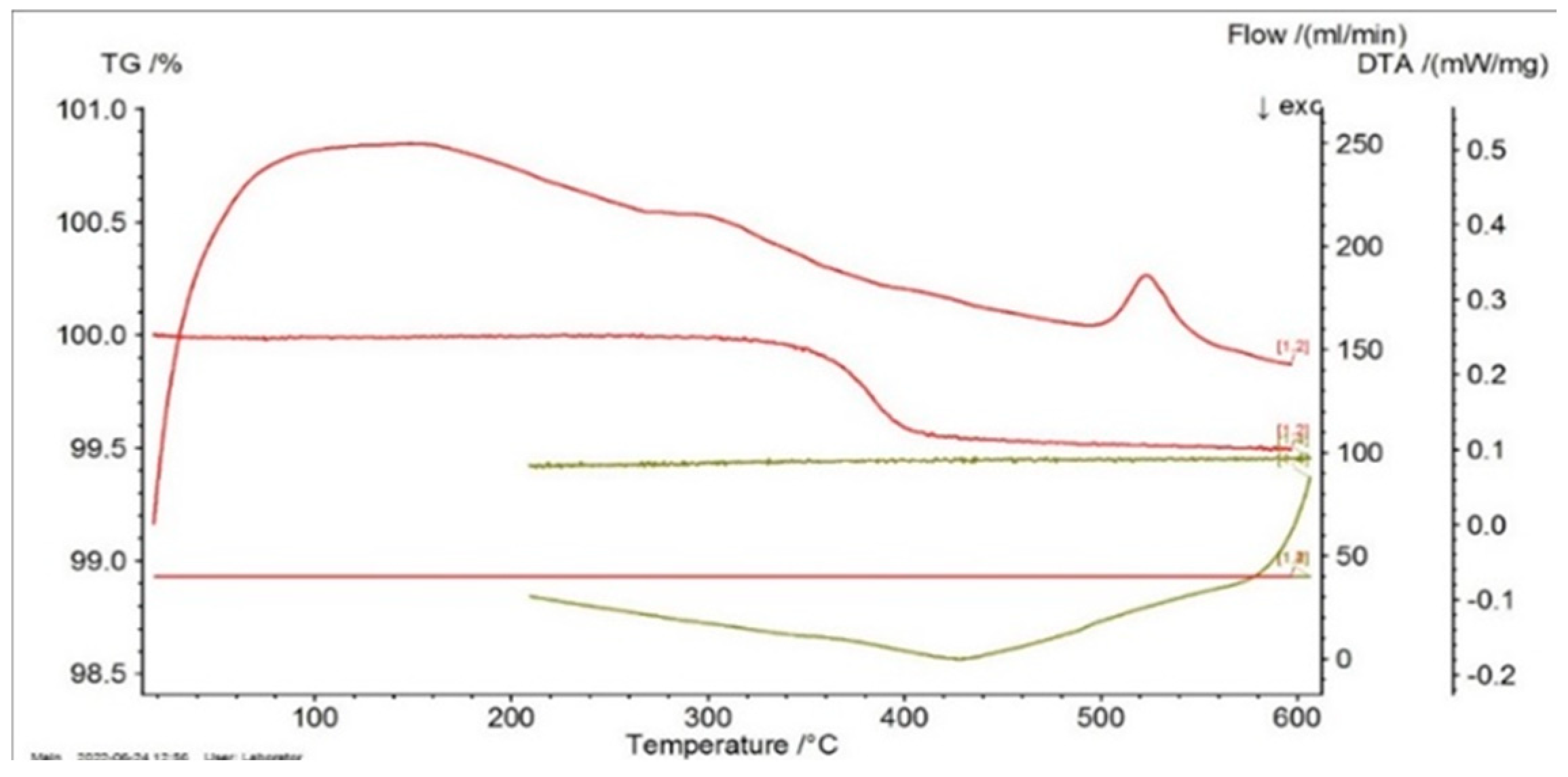

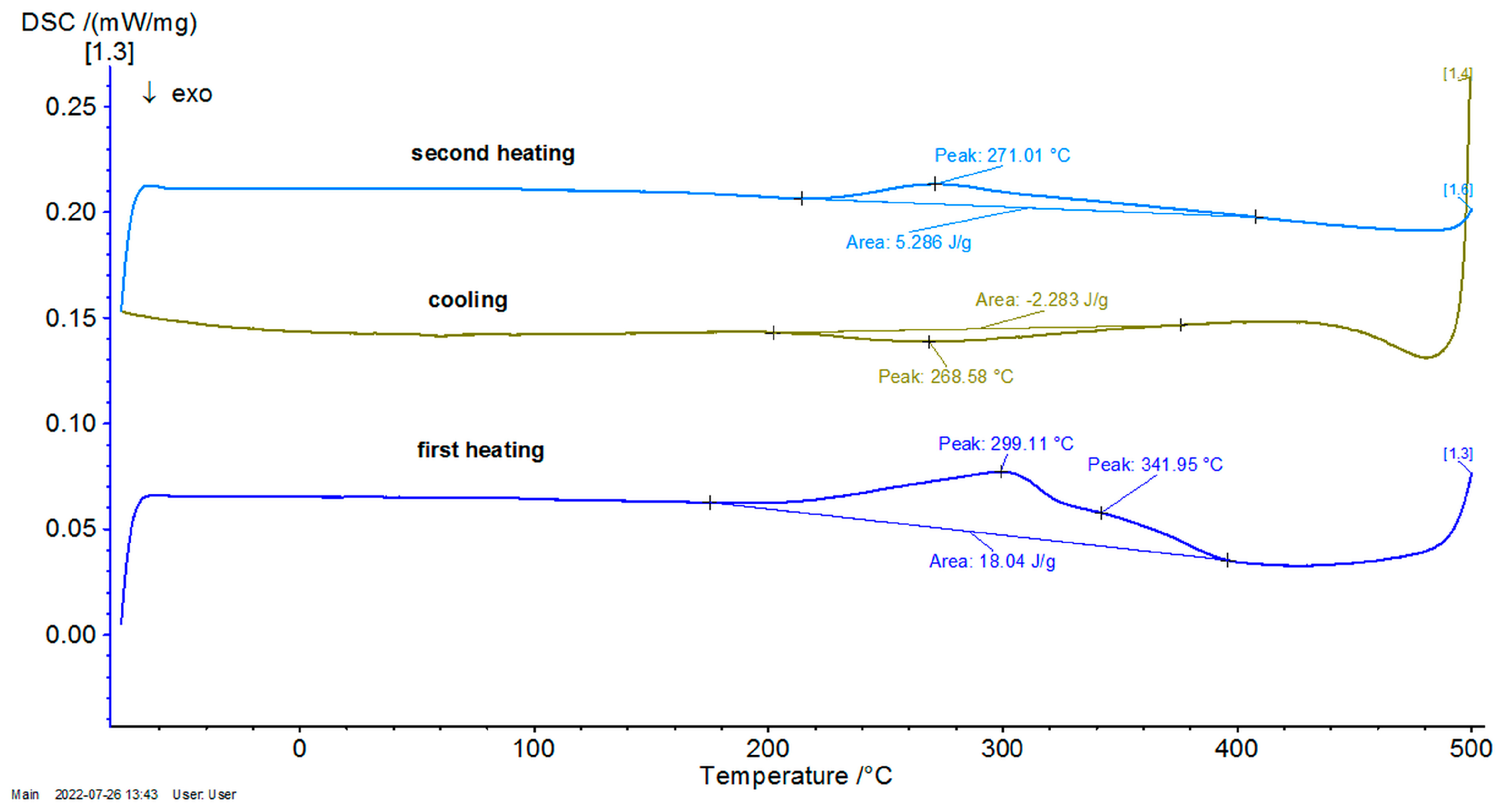

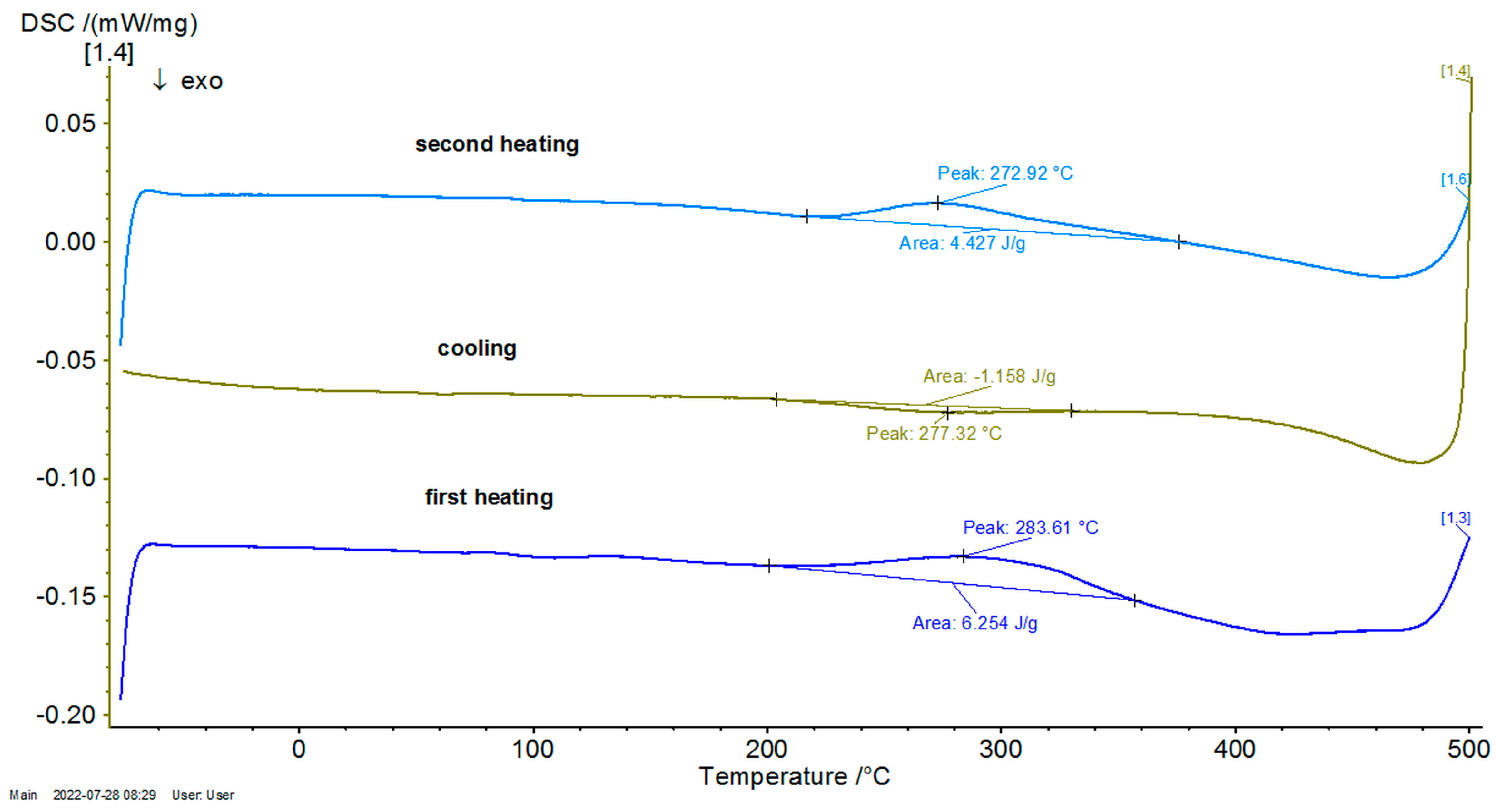

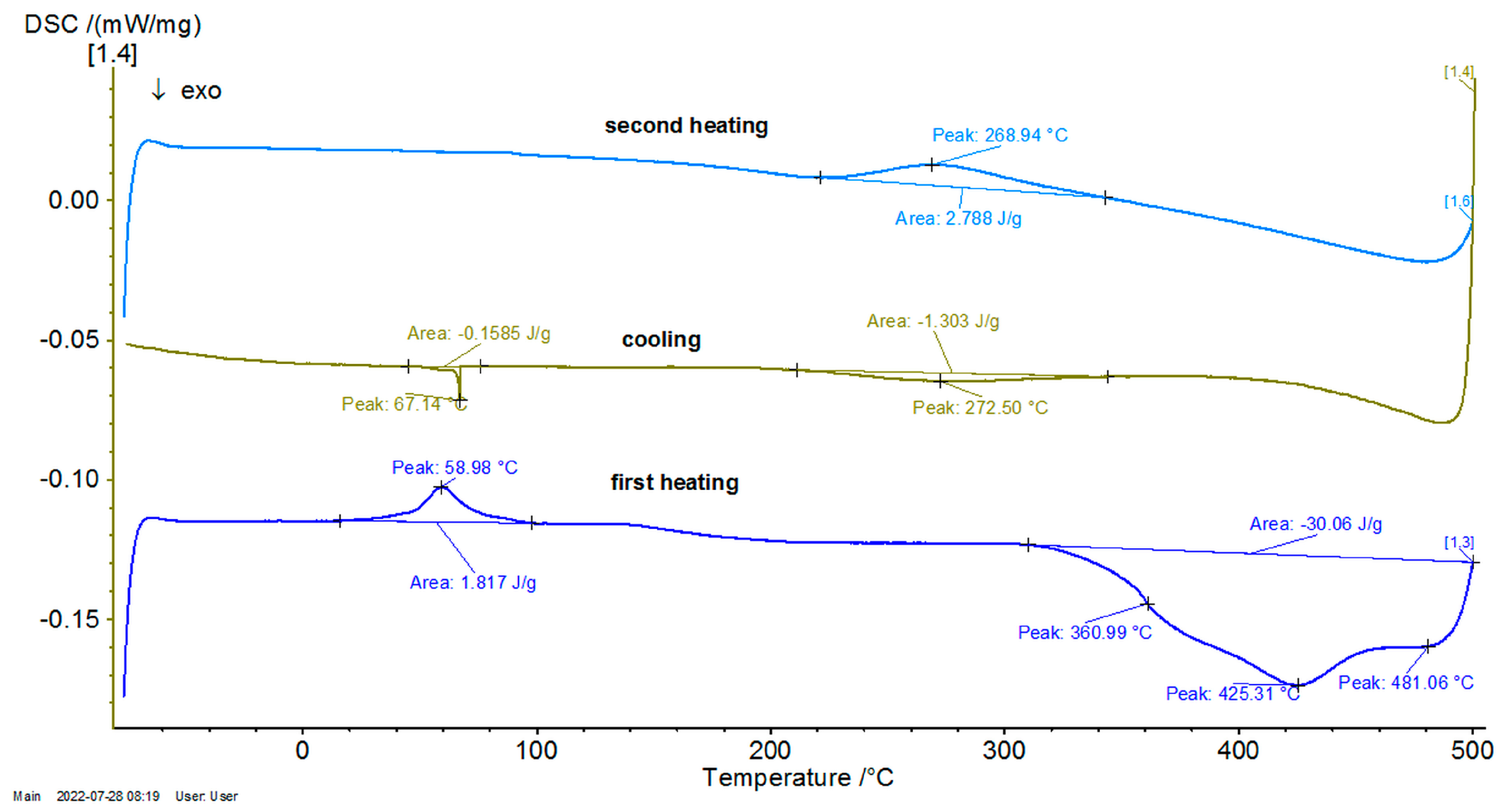

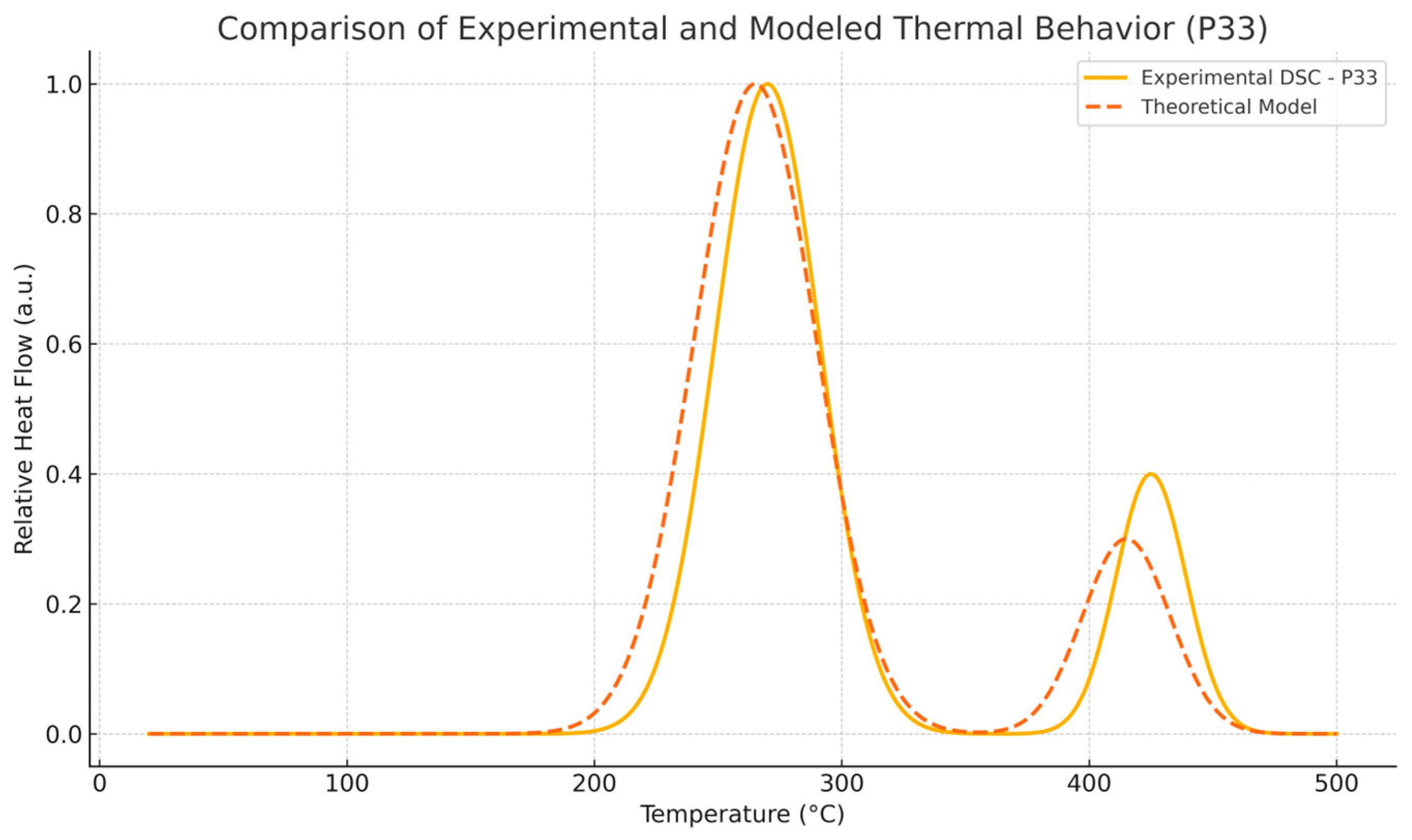

2.2. Thermal Properties

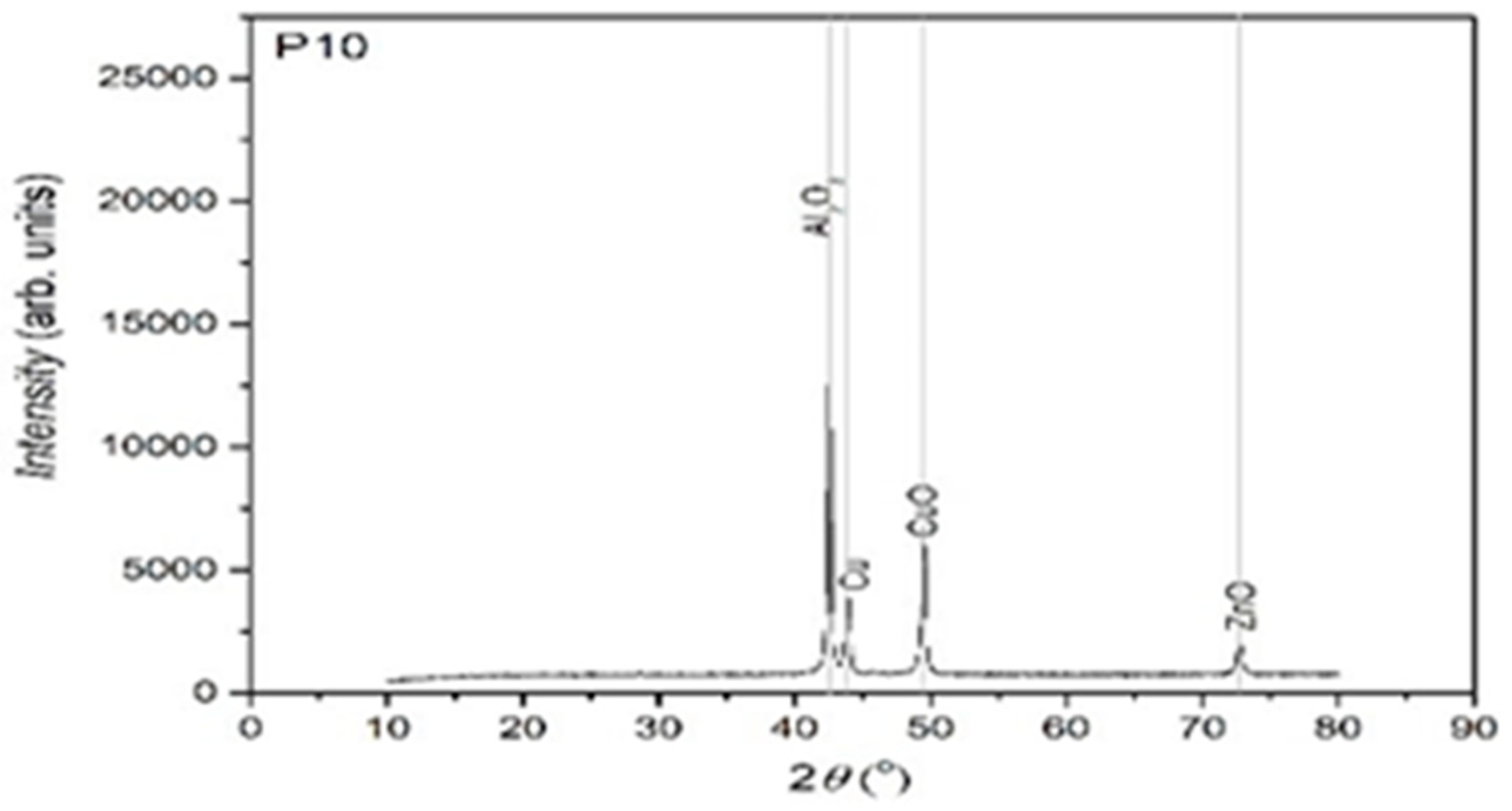

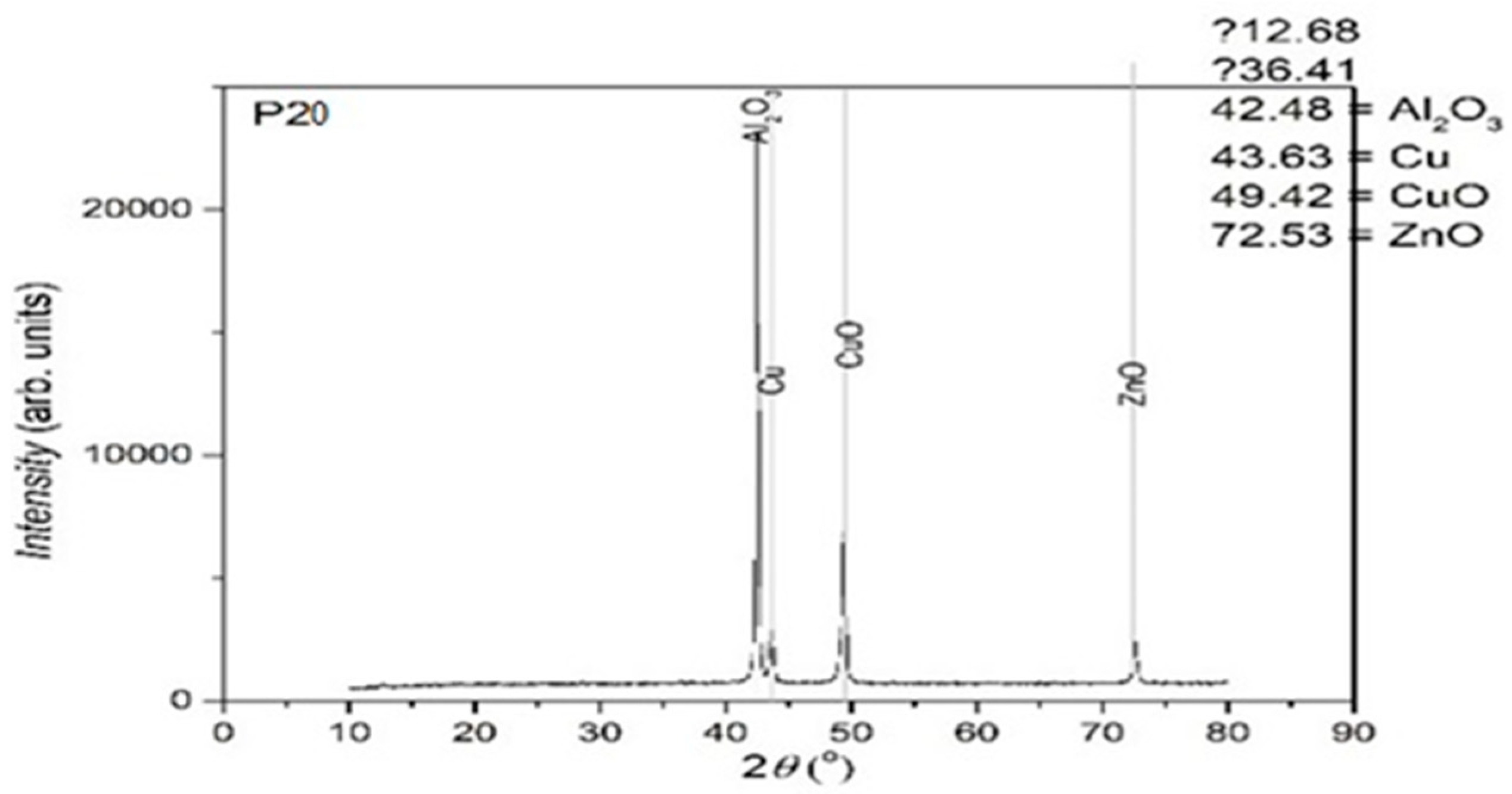

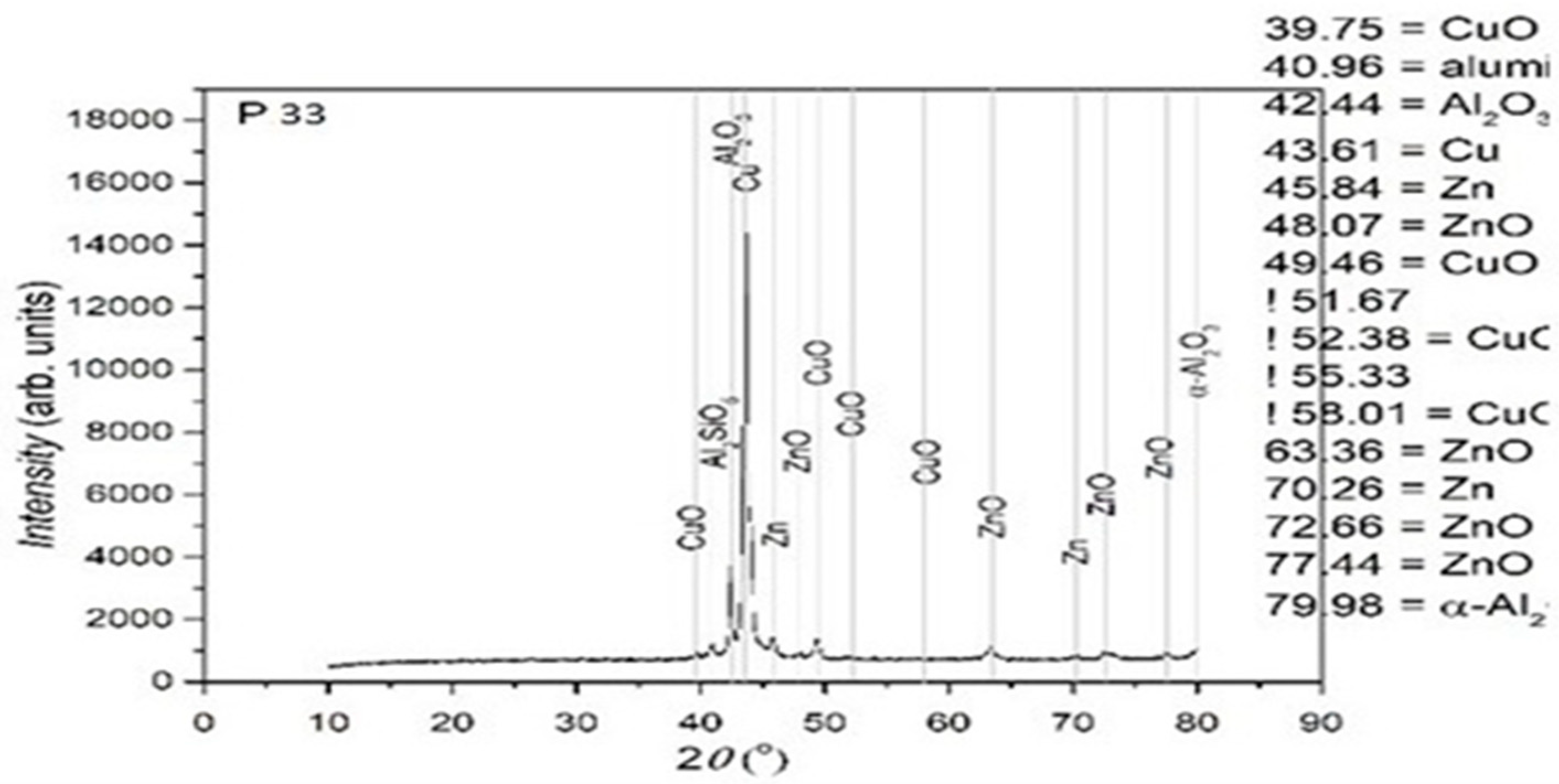

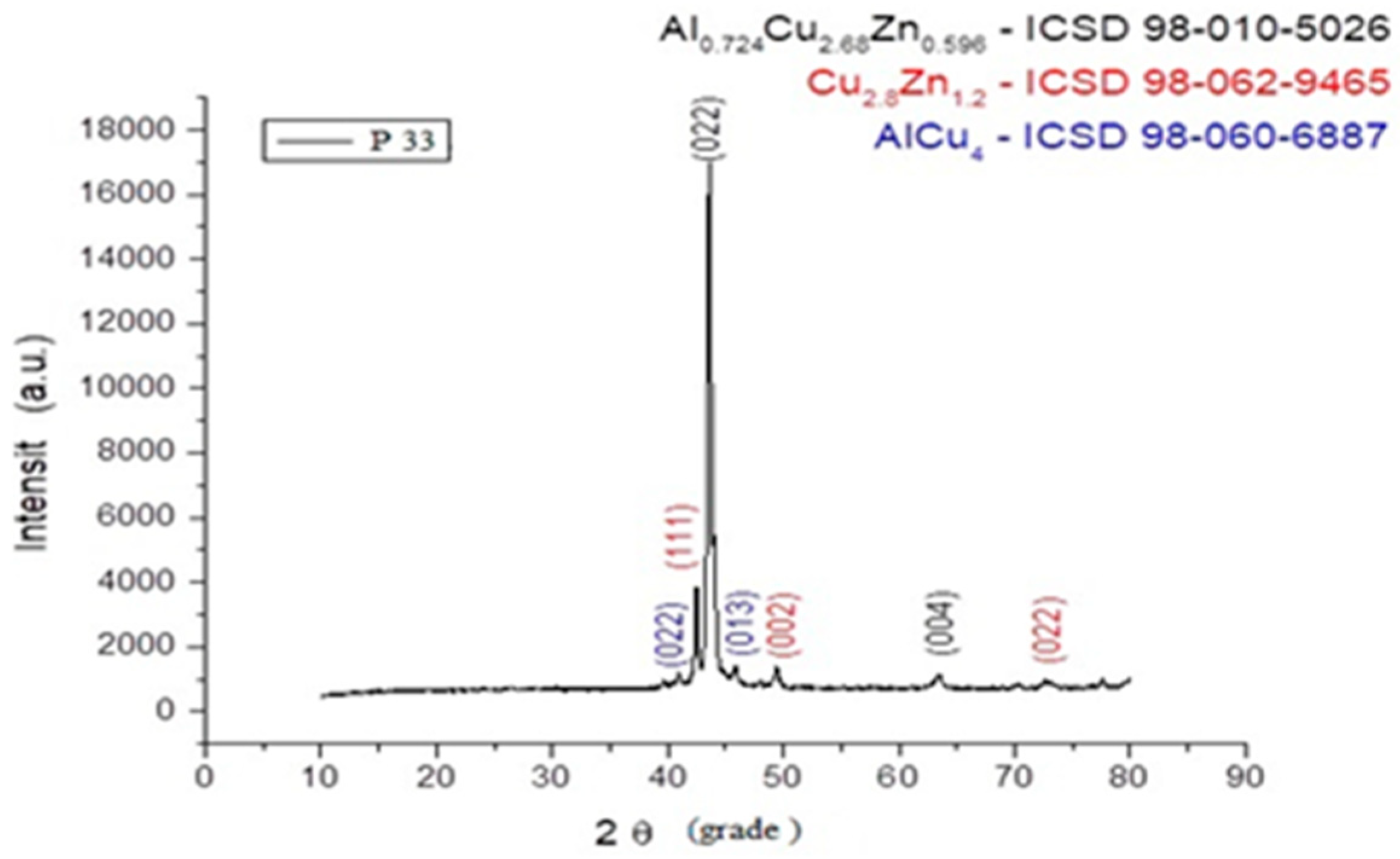

2.3. XRD Structural Analysis

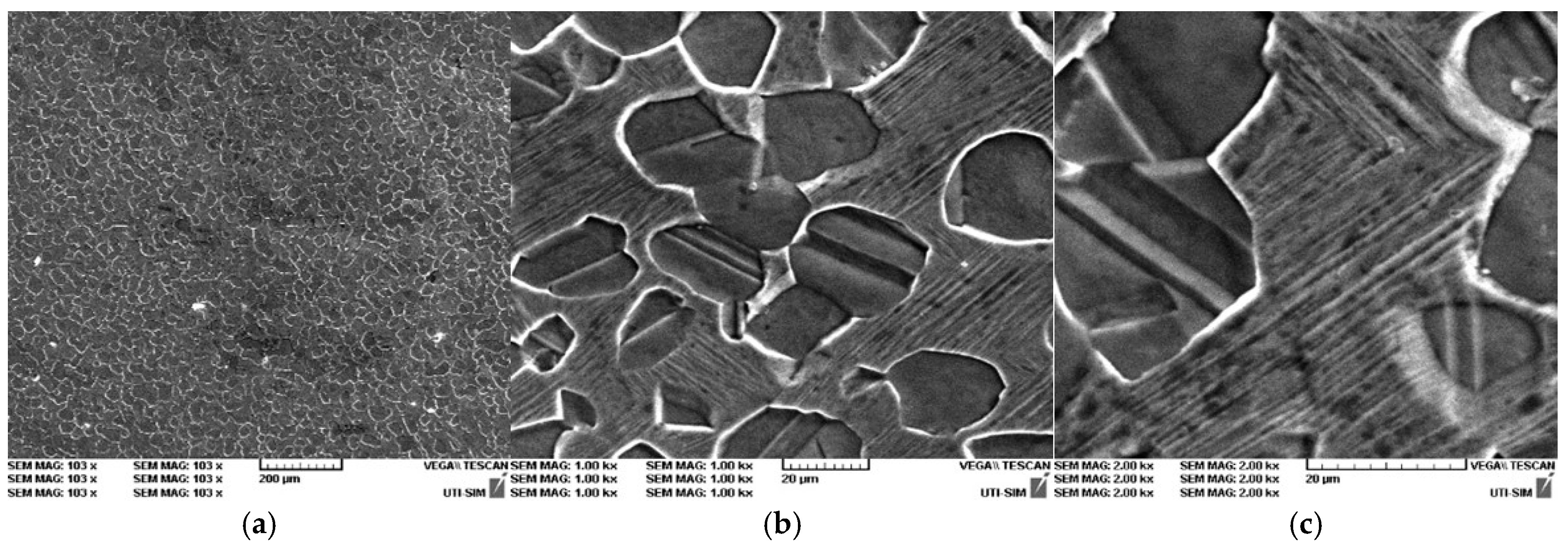

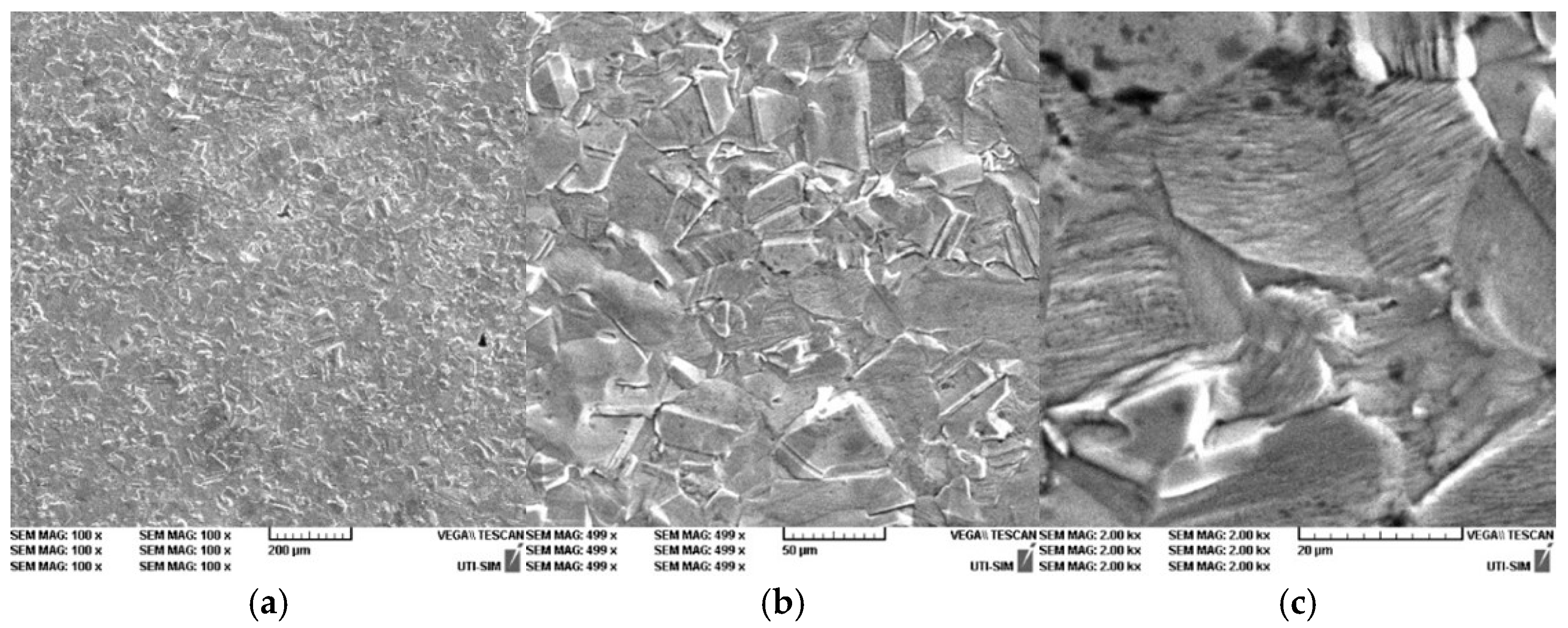

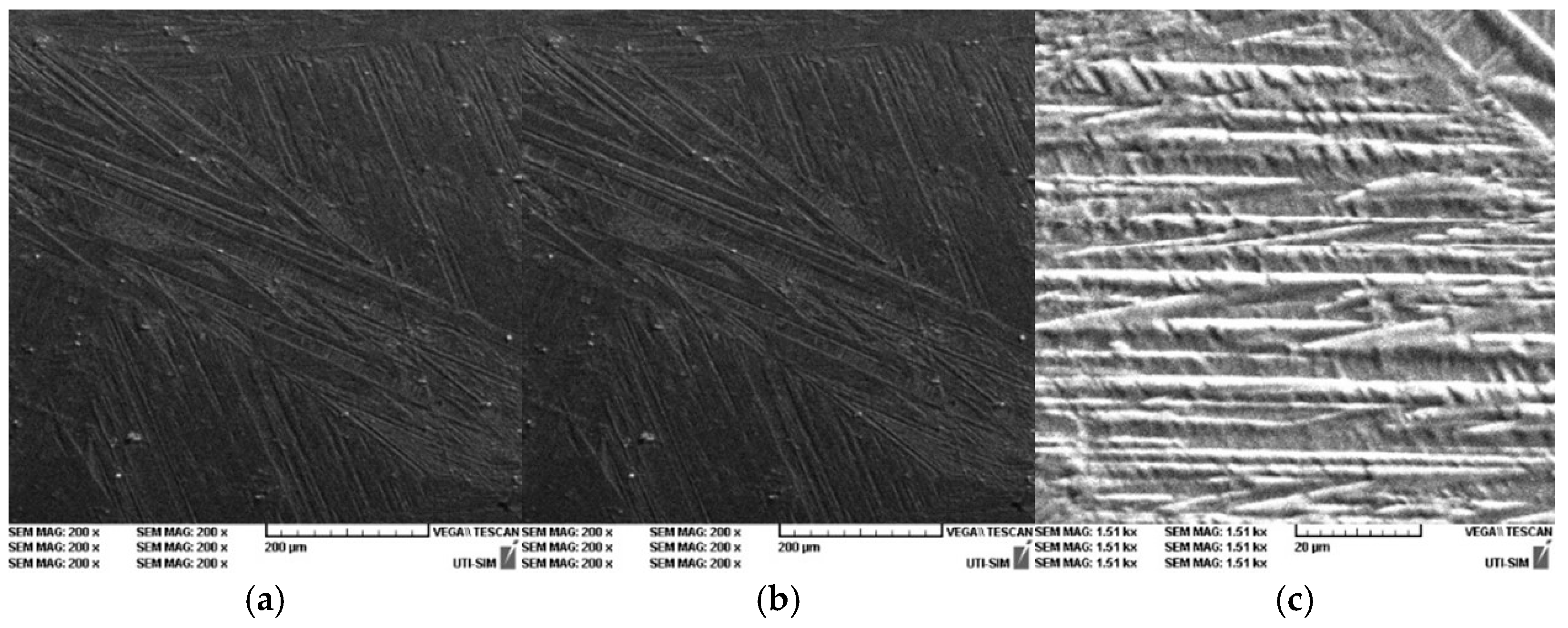

2.4. SEM Morphological Surface Analysis

3. Theoretical Design

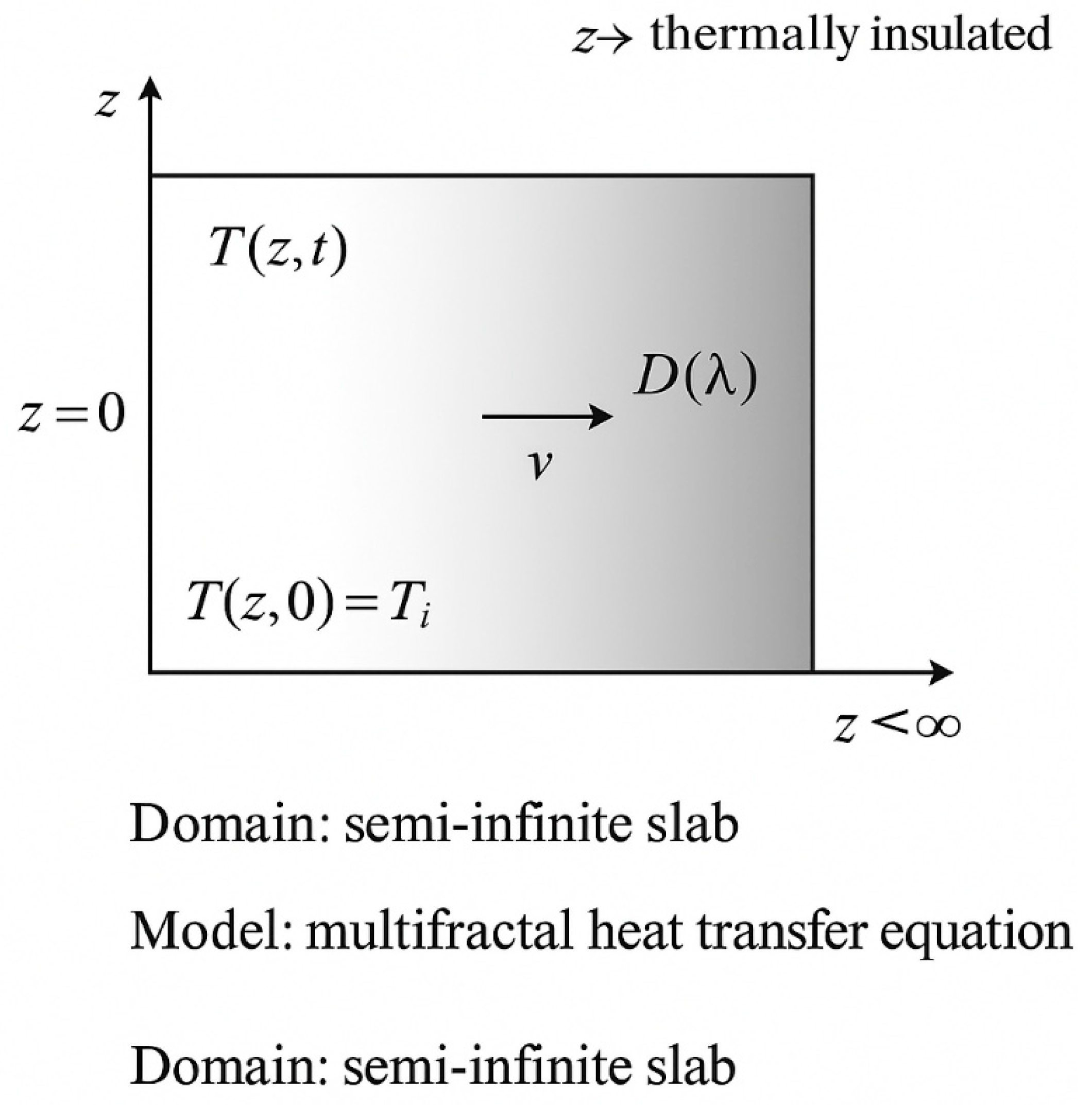

3.1. Multifractal Differential Equation of Thermal Transfer and Its Implications

- Thermal conductivity becomes a function of the resolution scale;

- Heat transfer is modified to reflect the multifractal, non-differentiable paths in the material;

- This leads to anomalous diffusion and complex thermal behaviour, which must be modelled with new, generalized equations that account for the multifractal structure of space and matter. It is noted that the thermal transfer Equation (1) reflects precisely the above statements.

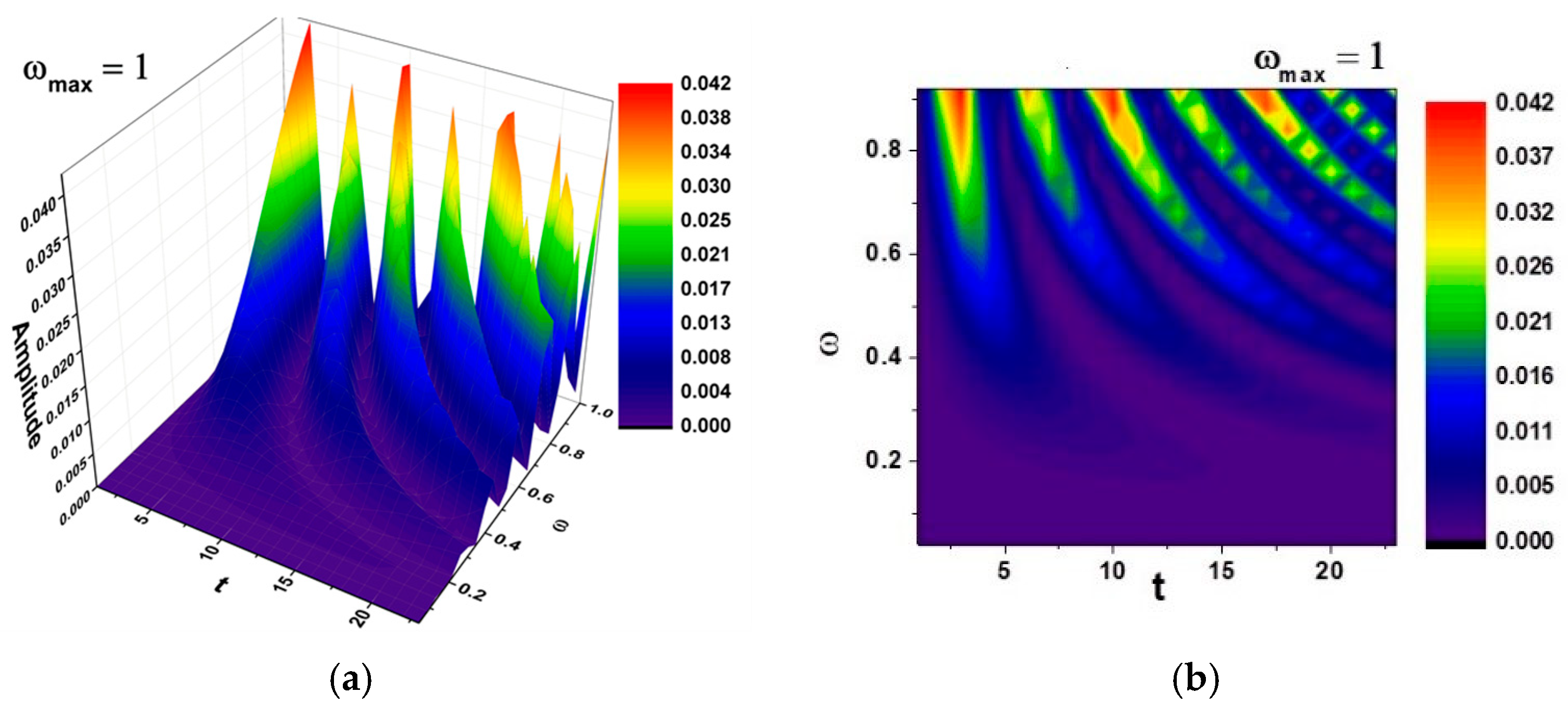

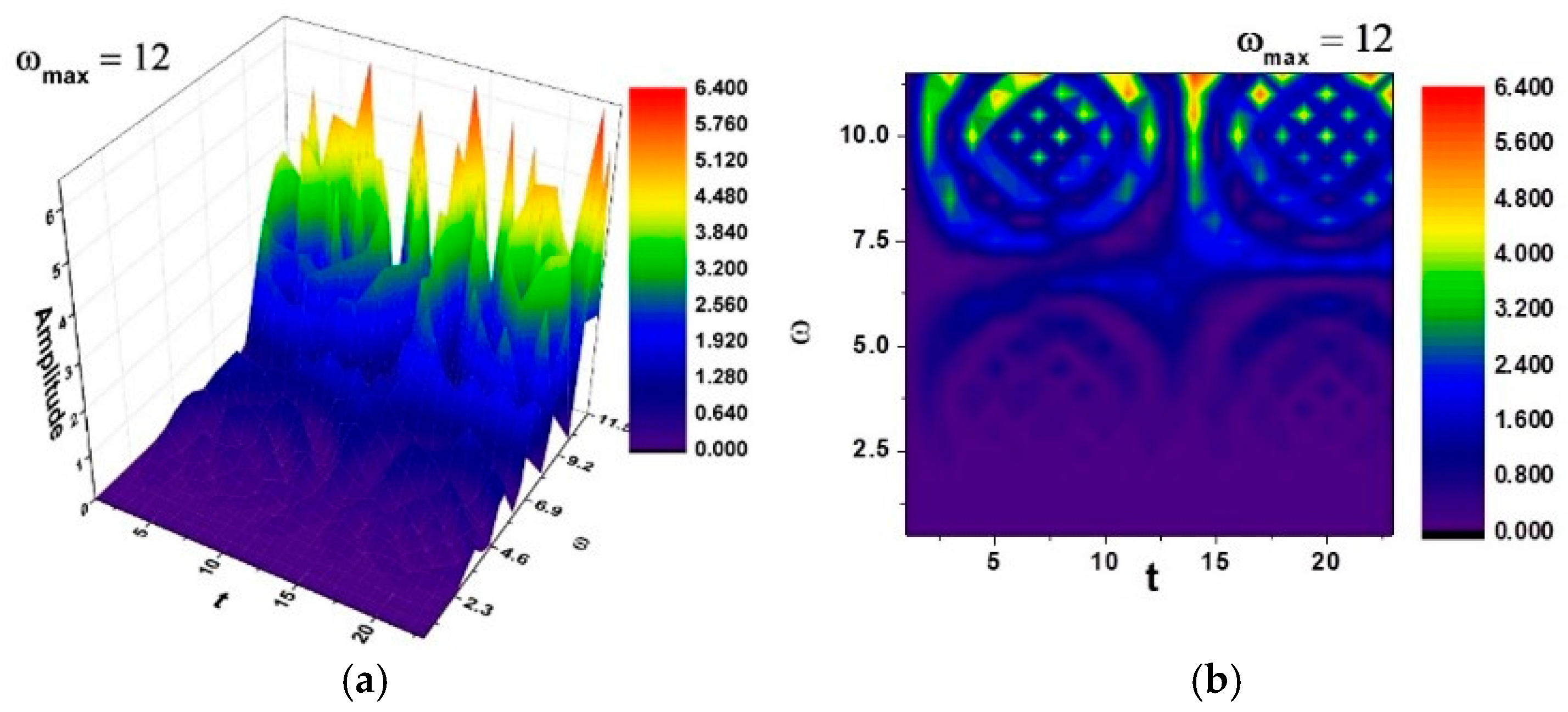

3.2. Thermal-Type Patterns

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

- i.

- The dynamics pertaining to the structural units of the SMA may reveal a dominant fractal dimension, which may help in pinpointing a global SMA pattern which is consistent with a particular global SMA structurality and functionality.

- ii.

- The dynamics pertaining to the structural units of the SMA could include a “collection” of fractal dimensions, which may help in pinpointing local SMA patterns that are compatible with particular, zone-specific SMA structures and functions.

- iii.

- By means of the -order singularity spectrum, one can pinpoint universality classes in the domain of SMA dynamics, even when the attractors related to said dynamics have distinct aspects.

- i.

- ii.

- Multifractal SMA dynamics through non-Markov stochasticity dictated by the subsequent boundaries [3]:

References

- Arun, D.I.; Chakravarthy, P.; Arockia Kumar, R.; Santhosh, B. Shape Memory Materials; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Concilio, A.; Lecce, L. Shape Memory Alloy Engineering: For Aerospace, Structural, and Biomedical Applications, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2021. [Google Scholar]

- Mazzer, E.M.; Da Silva, M.R.; Gargarella, P. Revisiting Cu-Based Shape Memory Alloys: Recent Developments and New Perspectives. J. Mater. Res. 2022, 37, 162–182. [Google Scholar] [CrossRef]

- Balapgol, B.S.; Kulkarni, S.A.; Bajoria, K.M. A Review on Shape Memory Alloy Structures. Int. J. Acoust. Vib. 2004, 9, 61–68. [Google Scholar] [CrossRef]

- Naresh, C.; Bose, P.S.C.; Rao, C.S.P. Shape Memory Alloys: A State of Art Review. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012054. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Recent developments in the research of shape memory alloys. Intermetallics 1999, 7, 511–528. [Google Scholar] [CrossRef]

- Placinta, C. Contribuții Experimentale și Teoretice Asupra Studiului Proprietăților Aliajelor cu Memoria Formei CuZnAl. Ph.D. Thesis, “Gheorghe Asachi” Technical University of Iasi, Iași, Romania, 2022. [Google Scholar]

- Sampath, V. Improvement of Shape-Memory Characteristics and Mechanical Properties of Copper–Zinc–Aluminum Shape-Memory Alloy with Low Aluminum Content by Grain Refinement. Mater. Manuf. Process. 2006, 21, 789–795. [Google Scholar] [CrossRef]

- Sampath, V. Effect of Thermal Processing on Microstructure and Shape-Memory Characteristics of a Copper–Zinc–Aluminum Shape-Memory Alloy. Mater. Manuf. Process. 2007, 22, 9–14. [Google Scholar] [CrossRef]

- Awan, I.Z.; Khan, A.Q. Fascinating Shape Memory Alloys. J. Chem. Soc. Pak. 2018, 40. Available online: https://jcsp.org.pk/PublishedVersion/148524a9-bbff-4347-a553-9b3c10d5ed34Manuscript%20no%201,%20Final%20Gally%20Proof%20of%2011738%20(Dr.%20AQ%20Khan)%20(3).pdf (accessed on 25 May 2025).

- Gillet, Y. Dimensionnement D’éléments Simples en Alliage à Mémoire de Forme. Ph.D. Thesis, Université Paul Verlaine, Metz, France, 1994. [Google Scholar]

- Gomidželović, L.; Požega, E.; Kostov, A.; Vuković, N.; Krstić, V.; Živković, D.; Balanović, L. Thermodynamics and Characterization of Shape Memory Cu–Al–Zn Alloys. Trans. Nonferrous Met. Soc. China 2015, 25, 2630–2636. [Google Scholar] [CrossRef]

- Hane, K.F.; Shield, T.W. Microstructure in a cubic to orthorhombic transition. J. Elast. Phys. Sci. Solids 2000, 59, 267–318. [Google Scholar]

- Mandelbrot, B.B. The Fractal Geometry of Nature; W. H. Freeman and Co.: San Fracisco, CA, USA, 1982. [Google Scholar]

- Jackson, E.A. Perspectives of Nonlinear Dynamics; Cambridge University Press: New York, NY, USA, 1993. [Google Scholar]

- Nottale, L. Scale Relativity and Fractal Space-Time: A New Approach to Unifying Relativity and Quantum Mechanics; Imperial College Press: London, UK, 2011. [Google Scholar]

- Cristescu, C.P. Nonlinear Dynamics and Chaos. Theoretical Fundaments and Applications; Romanian Academy Publishing House: Bucharest, Romania, 2008. [Google Scholar]

- Ouadfeul, S.-A. Fractal Analysis—Applications and Updates; BoD–Books on Demand: Norderstedt, Germany, 2024. [Google Scholar]

- Agop, M.; Paun, V.P. On the New Perspectives of Fractal Theory. Fundaments and Applications; Romanian Academy Publishing House: Bucharest, Romania, 2017. [Google Scholar]

- Fels, M.; Olver, P.J. Moving coframes: I. A practical algorithm. Acta Appl. Math. 1998, 51, 161–213. [Google Scholar] [CrossRef]

- Carinena, J.F.; Ramos, A. Integrability of Riccati Equation form a Group Theoretical Viewpoint. arXiv 1998, arXiv:math.ph/9810005V1. [Google Scholar]

- Stoler, D. Generalized Coherent States. Phys. Rev. 1971, 4, 2309. [Google Scholar] [CrossRef]

- Neurohr, A.J.; Dunand, D.C. Mechanical Anisotropy of Shape-Memory NiTi with Two-Dimensional Networks of Micro-Channels. Acta Mater. 2011, 59, 4616–4630. [Google Scholar] [CrossRef]

- Ravari, M.K.; Esfahani, S.N.; Andani, M.T.; Kadkhodaei, M.; Ghaei, A.; Karaca, H.; Elahinia, M. On the Effects of Geometry, Defects, and Material Asymmetry on the Mechanical Response of Shape Memory Alloy Cellular Lattice Structures. Smart Mater. Struct. 2016, 25, 025008. [Google Scholar] [CrossRef]

| Sample No. | Cu (%) | Zn (%) | Al (%) | Trace Materials (%) |

|---|---|---|---|---|

| P5 | 65.45 | 20.71 | 11.72 | 0.05 |

| P10 | 68.35 | 16.36 | 15.25 | 0.04 |

| P13 | 67.36 | 18.16 | 14.45 | 0.03 |

| P16 | 68.85 | 16.28 | 14.81 | 0.04 |

| P20 | 72.22 | 13.56 | 14.19 | 0.03 |

| P26 | 70.19 | 16.51 | 13.18 | 0.04 |

| P30 | 68.81 | 19.45 | 11.69 | 0.05 |

| P33 | 68.89 | 20.14 | 10.92 | 0.05 |

| P36 | 69.87 | 17.52 | 12.57 | 0.04 |

| Pos. [°2Th.] | Maximum [cts] | FWHM [°2Th.] | Miller Index | Matching/Fitting | Material Structure | Lattice (Å) Parameter |

|---|---|---|---|---|---|---|

| 39.68 | 146 | 0.38(3) | 001 | 98-018-2360 | ZnO—cubic | |

| 40.893 | 361 | 0.45(3) | 022 | 98-060-6887 | AlCu4—cubic | |

| 42.464 | 2841 | 0.269(3) | 111 | 98-062-9465; 98-015-1371 | Cu2.8Zn1.2—cubic | 3.684 |

| 43.5909 | 15,790 | 0.345(1) | 022 | 98-010-5026; 98-060-6887 | Al0.724Cu2.68Zn0.596—cubic | 5.866 |

| 44.034 | 3264 | 0.294(5) | 033 | 98-015-1371 | Al4Cu9—cubic | |

| 45.779 | 493 | 0.71(3) | 013 | 98-060-6887; 98-015-1371 | AlCu4—cubic | 6.261 |

| 49.401 | 646 | 0.44(1) | 002 | 98-062-9465; 98-015-1371 | Cu2.8Zn1.2—cubic | |

| 63.405 | 412 | 0.72(3) | 004 | 98-010-5026 | Al0.724Cu2.68Zn0.596—cubic | |

| 70.26 | 115 | 0.68(5) | 233 | 98-060-6887 | AlCu4—cubic | |

| 72.83 | 190 | 1.17(4) | 022 | 98-062-9465 | Cu2.8Zn1.2—cubic | |

| 77.555 | 189 | 0.38(2) | 143 | 98-060-6887; 98-015-1371 | AlCu4—cubic |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Plăcintă, C.; Nedeff, V.; Panainte-Lehăduş, M.; Puiu Costescu, E.; Petrescu, T.-C.; Stanciu, S.; Agop, M.; Mirilă, D.-C.; Nedeff, F. Order–Disorder-Type Transitions Through a Multifractal Procedure in Cu-Zn-Al Alloys—Experimental and Theoretical Design. Entropy 2025, 27, 587. https://doi.org/10.3390/e27060587

Plăcintă C, Nedeff V, Panainte-Lehăduş M, Puiu Costescu E, Petrescu T-C, Stanciu S, Agop M, Mirilă D-C, Nedeff F. Order–Disorder-Type Transitions Through a Multifractal Procedure in Cu-Zn-Al Alloys—Experimental and Theoretical Design. Entropy. 2025; 27(6):587. https://doi.org/10.3390/e27060587

Chicago/Turabian StylePlăcintă, Constantin, Valentin Nedeff, Mirela Panainte-Lehăduş, Elena Puiu Costescu, Tudor-Cristian Petrescu, Sergiu Stanciu, Maricel Agop, Diana-Carmen Mirilă, and Florin Nedeff. 2025. "Order–Disorder-Type Transitions Through a Multifractal Procedure in Cu-Zn-Al Alloys—Experimental and Theoretical Design" Entropy 27, no. 6: 587. https://doi.org/10.3390/e27060587

APA StylePlăcintă, C., Nedeff, V., Panainte-Lehăduş, M., Puiu Costescu, E., Petrescu, T.-C., Stanciu, S., Agop, M., Mirilă, D.-C., & Nedeff, F. (2025). Order–Disorder-Type Transitions Through a Multifractal Procedure in Cu-Zn-Al Alloys—Experimental and Theoretical Design. Entropy, 27(6), 587. https://doi.org/10.3390/e27060587