Dynamic Behavior Analysis of Complex-Configuration Organic Rankine Cycle Systems Using a Multi-Time-Scale Dynamic Modeling Framework

Abstract

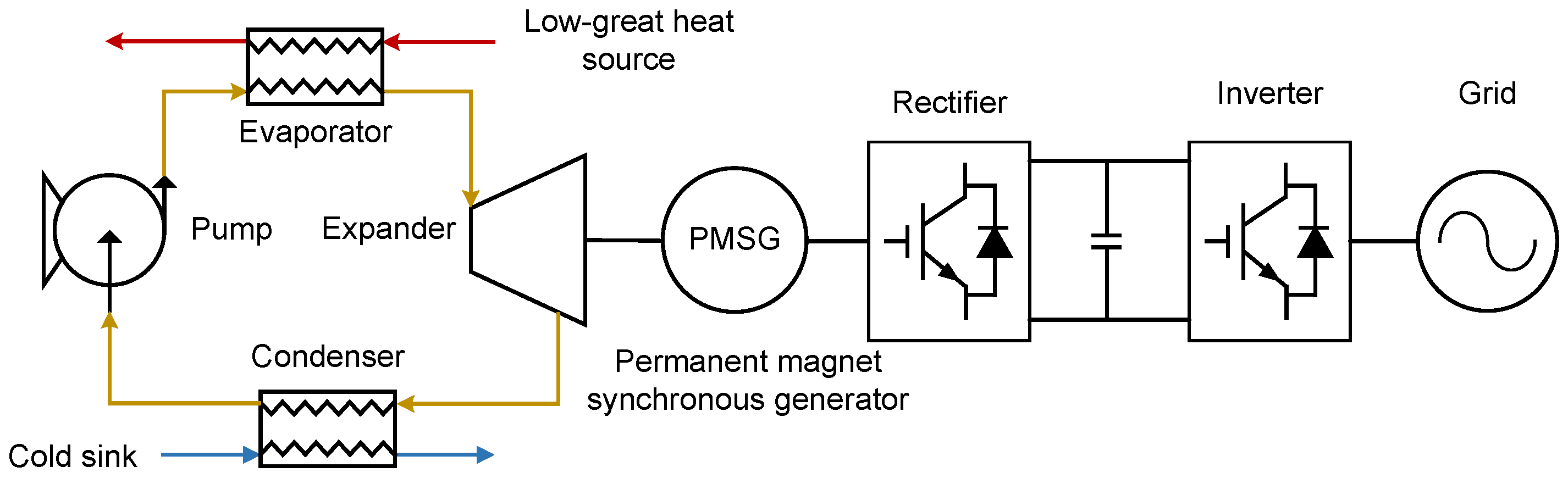

1. Introduction

2. Dynamic Modeling

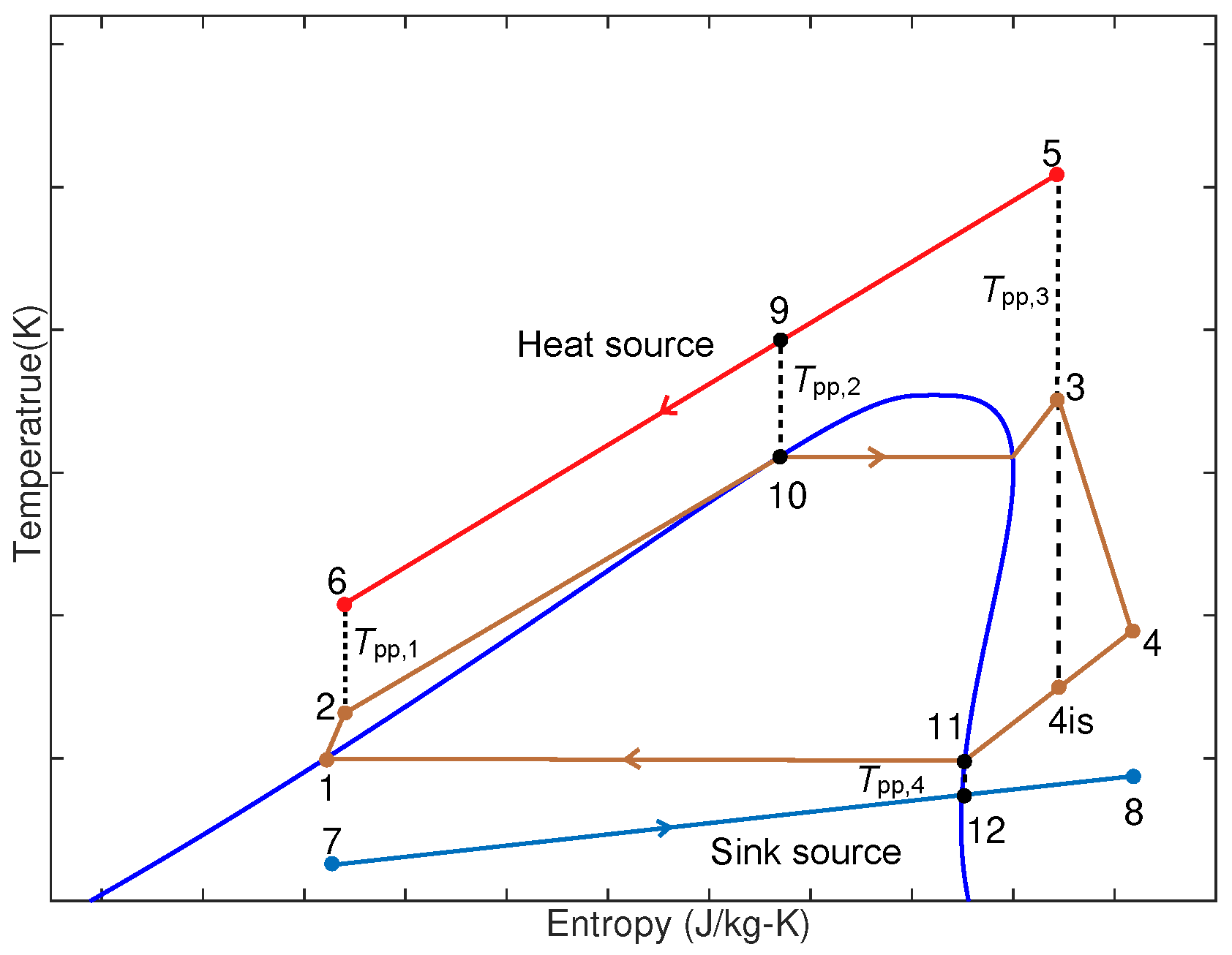

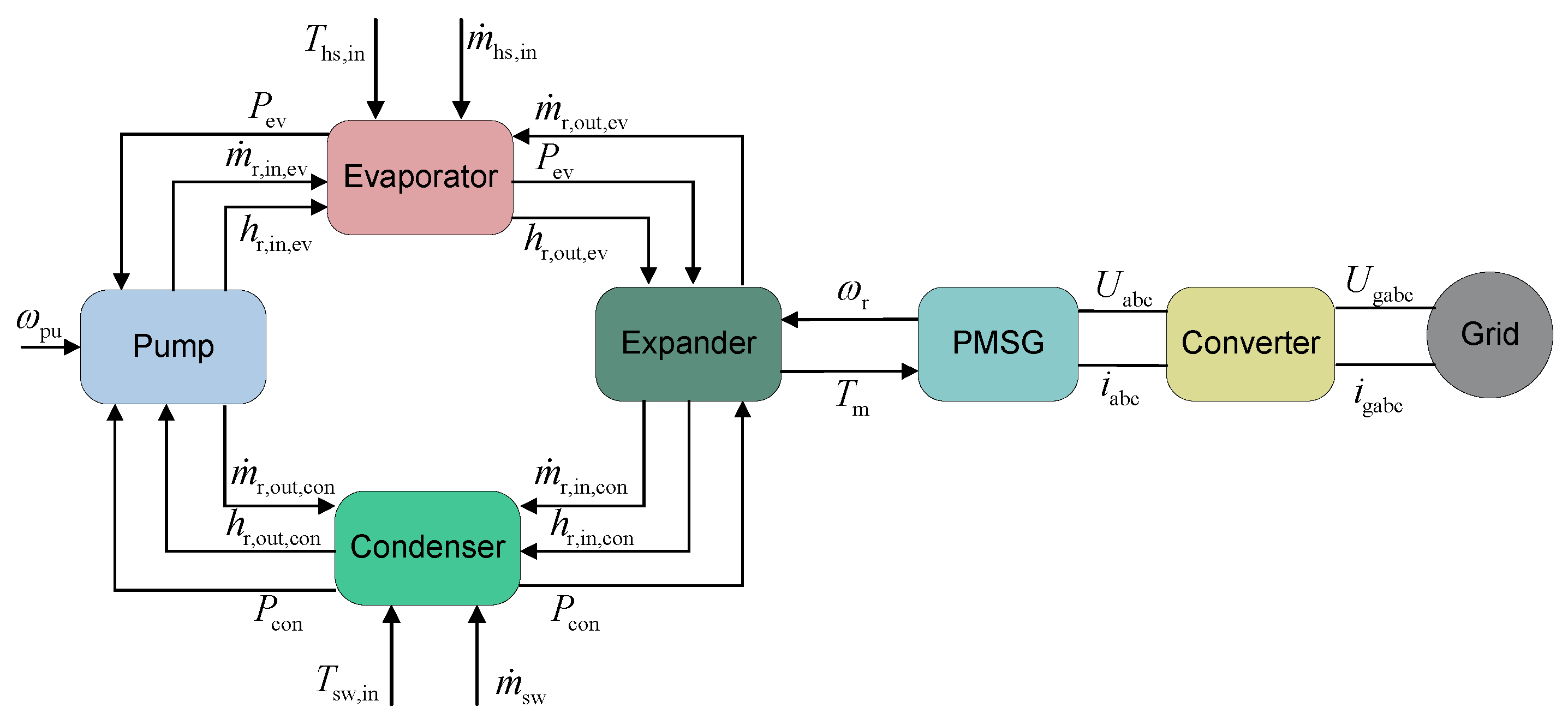

2.1. Description of the ORC

2.1.1. Basic ORC

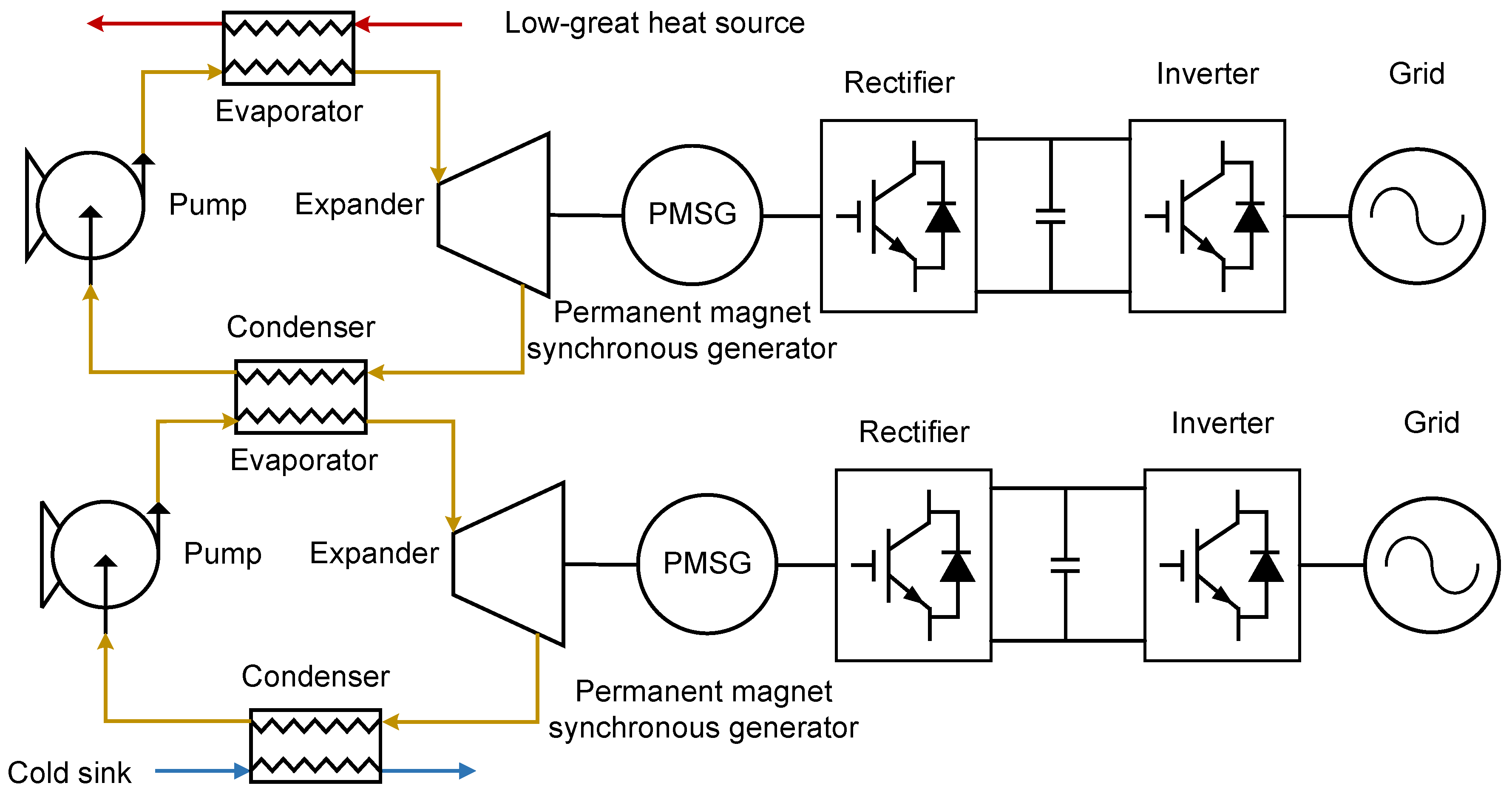

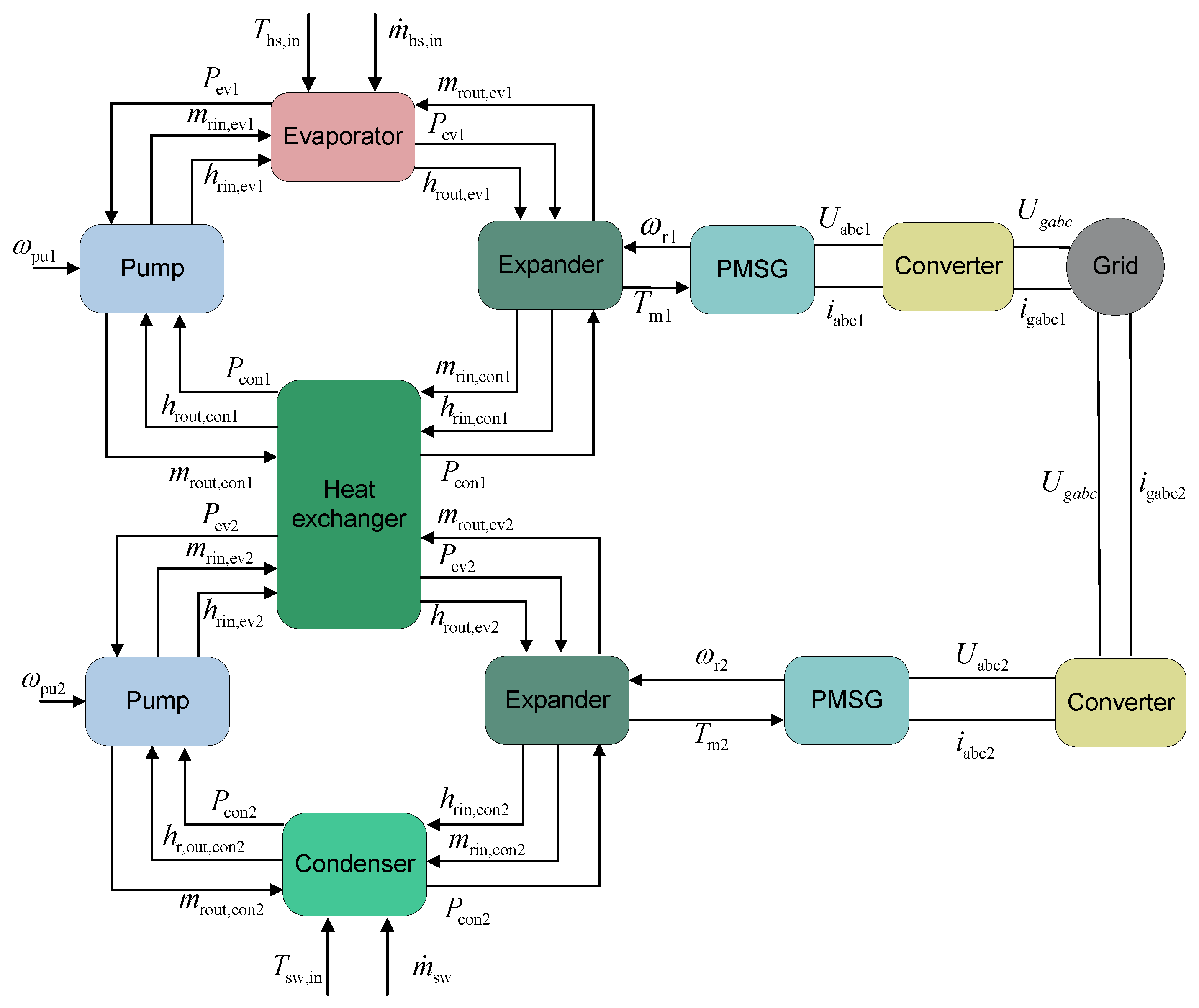

2.1.2. Multi-Loop ORC

- The working fluid is pumped as a subcooled liquid into the evaporator, absorbing heat from the low-grade heat source, and become high-pressure superheated vapor.

- The vapor expands through the expander, converting thermal energy into mechanical work, and change into low-pressure superheated vapor.

- The resulting low-pressure vapor enters the intermediate heat exchanger, where it transfers residual heat to the secondary loop. Working fluid in the primary loop is condensed into a subcooled liquid, whereas the working fluid in the secondary loop is heated into superheated gas.

- The subcooled liquid is then recirculated to the evaporator via working fluid pump.

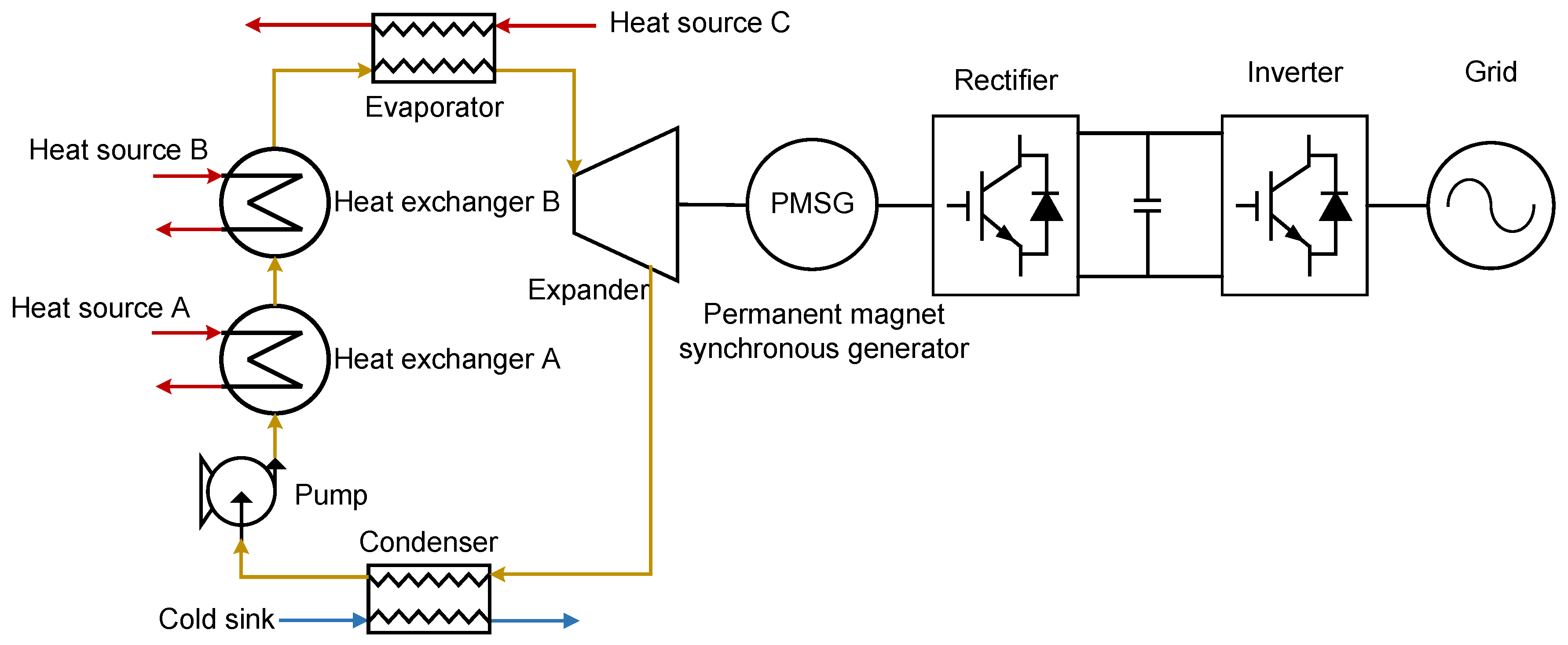

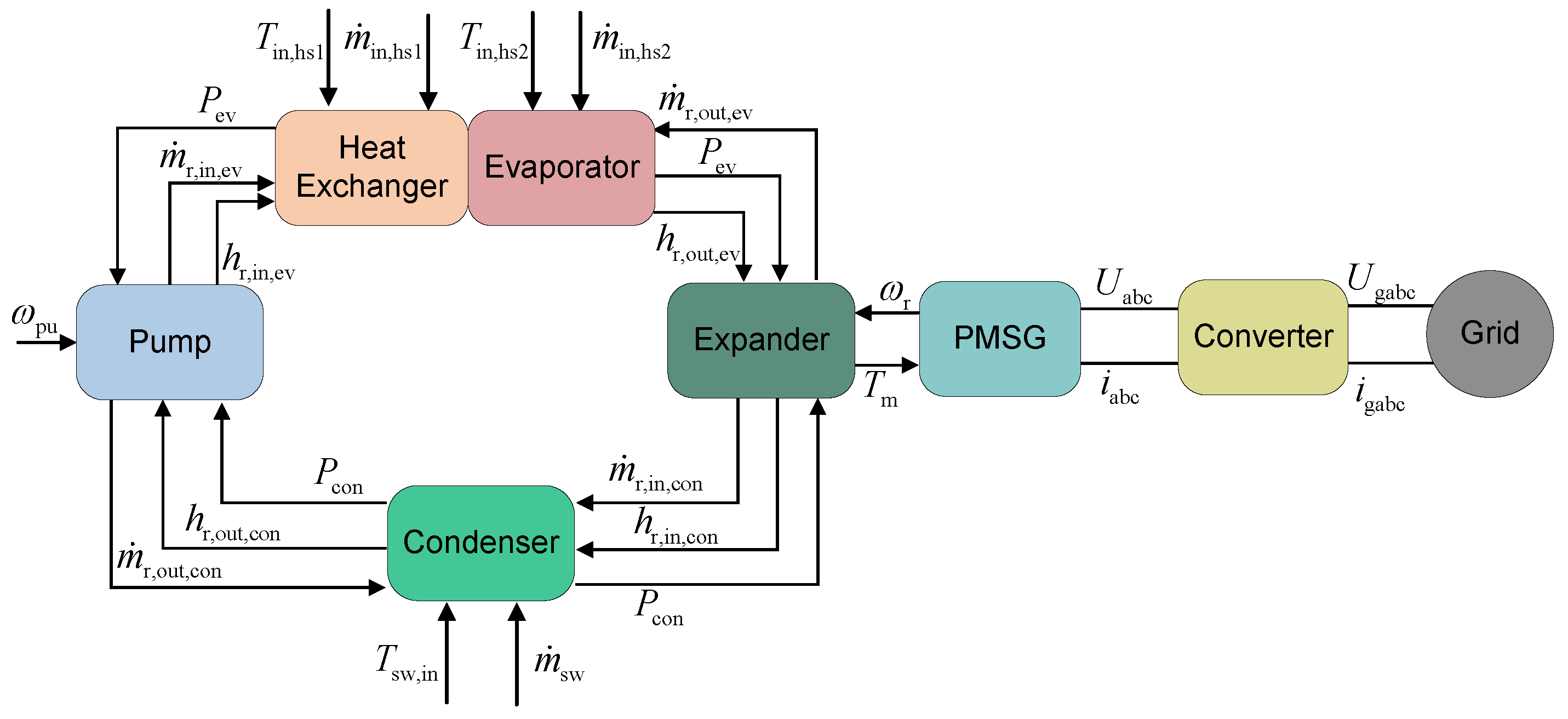

2.1.3. Multi-Source ORC

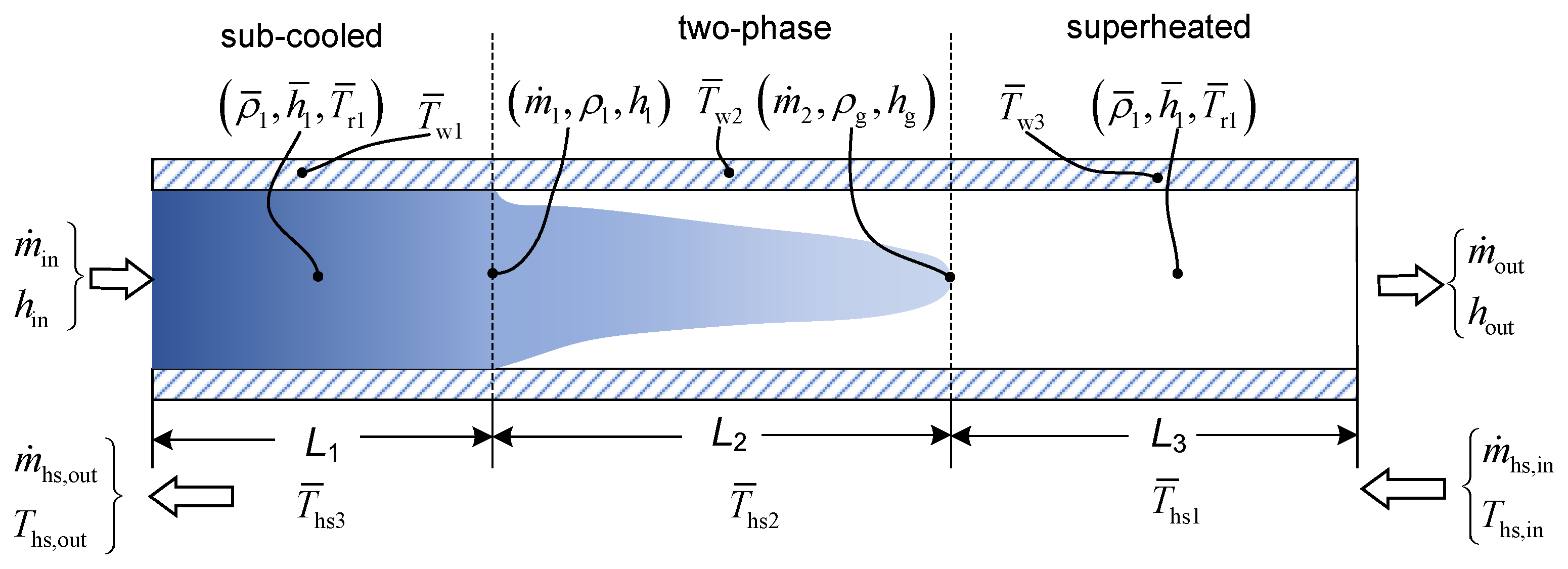

2.2. Evaporator and Condenser

- The pressure drop of the working fluid within the heat exchanger is assumed to be negligible;

- The working fluid flow within the heat exchanger tubes is modeled as an idealized one-dimensional flow;

- The axial conduction of both the working fluid and plate walls along the flow direction is neglected;

- The influence of gravitational forces on the working fluid flow is disregarded in the present model.

2.3. Expander

2.4. Pump

2.5. Permanent Magnet Synchronous Generator

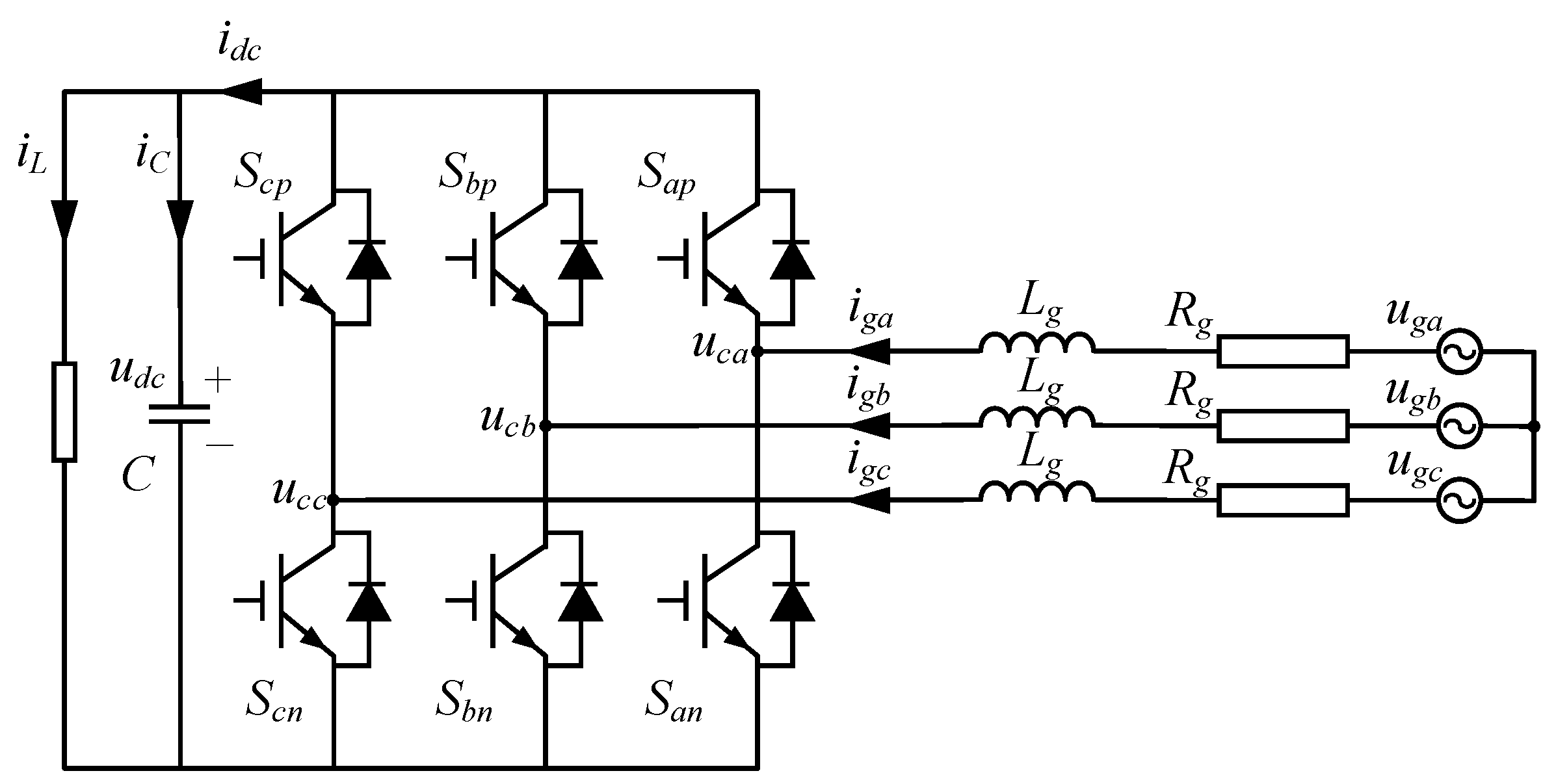

2.6. Converter

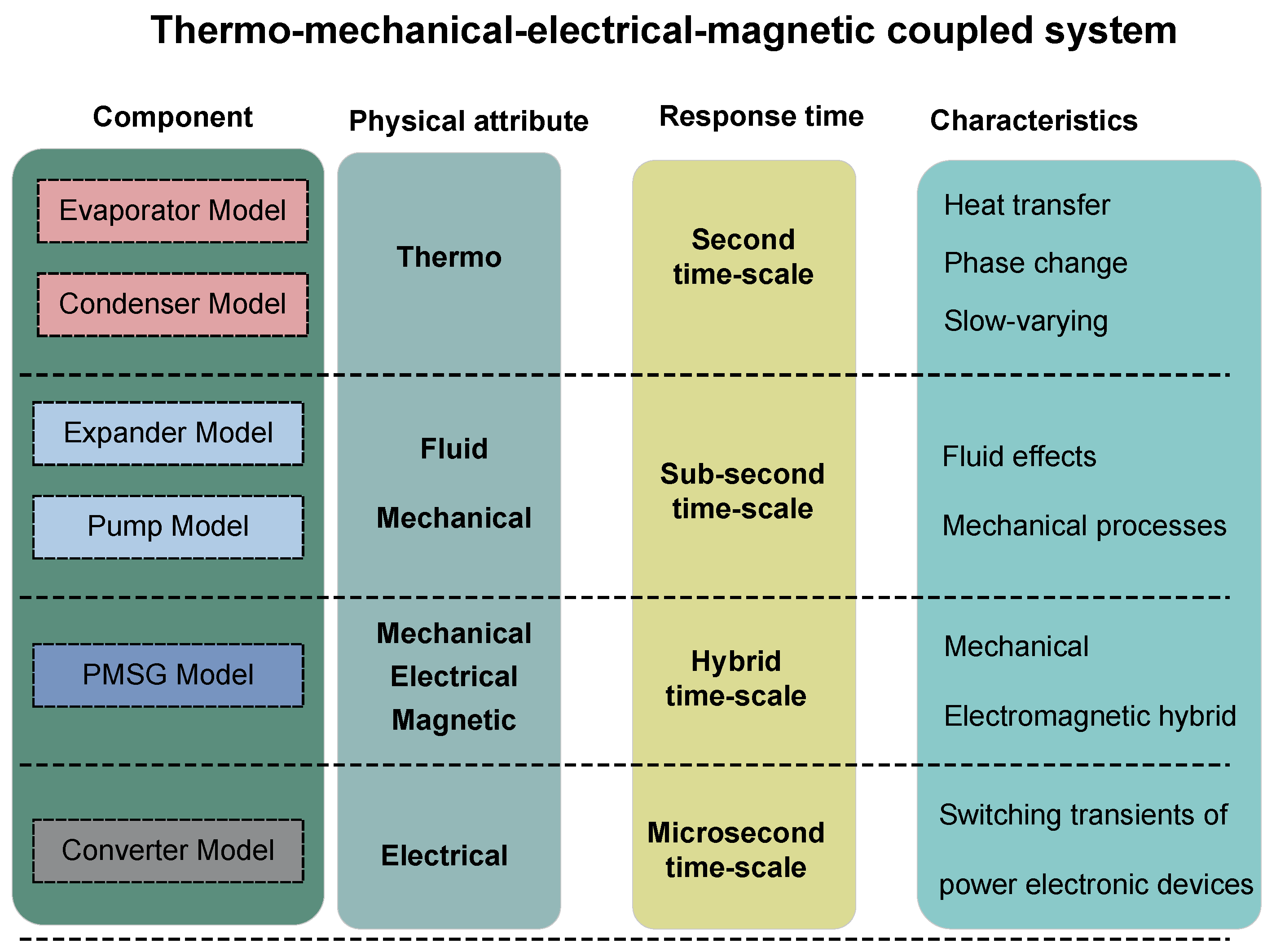

2.7. Multi-Time-Scale Modeling Methodology

- 1.

- Second-scale dynamicsThis time-scale layer is the slowest and governs coupled heat transfer and phase-change processes in the evaporator and condenser subsystems. Characterized by slow-varying thermal behavior driven by thermal inertia, this scale exhibits time constants exceeding .

- 2.

- Decisecond-scale dynamicsThis intermediate scale encompasses fluid–mechanical processes, including working fluid flow and turbomachinery rotation, and resolves the expander and working fluid pump models. Its dynamics are approximately one order of magnitude faster than those of the thermal subsystem owing to reduced inertial effects.

- 3.

- Hybrid-scale electromagnetic transientsThe PMSG operates over a hybrid time-scale. For front-end dynamics (fluid–mechanical coupling with the ORC unit), it is temporally coupled with the decisecond-scale subsystem. Conversely, for back-end dynamics (grid interaction via the power converter), it must be resolved concurrently with the electromagnetic transients of the converter. This dual-scale treatment captures the PMSG’s bidirectional coupling across the mechanical and electrical domains.

2.8. Model Development

2.8.1. Parameter Interaction

2.8.2. Time-Scale Selection

3. Results and Discussion

3.1. Parameters of ORC System

3.2. Model Validation

3.2.1. Simulink Model Configuration and Solver Settings

- Second-scale subsystem (thermal domain): A variable-step solver (ode23t, trapezoidal rule) with maximum step size of and relative tolerance of .

- Decisecond-scale subsystem (mechanical domain): A fixed-step solver (ode4, Runge Kutta method) with a step size of .

- Hybrid-scale subsystem (electrical and converter domain): A fixed-step discrete solver (Tustin method) with a sample time of to ensure accurate tracking of converter current and generator electromagnetic torque.

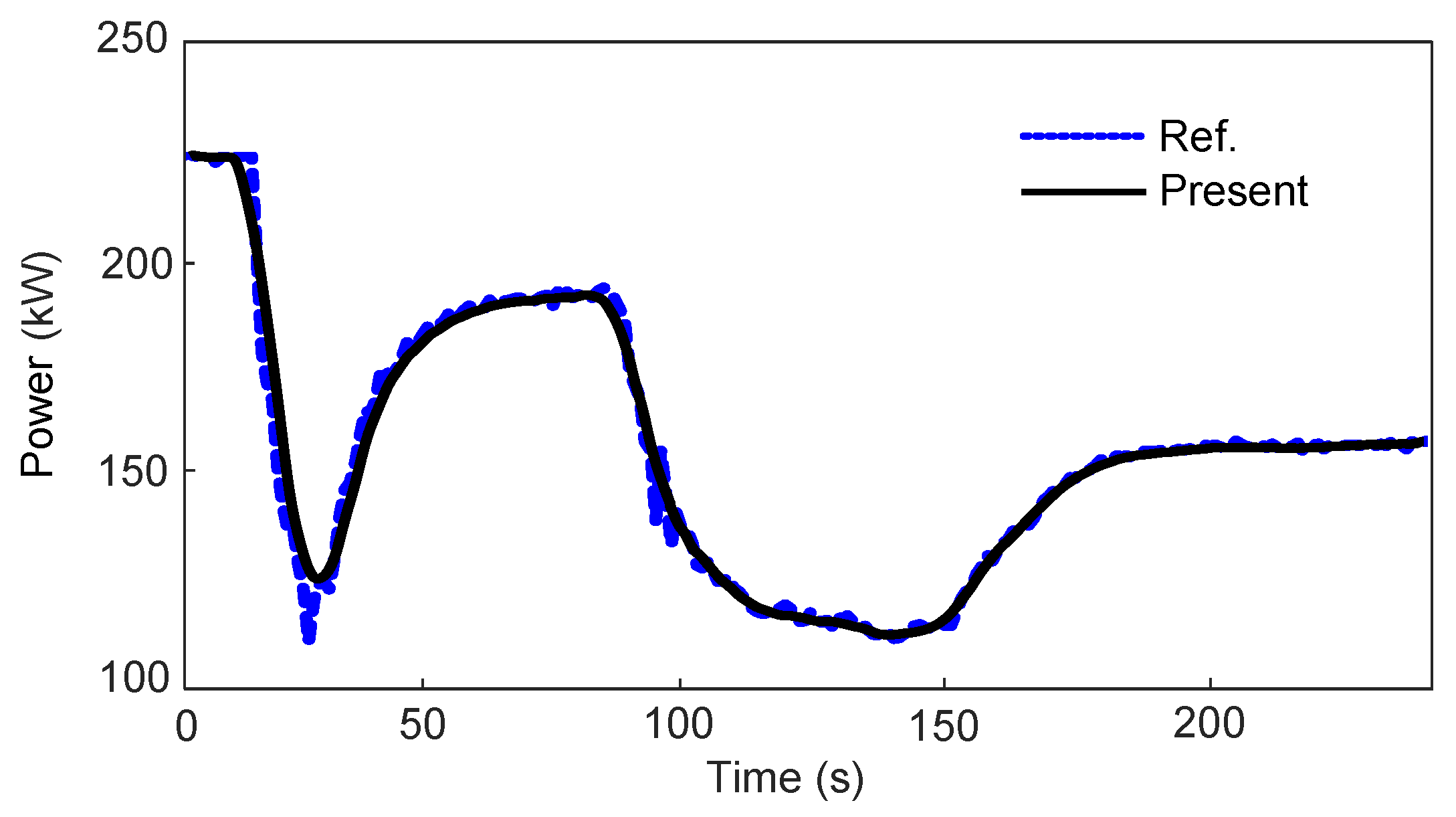

3.2.2. Validation Results

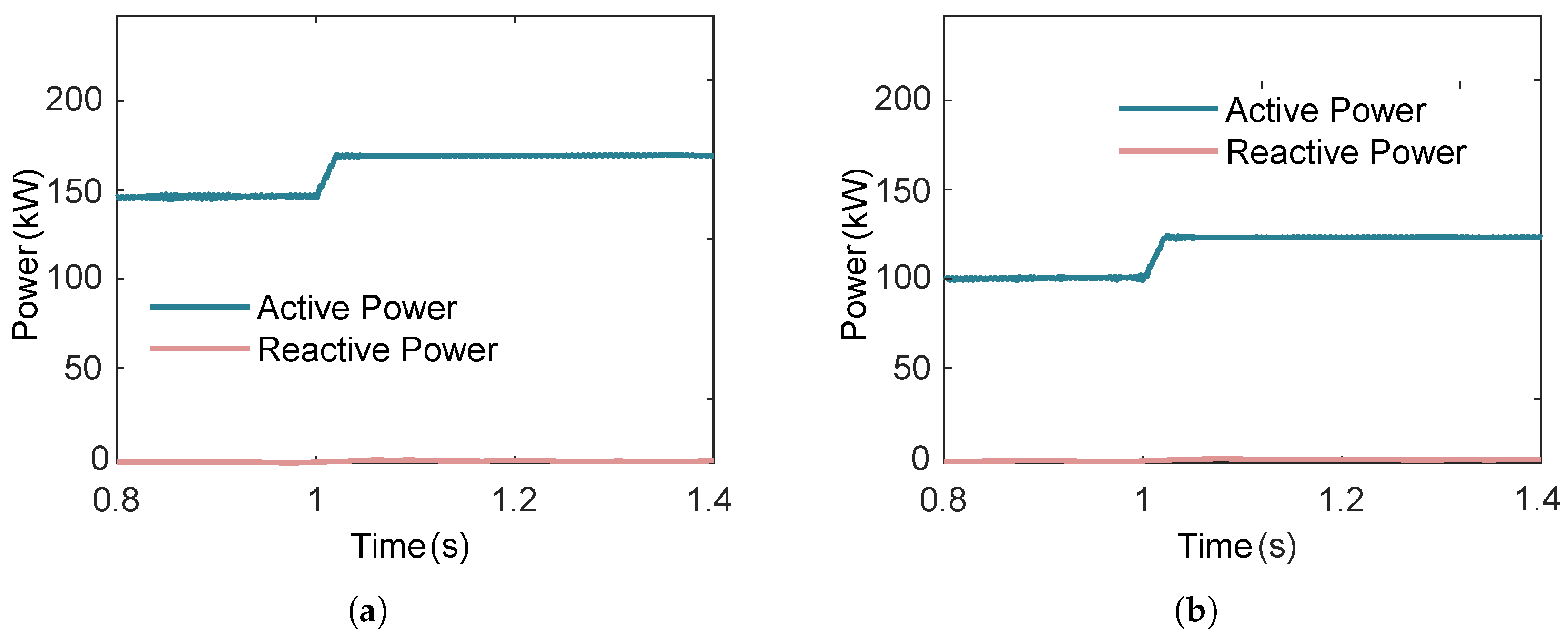

3.3. Dynamic Characteristics of the Series Dual-Loop ORC System

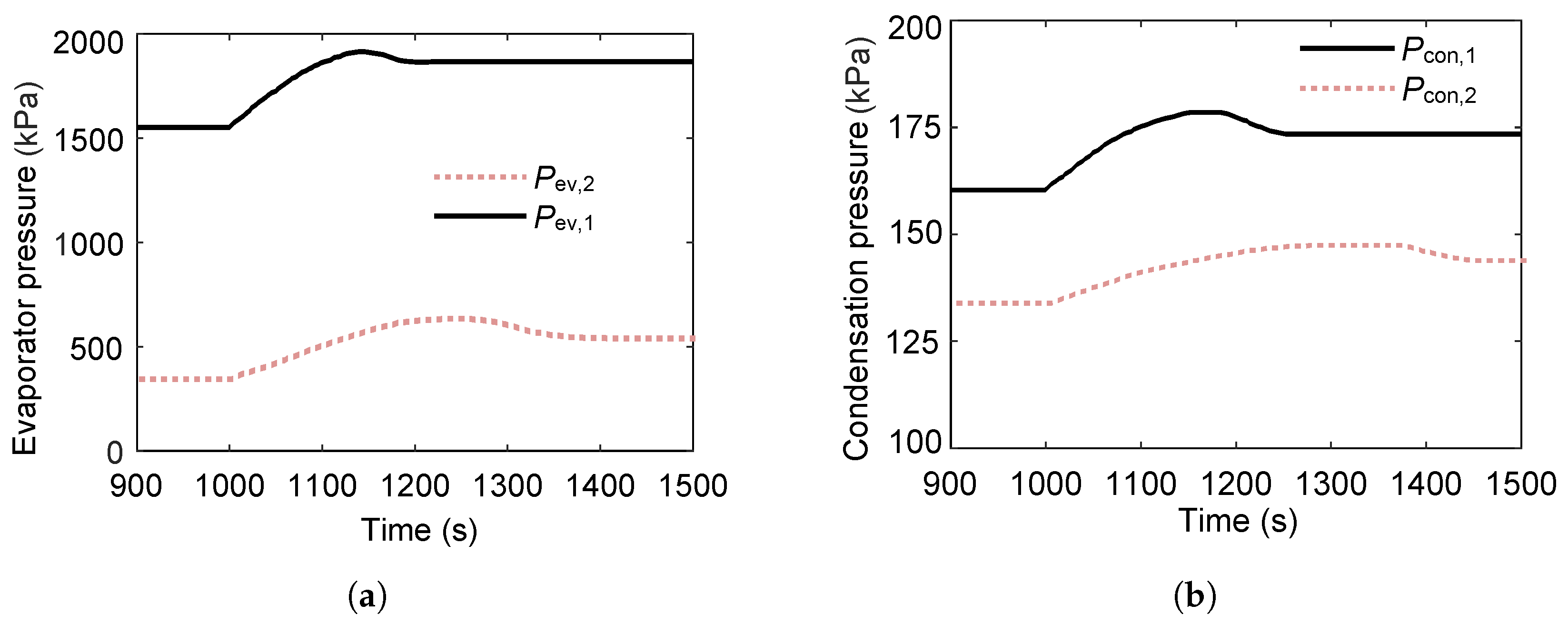

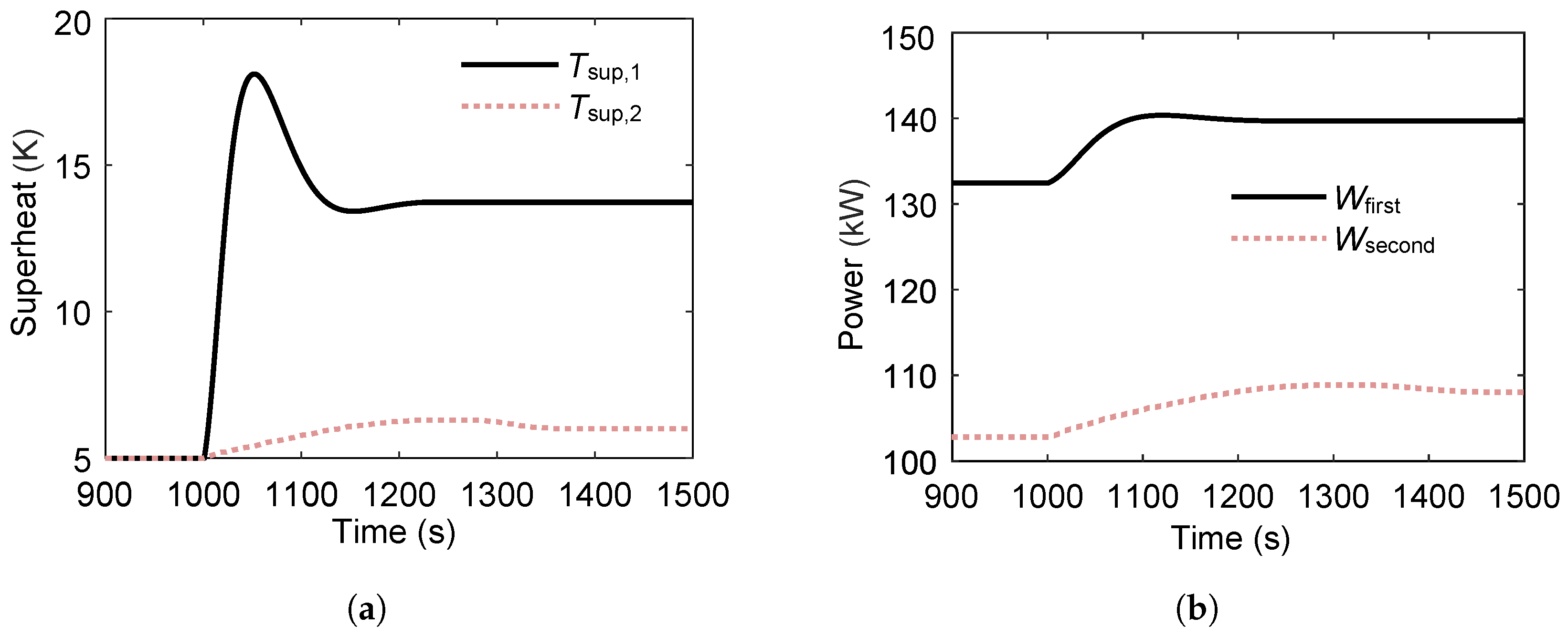

3.3.1. Effect of Heat Source

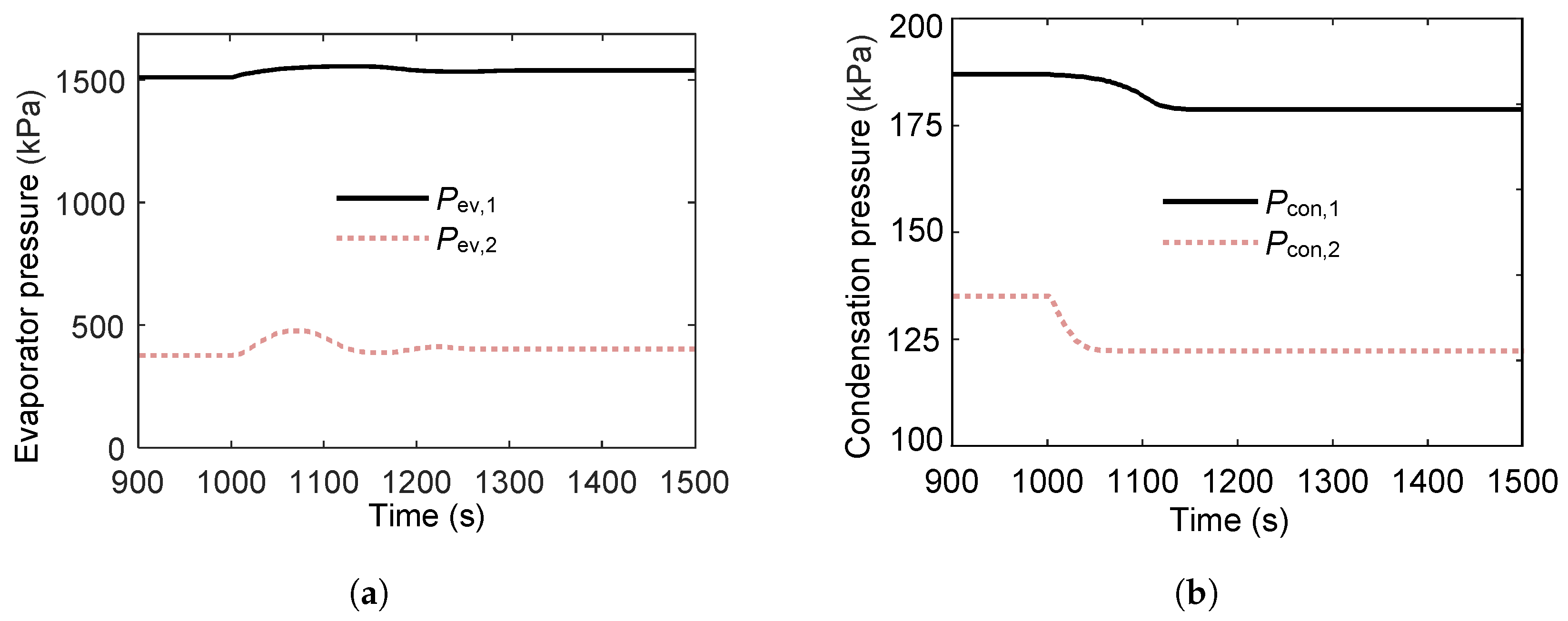

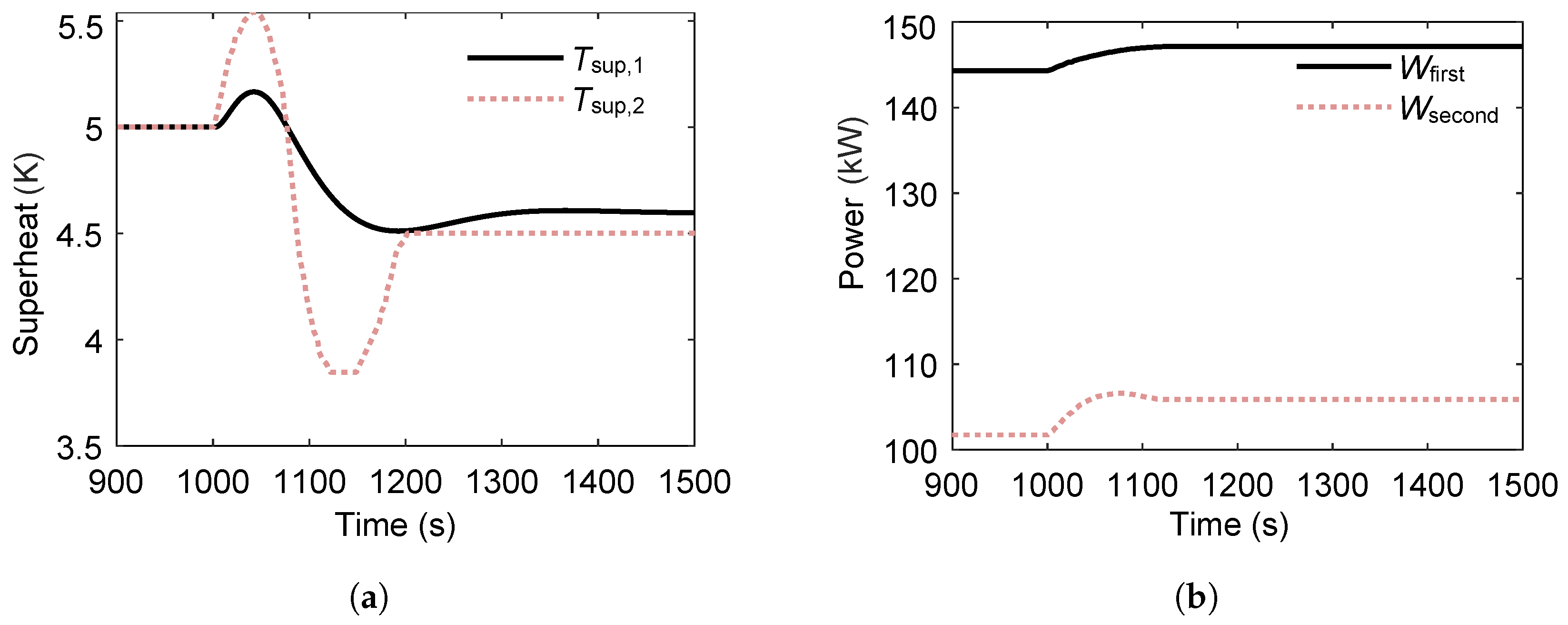

3.3.2. Effect of Sink Source

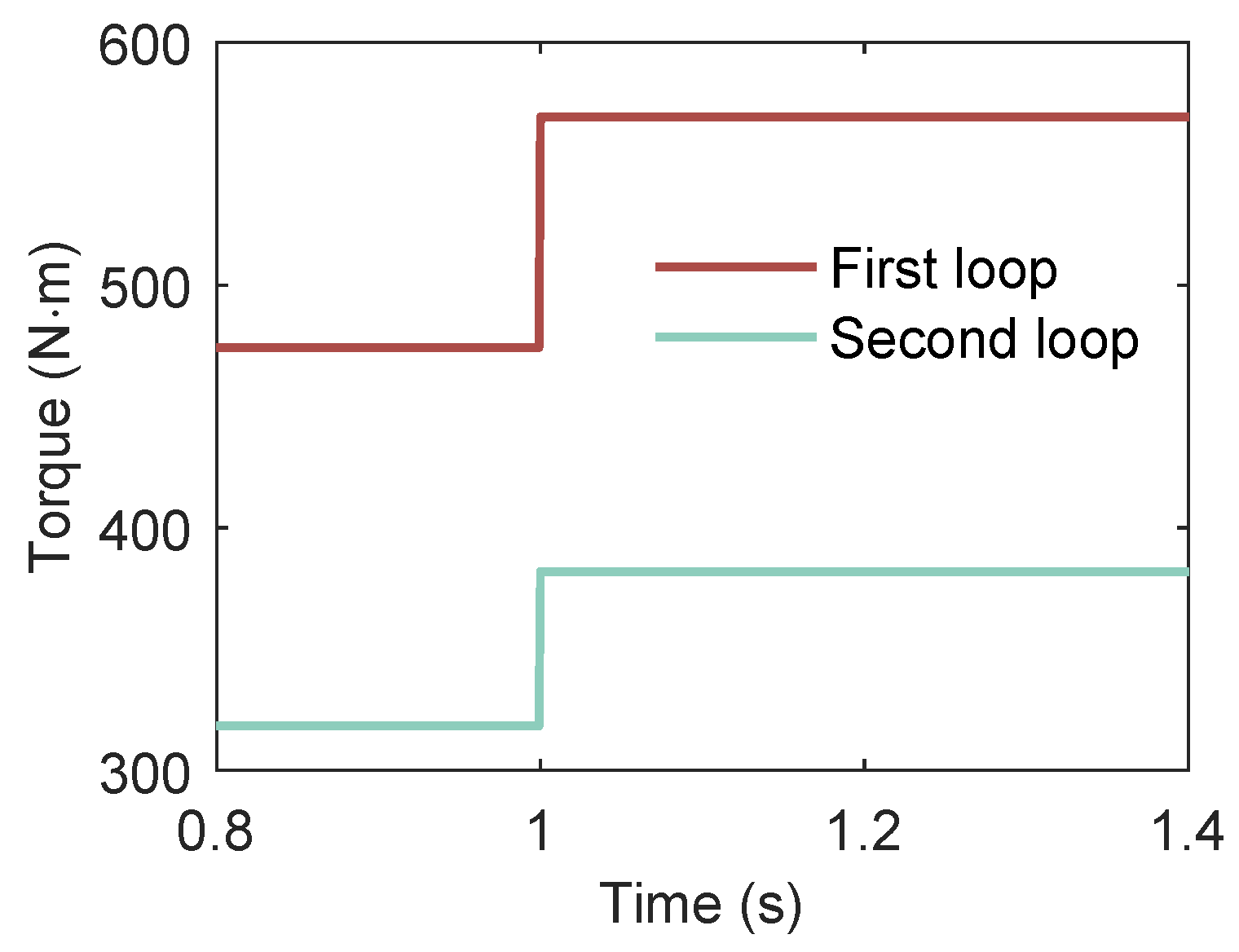

3.3.3. Effect of Expander Torque

3.4. Dynamic Characteristics of the Multi-Heat-Source ORC System

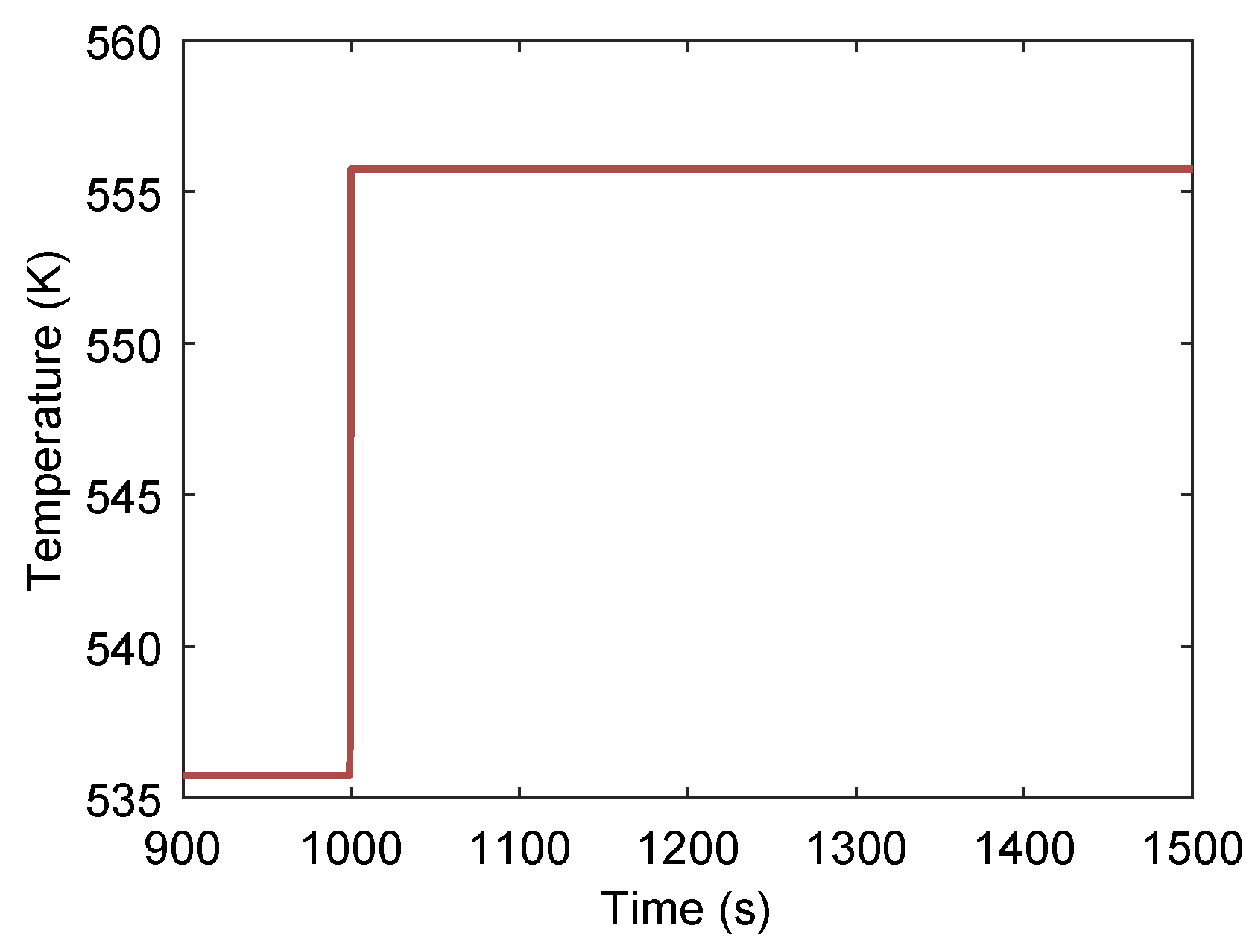

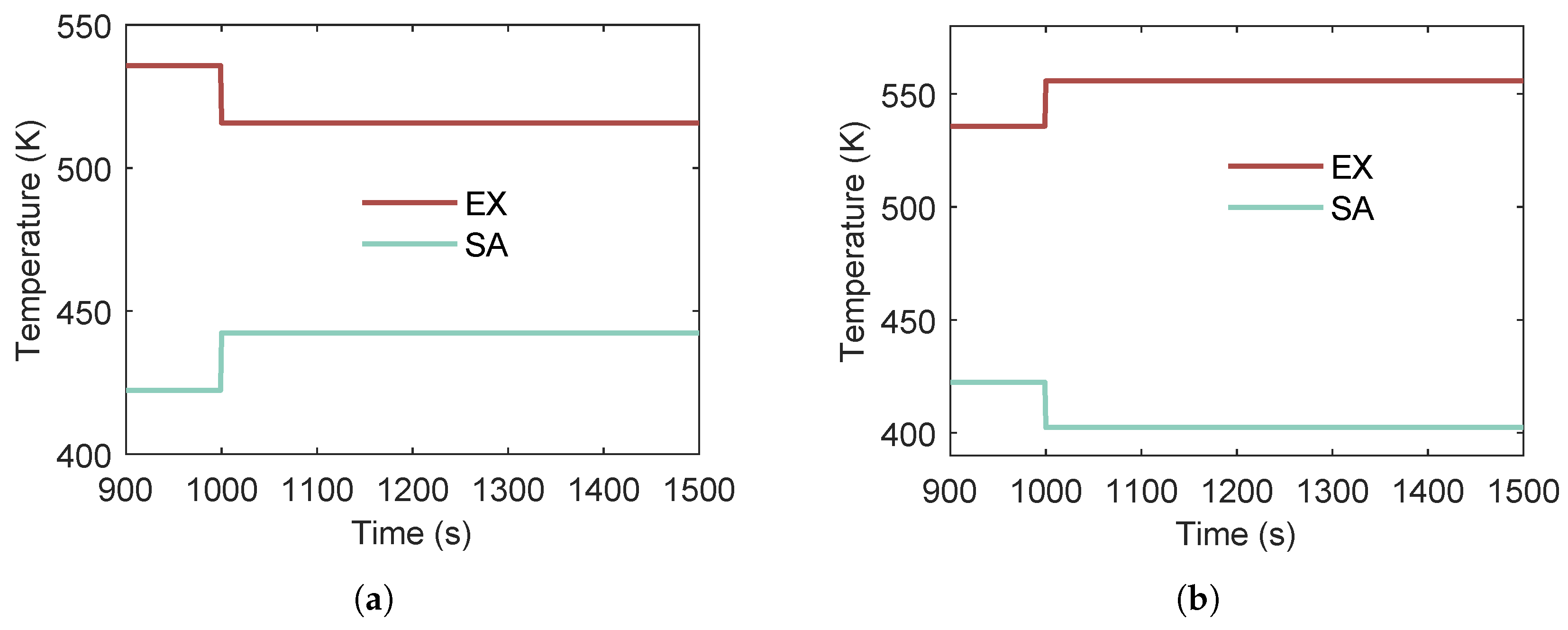

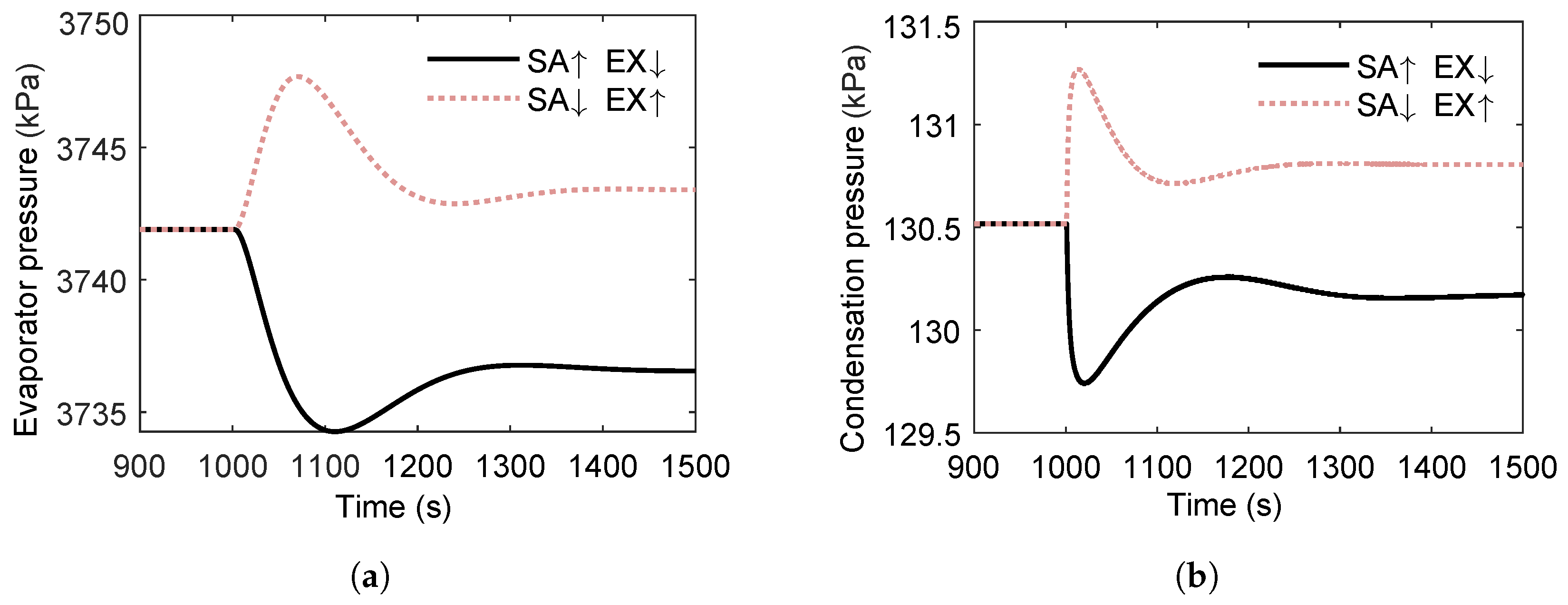

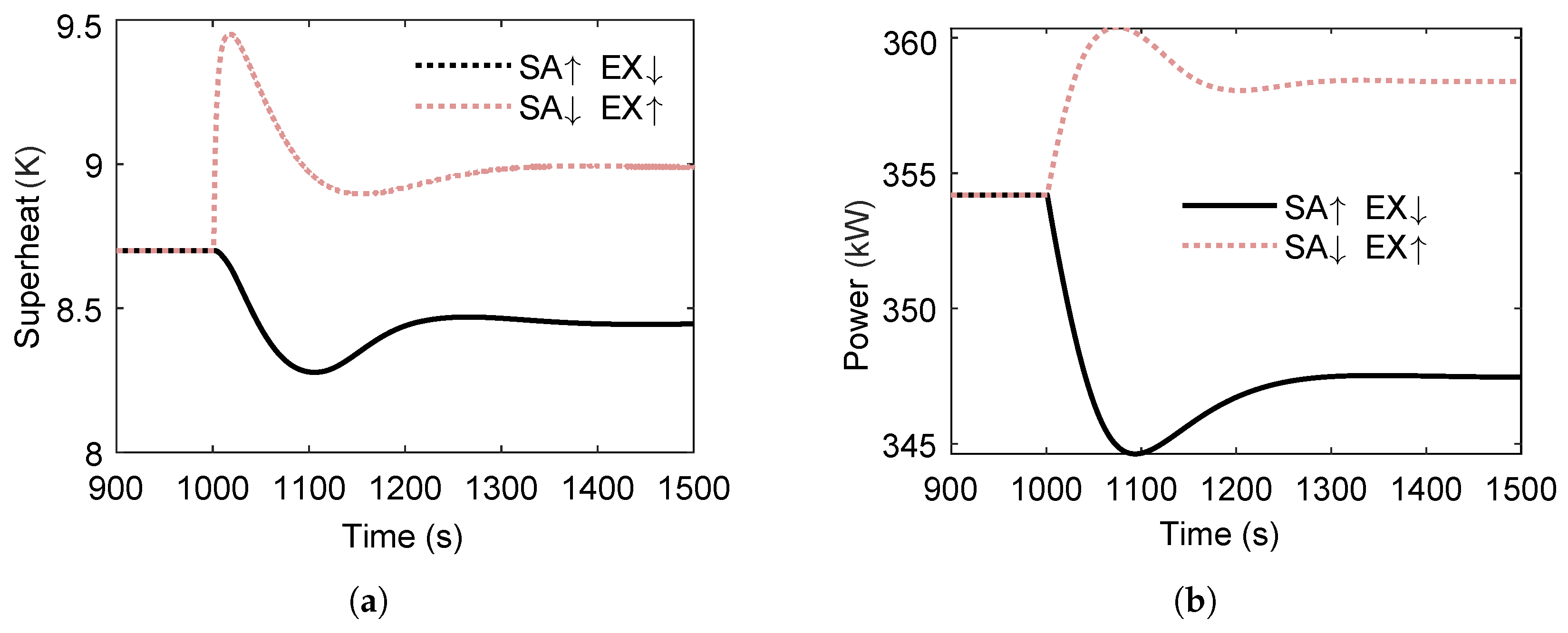

3.4.1. Effect of Multi-Heat-Source

- Case 1:

- SA temperature increases by 20 °C at while EX temperature decreases by 20 °C.

- Case 2:

- SA temperature decreases by 20 °C at while EX temperature increases by 20 °C.

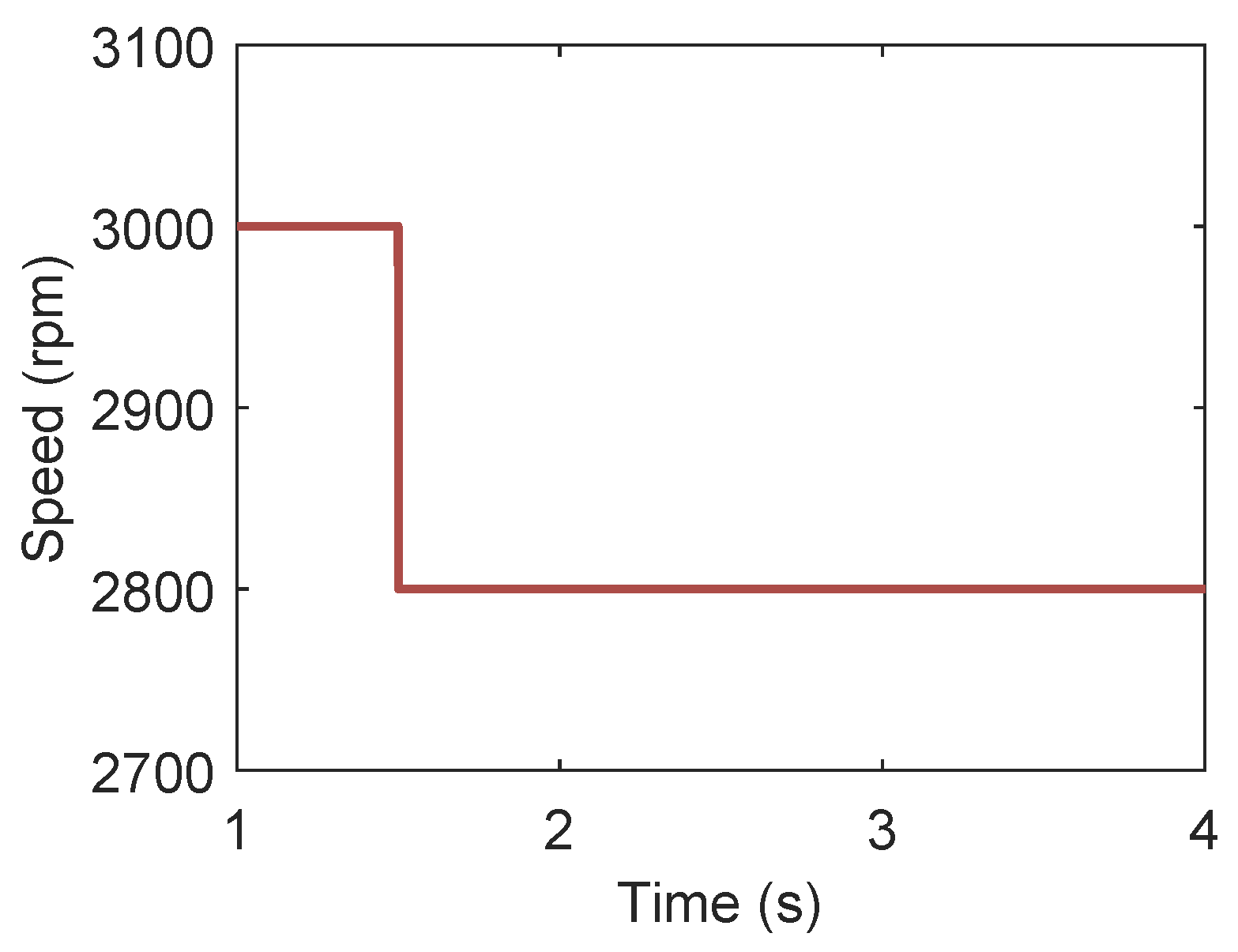

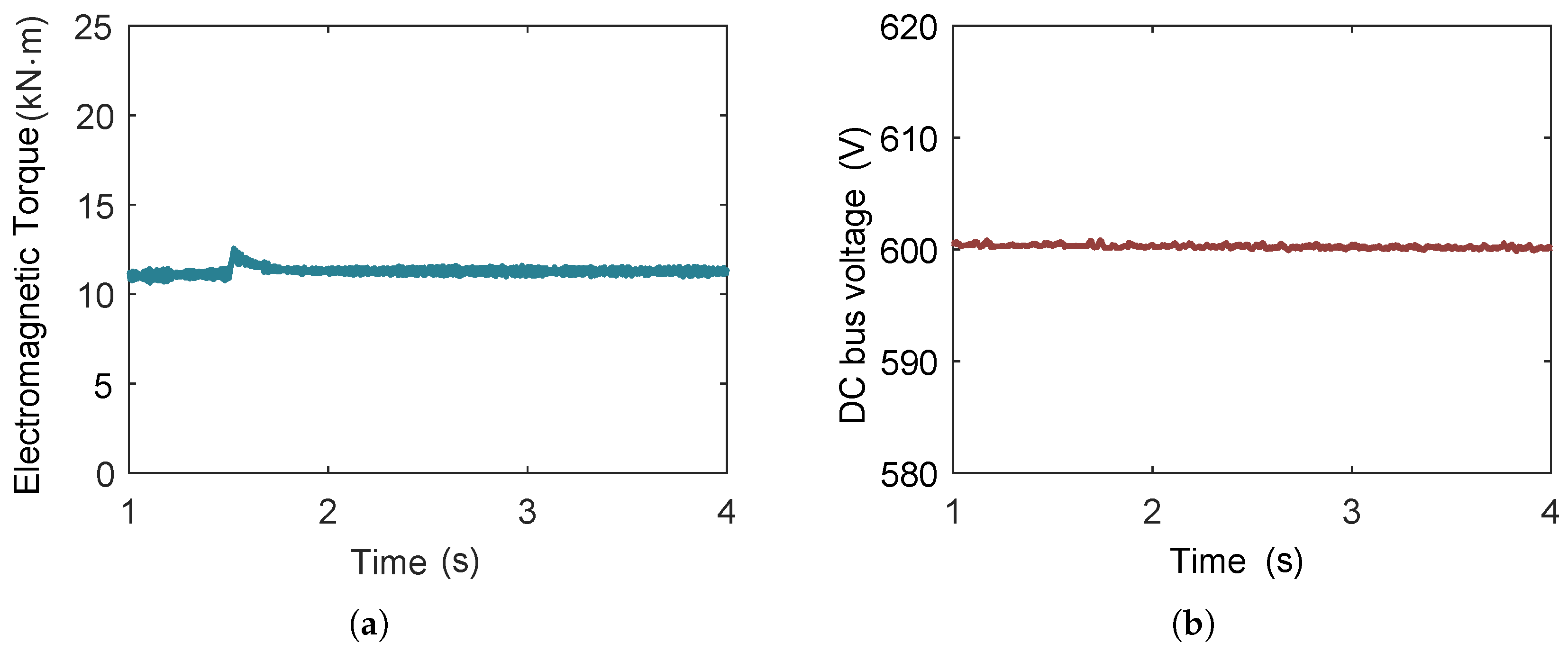

3.4.2. Effect of Expander Speed

4. Conclusions

- 1.

- The proposed multi-time-scale modeling method achieves high accuracy and significantly reduced computational demand for thermal–mechanical–electrical–magnetic coupled ORC systems. For the basic ORC model, the mean absolute error is 2.12% and the peak error is 9.53%.

- 2.

- In the series-type dual-loop ORC system, an increase in heat-source temperature has a smaller effect on the second loop, whereas a decrease in cold source temperature has a smaller effect on the first loop.

- 3.

- The dual-loop ORC system exhibits stronger anti-disturbance capability than a single-loop configuration when subjected to fluctuations in sink or heat-source conditions.

- 4.

- In the dual-heat-source ORC configuration, the overall system state and transient behavior are predominantly governed by the second (higher-quality) heat source.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ORC | Organic Rankine Cycle |

| MPC | Model Predictive Control |

| T-s | Temperature–Entropy |

| MBM | Moving Boundary Model |

| PMSG | Permanent Magnet Synchronous Generator |

| MSC | Machine-Side Converter |

| GSC | Grid-Side Converter |

| SA | Scavenge air |

| EX | Exhaust gas |

| Symbols | |

| A | Heat transfer area |

| Density | |

| Mass flow rate | |

| mass flux | |

| h | Enthalpy |

| P | Pressure |

| N | Rotational speed |

| D | Diameter |

| Heat transfer coefficient | |

| T | Temperature |

| L | Length of the region |

| Viscosity | |

| Specific heat | |

| Boling number | |

| k | Thermal conductivitym |

| Prandtl number | |

| Filling factor | |

| V | displacement volume |

| v | Specific volume |

| W | Power output |

| Angular velocity | |

| Efficiency | |

| R | Resistance |

| u | Voltage |

| i | Current |

| Flux linkage | |

| J | Moment of inertia |

| S | Switch |

| C | Capacitor |

| d | d-axis |

| q | q-axis |

| Subscripts | |

| wall of heat exchanger | |

| working fluid | |

| inlet | |

| saturated liquid state of the working fluid | |

| inner | |

| saturated vapor state of the working fluid | |

| outlet | |

| plate heat exchanger | |

| single-phase zone | |

| two-phase zone | |

| tube-and-shell heat exchanger | |

| Expander | |

| Pump | |

| Evaporator | |

| Condensor | |

| Electric | |

| Mechanical | |

| Phase A of the power grid | |

| Phase B of the power grid | |

| Phase C of the power grid | |

Appendix A

Appendix A.1

Appendix A.2

References

- Wang, K.; Zhou, J.; Yang, R.; Xu, S.; Hu, Z.; Xiao, W. Deploying Photovoltaic Systems in Global Open-Pit Mines for a Clean Energy Transition. Nat. Sustain. 2025, 8, 1037–1047. [Google Scholar] [CrossRef]

- Forman, C.; Muritala, I.K.; Pardemann, R.; Meyer, B. Estimating the Global Waste Heat Potential. Renew. Sustain. Energy Rev. 2016, 57, 1568–1579. [Google Scholar] [CrossRef]

- Chu, S.; Majumdar, A. Opportunities and Challenges for a Sustainable Energy Future. Nature 2012, 488, 294–303. [Google Scholar] [CrossRef] [PubMed]

- Ricks, W.; Voller, K.; Galban, G.; Norbeck, J.H.; Jenkins, J.D. The Role of Flexible Geothermal Power in Decarbonized Electricity Systems. Nat. Energy 2025, 10, 28–40. [Google Scholar] [CrossRef]

- Imran, M.; Pili, R.; Usman, M.; Haglind, F. Dynamic Modeling and Control Strategies of Organic Rankine Cycle Systems: Methods and Challenges. Appl. Energy 2020, 276, 115537. [Google Scholar] [CrossRef]

- Quoilin, S.; Aumann, R.; Grill, A.; Schuster, A.; Lemort, V.; Spliethoff, H. Dynamic Modeling and Optimal Control Strategy of Waste Heat Recovery Organic Rankine Cycles. Appl. Energy 2011, 88, 2183–2190. [Google Scholar] [CrossRef]

- Desideri, A.; Hernandez, A.; Gusev, S.; van den Broek, M.; Lemort, V.; Quoilin, S. Steady-State and Dynamic Validation of a Small-Scale Waste Heat Recovery System Using the ThermoCycle Modelica Library. Energy 2016, 115, 684–696. [Google Scholar] [CrossRef]

- Xu, B.; Rathod, D.; Kulkarni, S.; Yebi, A.; Filipi, Z.; Onori, S.; Hoffman, M. Transient Dynamic Modeling and Validation of an Organic Rankine Cycle Waste Heat Recovery System for Heavy Duty Diesel Engine Applications. Appl. Energy 2017, 205, 260–279. [Google Scholar] [CrossRef]

- Chen, X.; Liu, C.; Li, Q.; Wang, X.; Xu, X. Dynamic Analysis and Control Strategies of Organic Rankine Cycle System for Waste Heat Recovery Using Zeotropic Mixture as Working Fluid. Energy Convers. Manag. 2019, 192, 321–334. [Google Scholar] [CrossRef]

- Cai, J.; Shu, G.; Tian, H.; Wang, X.; Wang, R.; Shi, X. Validation and Analysis of Organic Rankine Cycle Dynamic Model Using Zeotropic Mixture. Energy 2020, 197, 117003. [Google Scholar] [CrossRef]

- Zhou, Y.; Ruan, J.; Hong, G.; Miao, Z. Dynamic Modeling and Comparison Study of Control Strategies of a Small-Scale Organic Rankine Cycle. Energies 2022, 15, 5505. [Google Scholar] [CrossRef]

- Gu, Z.; Feng, K.; Ge, L.; Quan, L. Dynamic Modeling and Optimization of Organic Rankine Cycle in the Waste Heat Recovery of the Hydraulic System. Energy 2023, 263, 125673. [Google Scholar] [CrossRef]

- Wei, D.; Lu, X.; Lu, Z.; Gu, J. Dynamic Modeling and Simulation of an Organic Rankine Cycle (ORC) System for Waste Heat Recovery. Appl. Therm. Eng. 2008, 28, 1216–1224. [Google Scholar] [CrossRef]

- Casella, F.; Mathijssen, T.; Colonna, P.; van Buijtenen, J. Dynamic Modeling of Organic Rankine Cycle Power Systems. J. Eng. Gas Turbines Power 2013, 135, 042310. [Google Scholar] [CrossRef]

- Bamgbopa, M.O.; Uzgoren, E. Quasi-Dynamic Model for an Organic Rankine Cycle. Energy Convers. Manag. 2013, 72, 117–124. [Google Scholar] [CrossRef]

- Huster, W.R.; Vaupel, Y.; Mhamdi, A.; Mitsos, A. Validated Dynamic Model of an Organic Rankine Cycle (ORC) for Waste Heat Recovery in a Diesel Truck. Energy 2018, 151, 647–661. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Cheng, Z.; Sun, Q.; Zhao, P.; Dai, Y. Dynamic Performance of an Organic Rankine Cycle System with a Dynamic Turbine Model: A Comparison Study. Appl. Therm. Eng. 2020, 181, 115940. [Google Scholar] [CrossRef]

- Shi, Y.; Hu, X.; Zhang, Z.; Chen, Q.; Xie, L.; Su, H. Data-Driven Identification and Fast Model Predictive Control of the ORC Waste Heat Recovery System by Using Koopman Operator. Control Eng. Pract. 2023, 141, 105679. [Google Scholar] [CrossRef]

- Zhang, Q.; Feng, Y.Q.; Xu, K.J.; Liang, H.J.; Liu, Z.N.; Zhao, C.Y.; Wang, Y.Z.; Sapin, P.; Markides, C.N. Dynamic Behaviour and Performance Evaluation of a Biomass-Fired Organic Rankine Cycle Combined Heat and Power (ORC-CHP) System under Different Control Strategies. Appl. Therm. Eng. 2024, 248, 123236. [Google Scholar] [CrossRef]

- Dhanasegaran, R.; Uusitalo, A.; Honkatukia, J.; Turunen-Saaresti, T. Modeling Thermal Inertia Effects Using the Thermal Resistance Network Approach on a Small-Scale High-Temperature ORC System. Appl. Therm. Eng. 2025, 269, 126018. [Google Scholar] [CrossRef]

- Topcu, M.T.; Tozlu, A.; Bilen, K. Energy, Exergy and Economic Optimization Application of Integrated Dual-Loop Organic Rankine Cycle: A Case of Shopping Mall Power Plant. Case Stud. Therm. Eng. 2025, 74, 106762. [Google Scholar] [CrossRef]

- Gao, W.; Zheng, H.; Zhang, Y.; Tian, Z.; Zhou, J.; Jin, X. Simulation and Optimization of a Dual-Loop Organic Rankine Cycle-Onboard Carbon Capture System for LNG-powered Ships. J. Clean. Prod. 2025, 486, 144512. [Google Scholar] [CrossRef]

- Dou, Z.; Zou, Y.; Mohebbi, A. Design and Multi-Aspect Analysis of a Geothermal and Biomass Dual-Source Power, Cooling, Heating, and Hybrid Freshwater Production System. Energy 2024, 293, 130532. [Google Scholar] [CrossRef]

- Sanaye, S.; Ghaffari, A. Transient Modeling and Thermal Analysis of an Innovative Dual-Loop Rankine–Organic Rankine Heat Recovery System Integrated with a Gas Engine. J. Therm. Anal. Calorim. 2023, 148, 10951–10971. [Google Scholar] [CrossRef]

- Lu, B.; Zhang, Z.; Cai, J.; Wang, W.; Ju, X.; Xu, Y.; Lu, X.; Tian, H.; Shi, L.; Shu, G. Integrating Engine Thermal Management into Waste Heat Recovery under Steady-State Design and Dynamic off-Design Conditions. Energy 2023, 272, 127145. [Google Scholar] [CrossRef]

- Gonidaki, D.; Bellos, E.; Kaldellis, J.K. Design and Dynamic Simulation of a Solar-Driven Organic Rankine Cycle with Zeotropic Mixture. Sol. Energy 2025, 301, 113948. [Google Scholar] [CrossRef]

- He, T.; Ma, J.; Mao, N.; Qi, M.; Jin, T. Exploring the Stability and Dynamic Responses of Dual-Stage Series ORC Using LNG Cold Energy for Sustainable Power Generation. Appl. Energy 2024, 372, 123735. [Google Scholar] [CrossRef]

- Gonidaki, D.; Bellos, E. A Detailed Review of Organic Rankine Cycles Driven by Combined Heat Sources. Energies 2025, 18, 526. [Google Scholar] [CrossRef]

- Li, Y.; Tang, T. Configuration Selection of the Multi-Loop Organic Rankine Cycle for Recovering Energy from a Single Source. Entropy 2021, 23, 1435. [Google Scholar] [CrossRef]

- Li, Y.; Tang, T. Performance Analysis and Optimization of a Series Heat Exchangers Organic Rankine Cycle Utilizing Multi-Heat Sources from a Marine Diesel Engine. Entropy 2021, 23, 906. [Google Scholar] [CrossRef]

- Wu, J.; Liang, Y.; Dong, M.; Zhu, Y.; Zhou, J.; Ling, X.; Lu, J. Dynamic Analysis and Control Strategy of Solar-Driven ORC-VCC System Using Zeotropic Mixture. Energy 2025, 317, 134706. [Google Scholar] [CrossRef]

- Herisanu, N.; Marinca, V.; Madescu, G.; Dragan, F. Dynamic Response of a Permanent Magnet Synchronous Generator to a Wind Gust. Energies 2019, 12, 915. [Google Scholar] [CrossRef]

- Ait Hammouda, C.; Bradai, R.; Bendib, A.; Kherbachi, A.; Kara, K.; Boukenoui, R.; Ahmed, H. Modelling, Control Design, and Analysis of the Inner Control’s Loops Intended for Single-Phase Voltage-Controlled Inverter-Based Microgrid. IET Gener. Transm. Distrib. 2024, 18, 568–584. [Google Scholar] [CrossRef]

- Fu, B.R.; Lee, Y.R.; Hsieh, J.C. Design, Construction, and Preliminary Results of a 250-kW Organic Rankine Cycle System. Appl. Therm. Eng. 2015, 80, 339–346. [Google Scholar] [CrossRef]

- Ma, R.; Lu, Y.; Yu, X.; Yang, B. Thermodynamic, Economic, and Environmental Multi-Criteria Optimization of a Multi-Stage Rankine System for LNG Cold Energy Utilization. Modelling 2025, 6, 45. [Google Scholar] [CrossRef]

- Wu, J.; Liang, Y.; Sun, Z.; Zhu, Y.; Ye, J.; Lu, J. Dynamic Analysis and Control Strategy of ORC Coupled Ejector Expansion Refrigeration Cycle Driven by Geothermal Water. J. Clean. Prod. 2024, 445, 141309. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Exhaust gas temperature | K | 535.75 |

| Scavenge air temperature | K | 422.37 |

| Exhaust gas mass flow | kg/s | 10.33 |

| Scavenge air mass flow | kg/s | 10.45 |

| Component | Parameter | Value | Unit |

|---|---|---|---|

| Evaporator (shell-and-tube) | Outer tube diameter | 32 | mm |

| Wall thickness | 2 | mm | |

| Tube length | 8.8 | m | |

| Number of tubes | 206 | ~ | |

| Heat exchanger (plate) | Plate length | 1130 | mm |

| Plate width | 469 | mm | |

| Number of plates | 215 | ~ | |

| Plate spacing | 4 | mm | |

| Plate thickness | 2 | mm | |

| Condenser (shell-and-tube) | Outer tube diameter | 25 | mm |

| Wall thickness | 2 | mm | |

| Tube length | 7.5 | m | |

| Number of tubes | 198 | ~ |

| Component | Parameter | Value | Unit |

|---|---|---|---|

| Heat exchanger A (shell-and-tube) | Outer tube diameter | 25 | mm |

| Wall thickness | 2.5 | mm | |

| Tube length | 8.9 | m | |

| Number of tubes, | 817 | ~ | |

| Heat exchanger B (shell-and-tube) | Outer tube diameter | 25 | mm |

| Wall thickness | 2.5 | mm | |

| Tube length | 7.0 | m | |

| Number of tubes | 155 | ~ | |

| Condenser (shell-and-tube) | Outer tube diameter | 25 | mm |

| Wall thickness | 2.5 | mm | |

| Tube length | 7.9 | m | |

| Number of tubes | 413 | ~ |

| Component | Parameter | Value | Unit |

|---|---|---|---|

| Expander | Rated speed | 3000 | rpm |

| Suction volume | 0.016 | ||

| Isentropic efficiency | 0.7 | ~ | |

| Pump | Rated speed | 1500 | rpm |

| Rated flow rate | 2.48 | ||

| PMSG | Stator resistance | 0.0086 | |

| dq-axis inductance | 6 | ||

| Moment of inertia | 0.029 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, J.; Li, Y. Dynamic Behavior Analysis of Complex-Configuration Organic Rankine Cycle Systems Using a Multi-Time-Scale Dynamic Modeling Framework. Entropy 2025, 27, 1170. https://doi.org/10.3390/e27111170

Shen J, Li Y. Dynamic Behavior Analysis of Complex-Configuration Organic Rankine Cycle Systems Using a Multi-Time-Scale Dynamic Modeling Framework. Entropy. 2025; 27(11):1170. https://doi.org/10.3390/e27111170

Chicago/Turabian StyleShen, Jinao, and Youyi Li. 2025. "Dynamic Behavior Analysis of Complex-Configuration Organic Rankine Cycle Systems Using a Multi-Time-Scale Dynamic Modeling Framework" Entropy 27, no. 11: 1170. https://doi.org/10.3390/e27111170

APA StyleShen, J., & Li, Y. (2025). Dynamic Behavior Analysis of Complex-Configuration Organic Rankine Cycle Systems Using a Multi-Time-Scale Dynamic Modeling Framework. Entropy, 27(11), 1170. https://doi.org/10.3390/e27111170