Dynamic Modeling and Analysis of Rotary Joints with Coupled Bearing Tilt-Misalignment Faults

Abstract

1. Introduction

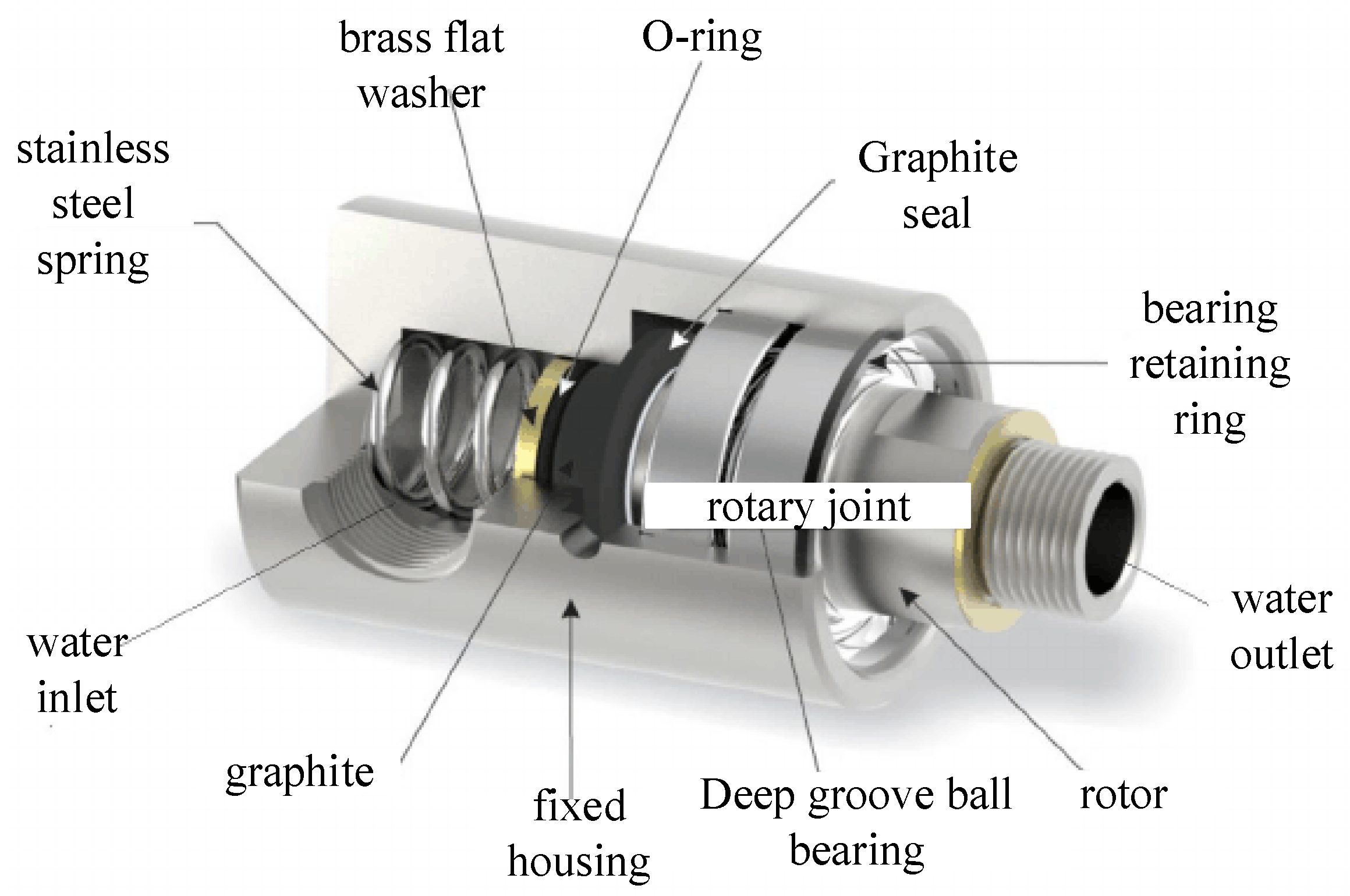

2. Dynamic Analysis of the System Model

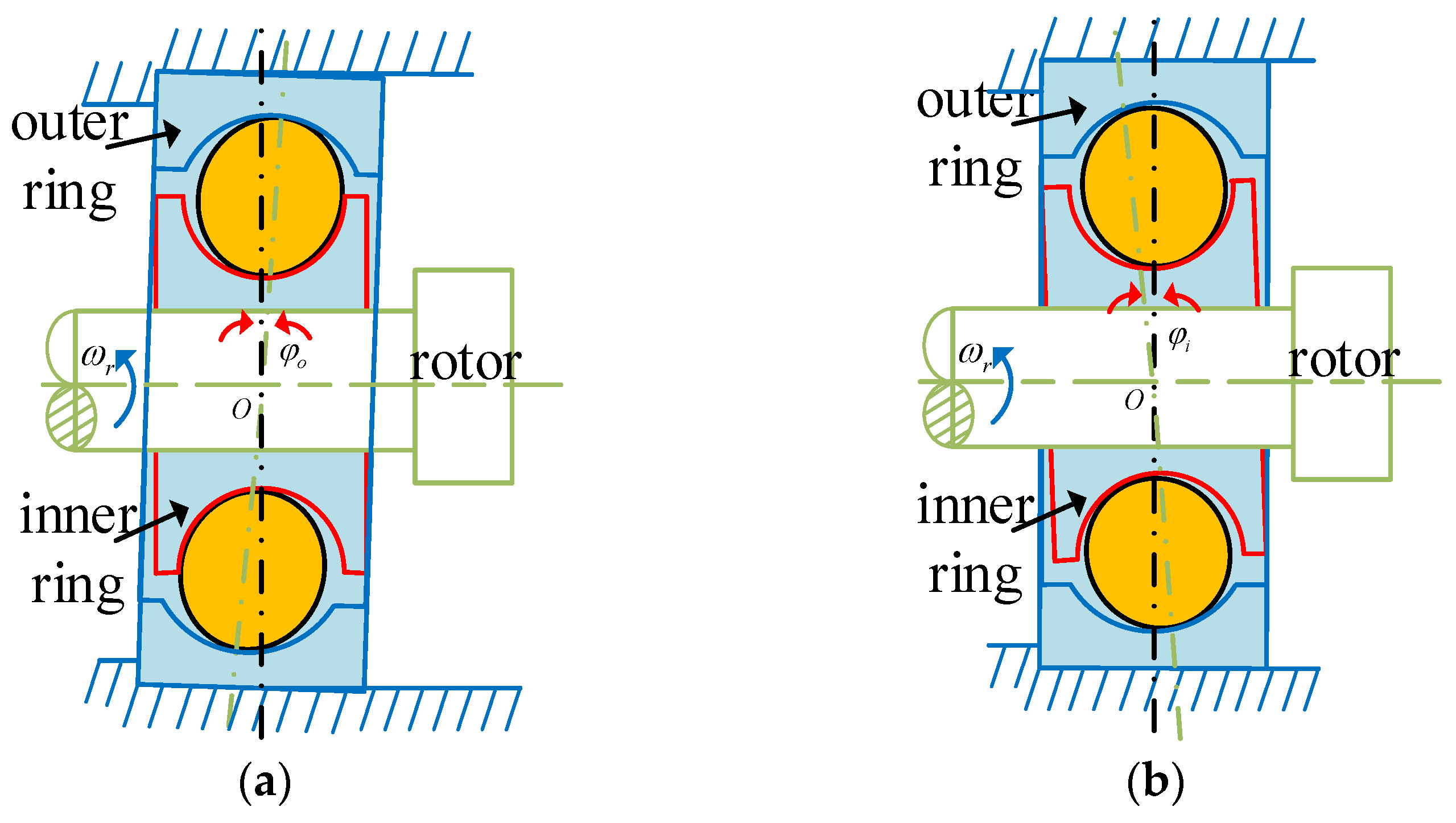

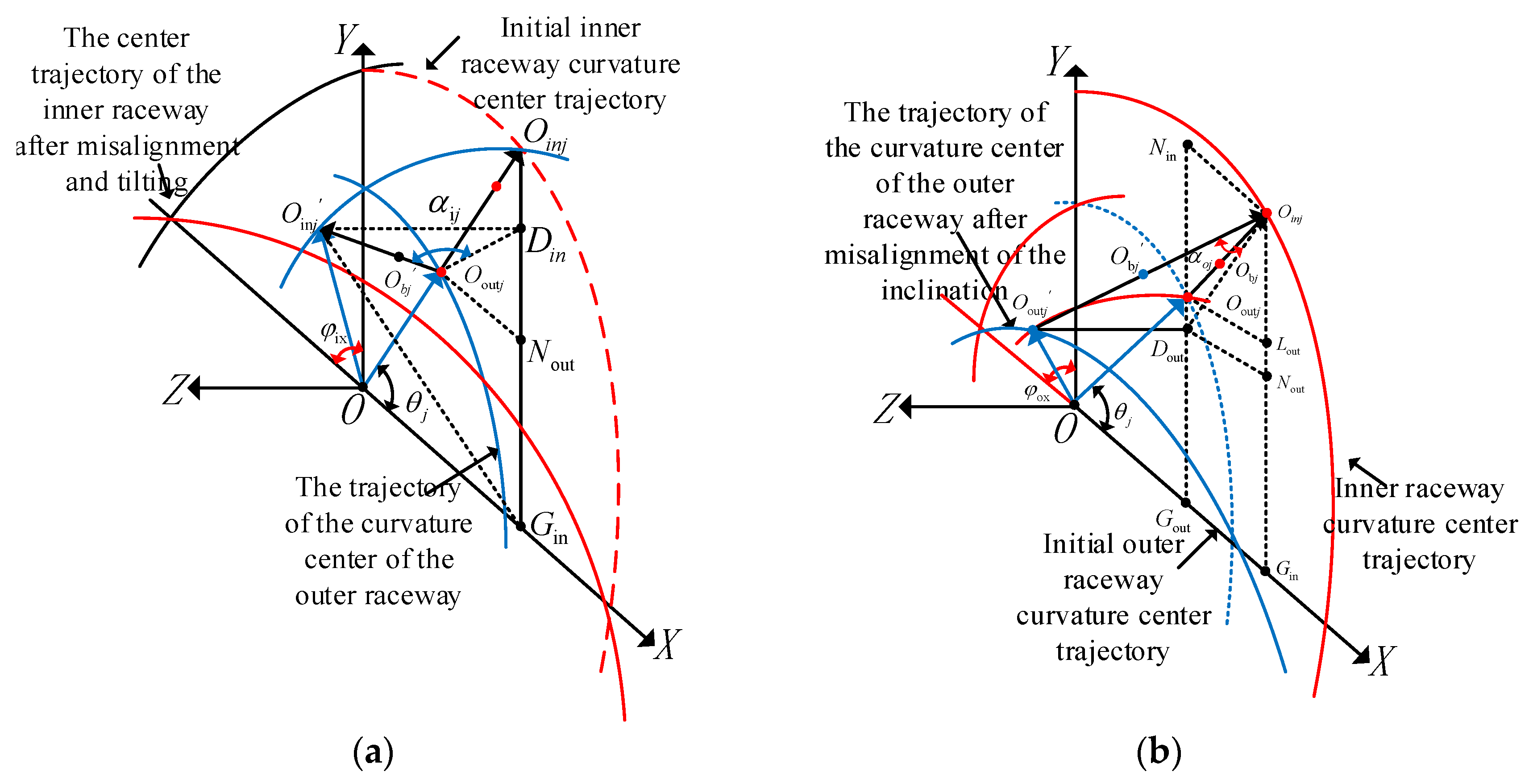

2.1. Generation Mechanism of Bearing Inner/Outer Ring Tilt and Misalignment

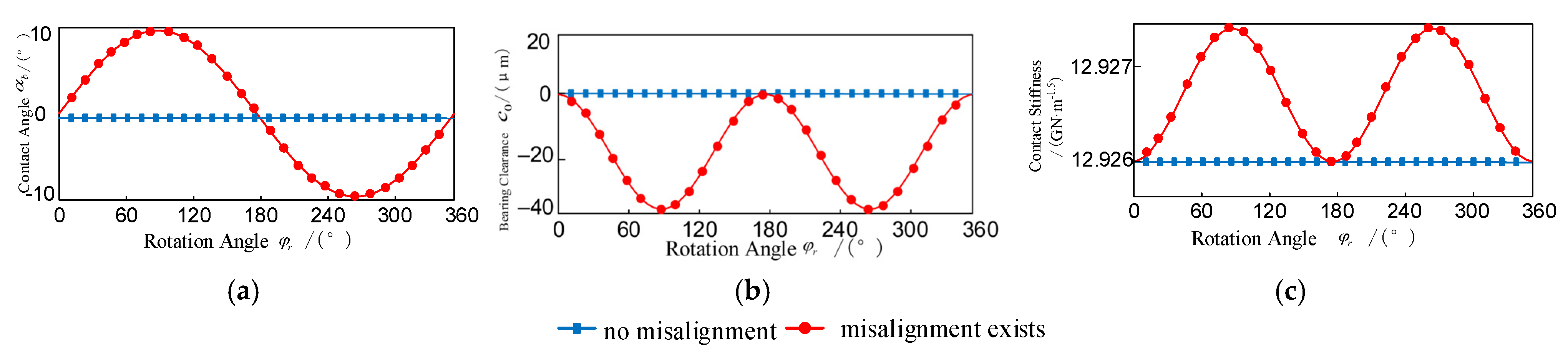

2.2. Rolling Body Contact Model and Nonlinear Mechanical Properties

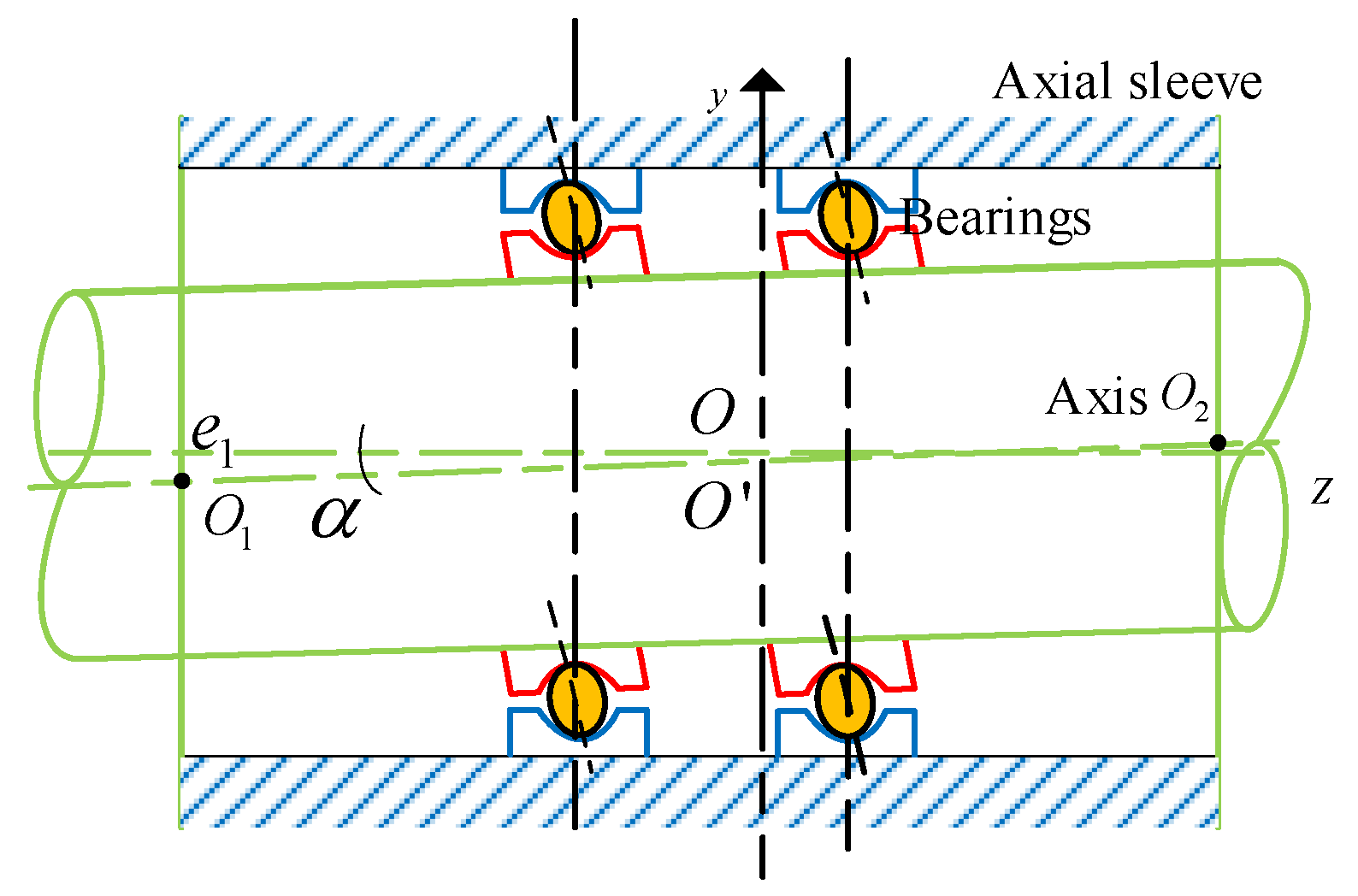

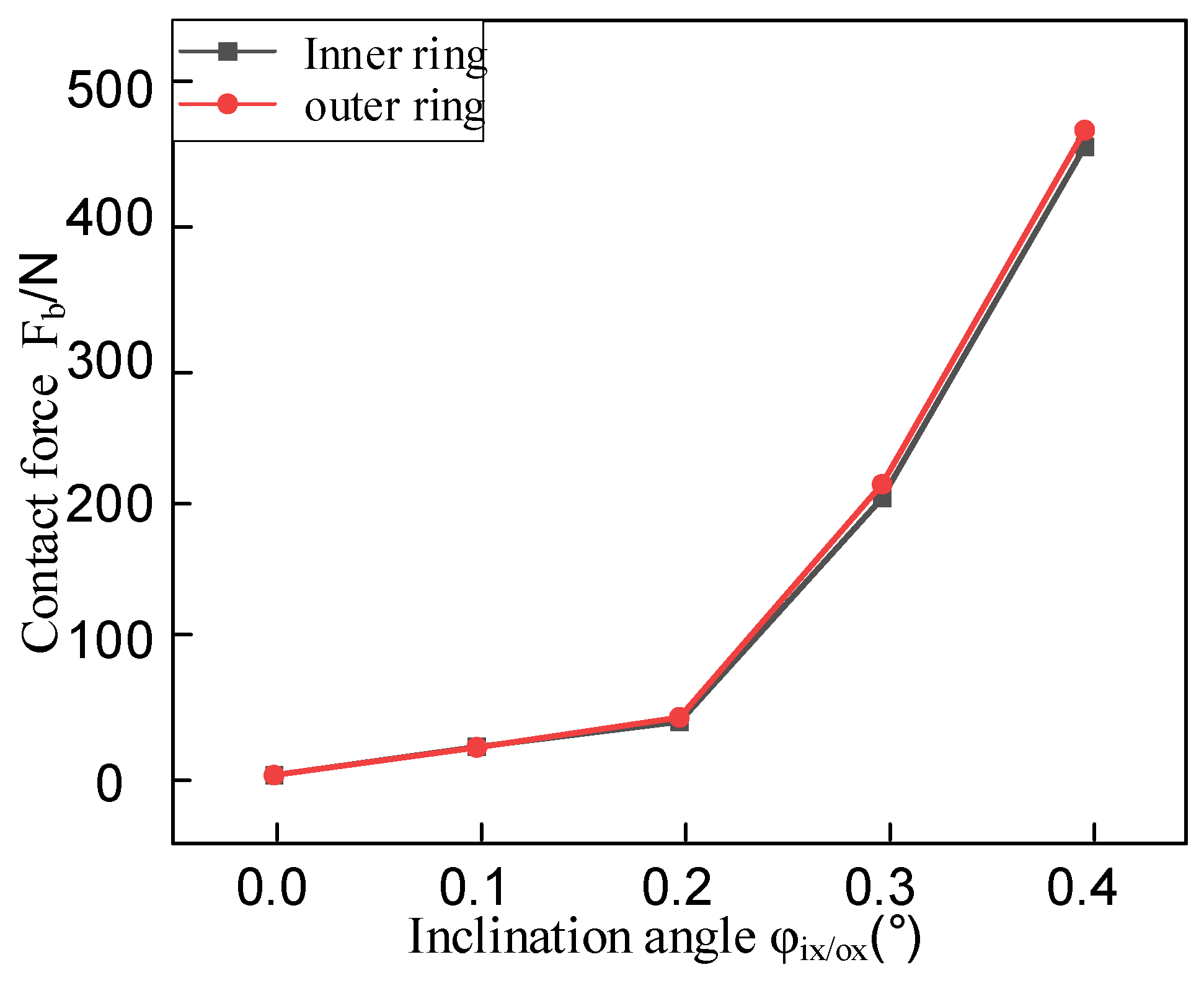

2.3. The Reactive Force Caused by the Misalignment of the Axis

3. Dynamics Modeling and Simulation

3.1. System Finite Element Model

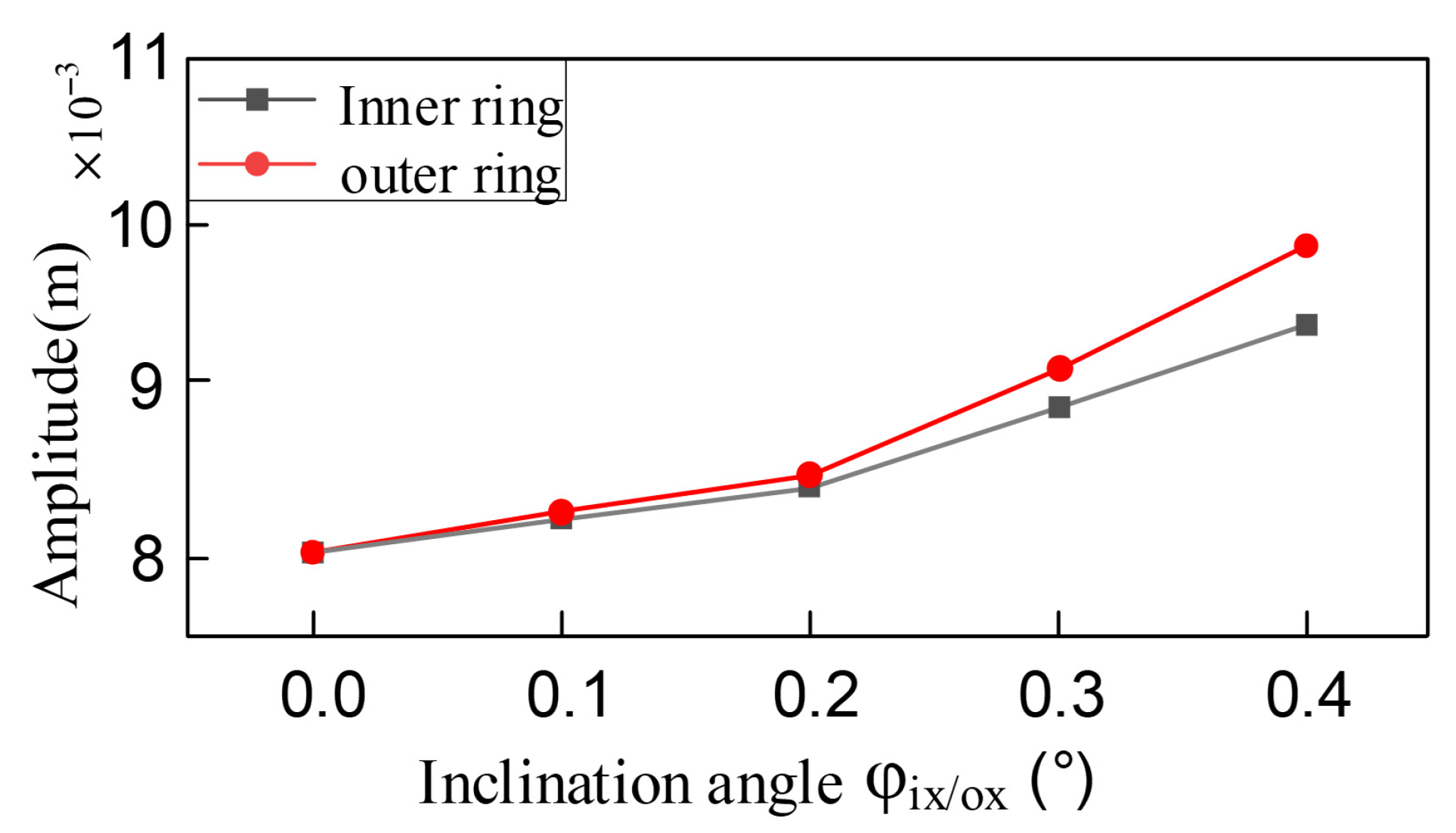

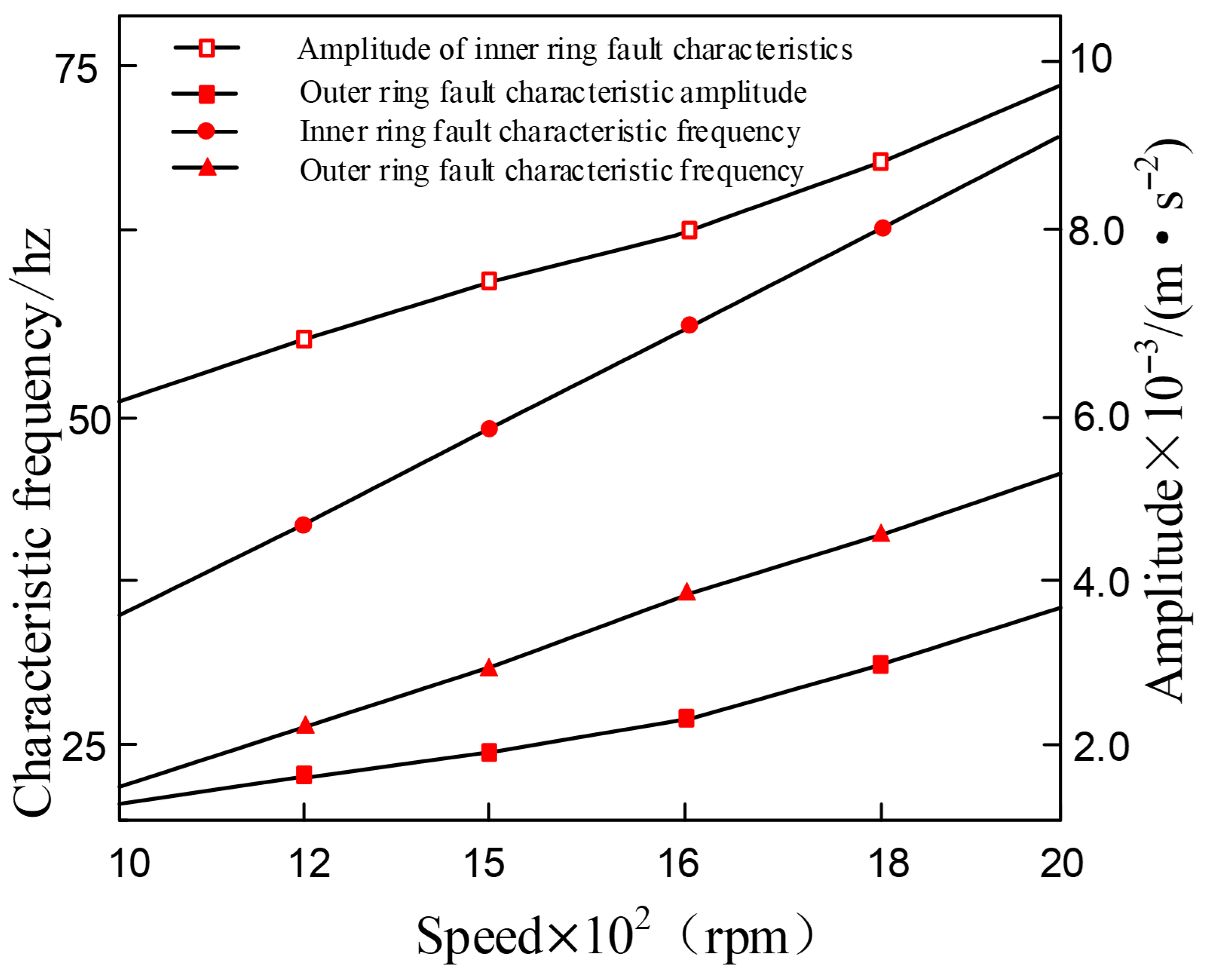

3.2. Changes in the Dynamic Characteristics of the System

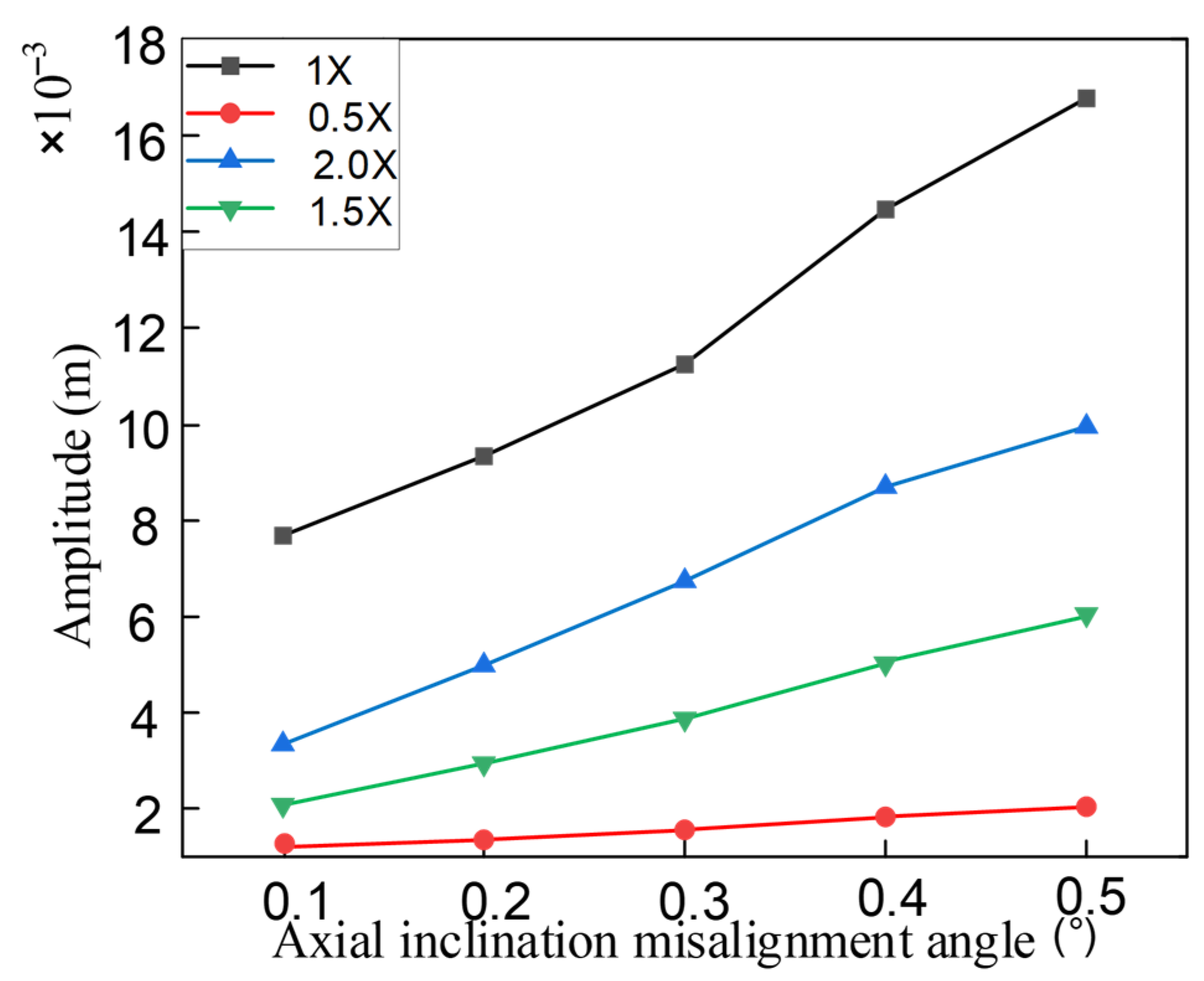

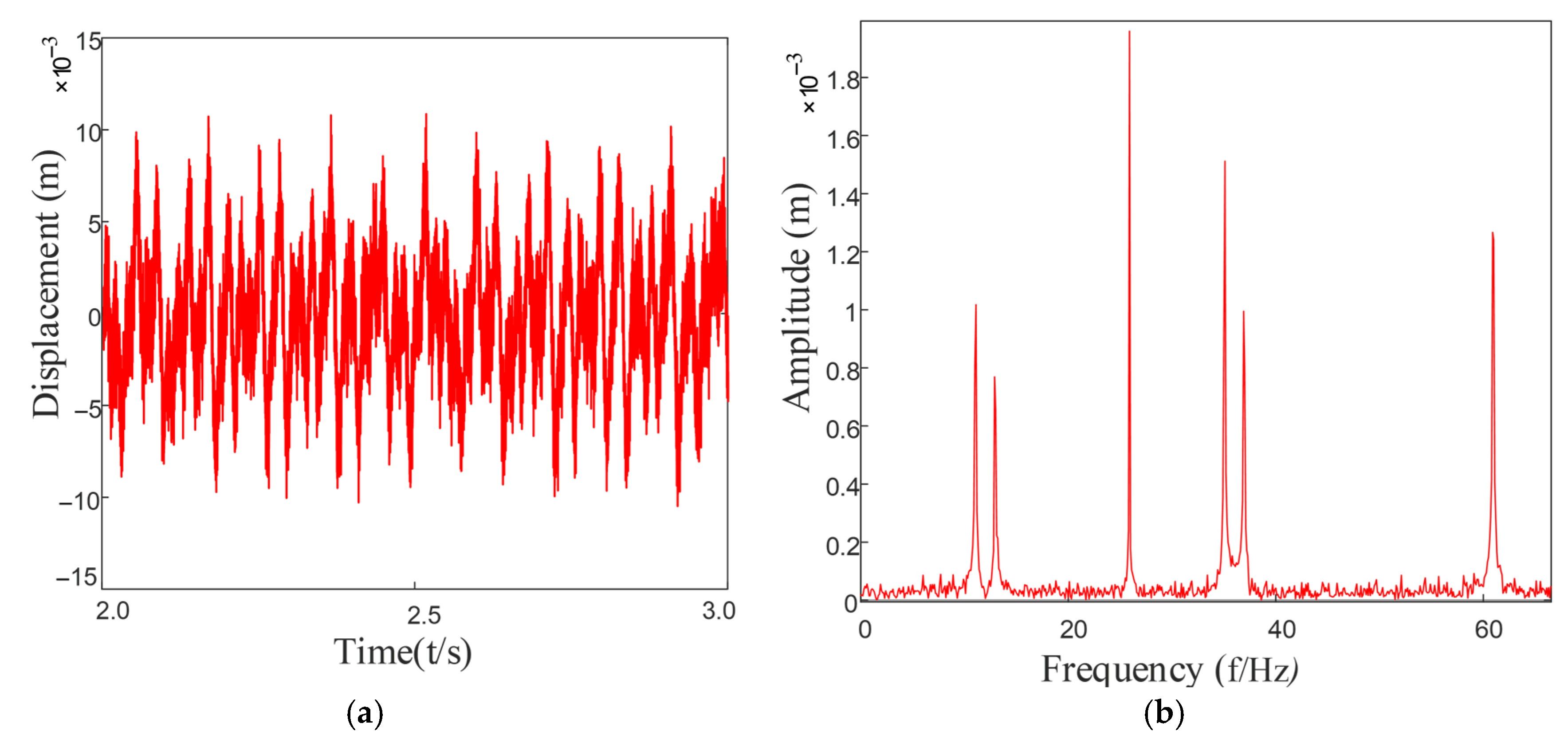

3.3. Analysis of System Vibration Response Characteristics

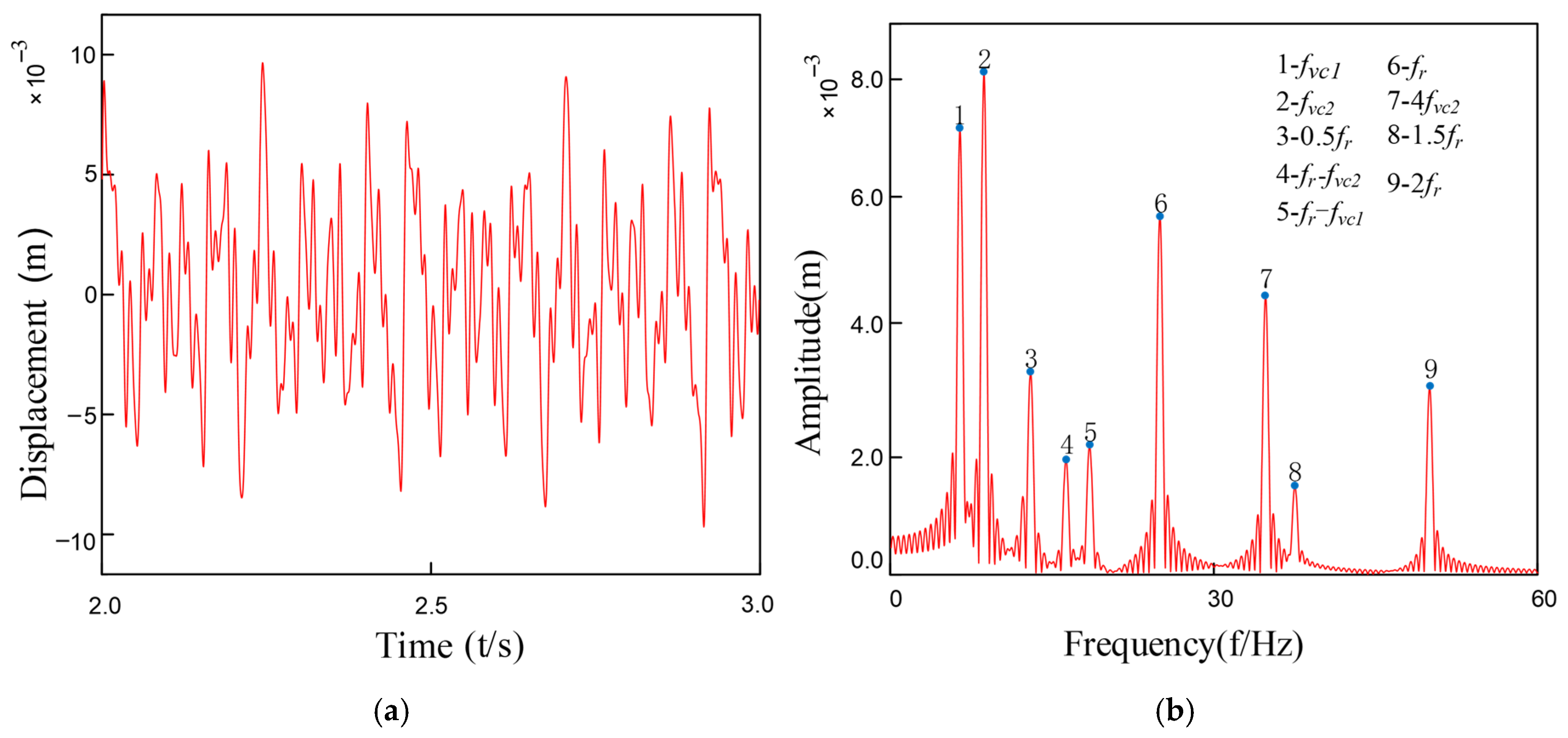

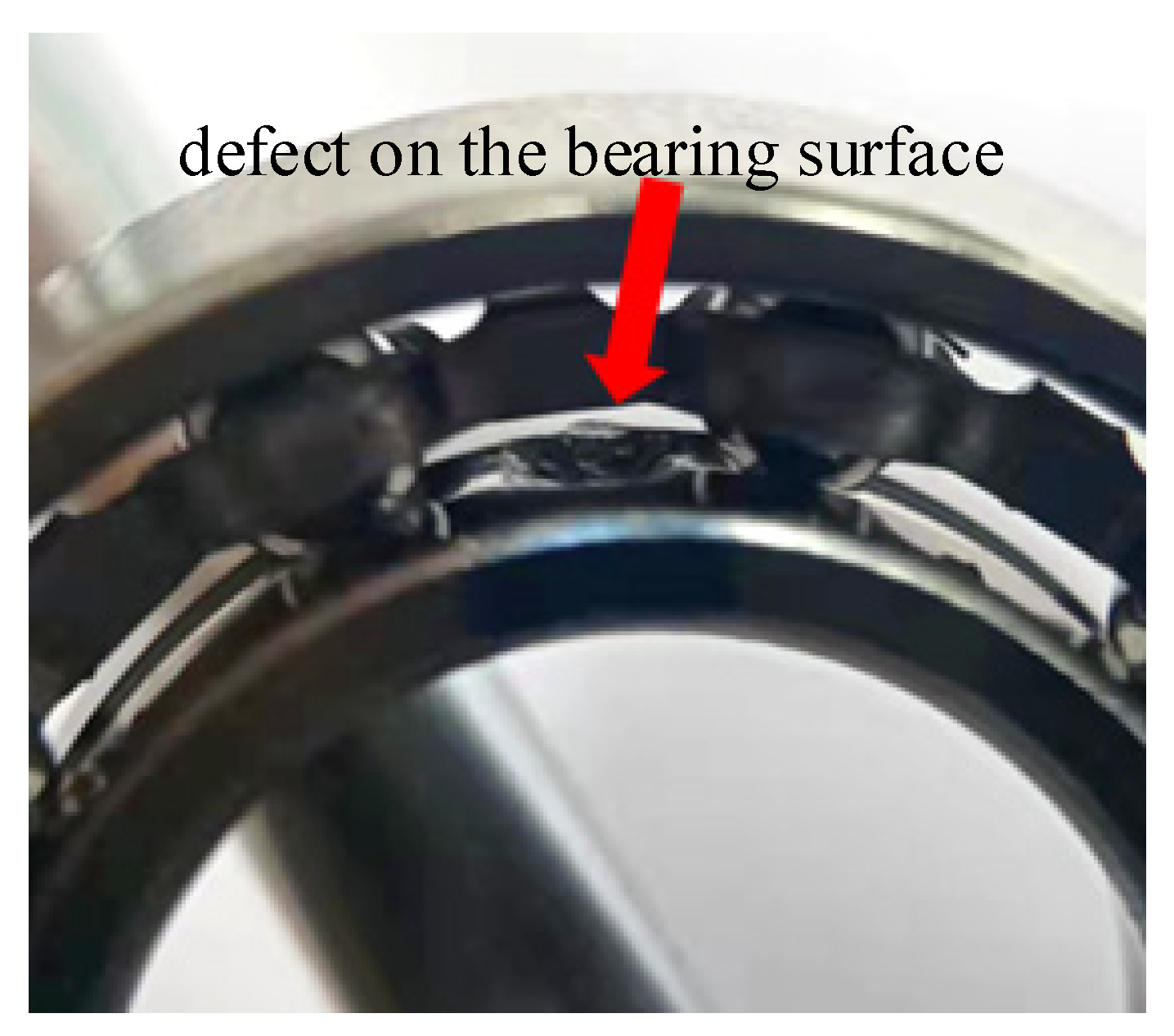

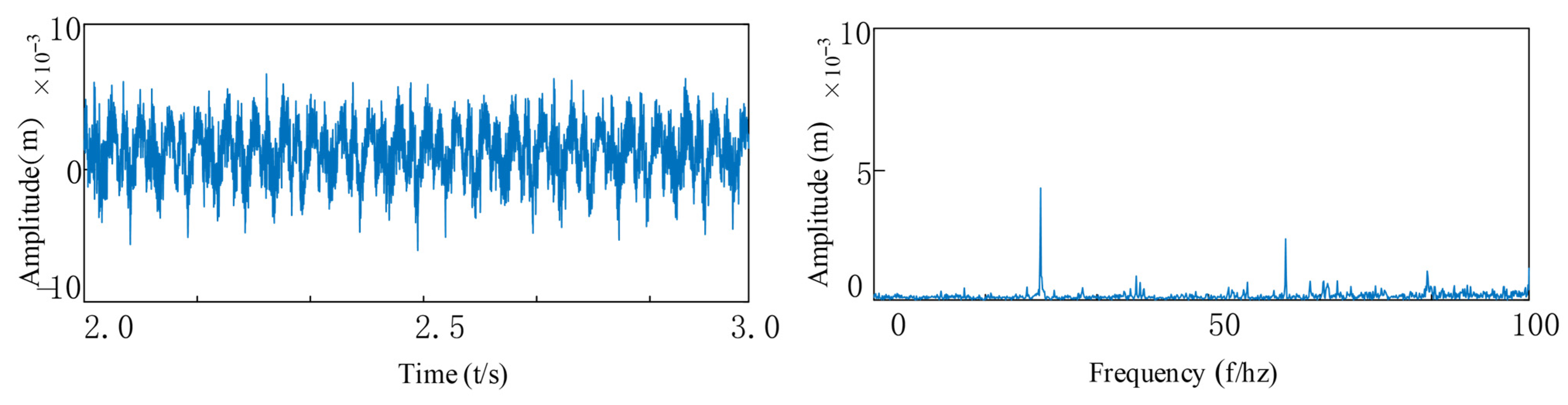

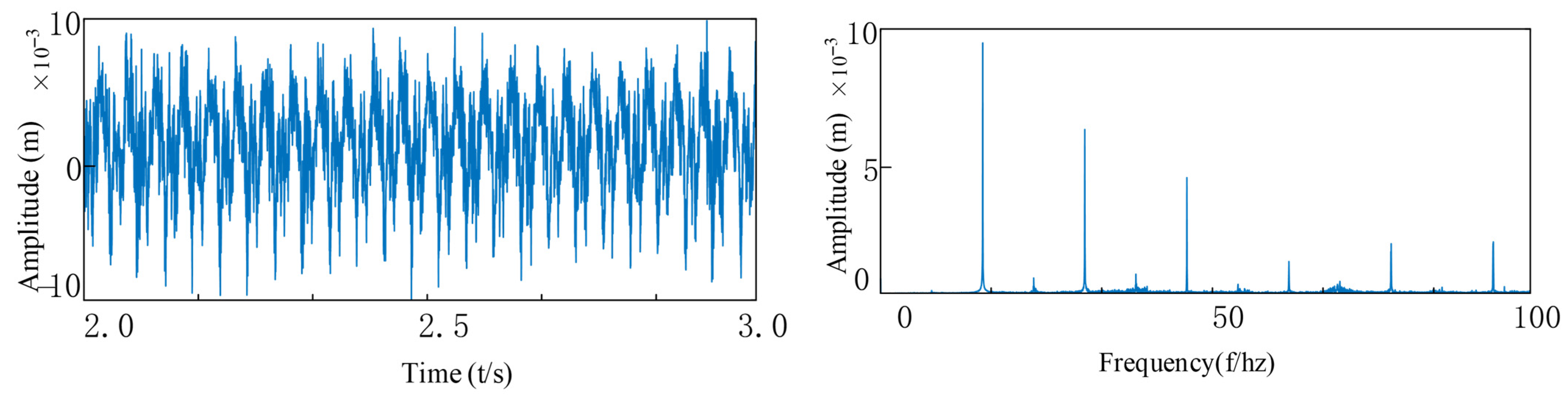

3.4. Modeling of Rolling Bearing Outer Ring Faults and Response Analysis

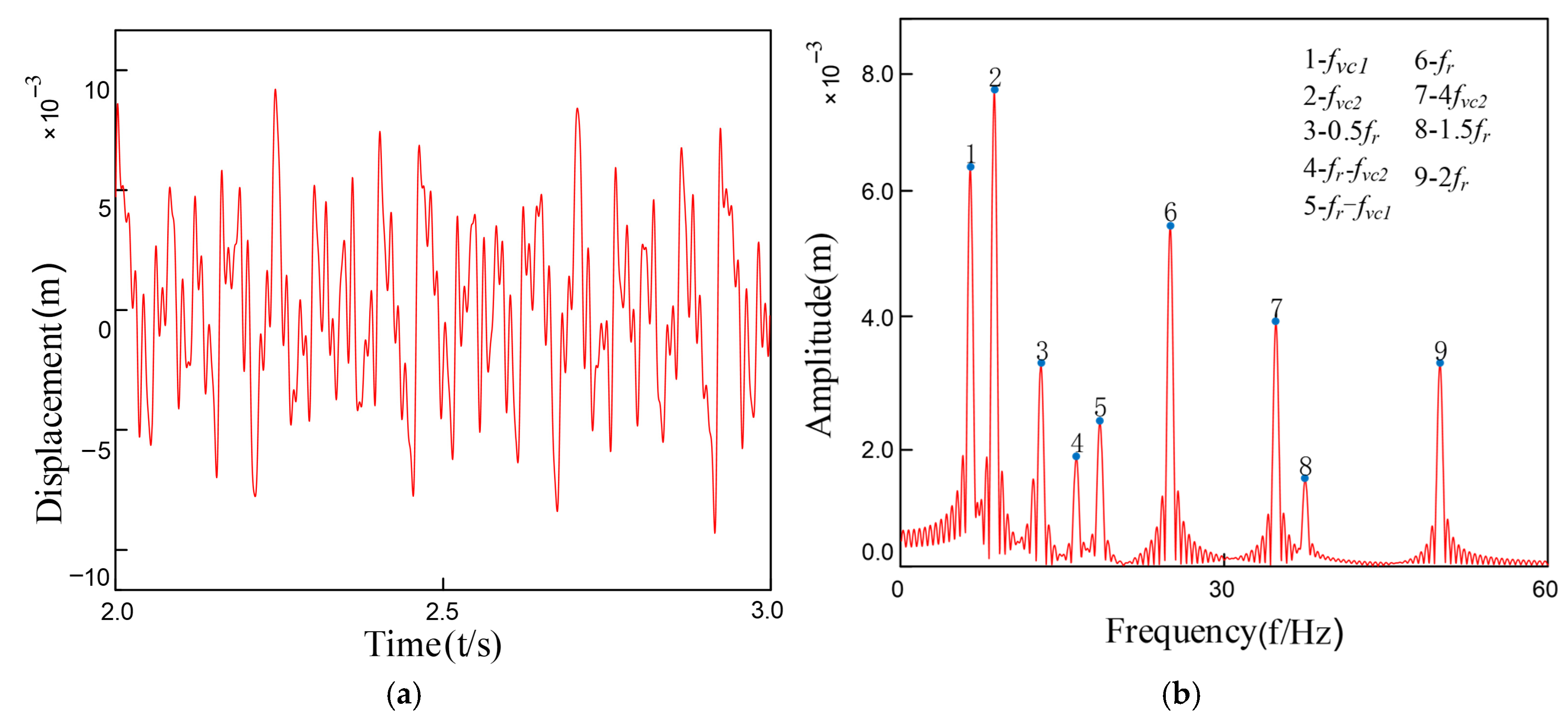

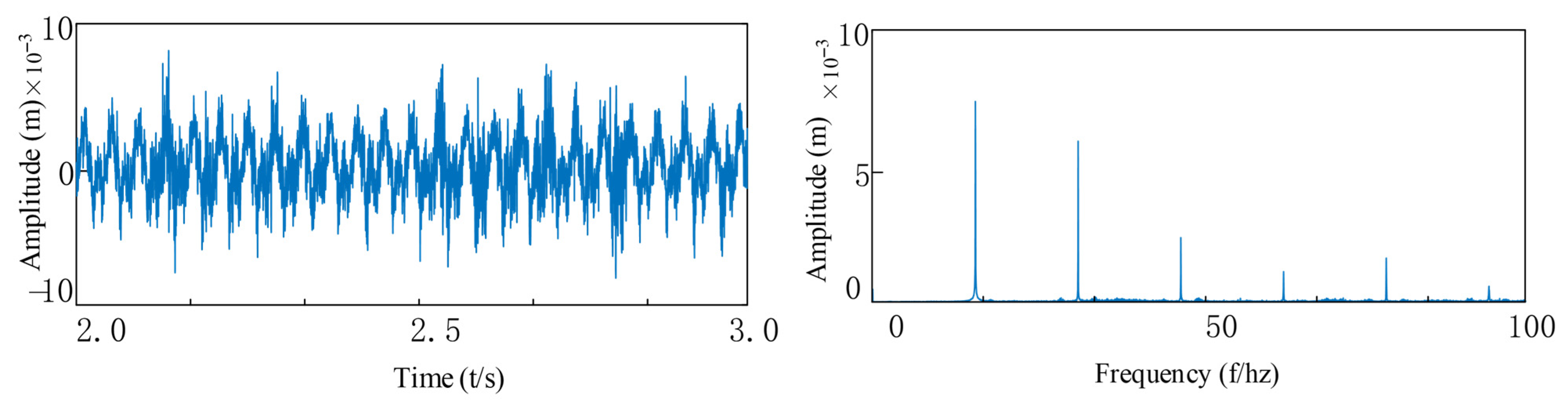

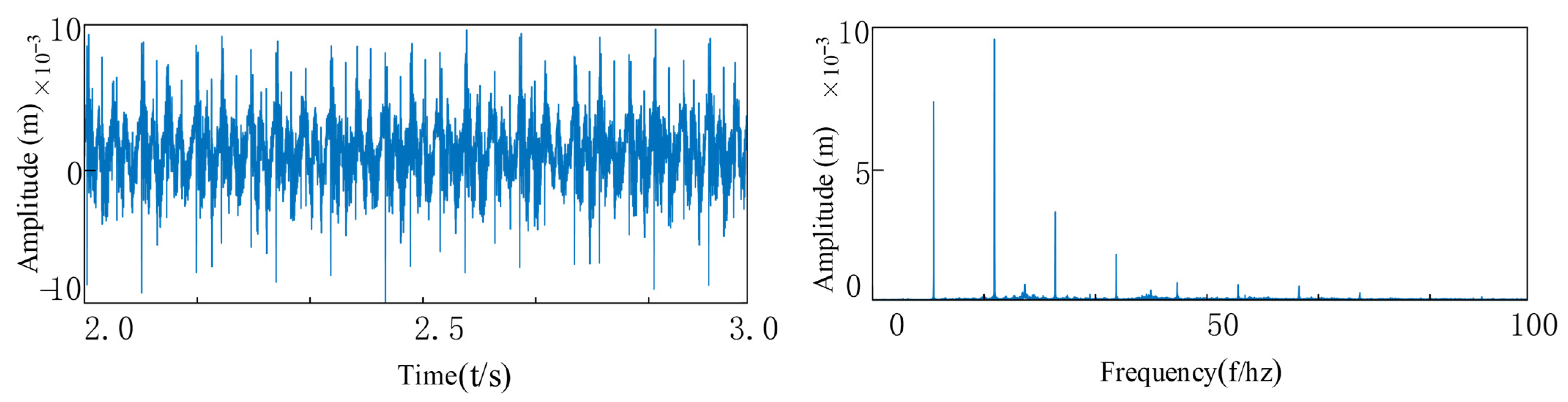

3.5. Modeling of Rolling Bearing Inner Ring Faults and Response Analysis

4. Random Roughness Characterization Method Based on Gaussian Filtering

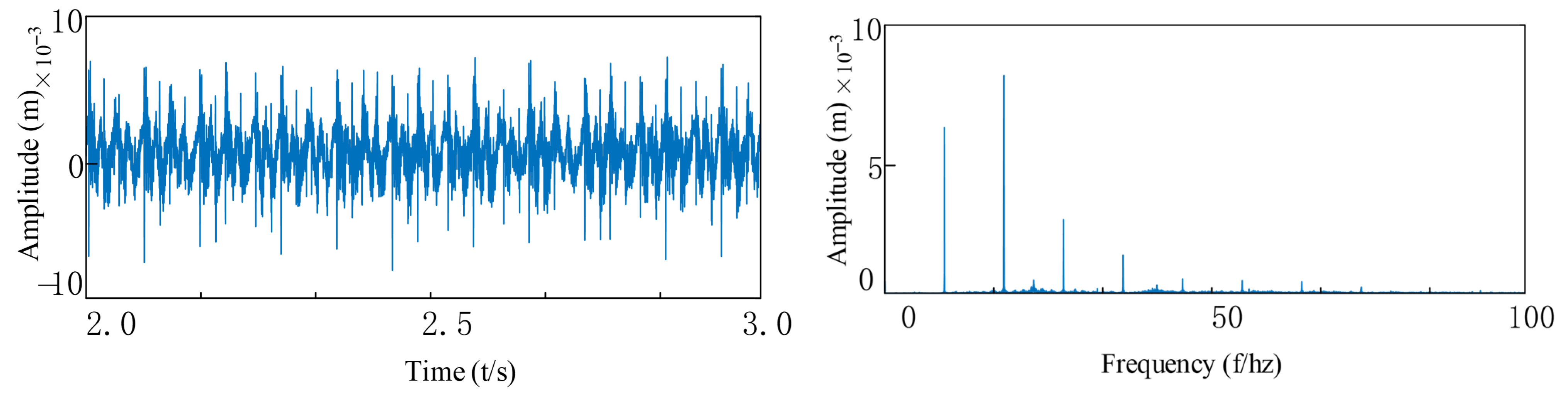

5. Model of Composite Fault Vibration Signals for Internal Bearings of Rotary Joint

6. Test Verification

6.1. Experimental Protocol Design

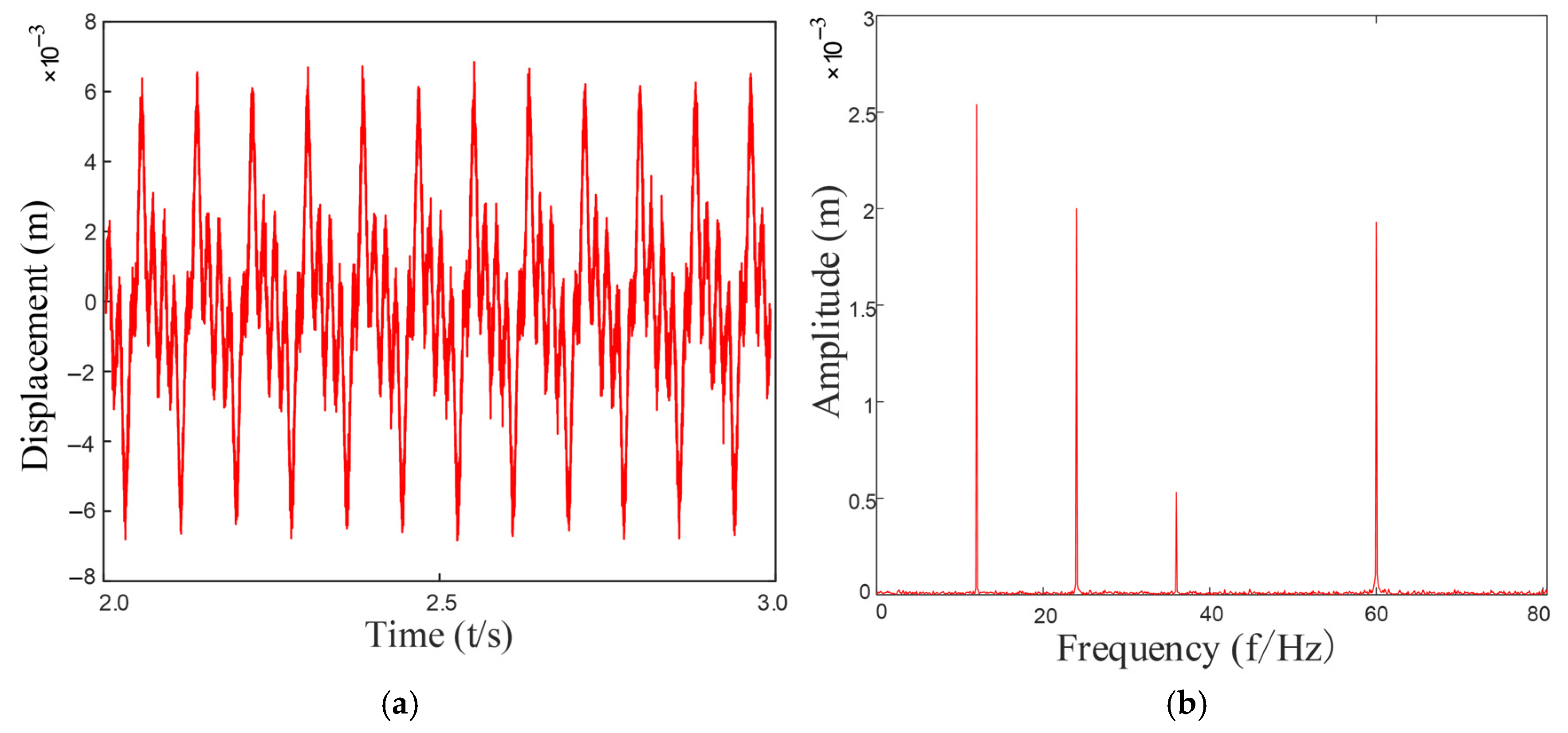

6.2. Data Collection and Analysis of Test Results

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Q.; Li, Q.; Qian, H.; Wang, Y.; Jiang, D. Diagnosis of rotor faults through generative adversarial networks enhanced by embedded wavelet scattering transforms. Nondestruct. Test. Eval. 2024, 1–18. [Google Scholar] [CrossRef]

- Salunkhe, V.G.; Desavale, R.G.; Kumbhar, S.G. Vibration analysis of deep groove ball bearing using finite element analysis and dimension analysis. J. Tribol. 2022, 144, 081202. [Google Scholar] [CrossRef]

- Zhang, J.H.; Ma, L.; Lin, J.W.; Zhang, G.C. Dynamic analysis of flexible rotor-ball bearings system with unbalance-misalignment-rubbing coupling faults. Appl. Mech. Mater. 2012, 105, 448–453. [Google Scholar]

- Xu, T.; Yang, L.; Wu, W.; Wang, K. Effect of angular misalignment of inner ring on the contact characteristics and stiffness coefficients of duplex angular contact ball bearings. Mech. Mach. Theory 2021, 157, 104178. [Google Scholar] [CrossRef]

- Zheng, J.; Ji, J.; Yin, S.; Tong, V.C. Internal loads and contact pressure distributions on the main shaft bearing in a modern gearless wind turbine. Tribol. Int. 2020, 141, 105960. [Google Scholar] [CrossRef]

- Yang, L.; Xu, T.; Xu, H.; Wu, Y. Mechanical behavior of double-row tapered roller bearing under combined external loads and angular misalignment. Int. J. Mech. Sci. 2018, 142, 561–574. [Google Scholar] [CrossRef]

- Zhang, Y.; Fu, X.; Li, S.; Li, S. Bearing wear analysis in multi-bearing spindle system. J. Mech. Strength 2022, 43, 1393–1401. [Google Scholar]

- Xu, H.; Wang, P.; Ma, H.; He, D.; Zhao, X.; Bao, Y.; Yang, Y. Contact characteristics analysis of deep groove ball bearings under combined angular misalignments and external loads. J. Tribol. 2022, 144, 121201. [Google Scholar] [CrossRef]

- Wen, C.; Meng, X.; Lyu, B.; Gu, J.; Xiao, L. Influence of angular misalignment on the tribological performance of high-speed micro ball bearings considering full multibody interactions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 1168–1189. [Google Scholar] [CrossRef]

- Cheng, H.; Zhang, Y.; Lu, W.; Yang, Z. Mechanical characteristics and nonlinear dynamic response analysis of rotor-bearing-coupling system. Appl. Math. Model. 2021, 93, 708–727. [Google Scholar] [CrossRef]

- Wu, K.; Liu, Z.; Ding, Q. Vibration responses of rotating elastic coupling with dynamic spatial misalignment. Mech. Mach. Theory 2020, 151, 103916. [Google Scholar] [CrossRef]

- Yi, J.; Pang, B.; Liu, H.; Wang, F.; Ji, B.; Jing, M. Influence of misalignment on nonlinear dynamic characteristics for matched bearings-rotor system. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2014, 228, 172–181. [Google Scholar] [CrossRef]

- Wang, P.; Xu, H.; Yang, Y.; Ma, H.; He, D.; Zhao, X. Dynamic characteristics of ball bearing-coupling-rotor system with angular misalignment fault. Nonlinear Dyn. 2022, 108, 3391–3415. [Google Scholar] [CrossRef]

- Parmar, V.; Saran, V.H.; Harsha, S.P. Effect of dynamic misalignment on the vibration response, trajectory followed and defect-depth achieved by the rolling-elements in a double-row spherical rolling-element bearing. Mech. Mach. Theory 2021, 162, 104366. [Google Scholar] [CrossRef]

- Wen, B.; Wang, M.; Han, Q.; Yu, C. Effect of ball bearing misalignment on dynamic characteristics of rotor system. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1081, p. 012014. [Google Scholar]

- Liu, J.; Wang, C.; Wu, W. Research on meshing stiffness and vibration response of pitting fault gears with different degrees. Int. J. Rotating Mach. 2020, 2020, 4176430. [Google Scholar] [CrossRef]

- Dong, J.; Pei, W.; Long, H.; Chu, J.; Ji, H. Solution of spur gear meshing stiffness and analysis of degradation characteristics. Mechanics 2020, 26, 153–160. [Google Scholar] [CrossRef]

- Wu, J.; Yang, Y.; Wang, P.; Wang, J.; Cheng, J. A novel method for gear crack fault diagnosis using improved analytical-FE and strain measurement. Measurement 2020, 163, 107936. [Google Scholar] [CrossRef]

- Yang, H.; Li, X.; Xu, J.; Yang, Z.; Chen, R. Dynamic characteristics analysis of planetary gear system with internal and external excitation under turbulent wind load. Sci. Prog. 2021, 104, 00368504211035604. [Google Scholar] [CrossRef]

- Jia, Y.-Z.; Zheng, Q.-C.; Ma, W.-P.; Zhu, P.-H. Analysis and Modeling of Dynamic Performance of Planetary Gears with Complex Broken Tooth Fault. Noise Vib. Control 2023, 43, 89. [Google Scholar]

- Asi, O. Fatigue failure of a helical gear in a gearbox. Eng. Fail. Anal. 2006, 13, 1116–1125. [Google Scholar] [CrossRef]

- Zhao, J.; Ma, C.; Zhang, Y.; Li, Z.; Yu, X.; Sheng, W. Effect of tooth surface pitting on dynamic characteristics under mixed lubrication. Eng. Fail. Anal. 2025, 167, 108961. [Google Scholar] [CrossRef]

- Liu, C.; Zhu, L.; Ni, C. Chatter detection in milling process based on VMD and energy entropy. Mech. Syst. Signal Process. 2018, 105, 169–182. [Google Scholar] [CrossRef]

- Chen, H. A vibration signal processing method based on SE-PSO-VMD for ultrasonic machining. Syst. Soft Comput. 2024, 6, 200081. [Google Scholar] [CrossRef]

- Sang, M.; Huang, K.; Xiong, Y.; Han, G.; Cheng, Z. Dynamic modeling and vibration analysis of a cracked 3K-II planetary gear set for fault detection. Mech. Sci. 2021, 12, 847–861. [Google Scholar] [CrossRef]

- Xiong, Y.; Yu, D.; Huang, K. Research on the time-varying mesh stiffness and dynamic characteristics of steel–POM gear pair with off-line meshing. Nonlinear Dyn. 2024, 112, 6015–6035. [Google Scholar] [CrossRef]

- Meng, Z.; Shi, G.; Wang, F. Vibration response and fault characteristics analysis of gear based on time-varying mesh stiffness. Mech. Mach. Theory 2020, 148, 103786. [Google Scholar] [CrossRef]

- Han, H.; Zhao, Z.; Tian, H.; Ma, H.; Yang, Y.; Li, X. Fault feature analysis of planetary gear set influenced by cracked gear tooth and pass effect of the planet gears. Eng. Fail. Anal. 2021, 121, 105162. [Google Scholar] [CrossRef]

- Wang, P.; Xu, H.; Ma, H.; Han, H.; Yang, Y. Effects of three types of bearing misalignments on dynamic characteristics of planetary gear set-rotor system. Mech. Syst. Signal Process. 2022, 169, 108736. [Google Scholar] [CrossRef]

- Reddy, M.C.S.; Sekhar, A.S. Detection and monitoring of coupling misalignment in rotors using torque measurements. Measurement 2015, 61, 111–122. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, Y.; Guan, J.; Tian, J.; Wang, Y. Fault dynamic modeling and characteristic parameter simulation of rolling bearing with inner ring local defects. Shock Vib. 2021, 2021, 5077366. [Google Scholar]

- Zhao, C.; Zio, E.; Shen, W. Multi-domain class-imbalance generalization with fault relationship-induced augmentation for intelligent fault diagnosis. IEEE Trans. Instrum. Meas. 2024, 73, 3526311. [Google Scholar]

| Rotor | Numerical Value |

|---|---|

| Outer diameter d (mm) | 8.5 |

| Axial segment length L (mm) | 230 |

| Number of units N | 10 |

| Speed ω (rpm) | 1000 |

| Bearings | Numerical Value |

|---|---|

| Outer track radius Ro (mm) | 19.98 |

| Inner track radius Ri (mm) | 14.55 |

| Number of rolling elements Z | 8 |

| Radial clearance c0/δr (μmm) | 2 |

| Roller length l (mm) | 10 |

| Fault Size | Medium | Serious |

|---|---|---|

| Inner ring | 0.15 mm | 0.3 mm |

| Outer ring | 0.15 mm | 0.3 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, J.; Zhu, Z.; Ji, J.; Yang, Y.; Miao, X.; Yan, X.; Liu, Q. Dynamic Modeling and Analysis of Rotary Joints with Coupled Bearing Tilt-Misalignment Faults. Entropy 2025, 27, 1123. https://doi.org/10.3390/e27111123

Lu J, Zhu Z, Ji J, Yang Y, Miao X, Yan X, Liu Q. Dynamic Modeling and Analysis of Rotary Joints with Coupled Bearing Tilt-Misalignment Faults. Entropy. 2025; 27(11):1123. https://doi.org/10.3390/e27111123

Chicago/Turabian StyleLu, Jun, Zixiang Zhu, Jie Ji, Yichao Yang, Xueyang Miao, Xiaoan Yan, and Qinghua Liu. 2025. "Dynamic Modeling and Analysis of Rotary Joints with Coupled Bearing Tilt-Misalignment Faults" Entropy 27, no. 11: 1123. https://doi.org/10.3390/e27111123

APA StyleLu, J., Zhu, Z., Ji, J., Yang, Y., Miao, X., Yan, X., & Liu, Q. (2025). Dynamic Modeling and Analysis of Rotary Joints with Coupled Bearing Tilt-Misalignment Faults. Entropy, 27(11), 1123. https://doi.org/10.3390/e27111123