Cooling Rate and Compositional Effects on Microstructural Evolution and Mechanical Properties of (CoCrCuTi)100−xFex High-Entropy Alloys

Abstract

1. Introduction

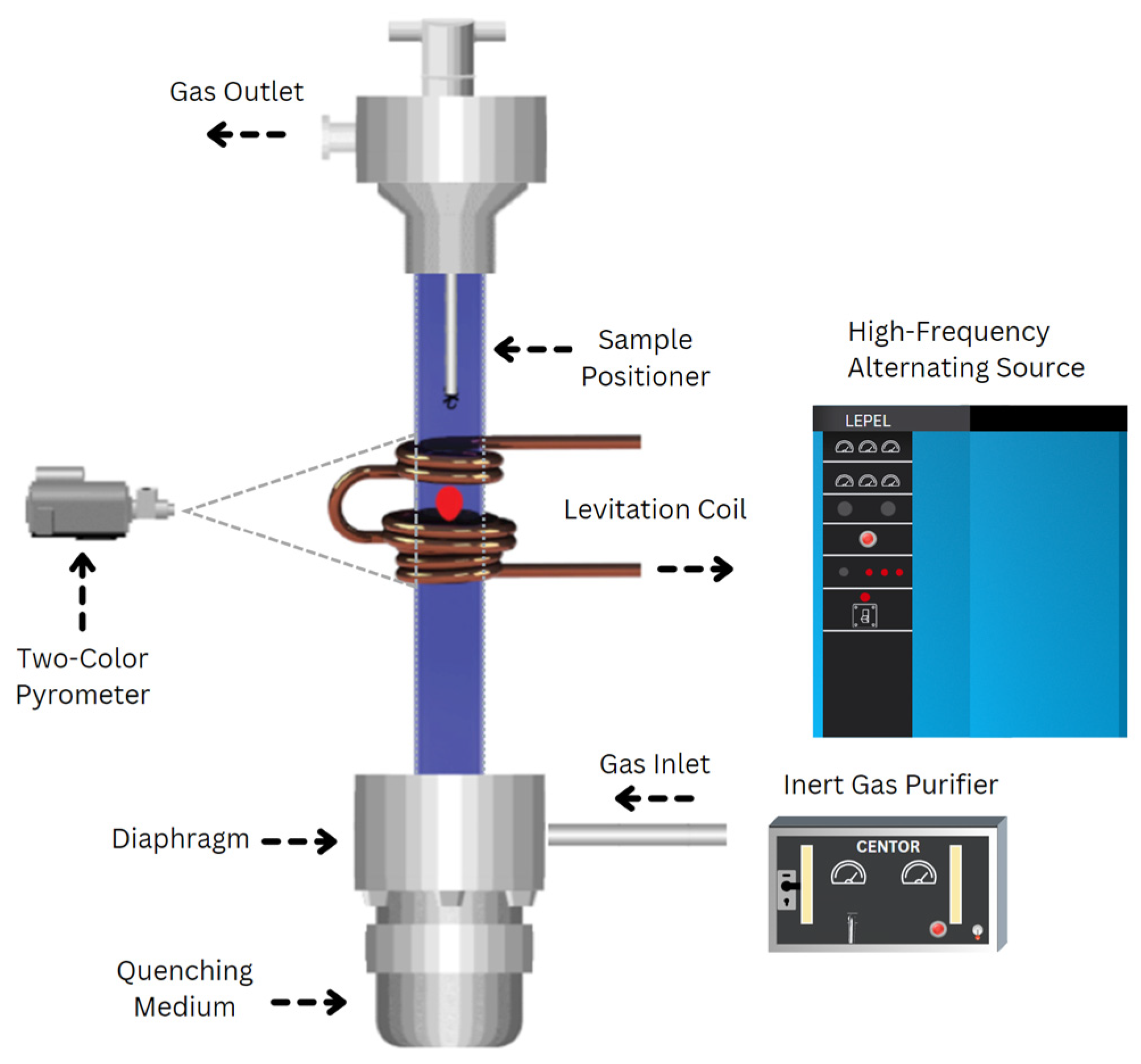

2. Materials and Methods

3. Results and Discussion

3.1. Cooling Rate (K/s) Calculation

= 16 ε−1/2

3.2. Microstructural Analysis of Arc-Melted (AM) Samples

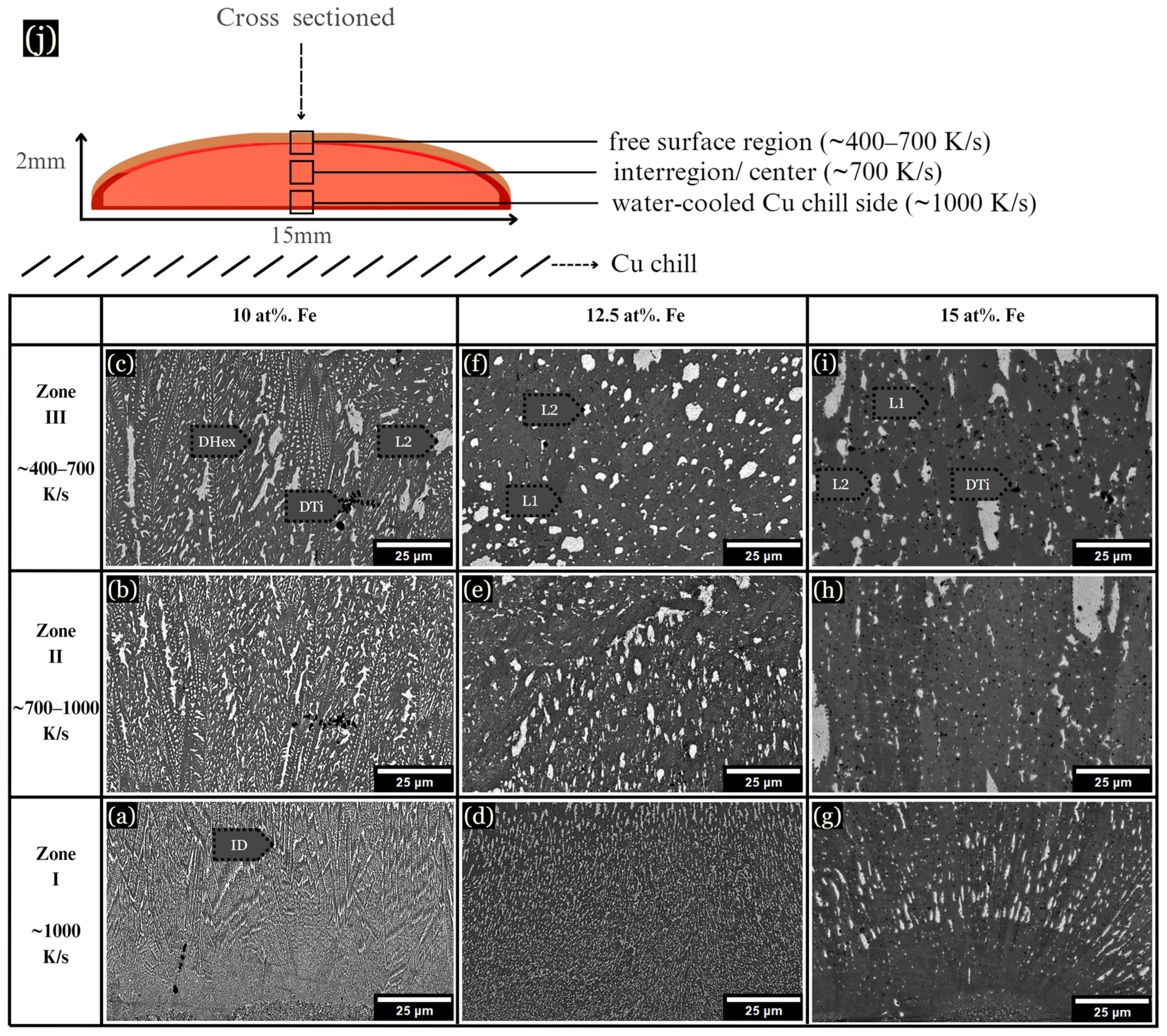

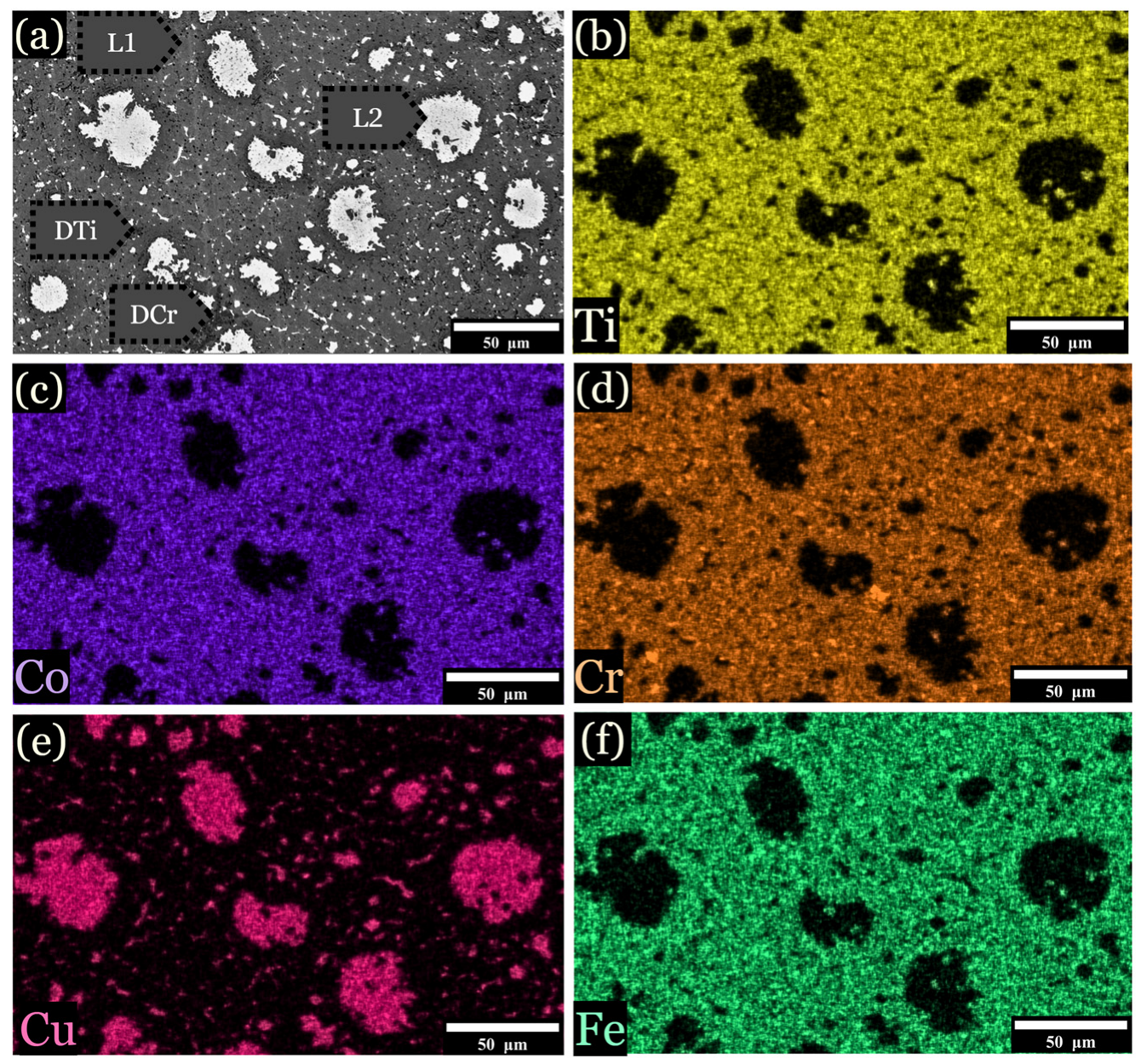

3.3. Microstructural Analysis of Quenched Levitated Samples

3.4. Vickers Hardness

3.5. Fracture Toughness

- KIC = Fracture toughness (MPa√m),

- c = Average crack length,

- a = Half of the average diagonal length of the Vickers marks (microns),

- H = Vickers hardness (MPa).

4. Summary

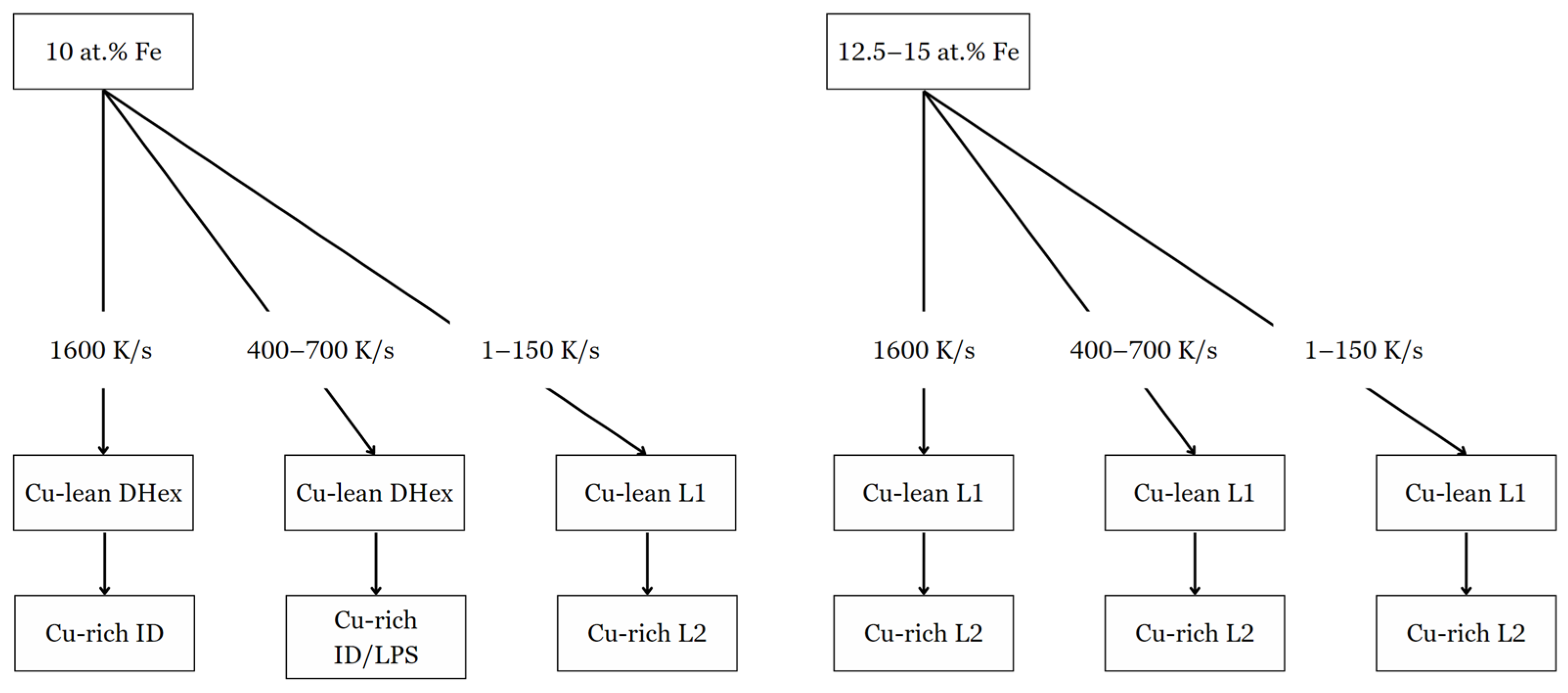

- The influence of composition and cooling rate on the microstructural development and properties of (CoCrCuTi)100−xFex (x = 0, 5, 10, 12.5, 15) high-entropy alloys (HEAs) were investigated utilizing arc-melting and EM levitation-melting, followed by quenching against a copper substrate or chill mold.

- Arc-melted samples with no iron addition revealed BCC1 + BCC2 phases, followed by an interdendritic FCC Cu-rich phase. However, with the addition of 5 to 15% Fe, a Cu-lean C14 Laves phase emerged, accompanied by an interdendritic Cu-rich FCC phase.

- At 10 at. % Fe, lower cooling rates (1–75 K/s) resulted in LPS, leading to the formation of Cu-lean L1 and Cu-rich L2 liquid phases. Increasing the cooling rate to ~400–700 K/s, the microstructure transformed into Cu-lean dendrites, with an interdendritic Cu-rich phase. However, coarse dendrites developed with a DAS of ~0.6–0.8 μm, surrounded by the Cu-rich liquid that was rejected and solidified at the end. At ~1000–1600 K/s, fine dendrites formed with a DAS of ~0.4–0.5 μm, alongside an interdendritic Cu-rich phase.

- Alloys with 12.5 to 15 at. % Fe developed LPS regardless of cooling rate. However, higher cooling rates resulted in a more uniform distribution of L2 throughout the microstructure.

- With the incorporation of Fe up to 15 at. % in the CoCrCuTi alloy, Vickers hardness increased from 444 to 891 HV when the hexagonal Laves C-14 phase was present.

- Rapid cooling rates generally enhanced hardness due to the formation of more-refined microstructures. However, fracture toughness decreased as the cooling rate increased. The highest Vickers hardness (891 ± 66 HV) and fracture toughness (5.5 ± 0.4 KIC) values were observed in 15 at. % Fe samples at 25–75 K/s.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Munitz, A.B.; Kaufman, M.J.; Nahmany, M.; Derimow, N.; Abbaschian, R. Microstructure and mechanical properties of heat treated Al1.25CoCrCuFeNi high entropy alloys. Mater. Sci. Eng. A 2018, 714, 146–159. [Google Scholar] [CrossRef]

- Derimow, N.; Clark, T.; Abbaschian, R. Solidification processing and cooling rate effects on hexagonal Co22Cr18Cu20Mn16Ti24 high-entropy alloys. Mater. Chem. Phys. 2020, 240, 122188. [Google Scholar] [CrossRef]

- Derimow, N.; MacDonald, B.E.; Lavernia, E.J.; Abbaschian, R. Duplex phase hexagonal-cubic multi-principal element alloys with high hardness. Mater. Today Commun. 2019, 21, 100658. [Google Scholar] [CrossRef]

- Takeuchi, A.; Amiya, K.; Wada, T. High-Entropy Alloys with a Hexagonal Close-Packed Structure Designed by Equi-Atomic Alloy Strategy and Binary Phase Diagrams. JOM 2014, 66, 1984–1992. [Google Scholar] [CrossRef]

- Derimow, N.; Jaime, R.F.; Le, B.; Abbaschian, R. Hexagonal (CoCrCuTi)100-xFex multi-principal element alloys. Mater. Chem. Phys. 2021, 261, 124190. [Google Scholar] [CrossRef]

- Tsai, M.H.; Yeh, J.W. High-Entropy Alloys: A Critical Review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Xiong, K.; Huang, L.; Wang, X.; Yu, L.; Feng, W. Cooling-Rate Effect on Microstructure and Mechanical Properties of Al0.5CoCrFeNi High-Entropy Alloy. Metals 2022, 12, 1254. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Wang, F.J.; Zhang, Y.; Chen, G.L.; Davies, H.A. Cooling Rate and Size Effect on the Microstructure and Mechanical Properties of AlCoCrFeNi High Entropy Alloy. J. Eng. Mater. Technol. 2009, 131, 034501. [Google Scholar] [CrossRef]

- Mishra, S.S.; Yadav, T.P.; Srivastava, O.N.; Mukhopadhyay, N.K.; Biswas, K. Formation, and stability of C14 type Laves phase in multi-component high-entropy alloys. J. Alloys Compd. 2020, 832, 153764. [Google Scholar] [CrossRef]

- Gorniewicz, D.; Przygucki, H.; Kopec, M.; Karczewski, K.; Jóźwiak, S. TiCoCrFeMn (BCC + C14) High-Entropy Alloy Multiphase Structure Analysis Based on the Theory of Molecular Orbitals. Materials 2021, 14, 5285. [Google Scholar] [CrossRef] [PubMed]

- Derimow, N.A. Solidification, Thermodynamics, and Mechanical Properties of Multi-Principal Element Alloys. Ph.D. Thesis, UC Riverside, Riverside, CA, USA, 2019. Available online: https://escholarship.org/uc/item/3t01k43p (accessed on 20 August 2022).

- Li, D.; Li, C.; Feng, T.; Zhang, Y.; Sha, G.; Lewandowski, J.J.; Liaw, P.K.; Zhang, Y. High-entropy Al0.3CoCrFeNi alloy fibers with high tensile strength and ductility at ambient and cryogenic temperatures. Acta Mater. 2017, 123, 285–294. [Google Scholar] [CrossRef]

- Zhang, Z.; Fu, S.; Aversano, F.; Bortolotti, M.; Zhang, H.; Hu, C.; Grasso, S. Arc melting: A novel method to prepare homogeneous solid solutions of transition metal carbides (Zr, Ta, Hf). Ceram. Int. 2019, 45, 9316–9319. [Google Scholar] [CrossRef]

- Chen, M.R.; Lin, S.J.; Yeh, J.W.; Chen, S.K.; Huang, Y.S.; Tu, C.P. Microstructure and Properties of Al0.5CoCrCuFeNiTix (x = 0–2.0) High-Entropy Alloys. Mater. Trans. 2006, 47, 1395–1401. [Google Scholar] [CrossRef]

- Singh, S.; Wanderka, N.; Murty, B.S.; Glatzel, U.; Banhart, J. Decomposition in multicomponent AlCoCrCuFeNi high-entropy alloy. Acta Mater. 2011, 59, 182–190. [Google Scholar] [CrossRef]

- Lin, C.-M.; Tsai, H.-L. Evolution of microstructure, hardness, and corrosion properties of high-entropy Al0.5CoCrFeNi alloy. Intermetallics 2011, 19, 288–294. [Google Scholar] [CrossRef]

- Suárez Ocaño, P.; Manzoni, A.; Lopez-Galilea, I.; Ruttert, B.; Laplanche, G.; Agudo Jácome, L. Influence of cooling rate on the microstructure and room temperature mechanical properties in the refractory AlMo0.5NbTa0.5TiZr superalloy. J. Alloys Compd. 2023, 949, 169871. [Google Scholar] [CrossRef]

- Ogura, M.; Fukushima, T.; Zeller, R.; Dederichs, P.H. Structure of the high-entropy alloy AlxCrFeCoNi: FCC versus BCC. J. Alloys Compd. 2017, 715, 454–459. [Google Scholar] [CrossRef]

- Zhu, C.; Xu, L.; Liu, M.; Guo, M.; Wei, S. A review on improving mechanical properties of high entropy alloy: Interstitial atom doping. J. Mater. Res. Technol. 2023, 24, 7832–7851. [Google Scholar] [CrossRef]

- Choi, J.W.; Kim, J.T.; Hong, S.H.; Park, H.J.; Jumaev, E.; Kim, K.B. Analysis of phase transformation and deformation behaviors on Laves phase of as-cast (CoCuFeNi)100-xZrx high entropy alloys. J. Alloys Compd. 2022, 928, 166999. [Google Scholar] [CrossRef]

- Ye, X.; Diao, Z.; Lei, H.; Wang, L.; Li, Z.; Li, B.; Feng, J.; Chen, J.; Liu, X.; Fang, D. Multi-phase FCC-based composite eutectic high entropy alloy with multi-scale microstructure. Mater. Sci. Eng. A 2023, 889, 145815. [Google Scholar] [CrossRef]

- Moradkhani, A.; Baharvandi, H.; Tajdari, M.; Vahdat, M.; Abedi, H. Determination of fracture toughness using the area of micro-crack tracks left in brittle materials by Vickers indentation test. J. Adv. Ceram. 2013, 2, 87–102. [Google Scholar] [CrossRef]

- Kim, J.; Jung, S.-G.; Han, Y.; Kim, J.; Rhyee, J.-S.; Yeo, S.; Park, T. Thermal-driven gigantic enhancement in critical current density of high-entropy alloy superconductors. J. Mater. Sci. Technol. 2024, 189, 60–67. [Google Scholar] [CrossRef]

- Zhao, Y.J.; Qiao, J.W.; Ma, S.G.; Gao, M.C.; Yang, H.J.; Chen, M.W.; Zhang, Y. A hexagonal close-packed high-entropy alloy: The effect of entropy. Mater. Des. 2016, 96, 10–15. [Google Scholar] [CrossRef]

- Zeng, Z.; Xiang, M.; Zhang, D.; Shi, J.; Wang, W.; Tang, X.; Morita, K. Mechanical properties of Cantor alloys driven by additional elements: A review. J. Mater. Res. Technol. 2021, 15, 1920–1934. [Google Scholar] [CrossRef]

- Chen, R.; Qin, G.; Zheng, H.; Wang, L.; Su, Y.; Chiu, Y.L.; Ding, H.; Guo, J.; Fu, H. Composition design of high entropy alloys using the valence electron concentration to balance strength and ductility. Acta Mater. 2018, 144, 129–137. [Google Scholar] [CrossRef]

- Farjam, R.; Akbari, A.; Nili-Ahmadabadi, M.; Shirazi, H. Co50Cr20Ni20Fe5Mn5 high entropy alloy: Overcoming the strength-ductility trade-off of Cantor alloy. J. Alloys Compd. 2024, 976, 173000. [Google Scholar] [CrossRef]

- Guo, J.; Cao, C.; Gong, S.; Song, R.; Bai, X.; Wang, J.; Sun, Z. Rapid solidification of Cu60Co30Cr10 alloy under different conditions. Trans. Nonferrous Met. Soc. China 2013, 23, 731–734. [Google Scholar] [CrossRef]

- Sreeramagiri, P.; Roy, A.; Balasubramanian, G. Effect of Cooling Rate on the Phase Formation of AlCoCrFeNi High-Entropy Alloy. J. Phase Equilibria Diffus. 2021, 42, 772–780. [Google Scholar] [CrossRef]

- George, E.P.; Curtin, W.A.; Tasan, C.C. High entropy alloys: A focused review of mechanical properties and deformation mechanisms. Acta Mater. 2019, 188, 435–474. [Google Scholar] [CrossRef]

- Nagase, T.; Mizuuchi, K.; Nakano, T. Solidification Microstructures of the Ingots Obtained by Arc Melting and Cold Crucible Levitation Melting in TiNbTaZr Medium-Entropy Alloy and TiNbTaZrX (X = V, Mo, W) High-Entropy Alloys. Entropy 2019, 21, 483. [Google Scholar] [CrossRef] [PubMed]

- Kozieł, T.; Pajor, K.; Gondek, Ł. Cooling rate evaluation during solidification in the suction casting process. J. Mater. Res. Technol. 2020, 9, 13502–13508. [Google Scholar] [CrossRef]

- Wang, L.; Sun, Y.; Bo, L.; Zuo, M.; Zhao, D. Effects of melt cooling rate on the microstructure and mechanical properties of Al-Cu alloy. Mater. Res. Express 2019, 6, 116507. [Google Scholar] [CrossRef]

- Luo, X.; Totten, G. Evolution from Cooling Modeling to Cooling Engineering of the Steel Quenching Process: A Technology Overview. Mater. Perform. Charact. 2018, 8, 20180028. [Google Scholar] [CrossRef]

- Pizetta Zordão, L.H.; Oliveira, V.A.; Totten, G.E.; Canale, L.C.F. Quenching power of aqueous salt solution. Int. J. Heat Mass Transf. 2019, 140, 807–818. [Google Scholar] [CrossRef]

- Afonso, C.R.M.; Aleixo, G.T.; Ramirez, A.J.; Caram, R. Influence of cooling rate on microstructure of Ti–Nb alloy for orthopedic implants. Mater. Sci. Eng. C 2007, 27, 908–913. [Google Scholar] [CrossRef]

- Elmer, J.W. The Influence of Cooling Rate on the Microstructure of Stainless-Steel Alloys; Lawrence Livermore National Lab (LLNL): Livermore, CA, USA, 1988. [Google Scholar]

- Rao, K.M.P.; Prabhu, K.N. A Comparative Study on Cooling Performance of Hot Oil and Molten Salt Quench Media for Industrial Heat Treatment. J. Materi Eng. Perform. 2020, 29, 3494–3501. [Google Scholar] [CrossRef]

- Žmak, I.; Ćorić, D.; Mandić, V.; Ćurković, L. Hardness and Indentation Fracture Toughness of Slip Cast Alumina and Alumina-Zirconia Ceramics. Materials 2019, 13, 122. [Google Scholar] [CrossRef]

- Chicot, D.; Pertuz, A.; Roudet, F.; Staia, M.H.; Lesage, J. New developments for fracture toughness determination by Vickers indentation. Mater. Sci. Technol. 2004, 20, 877–884. [Google Scholar] [CrossRef]

- Samuel, A.; Prabhu, K.N. Residual Stress and Distortion during Quench Hardening of Steels: A Review. J. Mater. Eng. Perform. 2022, 31, 5161–5188. [Google Scholar] [CrossRef]

| ɛ (K/s) | Phase | Co | Cr | Cu | Ti | Fe |

|---|---|---|---|---|---|---|

| Nominal | 25 | 25 | 25 | 25 | - | |

| ~1000 K/s | BCC1 | 6.9 | 85.9 | 1.2 | 6.0 | - |

| BCC2 | 37.0 | 14.5 | 10.6 | 37.9 | - | |

| ID | 6.3 | 1.9 | 86.0 | 5.9 | - |

| ɛ (K/s) | Phase | Co | Cr | Cu | Ti | Fe |

|---|---|---|---|---|---|---|

| Nominal | 22.5 | 22.5 | 22.5 | 22.5 | 10 | |

| ~1 K/s | L1 | 32.7 | 23.9 | 3.2 | 27.5 | 12.7 |

| L2 | 2.6 | 0.8 | 94.2 | 1.6 | 0.8 | |

| 50–150 K/s | L1 | 30.8 | 33.2 | 3.4 | 18.9 | 13.7 |

| L2 | 2.1 | 1.2 | 94.5 | 1.4 | 0.8 | |

| 400–700 K/s | DHex | 30.7 | 26.0 | 3.4 | 26.6 | 13.2 |

| ID/LPS | 2.2 | 0.8 | 95.3 | 1.5 | 0.3 | |

| ~1600 K/s | DHex | 26.8 | 18.1 | 20.9 | 24.0 | 10.4 |

| ID | 11.9 | 8.1 | 64.1 | 11.6 | 4.3 |

| ɛ (K/s) | Phase | Co | Cr | Cu | Ti | Fe |

|---|---|---|---|---|---|---|

| Nominal | 21.88 | 21.88 | 21.88 | 21.88 | 12.5 | |

| ~1 K/s | L1 | 30.2 | 24.7 | 2.5 | 26.2 | 16.5 |

| L2 | 0.8 | 1.0 | 97.2 | 0.7 | 0.4 | |

| ~25 K/s | L1 + L2 | 23.69 | 20.32 | 22.59 | 20.91 | 12.49 |

| 25–75 K/s | L1 | 27.9 | 26.1 | 4.5 | 25.4 | 16.1 |

| L2 | 0.8 | 0.8 | 95.8 | 2.2 | 0.4 | |

| 400–700 K/s | DHex | 27.8 | 25.6 | 6.7 | 23.4 | 16.5 |

| ID | 2.0 | 1.5 | 93.7 | 2.0 | 0.7 | |

| ~1600 K/s | DHex | 23.9 | 20.0 | 23.1 | 20.5 | 12.5 |

| ID | 2.5 | 2.1 | 89.4 | 5.5 | 0.5 |

| ɛ (K/s) | Phase | Co | Cr | Cu | Ti | Fe |

|---|---|---|---|---|---|---|

| Nominal | 21.25 | 21.25 | 21.25 | 21.25 | 15 | |

| ~1 K/s | L1 | 28.5 | 23.0 | 4.6 | 24.8 | 19.0 |

| L2 | 1.1 | 0.8 | 94.9 | 2.8 | 0.4 | |

| 50–150 K/s | L1 | 27.3 | 24.7 | 3.5 | 25.7 | 18.8 |

| L2 | 1.1 | 1.2 | 94.8 | 2.4 | 0.6 | |

| 400–700 K/s | L1 | 29.6 | 23.0 | 4.4 | 24.6 | 18.5 |

| L2 | 1.2 | 0.9 | 95.5 | 1.8 | 0.6 | |

| ~1600 K/s | L1 | 30.9 | 20.0 | 5.6 | 24.9 | 18.7 |

| L2 | 1.3 | 1.9 | 92.7 | 3.4 | 0.7 |

| ɛ (K/s) | Composition | Vickers Hardness (HV) | Fracture Toughness (KIC) |

|---|---|---|---|

| 10 at. % Fe | 598 ± 129 | 3.9 ± 0.3 | |

| 1 K/s | 12.5 at. % Fe | 683 ± 173 | 4.1 ± 0.2 |

| 15 at. % Fe | 623 ± 191 | 4.1 ± 0.3 | |

| 10 at. % Fe | 820 ± 35 | 4.2 ± 0.2 | |

| 25–75 K/s | 12.5 at. % Fe | 841 ± 59 | 3.9 ± 0.3 |

| 15 at. % Fe | 891 ± 66 | 5.5 ± 0.4 | |

| 10 at. % Fe | 658 ± 119 | 2.7 ± 0.6 | |

| 400–700 K/s | 12.5 at. % Fe | 673 ± 92 | 3.3 ± 0.4 |

| 15 at. % Fe | 638 ± 127 | 2.9 ± 0.5 | |

| 10 at. % Fe | 790 ± 33 | 1.7 ± 0.1 | |

| 1000 K/s | 12.5 at. % Fe | 765 ± 75 | 1.7 ± 0.4 |

| 15 at. % Fe | 760 ± 20 | 1.9 ± 0.6 | |

| 10 at. % Fe | 802 ± 22 | 2.8 ± 0.1 | |

| 1600 K/s | 12.5 at. % Fe | 877 ± 35 | 2.6 ± 0.1 |

| 15 at. % Fe | 827 ± 53 | 3.9 ± 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Terry, B.; Abbaschian, R. Cooling Rate and Compositional Effects on Microstructural Evolution and Mechanical Properties of (CoCrCuTi)100−xFex High-Entropy Alloys. Entropy 2024, 26, 826. https://doi.org/10.3390/e26100826

Terry B, Abbaschian R. Cooling Rate and Compositional Effects on Microstructural Evolution and Mechanical Properties of (CoCrCuTi)100−xFex High-Entropy Alloys. Entropy. 2024; 26(10):826. https://doi.org/10.3390/e26100826

Chicago/Turabian StyleTerry, Brittney, and Reza Abbaschian. 2024. "Cooling Rate and Compositional Effects on Microstructural Evolution and Mechanical Properties of (CoCrCuTi)100−xFex High-Entropy Alloys" Entropy 26, no. 10: 826. https://doi.org/10.3390/e26100826

APA StyleTerry, B., & Abbaschian, R. (2024). Cooling Rate and Compositional Effects on Microstructural Evolution and Mechanical Properties of (CoCrCuTi)100−xFex High-Entropy Alloys. Entropy, 26(10), 826. https://doi.org/10.3390/e26100826