Heat Transfer and Pressure Drop of Nanofluid with Rod-like Particles in Turbulent Flows through a Curved Pipe

Abstract

:1. Introduction

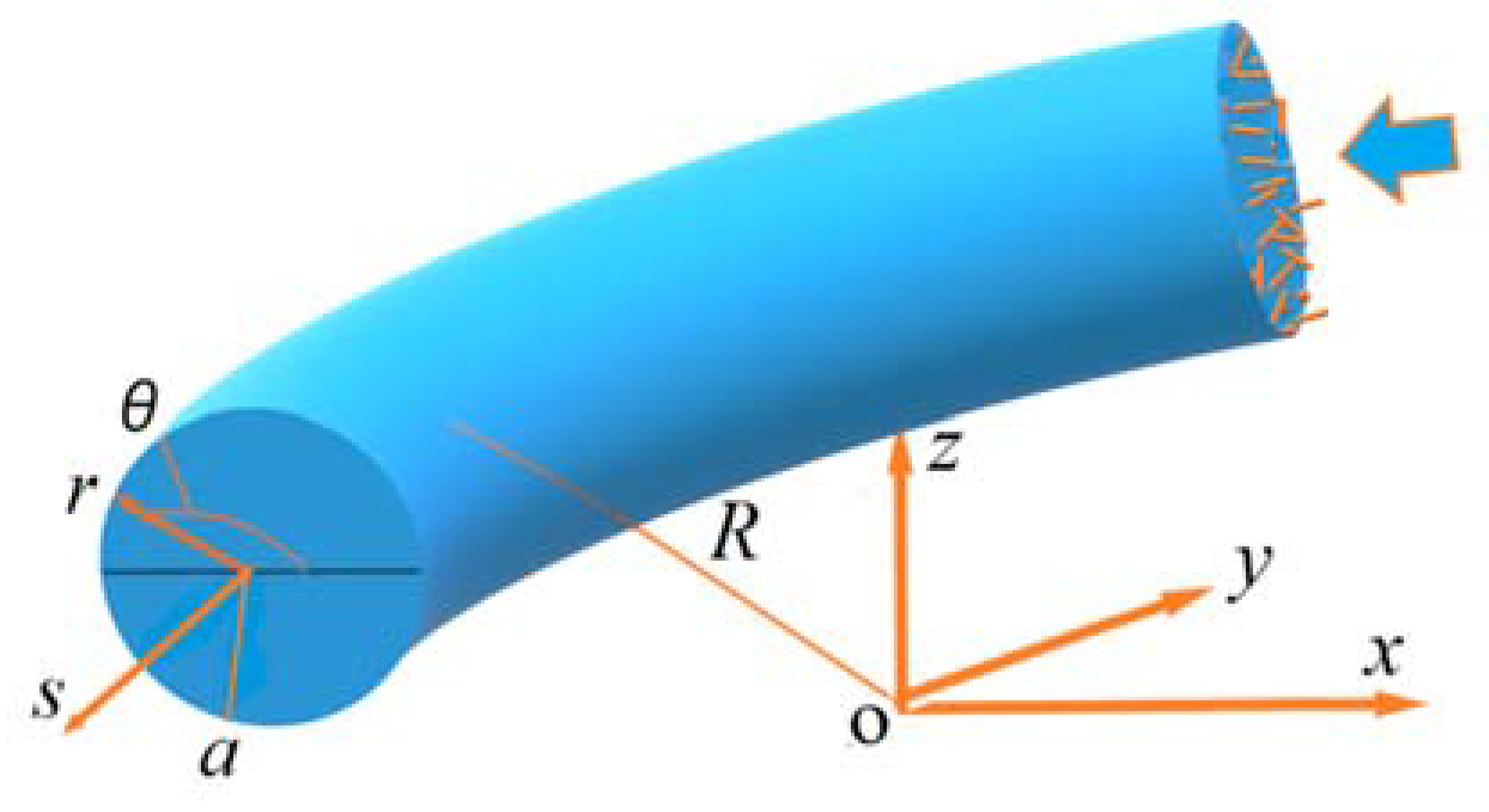

2. Model and Equation

2.1. Flow of Nanofluid

2.2. Density and Thermal Diffusivity of Nanofluid

2.3. Probability Density Function and Tensor of Particle Orientation

2.4. Turbulent Model

2.5. Equation of Particle Number Density

2.6. Pressure Drop and Nusselt Number

3. Numerical Method and Parameters

3.1. Main Steps

- (1)

- Solving Equations (1)–(4) and (12)–(14) with Φ = μa = Sk = Sɛ = 0 to obtain Uj, P, k, ε and .

- (2)

- Solving Equations (17)–(19) to obtain n(v) and Φ.

- (3)

- Substituting Φ into Equations (4)–(8) to obtain μa, ρnf,Dnf, knf and (ρCp)nf.

- (4)

- Substituting Uj, k, ε and Equation (11) into Equation (10) and solving it to obtain ψ.

- (5)

- Substituting ψ into Equation (9) to get aij and aijkl.

- (6)

- Substituting ρnf, μa, akl, aijkl and Dnf into Equations (1)–(4) and (12)–(14) to obtain Uj, P, k, ε, and T.

- (7)

- Repeating steps (2) to (6) using the new values of Uj, P, k, ε, , and T until the difference between the successive results of Ui, p, and T is less than a definite value.

- (8)

- Calculating the friction factor f and Nusselt number using Equations (20) and (21).

3.2. Numerical Method

3.3. Parameters in Numerical Simulation

3.4. Mesh Independence Test

4. Results and Discussion

4.1. Validation

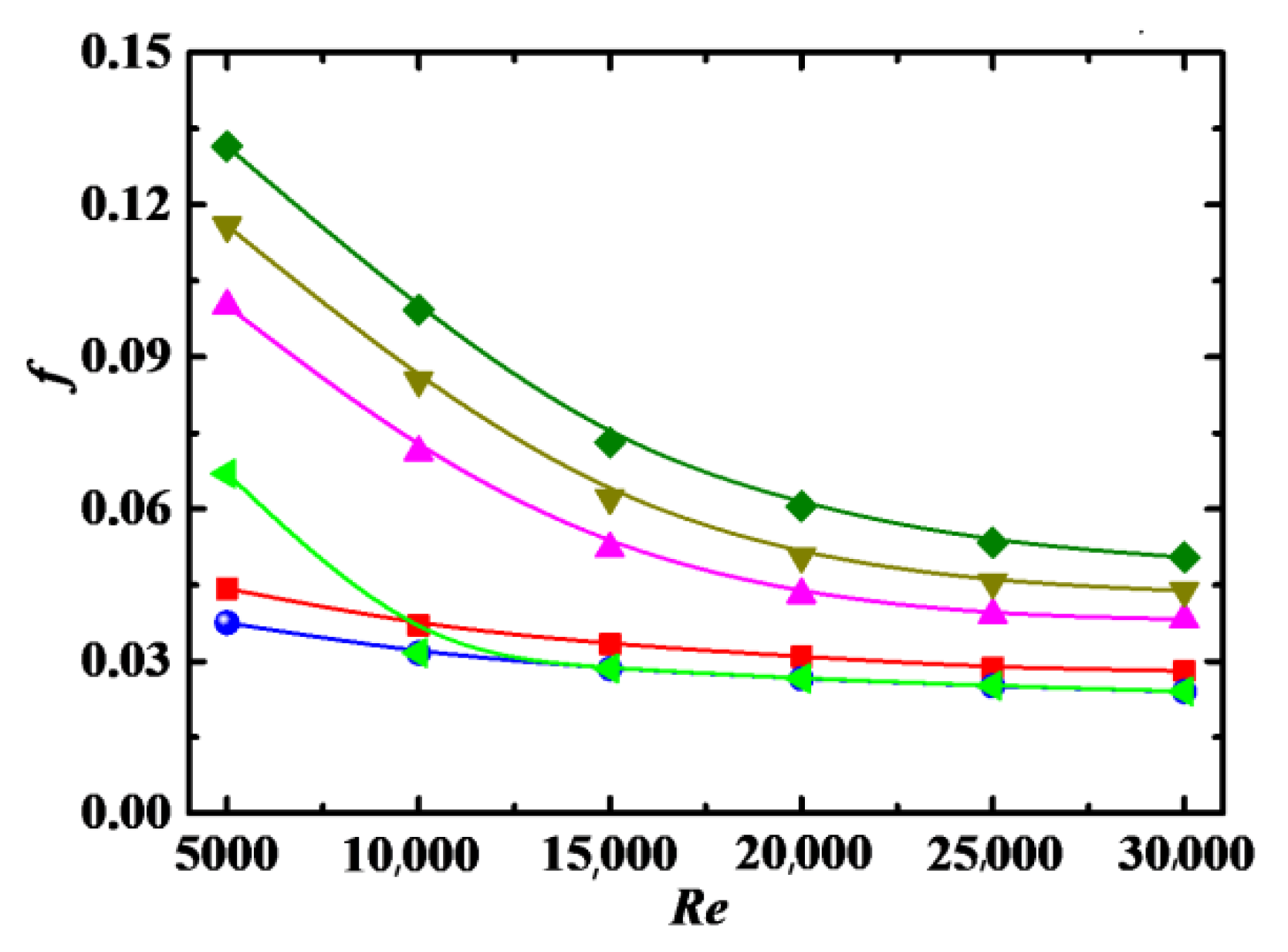

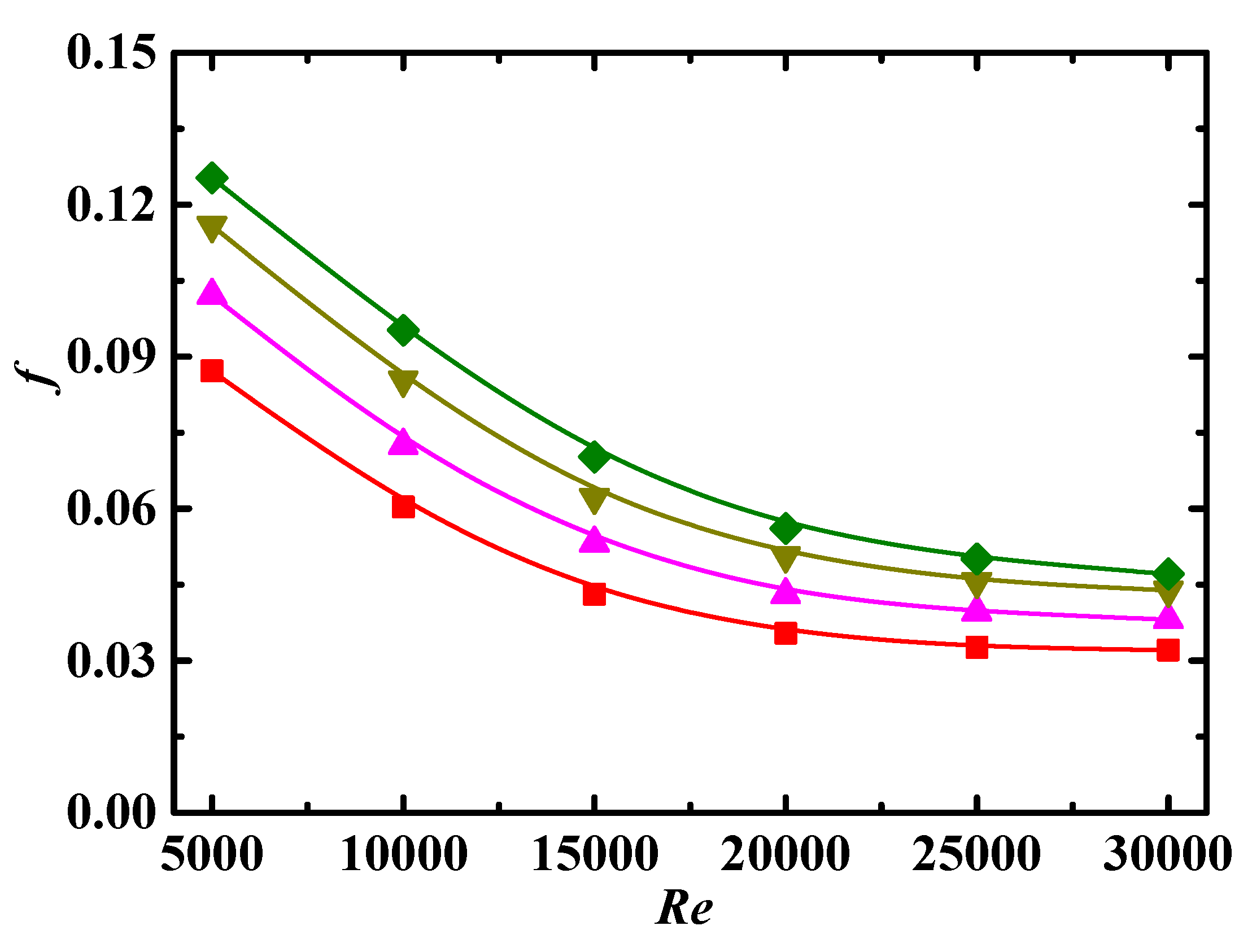

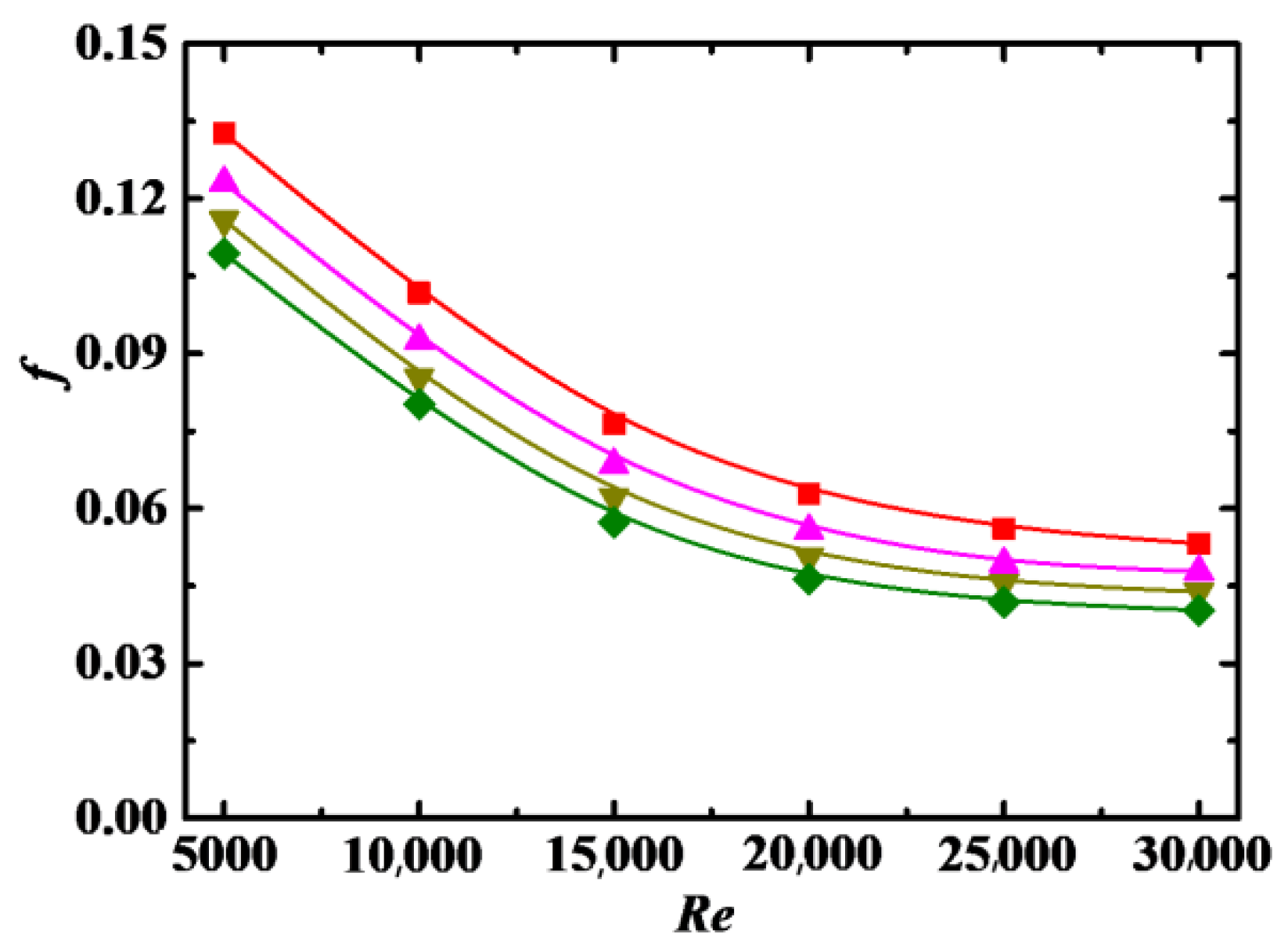

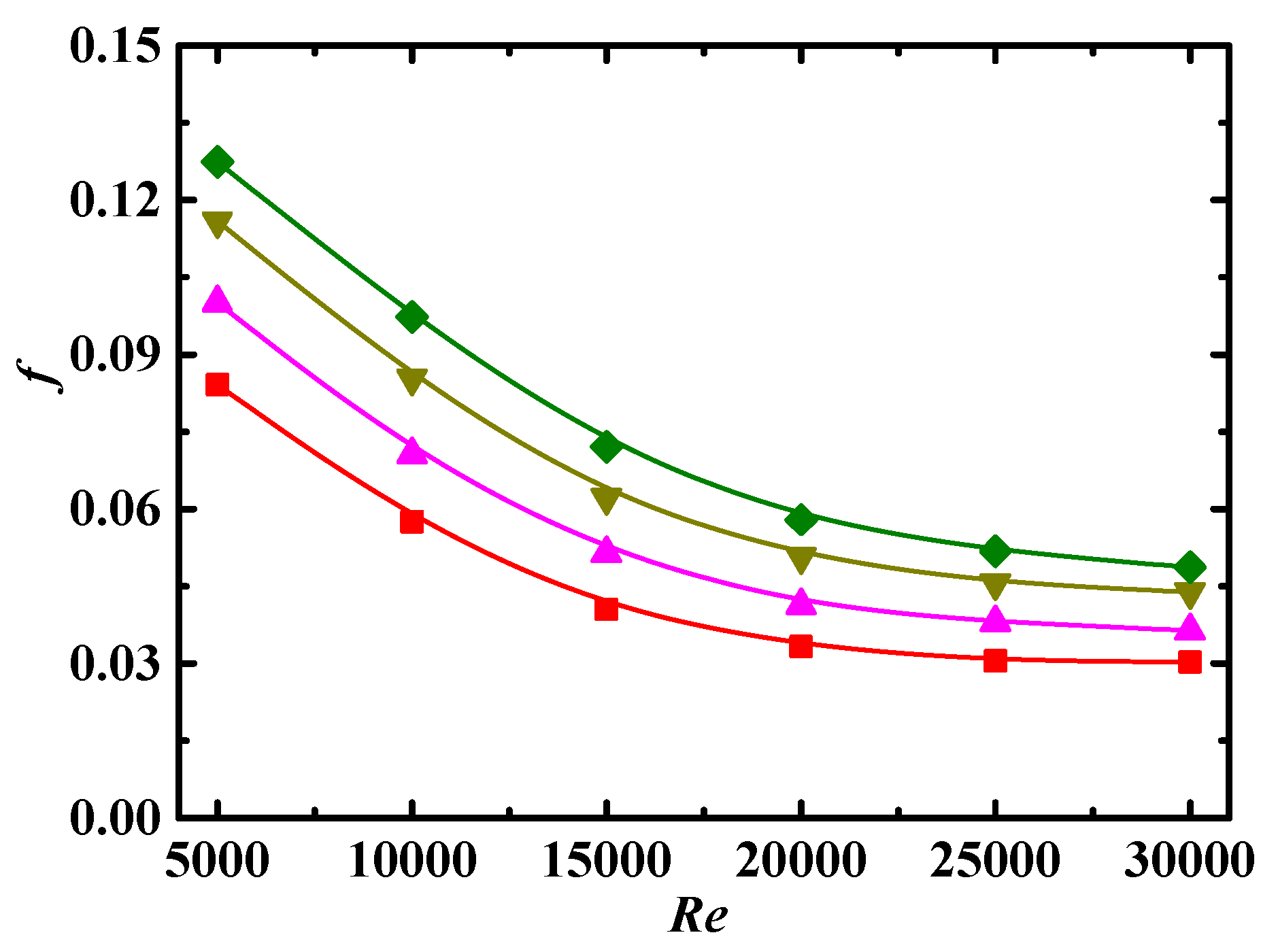

4.2. Friction Factor

4.2.1. Impact of Reynolds Number

4.2.2. Impact of Particle Volume Concentration

4.2.3. Impact of Schmidt Number

4.2.4. Impact of Particle Aspect Ratio

4.2.5. Impact of Dean Number

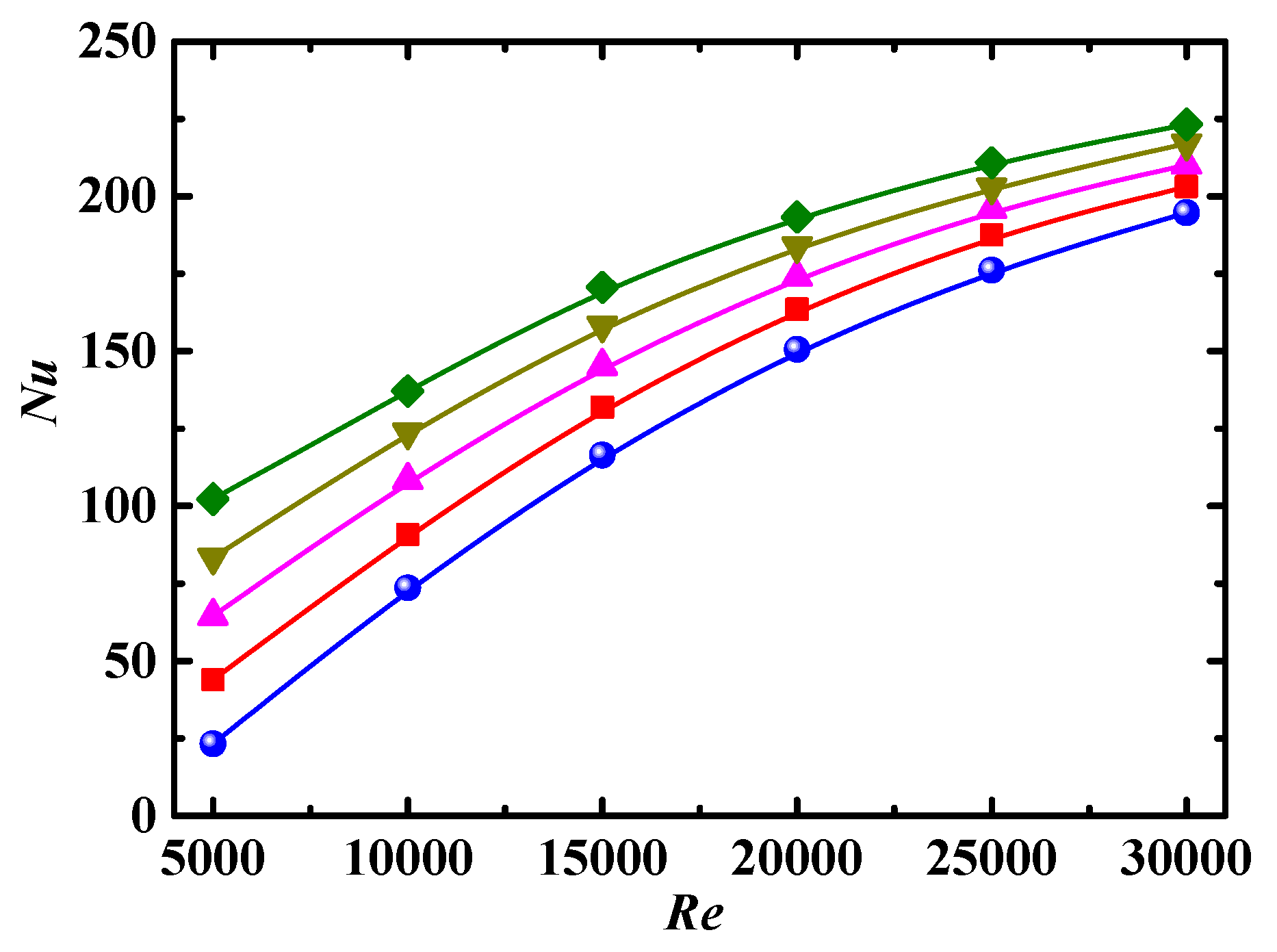

4.3. Heat Transfer

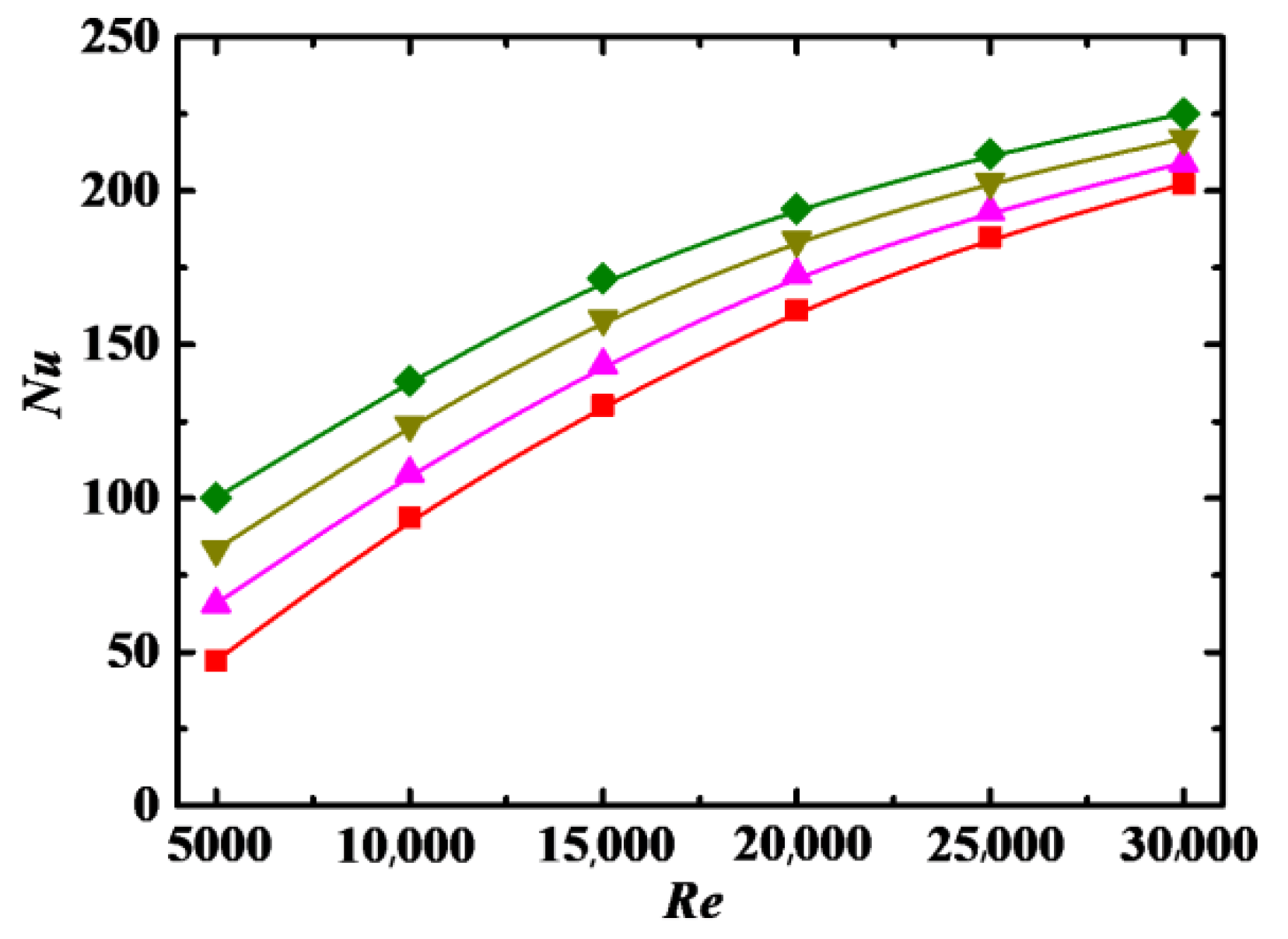

4.3.1. Impact of Reynolds Number

4.3.2. Impact of Particle Volume Concentration

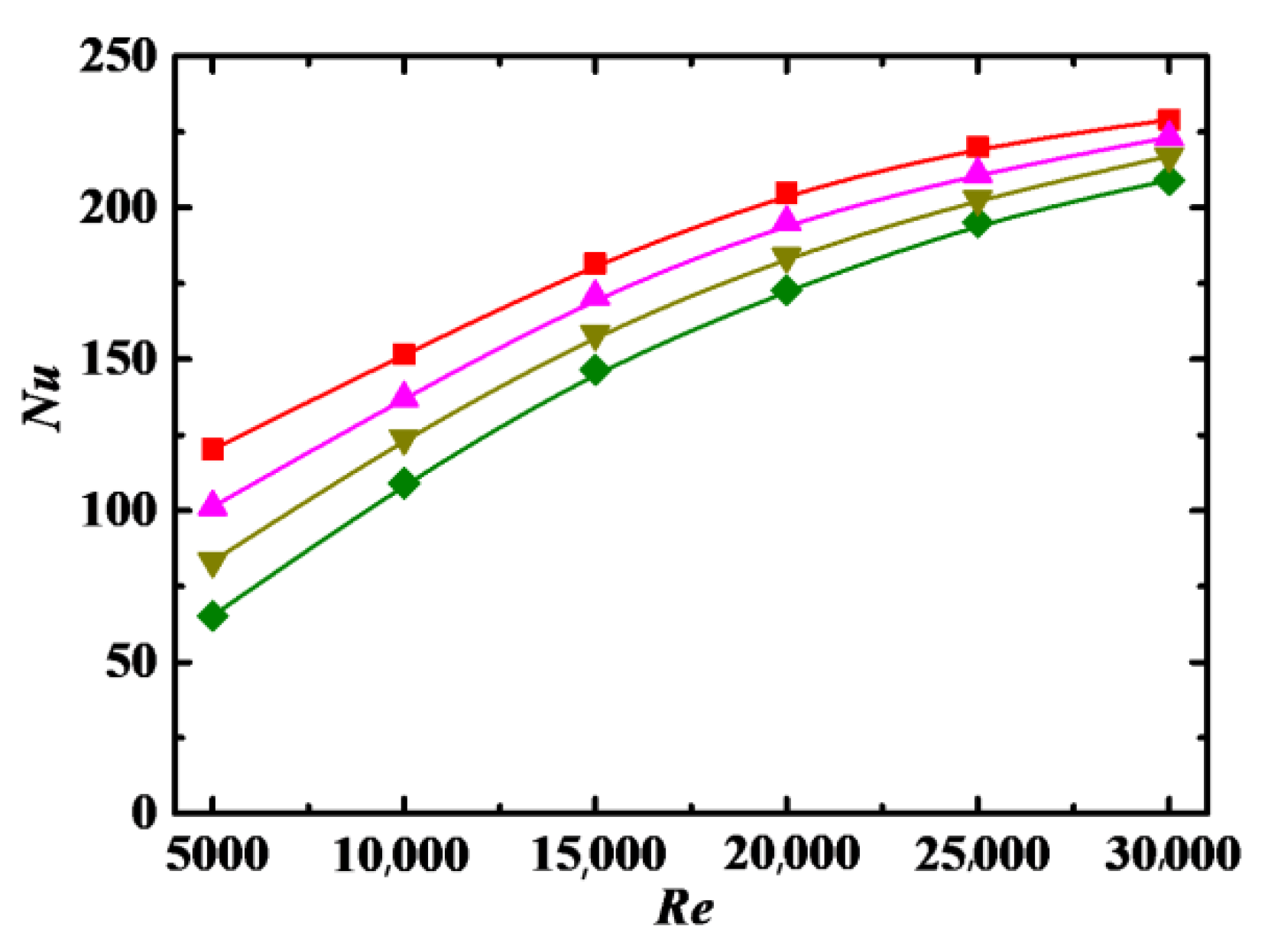

4.3.3. Impact of Schmidt Number

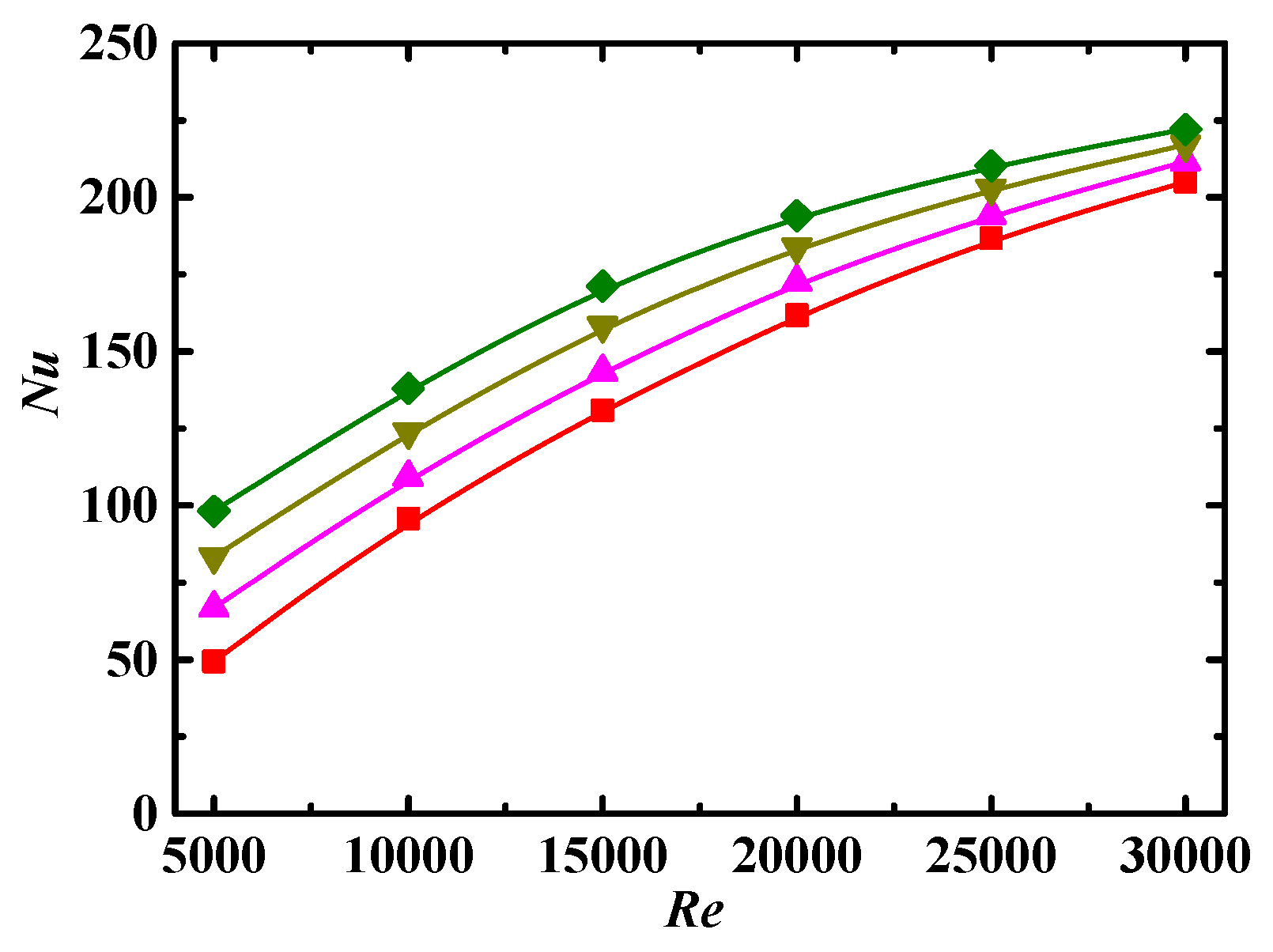

4.3.4. Impact of Particle Aspect Ratio

4.3.5. Impact of Dean Number

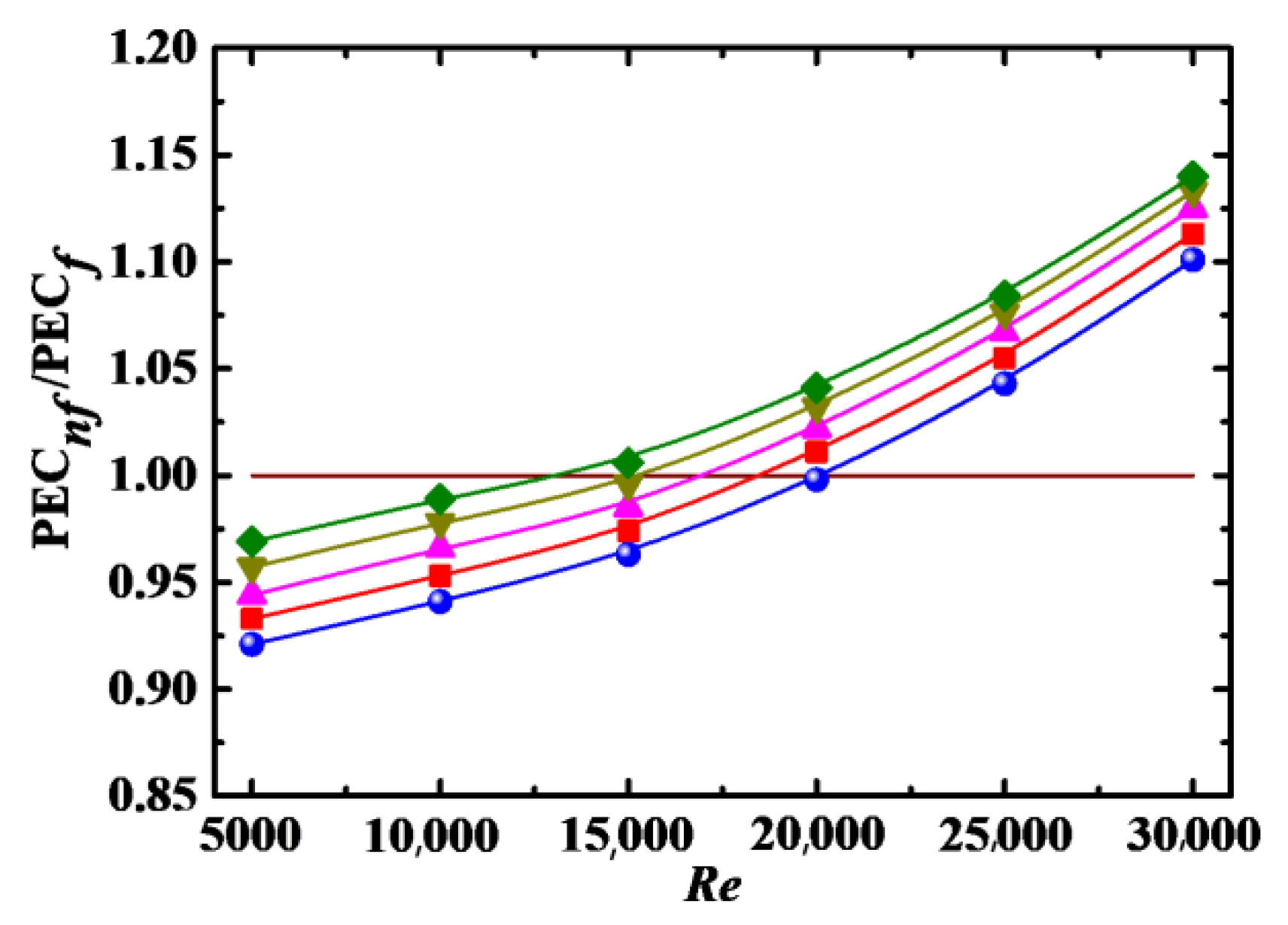

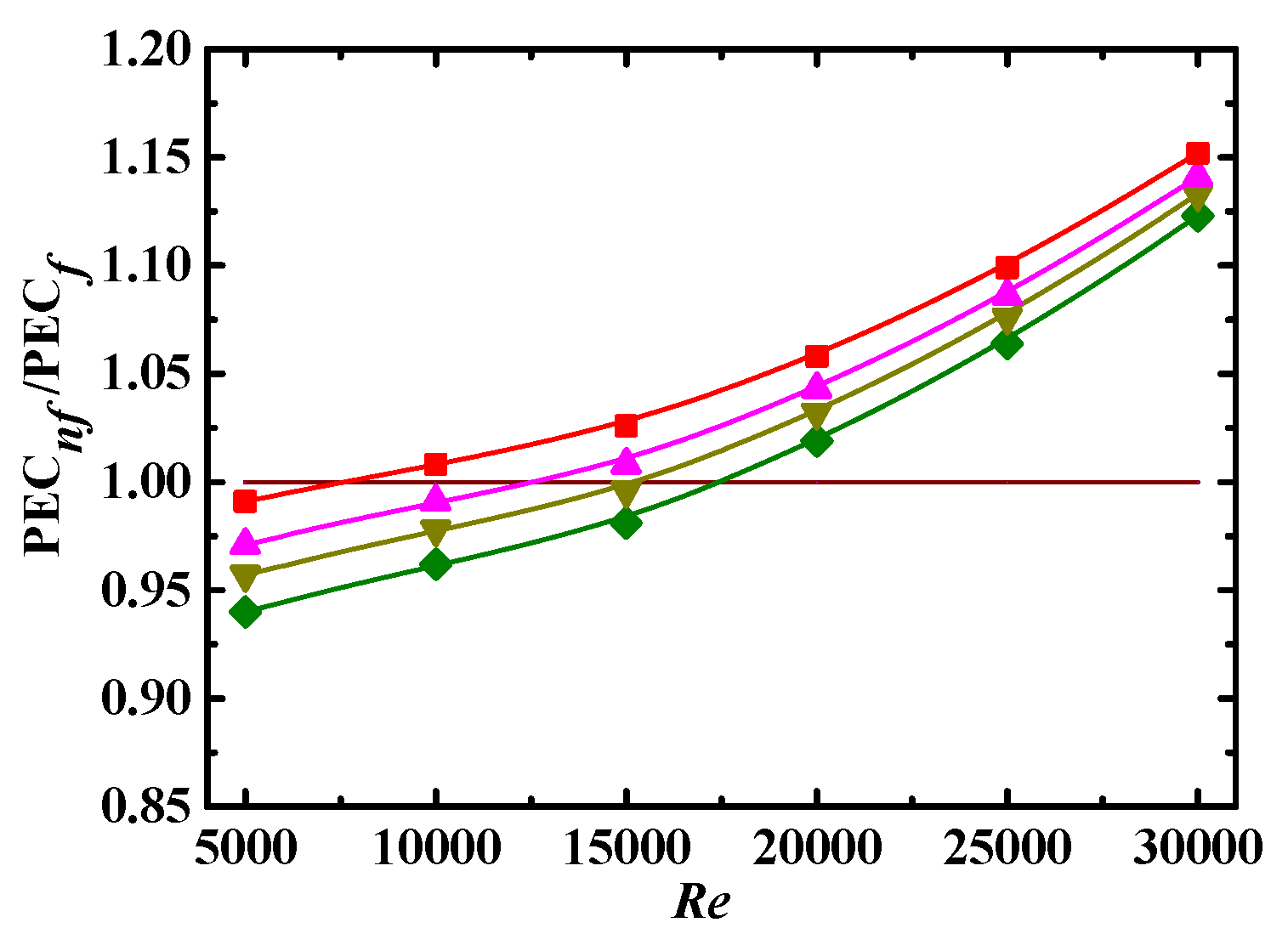

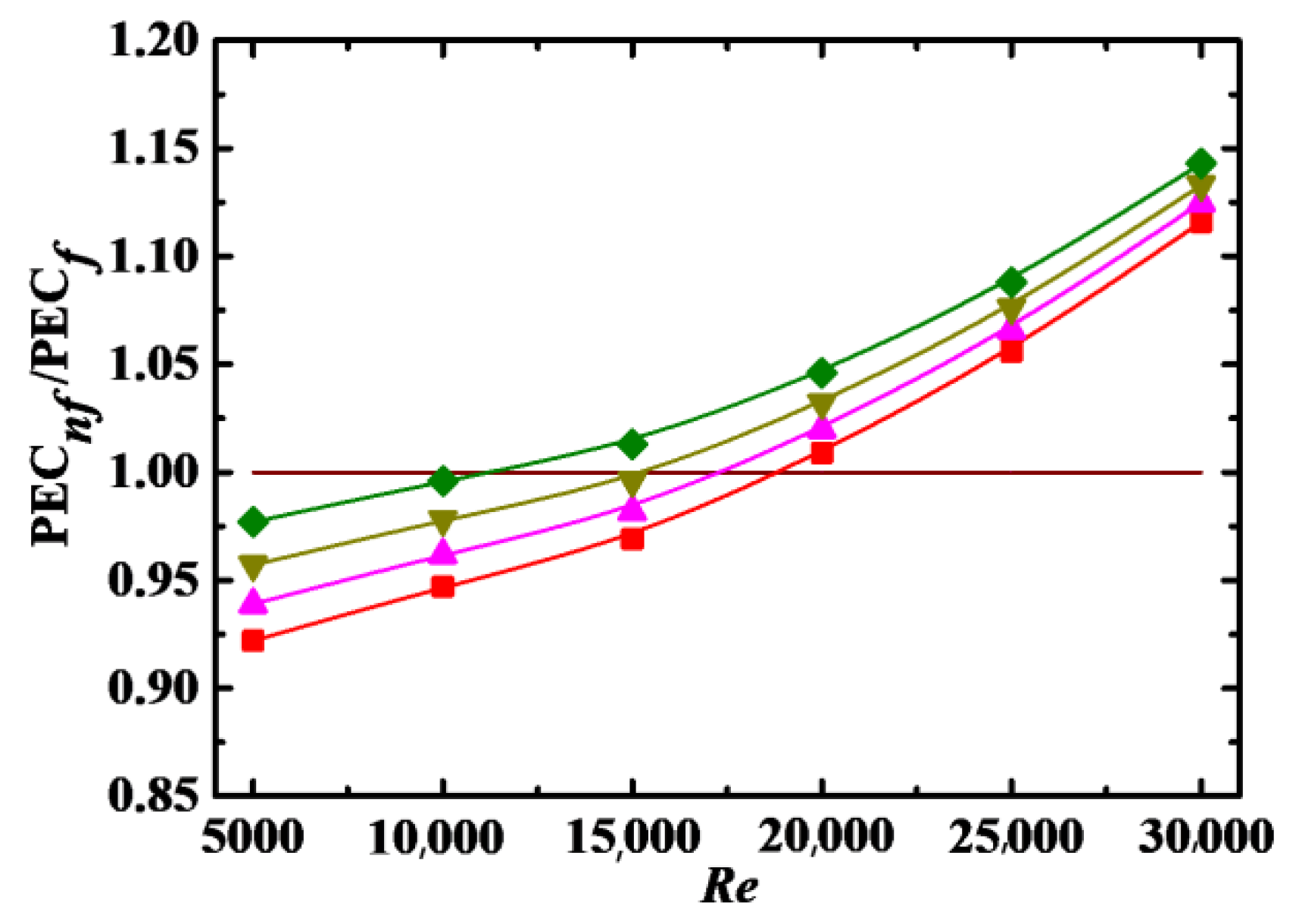

4.4. Energy Performance Evaluation Criterion

4.4.1. Impact of Re and Φ

4.4.2. Impact of Sc, λ and De

4.4.3. Correlation Model

5. Conclusions

- (1)

- The values of f in nanofluid are larger than that in pure water, and are increased with increases in Φ, Sc, and Re, and with decreases in Re and λ. The magnitude of decrease for f is large and small at Re < 20,000 and Re > 20,000, respectively.

- (2)

- Rod-like nanoparticles added to the base fluid can promote convective heat transfer. Heat transfer performance is enhanced with increasesinRe, Φ, λ, and De, and with decreases in Sc. The effect of Φ on the heat transfer is more obvious at low Re than that at high Re.

- (3)

- The ratios of energy PEC for the nanofluid to the base fluid are increased with increases in Re, Φ, λ, and De, and with decreases in Sc. Finally, the formula of ratio of energy PEC for nanofluid to the base fluid as a function of Re, Φ, Sc, λ, and De is derived based on the numerical data.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Choi, J.; Zhang, Y.W. Numerical simulation of laminar forced convection heat transfer of Al2O3-water nanofluid in a pipe with return bend. Int. J. Therm. Sci. 2012, 55, 90–102. [Google Scholar] [CrossRef]

- Prasad, P.V.D.; Gupta, A.V.S.S.K.S.; Sreeramulu, M.; Sundar, L.S.; Singh, M.K.; Sousa, A.C.M. Experimental study of heat transfer and friction factor of Al2O3 nanofluid in U-tube heat exchanger with helical tape inserts. Exp. Therm. Fluid Sci. 2015, 62, 141–150. [Google Scholar] [CrossRef]

- Vasa, A.; Barik, A.K.; Nayak, B. Turbulent convection heat transfer enhancement in a 180-degree U-bend of triangular cross-section using nanofluid. In Proceedings of the International Conference on Materials, Alloys and Experimental Mechanics, Conference Series-Materials Science and Engineering, Telangana, India, 3–4 July 2017. [Google Scholar]

- Barik, A.K.; Satapathy, P.K.; Sahoo, S.S. CFD study of forced convective heat transfer enhancement in a 90 degrees bend duct of square cross section using nanofluid. Sadhana-Acad. Proc. Eng. Sci. 2016, 41, 795–804. [Google Scholar]

- Mukherjee, A.; Rout, S.; Barik, A.K. Entropy generation analysis in a 180-degree return bend pipe using nanofluid. In Proceedings of the International Conference on Functional Materials, Characterization, Solid State Physics, Power, Thermal and Combustion Energy, Visakhapatnam, India, 7–8 April 2017. [Google Scholar]

- Yasinm, N.J.; Jehhef, K.A.; Mohsen, Z.A. Assessment the effect of nanofluid on turbulent heat transfer and pressure drop in bend finned tube. In Proceedings of the 2nd International Conference on Sustainable Engineering Techniques, Baghdad, Iraq, 6–7 March 2019. [Google Scholar]

- Özbey, M. Experimental study on pressure drop of Aluminum-Oxide/Water nanofluids. J. Thermophys. Heat Transf. 2016, 30, 342–349. [Google Scholar] [CrossRef]

- Ma, Y.; Mohebbi, R.; Rashidi, M.M.; Yang, Z.G. Study of nanofluid forced convection heat transfer in a bent channel by means of lattice Boltzmann method. Phys. Fluids 2018, 30, 032001. [Google Scholar] [CrossRef]

- Kumar, N.T.R.; Bhramara, P.; Addis, B.M.; Sundar, L.S.; Singh, M.K.; Sousa, A.C.M. Heat transfer, friction factor and effectiveness analysis of Fe3O4/water nanofluid flow in a double pipe heat exchanger with return bend. Int. Commun. Heat Mass Transf. 2017, 81, 155–163. [Google Scholar] [CrossRef]

- Rao, V.N.; Sankar, B.R. Heat transfer and friction factor investigations of CuO nanofluid flow in a double pipe U-bend heat exchanger. Mater. Today-Proc. 2019, 18, 207–218. [Google Scholar]

- Tillman, P.; Hill, J. Modelling the thermal conductivity of nanofluids. Solid Mech. Appl. 2007, 144, 105–118. [Google Scholar]

- Murugesan, C.; Sivan, S. Limits for thermal conductivity of nanoflfluids. Therm. Sci. 2010, 14, 65–71. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Z.G.; Grulke, E.A.; Anderson, W.B.; Wu, G.F. Heat transfer properties of nanoparticle-in-fluid dispersions (nanofluids) in laminar flow. Int. J. Heat Mass Transf. 2005, 48, 1107–1116. [Google Scholar] [CrossRef]

- Xie, H.; Yu, W.; Li, Y. Thermal performance enhancement in nanofluids containing diamond nanoparticles. J. Phys. D Appl. Phys. 2009, 42, 095413. [Google Scholar] [CrossRef]

- Ji, Y.; Wilson, C.; Chen, H.; Ma, H. Particle shape effect on heat transfer performance in an oscillating heat pipe. Nanoscale Res. Lett. 2011, 6, 290–296. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jeong, J.; Li, C.; Kwon, Y.; Lee, J.; Kim, S.H.; Yun, R. Particle shape effect on the viscosity and thermal conductivity of ZnO nanofluids. Int. J. Refrig. 2013, 36, 2233–2241. [Google Scholar] [CrossRef]

- Ekiciler, R.; Cetinkaya, M.S.A.; Arslan, K. Effect of shape of nanoparticle on heat transfer and entropy generation of nanofluid-jet impingement cooling. Int. J. Green Energy 2020, 17, 555–567. [Google Scholar] [CrossRef]

- Anwar, T.; Kumam, P.; Shah, Z.; Sitthithakerngkiet, K. Significance of shape factor in heat transfer performance of molybdenum-disulfide nanofluid in multiple flow situations; A comparative fractional study. Molecules 2021, 26, 3711. [Google Scholar]

- Alsarraf, J.; Shahsavar, A.; Mahani, R.B.; Talebizadehsardari, P. Turbulent forced convection and entropy production of ananoflui dinasolar collector considering various shapes for nanoparticles. Int. Commun. Heat Mass Transf. 2020, 117, 104804. [Google Scholar] [CrossRef]

- Yu, L.; Liu, D.; Botz, F. Laminar convective heat transfer of aluminapoly alphaolef in nanofluids containing spherical and non-spherical nanoparticles. Exp. Therm. Fluid Sci. 2012, 37, 72–83. [Google Scholar] [CrossRef]

- Elias, M.M.; Miqdad, M.; Mahbubul, I.M.; Saidur, R.; Kamalisarvestani, M.; Sohel, M.R.; Hepbasli, A.; Rahim, N.A.; Amalina, M.A. Effect of nanoparticle shape on the heat transfer and thermodynamic performance of a shell and tube heat exchanger. Int. Commun. Heat Mass Transf. 2013, 44, 93–99. [Google Scholar] [CrossRef]

- Elias, M.M.; Shahrul, I.M.; Mahbubul, I.M.; Saidur, R.; Rahim, N.A. Effect of different nanoparticle shapes on shell and tube heat exchanger using different bafflfle angles and operated with nanoflfluid. Int. J. Heat Mass Transf. 2014, 70, 289–297. [Google Scholar] [CrossRef]

- Ghosh, M.M.; Ghosh, S.; Pabi, S.K. Effects of particle shape and fluid temperature on heat-transfer characteristics of nanoflfluids. J. Mater. Eng. Perform. 2013, 22, 1525–1529. [Google Scholar] [CrossRef]

- Lin, J.Z.; Xia, Y.; Ku, X.K. Friction factor and heat transfer of nanoflfluids containing cylindrical nanoparticles in laminar pipe flow. J. Appl. Phys. 2014, 116, 133513. [Google Scholar] [CrossRef]

- Batchelor, G.K. Stress generated in anon-dilute suspension of elongated particles by pure straining motion. J. Fluid Mech. 1971, 46, 813–829. [Google Scholar] [CrossRef]

- Mackaplow, M.B.; Shaqfeh, E.S.G. A numerical study of the rheological properties of suspensions of rigid, non-Brownian fibres. J. Fluid Mech. 1996, 329, 155–186. [Google Scholar] [CrossRef]

- Batchelor, G.K. The effect of brownian motion on the bulk stress in a suspension of spherical particles. J. Fluid Mech. 1977, 83, 97–117. [Google Scholar] [CrossRef]

- Zhang, X.; Gu, H.; Fujii, M. Effective thermal conductivity and thermal diffusivity of nanofluids containing spherical and rod-like nanoparticles. Exp. Therm. Fluid Sci. 2007, 31, 593–599. [Google Scholar] [CrossRef]

- Advani, S.G.; Tucker, C.L. The use of tensors to describe and predict fiber orientation in short fiber composites. J. Rheol. 1987, 31, 751–784. [Google Scholar] [CrossRef]

- Folgar, F.; Tucker, C.L., III. Orientation behaviour of fibres in concentrated suspensions. J. Reinf. Plast. Comp. 1984, 3, 98–119. [Google Scholar] [CrossRef]

- Olson, J.A. The motion of fibers in turbulent flow, stochastic simulation of isotropic homogeneous turbulence. Int. J. Multiph. Flow 2001, 27, 2083–2103. [Google Scholar] [CrossRef]

- Li, G.; Tang, J.X. Diffusion of Actin filaments within a thin layer between two walls. Phys. Rev. E 2004, 69, 061921. [Google Scholar] [CrossRef]

- de la Torre, J.G.; Bloomfield, V.A. Hydrodynamic properties of complex, rigid, biological macromolecules: Theory and application. Quart. Rev. Biophys. 1981, 14, 81–139. [Google Scholar] [CrossRef]

- Lin, J.Z.; Shen, S.H. A theoretical model of turbulent fiber suspension and its application to the channel flow. Sci. China Phys. Mech. Astron. 2010, 53, 1659–1670. [Google Scholar] [CrossRef]

- Friedlander, S.K. Smoke, Dust and Haze: Fundamentals of Aerosol Behavior; Wiley: New York, NY, USA, 2000. [Google Scholar]

- Patankar, S.V.; Spalding, D.B. Calculation procedure for heat, mass and momentum-transfer in 3-dimensional parabolic flows. Int. J. Heat Mass Transf. 1972, 15, 1787–1806. [Google Scholar] [CrossRef]

- Ferrouillat, S.; Bontemps, A.; Poncelet, O.; Soriano, O.; Gruss, J.A. Influence of nanoparticle shape factor on convective heat transfer and energetic performance of water-based SiO2 and ZnO nanofluids. Appl. Therm. Eng. 2013, 51, 839–851. [Google Scholar] [CrossRef]

- Blasius, H. Grenzschichten in flüssigkeiten mit kleiner reibung. Z. Math.Phys. 1908, 56, 1–37. [Google Scholar]

- Steele, A.; Bayer, I.S.; Loth, E. Pipe flow drag reduction effects from carbon nanotube additives. Carbon 2014, 77, 1183–1186. [Google Scholar] [CrossRef]

- Bernstein, O.; Shapiro, M. Direct determination of the orientation distribution function of cylindrical particles immersed in laminar and turbulent shear flows. J. Aerosol Sci. 1994, 25, 113–136. [Google Scholar] [CrossRef]

| r × θ × S Nu | r × θ × S Nu | r × θ × S Nu |

|---|---|---|

| 56 × 48 × 112 177.308 | 64 × 40 × 112 177.315 | 64 × 48 × 104 177.301 |

| 60 × 48 × 112 177.336 | 64 × 44 × 112 177.338 | 64 × 48 × 108 177.333 |

| 64 × 48 × 112 177.357 | 64 × 48 × 112 177.357 | 64 × 48 × 112 177.357 |

| 68 × 48 × 112 177.372 | 64 × 52 × 112 177.370 | 64 × 48 × 116 177.374 |

| 72 × 48 × 112 177.383 | 64 × 56 × 112 177.378 | 64 × 48 × 120 177.386 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, W.; Shi, R.; Lin, J. Heat Transfer and Pressure Drop of Nanofluid with Rod-like Particles in Turbulent Flows through a Curved Pipe. Entropy 2022, 24, 416. https://doi.org/10.3390/e24030416

Lin W, Shi R, Lin J. Heat Transfer and Pressure Drop of Nanofluid with Rod-like Particles in Turbulent Flows through a Curved Pipe. Entropy. 2022; 24(3):416. https://doi.org/10.3390/e24030416

Chicago/Turabian StyleLin, Wenqian, Ruifang Shi, and Jianzhong Lin. 2022. "Heat Transfer and Pressure Drop of Nanofluid with Rod-like Particles in Turbulent Flows through a Curved Pipe" Entropy 24, no. 3: 416. https://doi.org/10.3390/e24030416

APA StyleLin, W., Shi, R., & Lin, J. (2022). Heat Transfer and Pressure Drop of Nanofluid with Rod-like Particles in Turbulent Flows through a Curved Pipe. Entropy, 24(3), 416. https://doi.org/10.3390/e24030416