Bibliometric Mapping of Literature on High-Entropy/Multicomponent Alloys and Systematic Review of Emerging Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Data Mining Strategy

2.2. Text Cleaning

2.3. Statistical, Bibliometric Analyses, and Systematic Review of Some Emerging Applications

3. Results

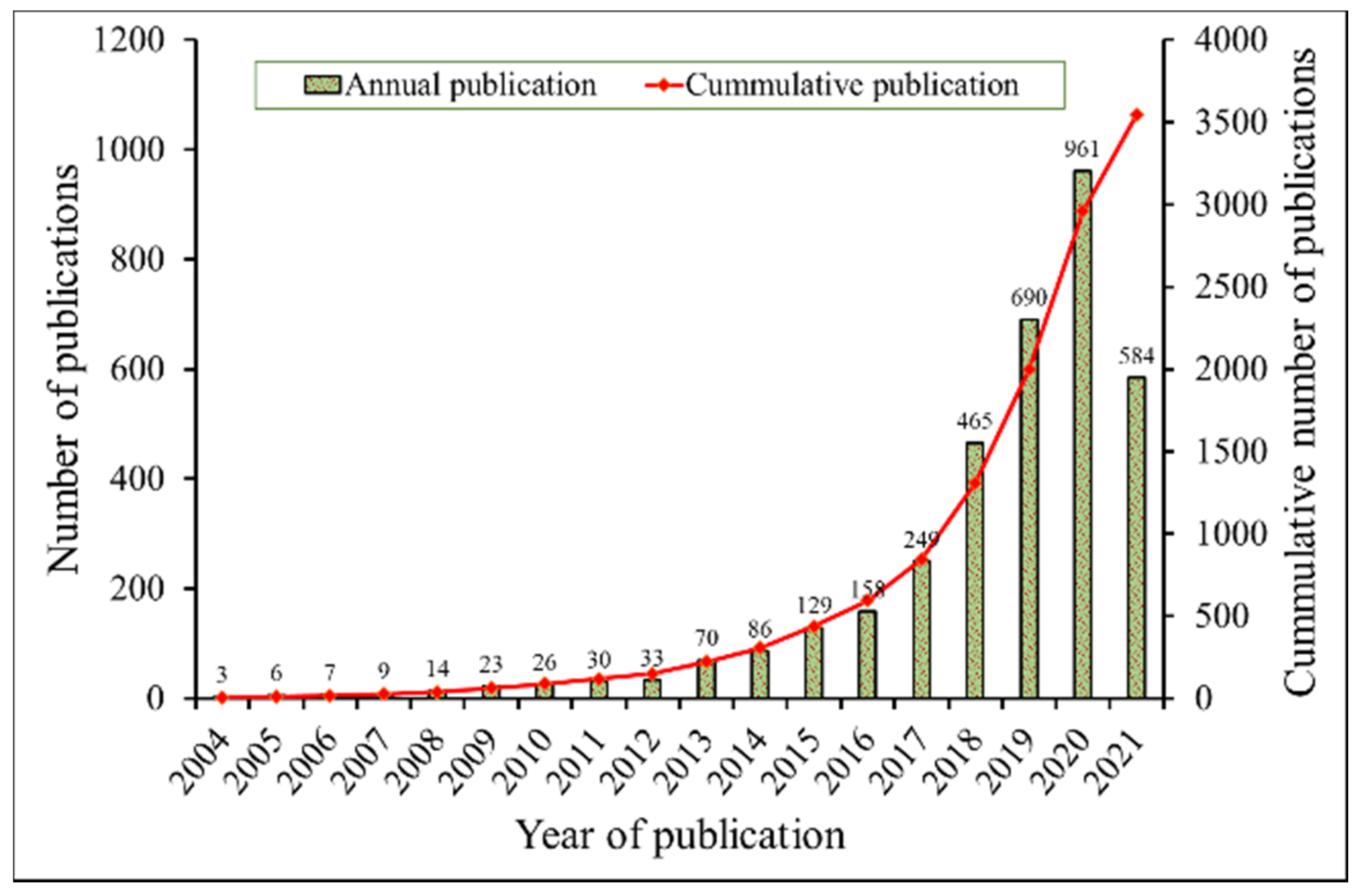

3.1. Trend of Scientific Publication in HEA/MCA, from 2004 to April 2021

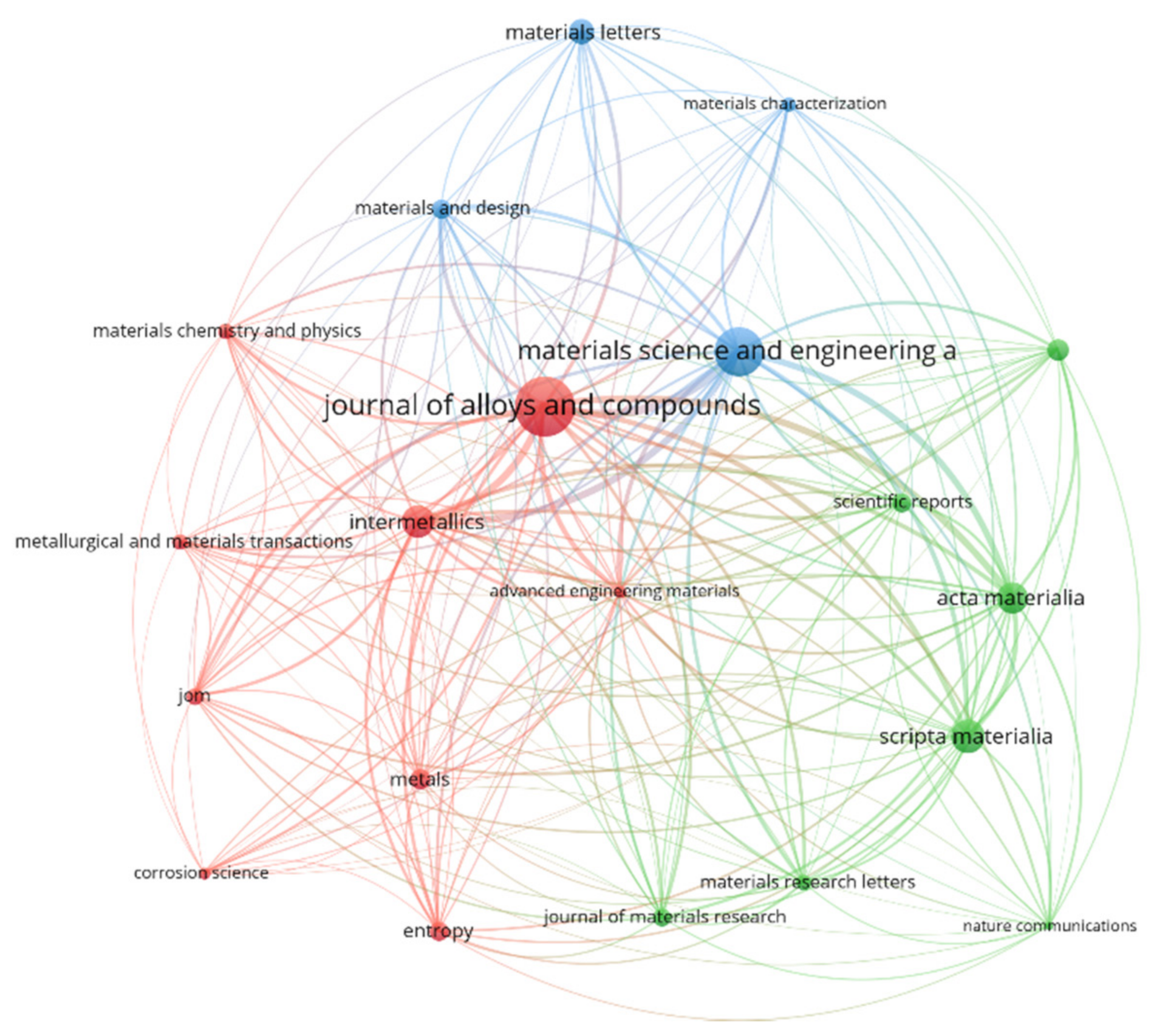

3.2. HEA/MCA Research Outlets

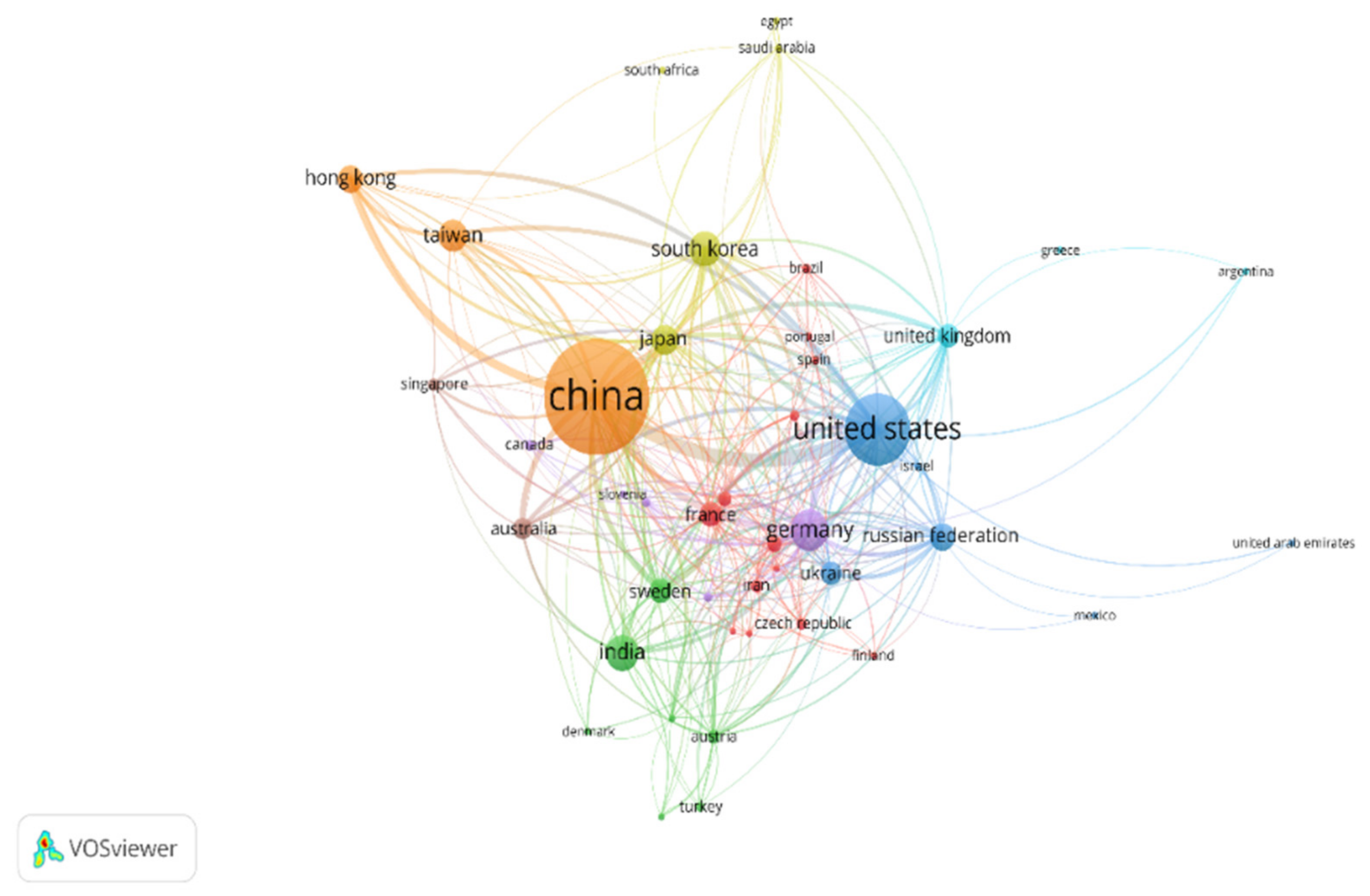

3.3. Scientific Collaboration Networks

3.3.1. Co-Authorship of Researchers

3.3.2. Co-Authorship between Institutions and Countries

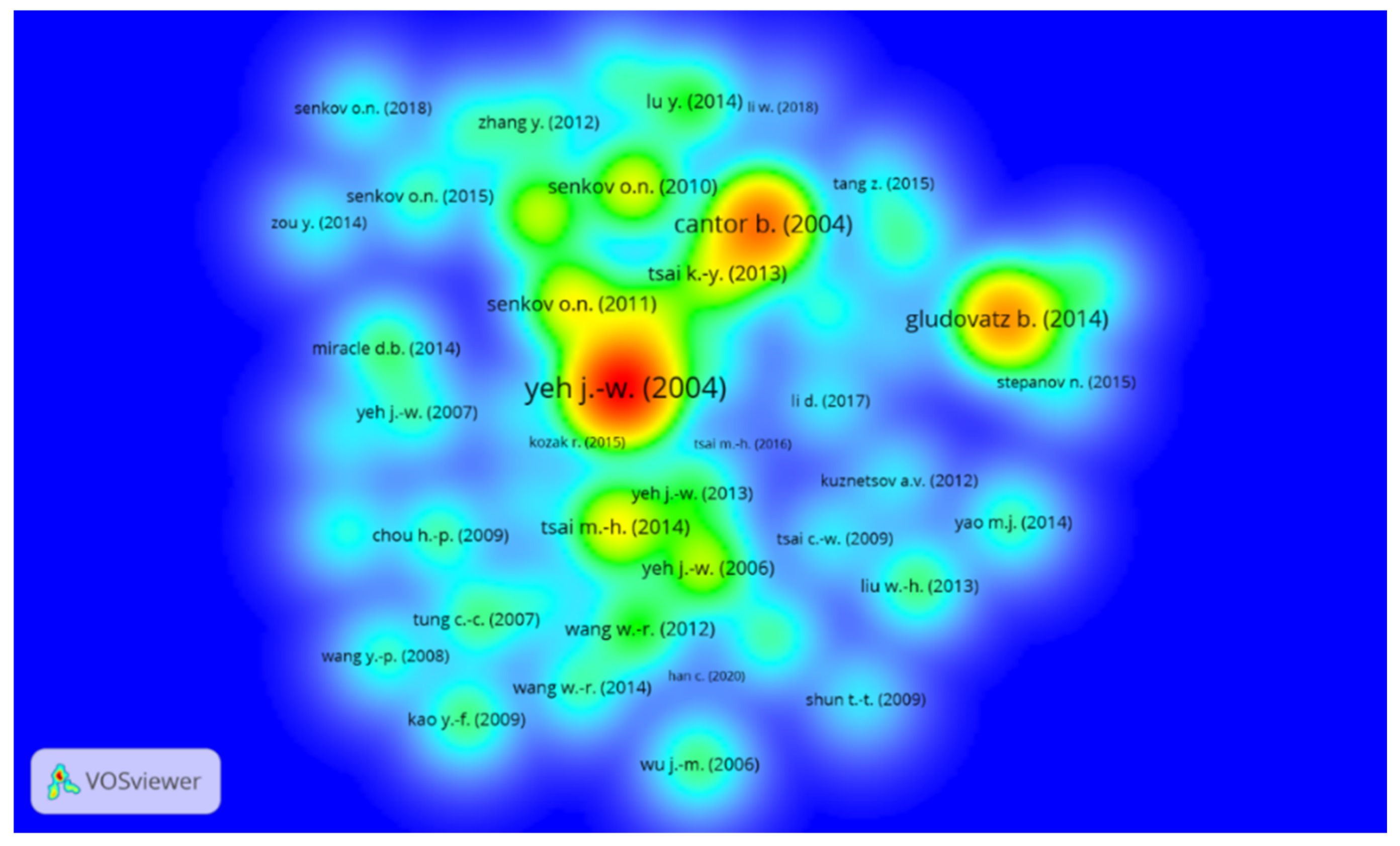

3.4. Citations Analysis of HEA/MCA Publications

3.5. HEA/MCA Keywords Analysis

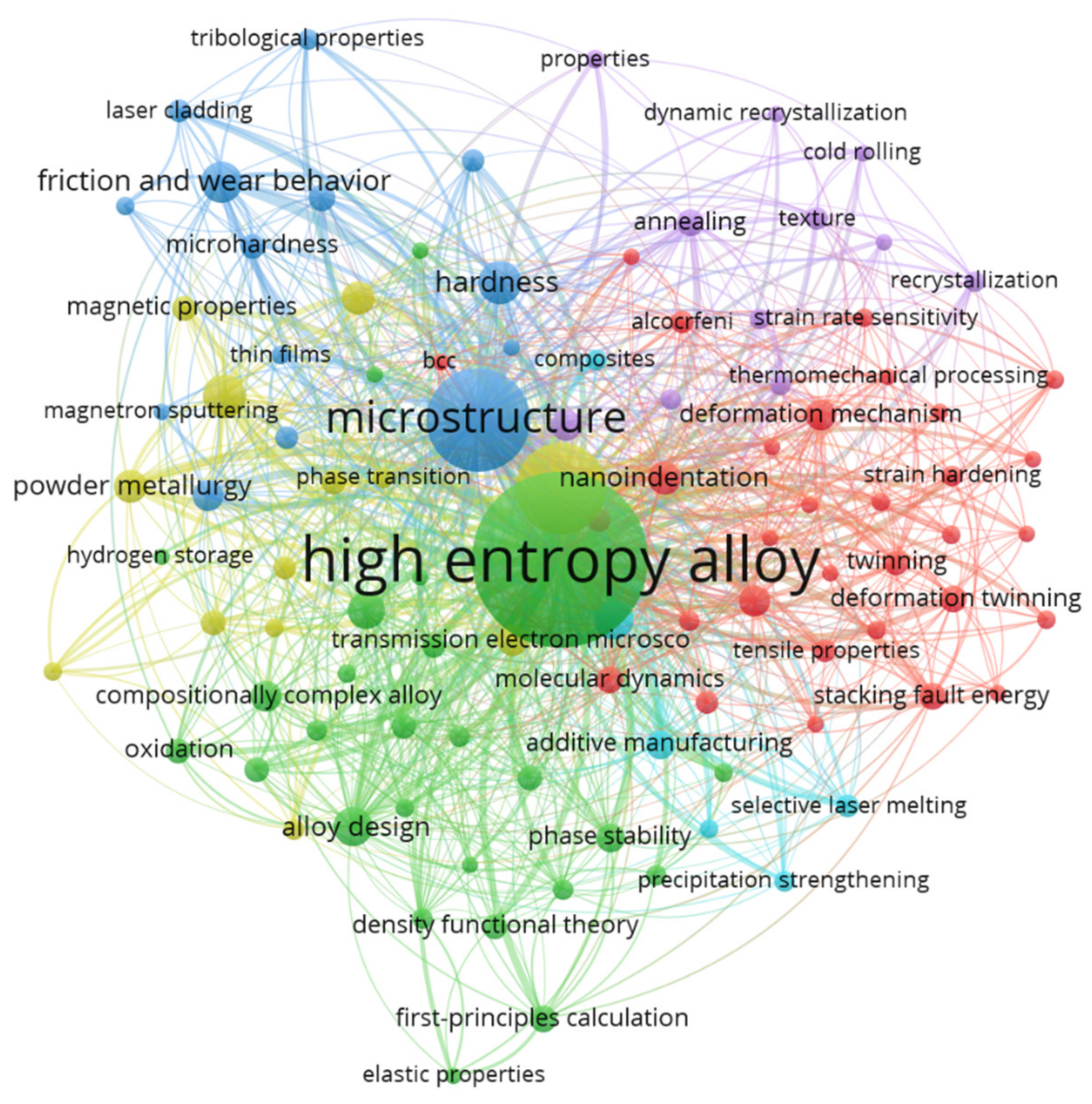

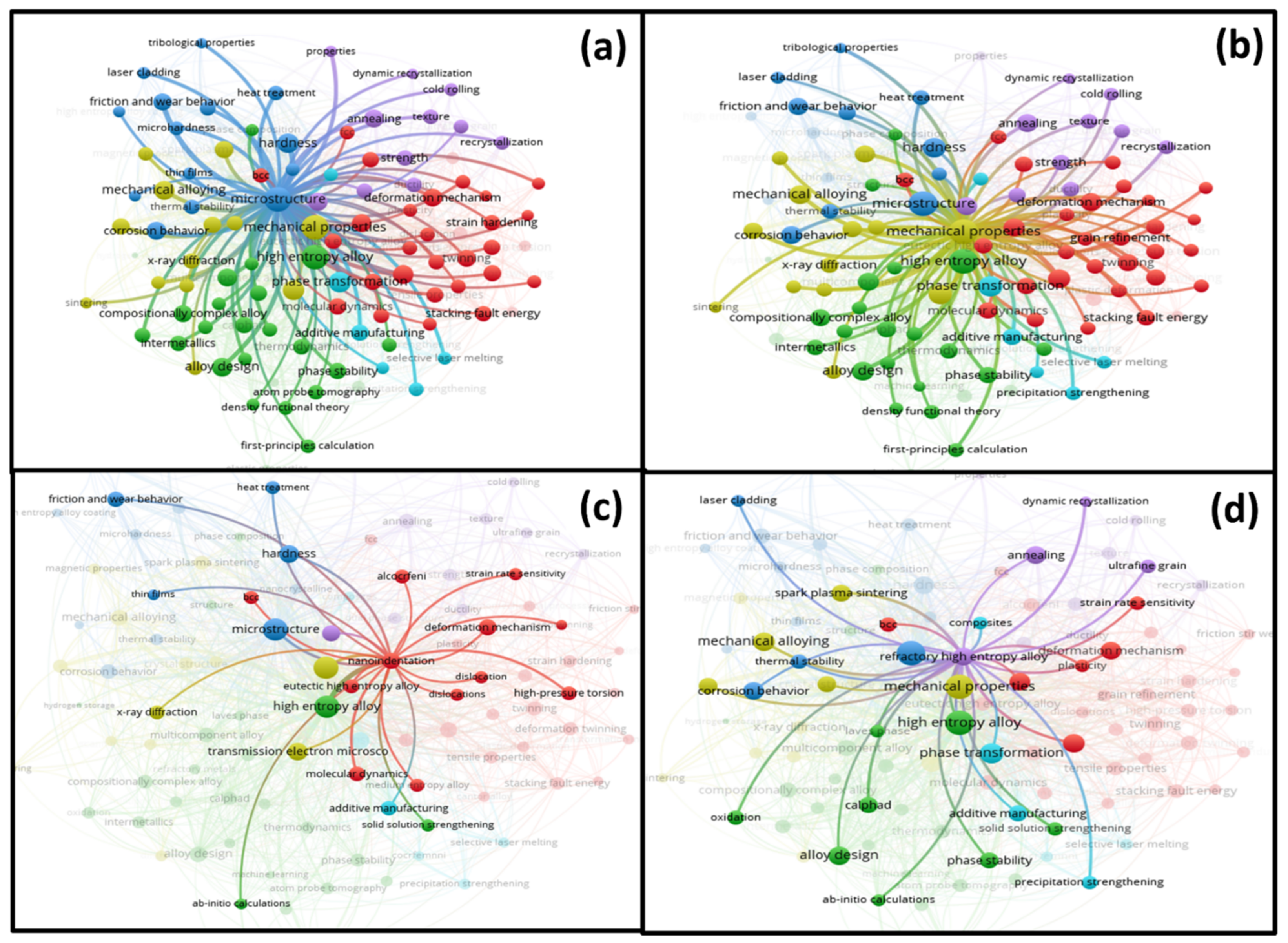

Co-Occurrence Network of HEA/MCA Author Keywords

3.6. Research Gaps and Potential Future Directions

- “Machine learning” is another keyword that requires further and elaborate investigation from researchers in this field. Its total link strength and link of 36 and 15, respectively, indicate that it has not been fully explored. Machine learning (ML) belongs to the soft computing method that can be used to optimize the synthesis of HEA/MCA, predict phases, properties, and minimize expensive and time-intensive experimentations [79,80]. This approach has been successfully deployed to predict the particle sizes of mechanically milled, magnesium-based metal powder [81] and discover novel active layers in organic solar cells [82], light-emitting diodes [83], and nickel superalloys [84]. Furthermore, ML tools can be conveniently deployed to extract greater and more accurate information from synthesis conditions and parameters [85]. Nonetheless, some recent works on HEA/MCA, applying the ML approach, have appeared in the literature [80,86,87]. More efforts are, however, needed in this direction. HEA/MCA can also benefit from this technique to accelerate the discovery, development, and deployment of novel HEA/MCA materials.

- Another keyword that is less explored is “tribological properties” (32 occurrences), with 14 links with other keywords. A decent number of articles have been published with the keyword “friction and wear behavior” (45 links and 129 occurrences) under dry conditions. However, only a handful of research has emerged in the HEA/MCA literature discussing the effect of lubrication [88,89]. Many industrial processes involve metallic parts that are in motion, relative to one another, where lubricants are used to minimize wear and friction. For practical purposes, it is imperative to investigate the tribological properties and understand the friction and wear mechanisms of HEA parts under lubricating conditions. This is an important research gap that requires research attention. Some other functional application areas that need further and in-depth research include catalysis (8 occurrences), superconductivity (13 occurrences), and thermo-electricity (14 occurrences). Although some researchers have reported some results in HEA/MCA catalysis [32,33,34,90], superconductivity [35,36], and thermo-electric properties [39], research in these areas is still exploratory and fairly recent. These application areas are important, and HEA/MCA materials are good contenders to perform very well.

- An important research area, with a huge potential to generate important discoveries, is developing composites of HEA to enhance their properties. According to the analysis of the keyword “composites”, it is rarely used, as it co-occurred with only 23 other keywords and appears about 34 times in the surveyed literature. Composite development can be employed to improve the properties of HEA, such as hardness/wear [91,92], tensile strength [93], and application as binders in cermets [94]. More studies are required to unravel the effect of different reinforcement materials and their phases on the properties of HEA/MCA composite materials.

4. Systematic Review of Emerging Application Areas

4.1. Hydrogen Storage

4.2. Additive Manufacturing

4.3. Catalysis

4.4. Superconductivity

5. Limitations of Study

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Gan, J.Y.; Lin, S.J.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Formation of simple crystal structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2004, 35, 2533–2536. [Google Scholar] [CrossRef]

- Cantor, B. Multicomponent high-entropy Cantor alloys. Prog. Mater. Sci. 2020, 120, 100754. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Takeuchi, A.; Wada, T.; Kato, H. Solid solutions with bcc, hcp, and fcc structures formed in a composition line in multicomponent Ir–Rh–Ru–W–Mo system. Mater. Trans. 2019, 60, 2267–2276. [Google Scholar] [CrossRef] [Green Version]

- Tang, J.; Xu, J.L.; Ye, Z.G.; Li, X.B.; Luo, J.M. Microwave sintered porous CoCrFeNiMo high entropy alloy as an efficient electrocatalyst for alkaline oxygen evolution reaction. J. Mater. Sci. Technol. 2021, 79, 171–177. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [Green Version]

- Senkov, O.N.; Wilks, G.B.; Miracle, D.B.; Chuang, C.P.; Liaw, P.K. Refractory high-entropy alloys. Intermetallics 2010, 18, 1758–1765. [Google Scholar] [CrossRef]

- Gao, M.C. Progress in high-entropy alloys. JOM 2014, 66, 1964–1965. [Google Scholar] [CrossRef] [Green Version]

- Xin, Y.; Li, S.; Qian, Y.; Zhu, W.; Yuan, H.; Jiang, P.; Guo, R.; Wang, L. High-entropy alloys as a platform for catalysis: Progress, challenges, and opportunities. ACS Catal. 2020, 10, 11280–11306. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Tsai, M.H.; Yeh, J.W. High-entropy alloys: A critical review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Huang, P.K.; Yeh, J.W.; Shun, T.T.; Chen, S.K. Multi-principal-element alloys with improved oxidation and wear resistance for thermal spray coating. Adv. Eng. Mater. 2004, 6, 74–78. [Google Scholar] [CrossRef]

- Varalakshmi, S.; Kamaraj, M.; Murty, B.S. Synthesis and characterization of nanocrystalline AlFeTiCrZnCu high entropy solid solution by mechanical alloying. J. Alloys Compd. 2008, 460, 253–257. [Google Scholar] [CrossRef]

- Wang, C.; Ji, W.; Fu, Z. Mechanical alloying and spark plasma sintering of CoCrFeNiMnAl high-entropy alloy. Adv. Powder Technol. 2014, 25, 1334–1338. [Google Scholar] [CrossRef]

- Xu, Z.; Zhu, Z.; Wang, P.; Meenashisundaram, G.K.; Nai, S.M.L.; Wei, J. Fabrication of porous CoCrFeMnNi high entropy alloy using binder jetting additive manufacturing. Addit. Manuf. 2020, 35, 101441. [Google Scholar] [CrossRef]

- Yang, X.; Chen, S.Y.; Cotton, J.D.; Zhang, Y. Phase Stability of Low-Density, Multiprincipal Component Alloys Containing Aluminum, Magnesium, and Lithium. JOM 2014, 66, 2009–2020. [Google Scholar] [CrossRef]

- Hammond, V.H.; Atwater, M.A.; Darling, K.A.; Nguyen, H.Q.; Kecskes, L.J. Equal-Channel Angular Extrusion of a Low-Density High-Entropy Alloy Produced by High-Energy Cryogenic Mechanical Alloying. JOM 2014, 66, 2021–2029. [Google Scholar] [CrossRef]

- Coury, F.G.; Kaufman, M.; Clarke, A.J. Solid-solution strengthening in refractory high entropy alloys. Acta Mater. 2019, 175, 66–81. [Google Scholar] [CrossRef]

- Waseem, O.A.; Ryu, H.J. Combinatorial synthesis and analysis of AlxTayVz-Cr20Mo20Nb20Ti20Zr10 and Al10CrMoxNbTiZr10 refractory high-entropy alloys: Oxidation behavior. J. Alloys Compd. 2020, 828, 154427. [Google Scholar] [CrossRef]

- Xu, Z.Q.; Ma, Z.L.; Wang, M.; Chen, Y.W.; Tan, Y.D.; Cheng, X.W. Design of novel low-density refractory high entropy alloys for high-temperature applications. Mater. Sci. Eng. A 2019, 755, 318–322. [Google Scholar] [CrossRef]

- Hsieh, M.H.; Tsai, M.H.; Shen, W.J.; Yeh, J.W. Structure and properties of two Al-Cr-Nb-Si-Ti high-entropy nitride coatings. Surf. Coat. Technol. 2013, 221, 118–123. [Google Scholar] [CrossRef]

- Tsai, D.C.; Chang, Z.C.; Kuo, B.H.; Chang, S.Y.; Shieu, F.S. Effects of silicon content on the structure and properties of (AlCrMoTaTi)N coatings by reactive magnetron sputtering. J. Alloys Compd. 2014, 616, 646–651. [Google Scholar] [CrossRef]

- Luo, S.; Gao, P.; Yu, H.; Yang, J.; Wang, Z.; Zeng, X. Selective laser melting of an equiatomic AlCrCuFeNi high-entropy alloy: Processability, non-equilibrium microstructure and mechanical behavior. J. Alloys Compd. 2019, 771, 387–397. [Google Scholar] [CrossRef]

- Senkov, O.N.; Woodward, C.; Miracle, D.B. Microstructure and properties of aluminum-containing refractory high-entropy alloys. JOM 2014, 66, 2030–2042. [Google Scholar] [CrossRef]

- Couzinié, J.P.; Senkov, O.N.; Miracle, D.B.; Dirras, G. Comprehensive data compilation on the mechanical properties of refractory high-entropy alloys. Data Br. 2018, 21, 1622–1641. [Google Scholar] [CrossRef]

- Gorsse, S.; Nguyen, M.H.; Senkov, O.N.; Miracle, D.B. Database on the mechanical properties of high entropy alloys and complex concentrated alloys. Data Br. 2018, 21, 2664–2678. [Google Scholar] [CrossRef]

- Soni, V.; Senkov, O.N.; Gwalani, B.; Miracle, D.B.; Banerjee, R. Microstructural Design for Improving Ductility of An Initially Brittle Refractory High Entropy Alloy. Sci. Rep. 2018, 8, 8816. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Zhang, Y.; Ma, X. High temperature deformation and dynamic recrystallization behavior of AlCrCuFeNi high entropy alloy. Mater. Sci. Eng. A 2020, 778, 139077. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, S.; Gao, M.C.; Zhang, C.; Zhang, T.; Yang, H.; Wang, Z.; Qiao, J. Tribological Properties of AlCrCuFeNi2 High-Entropy Alloy in Different Conditions. Metall. Mater. Trans. A 2016, 47, 3312–3321. [Google Scholar] [CrossRef]

- Li, S.; Tang, X.; Jia, H.; Li, H.; Xie, G.; Liu, X.; Lin, X.; Qiu, H.J. Nanoporous high-entropy alloys with low Pt loadings for high-performance electrochemical oxygen reduction. J. Catal. 2020, 383, 164–171. [Google Scholar] [CrossRef]

- Pedersen, J.K.; Batchelor, T.A.A.; Bagger, A.; Rossmeisl, J. High-entropy alloys as catalysts for the CO2 and CO reduction reactions. ACS Catal. 2020, 10, 2169–2176. [Google Scholar] [CrossRef]

- Qiu, H.J.; Fang, G.; Wen, Y.; Liu, P.; Xie, G.; Liu, X.; Sun, S. Nanoporous high-entropy alloys for highly stable and efficient catalysts. J. Mater. Chem. A 2019, 7, 6499–6506. [Google Scholar] [CrossRef]

- Vrtnik, S.; Koželj, P.; Meden, A.; Maiti, S.; Steurer, W.; Feuerbacher, M.; Dolinšek, J. Superconductivity in thermally annealed Ta-Nb-Hf-Zr-Ti high-entropy alloys. J. Alloys Compd. 2017, 695, 3530–3540. [Google Scholar] [CrossRef]

- Koželj, P.; Vrtnik, S.; Jelen, A.; Jazbec, S.; Jagličić, Z.; Maiti, S.; Feuerbacher, M.; Steurer, W.; Dolinšek, J. Discovery of a superconducting high-entropy alloy. Phys. Rev. Lett. 2014, 113, 107001. [Google Scholar] [CrossRef]

- Vrtnik, S.; Guo, S.; Sheikh, S.; Jelen, A.; Koželj, P.; Luzar, J.; Kocjan, A.; Jagličić, Z.; Meden, A.; Guim, H.; et al. Magnetism of CoCrFeNiZrx eutectic high-entropy alloys. Intermetallics 2018, 93, 122–133. [Google Scholar] [CrossRef]

- LuŽnik, J.; KoŽelj, P.; Vrtnik, S.; Jelen, A.; Jagličić, Z.; Meden, A.; Feuerbacher, M.; Dolinšek, J. Complex magnetism of Ho-Dy-Y-Gd-Tb hexagonal high-entropy alloy. Phys. Rev. B—Condens. Matter Mater. Phys. 2015, 92, 224201. [Google Scholar] [CrossRef]

- Shafeie, S.; Guo, S.; Hu, Q.; Fahlquist, H.; Erhart, P.; Palmqvist, A. High-entropy alloys as high-temperature thermoelectric materials. J. Appl. Phys. 2015, 118, 5489. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Visualizing bibliometric networks. In Measuring Scholarly Impact; Ding, Y., Rousseau, R., Wolfram, D., Eds.; Springer: Cham, Switzerland, 2014; pp. 285–320. ISBN 9783319103778. [Google Scholar]

- Chang, Y.W.; Huang, M.H.; Lin, C.W. Evolution of research subjects in library and information science based on keyword, bibliographical coupling, and co-citation analyses. Scientometrics 2015, 105, 2071–2087. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Bibliometric mapping of the computational intelligence field. Int. J. Uncertain. Fuzziness Knowlege-Based Syst. 2007, 15, 625–645. [Google Scholar] [CrossRef]

- Md Khudzari, J.; Kurian, J.; Tartakovsky, B.; Raghavan, G.S.V. Bibliometric analysis of global research trends on microbial fuel cells using Scopus database. Biochem. Eng. J. 2018, 136, 51–60. [Google Scholar] [CrossRef]

- Xing, Y.; Ma, Z.; Su, W.; Wang, Q.; Wang, X.; Zhang, H. Analysis of research status of CO2 conversion technology based on bibliometrics. Catalysts 2020, 10, 370. [Google Scholar] [CrossRef] [Green Version]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- He, G.; Eckert, J.; Hagiwara, M. Effect of Sn on microstructure and mechanical properties of Ti-base dendrite/ultrafine-structured multicomponent alloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2004, 35, 3605–3612. [Google Scholar] [CrossRef]

- Jacob, P.O. Advanced materials for hydrogen storage and retrieval systems for fuel cell applications. Fuel Cell 2006, 6, 28–30. [Google Scholar]

- Moody, M.P.; Stephenson, L.T.; Liddicoat, P.V.; Ringer, S.P. Contingency table techniques for three dimensional atom probe tomography. Microsc. Res. Tech. 2007, 70, 258–268. [Google Scholar] [CrossRef]

- He, J.; Li, H.; Yang, B.; Zhao, J.; Zhang, H.; Hu, Z. Liquid phase separation and microstructure characterization in a designed Al-based amorphous matrix composite with spherical crystalline particles. J. Alloys Compd. 2010, 489, 535–540. [Google Scholar] [CrossRef]

- Kimizuka, H.; Ogata, S. Predicting atomic arrangement of solute clusters in dilute Mg Alloys. Mater. Res. Lett. 2013, 1, 213–219. [Google Scholar] [CrossRef]

- Ye, M.; Li, Y.; Wu, J.; Su, T.; Zhang, J.; Tang, J. SECM screening of the catalytic activities of AuPd bimetallic patterns fabricated by electrochemical wet-stamping technique. J. Electroanal. Chem. 2016, 772, 96–102. [Google Scholar] [CrossRef] [Green Version]

- OpenRefine: A Free, Open Source, Powerful Tool for Working with Messy Data. 2021. Available online: https://openrefine.org/ (accessed on 31 May 2021).

- Liskiewicz, T.; Liskiewicz, G.; Paczesny, J. Factors affecting the citations of papers in tribology journals. Scientometrics 2021, 126, 3321–3336. [Google Scholar] [CrossRef]

- Tahamtan, I.; Askar, A.S.; Ahamdzadeh, K. Factors affecting number of citations: A comprehensive review of the literature. Scientometrics 2016, 107, 1195–1225. [Google Scholar] [CrossRef]

- Hussein, M.; Zayed, T. Crane operations and planning in modular integrated construction: Mixed review of literature. Autom. Constr. 2021, 122, 103466. [Google Scholar] [CrossRef]

- Matthews, K.R.W.; Yang, E.; Lewis, S.W.; Vaidyanathan, B.R.; Gorman, M. International scientific collaborative activities and barriers to them in eight societies. Account. Res. 2020, 27, 477–495. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. VOSviewer Manual Version 1.6.16; Univeristeit Leiden: Leiden, The Netherlands, 2020; pp. 1–52. Available online: https://www.vosviewer.com/download/f-33t2.pdf (accessed on 31 May 2021).

- Chen, T.K.; Shun, T.T.; Yeh, J.W.; Wong, M.S. Nanostructured nitride films of multi-element high-entropy alloys by reactive DC sputtering. Surf. Coat. Technol. 2004, 188–189, 193–200. [Google Scholar] [CrossRef]

- Yeh, J.-W. Recent progress in high-entropy alloys. Ann. Chim. Sci. Mater. 2006, 31, 633. [Google Scholar] [CrossRef]

- KY Tsai, M.T.J.Y. Sluggish diffusion in Co-Cr-Fe-Mn-Ni high-entropy alloys. Acta Mater. 2013, 61, 4887. [Google Scholar] [CrossRef]

- Senkov, O.N.; Miracle, D.B.; Chaput, K.J.; Couzinie, J.P. Development and exploration of refractory high entropy alloys—A review. J. Mater. Res. 2018, 33, 3092–3128. [Google Scholar] [CrossRef] [Green Version]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Guo, S.; Liu, C.T. Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase. Prog. Nat. Sci. Mater. Int. 2011, 21, 433–446. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-solution phase formation rules for multi-component alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Guo, S.; Ng, C.; Lu, J.; Liu, C.T. Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J. Appl. Phys. 2011, 109, 103505. [Google Scholar] [CrossRef] [Green Version]

- Ma, D.; Grabowski, B.; Körmann, F.; Neugebauer, J.; Raabe, D. Ab initio thermodynamics of the CoCrFeMnNi high entropy alloy: Importance of entropy contributions beyond the configurational one. Acta Mater. 2015, 100, 90–97. [Google Scholar] [CrossRef]

- Otto, F.; Yang, Y.; Bei, H.; George, E.P. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 2013, 61, 2628–2638. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Z.G.; Ma, K.H.; Wang, Q.; Shek, C.H. Compositional dependence of phase formation and mechanical properties in three CoCrFeNi-(Mn/Al/Cu) high entropy alloys. Intermetallics 2016, 79, 1–11. [Google Scholar] [CrossRef]

- Alvi, S.; Akhtar, F. High temperature tribology of CuMoTaWV high entropy alloy. Wear 2019, 426–427, 412–419. [Google Scholar] [CrossRef]

- Liu, C.M.; Wang, H.M.; Zhang, S.Q.; Tang, H.B.; Zhang, A.L. Microstructure and oxidation behavior of new refractory high entropy alloys. J. Alloys Compd. 2014, 583, 162–169. [Google Scholar] [CrossRef]

- Imam, M.A.; Bruce, R.W.; Feng, J.; Fliflet, A.W. Consolidation of blended Ti magnesium powders by microwave processing. Key Eng. Mater. 2013, 551, 73–85. [Google Scholar] [CrossRef]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. R Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

- Baburin, I.A.; Klechikov, A.; Mercier, G.; Talyzin, A.; Seifert, G. Hydrogen adsorption by perforated graphene. Int. J. Hydrog. Energy 2015, 40, 6594–6599. [Google Scholar] [CrossRef] [Green Version]

- Mkhondo, N.B.; Magadzu, T.; Sciences, M.; Africa, S. Effects of different acid-treatment on the nanostructure and performance of carbon nanotubes in electrochemical hydrogen storage. Dig. J. Nanomater. Biostruct. 2014, 9, 1331–1338. [Google Scholar]

- Sahlberg, M.; Karlsson, D.; Zlotea, C.; Jansson, U. Superior hydrogen storage in high entropy alloys. Sci. Rep. 2016, 6, 36770. [Google Scholar] [CrossRef] [Green Version]

- Edalati, P.; Floriano, R.; Mohammadi, A.; Li, Y.; Zepon, G.; Li, H.W.; Edalati, K. Reversible room temperature hydrogen storage in high-entropy alloy TiZrCrMnFeNi. Scr. Mater. 2020, 178, 387–390. [Google Scholar] [CrossRef]

- Strozi, R.B.; Leiva, D.R.; Huot, J.; Botta, W.J.; Zepon, G. Synthesis and hydrogen storage behavior of Mg–V–Al–Cr–Ni high entropy alloys. Int. J. Hydrog. Energy 2021, 46, 2351–2361. [Google Scholar] [CrossRef]

- Dai, D.; Xu, T.; Wei, X.; Ding, G.; Xu, Y.; Zhang, J.; Zhang, H. Using machine learning and feature engineering to characterize limited material datasets of high-entropy alloys. Comput. Mater. Sci. 2020, 175, 109618. [Google Scholar] [CrossRef]

- Xiong, J.; Shi, S.Q.; Zhang, T.Y. Machine learning of phases and mechanical properties in complex concentrated alloys. J. Mater. Sci. Technol. 2021, 87, 133–142. [Google Scholar] [CrossRef]

- Akinwekomi, A.D.; Lawal, A.I. Neural network-based model for predicting particle size of AZ61 powder during high-energy mechanical milling. Neural Comput. Appl. 2021, 33, 17611–17619. [Google Scholar] [CrossRef]

- Lopez, S.A.; Sanchez-Lengeling, B.; de Goes Soares, J.; Aspuru-Guzik, A. Design principles and top non-fullerene acceptor candidates for organic photovoltaics. Joule 2017, 1, 857–870. [Google Scholar] [CrossRef] [Green Version]

- Gómez-Bombarelli, R.; Aguilera-Iparraguirre, J.; Hirzel, T.D.; Duvenaud, D.; Maclaurin, D.; Blood-Forsythe, M.A.; Chae, H.S.; Einzinger, M.; Ha, D.-G.; Wu, T.; et al. Design of efficient molecular organic light-emitting diodes by a high-throughput virtual screening and experimental approach. Nat. Mater. 2016, 15, 1120–1127. [Google Scholar] [CrossRef]

- Conduit, B.D.; Jones, N.G.; Stone, H.J.; Conduit, G.J. Design of a nickel-base superalloy using a neural network. Mater. Des. 2017, 131, 358–365. [Google Scholar] [CrossRef] [Green Version]

- Correa-Baena, J.P.; Hippalgaonkar, K.; van Duren, J.; Jaffer, S.; Chandrasekhar, V.R.; Stevanovic, V.; Wadia, C.; Guha, S.; Buonassisi, T. Accelerating materials development via automation, machine learning, and high-performance computing. Joule 2018, 2, 1410–1420. [Google Scholar] [CrossRef] [Green Version]

- Huang, W.; Martin, P.; Zhuang, H.L. Machine-learning phase prediction of high-entropy alloys. Acta Mater. 2019, 169, 225–236. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, Y.; Wang, C.; Xue, D.; Bai, Y.; Antonov, S.; Dai, L.; Lookman, T.; Su, Y. Machine learning assisted design of high entropy alloys with desired property. Acta Mater. 2019, 170, 109–117. [Google Scholar] [CrossRef] [Green Version]

- Nair, R.B.; Arora, H.S.; Boyana, A.V.; Saiteja, P.; Grewal, H.S. Tribological behavior of microwave synthesized high entropy alloy claddings. Wear 2019, 436–437, 203028. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, J.; Li, J.; Yang, J.; Kou, H.; Liu, W. Tribological behavior of AlCoCrFeNi(Ti0.5) high entropy alloys under oil and MACs lubrication. J. Mater. Sci. Technol. 2016, 32, 470–476. [Google Scholar] [CrossRef]

- Wang, X.; Dong, Q.; Qiao, H.; Huang, Z.; Saray, M.T.; Zhong, G.; Lin, Z.; Cui, M.; Brozena, A.; Hong, M.; et al. Continuous synthesis of hollow high-entropy nanoparticles for energy and catalysis applications_spt info. Adv. Mater. 2020, 32, 2002853. [Google Scholar] [CrossRef]

- Fan, Q.C.; Li, B.S.; Zhang, Y. The microstructure and properties of (FeCrNiCo)AlxCuy high-entropy alloys and their TiC-reinforced composites. Mater. Sci. Eng. A 2014, 598, 244–250. [Google Scholar] [CrossRef]

- Li, J.; Xiang, S.; Luan, H.; Amar, A.; Liu, X.; Lu, S.; Zeng, Y.; Le, G.; Wang, X.; Qu, F.; et al. Additive manufacturing of high-strength CrMnFeCoNi high-entropy alloys-based composites with WC addition. J. Mater. Sci. Technol. 2019, 35, 2430–2434. [Google Scholar] [CrossRef]

- Wu, H.; Huang, S.; Zhu, H.; Xie, Z. Strengthening FeCrNiCu high entropy alloys via combining V additions with in-situ TiC particles. Scr. Mater. 2021, 195, 113724. [Google Scholar] [CrossRef]

- Fu, Z.; Koc, R. TiNiFeCrCoAl high-entropy alloys as novel metallic binders for TiB2-TiC based composites. Mater. Sci. Eng. A 2018, 735, 302–309. [Google Scholar] [CrossRef]

- Bououdina, M.; Grant, D.; Walker, G. Review on hydrogen absorbing materials—Structure, microstructure, and thermodynamic properties. Int. J. Hydrog. Energy 2006, 31, 177–182. [Google Scholar] [CrossRef]

- Züttel, A. Materials for hydrogen storage. Mater. Today 2003, 6, 24–33. [Google Scholar] [CrossRef]

- Sakintuna, B.; Lamari-Darkrim, F.; Hirscher, M. Metal hydride materials for solid hydrogen storage: A review. Int. J. Hydrogen Energy 2007, 32, 1121–1140. [Google Scholar] [CrossRef]

- Zhang, C.; Song, A.; Yuan, Y.; Wu, Y.; Zhang, P.; Lu, Z.; Song, X. Study on the hydrogen storage properties of a TiZrNbTa high entropy alloy. Int. J. Hydrog. Energy 2020, 45, 5367–5374. [Google Scholar] [CrossRef]

- Kunce, I.; Polanski, M.; Bystrzycki, J. Structure and hydrogen storage properties of a high entropy ZrTiVCrFeNi alloy synthesized using Laser Engineered Net Shaping (LENS). Int. J. Hydrog. Energy 2013, 38, 12180–12189. [Google Scholar] [CrossRef]

- Kao, Y.F.; Chen, S.K.; Sheu, J.H.; Lin, J.T.; Lin, W.E.; Yeh, J.W.; Lin, S.J.; Liou, T.H.; Wang, C.W. Hydrogen storage properties of multi-principal-component CoFeMnTixVyZrz alloys. Int. J. Hydrog. Energy 2010, 35, 9046–9059. [Google Scholar] [CrossRef]

- Karlsson, D.; Ek, G.; Cedervall, J.; Zlotea, C.; Møller, K.T.; Hansen, T.C.; Bednarčík, J.; Paskevicius, M.; Sørby, M.H.; Jensen, T.R.; et al. Structure and hydrogenation properties of a HfNbTiVZr high-entropy alloy. Inorg. Chem. 2018, 57, 2103–2110. [Google Scholar] [CrossRef]

- Kunce, I.; Polański, M.; Czujko, T. Microstructures and hydrogen storage properties of LaNiFeVMn alloys. Int. J. Hydrog. Energy 2017, 42, 27154–27164. [Google Scholar] [CrossRef]

- Zepon, G.; Leiva, D.R.; Strozi, R.B.; Bedoch, A.; Figueroa, S.J.A.; Ishikawa, T.T.; Botta, W.J. Hydrogen-induced phase transition of MgZrTiFe0.5Co0.5Ni0.5 high entropy alloy. Int. J. Hydrog. Energy 2018, 43, 1702–1708. [Google Scholar] [CrossRef]

- De Marco, M.O.; Li, Y.; Li, H.-W.; Edalati, K.; Floriano, R. Mechanical Synthesis and Hydrogen Storage Characterization of MgVCr and MgVTiCrFe High-Entropy Alloy. Adv. Eng. Mater. 2020, 22, 1901079. [Google Scholar] [CrossRef]

- Marques, F.; Pinto, H.C.; Figueroa, S.J.A.; Winkelmann, F.; Felderhoff, M.; Botta, W.J.; Zepon, G. Mg-containing multi-principal element alloys for hydrogen storage: A study of the MgTiNbCr0.5Mn0.5Ni0.5 and Mg0.68TiNbNi0.55 compositions. Int. J. Hydrog. Energy 2020, 45, 19539–19552. [Google Scholar] [CrossRef]

- Chen, S.; Tong, Y.; Liaw, P.K. Additive manufacturing of high-entropy alloys: A review. Entropy 2018, 20, 937. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ostovari Moghaddam, A.; Shaburova, N.A.; Samodurova, M.N.; Abdollahzadeh, A.; Trofimov, E.A. Additive manufacturing of high entropy alloys: A practical review. J. Mater. Sci. Technol. 2021, 77, 131–162. [Google Scholar] [CrossRef]

- Guan, S.; Ren, J.; Mooraj, S.; Liu, Y.; Feng, S.; Zhang, S.; Liu, J.; Fan, X.; Liaw, P.K.; Chen, W. Additive manufacturing of high-entropy alloys: Microstructural Metastability and mechanical behavior. J. Phase Equilibria Diffus. 2021, 42, 748–771. [Google Scholar] [CrossRef]

- Torralba, J.M.; Alvaredo, P.; García-Junceda, A. High-entropy alloys fabricated via powder metallurgy. A critical review. Powder Metall. 2019, 62, 84–114. [Google Scholar] [CrossRef]

- Torralba, J.M.; Campos, M. High entropy alloys manufactured by additive manufacturing. Metals 2020, 10, 639. [Google Scholar] [CrossRef]

- Zhang, H.; Pan, Y.; He, Y.Z. Synthesis and characterization of FeCoNiCrCu high-entropy alloy coating by laser cladding. Mater. Des. 2011, 32, 1910–1915. [Google Scholar] [CrossRef]

- Zhang, H.; Pan, Y.; He, Y. Effects of annealing on the microstructure and properties of 6FeNiCoCrAlTiSi high-entropy alloy coating prepared by laser cladding. J. Therm. Spray Technol. 2011, 20, 1049–1055. [Google Scholar] [CrossRef]

- Fujieda, T.; Shiratori, H.; Kuwabara, K.; Kato, T.; Yamanaka, K.; Koizumi, Y.; Chiba, A. First demonstration of promising selective electron beam melting method for utilizing high-entropy alloys as engineering materials. Mater. Lett. 2015, 159, 12–15. [Google Scholar] [CrossRef]

- Kunce, I.; Polanski, M.; Karczewski, K.; Plocinski, T.; Kurzydlowski, K.J. Microstructural characterisation of high-entropy alloy AlCoCrFeNi fabricated by laser engineered net shaping. J. Alloys Compd. 2015, 648, 751–758. [Google Scholar] [CrossRef]

- Brif, Y.; Thomas, M.; Todd, I. The use of high-entropy alloys in additive manufacturing. Scr. Mater. 2015, 99, 93–96. [Google Scholar] [CrossRef]

- Wu, W.; Zhou, R.; Wei, B.; Ni, S.; Liu, Y.; Song, M. Nanosized precipitates and dislocation networks reinforced C-containing CoCrFeNi high-entropy alloy fabricated by selective laser melting. Mater. Charact. 2018, 144, 605–610. [Google Scholar] [CrossRef]

- Haase, C.; Tang, F.; Wilms, M.B.; Weisheit, A.; Hallstedt, B. Combining thermodynamic modeling and 3D printing of elemental powder blends for high-throughput investigation of high-entropy alloys—Towards rapid alloy screening and design. Mater. Sci. Eng. A 2017, 688, 180–189. [Google Scholar] [CrossRef]

- Moorehead, M.; Bertsch, K.; Niezgoda, M.; Parkin, C.; Elbakhshwan, M.; Sridharan, K.; Zhang, C.; Thoma, D.; Couet, A. High-throughput synthesis of Mo-Nb-Ta-W high-entropy alloys via additive manufacturing. Mater. Des. 2020, 187, 108358. [Google Scholar] [CrossRef]

- Dobbelstein, H.; Gurevich, E.L.; George, E.P.; Ostendorf, A.; Laplanche, G. Laser metal deposition of compositionally graded TiZrNbTa refractory high-entropy alloys using elemental powder blends. Addit. Manuf. 2019, 25, 252–262. [Google Scholar] [CrossRef]

- Melia, M.A.; Whetten, S.R.; Puckett, R.; Jones, M.; Heiden, M.J.; Argibay, N.; Kustas, A.B. High-throughput additive manufacturing and characterization of refractory high entropy alloys. Appl. Mater. Today 2020, 19, 100560. [Google Scholar] [CrossRef]

- Popov, V.V.; Katz-Demyanetz, A.; Koptyug, A.; Bamberger, M. Selective electron beam melting of Al0.5CrMoNbTa0.5 high entropy alloys using elemental powder blend. Heliyon 2019, 5, e01188. [Google Scholar] [CrossRef] [Green Version]

- Peyrouzet, F.; Hachet, D.; Soulas, R.; Navone, C.; Godet, S.; Gorsse, S. Selective Laser Melting of Al0.3CoCrFeNi High-Entropy Alloy: Printability, Microstructure, and Mechanical Properties. JOM 2019, 71, 3443–3451. [Google Scholar] [CrossRef] [Green Version]

- Luo, S.; Zhao, C.; Su, Y.; Liu, Q.; Wang, Z. Selective laser melting of dual phase AlCrCuFeNix high entropy alloys: Formability, heterogeneous microstructures and deformation mechanisms. Addit. Manuf. 2020, 31, 100925. [Google Scholar] [CrossRef]

- Ren, F.; Ward, L.; Williams, T.; Laws, K.J.; Wolverton, C.; Hattrick-Simpers, J.; Mehta, A. Accelerated discovery of metallic glasses through iteration of machine learning and high-throughput experiments. Sci. Adv. 2018, 4, eaaq1566. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharma, A.; Oh, M.C.; Ahn, B. Microstructural evolution and mechanical properties of non-Cantor AlCuSiZnFe lightweight high entropy alloy processed by advanced powder metallurgy. Mater. Sci. Eng. A 2020, 797, 140066. [Google Scholar] [CrossRef]

- Jin, Z.; Lv, J.; Jia, H.; Liu, W.; Li, H.; Chen, Z.; Lin, X.; Xie, G.; Liu, X.; Sun, S.; et al. Nanoporous Al-Ni-Co-Ir-Mo high-entropy alloy for record-high water splitting activity in acidic environments. Small 2019, 15, 1904180. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Xi, C.; Xin, J.; Zhang, G.; Zhang, S.; Zhang, Z.; Huang, Q.; Li, J.; Liu, H.; Kang, J. Free-standing nanoporous NiMnFeMo alloy: An efficient non-precious metal electrocatalyst for water splitting. Chem. Eng. J. 2021, 404, 126530. [Google Scholar] [CrossRef]

- Lv, Z.Y.; Liu, X.J.; Jia, B.; Wang, H.; Wu, Y.; Lu, Z.P. Development of a novel high-entropy alloy with eminent efficiency of degrading azo dye solutions. Sci. Rep. 2016, 6, 34213. [Google Scholar] [CrossRef]

- Nellaiappan, S.; Katiyar, N.K.; Kumar, R.; Parui, A.; Malviya, K.D.; Pradeep, K.G.; Singh, A.K.; Sharma, S.; Tiwary, C.S.; Biswas, K. High-entropy alloys as catalysts for CO2 and CO reduction reactions: Experimental realization. ACS Catal. 2020, 10, 3658–3663. [Google Scholar] [CrossRef]

- Peng, H.; Xie, Y.; Xie, Z.; Wu, Y.; Zhu, W.; Liang, S.; Wang, L. Large-scale and facile synthesis of a porous high-entropy alloy CrMnFeCoNi as an efficient catalyst. J. Mater. Chem. A 2020, 8, 18318–18326. [Google Scholar] [CrossRef]

- Li, H.; Zhu, H.; Zhang, S.; Zhang, N.; Du, M.; Chai, Y. Nano high-entropy materials: Synthesis strategies and catalytic applications. Small Struct. 2020, 1, 2000033. [Google Scholar] [CrossRef]

- Yao, R.Q.; Zhou, Y.T.; Shi, H.; Wan, W.B.; Zhang, Q.H.; Gu, L.; Zhu, Y.F.; Wen, Z.; Lang, X.Y.; Jiang, Q. Nanoporous surface high-entropy alloys as highly efficient multisite electrocatalysts for nonacidic hydrogen evolution reaction. Adv. Funct. Mater. 2020, 31, 2009613. [Google Scholar] [CrossRef]

- Zhang, G.; Ming, K.; Kang, J.; Huang, Q.; Zhang, Z.; Zheng, X.; Bi, X. High entropy alloy as a highly active and stable electrocatalyst for hydrogen evolution reaction. Electrochim. Acta 2018, 279, 19–23. [Google Scholar] [CrossRef]

- Yusenko, K.V.; Riva, S.; Carvalho, P.A.; Yusenko, M.V.; Arnaboldi, S.; Sukhikh, A.S.; Hanfland, M.; Gromilov, S.A. First hexagonal close packed high-entropy alloy with outstanding stability under extreme conditions and electrocatalytic activity for methanol oxidation. Scr. Mater. 2017, 138, 22–27. [Google Scholar] [CrossRef] [Green Version]

- Lu, Z.; Chen, Z.W.; Singh, C.V. Neural network-assisted development of high-entropy alloy catalysts: Decoupling ligand and coordination effects. Matter 2020, 3, 1318–1333. [Google Scholar] [CrossRef]

- Slocombe, D.R.; Kuznetsov, V.L.; Grochala, W.; Williams, R.J.P.; Edwards, P.P. Superconductivity in transition metals. Philos. Trans. R Soc. A Math. Phys. Eng. Sci. 2015, 373, 20140476. [Google Scholar] [CrossRef] [Green Version]

- Maple, M.B. High-temperature superconductivity. J. Magn. Magn. Mater. 1998, 177–181, 18–30. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.; Wang, H.; von Rohr, F.; Wang, Z.; Cai, S.; Zhou, Y.; Yang, K.; Li, A.; Jiang, S.; Wu, Q.; et al. Robust zero resistance in a superconducting high-entropy alloy at pressures up to 190 GPa. Proc. Natl. Acad. Sci. USA 2017, 114, 13144–13147. [Google Scholar] [CrossRef] [Green Version]

- Ishizu, N.; Kitagawa, J. New high-entropy alloy superconductor Hf21Nb25Ti15V15Zr24. Results Phys. 2019, 13, 102275. [Google Scholar] [CrossRef]

- Yuan, Y.; Wu, Y.; Luo, H.; Wang, Z.; Liang, X.; Yang, Z.; Wang, H.; Liu, X.; Lu, Z. Superconducting Ti15Zr15Nb35Ta35 High-Entropy Alloy With Intermediate Electron-Phonon Coupling. Front. Mater. 2018, 5, 72. [Google Scholar] [CrossRef] [Green Version]

- Stolze, K.; Cevallos, F.A.; Kong, T.; Cava, R.J. High-entropy alloy superconductors on an α-Mn lattice. J. Mater. Chem. C 2018, 6, 10441–10449. [Google Scholar] [CrossRef]

- Marik, S.; Motla, K.; Varghese, M.; Sajilesh, K.P.; Singh, D.; Breard, Y.; Boullay, P.; Singh, R.P. Superconductivity in a new hexagonal high-entropy alloy. Phys. Rev. Mater. 2019, 3, 60602. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Wu, J.; Cui, Y.; Zhu, Q.; Xiao, G.; Wu, S.; Cao, G.; Ren, Z. Superconductivity in hexagonal Nb-Mo-Ru-Rh-Pd high-entropy alloys. Scr. Mater. 2020, 182, 109–113. [Google Scholar] [CrossRef] [Green Version]

- Stolze, K.; Tao, J.; von Rohr, F.O.; Kong, T.; Cava, R.J. Sc–Zr–Nb–Rh–Pd and Sc–Zr–Nb–Ta–Rh–Pd High-Entropy Alloy Superconductors on a CsCl-Type Lattice. Chem. Mater. 2018, 30, 906–914. [Google Scholar] [CrossRef]

| Rank | Journal | Number of Publications | Total Citations | Total Link Strength |

|---|---|---|---|---|

| 1 | Journal of Alloys and Compounds | 387 | 9432 | 5217 |

| 2 | Materials Science and Engineering A | 279 | 8993 | 4529 |

| 3 | Scripta Materialia | 160 | 3296 | 2218 |

| 4 | Intermetallics | 149 | 6836 | 3455 |

| 5 | Acta Materialia | 139 | 6914 | 3122 |

| 6 | Materials Letters | 102 | 2062 | 966 |

| 7 | Journal of Materials Science and Technology | 82 | 818 | 1099 |

| 8 | Metals | 74 | 734 | 942 |

| 9 | Entropy | 71 | 1787 | 1157 |

| 10 | Scientific Reports | 70 | 2620 | 1198 |

| 11 | Materials and Design | 69 | 2462 | 1278 |

| 12 | Journal of Materials Research | 61 | 1142 | 1164 |

| 13 | JOM | 55 | 2883 | 1329 |

| 14 | Materials Chemistry and Physics | 52 | 1527 | 827 |

| 15 | Materials Research Letters | 52 | 2930 | 1166 |

| 16 | Metallurgical and Materials Transactions A | 48 | 1513 | 746 |

| 17 | Materials Characterization | 46 | 915 | 821 |

| 18 | Advanced Engineering Materials | 36 | 4934 | 1829 |

| 19 | Corrosion Science | 32 | 1181 | 493 |

| 20 | Nature Communications | 19 | 2708 | 796 |

| Rank | Author | Cluster | Institution/Country | Total Link Strength | Documents | Total Citations | Normalized Citations |

|---|---|---|---|---|---|---|---|

| 1 | Zhang Y. | 2 | University of Science and Technology, Beijing, China | 205 | 157 | 6261 | 201.81 |

| 2 | Liaw P.K. | 2 | University of Tennessee, Knoxville, United States | 198 | 149 | 6886 | 268.67 |

| 3 | Liu Y. | 1 | Tsinghua University, Beijing, China | 189 | 132 | 2414 | 146.40 |

| 4 | Li J. | 3 | Hunan University, Changsha, China | 180 | 102 | 1654 | 150.29 |

| 5 | Wang J. | 3 | Northwestern Polytechnical University, Xi’an, China | 154 | 81 | 1240 | 95.58 |

| 6 | Wang Z. | 3 | City University of Hong Kong, Kowloon, Hong Kong | 131 | 83 | 1493 | 70.35 |

| 7 | Wang L. | 2 | Harbin Institute of Technology, Harbin, China | 129 | 104 | 1492 | 110.06 |

| 8 | Wang Y. | 1 | University of Science and Technology Beijing, Beijing, China | 125 | 80 | 1320 | 113.23 |

| 9 | Liu X. | 4 | University of Science and Technology Beijing, Beijing, China | 120 | 74 | 1470 | 128.15 |

| 10 | Liu C.T. | 3 | City University of Hong Kong, Kowloon, Hong Kong | 118 | 51 | 2929 | 86.86 |

| 11 | Wang H. | 4 | Wuhan University of Technology, Wuhan, China | 108 | 64 | 1936 | 112.10 |

| 12 | Wu Y. | 4 | Shandong University, Jinan, China | 107 | 59 | 1993 | 125.13 |

| 13 | Wang T. | 5 | Dalian University of Technology, Dalian, China | 106 | 58 | 2198 | 75.00 |

| 14 | Liu B. | 1 | Central South University, Changsha, China | 105 | 58 | 1185 | 72.76 |

| 15 | Lu Y. | 5 | Dalian University of Technology, Dalian, China | 99 | 54 | 2044 | 81.19 |

| 16 | Kai J.J. | 3 | City University of Hong Kong, Kowloon, Hong Kong | 93 | 34 | 519 | 40.07 |

| 17 | Zhang H. | 1 | Tsinghua University, Beijing, China | 85 | 65 | 1331 | 53.66 |

| 18 | Wang X. | 1 | University of Science and Technology Beijing, China | 80 | 52 | 533 | 36.97 |

| 19 | Yang T. | 3 | Peking University, Beijing, China | 77 | 30 | 836 | 48.28 |

| 20 | Chen D. | 3 | City University of Hong Kong, Kowloon, Hong Kong | 72 | 25 | 609 | 52.49 |

| Institution | Country | Number of Research Articles | Total Citations | Total Link Strength | |

|---|---|---|---|---|---|

| 1 | University of Tennessee (Department of Materials Science and Engineering), Knoxville, United States | United States | 137 | 5693 | 93 |

| 2 | University of Science and Technology Beijing (State Key Laboratory for Advanced Metals and Materials), Beijing, China | China | 78 | 3150 | 46 |

| 3 | Central South University (State Key Laboratory of Powder Metallurgy), Changsha, China | China | 62 | 749 | 22 |

| 4 | Northwestern Polytechnical University (State Key Laboratory of Solidification Processing), Xi’an, China | China | 50 | 878 | 7 |

| 5 | Beijing Institute of Technology (School of Materials Science and Engineering), Beijing, China | China | 42 | 532 | 10 |

| 6 | Oak Ridge National Laboratory (Materials Science and Technology Division), Oak Ridge, United States | United States | 33 | 1723 | 26 |

| 7 | National Tsing Hua University, Hsinchu (Department of Materials Science and Engineering), Taiwan | Taiwan | 31 | 3218 | 6 |

| 8 | Dalian University of Technology (Key Laboratory of Solidification Control and Digital Preparation Technology), Dalian, China | China | 28 | 927 | 8 |

| 9 | Taiyuan University of Technology (College of Materials Science and Engineering), Taiyuan, China | China | 21 | 245 | 20 |

| 10 | Hunan University (State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body), Changsha, China | China | 20 | 184 | 19 |

| 11 | Royal Institute of Technology (Department of Materials Science and Engineering), Stockholm, Sweden | Sweden | 19 | 431 | 8 |

| 12 | National Energy Technology Laboratory, Albany, United States | United States | 18 | 1382 | 19 |

| 13 | Taiyuan University of Technology (Key Laboratory of Interface Science and Engineering in Advanced Materials), Taiyuan, China | China | 14 | 111 | 14 |

| 14 | Argonne National Laboratory (X-ray Science Division), Argonne, United States | United States | 13 | 368 | 17 |

| 15 | Uppsala University (Department of Physics and Astronomy, Division of Materials Theory), Uppsala, Sweden | Sweden | 11 | 294 | 8 |

| Rank | Authors | Title of Publication | Journal | Citations | Norm. Citations |

|---|---|---|---|---|---|

| 1 | Yeh J.-W. et al. (2004) | Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes | Advanced Engineering Materials | 4409 | 1.86 |

| 2 | Cantor B. et al. (2004) | Microstructural development in equiatomic multicomponent alloys | Materials Science and Engineering A | 2490 | 1.05 |

| 3 | Gludovatz B. et al. (2014) | A fracture-resistant high-entropy alloy for cryogenic applications | Science | 2010 | 16.54 |

| 4 | Tsai M.-H. et al. (2014) | High-entropy alloys: a critical review | Materials Research Letters | 1036 | 8.53 |

| 5 | Senkov O.N. et al. (2011) | Mechanical properties of Nb25Mo25Ta 25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys | Intermetallics | 1023 | 9.26 |

| 6 | Senkov O.N. et al. (2010) | Refractory high-entropy alloys | Intermetallics | 928 | 7.77 |

| 7 | Tsai K.-Y. et al. (2013) | Sluggish diffusion in Co-Cr-Fe-Mn-Ni high-entropy alloys | Acta Materialia | 815 | 10.06 |

| 8 | Guo S. and Liu C. T. (2011) | Phase stability in high entropy alloys: formation of solid-solution phase or amorphous phase | Progress in Natural Science: Materials International | 788 | 7.14 |

| 9 | Yeh J.-W. (2006) | Recent progress in high-entropy alloys | Annales de Chimie Science des Matériaux | 748 | 3.30 |

| 10 | Tong C.-J. et al. (2005) | Microstructure characterization of AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements | Metallurgical and Materials Transactions A | 736 | 3.85 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akinwekomi, A.D.; Akhtar, F. Bibliometric Mapping of Literature on High-Entropy/Multicomponent Alloys and Systematic Review of Emerging Applications. Entropy 2022, 24, 329. https://doi.org/10.3390/e24030329

Akinwekomi AD, Akhtar F. Bibliometric Mapping of Literature on High-Entropy/Multicomponent Alloys and Systematic Review of Emerging Applications. Entropy. 2022; 24(3):329. https://doi.org/10.3390/e24030329

Chicago/Turabian StyleAkinwekomi, Akeem Damilola, and Farid Akhtar. 2022. "Bibliometric Mapping of Literature on High-Entropy/Multicomponent Alloys and Systematic Review of Emerging Applications" Entropy 24, no. 3: 329. https://doi.org/10.3390/e24030329

APA StyleAkinwekomi, A. D., & Akhtar, F. (2022). Bibliometric Mapping of Literature on High-Entropy/Multicomponent Alloys and Systematic Review of Emerging Applications. Entropy, 24(3), 329. https://doi.org/10.3390/e24030329