According to the proposed tuning method, the coefficient

a should be determined before the calculation of the FOPID controller parameters. Thus, in order to improve the control performance, the distribution of the optimal

a should be studied. In this paper, we concentrate on the third-order plant model described by (

18),

where

K,

, and

are the parameters of the plant. The estimation model of

a is established in the hyperspace defined by the ranges of the plant model parameters (

,

) and the design specifications (

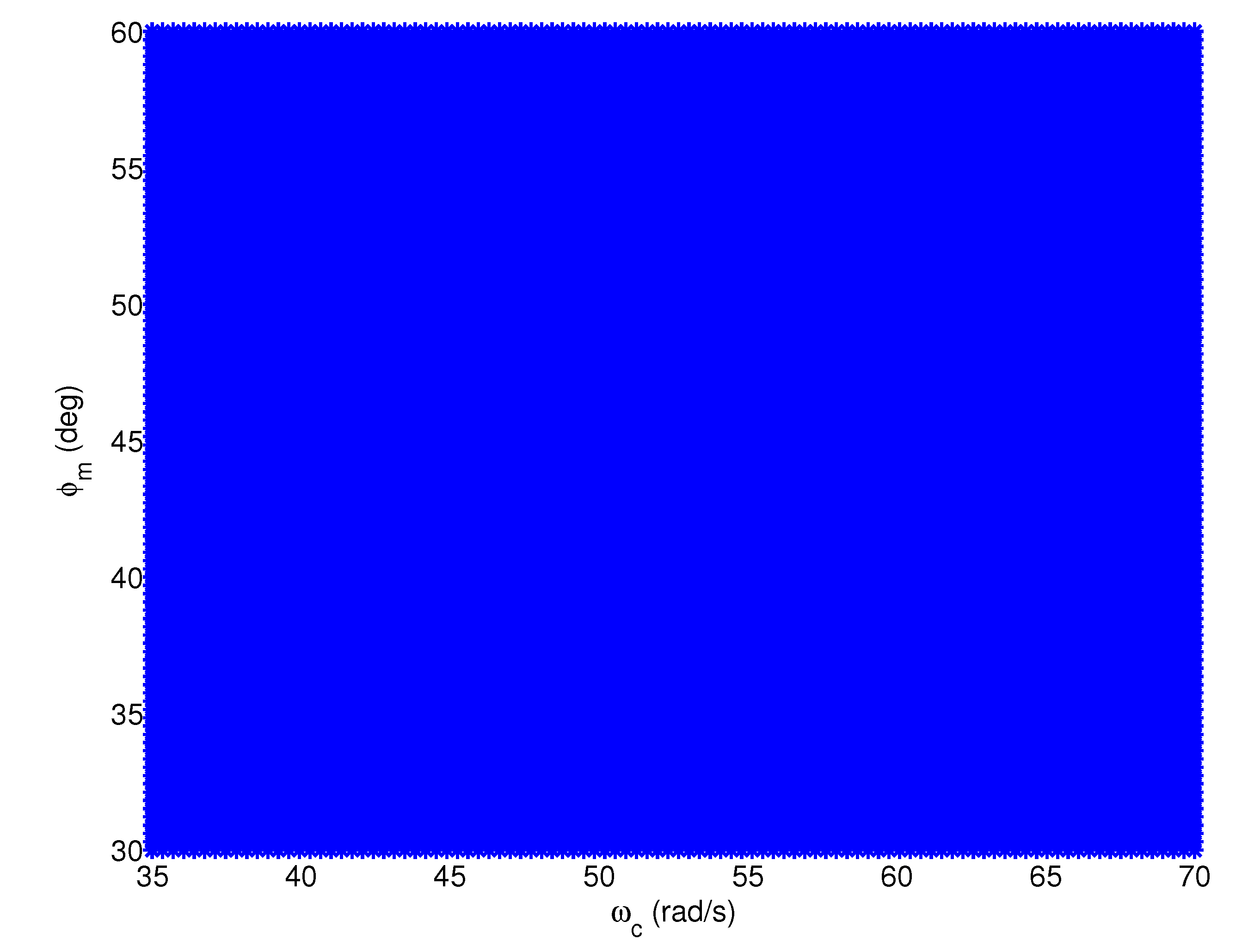

,

). The ranges of

and

are determined according to the parameters of the plant models in actual applications, while those of

and

are determined according to the design requirements. In this paper, the range of

is set from 90 to 180 and that of

is set from 6000 to 11,000. The range of the gain crossover frequency

is set from 35 rad/s to 70 rad/s, and that of the phase margin

is set from

to

, covering the design requirements of a class of motion control systems [

23].

3.1. Optimal Samples’ Collection

Several values of

and

are uniformly selected from their ranges, respectively, obtaining (

,

, ...,

) and (

,

, ...,

). Since the plant model gain

K has no influence on the estimation of

a, it is given a fixed value. Thus, several test models can be established by combining the values of

and

,

where

. Similarly, several values of

(

) and

(

) are selected from their ranges to be the given design specifications.

The integral of time and absolute error (ITAE) is adopted as the loss function to evaluate the dynamic performance of the control system,

where

represents the error between the reference and output signals.

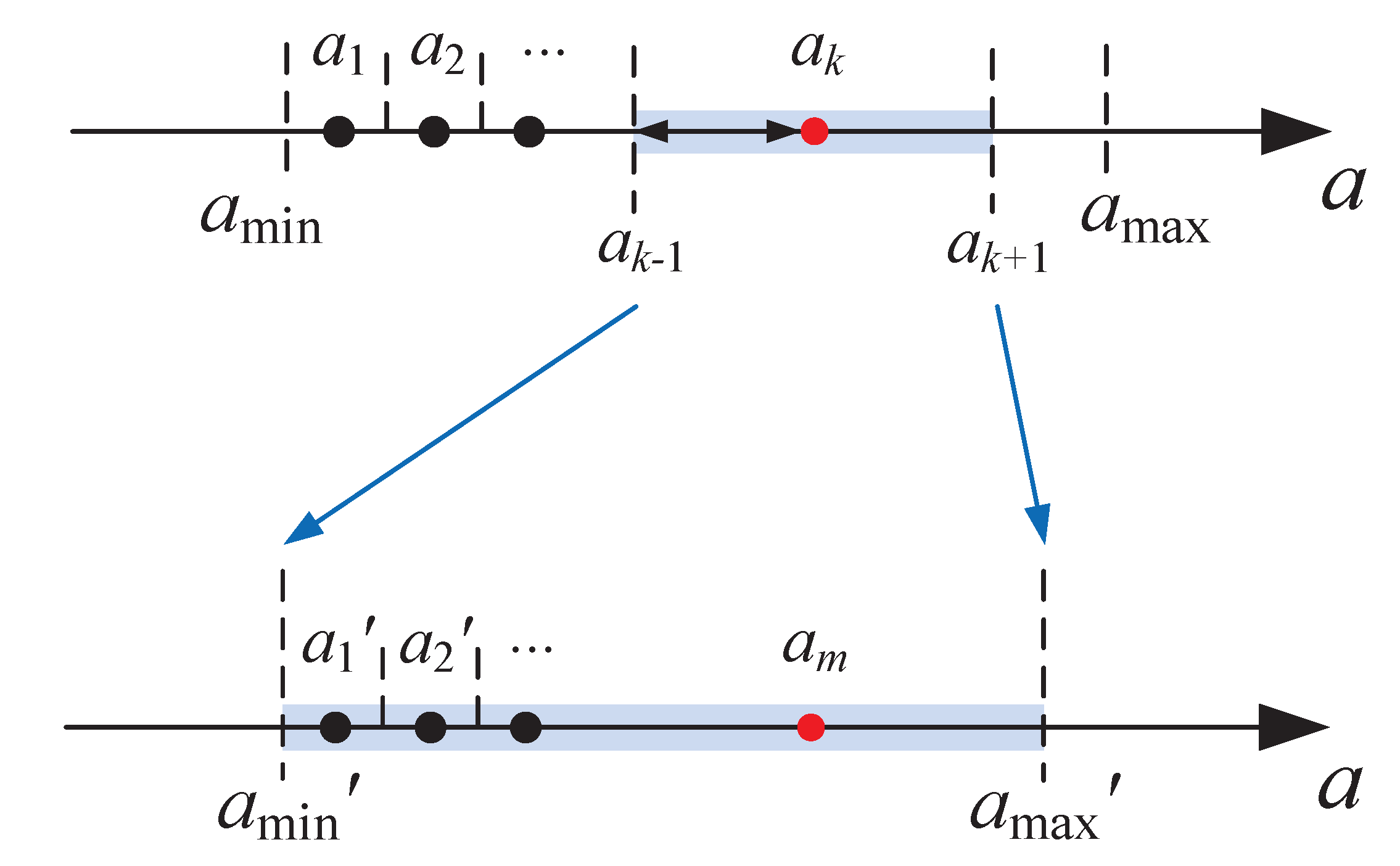

The optimal sample of

a for each test model (

,

) and design index (

,

) is collected following the steps shown in

Figure 2. An accuracy threshold

is set for the search of the optimal

a. If the value resolution of the obtained

a is smaller than

, this value is considered to be the optimum; otherwise, another loop of search needs to be performed in a smaller range of

a. For example, as shown in

Figure 3, if the

kth value of

a,

, is the current optimal value, but its resolution is larger than

, namely

, then a new range of

a will be created as (

,

), in which a new optimum will be obtained.

According to the model parameter ranges, several values of

: 90, 100, ..., 180, and

: 6000, 6200, ..., 11,000, are selected to generate the test models. Similarly, several values of

: 34 rad/s, 36 rad/s, ..., 70 rad/s and

:

,

, ...,

are selected to be the design specifications. The initial range of

a is from 0.001 to 500. The accuracy threshold

is 0.001. Thus, following the steps shown in

Figure 2, the optimal values of

a corresponding to all the test models and design specifications are collected.

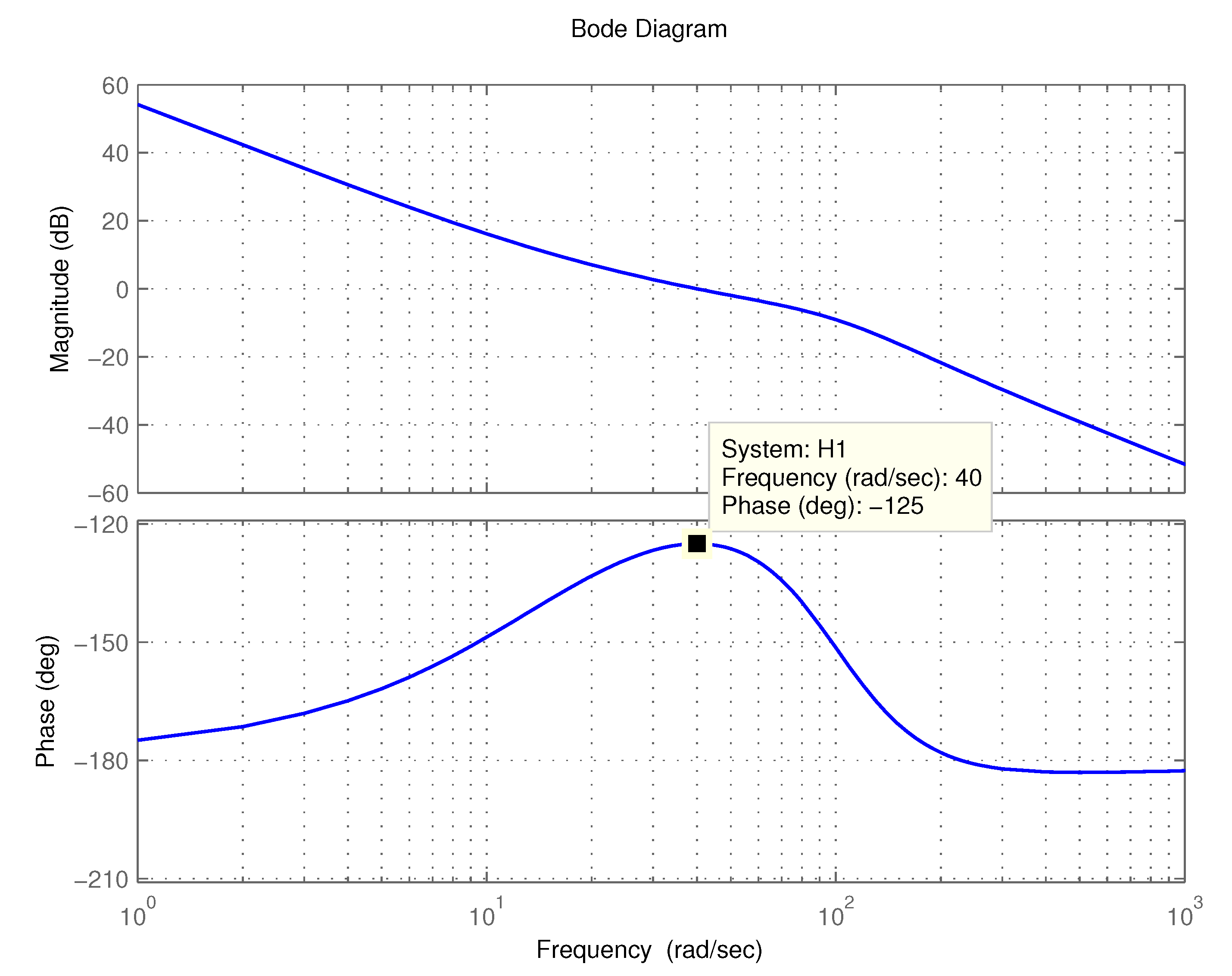

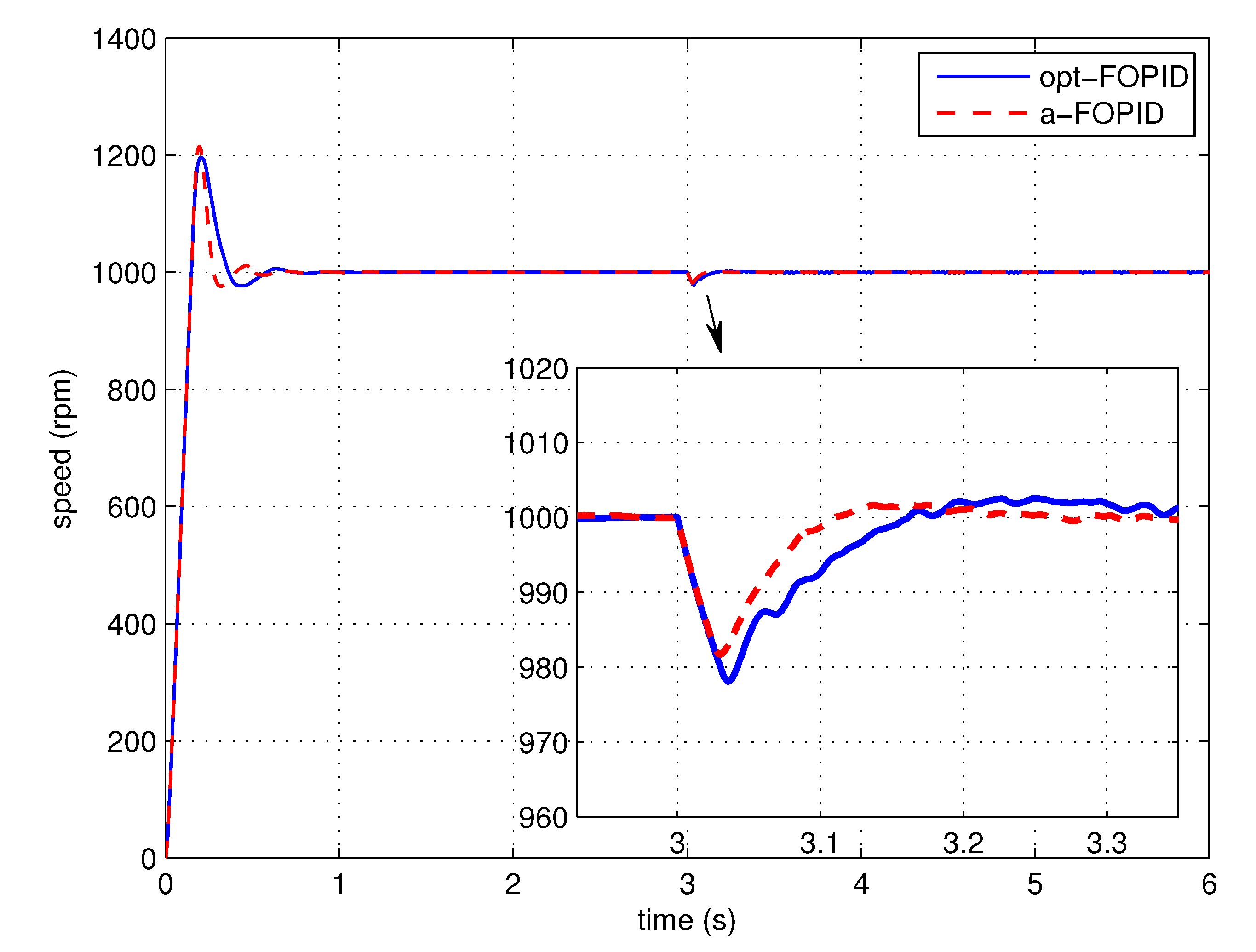

3.2. Estimation Model Establishment

Given the design specifications (, ), an optimal FOPID controller can be designed for a plant model , according to an optimal value of a, which depends on the plant model characteristics and design specifications . The estimation model is established to approximate the distribution law of the optimal a.

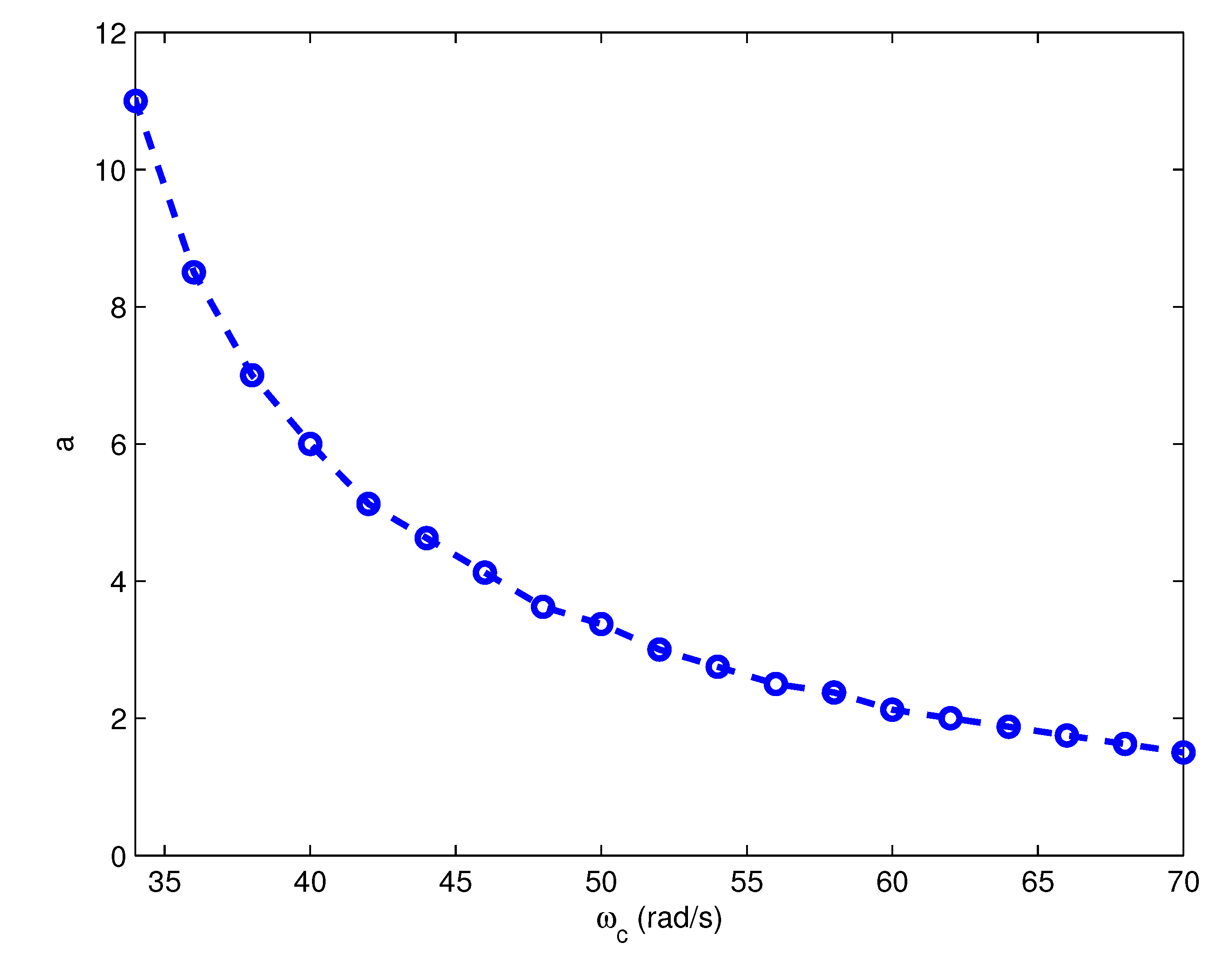

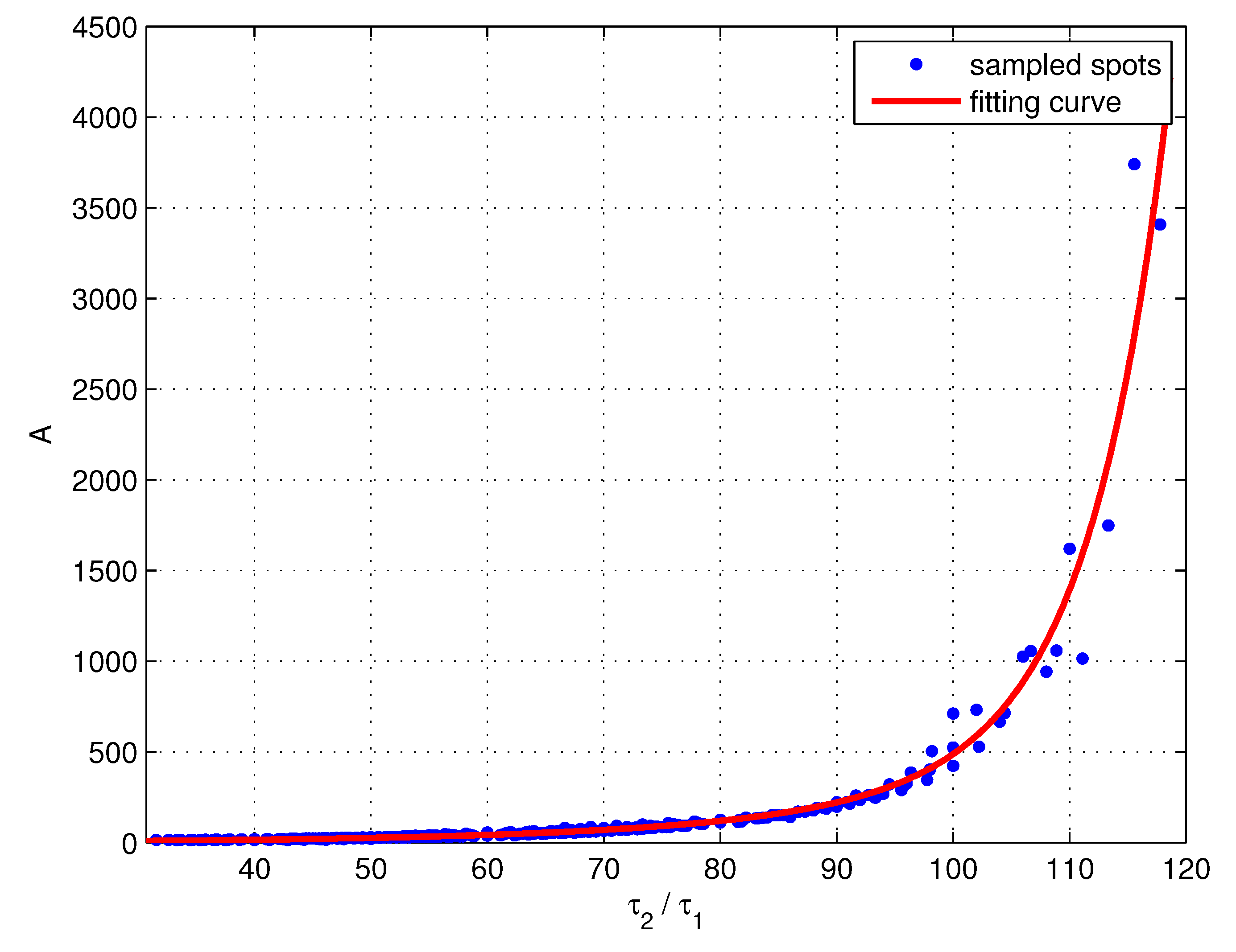

Firstly, the distribution of the optimal

a for a single plant model with regard to

and

is studied. Taking the test model

(

,

) as an example, the optimal values of

a corresponding to different given crossover frequencies

and a fixed phase margin

(

) are selected and plotted as the

–

a relation curve in

Figure 4. According to

Figure 4, the distribution of the optimal

a can be approximated as a curve.

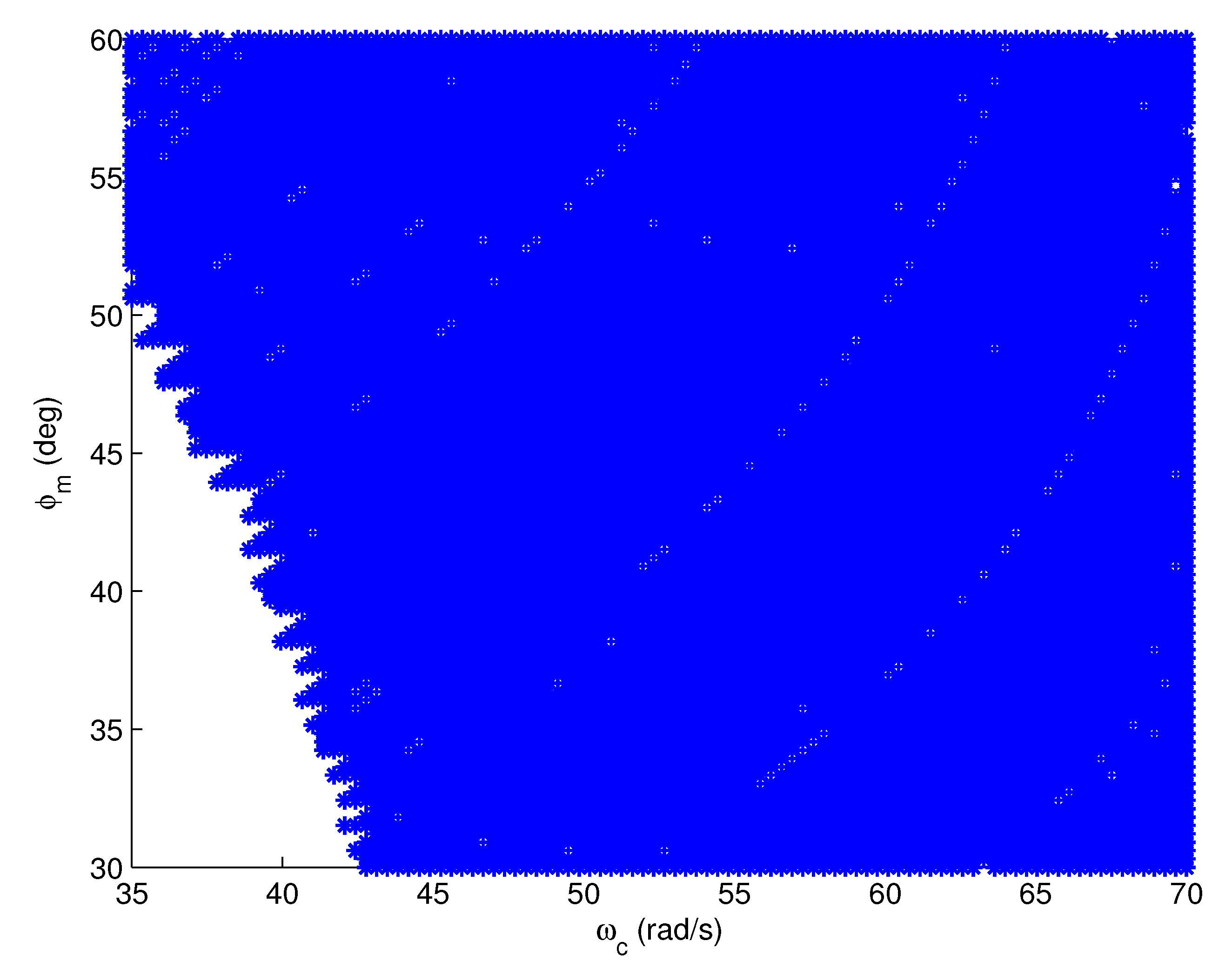

The

–

a relation curves of different

for test model

are plotted in

Figure 5. It can be seen that the

–

a relation curves corresponding to different

are close to each other. Thus, an assumption is adopted to simplify the analysis, i.e., the difference between the

–

a relation curves corresponding to different

can be ignored. Therefore, for the same plant model, the optimal value of

a is assumed to be only determined by

.

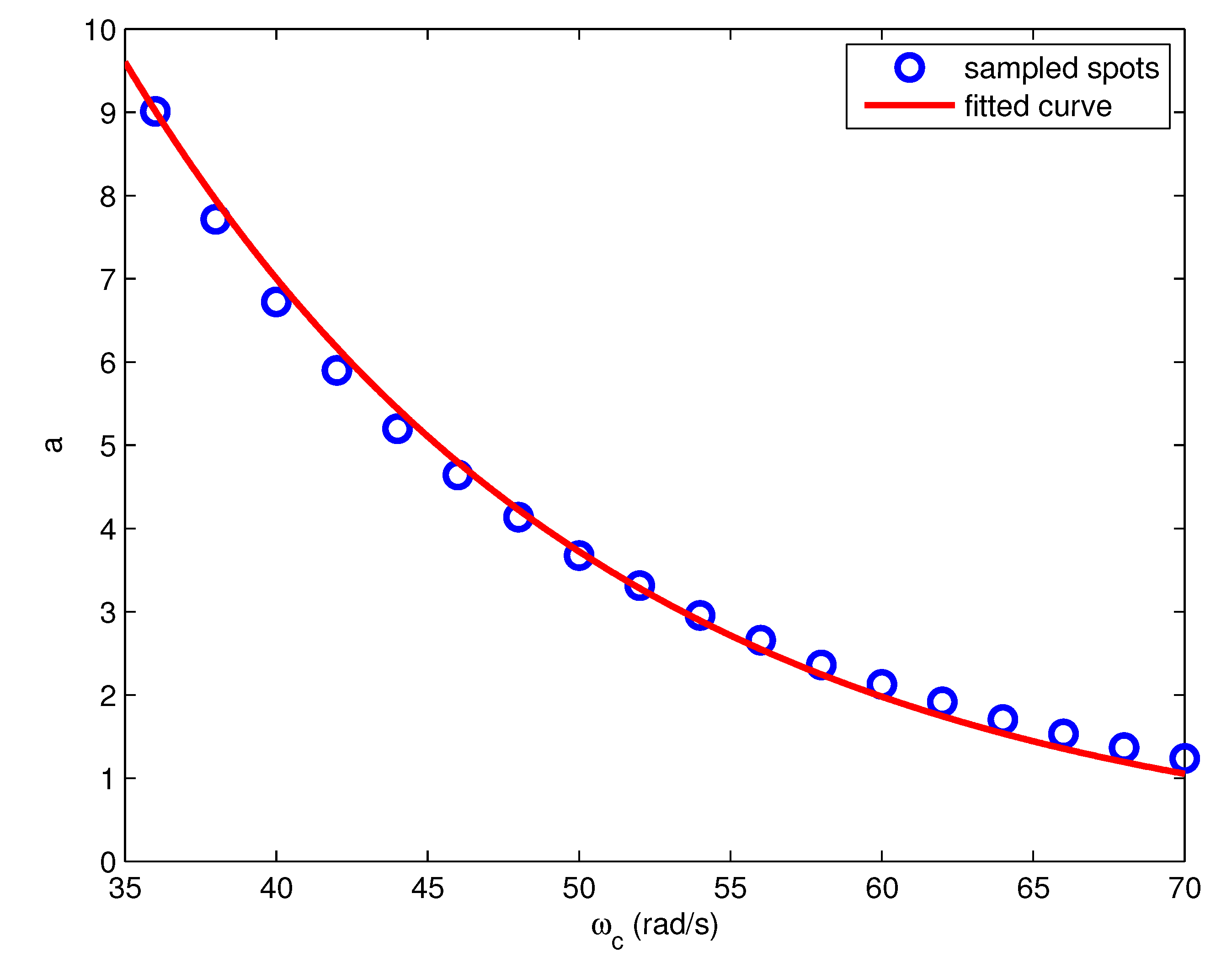

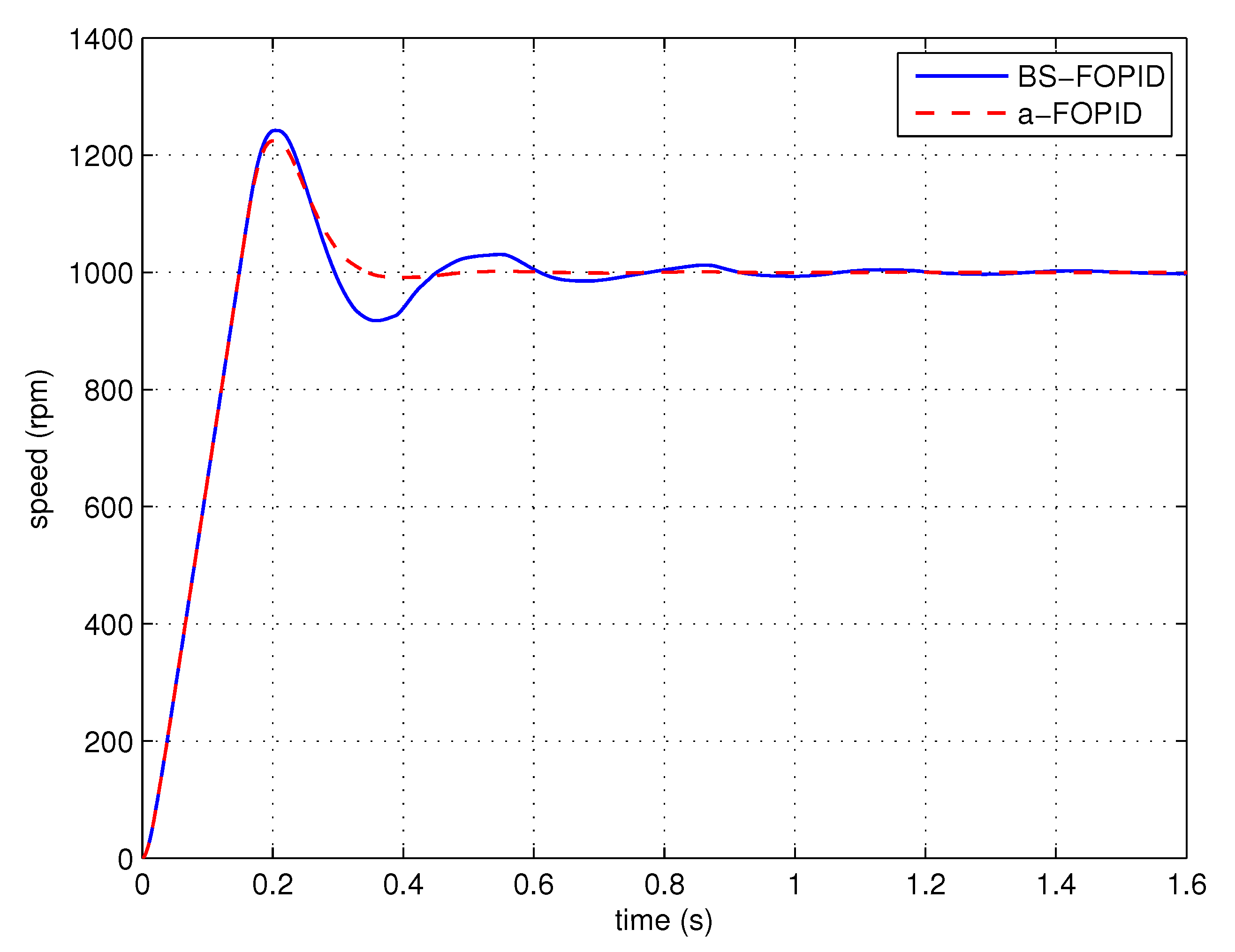

Adopting the simplifying assumption, an estimation model needs to be built for the mean values of the optimal

a. The

–mean

a relation corresponding to

is plotted as data spots in

Figure 6.

It can be seen that the mean

a values with regard to

obey an obvious distribution law, which can be described by an exponential function,

where

A and

B are the coefficients determined by the model parameters

and

. The values of

A and

B can be obtained using the numerical fitting methods. The fitting function is plotted as the red curve in

Figure 6. Fitting the

–mean

a relations of all the plant models, the values of

A and

B corresponding to different plant models:

and

, are obtained, where the subscript

i corresponds to that of

and the subscript

j corresponds to that of

,

.

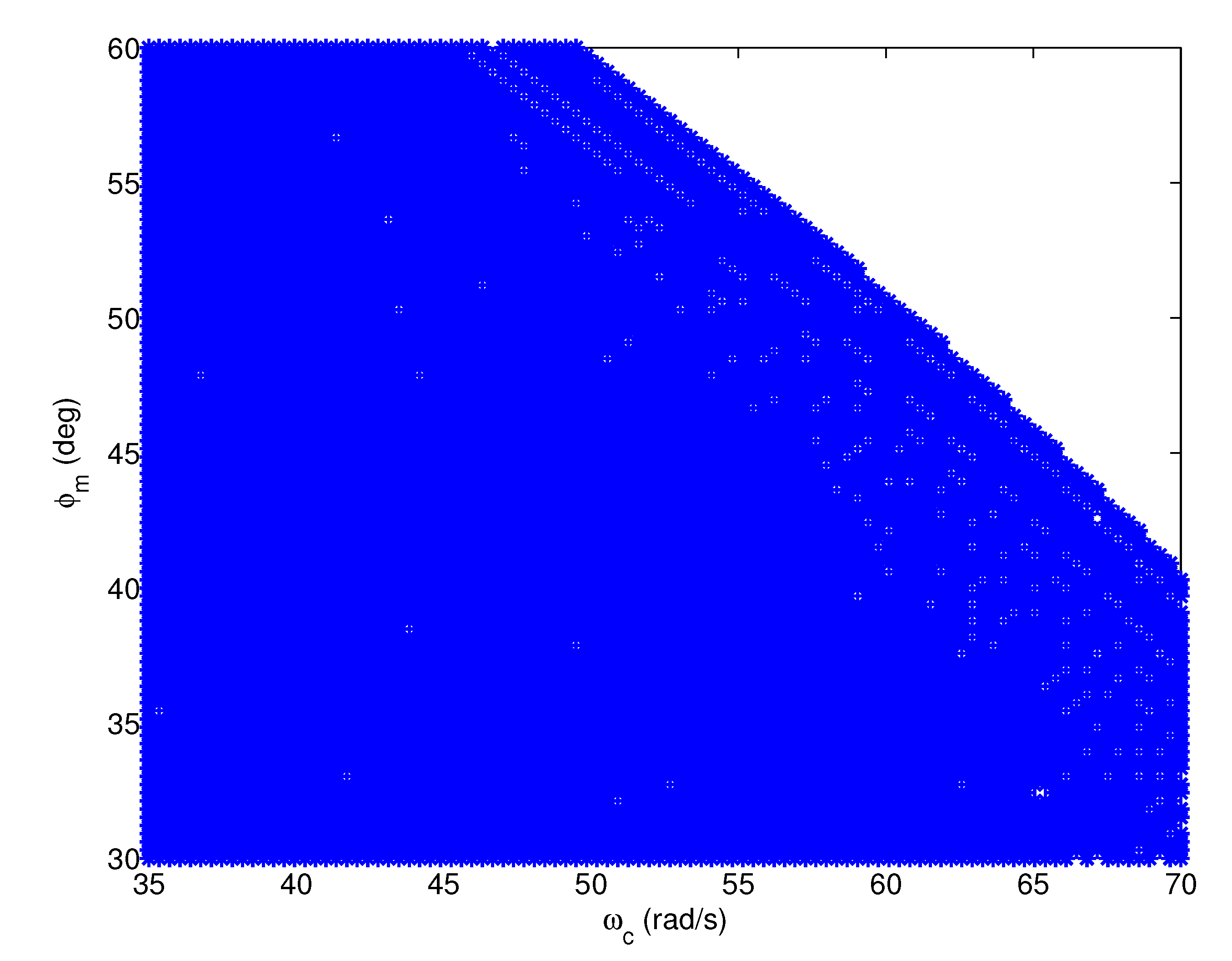

Secondly, the relation between the coefficient

A and the model parameters (

,

) is studied. Taking

as the abscissa and the corresponding coefficient

A as the ordinate, the distribution of

A with regard to

is plotted in

Figure 7. As can be seen, the distribution of

A with regard to

can be approximated as a curve.

The

–

A relation is plotted again in

Figure 8, without distinguishing the data spots corresponding to different plant models. According to the distribution of the data spots, the

–

A relation can be fitted by a model with two exponential functions,

where

M,

N,

P, and

Q are the model coefficients, which can be obtained using numerical fitting methods. The fitting function is plotted as the red curve in

Figure 8.

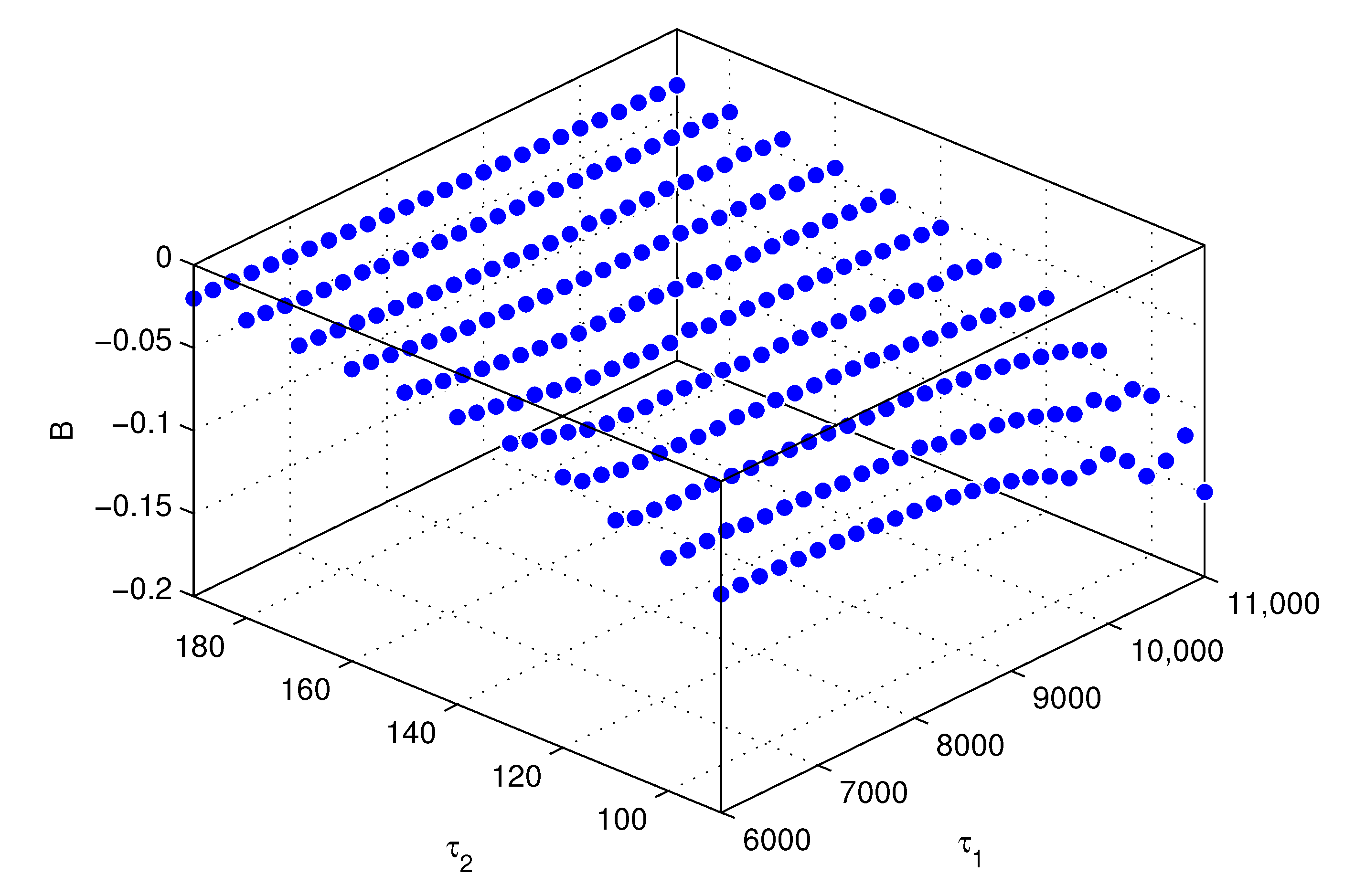

Thirdly, the three-dimensional distribution of coefficient

B with regard to

and

is plotted in

Figure 9.

Taking

and

as the independent variables, the (

,

)–

B relation can be fitted by a cubic polynomial function,

where

,

,

,

,

,

,

,

, and

are the model coefficients, which can be obtained using the numerical fitting methods. Therefore, all the coefficients of the estimation model are obtained.