Frictional Wear and Corrosion Behavior of AlCoCrFeNi High-Entropy Alloy Coatings Synthesized by Atmospheric Plasma Spraying

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussion

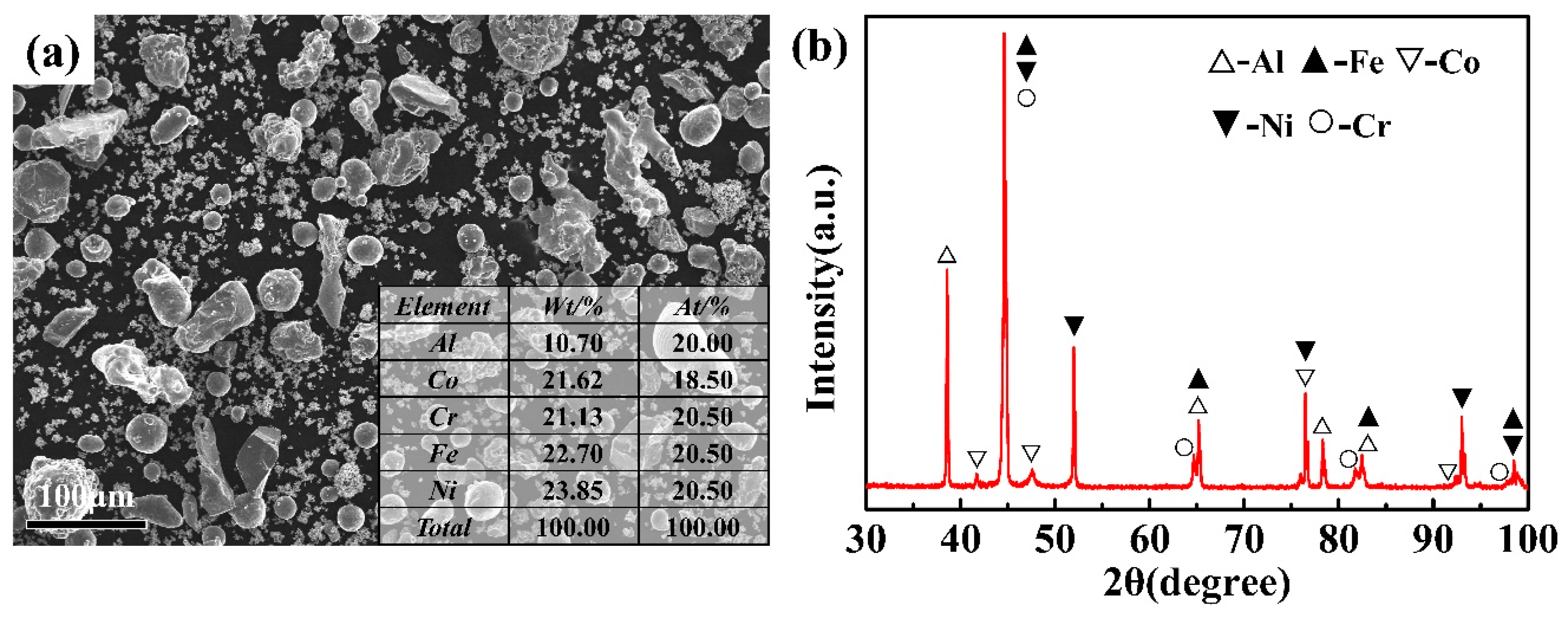

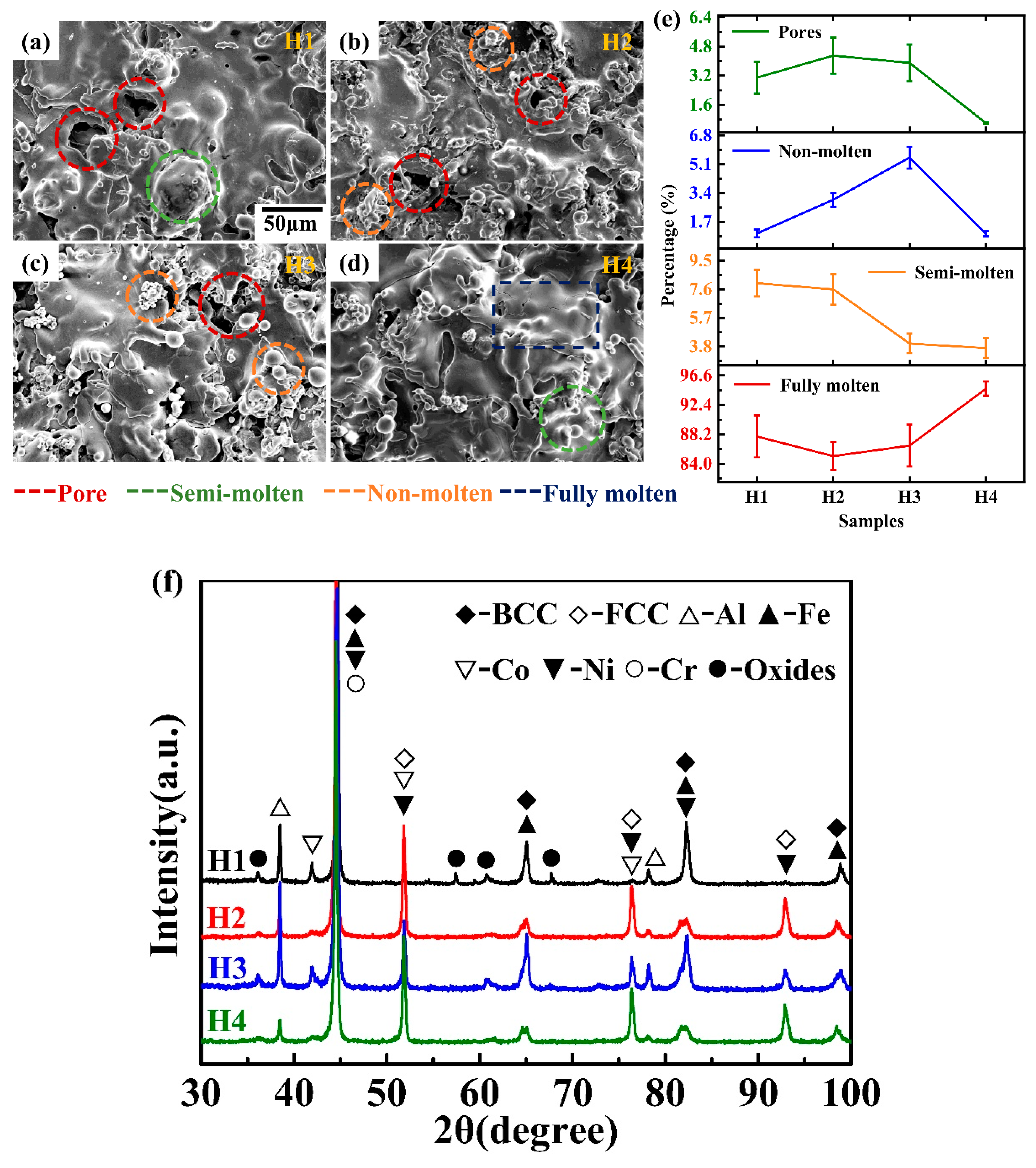

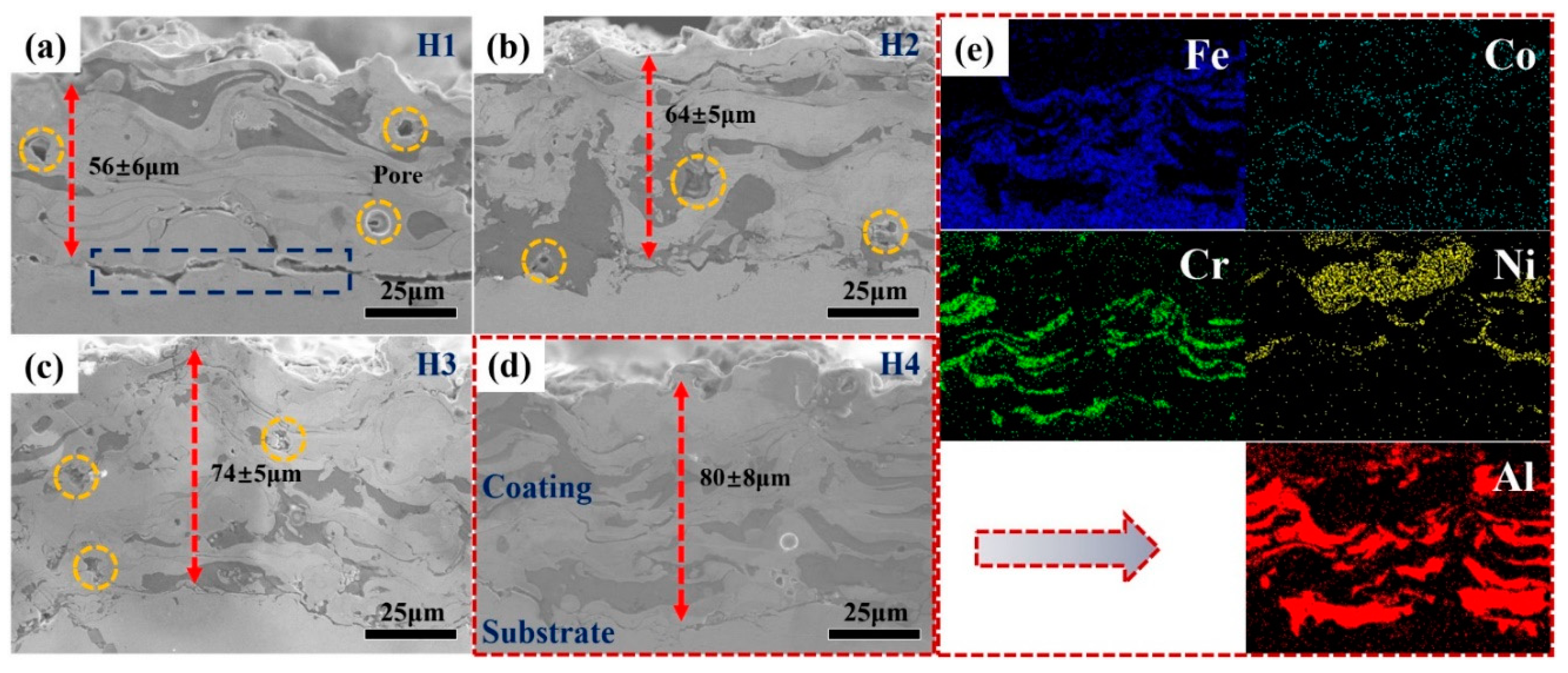

3.1. Microstructure and Phase Constitution

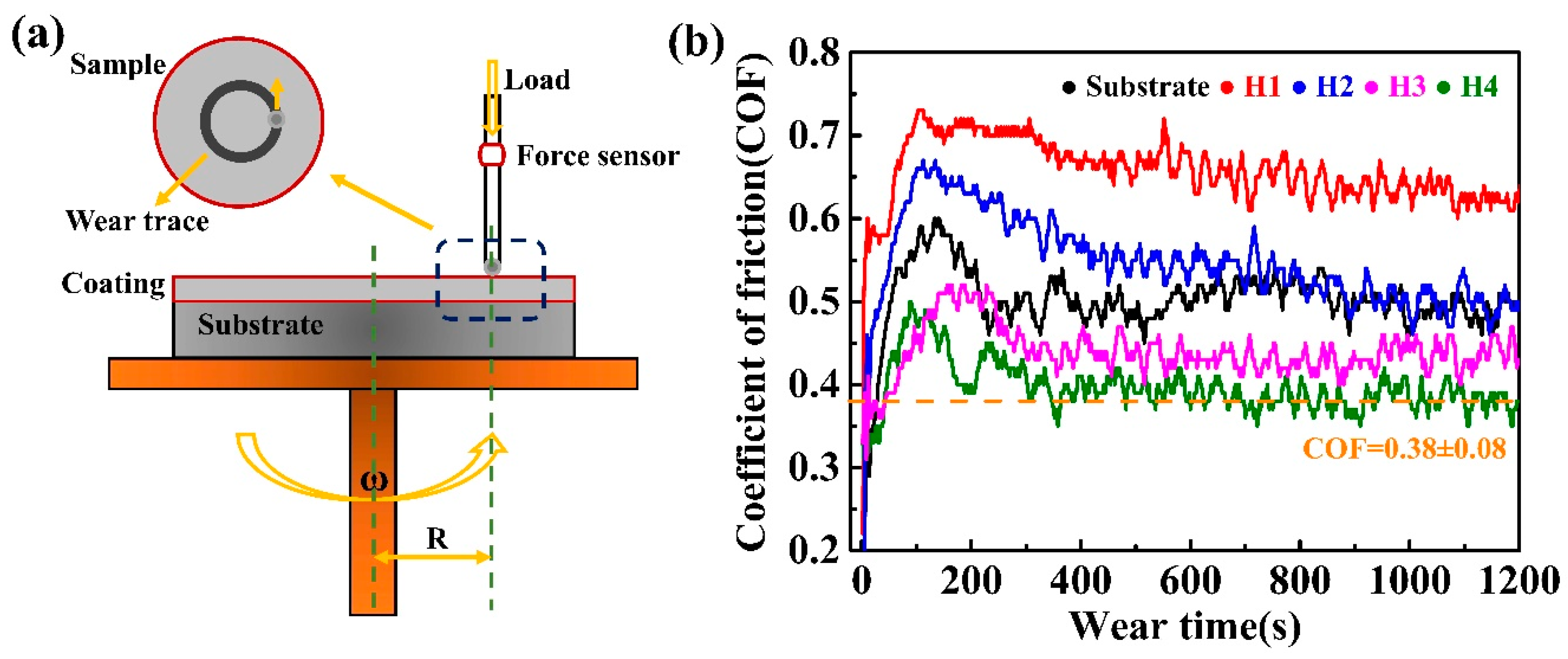

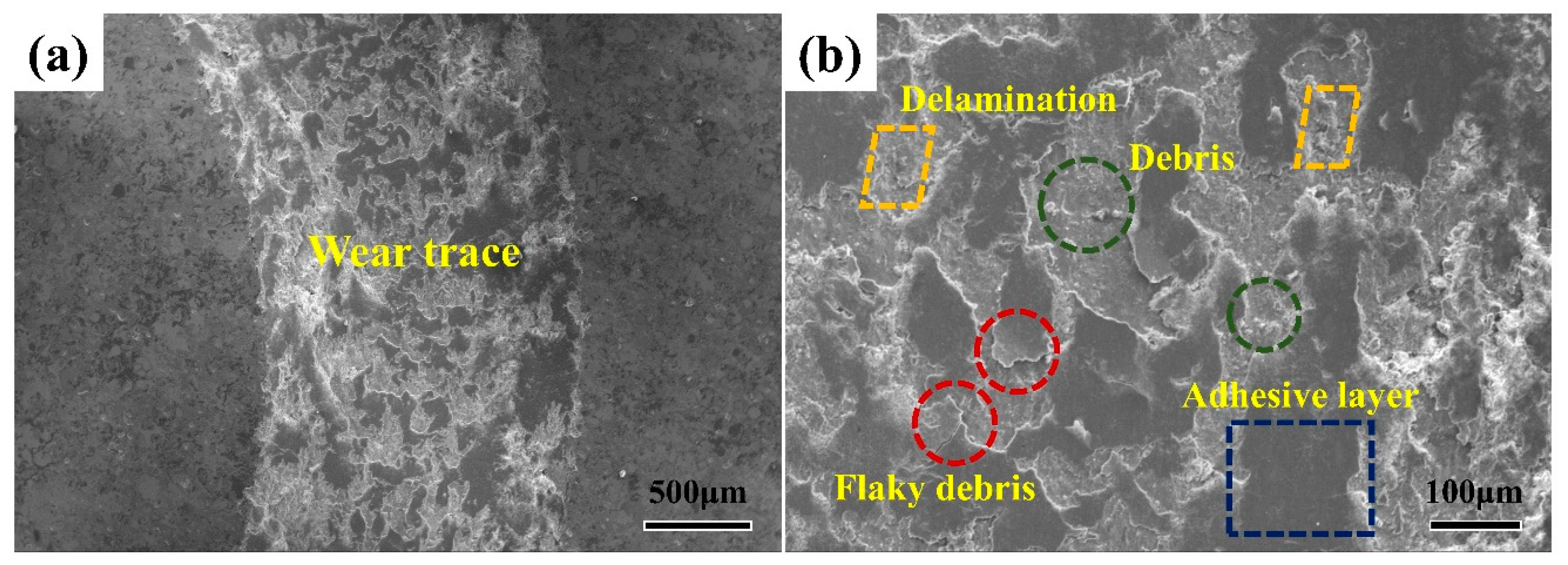

3.2. Nanoindentation and Frictional Wear

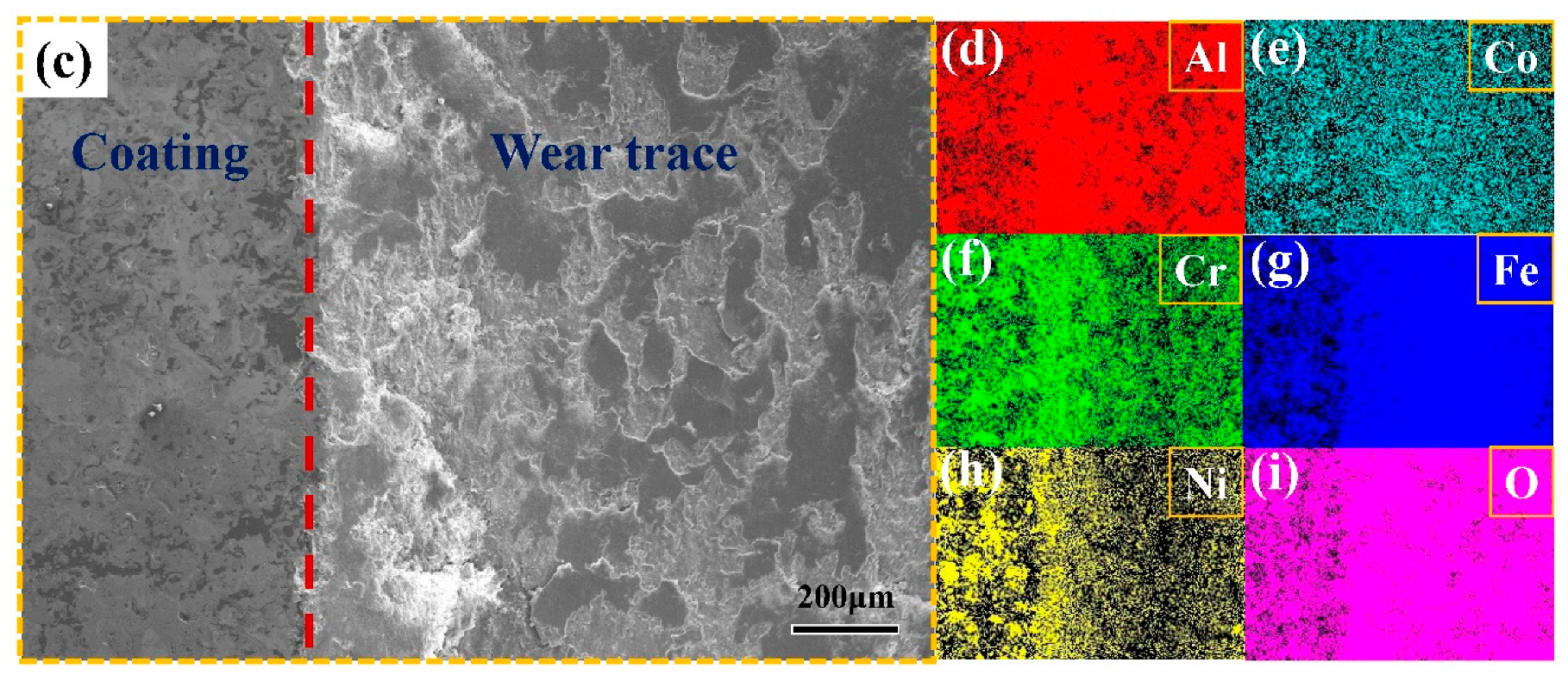

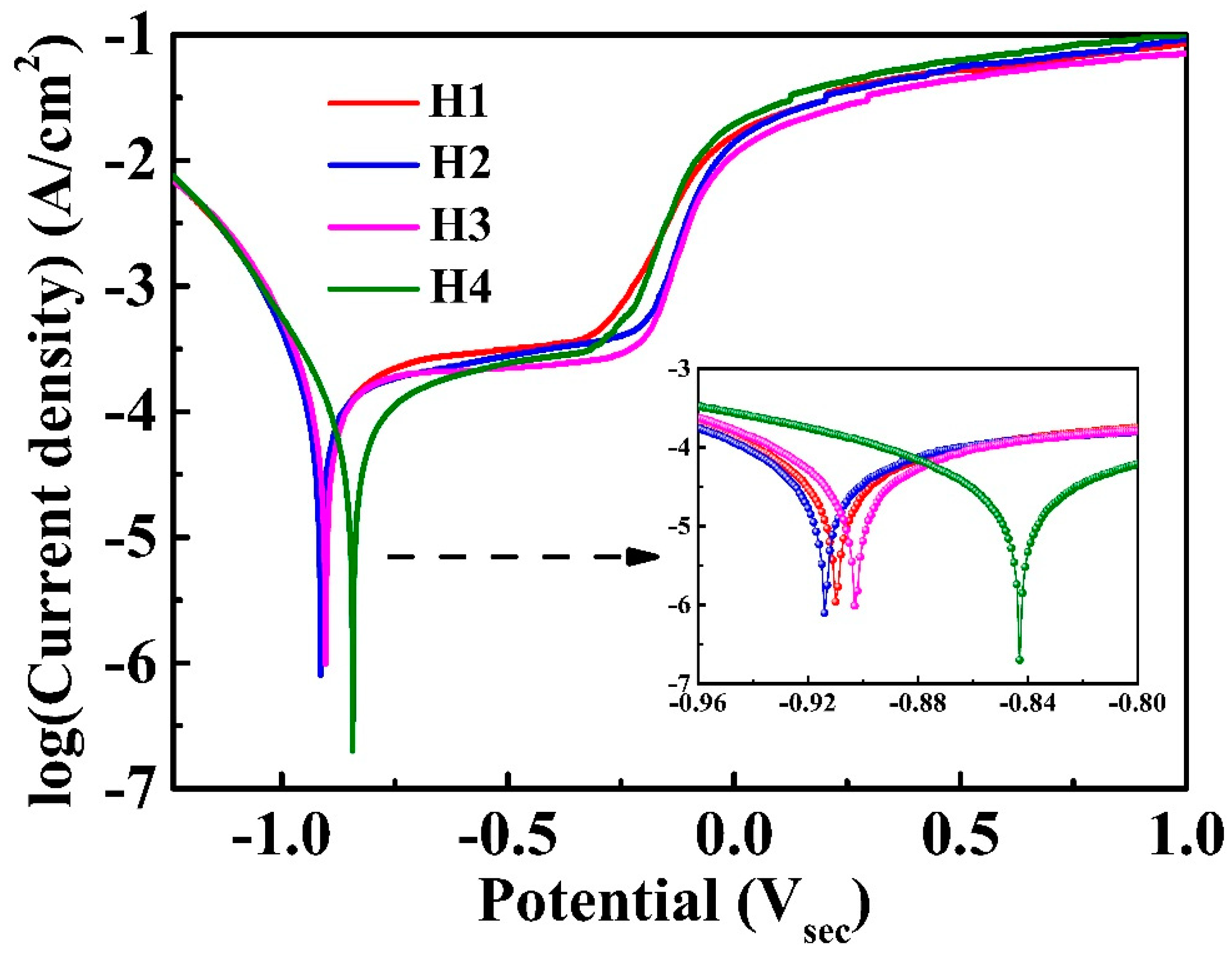

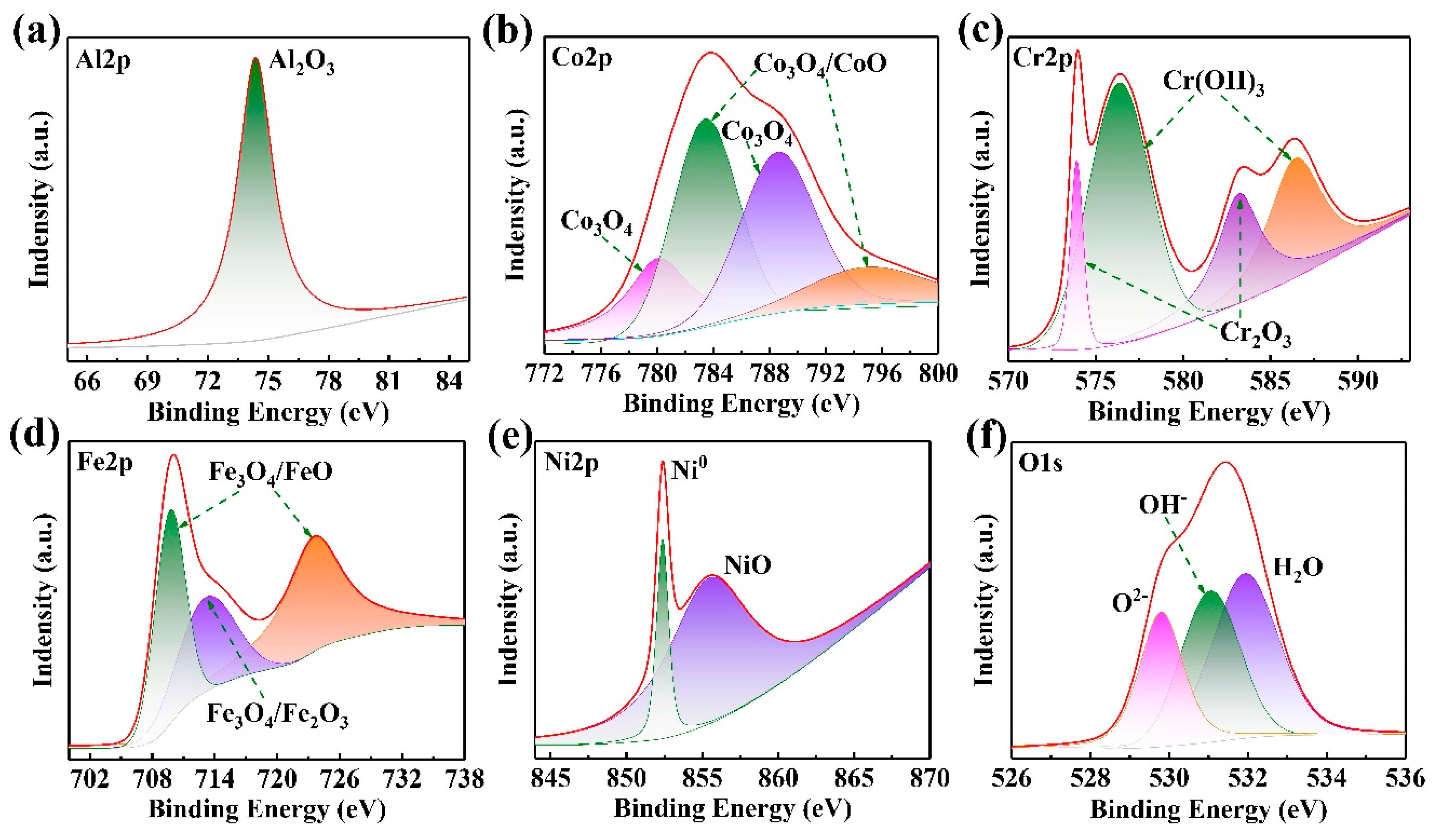

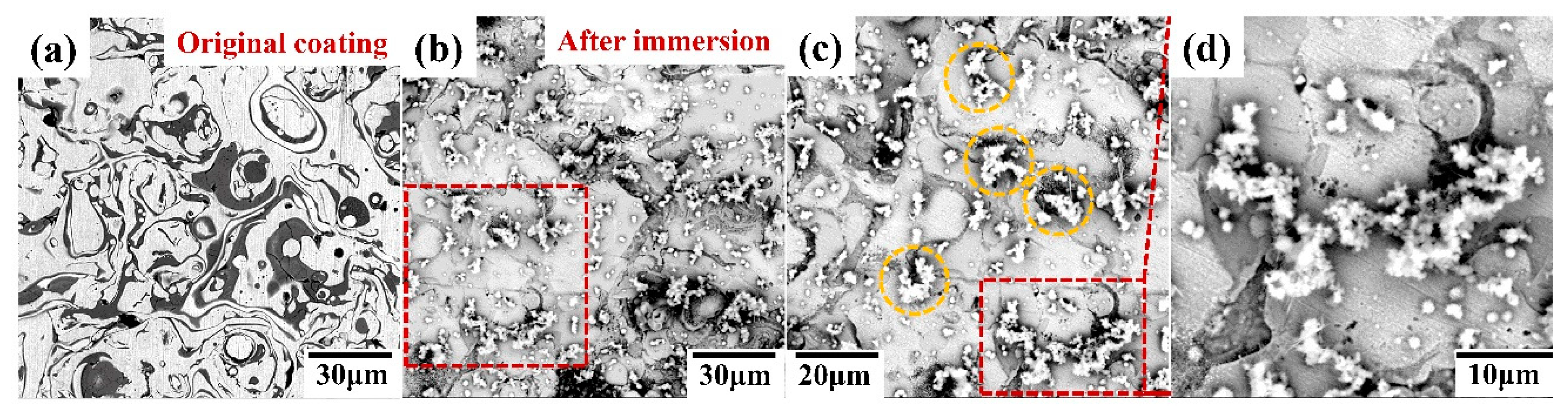

3.3. Corrosion Behavior in 3.5 wt.% NaCl Solution

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375, 213–218. [Google Scholar] [CrossRef]

- Karimi, J.; Ma, P.; Jia, Y.D.; Gokuldoss, P.K. Linear patterning of high entropy alloy by additive manufacturing. Manuf. Lett. 2020, 24, 9–13. [Google Scholar] [CrossRef]

- Wu, S.W.; Wang, G.; Wang, Q.; Jia, Y.D.; Yi, J.; Zhai, Q.J.; Liu, J.B.; Sun, B.A.; Chu, H.J.; Shen, J.; et al. Enhancement of strength-ductility trade-off in a high-entropy alloy through a heterogeneous structure. Acta Mater. 2019, 165, 444–458. [Google Scholar] [CrossRef]

- Liu, K.; Komarasamy, M.; Gwalani, B.; Shukla, S.; Mishra, R.S. Fatigue behavior of ultrafine grained triplex Al0.3CoCrFeNi high entropy alloy. Scr. Mater. 2019, 158, 116–120. [Google Scholar] [CrossRef]

- Butler, T.M.; Weaver, M.L. Oxidation behavior of arc melted AlCoCrFeNi multi-component high-entropy alloys. J. Alloys Compd. 2016, 674, 229–244. [Google Scholar] [CrossRef]

- Shi, Y.Z.; Yang, B.; Xie, X.; Brechtl, J.; Dahmen, K.A.; Liaw, P.K. Corrosion of AlxCoCrFeNi high-entropy alloys: Al-content and potential scan-rate dependent pitting behavior. Corros. Sci. 2017, 119, 33–45. [Google Scholar] [CrossRef]

- Li, Z.; Xu, H.; Gu, Y.; Pan, M.; Yu, L.; Tan, X.; Hou, X. Correlation between the magnetic properties and phase constitution of FeCoNi(CuAl)0.8Ga (0 ≤ x ≤ 0.08) high-entropy alloys. J. Alloys Compd. 2018, 746, 285–291. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, G.; Sui, X.; Liu, Y.; Li, X.; Yang, J. Microstructure and mechanical properties of ultra-fine grained MoNbTaTiV refractory high-entropy alloy fabricated by spark plasma sintering. J. Mater. Sci. Technol. 2019, 35, 2600–2607. [Google Scholar] [CrossRef]

- Liu, C.; Peng, W.; Jiang, C.S.; Guo, H.; Tao, J.; Deng, X.; Chen, Z. Composition and phase structure dependence of mechanical and magnetic properties for AlCoCuFeNi high entropy alloys. J. Mater. Sci. Technol. 2019, 35, 1175–1183. [Google Scholar] [CrossRef]

- Asghari-Rad, P.; Sathiyamoorthi, P.; Nguyen, N.T.-C.; Bae, J.W.; Shahmir, H.; Kim, H.S. Fine-tuning of mechanical properties in V10Cr15Mn5Fe35Co10Ni25 high-entropy alloy through high-pressure torsion and annealing. Mater. Sci. Eng. A 2020, 771, 138604. [Google Scholar] [CrossRef]

- Yang, T.; Zhao, Y.L.; Tong, Y.; Jiao, Z.B.; Wei, J.; Cai, J.X.; Han, X.D.; Chen, D.; Hu, A.; Kai, J.J.; et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 2018, 362, 933–937. [Google Scholar] [CrossRef] [Green Version]

- Lan, L.W.; Wang, X.J.; Guo, R.P.; Yang, H.J.; Qiao, J.W. Effect of environments and normal loads on tribological properties of nitrided Ni45(FeCoCr)40(AlTi)15 high-entropy alloys. J. Mater. Sci. Technol. 2020, 42, 85–96. [Google Scholar] [CrossRef]

- Zhang, J.; Jia, T.; Qiu, H.; Zhu, H.; Xie, Z. Effect of cooling rate upon the microstructure and mechanical properties of in-situ TiC reinforced high entropy alloy CoCrFeNi. J. Mater. Sci. Technol. 2020, 42, 122–129. [Google Scholar] [CrossRef]

- Gao, M.C.; Miracle, D.B.; Maurice, D.; Yan, X.; Zhang, Y.; Hawk, J.A. High-entropy functional materials. J. Mater. Res. 2018, 33, 3138–3155. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Liu, P.; Liaw, P.K. Microstructures and properties of high-entropy alloy films and coatings: A review. Mater. Res. Lett. 2018, 6, 199–229. [Google Scholar] [CrossRef] [Green Version]

- Yan, X.H.; Li, J.S.; Zhang, W.R.; Zhang, Y. A brief review of high-entropy films. Mater. Chem. Phys. 2018, 210, 12–19. [Google Scholar] [CrossRef]

- L Liao, W.B.; Zhang, H.; Liu, Z.Y.; Li, P.F.; Huang, J.J.; Yu, C.Y.; Lu, Y. High Strength and Deformation Mechanisms of Al0.3CoCrFeNi High-Entropy Alloy Thin Films Fabricated by Magnetron Sputtering. Entropy 2019, 21, 146. [Google Scholar] [CrossRef] [Green Version]

- Hsu, Y.C.; Li, C.L.; Hsueh, C.H. Effects of Al Addition on Microstructures and Mechanical Properties of CoCrFeMnNiAlx High Entropy Alloy Films. Entropy 2019, 22, 2. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.L.; Zhang, S.; Zhang, C.H.; Chen, J.; Dong, S.Y. Phase evolution characteristics and corrosion behavior of FeCoCrAlCu-X 0.5 coatings on cp Cu by laser high-entropy alloying. Opt. Laser Technol. 2017, 94, 68–71. [Google Scholar] [CrossRef]

- Jin, G.; Cai, Z.B.; Guan, Y.J.; Cui, X.F.; Liu, Z.; Li, Y.; Dong, M.L.; Zhang, D. High temperature wear performance of laser-cladded FeNiCoAlCu high-entropy alloy coating. Appl. Surf. Sci. 2018, 445, 113–122. [Google Scholar] [CrossRef]

- Cheng, K.C.; Chen, J.H.; Stadler, S.; Chen, S.H. Properties of atomized AlCoCrFeNi high-entropy alloy powders and their phase-adjustable coatings prepared via plasma spray process. Appl. Surf. Sci. 2019, 478, 478–486. [Google Scholar] [CrossRef]

- Yin, S.; Li, W.Y.; Song, B.; Yan, X.C.; Kuang, M.; Xu, Y.X.; Wen, K.; Lupoi, R. Deposition of FeCoNiCrMn high entropy alloy (HEA) coating via cold spraying. J. Mater. Sci. Technol. 2019, 35, 1003–1007. [Google Scholar]

- Mu, Y.K.; Jia, Y.D.; Xu, L.; Jia, Y.F.; Tan, X.H.; Yi, J.; Wang, G.; Liaw, P.K. Nano oxides reinforced high-entropy alloy coatings synthesized by atmospheric plasma spraying. Mater. Res. Lett. 2019, 7, 312–319. [Google Scholar] [CrossRef]

- Wang, B.; Huang, J.; Fan, J.H.; Dou, Y.P.; Zhu, H.; Wang, D.H. Preparation of FeCoNiCrMn High Entropy Alloy by Electrochemical Reduction of Solid Oxides in Molten Salt and Its Corrosion Behavior in Aqueous Solution. J. Electrochem. Soc. 2017, 164, E575–E579. [Google Scholar] [CrossRef]

- Lu, J.B.; Wang, B.F.; Qiu, X.K.; Peng, Z.Q.; Ma, M.X. Microstructure evolution and properties of CrCuFe x NiTi high-entropy alloy coating by plasma cladding on Q235. Surf. Coat. Technol. 2017, 328, 313–318. [Google Scholar] [CrossRef]

- Ye, Q.F.; Feng, K.; Li, Z.G.; Lu, F.G.; Li, R.F.; Huang, J.; Wu, Y.X. Microstructure and corrosion properties of CrMnFeCoNi high entropy alloy coating. Appl. Surf. Sci. 2017, 396, 1420–1426. [Google Scholar] [CrossRef]

- Jin, B.Q.; Zhang, N.N.; Guan, S.; Zhang, Y.; Li, D.Y. Microstructure and properties of laser re-melting FeCoCrNiAl0.5Six high-entropy alloy coatings. Surf. Coat. Technol. 2018, 349, 867–873. [Google Scholar] [CrossRef]

- Huang, K.J.; Lin, X.; Wang, Y.Y.; Xie, C.S.; Yue, T.M. Microstructure and corrosion resistance of Cu0·9NiAlCoCrFe high entropy alloy coating on AZ91D magnesium alloys by laser cladding. Mater. Res. Innov. 2014, 18, S2-1008–S2-1011. [Google Scholar] [CrossRef]

- Janusz, K. Plasma and Thermal Spraying; Springer Briefs in Applied Sciences and Technology: Berlin/Heidelberger, Germany, 2017. [Google Scholar]

- Díez-Pascual, A.M.; Gómez-Fatou, M.A.; Ania, F.; Flores, A. Nanoindentation in polymer nanocomposites. Prog. Mater. Sci. 2015, 67, 1–94. [Google Scholar]

- Wu, J.M.; Lin, S.J.; Yeh, J.W.; Chen, S.K.; Huang, Y.S.; Chen, H.C. Adhesive wear behavior of AlxCoCrCuFeNi high-entropy alloys as a function of aluminum content. Wear 2006, 261, 513–519. [Google Scholar] [CrossRef] [Green Version]

- Ian, H.; Philip, S. Tribology: Friction and Wear of Engineering Materials, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Fauchais, P.L.; Heberlein, J.V.R.; Boulos, M.I. Thermal Spray Fundamentals from Powder to Part; Springer: New York, NY, USA, 2014. [Google Scholar]

- Telliskivi, T. Simulation of wear in a rolling–sliding contact by a semi-Winkler model and the Archard’s wear law. Wear 2004, 256, 817–831. [Google Scholar] [CrossRef]

- Luo, H.; Li, Z.M.; Mingers, A.M.; Raabe, D. Corrosion behavior of an equiatomic CoCrFeMnNi high-entropy alloy compared with 304 stainless steel in sulfuric acid solution. Corros. Sci. 2018, 134, 131–139. [Google Scholar] [CrossRef]

- Wei, L.; Liu, Y.; Li, Q.; Cheng, Y.F. Effect of roughness on general corrosion and pitting of (FeCoCrNi)0.89(WC)0.11 high-entropy alloy composite in 3.5 wt.% NaCl solution. Corros. Sci. 2019, 146, 44–57. [Google Scholar] [CrossRef]

- Koga, G.Y.; Wolf, W.; Schulz, R.; Savoie, S.; Bolfarini, C.; Kiminami, C.S.; Botta, W.J. Corrosion and wear properties of FeCrMnCoSi HVOF coatings. Surf. Coat. Technol. 2019, 357, 993–1003. [Google Scholar] [CrossRef]

- Kuang, W.J.; Wu, X.Q.; Han, E.H. Influence of dissolved oxygen concentration on the oxide film formed on 304 stainless steel in high temperature water. Corros. Sci. 2012, 63, 259–266. [Google Scholar] [CrossRef]

- Han, G.D.; Lu, Z.P.; Ru, X.K.; Chen, J.J.; Zhang, J.L.; Shoji, T. Properties of oxide films formed on 316L SS and model alloys with modified Ni, Cr and Si contents in high temperature water. Corros. Sci. 2016, 106, 157–171. [Google Scholar] [CrossRef]

- Quiambao, K.F.; McDonnell, S.J.; Schreiber, D.K.; Gerard, A.Y.; Freedy, K.M.; Lu, P.; Saal, J.E.; Frankel, G.S.; Scully, J.R. Passivation of a corrosion resistant high entropy alloy in non-oxidizing sulfate solutions. Acta Mater. 2019, 164, 362–376. [Google Scholar] [CrossRef]

- Zhou, Q.Y.; Sheikh, S.; Ou, P.; Chen, D.C.; Hu, Q.; Guo, S. Corrosion behavior of Hf0.5Nb0.5Ta0.5Ti1.5Zr refractory high-entropy in aqueous chloride solutions. Electrochem. Commun. 2019, 98, 63–68. [Google Scholar] [CrossRef]

| Samples/ Parameters | Current (A) | Voltage (V) | Ar (Slpm) | H2 (Slpm) | Spraying Distance (mm) | Powders Feeding Rate (g/min) |

|---|---|---|---|---|---|---|

| H1 | 550 | 43.6 | 45 | 0.7 | 117 | 35 |

| H2 | 550 | 46.7 | 45 | 1.1 | 117 | 35 |

| H3 | 550 | 51.2 | 45 | 1.9 | 117 | 35 |

| H4 | 550 | 55.4 | 45 | 2.7 | 117 | 35 |

| Parameters/Samples | Substrate | H1 | H2 | H3 | H4 |

|---|---|---|---|---|---|

| Hardness (H)/GPa | 4.04 ± 0.05 | 4.94 ± 0.08 | 5.48 ± 0.05 | 5.83 ± 0.07 | 5.97 ± 0.08 |

| Young modulus (E)/GPa | 139 ± 5 | 118 ± 6 | 151 ± 5 | 142 ± 4 | 160 ± 8 |

| Regions/Composition | Al | Co | Cr | Fe | Ni | O |

|---|---|---|---|---|---|---|

| Delamination | 12.24 | 8.47 | 9.72 | 46.01 | 9.29 | 14.27 |

| Debris | 18.84 | 6.99 | 15.70 | 22.73 | 15.52 | 20.22 |

| Flaky debris | 10.41 | 9.20 | 19.34 | 29.77 | 13.29 | 17.99 |

| Adhesive layer | 12.79 | 9.11 | 18.21 | 25.44 | 14.67 | 19.78 |

| Samples/Parameters | Ecorr (V) | Epit (V) | ΔEp | log(Icorr) (A/cm2) |

|---|---|---|---|---|

| H1 | −0.91 ± 0.04 | −0.28 ± 0.04 | 0.63 | −4.09 ± 0.18 |

| H2 | −0.91 ± 0.02 | −0.23 ± 0.03 | 0.68 | −4.15 ± 0.10 |

| H3 | −0.90 ± 0.02 | −0.26 ± 0.04 | 0.64 | −4.26 ± 0.09 |

| H4 | −0.84 ± 0.01 | −0.24 ± 0.02 | 0.60 | −4.47 ± 0.04 |

| Samples/Parameters | Re (Ω cm2) | Qdl | Rct (Ω·cm2) | Qdiff | ||

|---|---|---|---|---|---|---|

| Y0 (Ω−1·cm−2sn) | ndl | Y0 (Ω−1·cm−2sn) | ndiff | |||

| H1 | 13.69 | 5.11 × 10−5 | 0.90 | 276 | 5.67 × 10−2 | 0.64 |

| H2 | 12.21 | 2.44 × 10−5 | 0.89 | 367 | 3.73 × 10−2 | 0.58 |

| H3 | 17.49 | 1.12 × 10−5 | 0.90 | 649 | / | / |

| H4 | 11.44 | 9.48 × 10−4 | 0.93 | 1245 | / | / |

| Regions/Composition (at.%) | Al | Co | Cr | Fe | Ni | O |

|---|---|---|---|---|---|---|

| Immersion surface | 5.73 | 1.85 | 10.39 | 25.59 | 5.46 | 50.98 |

| Flocculent particles | 6.49 | 3.33 | 11.92 | 21.07 | 6.32 | 50.87 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mu, Y.; Zhang, L.; Xu, L.; Prashanth, K.; Zhang, N.; Ma, X.; Jia, Y.; Xu, Y.; Jia, Y.; Wang, G. Frictional Wear and Corrosion Behavior of AlCoCrFeNi High-Entropy Alloy Coatings Synthesized by Atmospheric Plasma Spraying. Entropy 2020, 22, 740. https://doi.org/10.3390/e22070740

Mu Y, Zhang L, Xu L, Prashanth K, Zhang N, Ma X, Jia Y, Xu Y, Jia Y, Wang G. Frictional Wear and Corrosion Behavior of AlCoCrFeNi High-Entropy Alloy Coatings Synthesized by Atmospheric Plasma Spraying. Entropy. 2020; 22(7):740. https://doi.org/10.3390/e22070740

Chicago/Turabian StyleMu, Yongkun, Liangbo Zhang, Long Xu, Kondagokuldoss Prashanth, Nizhen Zhang, Xindi Ma, Yuefei Jia, Yulai Xu, Yandong Jia, and Gang Wang. 2020. "Frictional Wear and Corrosion Behavior of AlCoCrFeNi High-Entropy Alloy Coatings Synthesized by Atmospheric Plasma Spraying" Entropy 22, no. 7: 740. https://doi.org/10.3390/e22070740

APA StyleMu, Y., Zhang, L., Xu, L., Prashanth, K., Zhang, N., Ma, X., Jia, Y., Xu, Y., Jia, Y., & Wang, G. (2020). Frictional Wear and Corrosion Behavior of AlCoCrFeNi High-Entropy Alloy Coatings Synthesized by Atmospheric Plasma Spraying. Entropy, 22(7), 740. https://doi.org/10.3390/e22070740