Fault Diagnosis for Rolling Bearings Using Optimized Variational Mode Decomposition and Resonance Demodulation

Abstract

1. Introduction

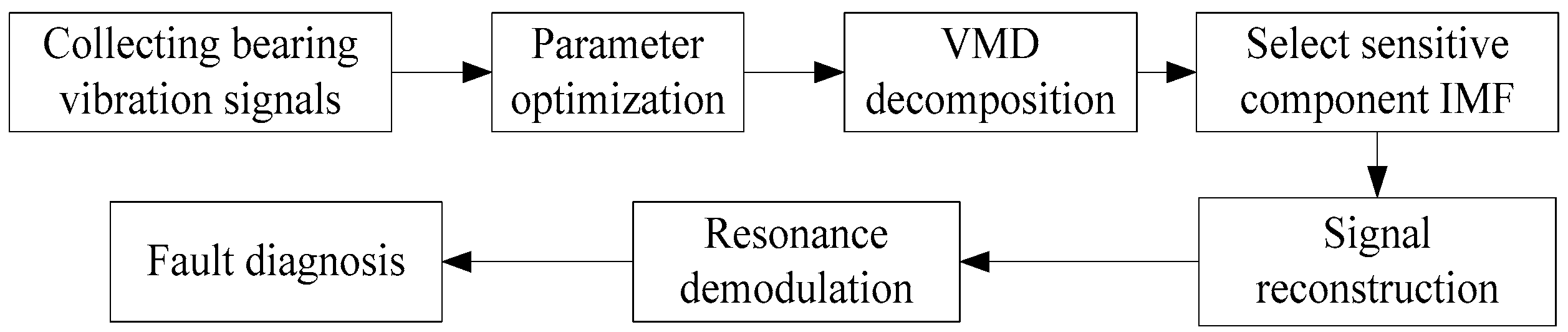

- A novel fault diagnosis method (GNVRFD) proposed to effectively realize the fault diagnosis of locomotive rolling bearings.

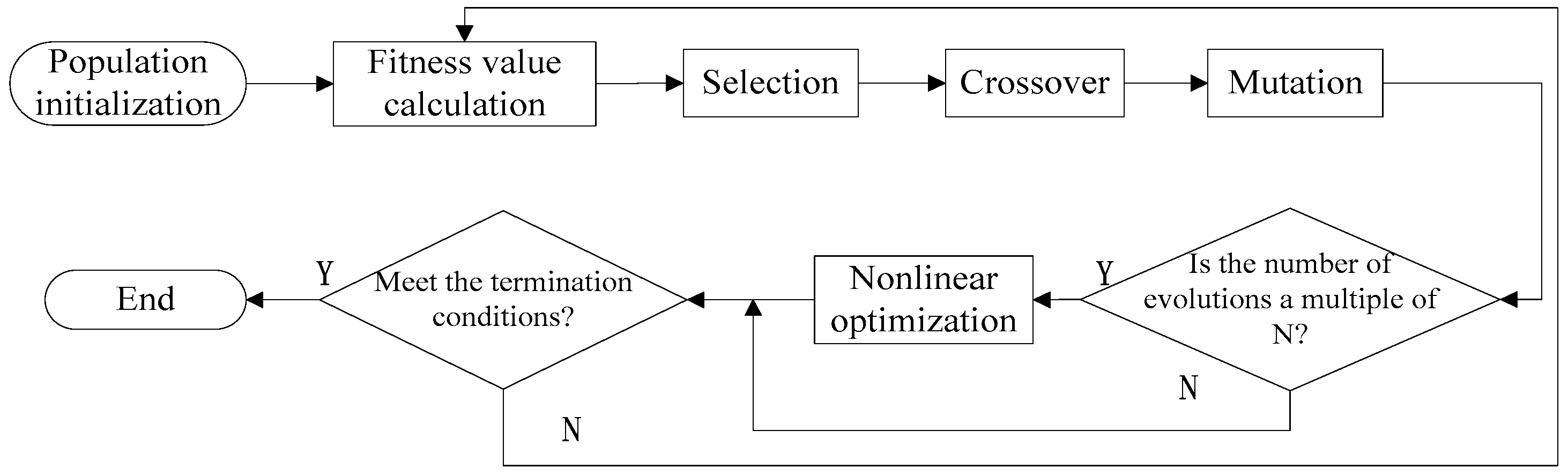

- A novel parameter optimization algorithm for VMD is designed to adaptively optimize the parameters.

- The resonance demodulation technology is employed to decompose the reconstructed vibration signal in order to obtain the envelope spectrum and the fault frequency.

- The effectiveness of GNVRFD is extensively investigated by the actual data of rolling bearings.

2. Basic Methods

2.1. VMD

- Step 1. Initialize ,,,.

- Step 2. Set the number of iterations .

- Step 3. For k = 1:K

- Update function for all .

- Update function .

- Step 4. For all , the following expression is executed.where represents the noise margin parameter. When the signal contains more interference, in order to reduce the influence of the interference signal, set .

- Step 5. Repeat Step 2~ Step 4 until the constraint is met.

2.2. Resonance Demodulation Technolgy

2.3. Information Entropy

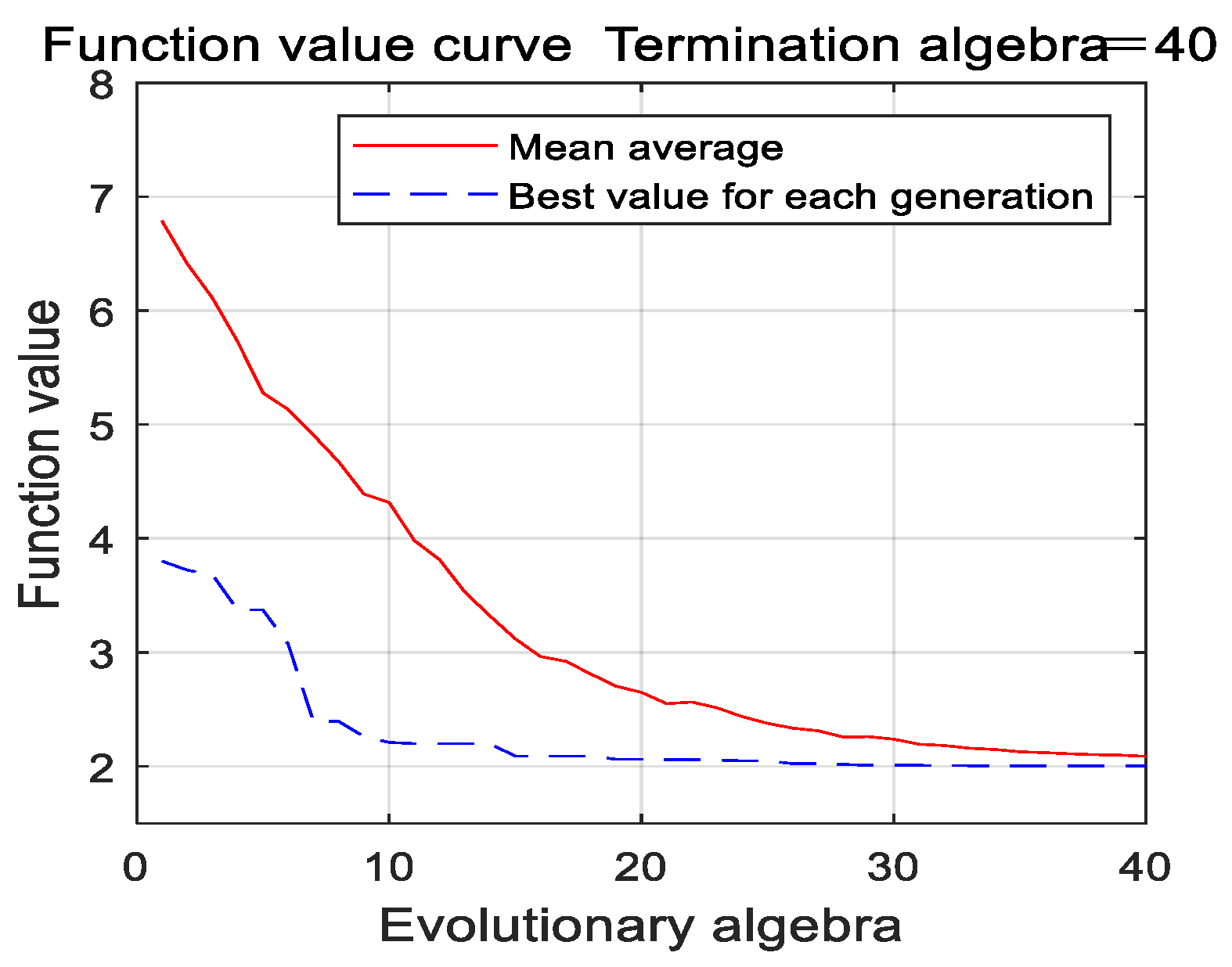

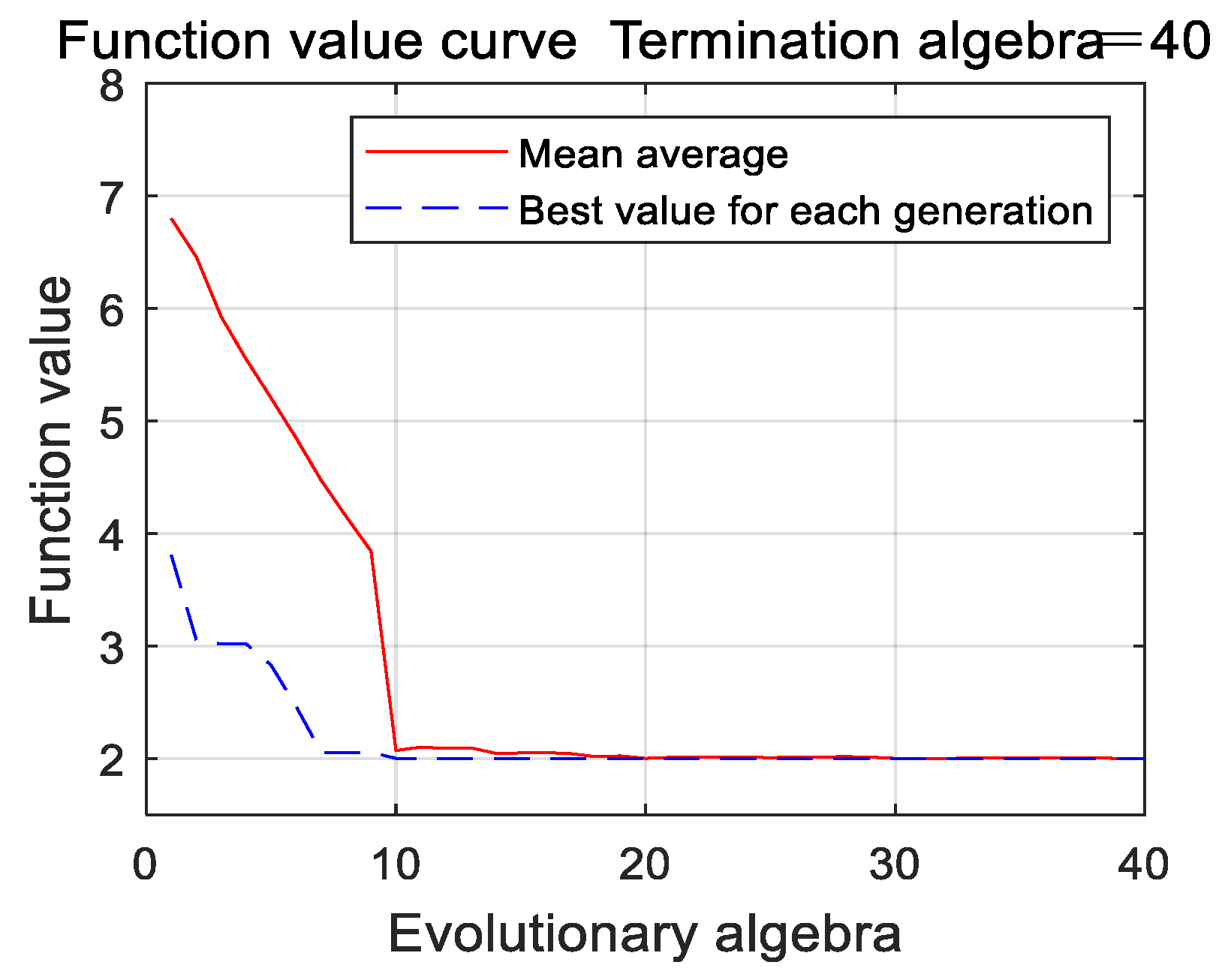

3. Parameter Optimization of VMD

4. A Novel Fault Diagnosis Method (GNVRFD)

4.1. Novel Fault Diagnosis Method

4.2. Implementation Steps of the GNVRFD

- Step 1. Initialize the parameters of the proposed GNVRFD method.

- Step 2. The designed parameter optimization algorithm is used to determine the modal number k and the penalty factor ∂ of the VMD.

- Step 3. The signal entropy function of the collected bearing vibration signal is used as an intermediate link to ensure the accuracy of the decomposition process.

- Step 4. According to the determined decomposition parameter, the collected vibration signal of rolling bearings is decomposed by the optimized VMD, and each modal component is output as a kurtosis value.

- Step 5. Among the obtained variables by the decomposition, two components with more sensitive kurtosis values are selected according to the maximum value principle to reconstruct the signal, and the reconstructed signal is subjected to resonance demodulation.

- Step 6. The envelope spectrum obtained by resonance demodulation can directly obtain the peak value of the vibration frequency of the locomotive rolling bearings.

- Step 7. Determine whether there is a potential fault of the locomotive rolling bearings and achieve the diagnosis of the locomotive rolling bearings.

5. Case Analysis

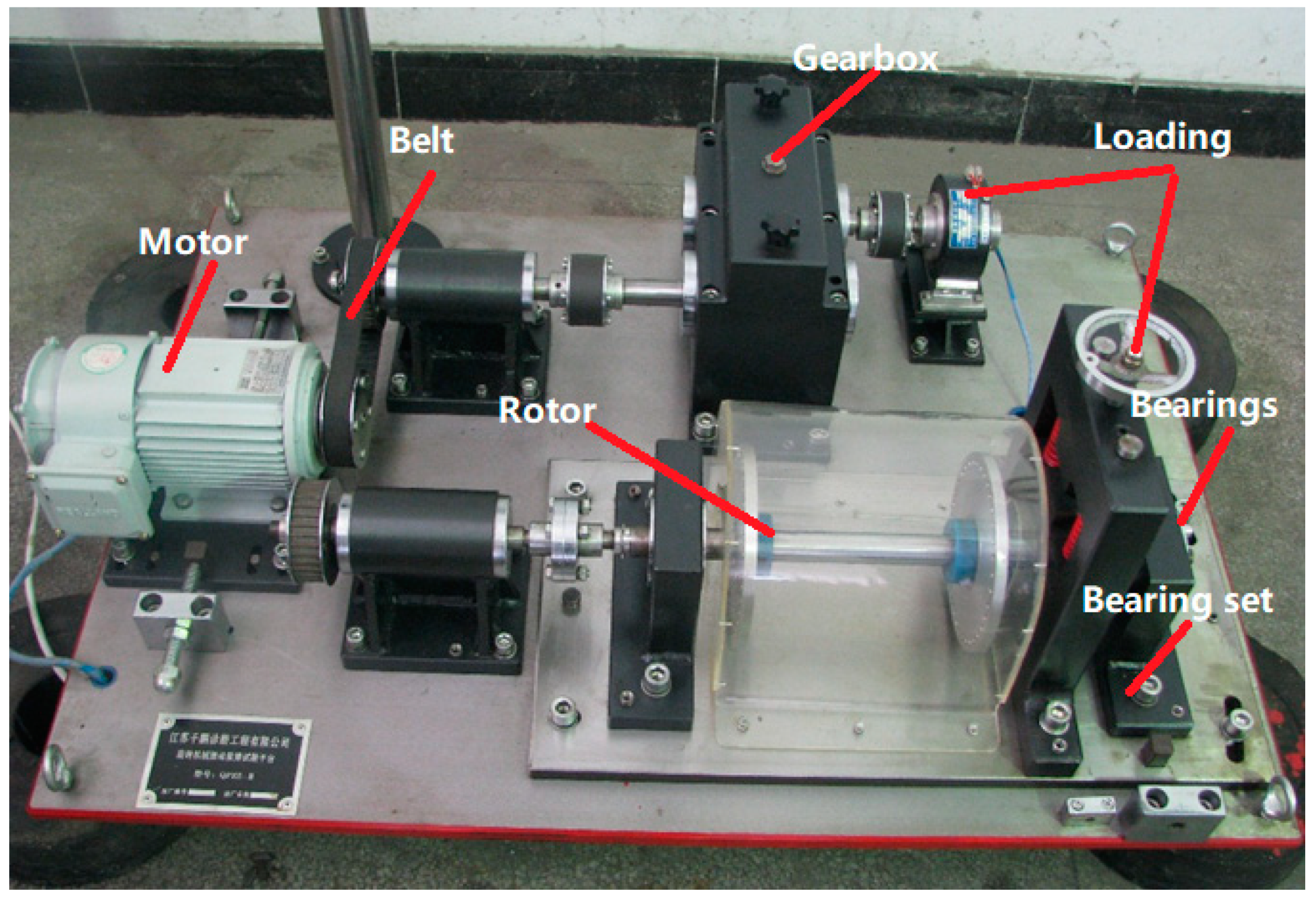

5.1. Data Source and Experimental Environment

BPFI = 900/60*1/2*13*[1 + (24/39)*cos0] = 157.5 Hz

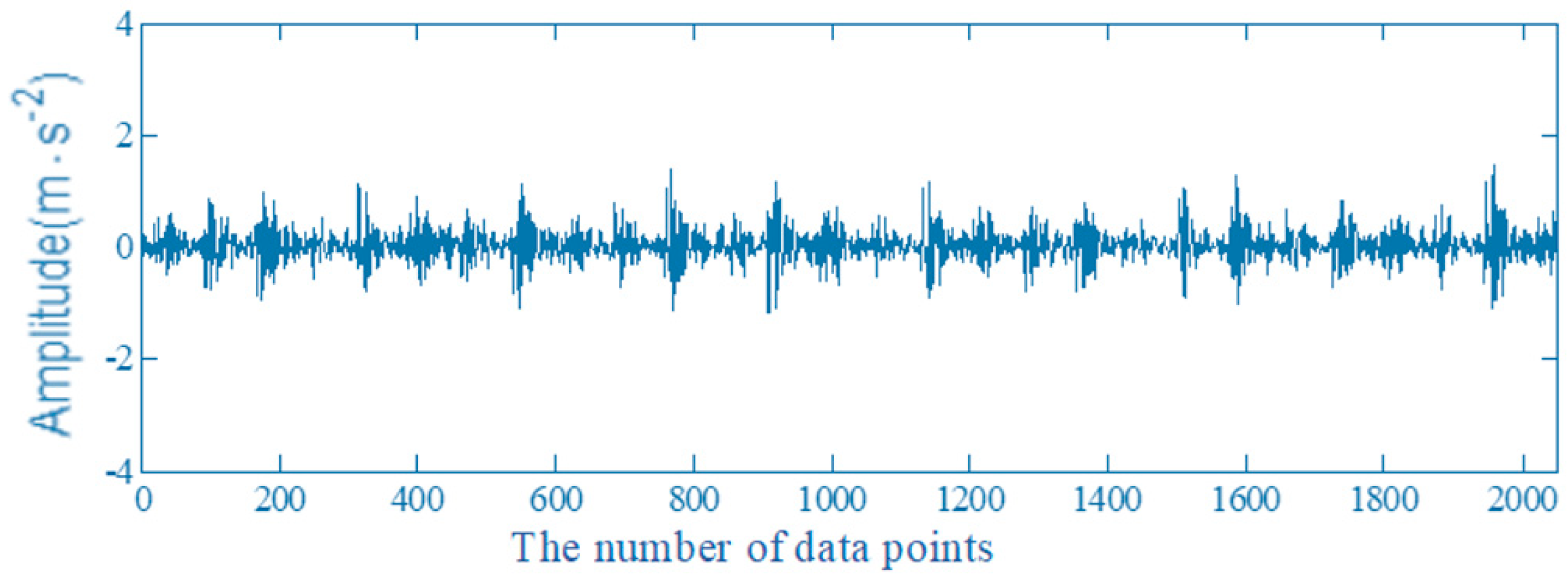

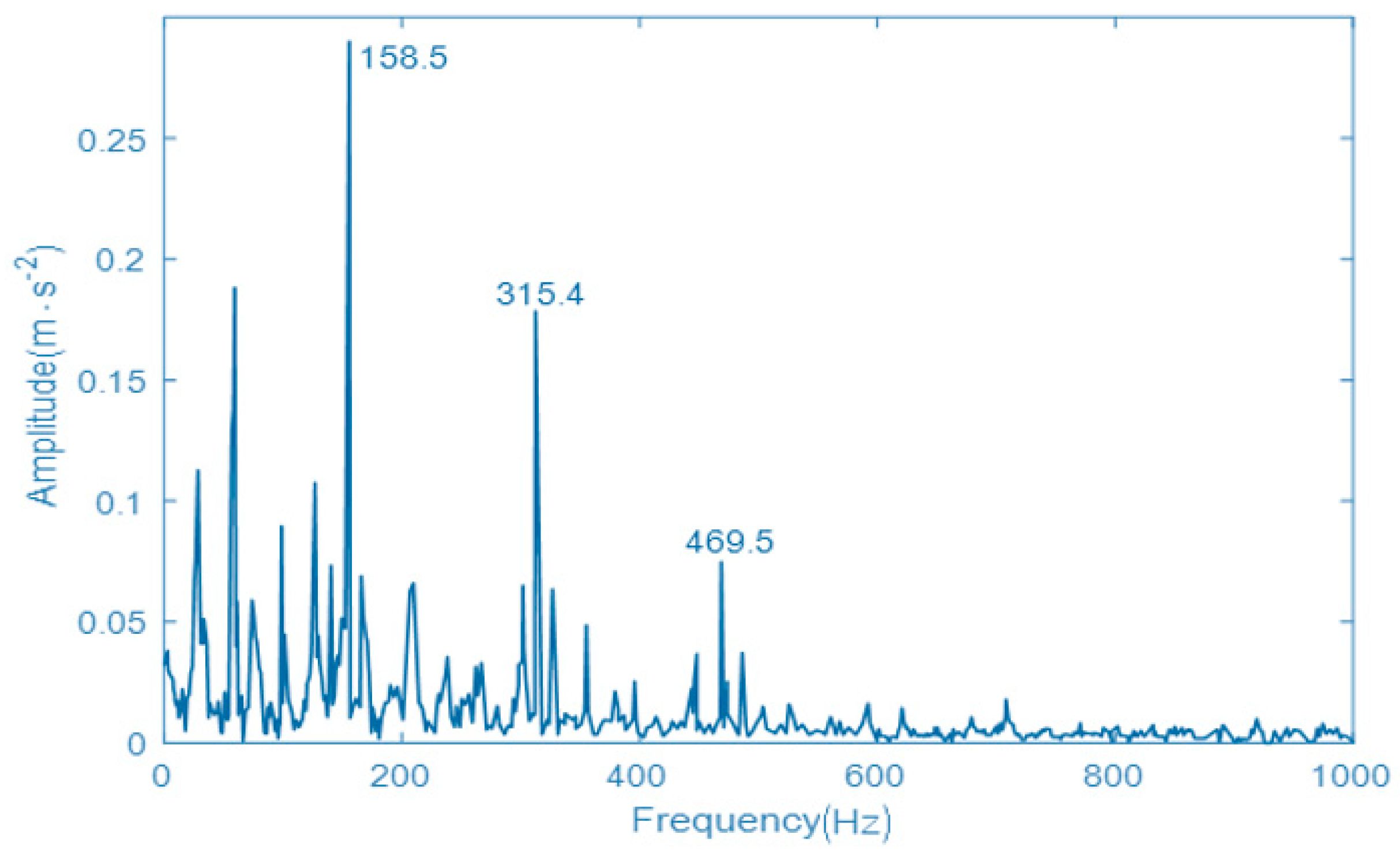

5.2. Experimental Result and Analysis

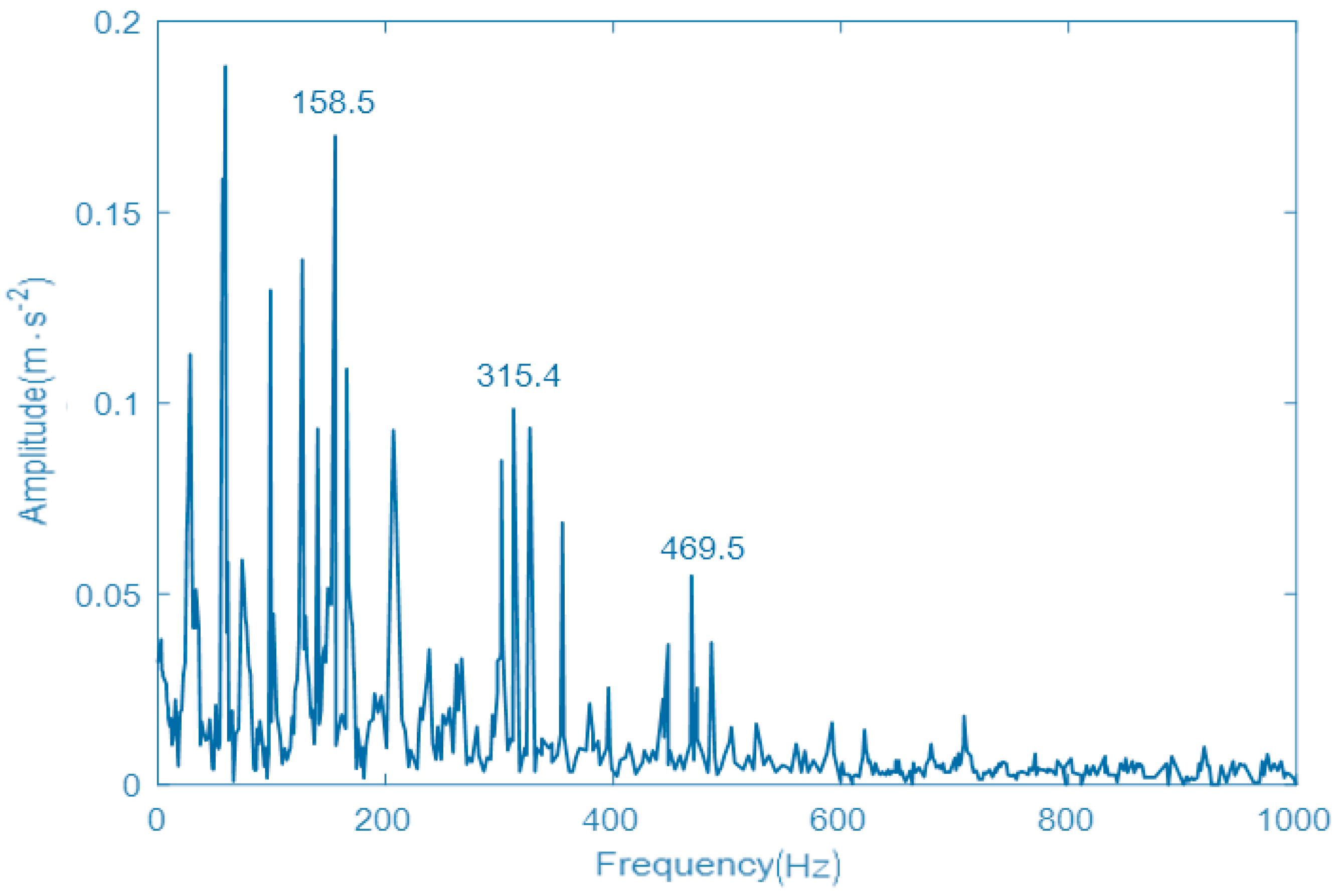

5.3. Comparison and Analysis

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, Y.; Cheng, G.; Liu, C.; Chen, X.H. Study on planetary gear fault diagnosis based on variational mode decomposition and deep neural networks. Measurement 2018, 130, 94–104. [Google Scholar] [CrossRef]

- He, Z.; Shao, H.; Zhang, X.; Cheng, J.; Yang, Y. Improved deep transfer auto-encoder for fault diagnosis of gearbox under variable working conditions with small training samples. IEEE Access 2019, 7, 115368–115377. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, H.; Heidari, A.A. An efficient chaotic mutative moth-flame-inspired optimizer for global optimization tasks. Expert Syst. Appl. 2019, 129, 135–155. [Google Scholar] [CrossRef]

- Rabi, J.; Balusamy, T.; Raj Jawahar, R. Analysis of vibration signal responses on pre induced tunnel defects in friction stir welding using wavelet transform and empirical mode decomposition. Def. Technol. 2019, 15, 885–896. [Google Scholar] [CrossRef]

- Shao, H.; Cheng, J.; Jiang, H.; Yang, Y.; Wu, Z. Enhanced deep gated recurrent unit and complex wavelet packet energy moment entropy for fault prognosis of bearing. Knowl. Based Syst. 2019, 188, 105022. [Google Scholar] [CrossRef]

- Seo, S.H.; Kim, Y.H.; Kim, K.J. Design of silencer using resonator arrays with high sound pressure and grazing flow. Appl. Acous. 2018, 138, 188–198. [Google Scholar] [CrossRef]

- Deng, W.; Li, W.; Yang, X.H. A novel hybrid optimization algorithm of computational intelligence techniques for highway passenger volume prediction. Expert Syst. Appl. 2011, 38, 4198–4205. [Google Scholar] [CrossRef]

- Seo, D.H.; Choi, J.W.; Kim, Y.H. Impulsive sound source localization using peak and RMS estimation of the time-domain beamformer output. Mech. Syst. Signal Pr. 2014, 49, 95–105. [Google Scholar] [CrossRef]

- Zhao, H.M.; Zuo, S.Y.; Hou, M.; Liu, W.; Yu, L.; Yang, X.H.; Deng, W. A novel adaptive signal processing method based on enhanced empirical wavelet transform technology. Sensors 2018, 18, 3323. [Google Scholar] [CrossRef]

- Park, C.S.; Jeon, J.H.; Kim, Y.H. Localization of a sound source in a noisy environment by hyperbolic curves in quefrency domain. J. Sound Vib. 2014, 333, 5630–5640. [Google Scholar] [CrossRef]

- Park, C.S.; Choi, Y.C.; Kim, Y.H. Early fault detection in automotive ball bearings using the minimum variance cepstrum. Mech. Syst. Signal Pr. 2013, 38, 534–548. [Google Scholar] [CrossRef]

- Li, L.; Cai, H.Y.; Han, H.X.; Jiang, Q.T. Adaptive short-time Fourier transform and synchrosqueezing transform for non-stationary signal separation. Signal Process. 2020, 166, 107231. [Google Scholar] [CrossRef]

- Fu, H.L.; Wang, M.M.; Li, P. Tracing knowledge development trajectories of the internet of things domain: A main path analysis. IEEE Trans. Ind. Inf. 2019, 15, 6531–6540. [Google Scholar] [CrossRef]

- Xue, Y.; Xue, B.; Zhang, M. Self-adaptive particle swarm optimization for large-scale feature selection in classification. ACM Trans. Knowl. Discov. Data 2019, 13, 50. [Google Scholar] [CrossRef]

- Yang, H.; Gong, S.S.; Liu, Y.Q.; Lin, Z.K.; Qu, Y. A multi-task learning model for daily activity forecast in smart home. Sensors 2020, 20, 1933. [Google Scholar] [CrossRef]

- Mateo, C.; Talavera, J.A. Short-time Fourier transform with the window size fixed in the frequency domain. Digit. Signal Process. 2018, 77, 13–21. [Google Scholar] [CrossRef]

- Pucciarelli, G. Wavelet analysis in volcanology: The case of phlegrean fields. J. Environ. Sci. Eng. 2017, A6, 300–307. [Google Scholar]

- Deng, W.; Liu, H.; Xu, J.; Zhao, H.; Song, Y. An improved quantum-inspired differential evolution algorithm for deep belief network. IEEE Trans. Instrum. Meas. 2020. [Google Scholar] [CrossRef]

- Upadhyay, N.; Kankar, P.K. Diagnosis of bearing defects using tunable Q-wavelet transform. J. Mech. Sci. Technol. 2018, 32, 549–558. [Google Scholar] [CrossRef]

- Liu, Y.; Mu, Y.; Chen, K. Daily activity feature selection in smart homes based on pearson correlation coefficient. Neural Process. Lett. 2020, 51, 1771–1787. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, H.; Luo, J. Enhanced Moth-flame optimizer with mutation strategy for global optimization. Inf. Sci. 2019, 492, 181–203. [Google Scholar] [CrossRef]

- Xia, S.Q.; Zhang, J.H.; Ye, S.G.; Xu, B.; Xiang, J.W.; Tang, H.S. A mechanical fault detection strategy based on the doubly iterative empirical mode decomposition. Appl. Acoust. 2019, 155, 346–357. [Google Scholar] [CrossRef]

- Zhao, H.; Zheng, J.; Xu, J.; Deng, W. Fault diagnosis method based on principal component analysis and broad learning system. IEEE ACCESS 2019, 7, 99263–99272. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, Z.; Chen, B.; Zhang, W.; Huang, G. An improved complementary ensemble empirical mode decomposition with adaptive noise and its application to rolling element bearing fault diagnosis. ISA Trans. 2019, 91, 218–234. [Google Scholar] [CrossRef]

- Deng, W.; Xu, J.; Zhao, H. An improved ant colony optimization algorithm based on hybrid strategies for scheduling problem. IEEE Access 2019, 7, 20281–20292. [Google Scholar] [CrossRef]

- Deng, W.; Yao, R.; Zhao, H.; Yang, X.; Li, G. A novel intelligent diagnosis method using optimal LS-SVM with improved PSO algorithm. Soft Comput. 2017, 23, 2445–2462. [Google Scholar] [CrossRef]

- Wang, Y.X.; Liu, F.Y.; Jiang, Z.S.; He, S.L.; Mo, Q.Y. Complex variational mode decomposition for signal processing applications. Mech. Syst. Signal Process. 2017, 86, 75–85. [Google Scholar] [CrossRef]

- Chen, R.; Guo, S.K.; Wang, X.Z.; Zhang, T.L. Fusion of multi-RSMOTE with fuzzy integral to classify bug reports with an imbalanced distribution. IEEE Trans. Fuzzy Syst. 2019, 27, 2406–2420. [Google Scholar] [CrossRef]

- Deng, W.; Xu, J.; Song, Y.; Zhao, H. An effective improved co-evolution ant colony optimization algorithm with multi-strategies and its application. Int. J. Bio-Inspired Comput. 2020, 1–10. [Google Scholar]

- Liu, X.; Liu, X.; Luo, X.; Fu, H.; Wang, M.; Li, L. Impact of Different policy instruments on diffusing energy consumption monitoring technology in public buildings: Evidence from Xi’an, China. J. Clean. Prod. 2020, 251, 119693. [Google Scholar] [CrossRef]

- Wang, Z.; Ji, Z.; Wang, X.; Wu, T.; Huang, W. A new parallel DNA algorithm to solve the task scheduling problem based on inspired computational model. BioSystems 2017, 162, 59–65. [Google Scholar] [CrossRef]

- Shi, P.M.; Ding, X.J.; Han, D.Y. Study on multi-frequency weak signal detection method based on stochastic resonance tuning by multi-scale noise. Measurement 2014, 47, 540–546. [Google Scholar] [CrossRef]

- Deng, W.; Zhao, H.M.; Zou, L.; Li, G.Y.; Yang, X.H.; Wu, D.Q. A novel collaborative optimization algorithm in solving complex optimization problems. Soft Comput. 2017, 21, 4387–4398. [Google Scholar] [CrossRef]

- Zhao, H.; Li, D.; Yang, X.; Deng, W. Research on vibration suppression method of alternating current motor based on fractional order control strategy. Proc. Inst. Mech. Eng. Part E J. Pro. Mech. Eng. 2017, 231, 786–799. [Google Scholar] [CrossRef]

- Zheng, J.; Yuan, Y.; Zou, L.; Deng, W.; Guo, C.; Zhao, H. Study on a novel fault diagnosis method based on VMD and BLM. Symmetry 2019, 11, 747. [Google Scholar] [CrossRef]

- Luo, J.; Chen, H.; Heidari, A.A.; Xu, Y.; Zhang, Q.; Li, C. Multi-strategy boosted mutative whale-inspired optimization approaches. Appl. Math. Model. 2019, 73, 109–123. [Google Scholar] [CrossRef]

- Deng, W.; Zhao, H.; Yang, X.; Xiong, J.; Sun, M.; Li, B. Study on an improved adaptive PSO algorithm for solving multi-objective gate assignment. Appl. Soft Comput. 2017, 59, 288–302. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Wang, X.X.; Zhai, Z.G. Timely daily activity recognition from headmost sensor events. ISA Trans. 2019, 94, 379–390. [Google Scholar] [CrossRef]

- Li, T.; Qian, Z.; He, T. Short-term load forecasting with improved CEEMDAN and GWO-based multiple kernel ELM. Complexity 2020, 2020, 1209547. [Google Scholar] [CrossRef]

- Zhao, H.; Zheng, J.; Deng, W.; Song, Y. Semi-supervised broad learning system based on manifold regularization and broad network. IEEE Trans. Circuits Syst. I 2020, 67, 983–994. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.-C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. A Math. Phys. Eng. Sci. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Li, T.; Shi, J.; Li, X. Image encryption based on pixel-level diffusion with dynamic filtering and DNA-level permutation with 3D Latin cubes. Entropy 2019, 21, 319. [Google Scholar] [CrossRef]

- Dragomiretskiy, K.; Zosso, D. Variational Mode Decomposition. IEEE Trans. Signal Process. 2014, 62, 31–44. [Google Scholar] [CrossRef]

- Bian, J. Bearing fault diagnosis based on genetic algorithm parameter optimization variational modal decomposition combined with 1.5-dimensional spectrum. Propuls. Technol. 2017, 38, 1618–1624. [Google Scholar]

- He, K.; Liao, Y.S.; Zhang, B.X.; Wang, Y. Research on fault detection of rolling bearings based on variational mode decomposition method and resonance demodulation technology. Mach. Manuf. 2018, 56, 94–96. [Google Scholar]

- Quaranta, G.; Mollaioli, F. Analysis of near-fault pulse-like seismic signals through variational mode decomposition technique. Eng. Struct. 2019, 193, 121–135. [Google Scholar] [CrossRef]

- Shan, Y.; Zhou, J.; Jiang, W.; Liu, J.; Xu, Y.; Zhao, Y. A fault diagnosis method for rotating machinery based on improved variational mode decomposition and a hybrid artificial sheep algorithm. Meas. Sci. Technol. 2019, 30, 055002. [Google Scholar] [CrossRef]

- Ma, P.; Zhang, H.; Fan, W.; Wang, C. Early fault detection of bearings based on adaptive variational mode decomposition and local tangent space alignment. Eng. Comput. 2019, 36, 509–532. [Google Scholar] [CrossRef]

- Wang, Z.; Ren, X.; Ji, Z.; Huang, W.; Wu, T. A novel bio-heuristic computing algorithm to solve the capacitated vehicle routing problem based on Adleman–Lipton model. Biosystems 2019, 184, 103997. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, H.; Xu, J.; Deng, W. Performance prediction using high-order differential mathematical morphology gradient spectrum entropy and extreme learning machine. IEEE Trans. Instrum. Meas. 2020, 69, 4165–4172. [Google Scholar] [CrossRef]

- Ma, H.; Tong, Q.; Zhang, Y. Application of variational modal decomposition of optimized parameters in fault diagnosis of rolling bearings. China Mech. Eng. 2018, 29, 390–397. [Google Scholar]

| Model | Pitch | Inside Diameter | Number of Rollers | Roller Diameter | Contact Angle |

|---|---|---|---|---|---|

| N205EM | D(mm) | d(mm) | z | d2(mm) | α |

| Cylindrical Roller Bearings | 39 | 24 | 13 | 7.5 | 0 |

| IMF | IMF1 | IMF2 | IMF3 | IMF4 | IMF5 |

|---|---|---|---|---|---|

| Kurtosis | 1.2132 | 2.8463 | 3.7825 | 1.6542 | 4.6253 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Wang, Y.; Deng, W. Fault Diagnosis for Rolling Bearings Using Optimized Variational Mode Decomposition and Resonance Demodulation. Entropy 2020, 22, 739. https://doi.org/10.3390/e22070739

Zhang C, Wang Y, Deng W. Fault Diagnosis for Rolling Bearings Using Optimized Variational Mode Decomposition and Resonance Demodulation. Entropy. 2020; 22(7):739. https://doi.org/10.3390/e22070739

Chicago/Turabian StyleZhang, Chunguang, Yao Wang, and Wu Deng. 2020. "Fault Diagnosis for Rolling Bearings Using Optimized Variational Mode Decomposition and Resonance Demodulation" Entropy 22, no. 7: 739. https://doi.org/10.3390/e22070739

APA StyleZhang, C., Wang, Y., & Deng, W. (2020). Fault Diagnosis for Rolling Bearings Using Optimized Variational Mode Decomposition and Resonance Demodulation. Entropy, 22(7), 739. https://doi.org/10.3390/e22070739