Control and Entropy Analysis of Corner Flow Separation in a Compressor Cascade Using Streamwise Grooves

Abstract

1. Introduction

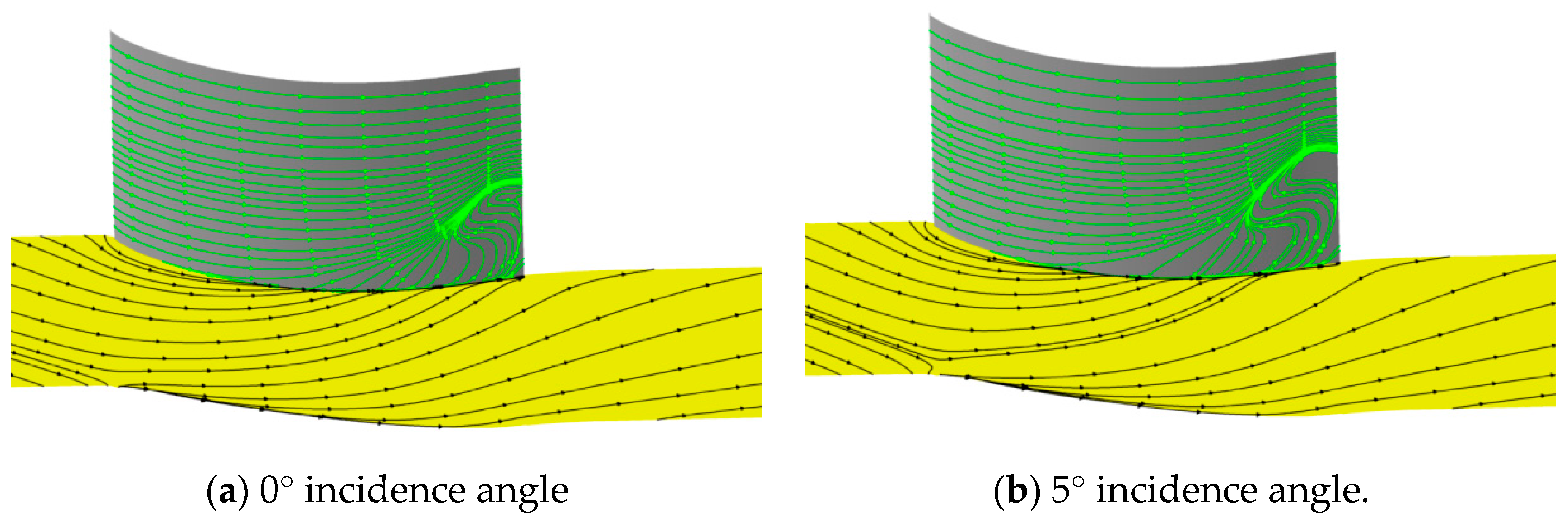

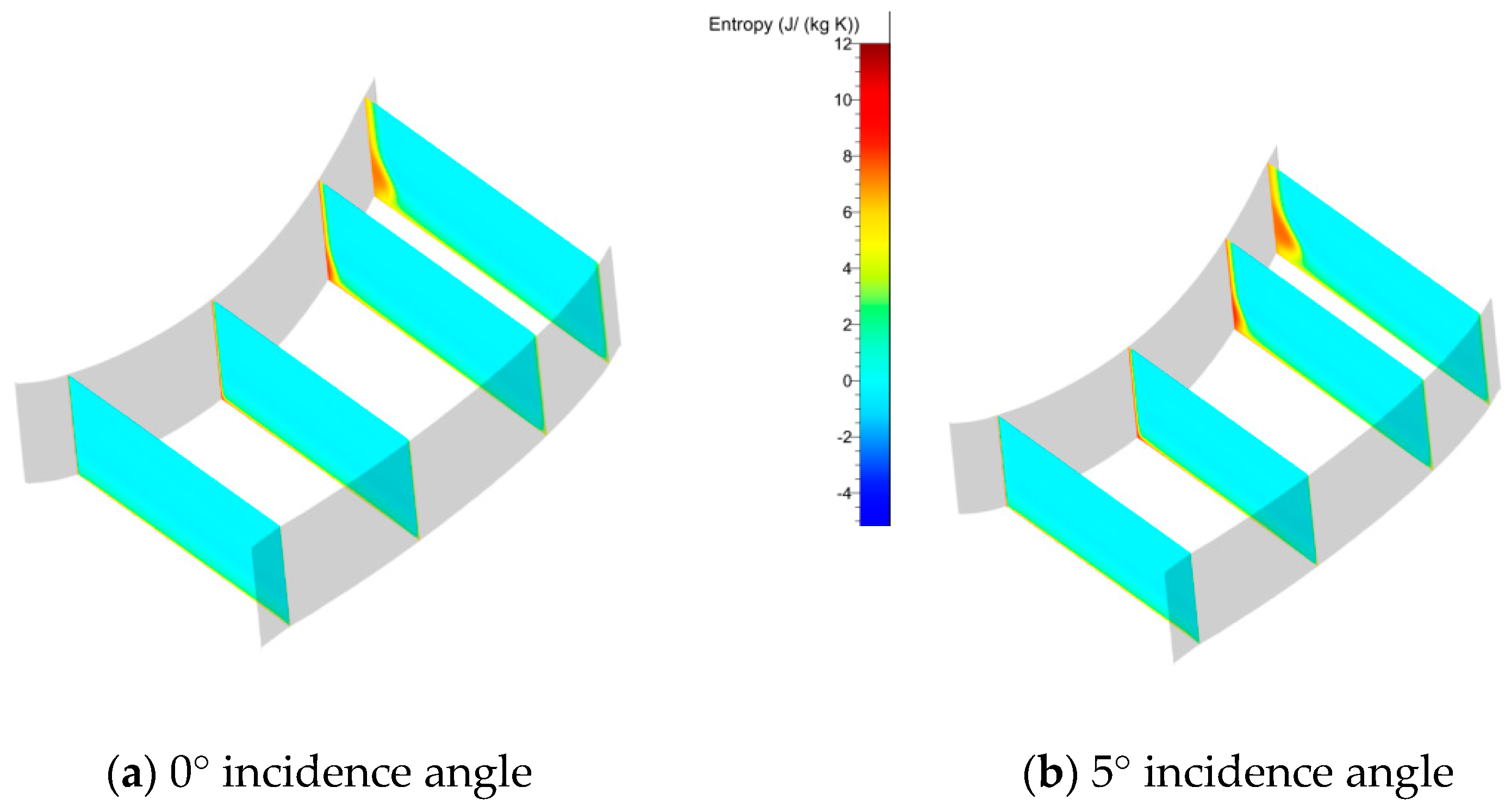

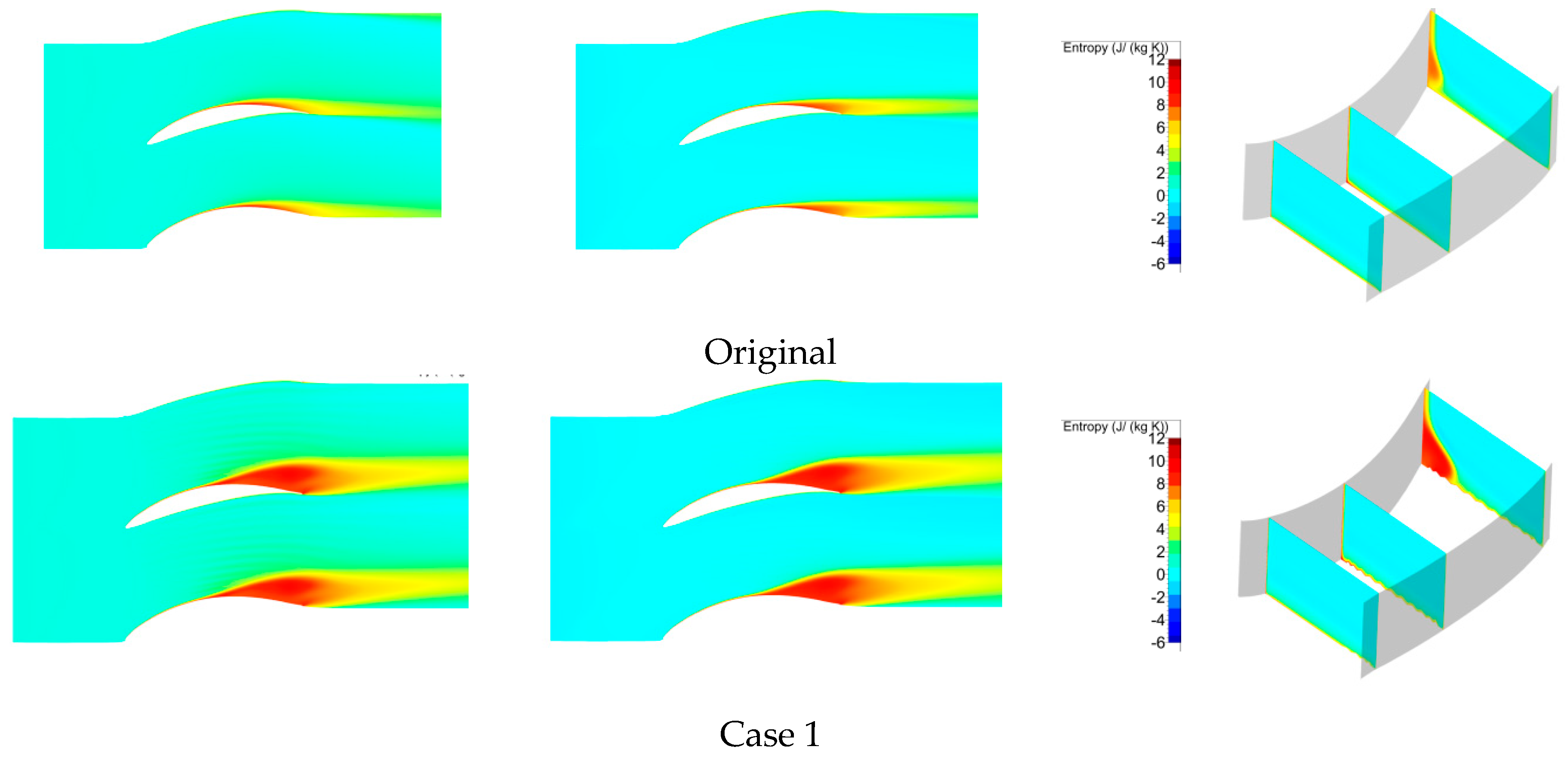

2. Geometry and Flow Analysis of the Baseline Cascade

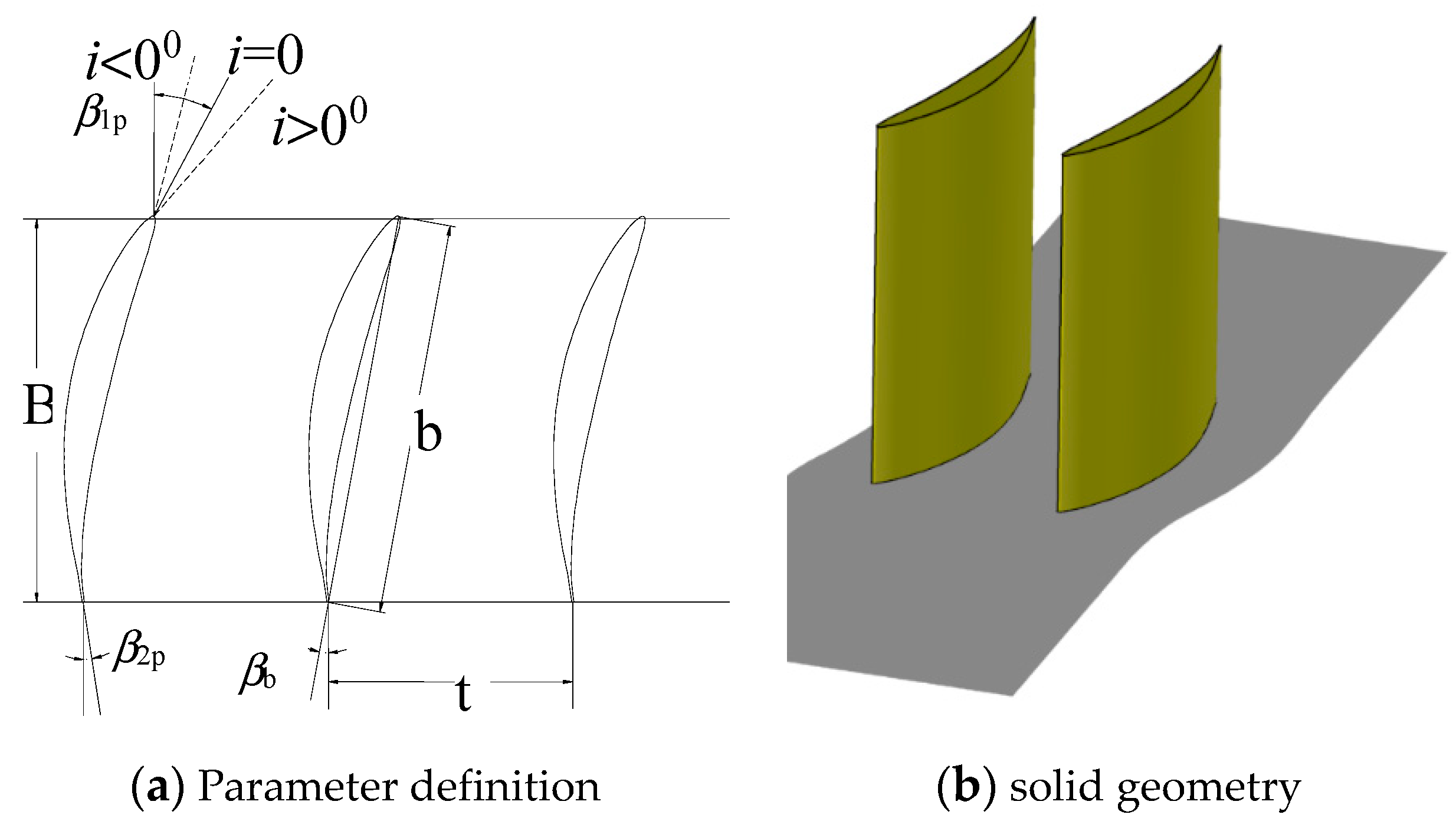

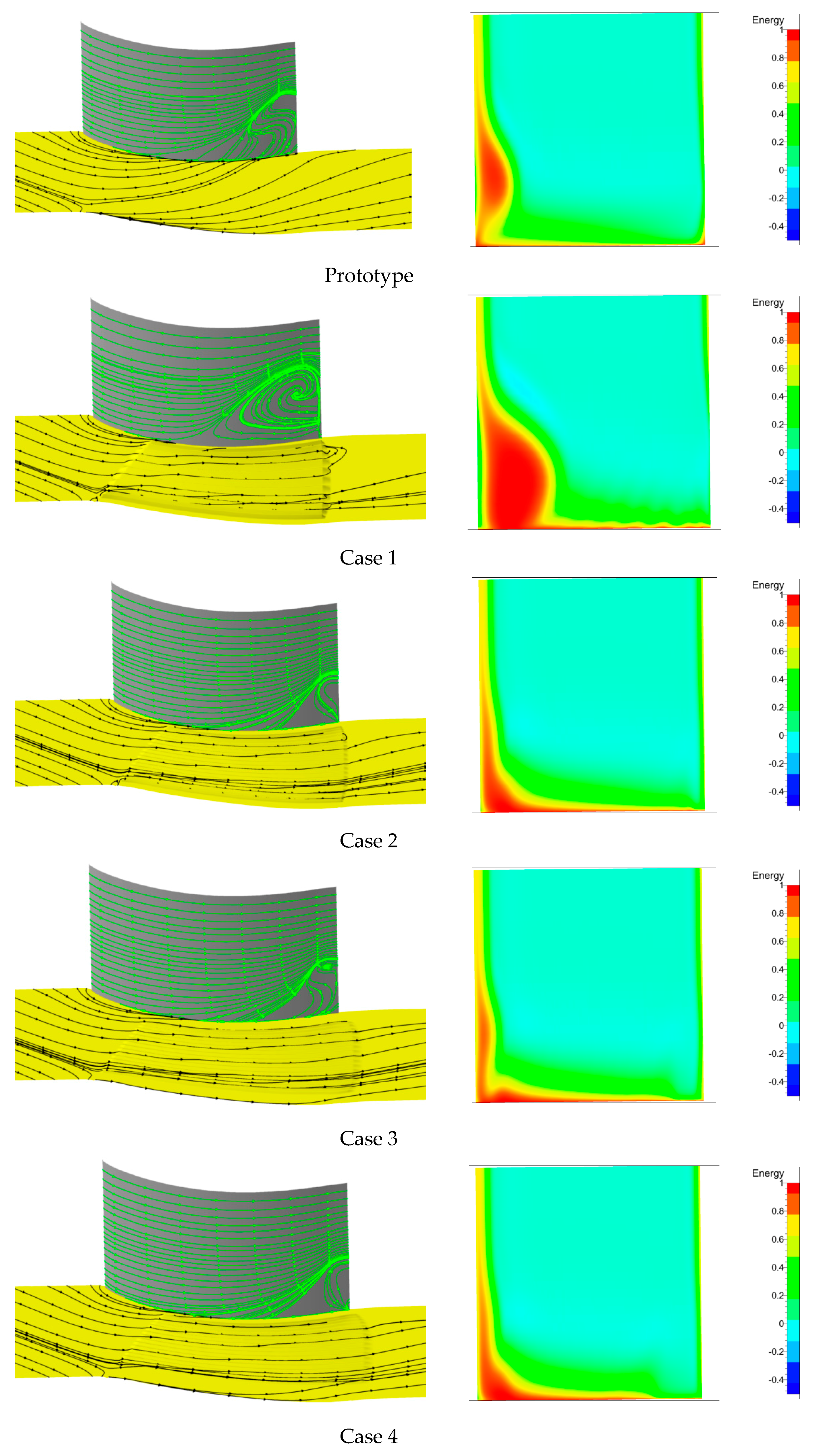

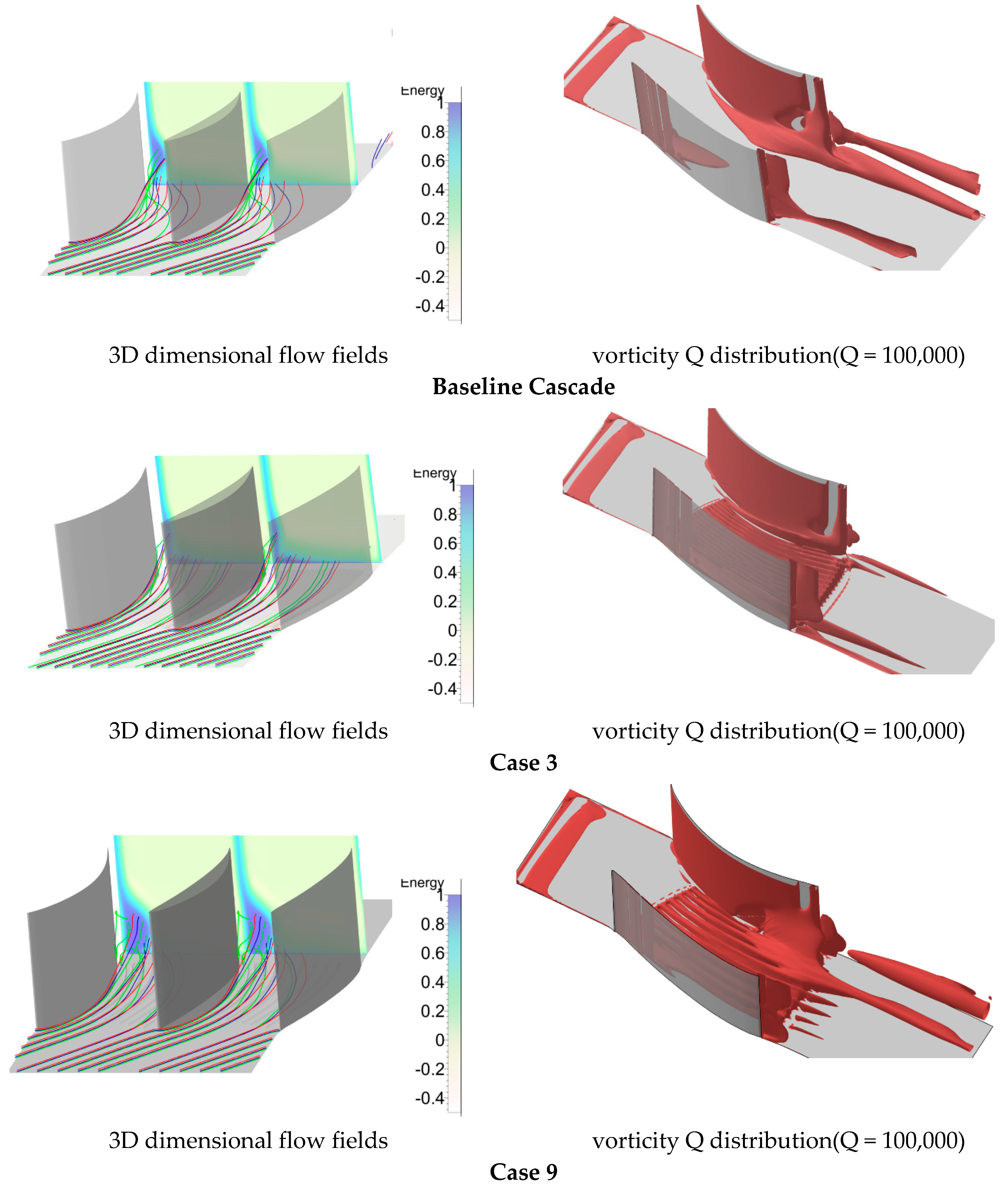

2.1. Geometrical Descriptions

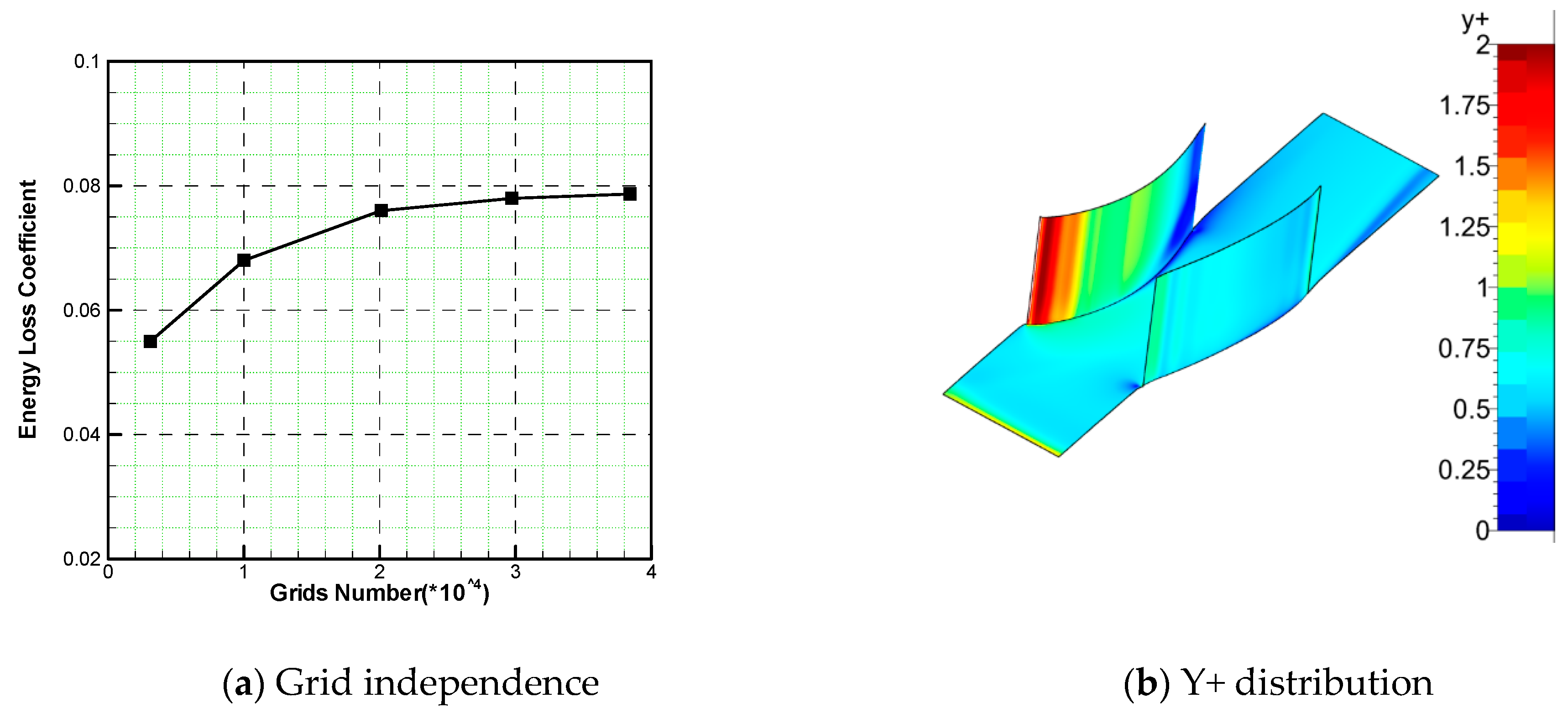

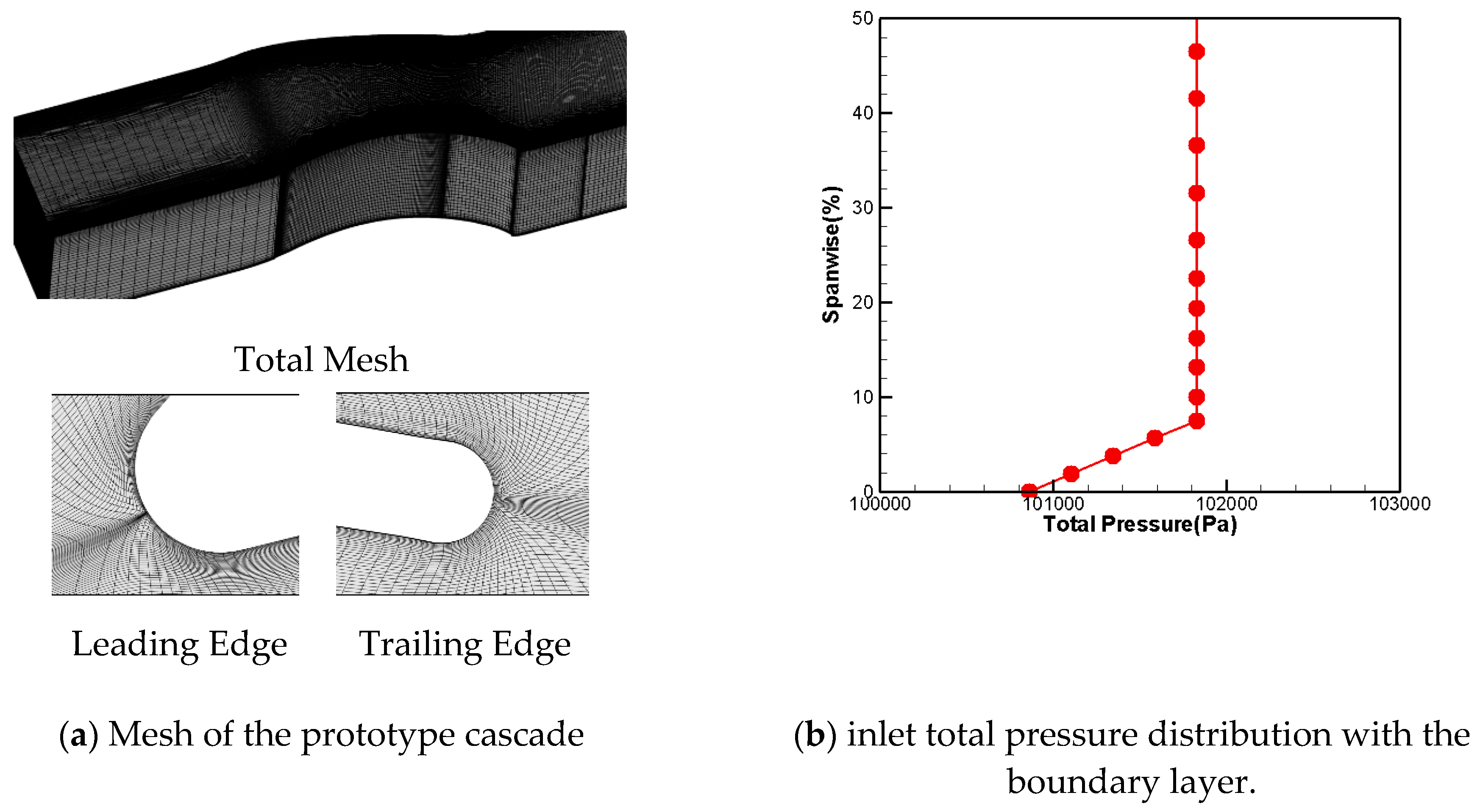

2.2. Computational Solver

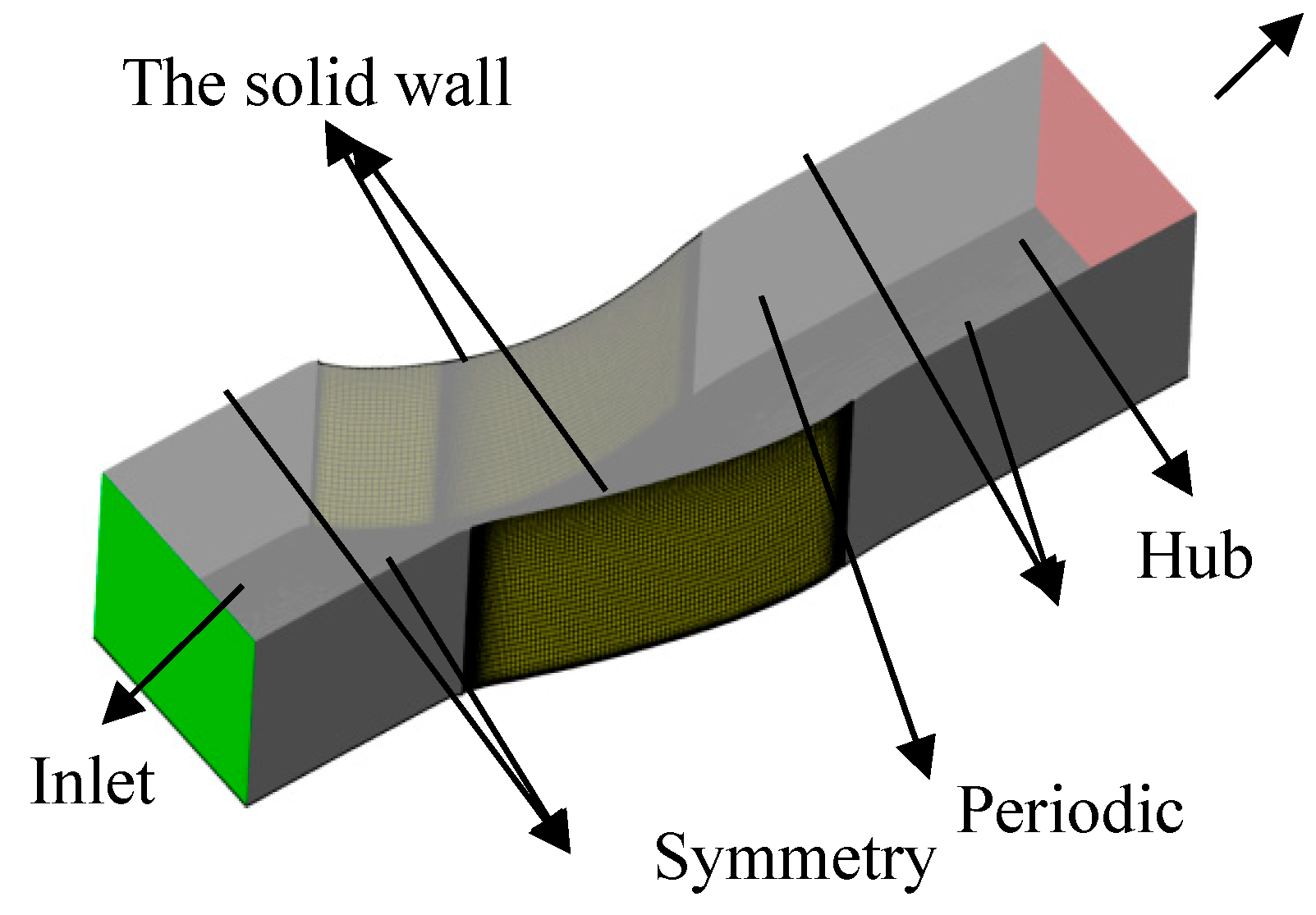

2.3. Computational Domain and Boundary Conditions

2.4. Computational Results

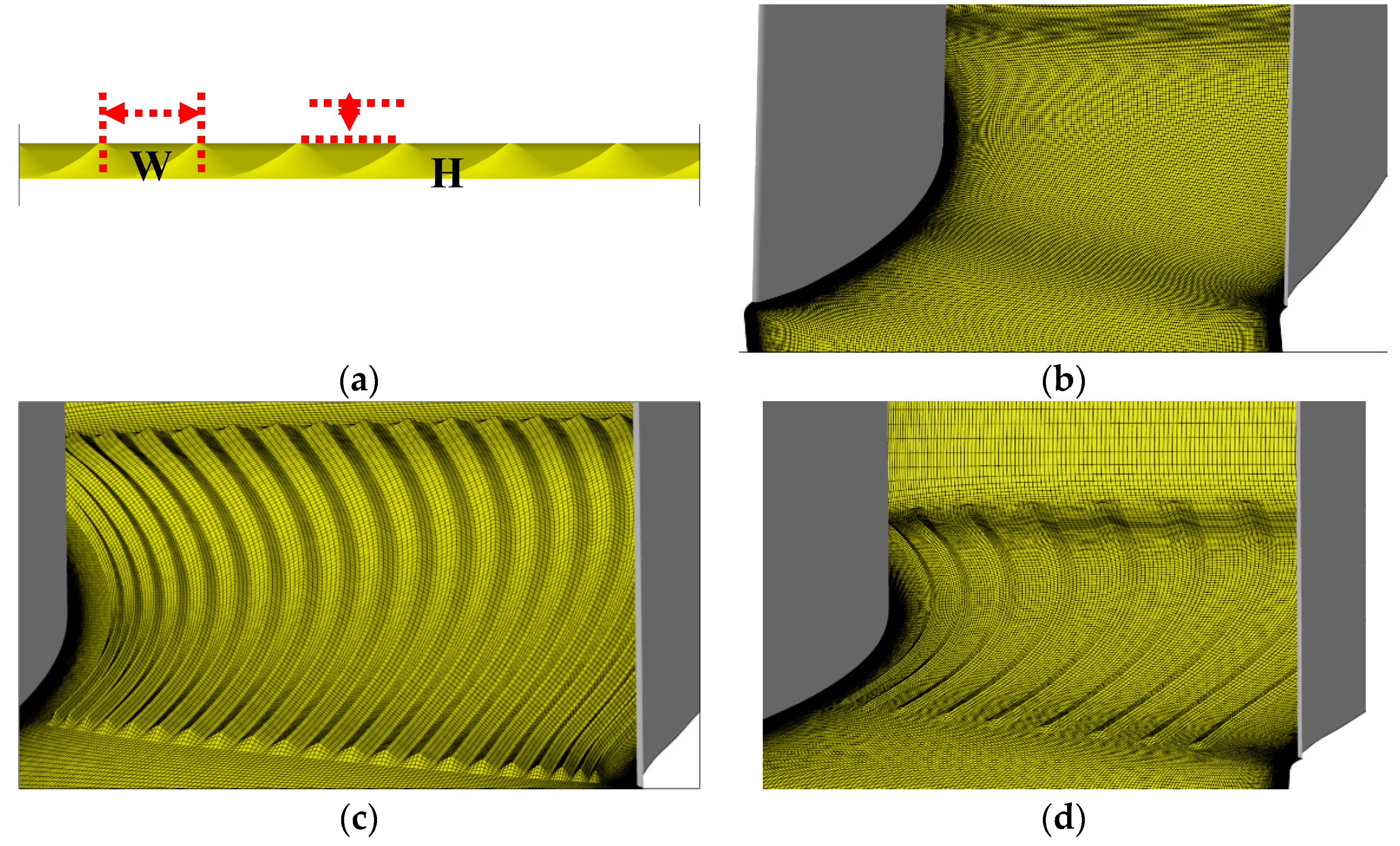

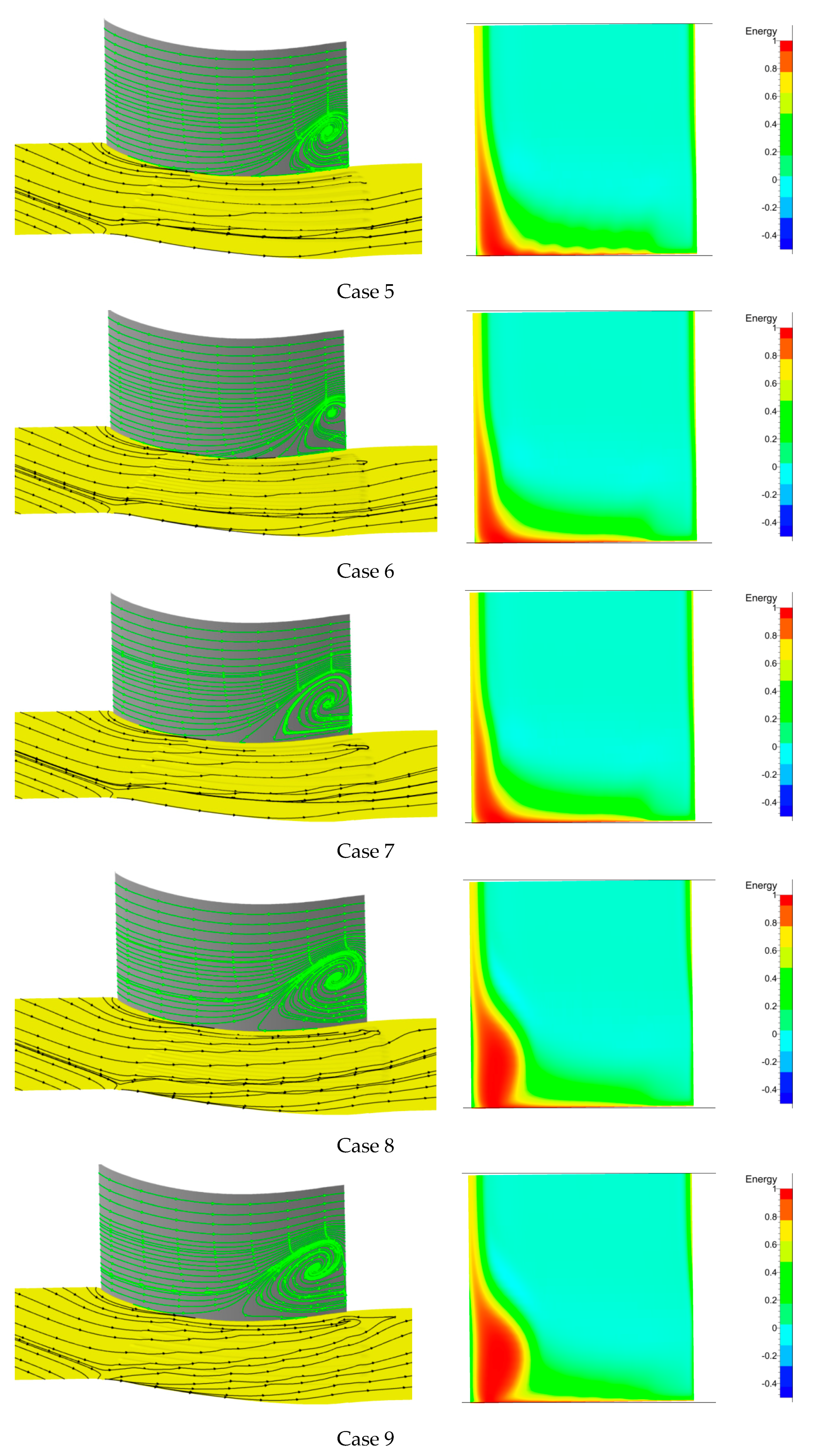

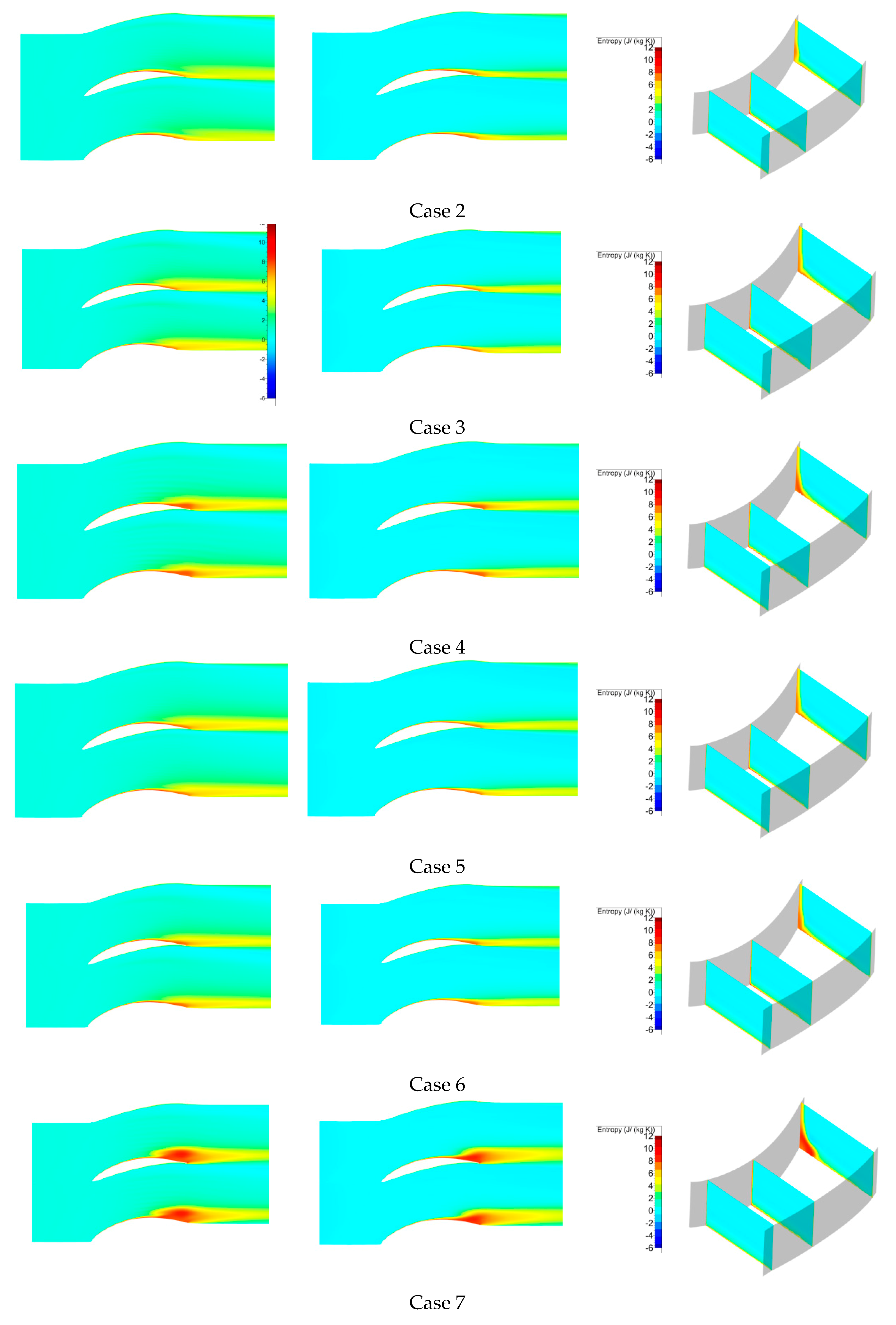

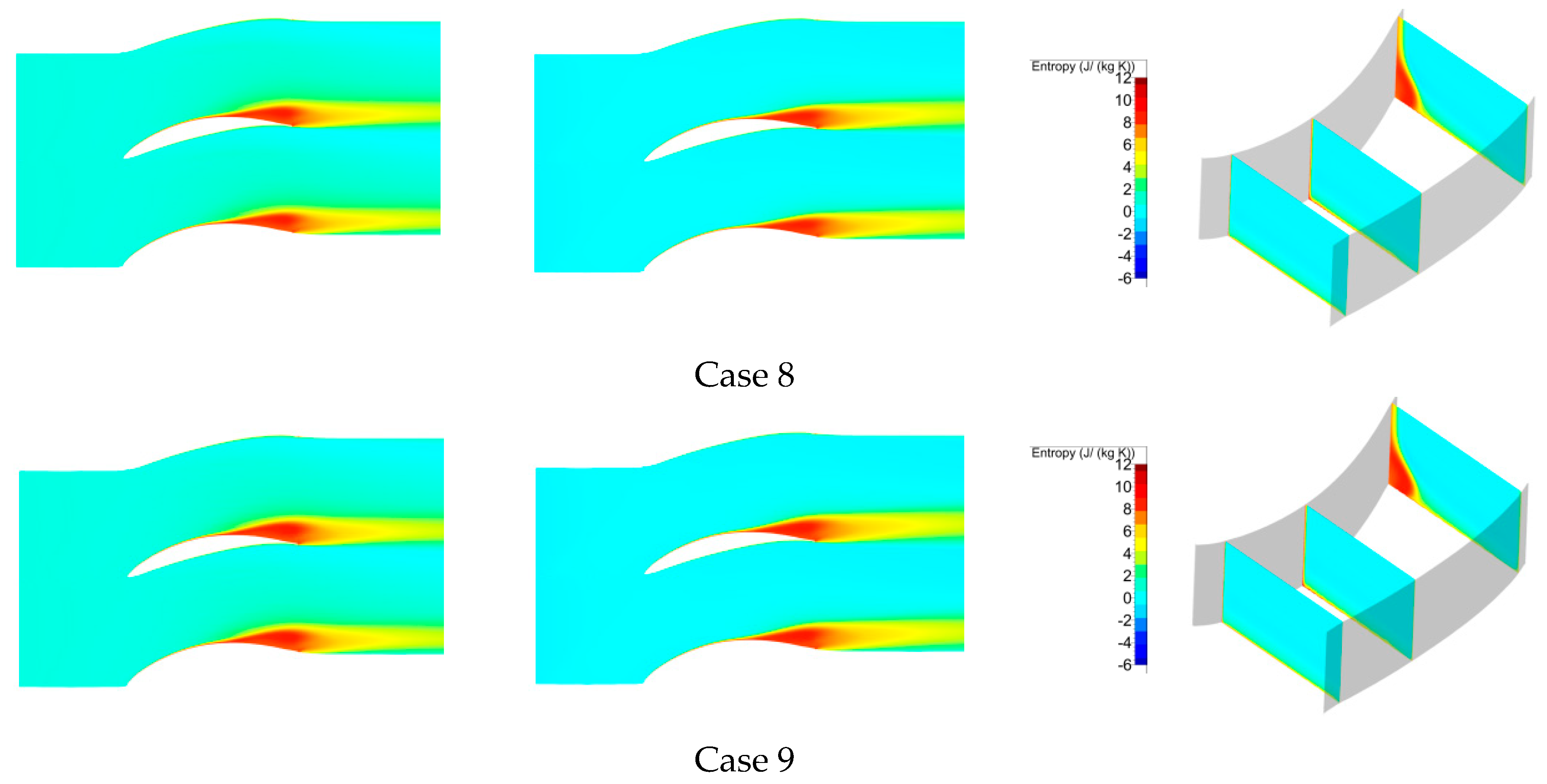

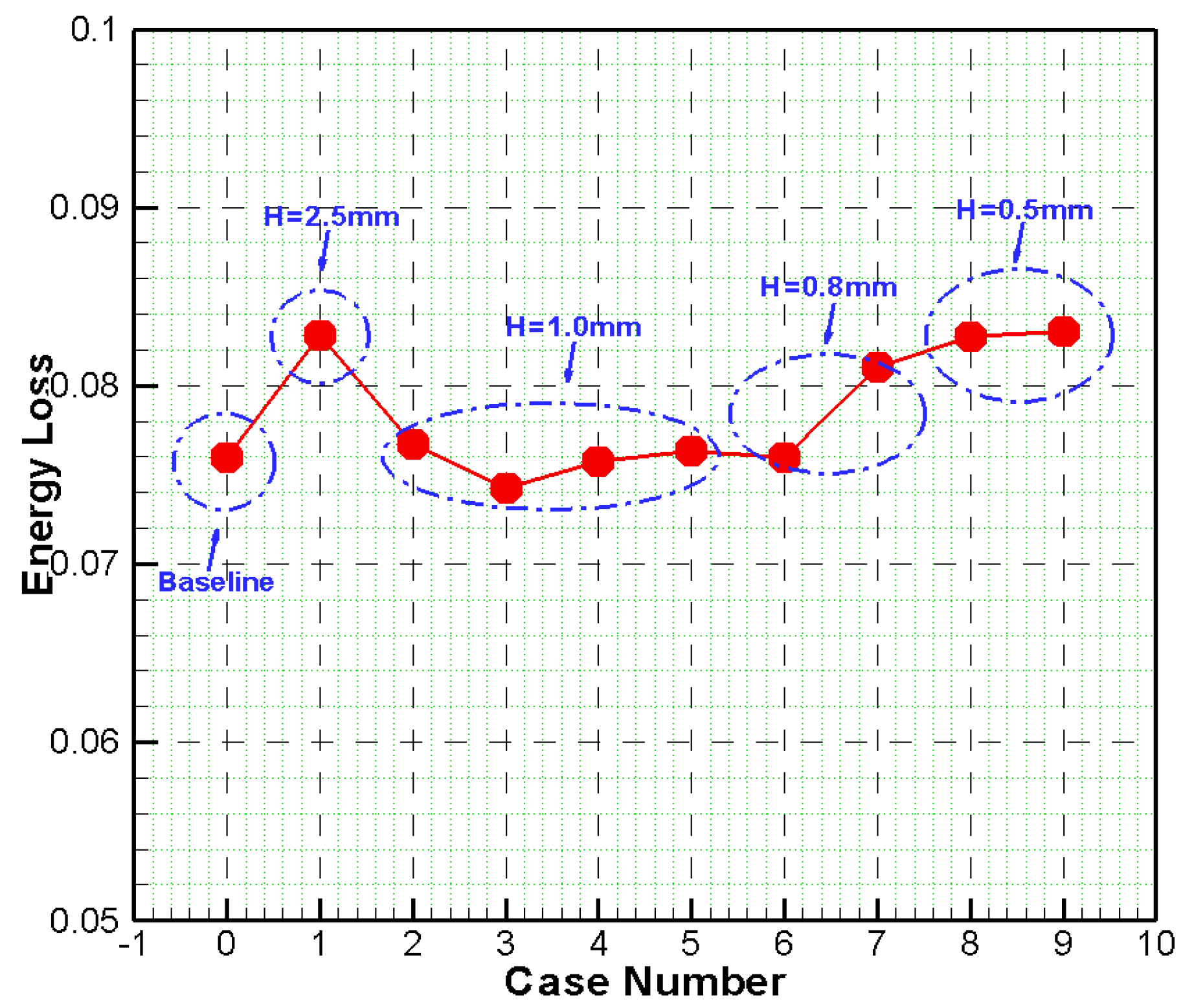

3. Design of the Streamwise Grooves at the Hub Wall

4. Results Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gbadebo, S.A.; Cumpsty, N.A.; Hynes, T.P. Three-Dimensional Separations in Axial Compressors. J. Turbomach. 2005, 127, 331–339. [Google Scholar] [CrossRef]

- Lei, V.M.; Spakovszky, Z.S. A Criterion for Axial Compressor Hub-Corner Stall. J. Turbomach. 2008, 130, 031006. [Google Scholar] [CrossRef]

- Vinuesa, R.; Schlatter, P.; Nagib, H.M. Secondary flow in Turbulent Ducts with Increasing Aspect Ratio. Phys. Rev. Fluids 2018, 3, 054606. [Google Scholar] [CrossRef]

- Denton, J.D. Loss Mechanisms in Turbomachinery. J. Turbomach. 1993, 115, 621–656. [Google Scholar] [CrossRef]

- de Haller, P. Das verhalten yon tragflfigelgittern in axialverdichtern und im windkanal. BWK 1953, 5, 333–336. [Google Scholar]

- Horlock, J.H.; Louis, J.F.; Percival, P.M.E.; Lakshminarayana, B. Wall Stall in Compressor Cascades. J. Basic Eng. 1966, 88, 637–648. [Google Scholar] [CrossRef]

- Joslyn, H.; Dring, R. Axial Compress or Stator Aerodynamics. ASME J. Eng. Gas Turbines Power 1985, 107, 485–493. [Google Scholar] [CrossRef]

- Dong, Y.; Gallimore, S.J.; Hodson, H.P. Three-Dimensional Flow and Loss Reduction in Axial Compressor. ASME J. Turbomach. 1987, 109, 351–354. [Google Scholar] [CrossRef]

- Schulz, H.D.; Gallus, H.D. Experimental Investigations of the Three-Dimensional Flows in an Annular Compressor Cascade. ASME J. Turbomach. 1988, 110, 467–478. [Google Scholar] [CrossRef]

- Wang, H.; Lin, D.; Su, X.; Yuan, X. Entropy Analysis of the Interaction between the Corner Sparation and Wakes in a Compressor Cascade. Entropy 2017, 19, 324. [Google Scholar] [CrossRef]

- Breugelmans, F.A.E.; Carels, Y.; Demut, M. Influence of Dihedral on the Secondary Flow in a Two Dimensional Compressor Cascade. ASME J. Eng. Gas Turbines Power 1984, 106, 578–584. [Google Scholar] [CrossRef]

- Weing old, H.D.; Neuber, T.R.J.; Behlke, R.F.; Potter, G.E. Bowed stator: An Example of CFD Applied to Improve Multistage Compressor Efficiency. ASME J. Turbomach. 1997, 119, 161–168. [Google Scholar] [CrossRef]

- Fischer, A. Performance of Strongly Bowed Stators in a 4-Stage High Speed Compressor. In Proceedings of the ASME Turbo Expo 2003, Collocated with the 2003 International Joint Power Generation Conference, Atlanta, GA, USA, 16–19 June 2003; pp. [Google Scholar]

- Tweedt, D.L.; Okiishi, T.H.; Hathaway, M.D. Stator Endwall Leading-Edge Sweep and Hub Shroud Influence on Compressor Performance. J. Turbomach. 1986, 108, 224–232. [Google Scholar] [CrossRef]

- Wadia, A.R. Some Advances in Fan and Compressor Aero at GE Aircraft Engines; Lecture; Tsinghua University: Beijing, China, 2005. [Google Scholar]

- Gummer, V.; Wenger, U.; Kau, H.P. Using Sweep and Dihedral to Control Three-Dimensional Flow in Transonic Stators of AxialCompressor. J. Turbomach. 2001, 123, 40–48. [Google Scholar] [CrossRef]

- Hartland, J.C.; Smith, G. Non-Axisymmetric Endwall Profiling in a Turbine Rotor Blade. In Proceedings of the ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition, Stockholm, Sweden, 2–5 June 1998; The ASME Digital Collection: New York, NY, USA, 1998. [Google Scholar]

- Dorfner, C.; Nicke, E.; Voss, C. Axissymmetric Profiled Endwall Design Using Multiobjective Optimization Linked with 3D Rans Flow Simulations. In Turbo Expo 2007: Power for Land, Sea, and Air; The ASME Digital Collection: New York, NY, USA, 2007; pp. 107–114. [Google Scholar]

- Harvey, N.W.; Offord, T.P. Some Effects of Non-Axisymmetric End Wall Profiling on Axial Flow Compressor Aerodynamics: Part II, Multi-Stage HPC CFD study. In ASME Turbo Expo 2008: Power for Land, Sea, and Air; ASME: New York, NY, USA, 2008. [Google Scholar]

- Merchant, A.A. Design and Analysis of Axial Aspirated Compressor Stage. Ph.D. Thesis, MIT, Cambridge, MA, USA, 1999. [Google Scholar]

- Gbadebo, S.A.; Cumpsty, N.A.; Hynes, T.P. Control of Three-Dimensional Separations in Axial Compressors by Tailored Boundary Layer Suction. J. Turbomach. 2008, 130, 011004. [Google Scholar] [CrossRef]

- Roth, J.R.; Dai, X. The Physics and Phenomenology of Paraelectric one Atmosphere Uniform Glow charge Plasma Actuarors for Aerodynamic flow Control. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005. [Google Scholar]

- Rethmel, C.; Little, J.; Takashima, K. Flow Separation Control Over an Airfoil with Nanosecond Pluse Driven DBD Plasma Actuators. In Proceedings of the 49th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. [Google Scholar]

- Jim’enez, J. Wall friction and the structure of near-Wall turbulence. In Proceedings of the 11th Australasian Fluid Mechanics Conference, Hobart, Australia, 10–14 December 1992; pp. 813–816. [Google Scholar]

- Suzuki, Y.; Kasagi, N. Turbulent drag reduction mechanism above a riblet surface. AIAA J. 1994, 32, 1781–1790. [Google Scholar] [CrossRef]

- Akinlade, O.G. Effects of Surface Roughness on the Low Charachteristics in a Turbulant Boundary Layer. Ph.D. Thesis, University of Saskatchewan, Saskatoon, SK, Canada, 2005. [Google Scholar]

- Luchini, P.; Manzo, F.; Pozzi, A. Resistance of a grooved surface to parallel flow and cross-Flow. J. Fluid Mech. 1991, 228, 87–109. [Google Scholar] [CrossRef]

- Ricardo, G.M.; Javier, J. Hydrodynamic stability and breakdown ofthe viscous regime over riblets. J. Fluid Mech. 2011, 678, 317–347. [Google Scholar]

- Miao, X.; Zhang, Q.; Atkin, C.; Sun, Z. End-Wall Secondary Flow Control Using Engineered Residual Surface Structure. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition. American Society of Mechanical Engineers Digital Collection, Seoul, South Korea, 13–17 June 2016. [Google Scholar]

- Miao, X.; Zhang, Q.; Wang, L.; Jiang, H.; Qi, H. Application of Riblets on Turbine Blade End-Wall Secondary Flow Control. J. Propuls. Power 2015, 31, 1578–1585. [Google Scholar] [CrossRef]

- Khader, M.A.; Saym, A.I. Effect of end-Wall riblets on radial turbine Performance. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017. [Google Scholar]

- Oehlert, K.; Seume, J. Exploratory Experiments on Machined Riblets on Compressor Blades. In ASME Fluids Engineering Division; ASME: Miami, FL, USA, 2006. [Google Scholar]

- Hergt, A.; Hage, W.; Grund, S.; Steinert, W.; Terhorst, M.; Schongen, F.; Wilke, Y. Riblet Application in Compressors: Toward Efficient Blade Design. J. Turbomach. 2015, 137, 111006. [Google Scholar] [CrossRef]

- Dorfner, C.; Hergt, A. Advanced Nonaxisymmetric Endwall Contouring for Axial Compressors by Generating an Aerodynamic Separator—Part I: Principal Cascade Design and Compressor Application. J. Turbomach. 2011, 133, 021026. [Google Scholar] [CrossRef]

- Li, J.; Ji, L.; Yi, W. The Use of Blended Blade and End Wall in Compressor Cascade: Optimization Design and Flow Mechanism. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Li, J.; Ji, L.; Yi, W. Experimental and Numerical Investigation on the Aerodynamic Performance of a Compressor Cascade Using Blended Blade and End Wall. In Proceedings of the ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition, Charlotte, NC, USA, 26–30 June 2017. [Google Scholar]

- Gmelin, C.; Zander, V. Active Flow Control Concepts on a Highly Loaded Subsonic Compressor Cascade: Re’sume’ of Experimental and Numerical Results. J. Turbomach. 2012, 134, 061021. [Google Scholar] [CrossRef]

- Mao, X.; Liu, B.; Tang, T. Effect of casing aspiration on the tip leakage flow in the axial flow compressor cascade. Proc. Inst. Mech. Eng. Part A 2018, 232, 225–239. [Google Scholar] [CrossRef]

- Spalart, P.R.; Allmaras, S.R. A One-Equation turbulence model for aerodynamic flows. In Proceedings of the 30th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1992. [Google Scholar]

- Numeca International. User Guide for FINE™/Turbo. 2016. [Google Scholar]

| Parameter | Numerical Value |

|---|---|

| b (mm) | 128.23 |

| h (mm) | 160 |

| t (mm) | 80.14 |

| b/t | 1.6 |

| h/b | 1.25 |

| B (mm) | 125.87 |

| β1P (°) | −32 |

| β2P (°) | 10 |

| θ (°) | 42 |

| βb (°) | −11 |

| Scheme | W (mm) | H (mm) |

|---|---|---|

| Case 1 | 3.0 | 2.5 |

| Case 2 | 1.5 | 1.0 |

| Case 3 | 2.0 | 1.0 |

| Case 4 | 2.5 | 1.0 |

| Case 5 | 5.5 | 1.0 |

| Case 6 | 2.5 | 0.8 |

| Case 7 | 5.5 | 0.8 |

| Case 8 | 2.5 | 0.5 |

| Case 9 | 5.5 | 0.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, W.; Ji, L. Control and Entropy Analysis of Corner Flow Separation in a Compressor Cascade Using Streamwise Grooves. Entropy 2019, 21, 928. https://doi.org/10.3390/e21100928

Yi W, Ji L. Control and Entropy Analysis of Corner Flow Separation in a Compressor Cascade Using Streamwise Grooves. Entropy. 2019; 21(10):928. https://doi.org/10.3390/e21100928

Chicago/Turabian StyleYi, Weilin, and Lucheng Ji. 2019. "Control and Entropy Analysis of Corner Flow Separation in a Compressor Cascade Using Streamwise Grooves" Entropy 21, no. 10: 928. https://doi.org/10.3390/e21100928

APA StyleYi, W., & Ji, L. (2019). Control and Entropy Analysis of Corner Flow Separation in a Compressor Cascade Using Streamwise Grooves. Entropy, 21(10), 928. https://doi.org/10.3390/e21100928