A Simple Explicit Expression for the Flocculation Dynamics Modeling of Cohesive Sediment Based on Entropy Considerations

Abstract

1. Introduction

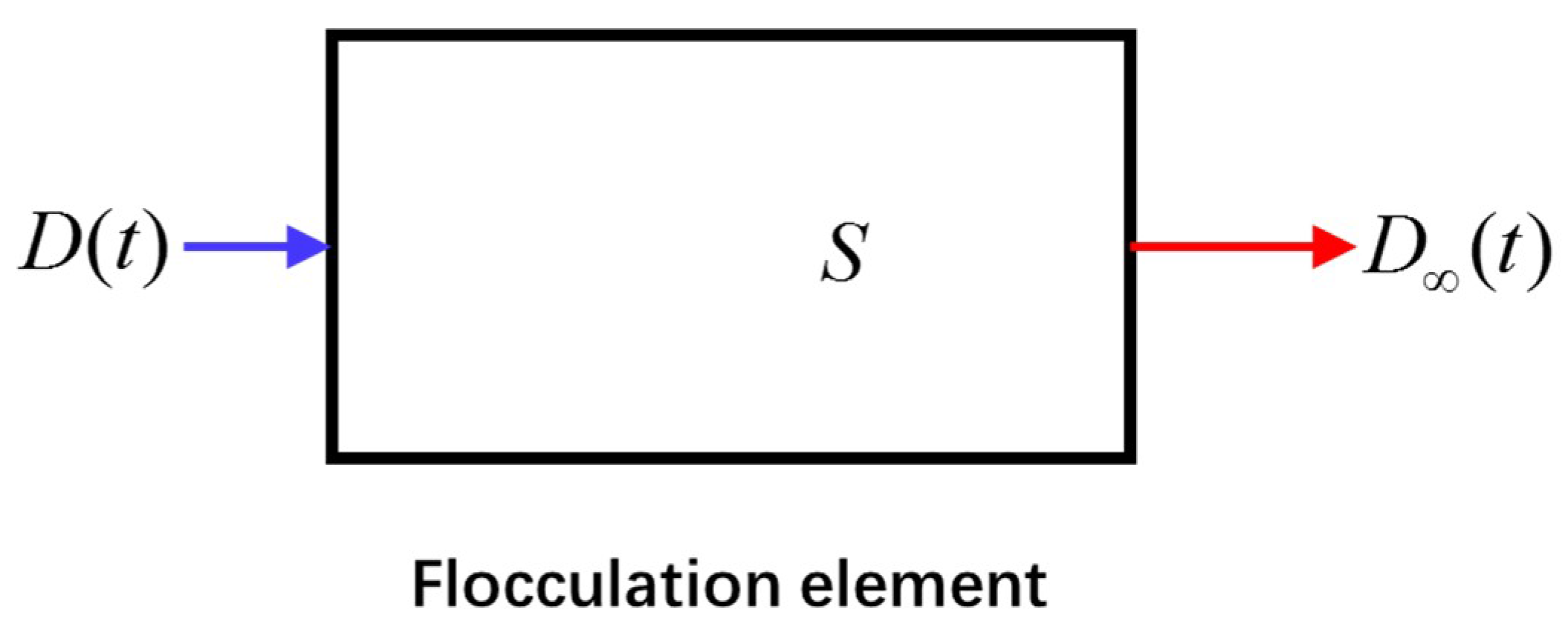

2. Shannon Entropy Theory for Flocculation Expression

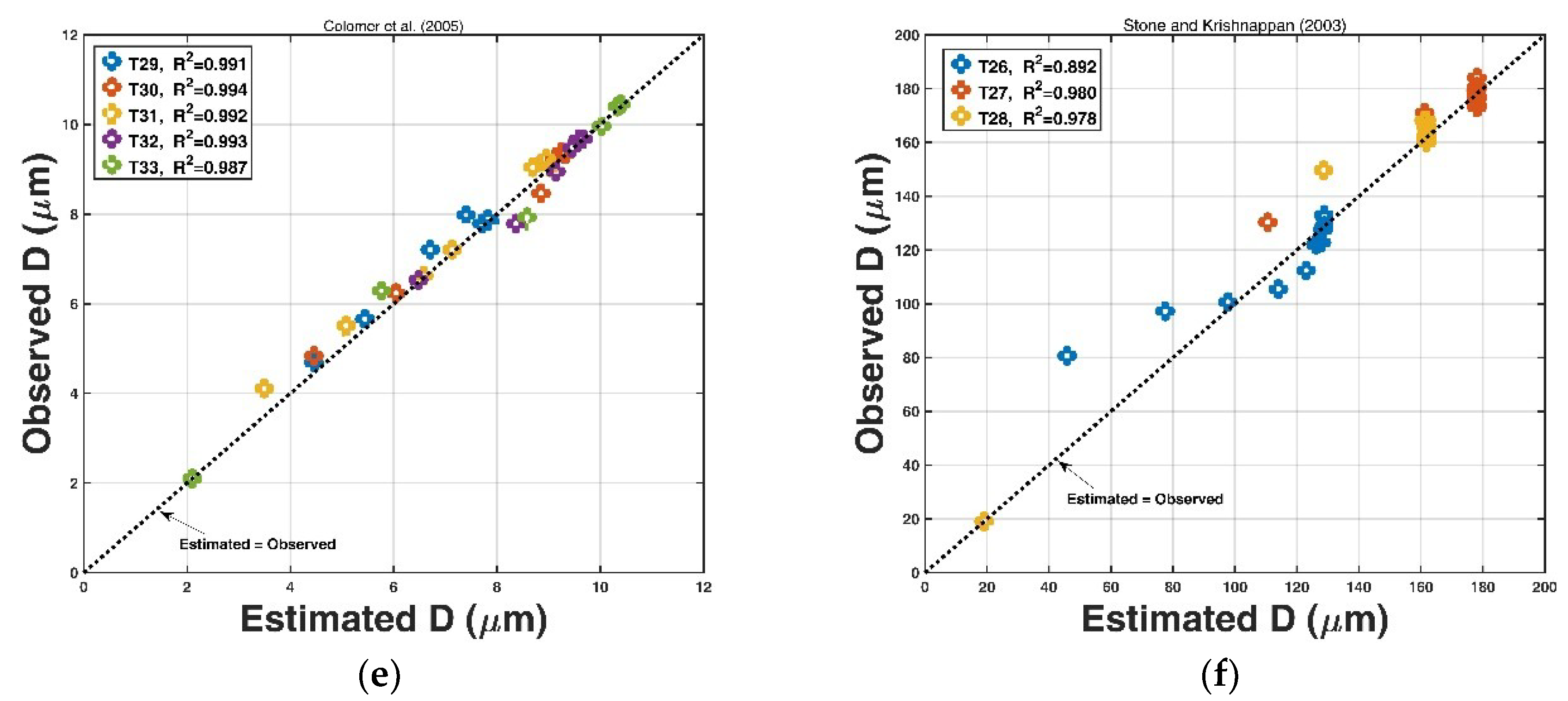

2.1. Definition of Shannon Entropy

2.2. Specification of Constraint

2.3. Maximization of Entropy

2.4. Determination of the Lagrange Multiplier

2.5. Hypothesis on the Cumulative Distribution Function

2.6. Derivation of the Flocculation Process

3. Tsallis Entropy Theory for the Flocculation Model

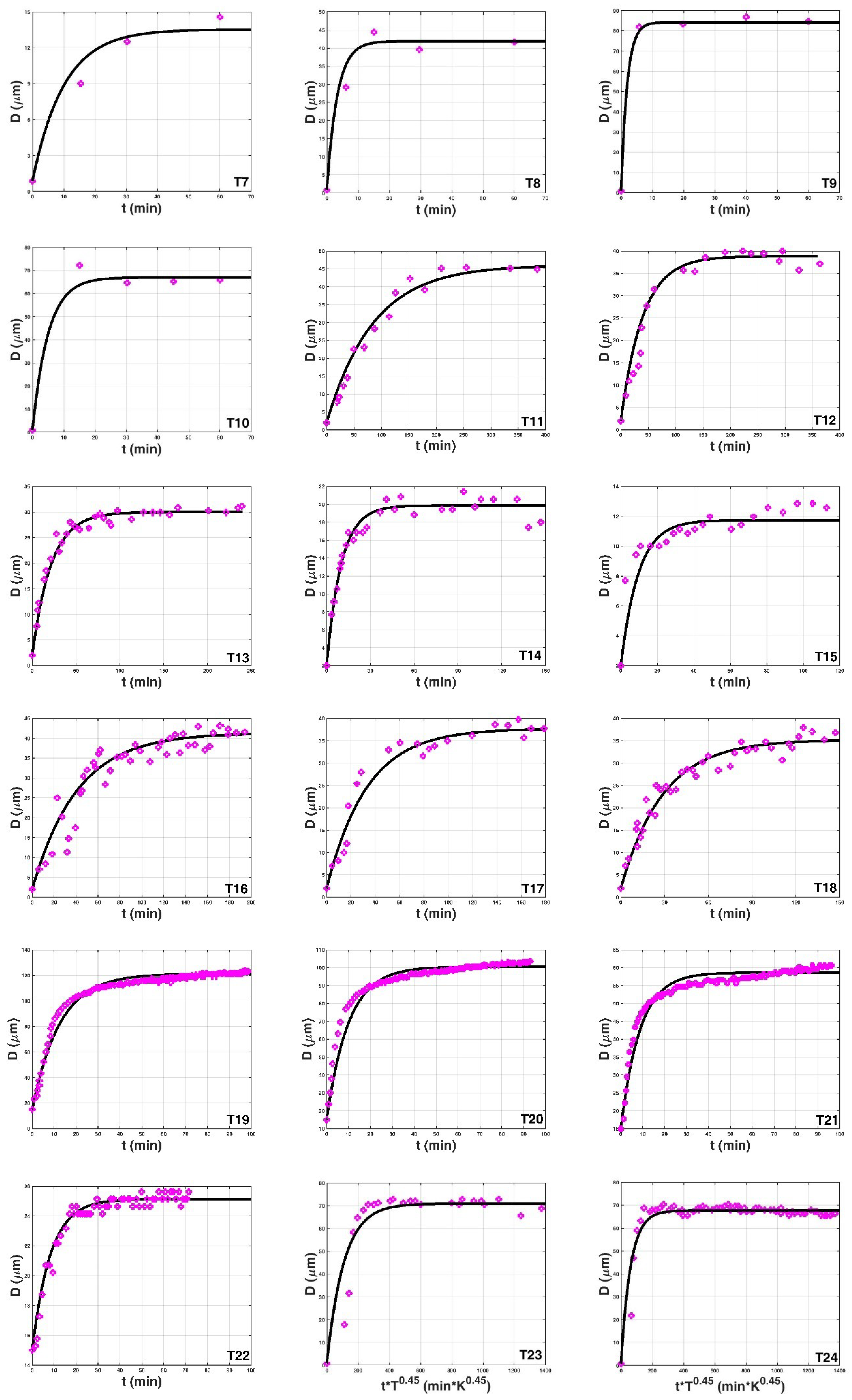

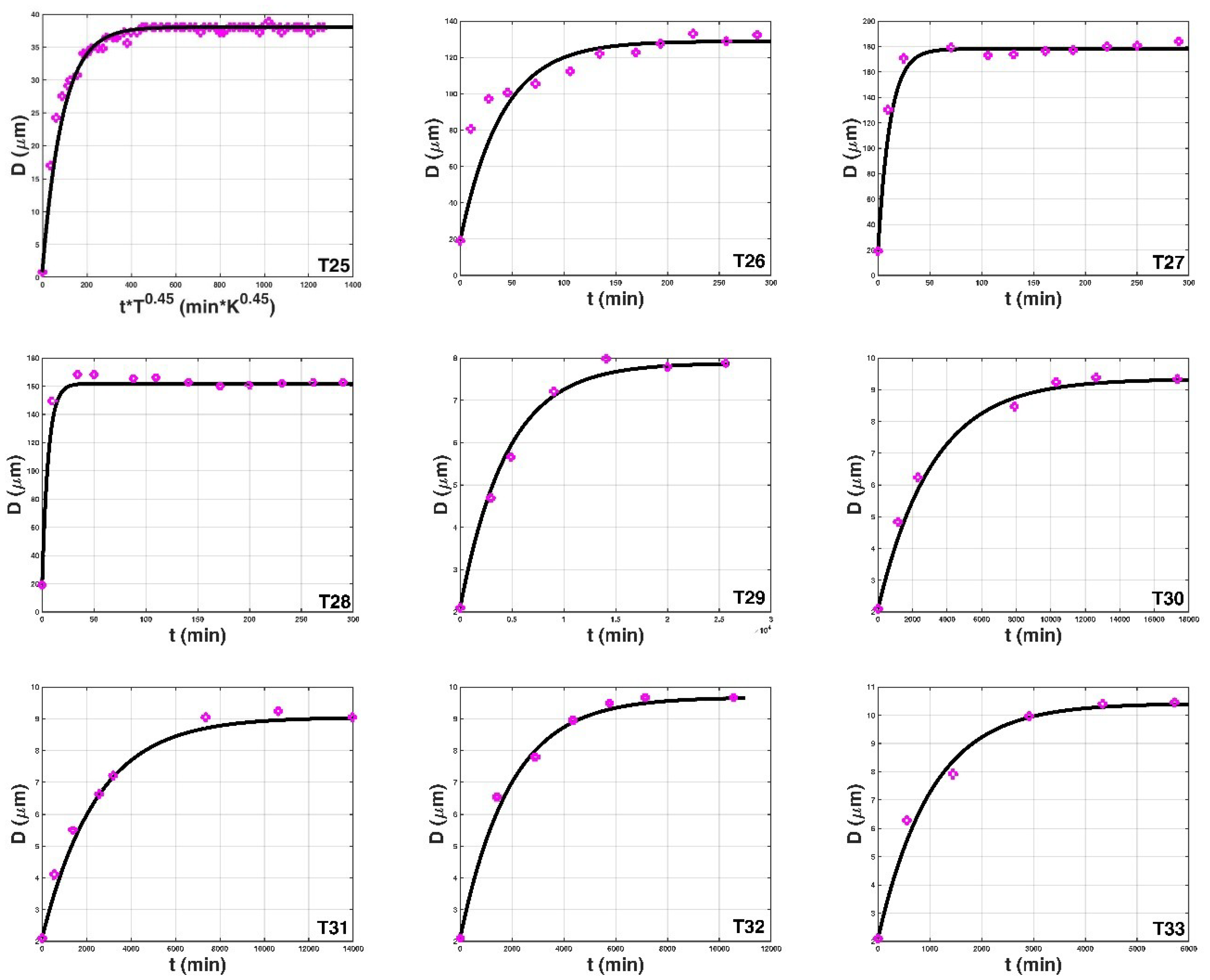

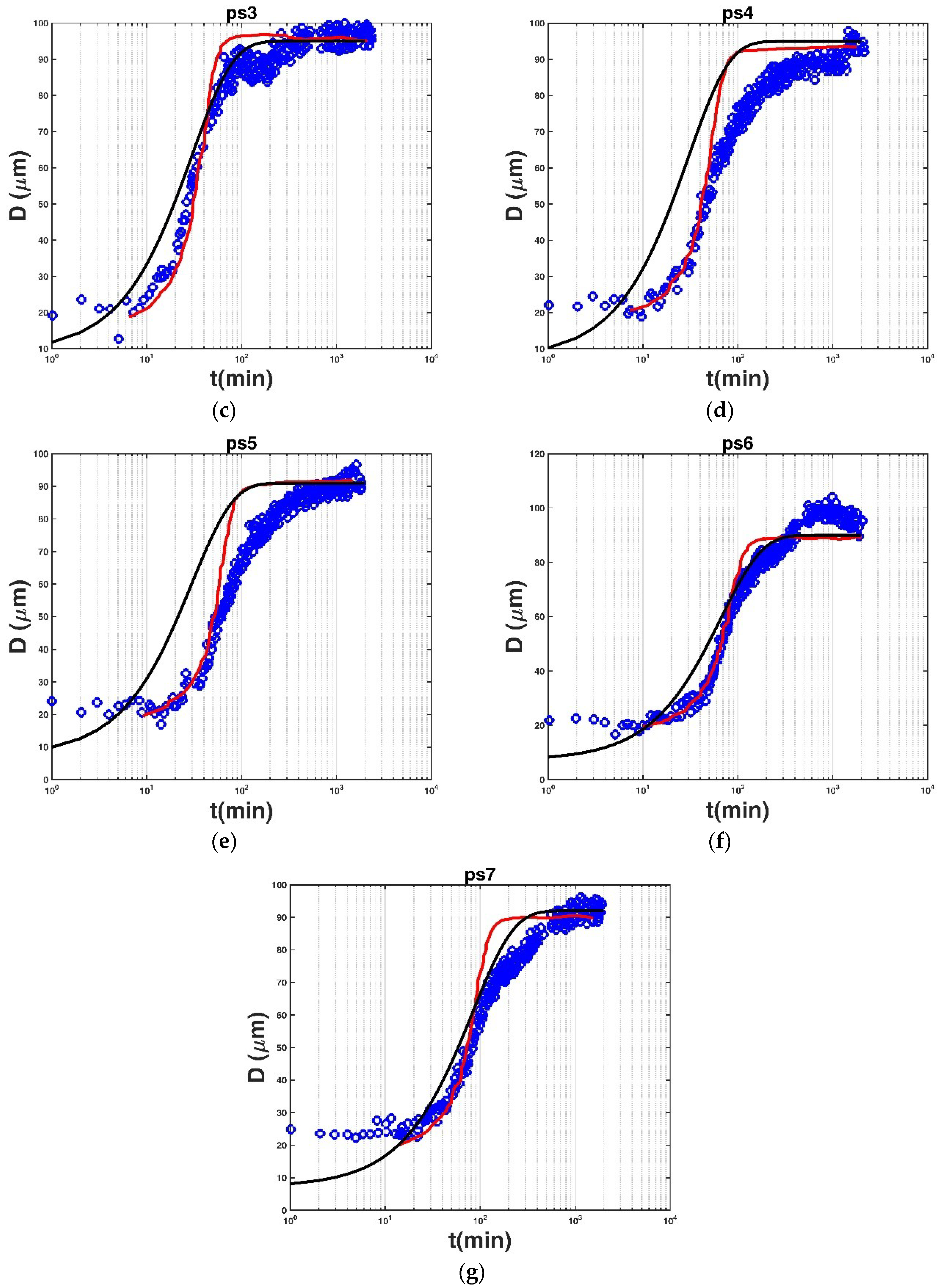

4. Results

5. Discussion

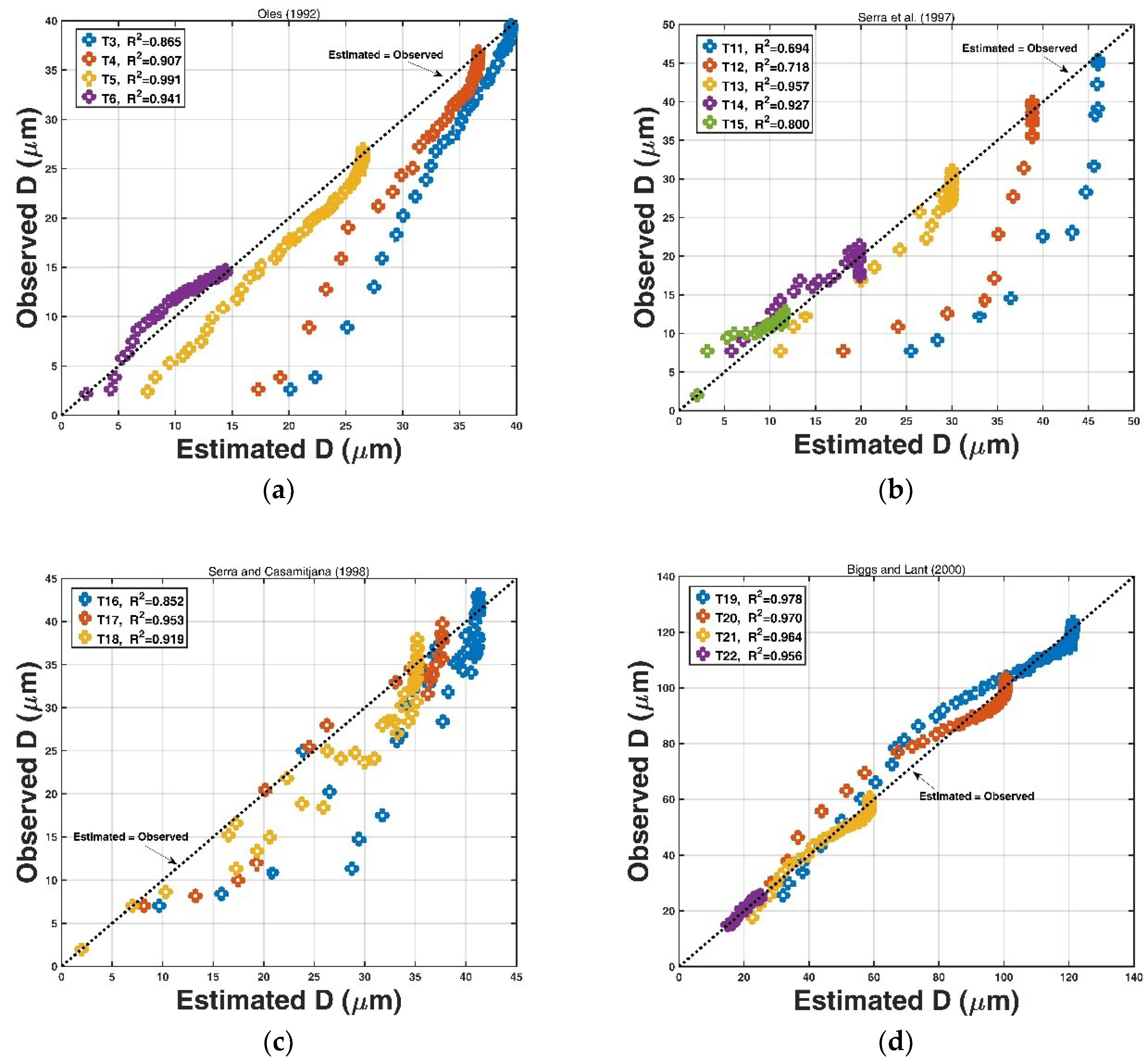

5.1. Comparison with the Deterministic Model

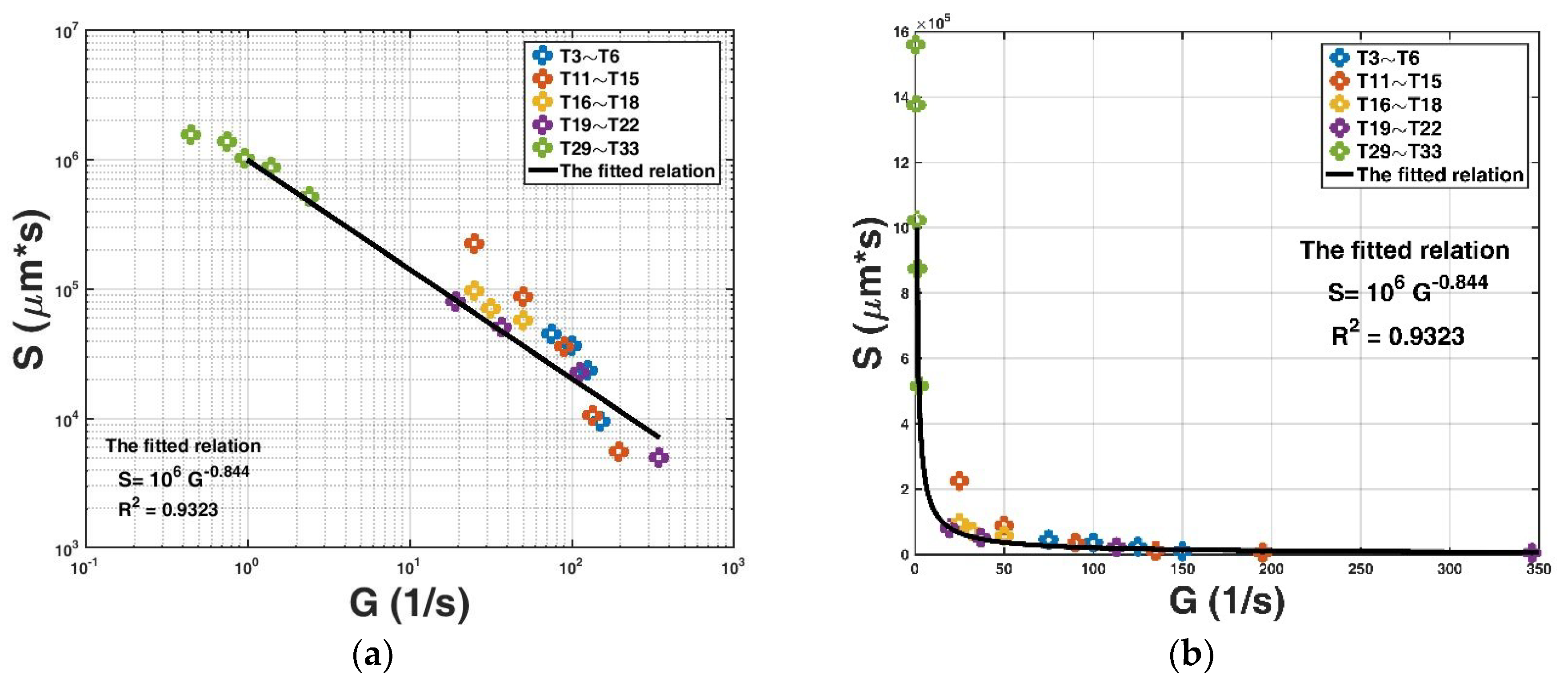

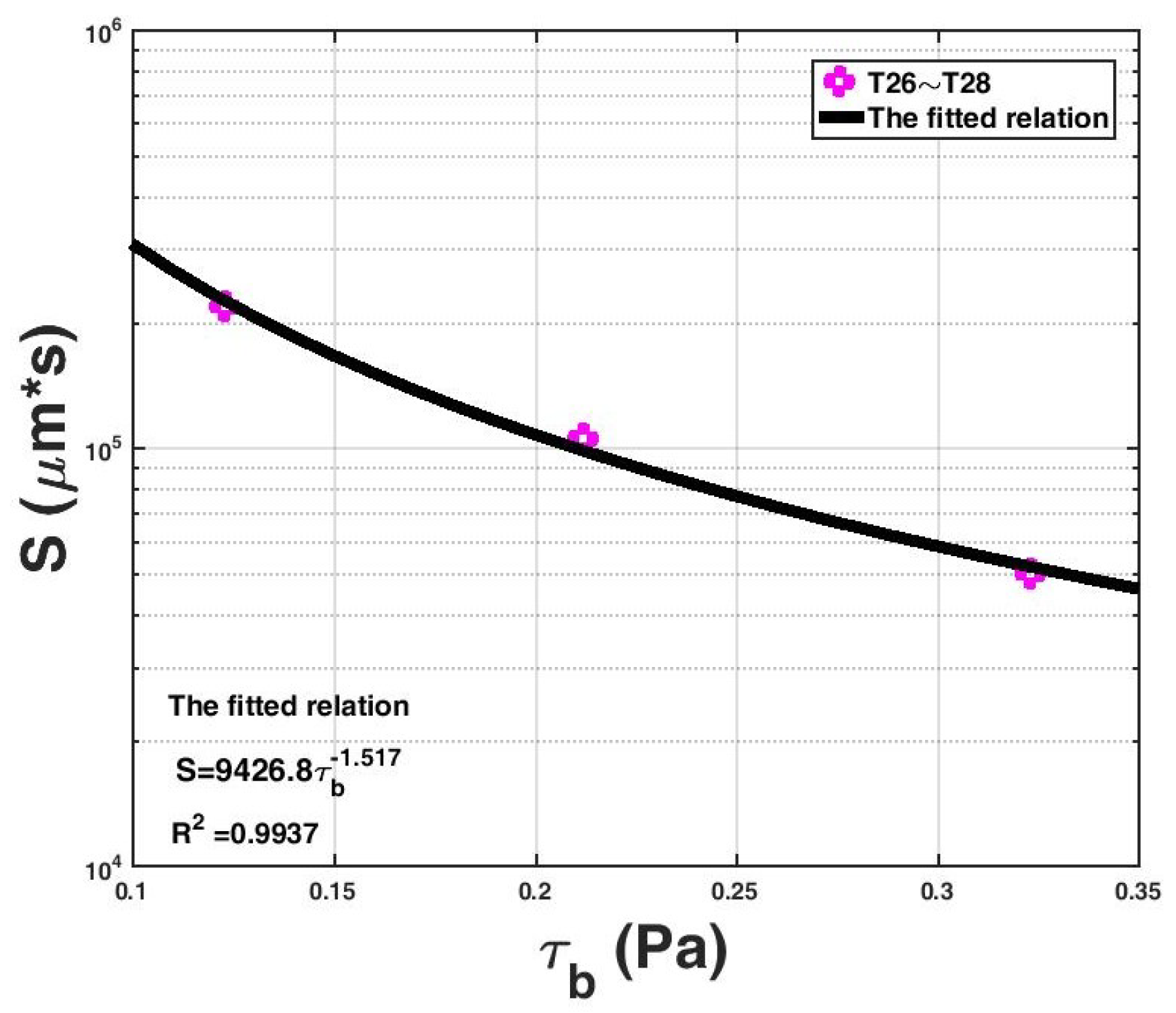

5.2. Estimation of the Key Parameter

6. Concluding Remarks

- A simple explicit expression that describes the temporal evolution of the characteristic floc size during turbulence-induced flocculation was derived based on the entropy theory.

- Both the Shannon entropy theory and the Tsallis entropy theory lead to the same expression for the function of floc size with respect to flocculation time.

- The entropy-based expression was tested against the experimental data in the literature, and a good agreement was found.

- The entropy-based expression was compared with other deterministic models, and it was found that the expression shows a better prediction accuracy for the logarithmic growth pattern of experimental data in comparison to the other models, whereas, for the sigmoid growth pattern of data, the model of Keyvani and Strom or the Son and Hsu (2009) model could be the better choice for floc size prediction.

- The maximum capacity of floc size growth, a key parameter that was incorporated into the expression, exhibits an empirical power-law relation with the flow shear rate. As the flow shear condition intensifies, the capacity for floc size growth in the flocculation system decreases. This is because the floc breakage caused by the increasing flow shear plays an increasingly important role in the flocculation process.

Funding

Conflicts of Interest

References

- Son, M.; Hsu, T.J. Flocculation model of cohesive sediment using variable fractal dimension. Environ. Fluid Mech. 2008, 8, 55–71. [Google Scholar] [CrossRef]

- Pejrup, M.; Mikkelsen, O.A. Factors controlling the field settling velocity of cohesive sediment in estuaries. Estuar. Coast Shelf Sci. 2010, 87, 177–185. [Google Scholar] [CrossRef]

- Winterwerp, J.C. A simple model for turbulence induced flocculation of cohesive sediment. J. Hydraul. Res. 1998, 36, 309–326. [Google Scholar] [CrossRef]

- Xu, F.; Wang, D.P.; Riemer, N. Modeling flocculation processes of fine-grained particles using a size-resolved method: Comparison with published laboratory experiments. Cont. Shelf Res. 2008, 28, 2668–2677. [Google Scholar] [CrossRef]

- Dyer, K. Sediment processes in estuaries: Future research requirements. J. Geophys. Res. Oceans 1978–2012 1989, 94, 14327–14339. [Google Scholar] [CrossRef]

- Zhu, Z.; Yu, J.; Wang, H.; Dou, J.; Wang, C. Fractal dimension of cohesive sediment flocs at steady state under seven shear flow conditions. Water 2015, 7, 4385–4408. [Google Scholar] [CrossRef]

- Maggi, F. The settling velocity of mineral, biomineral, and biological particles and aggregates in water. J. Geophys. Res. Ocean 2013, 118, 2118–2132. [Google Scholar] [CrossRef]

- Guo, C.; He, Q.; van prooijen, B.C.; Guo, L.C.; Manning, A.J.; Bass, S. Investigation of flocculation dynamics under changing hydrodynamic forcing on an intertidal mudflat. Mar. Geol. 2018, 395, 120–132. [Google Scholar] [CrossRef]

- Maggi, F. Biological flocculation of suspended particles in nutrient-rich aqueous ecosystems. J. Hydrol. 2009, 376, 116–125. [Google Scholar] [CrossRef]

- Fang, H.W.; Lai, H.J.; Cheng, W.; Huang, L.; He, G.J. Modeling sediment transport with an integrated view of the biofilm effects. Water Resour. Res. 2017, 53, 7536–7557. [Google Scholar] [CrossRef]

- Parker, D.; Kaufman, W.; Jenkins, D. Floc breakup in turbulent flocculation processes. J. Sanit. Eng. Div. 1972, 98, 79–99. [Google Scholar]

- Serra, T.; Colomer, J.; Casamitjana, X. Aggregation and breakup of particles in a shear flow. J. Colloid Interface Sci. 1997, 187, 466–473. [Google Scholar] [CrossRef]

- Lu, S.; Ding, Y.; Guo, J. Kinetics of fine particle aggregation in turbulence. Adv. Colloid Inter. Sci. 1998, 78, 197–235. [Google Scholar] [CrossRef]

- Biggs, C.; Lant, P. Activated sludge flocculation: On-line determination of floc size and the effect of shear. Water Res. 2000, 34, 2542–2550. [Google Scholar] [CrossRef]

- van Leussen, W. Macroflocs, fine-grained sediment transport, and their longitudinal variations. Ocean Dyn. 2011, 61, 387–401. [Google Scholar] [CrossRef]

- Shen, X.; Maa, J.P.Y. Modeling floc size distribution of suspended cohesive sediments using quadrature method of moments. Mar. Geol. 2015, 359, 106–119. [Google Scholar] [CrossRef]

- Moruzzi, R.B.; de Oliveira, A.L.; da Conceicao, F.T.; Gregory, J.; Campos, L.C. Fractal dimensions of large aggregates under different flocculation conditions. Sci. Total Environ. 2017, 609, 807–814. [Google Scholar] [CrossRef] [PubMed]

- Winterwerp, J.C.; Manning, A.J.; Martens, C.; de Mulder, T.; Vanlede, J. A heuristic formula for turbulence-induced flocculation of cohesive sediment. Estuar. Coast Shelf Sci. 2006, 68, 195–207. [Google Scholar] [CrossRef]

- Xu, F.; Wang, D.; Riemer, N. An idealized model study of flocculation on sediment trapping in an estuarine turbidity maximum. Cont. Shelf Res. 2010, 30, 1314–1323. [Google Scholar] [CrossRef]

- Verney, R.; Lafite, R.; Brun-cottan, J.C.; Le, P. Behaviour of a floc population during a tidal cycle: Laboratory experiments and numerical modelling. Cont. Shelf Res. 2011, 31, S64–S83. [Google Scholar] [CrossRef]

- Strom, K.; Keyvani, A. Flocculation in a decaying shear field and its implications for mud removal in near-field river mouth discharges. J. Geophys. Res. Oceans 2016, 121, 2142–2162. [Google Scholar] [CrossRef]

- Sherwood, C.R.; Aretxabaleta, A.L.; Harris, C.K.; Rinehimer, J.P.; Verney, R.; Ferre, B. Cohesive and mixed sediment in the regional ocean modeling system (ROMS v3.6) implemented in the coupled ocean atmosphere wave sediment-transport modeling system (COAWST r1179). Geosci. Model Develop. 2018, 11, 1849–1871. [Google Scholar] [CrossRef]

- Kuprenas, R.; Tran, D.; Strom, K. A shear-limited flocculation model for dynamically predicting average floc size. J. Geophys. Res. Oceans 2018, 123, 6736–6752. [Google Scholar] [CrossRef]

- Oles, V. Shear-induced aggregation and breakup of polystyrene latex particles. J. Colloid Interface Sci. 1992, 154, 351–358. [Google Scholar] [CrossRef]

- Bubakova, P.; Pivokonsky, M.; Filip, P. Effect of shear rate on aggregate size and structure in the process of aggregation and at steady state. Powder Technol. 2013, 235, 540–549. [Google Scholar] [CrossRef]

- Hopkins, D.C.; Ducoste, J.J. Characterizing flocculation under heterogeneous turbulence. J. Colloid Interface Sci. 2003, 264, 184–194. [Google Scholar] [CrossRef]

- Manning, A.; Dyer, K. A laboratory examination of floc characteristics with regard to turbulent shearing. Mar. Geol. 1999, 160, 147–170. [Google Scholar] [CrossRef]

- Thomas, D.; Judd, S.; Fawcett, N. Flocculation modelling: a review. Water Res. 1999, 33, 1579–1592. [Google Scholar] [CrossRef]

- Zhu, Z. Theory on orthokinetic flocculation of cohesive sediment: a review. J. Geosci. Environ. Prot. 2014, 2, 24–31. [Google Scholar] [CrossRef]

- Stone, M.; Krishnappan, B. Floc morphology and size distributions of cohesive sediment in steady-state flow. Water Res. 2003, 37, 2739–2747. [Google Scholar] [CrossRef]

- Serra, T.; Casamitjana, X. Structure of the aggregates during the process of aggregation and breakup under a shear flow. J. Colloid Interface Sci. 1998, 206, 505–511. [Google Scholar] [CrossRef] [PubMed]

- Maggi, F.; Mietta, F.; Winterwerp, J.C. Effect of variable fractal dimension on the floc size distribution of suspended cohesive sediment. J. Hydrol. 2007, 343, 43–55. [Google Scholar] [CrossRef]

- Keyvani, A.; Strom, K. Influence of cycles of high and low turbulent shear on the growth rate and equilibrium size of mud flocs. Mar. Geol. 2014, 354, 1–14. [Google Scholar] [CrossRef]

- Son, M.; Hsu, T.J. The effect of variable yield strength and variable fractal dimension on flocculation of cohesive sediment. Water Res. 2009, 43, 3582–3592. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Dong, P. A dynamic model for coastal mud flocs with distributed fractal dimension. J. Coast. Res. 2017, 33, 218–225. [Google Scholar] [CrossRef]

- Guerin, L.; Saudejaud, C.C.; Line, A.; Frances, C. Dynamics of aggregate size and shape properties under sequenced flocculation in a turbulent Taylor-Couette reactor. J. Colloid Interface Sci. 2017, 491, 167–178. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.P.; Sivakumar, B.; Cui, H.J. Tsallis entropy theory for modelling in water engineering: A review. Entropy 2017, 19, 641–666. [Google Scholar] [CrossRef]

- Chiu, C.L.; Said, C.A.A. Maximum and mean velocities and entropy in open-channel flow. J. Hydraul. Eng. 1995, 121, 26–35. [Google Scholar] [CrossRef]

- Cui, H.; Singh, V.P. One dimensional velocity distribution in open channels using Tsallis entropy. J. Hydrol. Eng. 2014, 19, 290–298. [Google Scholar] [CrossRef]

- Luo, H.; Singh, V.P. Entropy theory for two-dimensional velocity distribution. J. Hydrol. Eng. 2011, 16, 303–315. [Google Scholar] [CrossRef]

- Kumbhakar, M.; Ghoshal, K. One-dimensional velocity distribution in open channels using Renyi entropy. Stochastic. Environ. Res. Risk Assess. 2017, 31, 949–959. [Google Scholar] [CrossRef]

- Chiu, C.L.; Jin, W.; Chen, Y.C. Mathematical models of distribution of sediment concentration. J. Hydraul. Eng. 2000, 1, 16–23. [Google Scholar] [CrossRef]

- Cui, H.; Singh, V.P. Suspended sediment concentration in open channels using Tsallis entropy. J. Hydrol. Eng. 2013, 19, 966–977. [Google Scholar] [CrossRef]

- Kumbhakar, M.; Ghoshal, K.; Singh, V.P. Derivation of Rouse equation for sediment concentration using Shannon entropy. Physics A 2017, 465, 494–499. [Google Scholar] [CrossRef]

- Sterling, M.; Knight, D. An attempt at using the entropy approach to predict the transverse distribution of boundary shear stress in open channel flow. Stochastic. Environ. Res. Risk Assess. 2002, 16, 127–142. [Google Scholar] [CrossRef]

- Bonakdari, H.; Sheikh, Z.; Tooshmalani, M. Comparison between Shannon and Tsallis entropies for prediction of shear stress distribution in open channels. Stochastic. Environ. Res. Risk Assess. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Shannon, C.E. A mathematical theory of communications, I and II. Bell Syst. Tech. J. 1948, 27, 379–423. [Google Scholar] [CrossRef]

- Maggi, F. Stochastic flocculation of cohesive sediment: analysis of floc mobility within the floc size spectrum. Water Resour. Res. 2008, 440, 168–182. [Google Scholar] [CrossRef]

- Shin, H.J.; Son, M.W.; Lee, G.H. Stochastic flocculation model for cohesive sediment suspended in water. Water 2015, 47, 2527–2541. [Google Scholar] [CrossRef]

- Jaynes, E.T. Information theory and statistical mechanics I. Phys. Rev. 1957, 106, 620–630. [Google Scholar] [CrossRef]

- Jaynes, E.T. Information theory and statistical mechanics II. Phys. Rev. 1957, 108, 171–190. [Google Scholar] [CrossRef]

- Jaynes, E.T. On the rationale of maximum entropy methods. Proc. IEEE 1982, 70, 939–952. [Google Scholar] [CrossRef]

- Chiu, C.L. Entropy and probability concepts in hydraulics. J. Hydraul. Eng. 1987, 113, 583–600. [Google Scholar] [CrossRef]

- Khozani, Z.S.; Bonakdari, H. Formulating the shear stress distribution in circular open channels based on the Renyi entropy. Physics A 2018, 490, 114–126. [Google Scholar] [CrossRef]

- Singh, V.P. A Shannon entropy-based general derivation of infiltration equations. Trans. ASABE 2011, 54, 123–129. [Google Scholar] [CrossRef]

- Tsallis, C. Possible generalization of Boltzmann-Gibbs statistics. J. Stat. Phys. 1988, 52, 479–487. [Google Scholar] [CrossRef]

- Singh, V.P. Tsallis entropy theory for derivation of infiltration equations. Trans. ASABE 2010, 53, 447–463. [Google Scholar] [CrossRef]

- Burban, P.Y.; Lick, W.; Lick, J. The flocculation of fine—Grained sediments in estuarine waters. J. Geophys. Res. Ocean 1989, 94, 8323–8330. [Google Scholar] [CrossRef]

- Spicer, P.T.; Pratsinis, S.E. Shear induced flocculation: the evolution of floc structure and the shape of the size distribution at steady state. Water Res. 1996, 30, 1048–1056. [Google Scholar] [CrossRef]

- Selomulya, C.; Bushell, G.; Amal, R.; Waite, T.D. Aggregation mechanisms of rates of different particle sizes in a controlled shear environment. Langmuir 2002, 18, 1974–1984. [Google Scholar] [CrossRef]

- Colomer, J.; Peters, F.; Marrasé, C. Experimental analysis of coagulation of particles under low-shear flow. Water Res. 2005, 39, 2994–3000. [Google Scholar] [CrossRef] [PubMed]

| Experimental Data Number | Experimental Material | Turbulence-Generating Environment | Flow Shear Condition | Data Source | ||

|---|---|---|---|---|---|---|

| T1 | Detroit river sediment | Couette-flow chamber | = 1.04 × 10−4; G = 200 | 4 | 87 | Burban et al. [58] |

| T2 | = 1.66 × 10−3; G = 200 | 4 | 25.21 | |||

| T3 | Polystyrene latex | Couette-flow system formed by two cylinders | = 5 × 10−5; G = 75 | 2.17 | 39.54 | Oles [24] |

| T4 | = 5 × 10−5; G = 100 | 2.17 | 36.65 | |||

| T5 | = 5 × 10−5; G = 125 | 2.17 | 26.52 | |||

| T6 | = 5 × 10−5; G = 150 | 2.17 | 14.47 | |||

| T7 | Polystyrene particle | Baffled stirred tank | = 2.10 × 10−5; G = 63 s−1 Alum concentration: 4.3 mg/L | 0.87 | 13.54 | Spicer and Pratsinis [59] |

| T8 | = 2.10 × 10−5; G = 63 s−1 Alum concentration: 10.7 mg/L | 0.87 | 41.90 | |||

| T9 | = 2.10 × 10−5; G = 63 s−1 Alum concentration: 32 mg/L | 0.87 | 84.20 | |||

| T10 | = 2.10 × 10−5; G = 95 s−1 Alum concentration: 32 mg/L | 0.87 | 67.01 | |||

| T11 | Latex particle | Couette-flow system | = 2.5 × 10−5; G = 25 | 2 | 46.06 | Serra et al. [12] |

| T12 | = 2.5 × 10−5; G = 50 | 2 | 38.84 | |||

| T13 | = 2.5 × 10−5; G = 90 | 2 | 30 | |||

| T14 | = 2.5 × 10−5; G = 135 | 2 | 19.87 | |||

| T15 | = 2.5 × 10−5; G = 195 | 2 | 11.74 | |||

| T16 | Latex particle | Couette-flow system | = 5 × 10−5; G = 25 | 2 | 41.36 | Serra and Casamitjana [31] |

| T17 | = 5 × 10−5; G = 32 | 2 | 37.73 | |||

| T18 | = 5 × 10−5; G = 50 | 2 | 35.23 | |||

| T19 | Activated sludge | Baffled batch vessel | = 5 × 10−2; G = 19.4 | 15 *** | 121.27 | Biggs and Lant [20] |

| T20 | = 5 × 10−2; G = 37 | 15 *** | 100.56 | |||

| T21 | = 5 × 10−2; G = 113 | 15 *** | 58.66 | |||

| T22 | = 5 × 10−2; G = 346 | 15 *** | 24.14 | |||

| T23 | Polystyrene latex particle | Couette-flow system | = 3.76 × 10−5; G = 64 s−1 | 0.81 | 70.94 | Selomulya et al. [60] |

| T24 | = 3.76 × 10−5; G = 100 s−1 | 0.81 | 67.76 | |||

| T25 | = 3.76 × 10−5; G = 246 s−1 | 0.81 | 38.07 | |||

| T26 | Hay river sediment, Canada | Annular flume | Bed shear stress = 0.123 Pa | 19.1 | 128.97 | Stone and Krishnappan [30] |

| T27 | Bed shear stress = 0.212 Pa | 19.1 | 178.1 | |||

| T28 | Bed shear stress = 0.323 Pa | 19.1 | 161.84 | |||

| T29 | Polystyrene latex particle | Flask shaking table | = 2 × 10−5; = 0.45 | 2.1 | 7.88 | Colomer et al. [61] |

| T30 | = 2 × 10−5; = 0.75 | 2.1 | 9.34 | |||

| T31 | = 2 × 10−5; = 0.96 | 2.1 | 9.05 | |||

| T32 | = 2 × 10−5; = 1.41 | 2.1 | 9.68 | |||

| T33 | = 2 × 10−5; = 2.4 | 2.1 | 10.42 |

| Experimental Data Number | Data Source | Fitting Result | Entropy Function | |||

|---|---|---|---|---|---|---|

| RBIAS | RMSE | Assume m = 2 | ||||

| T1 | Burban et al. [58] | 0.975 | 0.054 | 4.170 | 4.419 | 82.988 |

| T2 | 0.995 | 0.023 | 0.640 | 3.054 | 21.163 | |

| T3 | Oles [24] | 0.944 | 0.213 | 3.134 | 3.621 | 37.343 |

| T4 | 0.948 | 0.160 | 2.341 | 3.540 | 34.451 | |

| T5 | 0.989 | 0.080 | 0.960 | 3.193 | 24.309 | |

| T6 | 0.982 | 0.044 | 0.512 | 2.510 | 12.219 | |

| T7 | Spicer and Pratsinis [59] | 0.962 | 0.076 | 1.053 | 2.539 | 12.591 |

| T8 | 0.964 | 0.069 | 3.280 | 3.714 | 41.006 | |

| T9 | 0.999 | 0.014 | 1.511 | 4.423 | 83.318 | |

| T10 | 0.978 | 0.039 | 4.038 | 4.192 | 66.125 | |

| T11 | Serra et al. [12] | 0.981 | 0.118 | 2.445 | 3.786 | 44.037 |

| T12 | 0.962 | 0.121 | 3.028 | 3.607 | 36.813 | |

| T13 | 0.976 | 0.045 | 1.261 | 3.332 | 27.964 | |

| T14 | 0.958 | 0.044 | 0.954 | 2.883 | 17.814 | |

| T15 | 0.850 | 0.076 | 1.078 | 2.276 | 9.637 | |

| T16 | Serra and Casamitjana [31] | 0.899 | 0.121 | 3.606 | 3.673 | 39.335 |

| T17 | 0.952 | 0.104 | 2.600 | 3.576 | 35.702 | |

| T18 | 0.956 | 0.072 | 2.019 | 3.503 | 33.200 | |

| T19 | Biggs and Lant [14] | 0.980 | 0.027 | 3.403 | 4.666 | 106.261 |

| T20 | 0.967 | 0.037 | 4.126 | 4.449 | 85.548 | |

| T21 | 0.960 | 0.036 | 2.087 | 3.776 | 43.637 | |

| T22 | 0.972 | 0.017 | 0.521 | 2.213 | 9.031 | |

| T23 | Selomulya et al. [60] | 0.845 | 0.124 | 7.607 | 4.250 | 70.116 |

| T24 | 0.899 | 0.041 | 3.623 | 4.204 | 66.935 | |

| T25 | 0.979 | 0.019 | 1.106 | 3.618 | 37.233 | |

| T26 | Stone and Krishnappan [30] | 0.887 | 0.085 | 13.304 | 4.699 | 109.861 |

| T27 | 0.974 | 0.035 | 8.351 | 5.069 | 158.994 | |

| T28 | 0.984 | 0.023 | 5.988 | 4.961 | 142.733 | |

| T29 | Colomer et al. [61] | 0.993 | 0.021 | 0.189 | 1.754 | 5.607 |

| T30 | 0.992 | 0.035 | 0.286 | 1.980 | 7.102 | |

| T31 | 0.993 | 0.038 | 0.304 | 1.939 | 6.806 | |

| T32 | 0.994 | 0.021 | 0.220 | 2.026 | 7.448 | |

| T33 | 0.988 | 0.032 | 0.350 | 2.119 | ||

| Model Name | Formulation |

|---|---|

| Winterwerp model | |

| Son and Hsu (2008) model | |

| Son and Hsu (2009) model |

| References | Experimental Conditions | Fitting Effect | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| The Present Model | Winterwerp Model | Son and Hsu (2008) Model | Son and Hsu (2009) Model | ||||||||||

| RBIAS | NRMSE | RBIAS | NRMSE | RBIAS | NRMSE | RBIAS | NRMSE | ||||||

| Burban et al. [58] | = 1.04 × 10−4; = 200 | 0.98 | 0.054 | 4.170 | 0.83 | 0.282 | 19.860 | 0.86 | 0.255 | 17.587 | 0.90 | 0.190 | 12.942 |

| = 1.66 × 10−3; = 200 | 0.99 | 0.023 | 0.640 | 0.97 | 0.037 | 1.083 | 0.97 | 0.026 | 0.424 | 0.98 | 0.036 | 1.053 | |

| Biggs and Lant [14] | = 5 × 10−2; = 19.4 | 0.98 | 0.027 | 3.403 | 0.89 | 0.053 | 7.218 | 0.90 | 0.059 | 7.917 | 0.90 | 0.067 | 8.889 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z. A Simple Explicit Expression for the Flocculation Dynamics Modeling of Cohesive Sediment Based on Entropy Considerations. Entropy 2018, 20, 845. https://doi.org/10.3390/e20110845

Zhu Z. A Simple Explicit Expression for the Flocculation Dynamics Modeling of Cohesive Sediment Based on Entropy Considerations. Entropy. 2018; 20(11):845. https://doi.org/10.3390/e20110845

Chicago/Turabian StyleZhu, Zhongfan. 2018. "A Simple Explicit Expression for the Flocculation Dynamics Modeling of Cohesive Sediment Based on Entropy Considerations" Entropy 20, no. 11: 845. https://doi.org/10.3390/e20110845

APA StyleZhu, Z. (2018). A Simple Explicit Expression for the Flocculation Dynamics Modeling of Cohesive Sediment Based on Entropy Considerations. Entropy, 20(11), 845. https://doi.org/10.3390/e20110845