Development of a Refractory High Entropy Superalloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

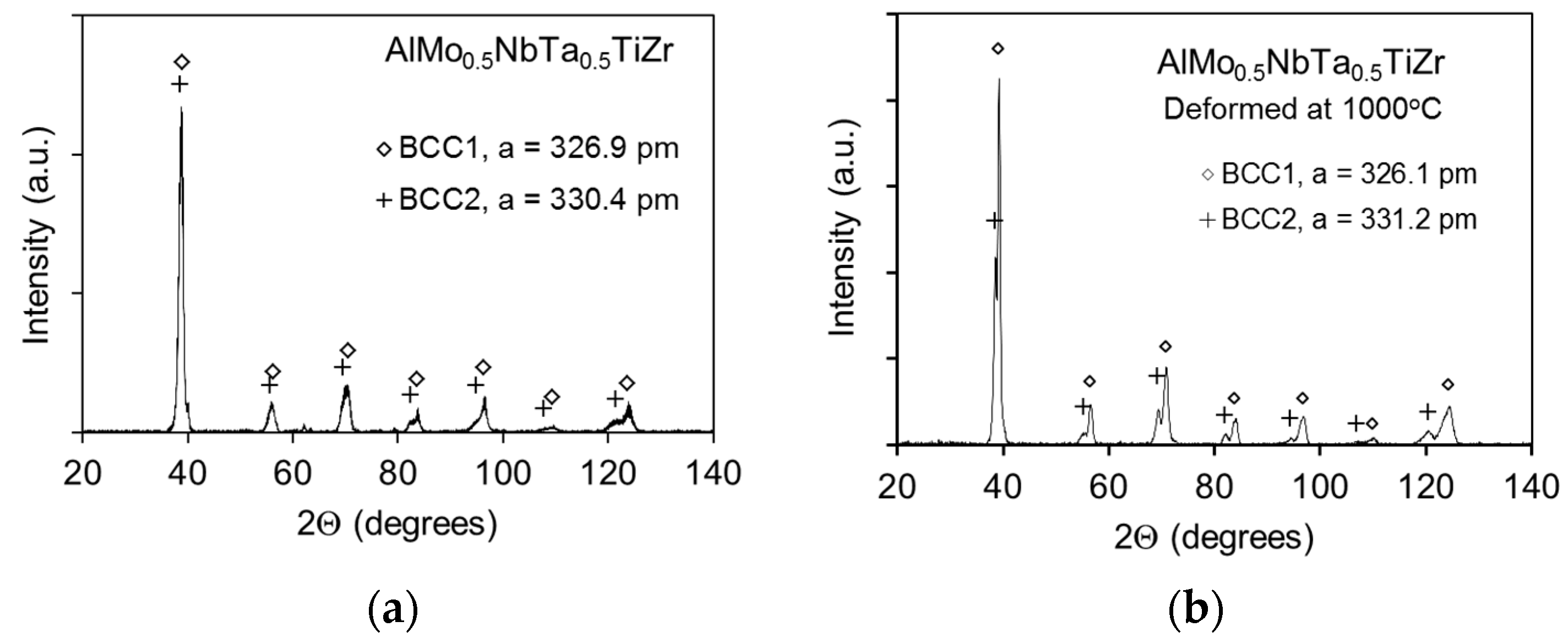

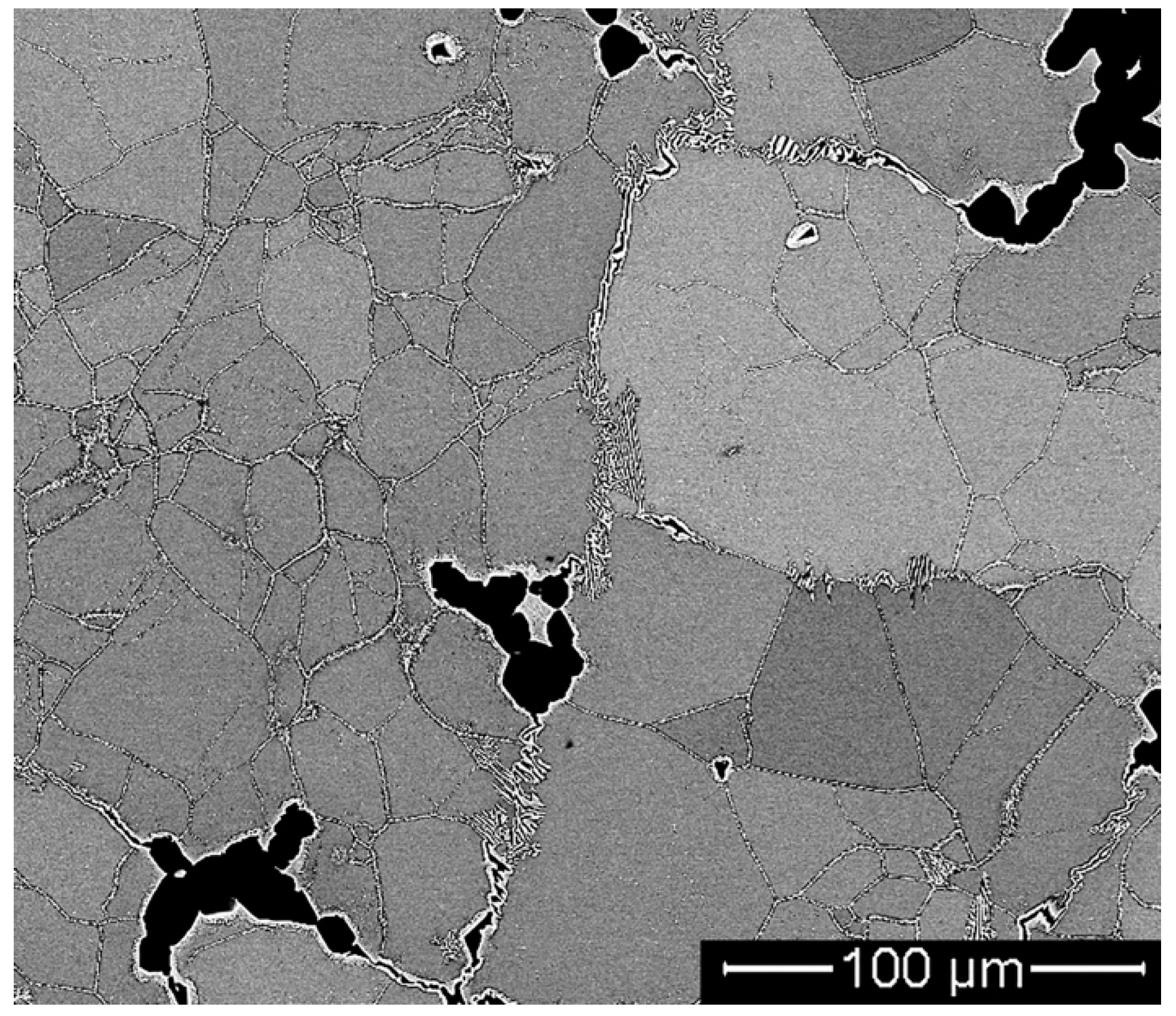

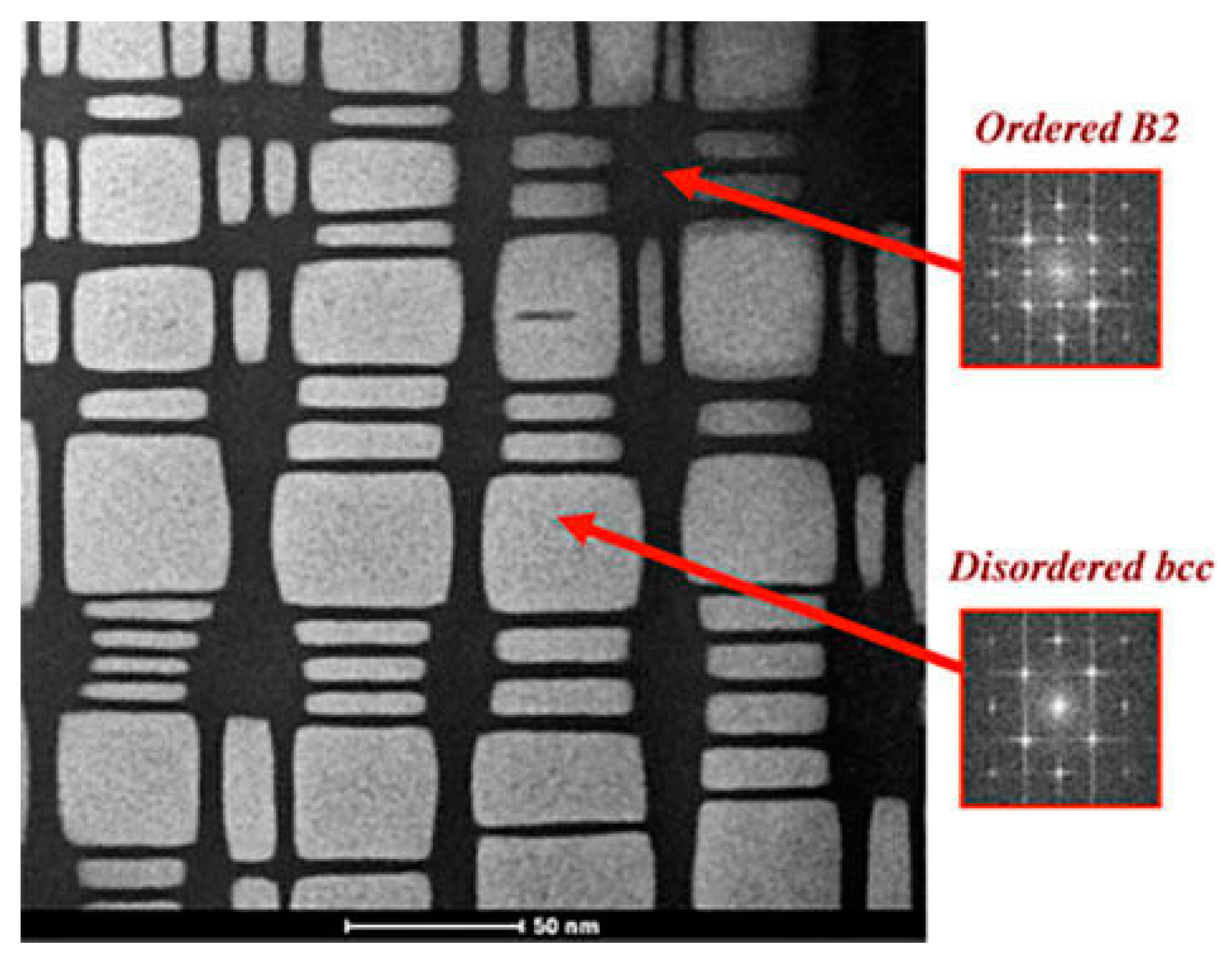

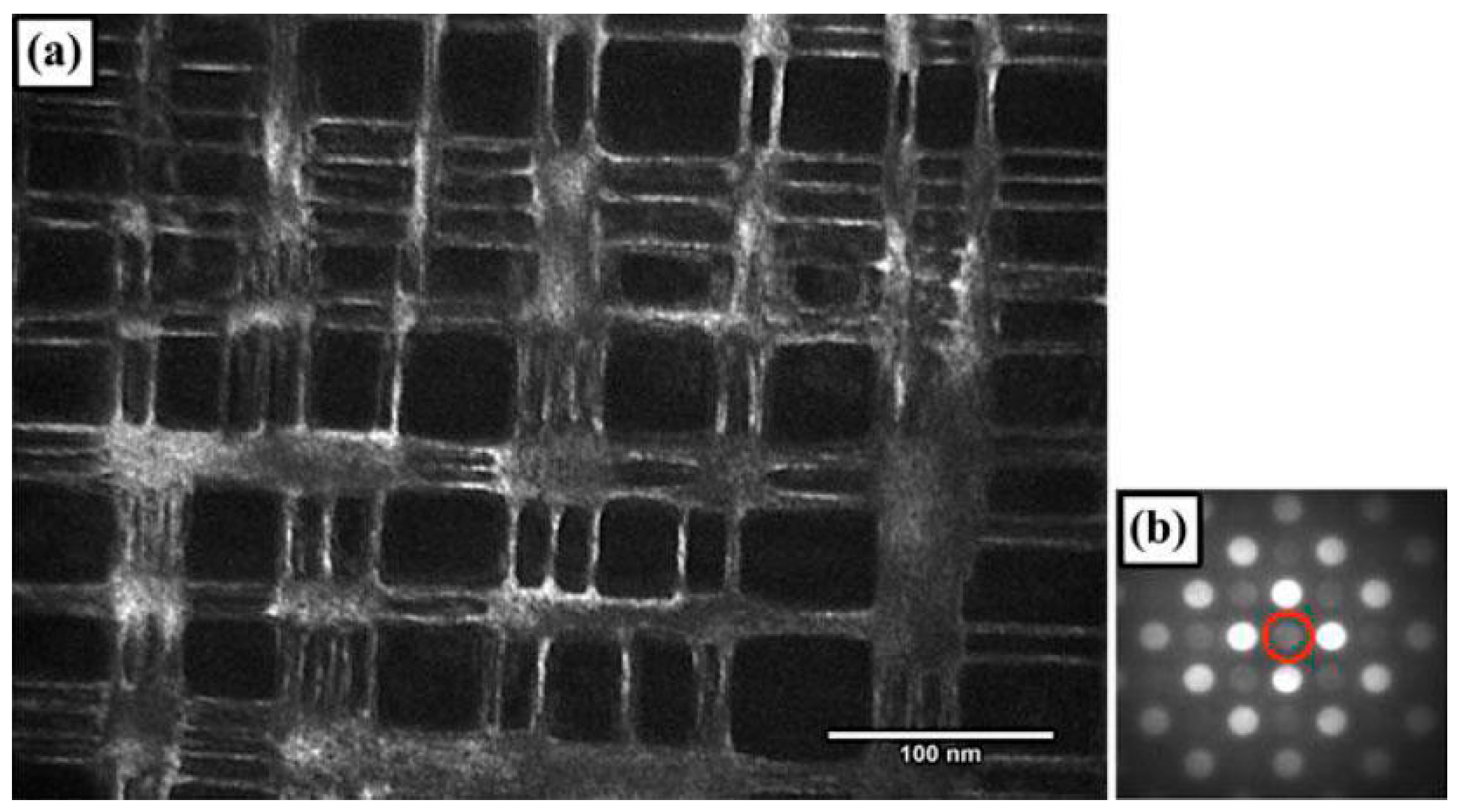

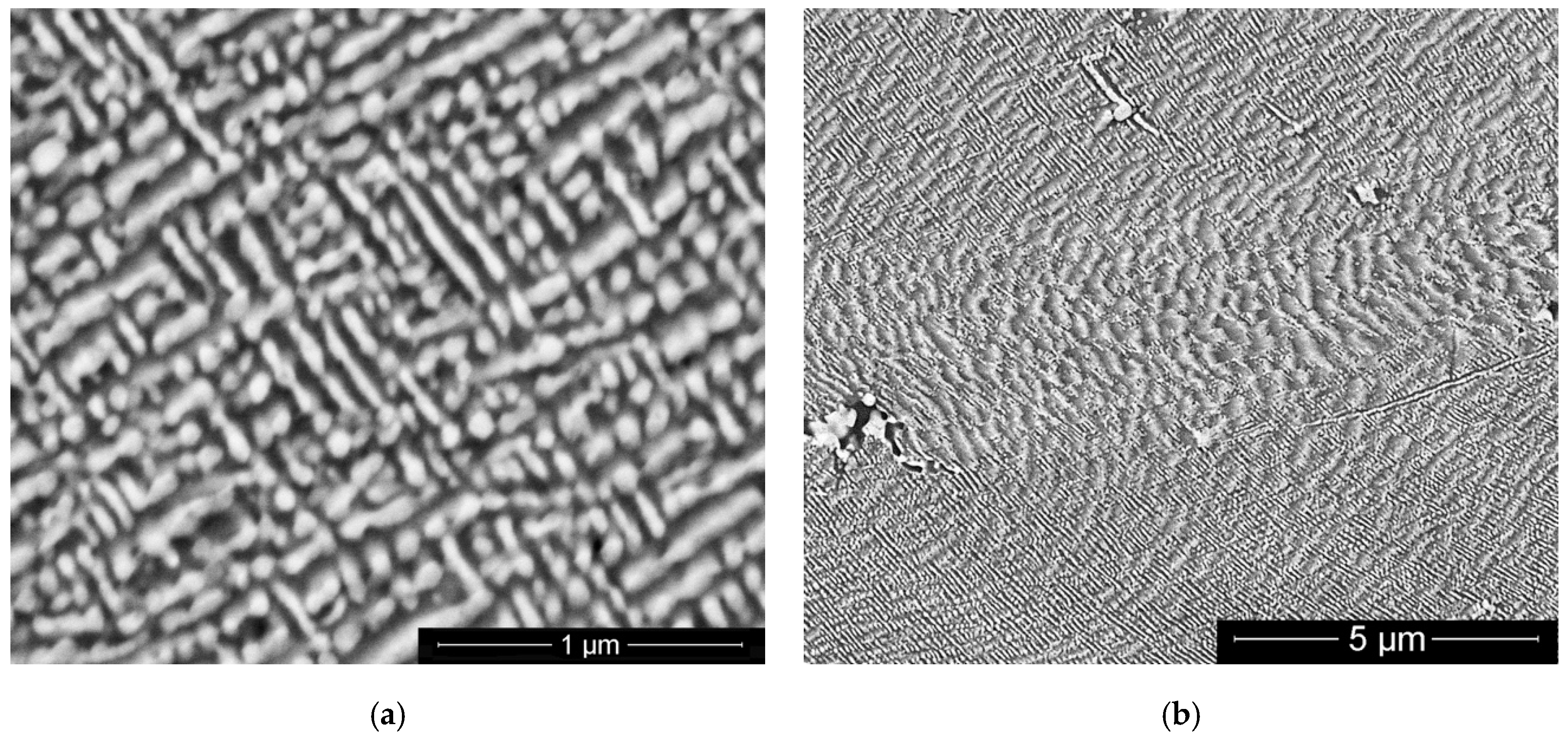

3.1. Microstructure Analysis

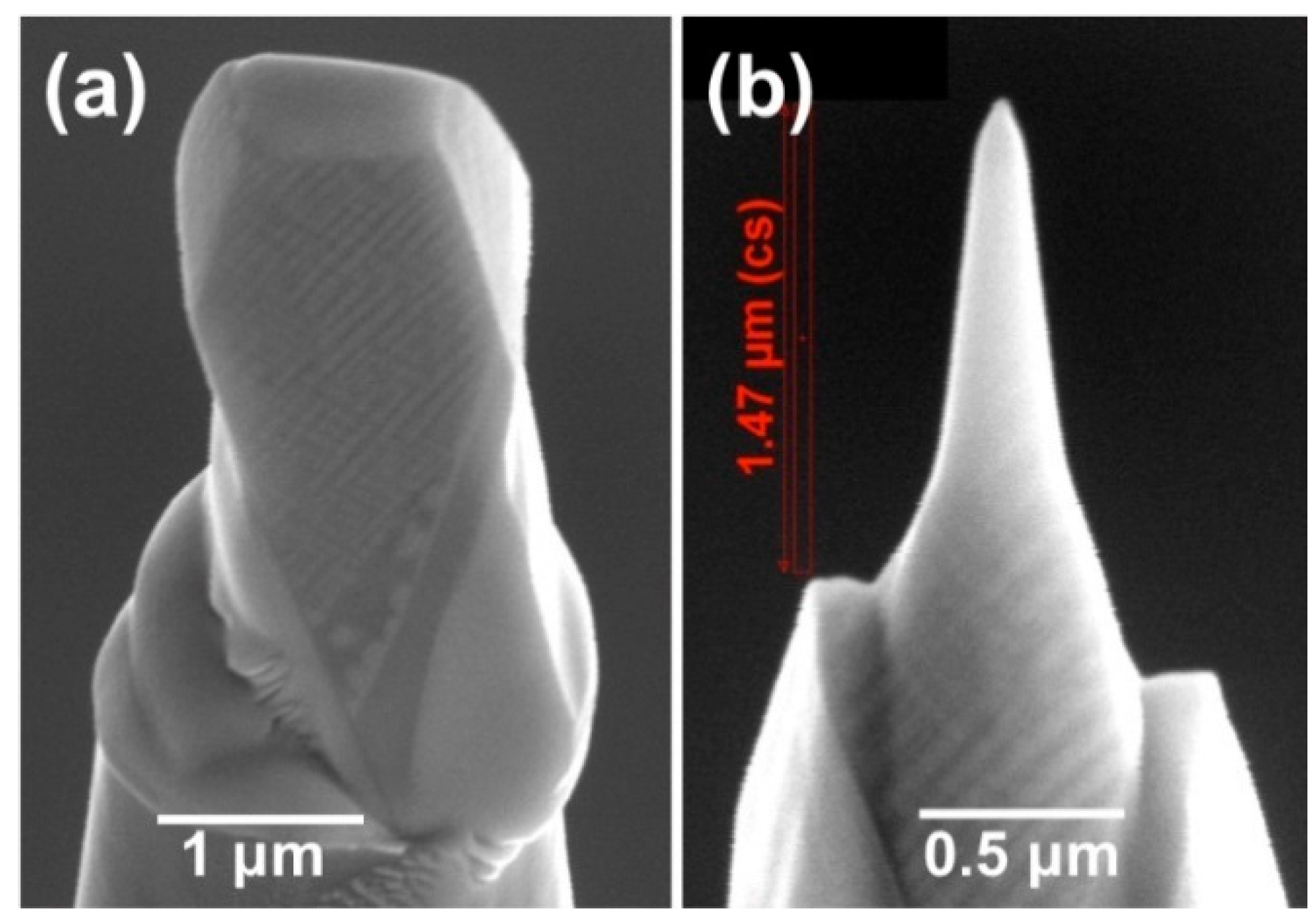

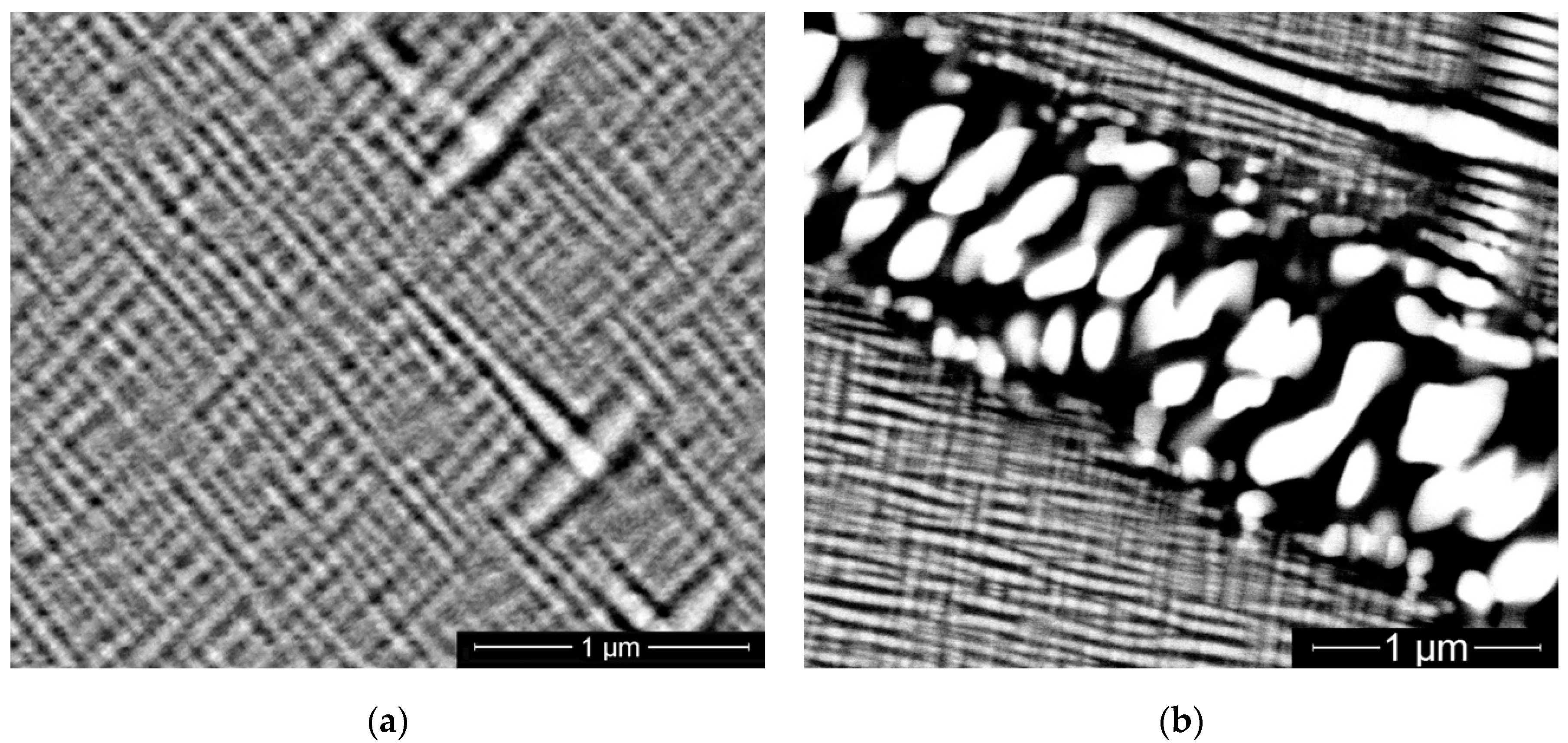

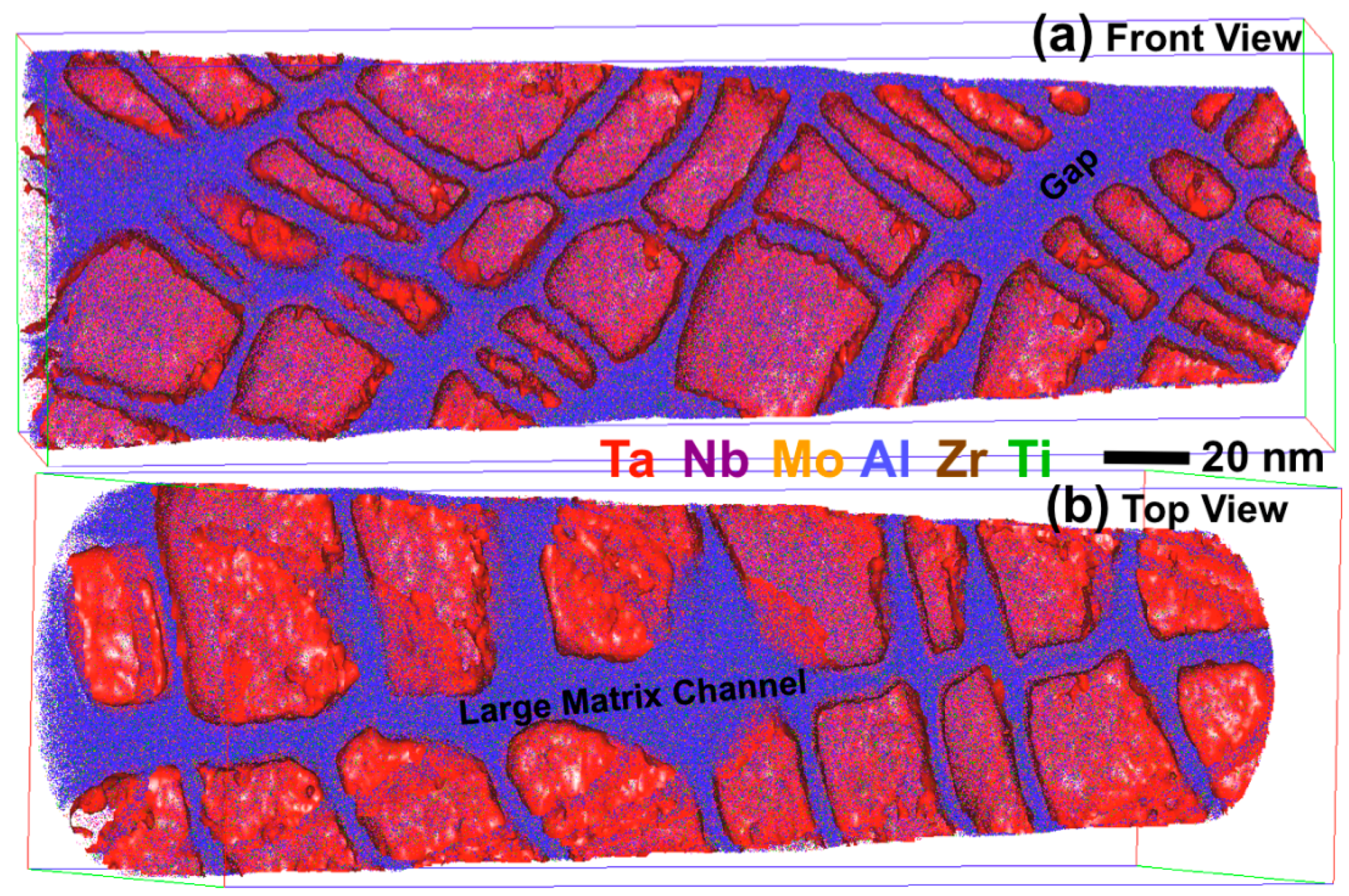

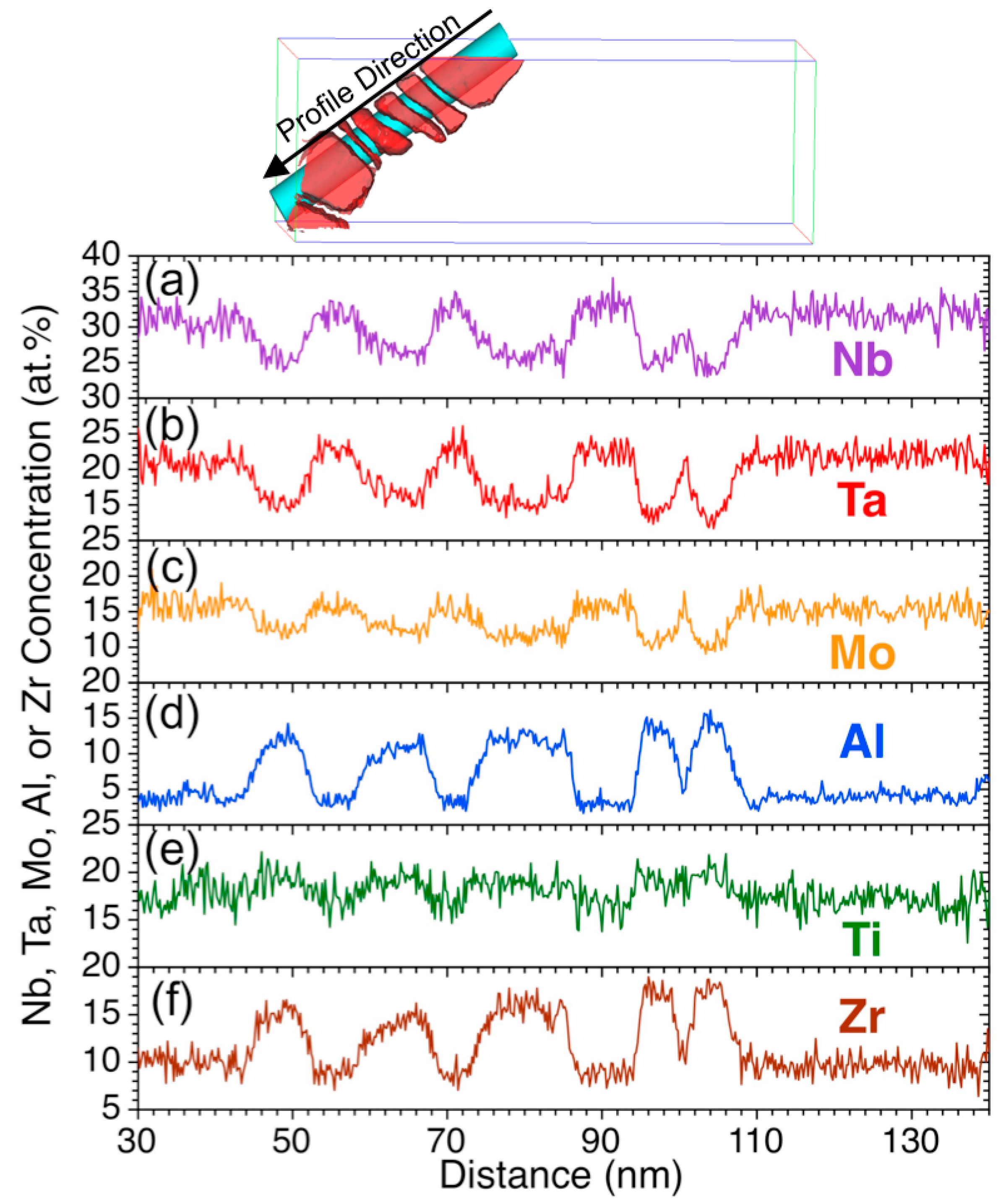

3.2. Atom-Probe Tomographic Analyses

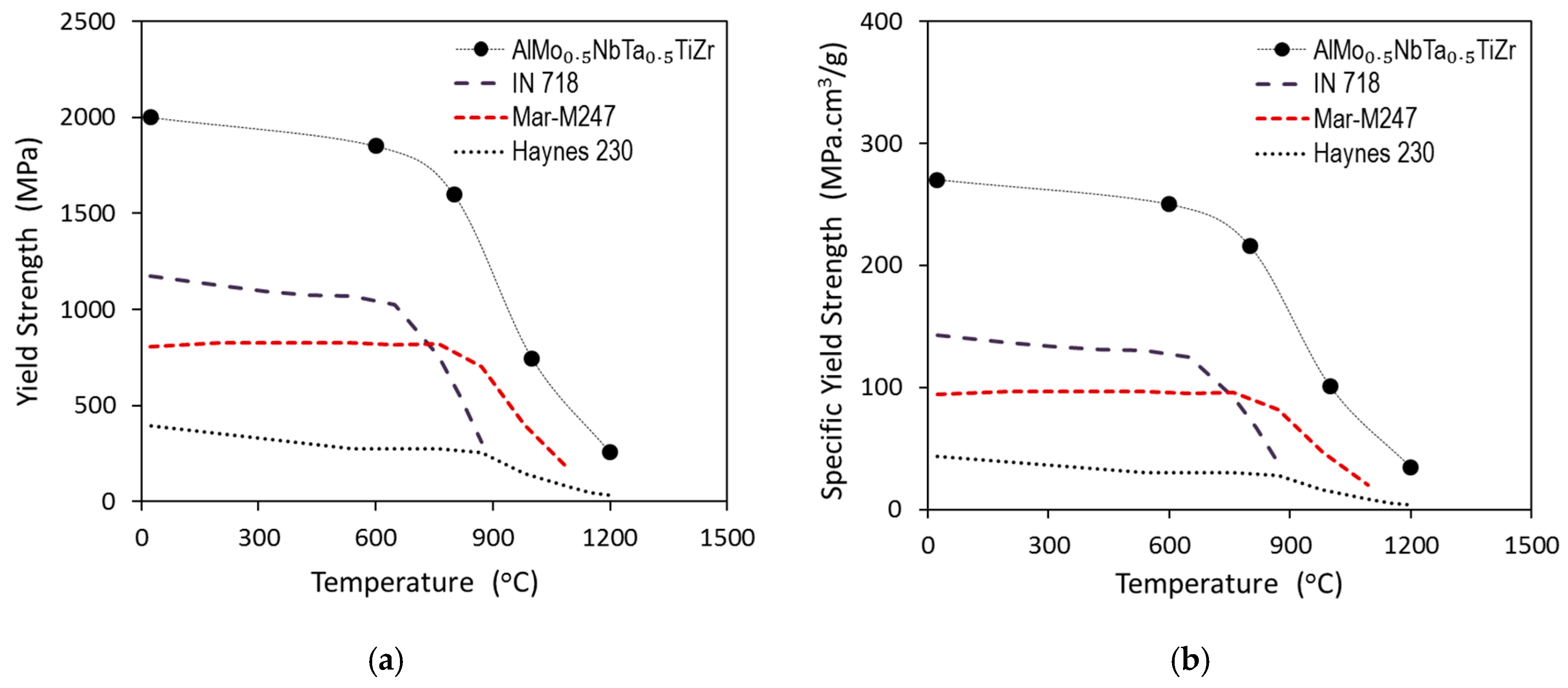

3.3. Mechanical Properties

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| APT | atom-probe tomography |

| BCC | body-centered cubic |

| BSE | back-scattered electron |

| EBSD | electron backscatter diffraction |

| FCC | face-centered cubic |

| FIB | focus ion beam |

| HEA | high entropy alloy |

| HIP | hot isostatic pressing |

| RHEA | refractory high entropy alloy |

| SEM | scanning electron microscopy |

| STEM | scanning transmission electron microscopy |

| TEM | transmission electron microscopy |

References

- Neergaard, L.J.; Pasiliao, C.L.; Witeof, Z.; Shelton, A. Materials data requirements for design of an expendable hypersonic airbreathing airframe. In Proceedings of Joint Army Navy NASA Air Force, Albuquerque, NM, USA, 8–12 December 2014.

- Brown, W.F.; Mindin, H.; Ho, C.Y. Aerospace Structural Metals Handbook; CINDAS/Purdue University: Weat Latayette, IN, USA, 1992; Volume 5, p. 4218 and p. 5502. [Google Scholar]

- Gorr, B.; Christ, H.J.; Mukherji, D.; Rosler, J. Thermodynamic calculations in the development of high-temperature Co-Re-based alloys. J. Alloys Compd. 2014, 582, 50–58. [Google Scholar] [CrossRef]

- Yamabe-Mitarai, Y.; Ro, Y.; Maruko, T.; Harada, H. Ir-base refractory superalloys for ultra-high temperatures. Metall. Mater. Trans. A 1998, 29A, 537–749. [Google Scholar] [CrossRef]

- Yamabe-Mitarai, Y.; Harada, H. Design of quaternary Ir-Nb-Ni-Al refractory superalloys. Metall. Mater. Trans. A 2000, 31, 173–178. [Google Scholar]

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Tsai, M.-H.; Yeh, J.-W. High-Entropy Alloys: A Critical Review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Murty, B.S.; Yeh, J.-W.; Ranganathan, S. High Entropy Alloys; Butterworth-Heinemann: London, UK, 2014. [Google Scholar]

- Miracle, D.B.; Miller, J.D.; Senkov, O.N.; Woodward, C.; Uchic, M.D.; Tiley, J. Exploration and development of high entropy alloys for structural applications. Entropy 2014, 16, 494–525. [Google Scholar] [CrossRef]

- Yeh, J.-W. Alloy Design Strategies and Future Trends in High-Entropy Alloys. JOM 2013, 65, 1759–1771. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Miracle, D.B.; Woodward, C. Mechanical properties of low-density, refractory multi-principal element alloys of the Cr-Nb-Ti-V-Zr system. Mat. Sci. Eng. A 2013, 565, 51–62. [Google Scholar] [CrossRef]

- Wang, Y.P.; Li, B.S.; Fu, H.Z. Solid solution or intermetallics in a high-entropy alloy. Adv. Eng. Mater. 2009, 11, 641–644. [Google Scholar] [CrossRef]

- Singh, S.; Wanderka, N.; Murty, B.S.; Glatzel, U.; Banhart, J. Decomposition in multi-component AlCoCrCuFeNi high-entropy alloy. Acta Mater. 2011, 59, 182–190. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Senkov, O.N.; Scott, J.M.; Senkova, S.V.; Miracle, D.B.; Woodward, C.F. Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy. J. Alloys Compd. 2011, 509, 6043–6048. [Google Scholar] [CrossRef]

- Senkov, O.N.; Woodward, C.F. Microstructure and properties of a refractory NbCrMo0.5Ta0.5TiZr alloy. Mater. Sci. Eng. A 2011, 529, 311–320. [Google Scholar] [CrossRef]

- Senkov, O.N.; Scott, J.M.; Senkova, S.V.; Meisenkothen, F.; Miracle, D.B.; Woodward, C.F. Microstructure and elevated temperature properties of a refractory TaNbHfZrTi alloy. J. Mater. Sci. 2012, 47, 4062–4074. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Dimiduk, D.M.; Woodward, C.; Miracle, D.B. Oxidation behavior of a refractory NbCrMo0.5Ta0.5TiZr alloy. J. Mater. Sci. 2012, 47, 6522–6534. [Google Scholar] [CrossRef]

- Senkov, O.N.; Woodward, C.; Miracle, D.B. Microstructure and properties of aluminum-containing refractory high-entropy alloys. JOM 2014, 66, 2030–2042. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Woodward, C. Effect of aluminum on the microstructure and properties of two refractory high entropy alloys. Acta Mater. 2014, 68, 214–228. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Woodward, C.; Miracle, D.B. Low-density, refractory multi-principal element alloys of the Cr–Nb–Ti–V–Zr system: microstructure and phase analysis. Acta Mater. 2013, 61, 1545–1557. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Shaysultanov, D.G.; Salishchev, G.A.; Tikhonovsky, M.A. Structure and mechanical properties of a light-weight AlNbTiV high entropy alloy. Mater. Lett. 2015, 142, 153–155. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Yurchenko, N.Y.; Sokolovsky, V.S.; Tikhonovsky, M.A.; Salishchev, G.A. An AlNbTiVZr0.5 high-entropy alloy combining high specific strength and good ductility. Mater. Lett. 2015, 161, 136–139. [Google Scholar] [CrossRef]

- Miller, M.K.; Forbes, R.G. Atom-Probe Tomography: The Local Electrode Atom Probe; Springer: New York, NY, USA, 2014. [Google Scholar]

- Seidman, D.N. Three-dimensional atom probe tomography: advances and applications. Annu. Rev. Mater. Res. 2007, 37, 127–158. [Google Scholar] [CrossRef]

- Seidman, D.N.; Stiller, K. An Atom-Probe Tomography Primer. Mater. Res. Soc. Bulletin 2009, 34, 717–721. [Google Scholar] [CrossRef]

- Miller, M.K.; Russell, K.F.; Thompson, G. Strategies for fabricating atom probe specimens with a dual beam FIB. Ultramicroscopy 2005, 102, 287–298. [Google Scholar] [CrossRef] [PubMed]

- Thompson, K.; Lawrence, D.J.; Larson, D.J.; Olson, J.D.; Kelly, T.F.; Gorman, B. In-situ site-specific specimen preparation for atom probe tomography. Ultramicroscopy 2007, 107, 131–139. [Google Scholar] [CrossRef] [PubMed]

- Sosa, J.M.; Jensen, J.K.; Huber, D.E.; Viswanathan, G.B.; Gibson, M.A.; Fraser, H.L. Three-dimensional characterisation of the microstructure of an high entropy alloy using STEM/HAADF tomography. Mater. Sci. Technol. 2015, 31, 1250–1258. [Google Scholar] [CrossRef]

- Okamoto, H. Phase Diagrams for Binary Alloys, 2nd ed.; ASM International: Materials Park, OH, USA, 2010. [Google Scholar]

- Donachie, M.J.; Donachie, S.J. Superalloys: A Technical Guide, 2nd ed.; ASM International: Materials Park, OH, USA, 2002. [Google Scholar]

- Cahn, J.W. On spinodal decomposition in cubic crystals. Acta Metall. 1962, 10, 179–183. [Google Scholar] [CrossRef]

- Cahn, J.W. Coherent fluctuations and nucleation in isotropic solids. Acta Metall. 1962, 10, 907–913. [Google Scholar] [CrossRef]

- Cahn, R.W.; Haasen, P. Physical Metallurgy, 4th ed.; North Holland: Amsterdam, The Netherlands, 1996; Volume 1. [Google Scholar]

- Binder, K.; Fratzl, P. Spinodal Decomposition. In Phase Transformations in Materials; Kostorz, G., Ed.; Wiley-VCH: Weinheim, Germany, 2001; pp. 409–480. [Google Scholar]

- Soffa, W.A.; Laughlin, D.E. Recent Experimental Studies of Continuous Transformations in Alloys: An Overview; Aaronson, H.I., Laughlin, D.E., Sekerka, R.F., Wayman, C.M., Eds.; AIME: Warrendale, PA, USA, 1982; pp. 159–183. [Google Scholar]

- Nishimori, H.; Onuki, A. Pattern formation in phase-separating alloys with cubic symmetry. Phys. Rev. B 1990, 42, 980. [Google Scholar] [CrossRef]

- Special Metals: Inconel® Alloy 718. Available online: www.specialmetals.com/documents/ Inconel%20alloy%20718.pdf (accessed on 1 February 2016).

- Kaufman, M. Properties of cast Mar-M247 for turbine blisk applications. Superalloys 1984, 1984, 43–52. [Google Scholar]

- Haynes International, High-temperature Tech Brief: HAYNES® 230® Alloy. Available online: www.haynesintl.com/pdf/h3060.pdf (accessed on 1 February 2016).

| Element | Al | Mo | Nb | Ta | Ti | Zr |

|---|---|---|---|---|---|---|

| Composition | 20.4 | 10.5 | 22.4 | 10.1 | 17.8 | 18.8 |

| Region | Al | Mo | Nb | Ta | Ti | Zr |

|---|---|---|---|---|---|---|

| Overall APT reconstruction 1 | 17.6 | 10.1 | 21.0 | 10.6 | 20.9 | 19.6 |

| Cuboidal precipitates 2 | 3.7 | 15.6 | 31.8 | 21.9 | 17.2 | 9.5 |

| Thin matrix channels between precipitates 2 | 12.1 | 11.7 | 25.8 | 15.2 | 19.2 | 15.8 |

| Large long matrix channel 2 | 25.9 | 5.5 | 14.2 | 4.0 | 24.1 | 25.9 |

| Large gap in cuboidal row 2 | 26.1 | 7.7 | 13.7 | 3.7 | 24.1 | 24.1 |

| T, °C | σ0.2, MPa | σp, MPa | δ, % |

|---|---|---|---|

| 23 | 2000 | 2368 | 10 |

| 600 | 1870 | 2210 | 10 |

| 800 | 1597 | 1810 | 11 |

| 1000 | 745 | 772 | > 50 |

| 1200 | 250 | 275 | > 50 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Senkov, O.N.; Isheim, D.; Seidman, D.N.; Pilchak, A.L. Development of a Refractory High Entropy Superalloy. Entropy 2016, 18, 102. https://doi.org/10.3390/e18030102

Senkov ON, Isheim D, Seidman DN, Pilchak AL. Development of a Refractory High Entropy Superalloy. Entropy. 2016; 18(3):102. https://doi.org/10.3390/e18030102

Chicago/Turabian StyleSenkov, Oleg N., Dieter Isheim, David N. Seidman, and Adam L. Pilchak. 2016. "Development of a Refractory High Entropy Superalloy" Entropy 18, no. 3: 102. https://doi.org/10.3390/e18030102

APA StyleSenkov, O. N., Isheim, D., Seidman, D. N., & Pilchak, A. L. (2016). Development of a Refractory High Entropy Superalloy. Entropy, 18(3), 102. https://doi.org/10.3390/e18030102