Exergy Analysis of Flat Plate Solar Collectors

Abstract

: This study proposes the concept of the local heat loss coefficient and examines the calculation method for the average heat loss coefficient and the average absorber plate temperature. It also presents an exergy analysis model of flat plate collectors, considering non-uniformity in temperature distribution along the absorber plate. The computation results agree well with experimental data. The effects of ambient temperature, solar irradiance, fluid inlet temperature, and fluid mass flow rate on useful heat rate, useful exergy rate, and exergy loss rate are examined. An optimal fluid inlet temperature exists for obtaining the maximum useful exergy rate. The calculated optimal fluid inlet temperature is 69 °C, and the maximum useful exergy rate is 101.6 W. Exergy rate distribution is analyzed when ambient temperature, solar irradiance, fluid mass flow rate, and fluid inlet temperature are set to 20 °C, 800 W/m2, 0.05 kg/s, and 50 °C, respectively. The exergy efficiency is 5.96%, and the largest exergy loss is caused by the temperature difference between the absorber plate surface and the sun, accounting for 72.86% of the total exergy rate.1. Introduction

Solar energy, a clean and renewable energy source with no harmful environmental effects, has received considerable attention for generating heat and electricity [1,2]. The flat plate solar collector is the main component of solar heating systems. Thus, the performance of the plate solar collector is important. To analyze the performance of solar collectors, the energy equation alone does not account for internal losses, so it is not a sufficient criterion for flat plate solar collector efficiency [3]. Therefore, an analysis based on the second law of thermodynamics that determines the exergy of the system is necessary. The effect of some vital parameters on the exergy of flat plate collectors is also necessary to optimize solar system design and operation.

Solar collectors have been examined in terms of their exergy, exergy efficiency, and entropy generation [4–6]. Bejan et al. conducted an exergy analysis of a solar collector and found that the amount of exergy delivered by solar collector systems is affected by heat transfer irreversibilities [7]. Suzuki compared flat plate and evacuated tube collectors in terms of exergy [8]. Jafarkazemi et al. conducted both energy and exergy analyses of a flat plate solar collector [9]. Luminosu and Fara proposed an exergy analysis of a flat plate solar collector based on the assumption that fluid inlet temperature is equal to ambient temperature [10]. Farahat et al. attempted to determine the optimum values of the mass flow rate, absorber plate area, and maximum exergy efficiency of a flat plate collector [11]. Akpinar et al. experimentally compared a flat plate solar air heater with several obstacles and one without and found that the efficiency of solar air collectors significantly depends on the solar radiation, the surface geometry of the collectors, and the extension of the air flow line [12]. Alta et al. experimentally compared three plate solar air heaters based on energy and exergy output and found that the heater with double glass covers and fins is more effective than the other two heaters [13]. In all of these studies, however, collector performance was evaluated without considering non-uniformity in the temperature distribution of the absorber plate or even assuming a constant overall heat loss coefficient.

The present work presents a theoretical model considering non-uniformity in temperature distribution along the absorber plate for the exergy analysis of flat plate solar collectors. The model has also been experimentally verified.

2. Theoretical Model

2.1. Energy Equation for Flat Plate Solar Collectors

A micro unit dA is taken from the absorber plate in steady state according to the first law of thermodynamics [14]:

where Qu is the useful heat rate gain of the flat plate solar collector, Qs is the radiation flux absorbed by the absorber plate, Ql is the heat loss from the solar collector to the environment, S is the radiation flux absorbed by a unit area of the absorber plate, Ul is the local heat loss coefficient of dA, Tp is the temperature of dA, and Ta is the ambient temperature.

According to the integral mean value theorem, the following can be deduced from Equation (1):

where Ap is the area of the absorber plate, is the integral average of Ul over the absorber plate, and is the integral average of Tp over the absorber plate.

2.2. Calculation Methodology for Average Heat Loss Coefficient and Average Absorber Plate Temperature

To simplify the model, the following assumptions are made:

- (1)

The plate is in a steady-state heat transfer condition.

- (2)

The temperature gradient in the direction of the fin thickness is negligible.

- (3)

The fluid mass flow rate inside metal tubes is uniform.

- (4)

The pressure drop of the fluid inside metal tubes is neglected.

The absorber plate is composed of metal tubes and fins, it is shown in Figure 1:

Establishing coordinate system as Figure 1, a micro unit dy is taken from the absorber plate. The heat transferred from the absorber plate to the glass comprises radiative heat and convective heat. The radiative heat transfer from the absorber plate to the glass of dy is:

where W is the width of the metal tube and fins (tube center to center distance), σ is the Stefan–Boltzmann constant, is the average temperature of dy, T1 is the temperature of the glass, εp is the emissivity of the absorber plate, and ε1 is the emissivity of the glass.

The convective heat transfer coefficient between the absorber plate and the glass is calculated from the Nusselt number according to the following Equation [15]:

where θ is the collector tilt relative to the horizontal, Ra is the Rayleigh number, g is the gravity, β is the thermal expansion coefficient, d is the distance between the absorber plate and glass, α is the thermal diffusivity, v is the kinematic viscosity, and kair is the thermal conductivity of air.

The convective heat transferred from the absorber plate to the glass of dy is:

The radiative heat transferred from the glass to the sky of dy is as follows [16]:

where the temperature of the sky is .

The convective heat transfer coefficient between the glass and the environment is as follows [17]:

where Va is the wind speed.

The convective heat transferred from the glass to the environment of dy is:

The following equation must hold in steady state:

The top local heat loss coefficient of dy is:

The heat loss coefficient consists of the top, back, and edge heat loss coefficients.

The back heat loss coefficient is calculated as follows [18]:

where kl is the thermal conductivity of the insulation material and Lb is the thickness of the insulation material in back.

The edge heat loss coefficient is estimated as follows [18]:

where Ae is the side area of the collector and Le is the thickness of the insulation material at the side.

The local heat loss coefficient of dy is as follows [18]:

According to Equations (3) to (15), if is known, can be calculated by a numerical method.

Given that the fin thickness is smaller than the width, the temperature gradient in the direction of the fin thickness is neglected. The temperature distribution of the fin in the x direction is as follows [18]:

where Tn is the fin temperature, , λ is the thermal conductivity of the fins, δ is the fin thickness, Tb is the metal tube temperature, and Do is the metal tube outer diameter.

In the steady state, the heat obtained by the absorber plate is equal to the heat obtained by the metal tube and fins. The heat obtained by dy is as follows [14,18]:

where F′ is the collector efficiency factor, Tf is the fluid temperature, Di is the metal tube inner diameter, and hf,i is the convective heat transfer coefficient between the metal tube and fluid.

Fin efficiency can be determined as follows [18]:

The heat obtained by the absorber plate is finally transferred to the fluid, thermal contact resistance is neglected, and δqu′ can be expressed as follows [18]:

The relationship between the metal tube and fluid temperatures can then be deduced by Equations (17)–(20):

According to Equation (21), if Tf is defined by an assumed initial value and is calculated by assumed , then Tb can be computed. Substituting Tb into Equation (16) yields the relationship between Tn and x:

The average fin temperature of dy Is:

The average temperature of dy is:

From Equation (24), the calculated value of can be obtained. If the difference between the calculated value of and the assumed value is greater than the admissible error, then another value of is assumed until the difference is less than the admissible error and the correctly assumed is considered the correct value. The correct value of is the output. The calculation procedure of is illustrated in Figure 2.

According to this method, if Tf is set to several values, then different corresponding values of can be obtained. As a result, the function of Tf and can be established by the least-square fitting method:

The energy equation of dy in the fluid flow direction can be expressed as:

where m is the fluid mass flow rate, n is the metal tube number of collectors, and cp is the heat capacity of the fluid.

Substituting Equation (17) into Equation (26) yields the following:

where Ti is the fluid inlet temperature.

Equation (27) shows the relationship between Tf and y. Substituting Equation (25) into Equation (27) yields the relationship between and y:

The average heat loss coefficient is:

where L is the metal tube length and UL is the overall heat loss coefficient.

Substituting into Equations (3) to (15) yields the average absorber plate temperature .

2.3. Exergy Analysis

The equation of exergy balance takes the following form [8,19]:

where Ein is the inlet exergy rate, Es is the stored exergy rate, Eout is the outlet exergy rate, and Ed is the exergy loss rate.

At steady conditions, Es = 0.

The inlet exergy rate consists of the inlet exergy carried by fluid flow and the radiation exergy rate from the sun. The rate of inlet exergy carried by fluid flow is as follows [20,21]:

The radiation exergy rate from the sun on the collector surface can be calculated as follows [6]:

where I is the solar irradiance and Ac is the aperture area. The apparent solar temperature as exergy source Ts is assumed to be 4350 K [11].

The rate of outlet exergy carried by fluid flow is as follows [20,21]:

where To is the fluid outlet temperature.

The exergy loss rate consists of the following four parts:

The first part of the exergy loss rate is caused by heat leakage from the absorber plate to the environment [3]:

The second part of the exergy loss rate is caused by the temperature difference between the absorber plate surface and the Sun [3]:

where (τα)e is the effective product transmittance–absorptance.

The third part of the exergy loss rate is due to solar radiation losses from the collector surface to the absorber plate:

The fourth part of the exergy loss rate is caused by the temperature difference between the absorber plate and fluid [21]:

According to Equations (30) to (37), the useful exergy rate is:

Solar collector exergy efficiency is calculated by dividing the increase in fluid flow exergy by the inlet radiation exergy [9]:

According to Equations (30)–(37), the fluid outlet temperature To can be obtained. Substituting relevant data into Equations (34)–(39) yields the useful exergy rate, exergy loss rate, and exergy efficiency.

3. Validation of Methodology

Experiments are conducted to validate the methodology. The flat plate collector is Sangpu PYT/L2.0-3, the metal tubes are made of copper, the fins are made of aluminum, the insulation material is rock wool board, and the working fluid is water. The relative parameters of the flat plate collector are listed in Table 1.

The experimental test platform is shown in Figure 3.

The values calculated by the above method and experimental data are compared, and the results are shown in Table 2.

An experiment is conducted in six time segments of a day. The fluid inlet temperature is controlled by an electrically heated constant-temperature water bath. The fluid inlet temperature of each measurement is different, and the mass flow rate is controlled at 0.05 kg/s by adjusting the valve. When the collector is in steady state (i.e., ambient temperature: ± 1 °C; solar irradiance: ± 50 W/m2; fluid inlet temperature: ± 0.1 °C; fluid mass flow rate: ± 1%), the experimental data are collected. Four independent data acquisition procedures are conducted for each individual test point, and the collection intervals are at least 3 minutes long. ηex.calc is the calculated exergy efficiency, ηex.exp is the experimental efficiency, and Eexergy is the relative error. Table 2 shows that only a small difference was observed between the calculated values and experimental results.

4. Results and Discussion

With the suggested calculation method of this study, the effects of ambient temperature, solar irradiance, fluid mass flow rate, and fluid inlet temperature on the useful heat rate, useful exergy rate, and exergy loss rate are examined.

Figure 4 shows the following conditions: (1) The useful heat rate increases with increasing ambient temperature because of decreasing heat loss. (2) The useful exergy rate decreases with increasing ambient temperature, indicating that increasing ambient temperature decreases exergy efficiency. (3) The exergy loss rate caused by heat leakage from the absorber plate to the environment decreases with increasing ambient temperature. This condition can be attributed to the increase in ambient temperature leading to a decrease in heat losses from the solar collector to the environment and consequently to a decrease in El. (4) The exergy loss rate caused by the temperature difference between the absorber plate surface and the sun increases with increasing ambient temperature. Although an increase in ambient temperature increases , the increasing tendency of is less than that of the ambient temperature. Consequently, increasing ambient temperature increases Ed1. (5) The exergy loss rate because of solar radiation losses from the collector surface to the absorber plate decreases slowly with increasing ambient temperature because the increment of ambient temperature is small relative to Ts. (6) The exergy loss rate caused by the temperature difference between the absorber plate and fluid increases with increasing ambient temperature because an increase in ambient temperature increases and consequently increases the temperature difference between the absorber plate and fluid.

The useful heat rate and useful exergy rate have conflicting behavior with increasing ambient temperature. Although El decreases from 65.7 W to 31.8 W with ambient temperature increasing from 14 °C to 28 °C (the reduction proportion is more than 50%), Eu decreases from 97.2 W to 74.0 W because of increasing Ed1 and Ed3 and decreasing Ein,Q.

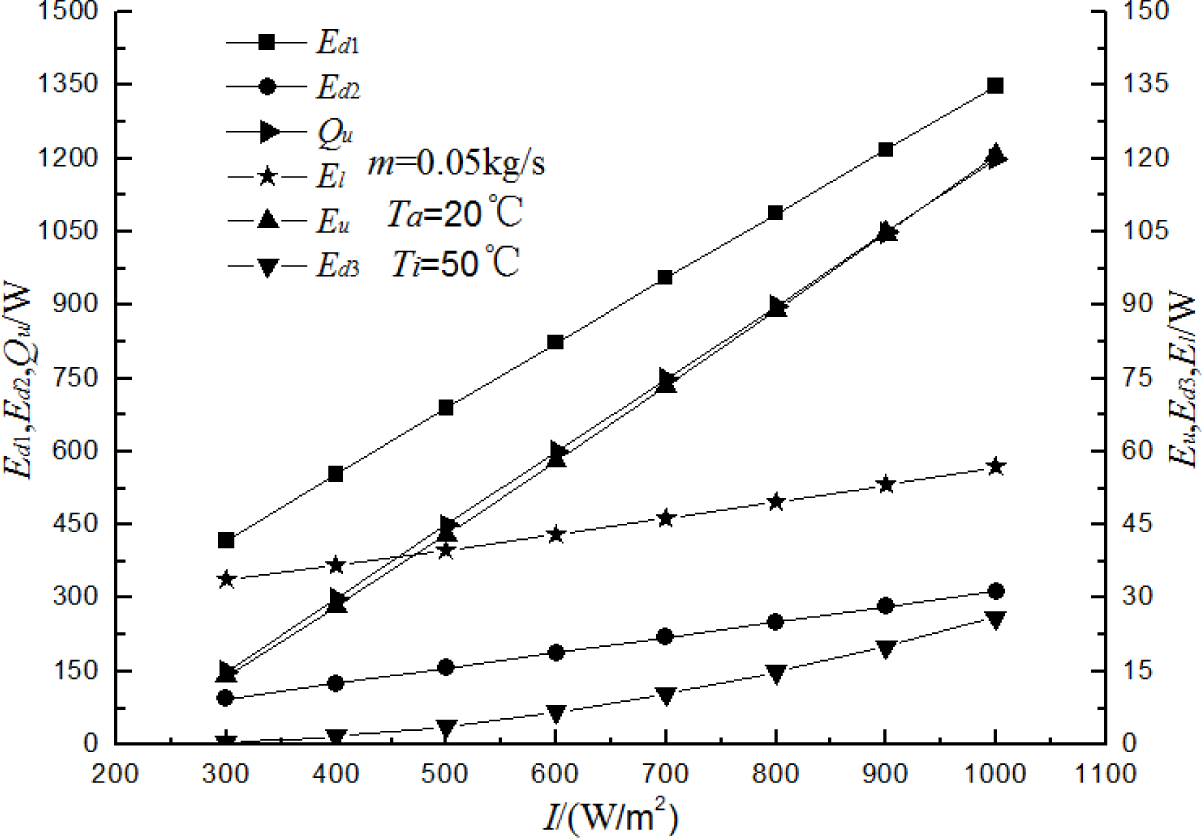

Figure 5 shows that the increase in solar irradiance increases the useful heat rate, useful exergy rate, and exergy loss rate. Qu has the largest increment, increasing from 149.6 W to 1199.0 W with solar irradiance increasing from 300 W to 1000 W. Ed1 has an increment of 417.1 W to 1347.3 W, but Eu increases from 14.0 W to 120.8 W. Solar irradiance significantly affects both the useful heat rate and useful exergy rate. Appropriate solar irradiance can improve collector performance effectively.

The variations of the useful heat rate, useful exergy rate, and exergy loss rate versus fluid inlet temperature are illustrated in Figure 6, leading to the following conclusions: (1) the useful heat rate decreases with increasing fluid inlet temperature because of increasing heat loss; (2) an optimum fluid inlet temperature exists for obtaining the maximum useful exergy rate. The useful exergy rate first increases and then decreases with increasing fluid inlet temperature. It reaches its maximum when the fluid inlet temperature is 69 °C because the increase in fluid inlet temperature increases both the average absorber plate temperature and fluid outlet temperature. When the fluid inlet temperature is low, increasing fluid outlet temperature considerably affects Eu, which increases with increasing fluid inlet temperature. However, while the fluid inlet temperature is higher than the optimized value, the increasing heat loss caused by the increasing average absorber plate temperature significantly affects Eu, which then decreases; (3) the exergy loss rate caused by heat leakage from the absorber plate to the environment increases with increasing fluid inlet temperature because the increase in fluid inlet temperature increases the average absorber plate temperature and consequently increases heat losses from the solar collector to the environment, thereby increasing El; (4) the exergy loss rate caused by the temperature difference between the absorber plate surface and the sun decreases with increasing fluid inlet temperature because the increase in fluid inlet temperature increases the average absorber plate temperature and consequently decreases the temperature difference of radiative heat transfer, thereby reducing Ed1; (5) the fluid inlet temperature has no effect on the exergy loss rate because of the solar radiation losses from the collector surface to the absorber plate. This part of the exergy loss rate remains constant with increasing fluid inlet temperature; (6) the exergy loss rate caused by the temperature difference between the absorber plate and fluid decreases with increasing fluid inlet temperature because the increase in fluid inlet temperature decreases the temperature difference of the absorber plate and fluid and consequently decreases this part of the exergy loss rate.

The useful heat rate and useful exergy rate also have conflicting behavior with increasing fluid inlet temperature. Qu is high when fluid inlet temperature is low, but Eu is only 11.8 W when the fluid inlet temperature is 20 °C. Eu increases significantly with increasing fluid inlet temperature, even to its maximum. The maximum Eu is 101.6 W, and a significant exergy performance improvement is observed. The optimum fluid inlet temperature varies. It is mainly affected by heat loss because of the flat plate collector’s structure. El increases rapidly from 4.3 W to 177.5 W when fluid inlet temperature rises from 20 °C to 90 °C. Selecting appropriate evaluation criteria for the collector based on specific conditions and allowing the collector to work with appropriate fluid inlet temperature are recommended.

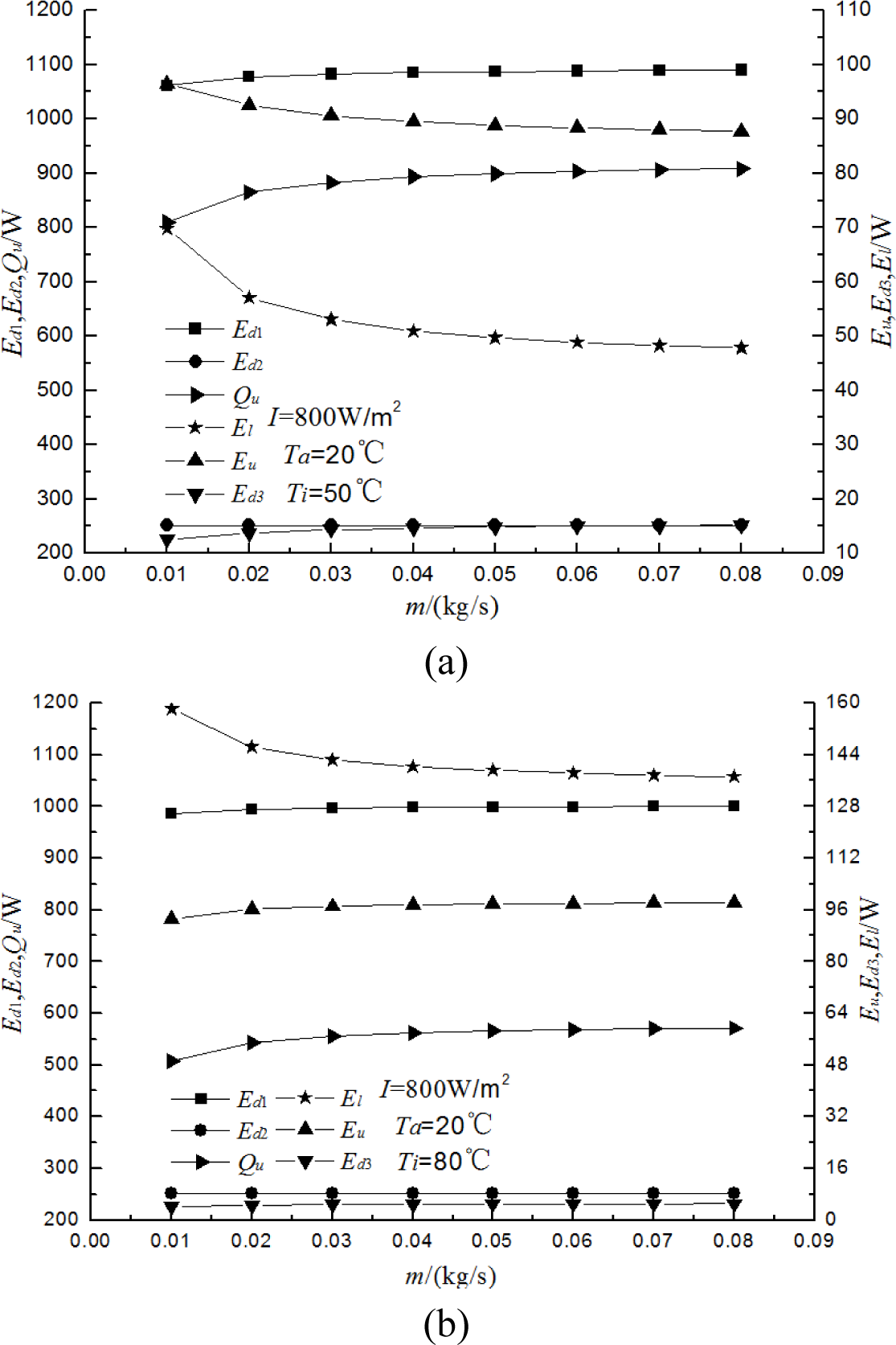

Figure 7 shows the variations of the useful heat rate, useful exergy rate, and exergy loss rate versus the fluid mass flow rate. The following conclusions are drawn: (1) the useful heat rate increases with increasing fluid mass flow rate because of decreasing heat loss, and the increasing tendency decreases; (2) from Figure 7(a), when the fluid inlet temperature is lower than the optimized value, the useful exergy rate decreases with increasing fluid mass flow rate and the decreasing tendency decreases because the increase in the fluid mass flow rate decreases the fluid outlet temperature. When the fluid inlet temperature is low, the decreasing fluid outlet temperature greatly affects Eu, which then decreases.

From Figure 7b, when the fluid inlet temperature is higher than the optimized value, the useful exergy rate increases with increasing fluid mass flow rate and the increasing tendency declines because increasing heat loss significantly affects Eu at this condition and increasing fluid mass flow rate decreases heat losses from the solar collector to the environment; (3) the exergy loss rate caused by heat leakage from the absorber plate to the environment decreases with increasing fluid mass flow rate and the decreasing tendency decreases because the increase in fluid mass flow rate decreases the average absorber plate temperature and consequently decreases heat losses from the solar collector to the environment; (4) The exergy loss rate caused by the temperature difference between the absorber plate surface and the sun increases with increasing fluid mass flow rate and the increasing tendency decreases because the increase in fluid mass flow rate decreases the average absorber plate temperature and consequently increases the temperature difference of radiative heat transfer. Thus, this part of the exergy loss rate increases; (5) the fluid mass flow rate has no effect on the exergy loss rate because of solar radiation losses from the collector surface to the absorber plate. This part of the exergy loss rate remains constant with increasing fluid mass flow rate; (6) the exergy loss rate caused by the temperature difference between the absorber plate and the fluid increases with increasing fluid mass flow rate because the increase in the fluid mass flow rate increases the heat transfer between the absorber plate and fluid and consequently increases this part of the exergy loss rate.

When the fluid inlet temperature is lower than the optimized value, the variation trends of Qu and Eu are opposite those of the increasing fluid mass flow rate. When the fluid inlet temperature is higher than the optimized value, the variation trends of Qu and Eu are the same. Notably, the effect of the mass flow rate on performance declines with increasing mass flow rate. The mass flow rate should be carefully controlled based on actual demand. Table 3 shows the exergy rate distribution of the collector when Ta = 20 °C, I = 800 W/m2, m = 0.05 kg/s, Ti = 50 °C. Percentage = Ex/(Eu+Ed1+Ed2+Ed3+El). Table 3 shows the following conditions: (1) the percentage of useful exergy rate (i.e., exergy efficiency) is 5.96%; (2) the largest exergy loss of the collector is the exergy loss rate caused by the temperature difference between the absorber plate surface and the sun, accounting for 72.87% of the total exergy rate; (3) the percentage of the exergy loss rate because of solar radiation losses from the collector surface to the absorber plate is 16.84%, mainly affected by the glass material and selective-absorption coating; (4) the percentage of the exergy loss rate caused by the temperature difference between the absorber plate and fluid and that caused by heat leakage from the absorber plate to the environment are 1% and 3.33%, respectively.

5. Conclusions

In this study, the first and second laws of thermodynamics are used to study the performance of a flat plate solar collector. A theoretical model for the exergy analysis of flat plate collectors is presented by considering non-uniformity in the temperature distribution of the absorber plate:

- (1)

The model is experimentally validated, with the results agreeing well with the experimental data.

- (2)

The useful heat rate increases with increasing ambient temperature, solar irradiance, and fluid mass flow rate and decreases with increasing fluid inlet temperature.

- (3)

The effects of ambient temperature, solar irradiance, fluid inlet temperature, and fluid mass flow rate on useful exergy rate and exergy loss rate are obtained. The conclusion can be summarized as follows: the useful exergy rate decreases with increasing ambient temperature and increases with increasing solar irradiance. It first increases and then decreases with increasing fluid inlet temperature, and an optimum fluid inlet temperature exists for obtaining the maximum useful exergy rate. When the fluid inlet temperature is lower than the optimized value, the useful exergy rate then decreases with increasing fluid mass flow rate. However, when the fluid inlet temperature is higher than the optimized value, the useful exergy rate increases with increasing fluid mass flow rate, the effect of mass flow rate on performance decreases with increasing mass flow rate, and the mass flow rate should be controlled carefully based on actual demand.

- (4)

The useful heat rate is greater than the useful exergy rate. The useful heat rate and useful exergy rate have conflicting behavior in many cases. Thus, selecting an appropriate evaluation criterion (energy or exergy) for the collector according to specific conditions is recommended.

- (5)

Solar irradiance considerably affects both the useful heat rate and useful exergy rate. In other words, high performance is based on appropriate solar irradiance.

- (6)

The optimum fluid inlet temperature varies, and it is mainly affected by heat loss because environmental parameters change during the day. The operating parameters could be adjusted to obtain the maximum useful exergy rate during the day, and exergy performance could be significantly improved by optimizing it.

- (7)

The exergy loss rate caused by the temperature difference between the absorber plate surface and the sun accounts for the largest exergy loss of the collector. When Ta = 20 °C, I = 800 W/m2, m = 0.05 kg/s, and Ti = 50 °C, it accounts for 72.87% of the total exergy rate.

Based on this analysis, the appropriate operating conditions for collectors could be determined with the given conditions and are useful for obtaining a higher useful exergy rate and decreasing internal irreversibilities.

| Roman symbols | ||

| Ac | the aperture area | m2 |

| Ae | the side area of the collector | m2 |

| Ap | the area of the absorber plate | m2 |

| cp | the heat capacity of the fluid | J/(kg·K) |

| d | the distance between the absorber plate and glass | m |

| Di | the metal tube inner diameter | m |

| Do | the metal tube outer diameter | m |

| Ed | the exergy loss rate | W |

| Ed1 | exergy loss rate caused by temperature difference between the absorber plate surface and the Sun | W |

| Ed2 | exergy loss rate because of solar radiation losses from the collector surface to the absorber plate | W |

| Ed3 | exergy loss rate caused by the temperature difference between the absorber plate and fluid | W |

| Ein | the inlet exergy rate | W |

| Ein,f | the inlet exergy rate carried by fluid flow | W |

| Ein,Q | the radiation exergy rate from the sun on the collector surface | W |

| El | exergy loss rate caused by heat leakage from the absorber plate to the environment | W |

| Eout | the outlet exergy rate | W |

| Eout,f | the outlet exergy rate carried by fluid flow | W |

| Es | the stored exergy rate | W |

| Eu | the useful exergy rate | W |

| F′ | the collector efficiency factor | |

| g | the gravity | m2/s |

| hc,p−1 | the convective heat transfer coefficient between the absorber plate and the glass | W/(m2·K) |

| hf,i | the convective heat transfer coefficient between the metal tube and fluid | W/(m2·K) |

| hw | the convective heat transfer coefficient between the glass and the environment | W/(m2·K) |

| I | the solar irradiance | W/m2 |

| kair | the thermal conductivity of air | W/(m·K) |

| kl | the thermal conductivity of the insulation material | W/(m·K) |

| L | the metal tube length | m |

| Lb | the thickness of the insulation material in back | m |

| Le | the thickness of the insulation material at the side | m |

| m | the fluid mass flow rate | kg/s |

| n | the metal tube number of collectors | |

| Nu | the Nusselt number | |

| δqc,p−1 | the convective heat transfer from the absorber plate to the glass of dy | W |

| δqc,1−a | the convective heat transfer from the glass to the environment of dy | W/(m2·K) |

| δqr,p−1 | the radiative heat transfer from the absorber plate to the glass of dy | W |

| δqr,1−a | the radiative heat transfer from the glass to the sky of dy | W |

| δqu′ | the heat obtained by dy | W |

| Ql | the heat loss from the solar collector to the environment | W |

| Qs | the radiation flux absorbed by the absorber plate | W |

| Qu | the useful heat rate gain of the flat plate solar collector | W |

| Ra | the Rayleigh number | |

| S | the radiation flux absorbed by a unit area of the absorber plate | W/m2 |

| Ta | the ambient temperature | K |

| Tb | the metal tube temperature | K |

| Tf | the fluid temperature | K |

| Ti | the fluid inlet temperature | K |

| Tn | the fin temperature | K |

| To | the fluid outlet temperature | K |

| Tp | the temperature of dA | K |

| the average temperature of dy | K | |

| the integral average of Tp over the absorber plate | K | |

| Ts | the apparent solar temperature as exergy source | K |

| Tsky | the temperature of the sky | K |

| T1 | the temperature of the glass | K |

| Ub | the back heat loss coefficient | W/(m2·K) |

| Ue | the edge heat loss coefficient | W/(m2·K) |

| Ul | the local heat loss coefficient of dA | W/(m2·K) |

| the local heat loss coefficient of dy | W/(m2·K) | |

| the top local heat loss coefficient of dy | W/(m2·K) | |

| the integral average of Ul over the absorber plate | W/(m2·K) | |

| UL | the overall heat loss coefficient | W/(m2·K) |

| v | the kinematic viscosity | m2/s |

| Va | the wind speed | m/s |

| W | the width of the metal tube and fins | m |

| Greek | ||

| α | the thermal diffusivity | m2/s |

| β | the thermal expansion coefficient | 1/K |

| δ | the fin thickness | m |

| εp | the emissivity of the absorber plate | |

| ε1 | the emissivity of the glass | |

| ηex | the exergy efficiency | |

| ηn | the fin efficiency | |

| θ | the collector tilt relative to the horizontal | ° |

| λ | the thermal conductivity of the fins | W/(m·K) |

| Σ | the Stefan–Boltzmann constant | W/(m2·K4) |

| (τα)e | the effective product transmittance–absorptance | |

Acknowledgments

The study presented in this paper is financially supported by National Natural Science Foundation Programs of China (Grant Nos. 51066002, 51366005, U0937604), Yunnan Provincial Natural Science Foundation Programs (Grant Nos. 2008KA002, 2008CD001), high-tech development project by the Development and Reform Commission of Yunnan province (Grant Nos.2008CD001) and Applied Basic Research Projects of Yunnan Province(Grant Nos. KKSY201252024).

Author Contributions

Huitao Wang and Zhong Ge contributed to the conception of the study. Huitao Wang and Zhong Ge contributed to the building of model. Hua Wang, Songyuan Zhang and Xin Guan designed the experiment. Zhong Ge, Songyuan Zhang contributed to the data collecting. Zhong Ge performed the data analyses and wrote the manuscript. Hua Wang and Huitao Wang helped in the analysis with constructive discussions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhai, R.R.; Zhu, Y.; Yang, Y.P.; Tan, K.Y.; Eric, H. Exergetic and Parametric Study of a Solar Aided Coal-Fired Power Plant. Entropy 2013, 15, 1014–1034. [Google Scholar]

- Fahad, A.A.; Ibrahim, D.; Feridum, H. Exergy modeling of a new solar driven trigeneration system. Sol. Energ 2011, 85, 2228–2243. [Google Scholar]

- Dutta, G.K.K.; Saha, S.K. Energy analysis of solar thermal collectors. Renew. Energ. Environ 1990, 33, 283–287. [Google Scholar]

- Tyagi, S.K.; Wang, S.W.; Singhal, M.K.; Kaushik, S.C.; Park, S.R. Exergy analysis and parametric study of concentrating type solar collectors. Int. J. Therm. Sci 2007, 46, 1304–1310. [Google Scholar]

- Liu, G.; Cengel, Y.A.; Turner, R.H. Exergy analysis of a solar heating system. J. Sol. Energ 1995, 117, 249–251. [Google Scholar]

- Torres-Reyes, E.; Cervantes de Gortari, J.G.; Ibarra-Salazar, B.A.; Picon-Nunez, M.A. design method of flat-plate solar collectors based on minimum entropy generation. Exergy 2001, 1, 46–52. [Google Scholar]

- Bejan, A.; Keary, D.W.; Kreith, F. Second law analysis and synthesis of solar collector systems. J. Sol. Energ 1981, 103, 23–28. [Google Scholar]

- Suzuki, A. A fundamental equation for exergy balance on solar collectors. J. Sol. Energ 1988, 110, 102–106. [Google Scholar]

- Farzad, J.; Emad, A. Energetic and exergetic evaluation of flat plate solar collectors. Renew. Energ 2013, 56, 55–63. [Google Scholar]

- Luminosua, I.; Fara, L. Determination of the optimal operation mode of a flat solar collector by exergetic analysis and numerical simulation. Energy 2005, 30, 731–747. [Google Scholar]

- Farahat, S.; Sarhaddi, F.; Ajam, H. Exergetic optimization of flat plate solar collectors. Renew. Energ 2009, 34, 1169–1174. [Google Scholar]

- Akpinar, E.K.; Koçyigit, F. Energy and exergy analysis of a new flat-plate solar air heater having different obstacles on absorber plates. Appl. Energ 2010, 87, 3438–3450. [Google Scholar]

- Altaa, D.; Bilgilib, E.; Ertekina, C.; Yaldiz, O. Experimental investigation of three different solar air heaters: Energy and exergy analyses. Appl. Energ 2010, 87, 2953–2973. [Google Scholar]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes; Wiley-Interscience: New York, NY, USA, 1991. [Google Scholar]

- Dorfling, C.; Hornung, C.H.; Hallmark, B.; Beaumont, R.J.J.; Fovargue, H.; Mackley, M.R. The experimental response and modelling of a solar heat collector fabricated from plastic microcapillary films. Sol. Energ. Mat. Sol. C 2010, 94, 1207–1221. [Google Scholar]

- Incropera, F.P.; DeWitt, D.P. Fundamentals of Heat and Mass Transfer; JohnWiley and Sons: New York, NY, USA, 1990. [Google Scholar]

- Taherian, H.; Rezania, A.; Sadeghi, S.; Ganjia, D.D. Experimental validation of dynamic simulation of the flat plate collector in a closed thermosyphon solar water heater. Energ. Convers. Manag 2011, 52, 301–307. [Google Scholar]

- Zhang, H.F. Solar Thermal Utilization Principles and Computer Simulation; Northwestern Polytechnical University Press: Xi’an, China, 2004. [Google Scholar]

- Suzuki, A. General theory of exergy balance analysis and application to solar collectors. Energy 1988, 13, 153–160. [Google Scholar]

- Kotas, T.J. The Exergy Method of Thermal Plant Analysis; Krieger Publish Company: Malabar, FL, USA, 1995. [Google Scholar]

- Bejan, A. Advanced Engineering Thermodynamics; Wiley Interscience: New York, NY, USA, 1988. [Google Scholar]

| Parameter | Value |

|---|---|

| Tube center to center distance | 0.135 m |

| The metal tube length | 2 m |

| The metal tube number of collectors | 7 |

| The metal tube outer diameter | 0.015 m |

| Thermal conductivity of the fins | 236 W/(m·K) |

| Thermal conductivity of the insulation material | 0.055 W/(m·K) |

| Effective product transmittance–absorptance | 0.88 |

| Emissivity of the absorber plate | 0.05 |

| Emissivity of the glass | 0.88 |

| Size of the flat plate collector | 2 m × 1 m ×0.07 m |

| Collector tilt relative to the horizontal | 45° |

| Time

| ||||||

|---|---|---|---|---|---|---|

| 10–11 | 11–12 | 12–13 | 13–14 | 14–15 | 15–16 | |

| I/(W/m2) | 631 | 702 | 713 | 640 | 535 | 374 |

| Ta/°C | 25.5 | 26.4 | 27.7 | 27.5 | 26.8 | 25.7 |

| Ti/°C | 29.4 | 37.3 | 44.6 | 51.9 | 61.1 | 67.2 |

| ηex.calc/% | 1.56 | 3.09 | 4.10 | 4.85 | 4.86 | 2.44 |

| ηex.exp/% | 1.62 | 2.96 | 3.95 | 4.79 | 4.90 | 2.59 |

| Eexergy/% | 3.70 | 4.39 | 3.80 | 1.25 | 0.82 | 5.79 |

| Exergy Rate | Value/W | Percentage/% |

|---|---|---|

| Eu | 88.860 | 5.96 |

| Ed1 | 1087.427 | 72.87 |

| Ed2 | 251.282 | 16.84 |

| Ed3 | 14.880 | 1.00 |

| El | 49.713 | 3.33 |

© 2014 by the authors; licensee MDPI, Basel, Switzerland This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Ge, Z.; Wang, H.; Wang, H.; Zhang, S.; Guan, X. Exergy Analysis of Flat Plate Solar Collectors. Entropy 2014, 16, 2549-2567. https://doi.org/10.3390/e16052549

Ge Z, Wang H, Wang H, Zhang S, Guan X. Exergy Analysis of Flat Plate Solar Collectors. Entropy. 2014; 16(5):2549-2567. https://doi.org/10.3390/e16052549

Chicago/Turabian StyleGe, Zhong, Huitao Wang, Hua Wang, Songyuan Zhang, and Xin Guan. 2014. "Exergy Analysis of Flat Plate Solar Collectors" Entropy 16, no. 5: 2549-2567. https://doi.org/10.3390/e16052549

APA StyleGe, Z., Wang, H., Wang, H., Zhang, S., & Guan, X. (2014). Exergy Analysis of Flat Plate Solar Collectors. Entropy, 16(5), 2549-2567. https://doi.org/10.3390/e16052549