Application of Date (Phoenix dactylifera L.) Fruit in the Composition of a Novel Snack Bar

Abstract

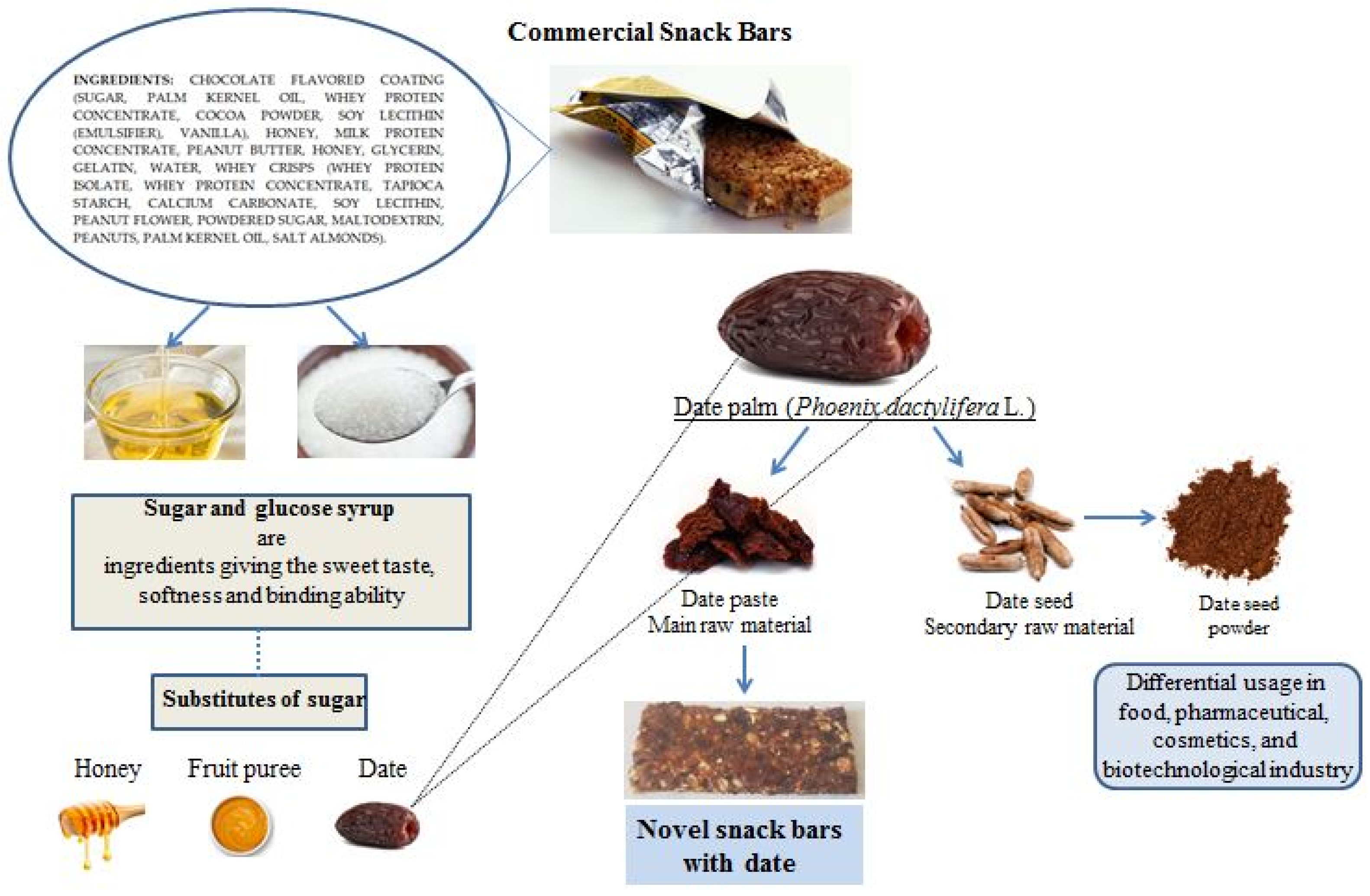

1. Introduction

2. Materials and Methods

2.1. Raw Materials Preparation

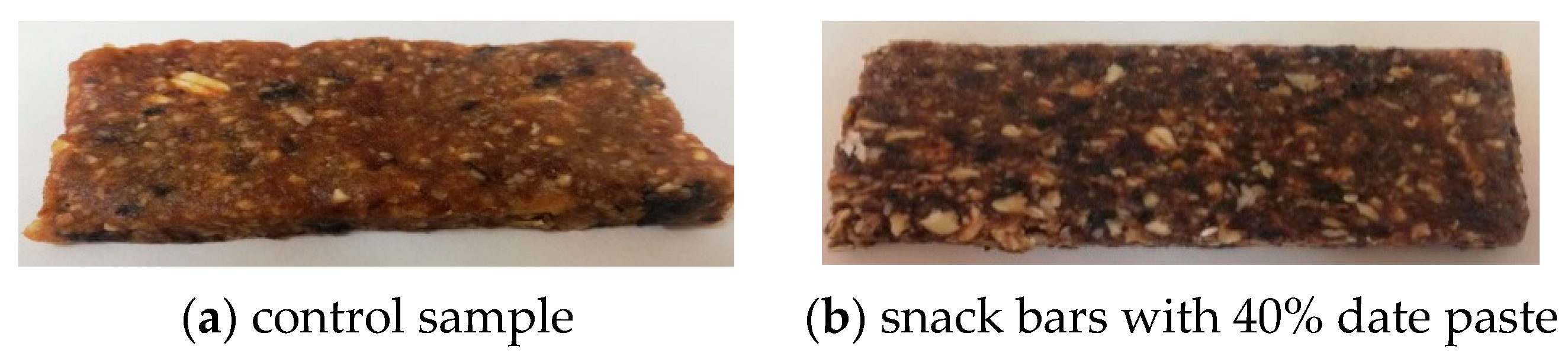

2.2. Preparation of Date Bar’s Formulation

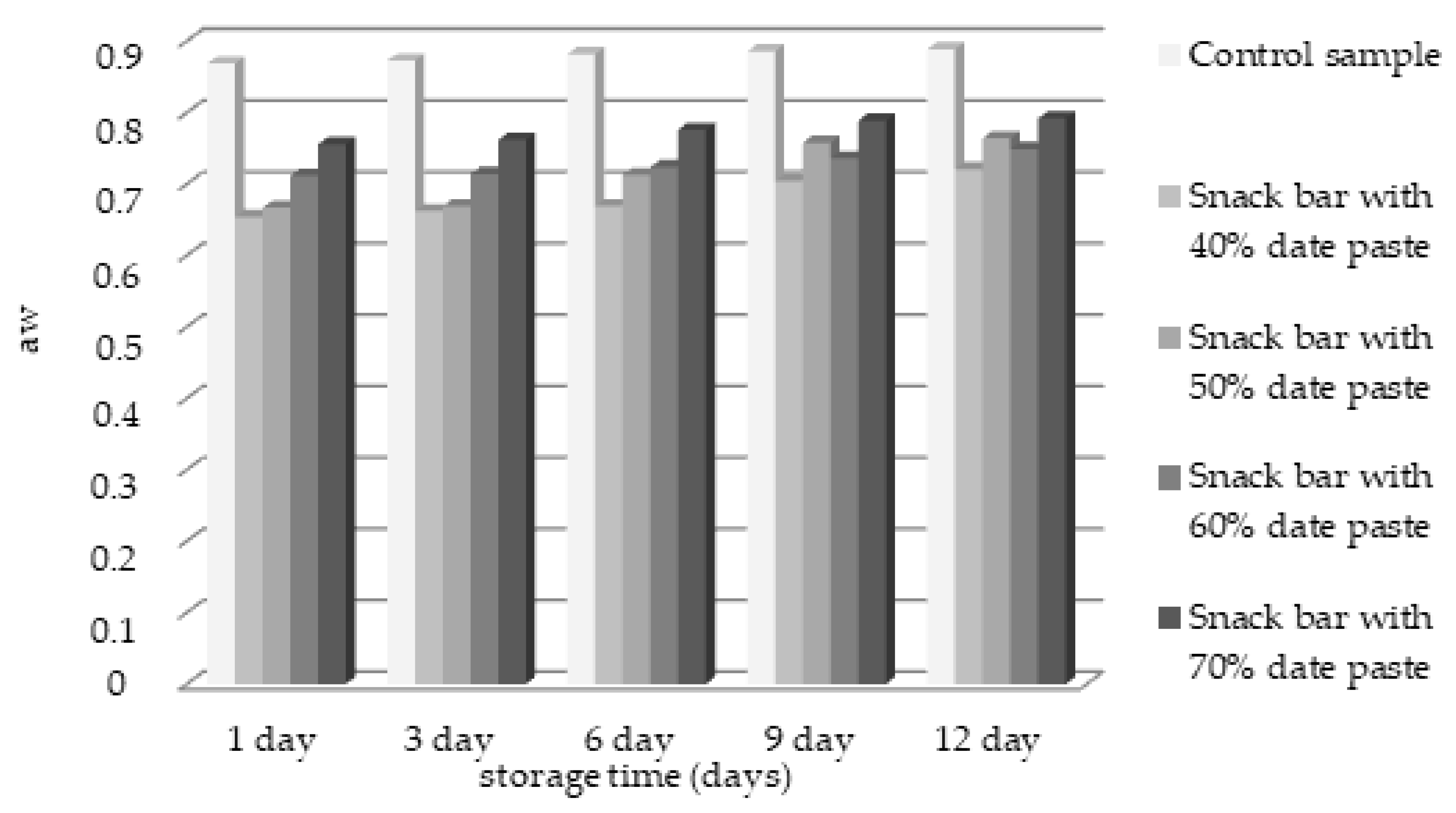

2.3. Water Activity of the Snack Bars with Date Paste

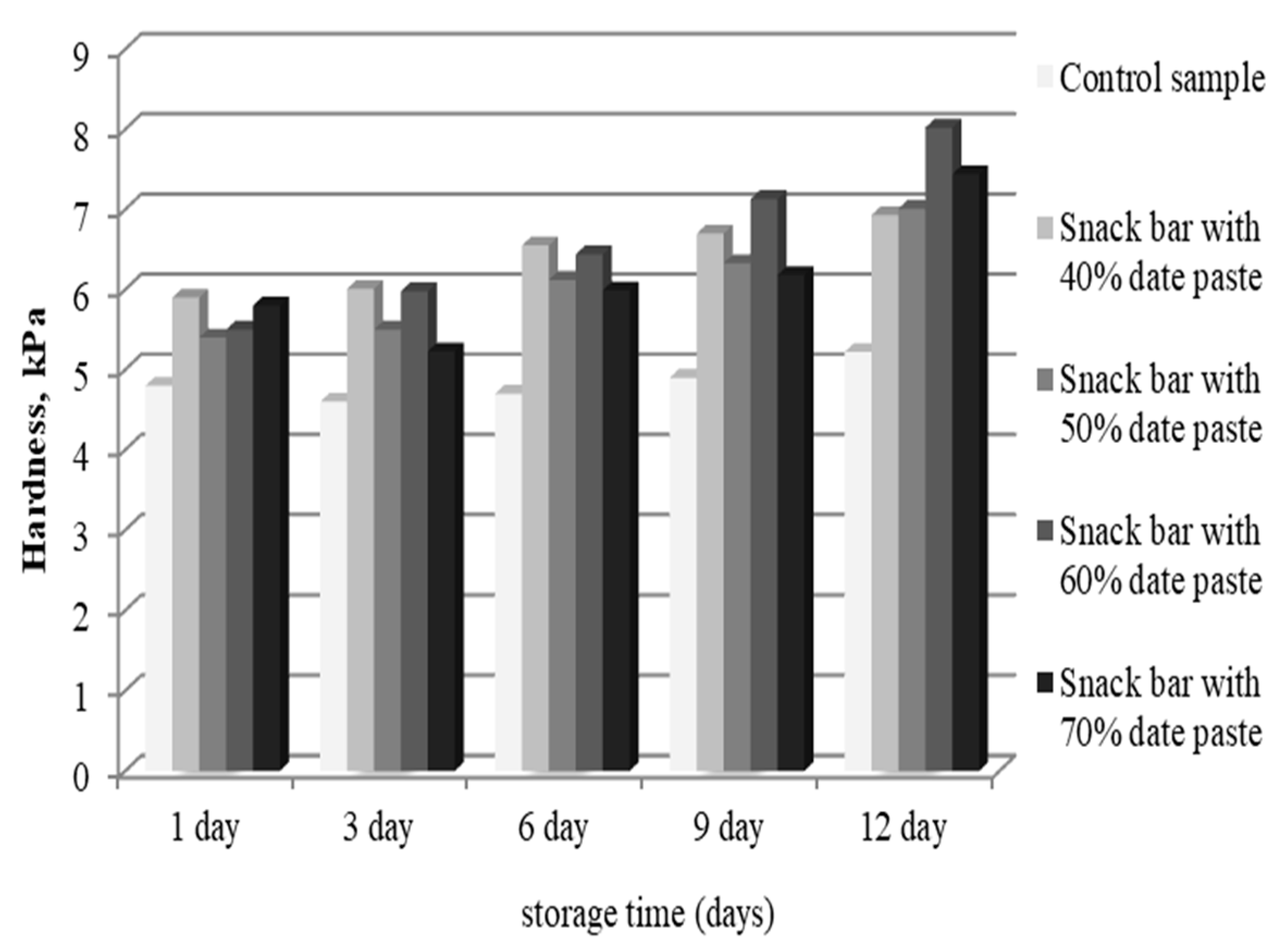

2.4. The Instrumental Texture of Snack Bars with Date Paste

2.5. Nutrition Information

2.6. Microbiological Analyses

2.7. Sensorial Evaluation

2.8. Statistical Analysis

3. Results and Discussion

3.1. Water Activity and Hardness of Snack Bars Supplemented with Different Concentrations of Date Paste during Storage

3.2. The Instrumental Texture of Snack Bars with Date Paste

3.3. Nutritional Composition of Snack Bars Supplemented with Different Concentrations of Date Paste

3.4. Microbiological Analysis

3.5. Sensorial Evaluation of Snack Bars, Supplemented with Different Concentration of Date Paste

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Aljaloud, S.; Colleran, H.L.; Ibrahim, S.A. Nutritional Value of Date Fruits and Potential Use in Nutritional Bars for Athletes. Food Nutr. Sci. 2020, 11, 463–480. [Google Scholar] [CrossRef]

- Pinto, V.R.A.; Freitas, T.B.d.O.; Dantas, M.I.d.S.; Lucia, S.M.D.; Melo, L.F.; Minim, V.P.R.; Bressan, J. Influence of package and health-related claims on perception and sensory acceptability of snack bars. Food Res. Int. 2017, 101, 103–113. [Google Scholar] [CrossRef]

- Tylewicz, U.; Nowacka, M.; Rybak, K.; Drozdzal, K.; Rosa, M.D.; Mozzon, M. Design of healthy snack based on kiwifruit. Molecules 2020, 25, 3309. [Google Scholar] [CrossRef]

- Aramouni, F.M.; Abu-Ghoush, M.H. Physicochemical and sensory characteristics of no-bake wheat–soy snack bars. J. Sci. Food Agric. 2011, 91, 44–51. [Google Scholar] [CrossRef]

- Aguiar, R.; Duarte, F.C.; Mendes, A.; Bartolome, B.; Barbosa, M.P. Anaphylaxis caused by honey: A case report. Asia Pac. Allergy 2017, 7, 48–50. [Google Scholar] [CrossRef]

- Curtain, F.; Grafenauer, S. Comprehensive Nutrition Review of Grain-Based Muesli Bars in Australia: An Audit of Supermarket Products. Foods 2019, 8, 370. [Google Scholar] [CrossRef]

- Małecki, J.; Tomasevic, I.; Djekic, I.; Sołowie, B.G. The Effect of Protein Source on the Physicochemical, Nutritional Properties and Microstructure of High-Protein Bars Intended for Physically Active People. Foods 2020, 9, 1467. [Google Scholar] [CrossRef]

- Cheboi, P.K.; Siddiqui, S.A.; Onyando, J.; Kiptum, C.K.; Heinz, V. Effect of Ploughing Techniques on Water Use and Yield of Rice in Maugo Small-Holder Irrigation Scheme, Kenya. AgriEngineering 2021, 3, 110–117. (accessed on 12 March 2021). [Google Scholar] [CrossRef]

- Powers, P.M.; Hoover, L.W. Calculating the nutrient composition of recipes with computers. J. Am. Diet. Assoc. 1989, 89, 224–232. [Google Scholar] [PubMed]

- ISO 4833-1:2013. Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 1: Colony Count at 30 Degrees C by the Pour Plate Technique; ISO: Geneva, Switzerland, 2013; Volume 4833, pp. 1–2013. [Google Scholar]

- ISO 21527-2: 2011. Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Yeasts and Moulds—Part 2: Colony Count Technique in Products with Water Activity Less than or Equal to 0.95; ISO: Geneva, Switzerland, 2011; pp. 1–9. [Google Scholar]

- ISO 4831: 2006. Microbiology—General Guidance for the Enumeration of Coliforms—Most Probable Number Technique; ISO: Geneva, Switzerland, 2006; pp. 1–11. [Google Scholar]

- ISO 6579-1:2017. Microbiology of the Food Chain—Horizontal Method for the Detection, Enumeration and Serotyping of Salmonella—Part 1: Detection of Salmonella spp.; ISO: Geneva, Switzerland, 2003; pp. 1–50. [Google Scholar]

- ISO 6888-1: 2000. Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Coagulase-Positive Staphylococci (Staphylococcus aureus and Other Species)—Part 1: Technique Using Baird-Parker Agar Medium; ISO: Geneva, Switzerland, 2000; pp. 1–11. [Google Scholar]

- Padmashree, A.; Sharma, G.K.; Srihari, K.A.; Bawa, A.S. Development of shelf stable protein rich composite cereal bar. J. Food Sci. Technol. 2012, 49, 335–341. [Google Scholar] [CrossRef] [PubMed]

- Damasceno, K.A.; Goncalves, C.A.A.; Dos Santos Pereira, G.; Costa, L.L.; Campagnol, P.C.B.; De Almeida, P.L.; Arantes-Pereira, L. Development of cereal bars containing pineapple peel flour (Ananas comosus L. merril). J. Food Qual. 2016, 39, 1–9. [Google Scholar]

- Gutkoski, L.C.; Bonamigo, J.M.A.; Teixeira, D.M.F.; Pedó, I. Desenvolvimento de barras de cereais à base de aveia com alto teor de fibra alimentar. Ciênc. Tecnol. Aliment. 2007, 27, 355–363. [Google Scholar] [CrossRef]

- Guimarães, M.M.; Silva, M.S. Qualidade nutricional e aceitabilidade de barras de cereais adicionadas de frutos de muricipassa. Rev. Inst. Adolfo Lutz 2009, 68, 426–433. [Google Scholar]

- Silva, I.Q.; Oliveira, B.C.F.; Lopes, A.S.; Pena, R.S. Obtenção de barra de cereais adicionada do resíduo industrial de maracujá. Aliment. Nutr. 2009, 20, 321–329. [Google Scholar]

- Mourão, L.H.E.; Pontes, D.F.; Rodrigues, M.C.P.; Brasil, I.M.; Souza, M.A.; Cavalcante, M.T.B. Obtenção de barras de cereais de caju ameixa com alto teor de fibras. Aliment. Nutr. 2009, 20, 427–433. [Google Scholar]

- Brito, I.P.; Campos, J.M.; Souza, T.F.L.; Wakiyama, C.; Azeredo, G.A. Elaboração de avaliação global de barra de cereais caseira. Bol. Cent. Pesqui. Process. Aliment. 2004, 22, 35–50. [Google Scholar] [CrossRef]

- Regulation (EC). No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on Nutrition and Health Claims Made on Foods. Off. J. Eur. Union 2007, 50, 3–18.

- Szydłowska, A.; Zielienska, D.; Łepecka, A.; Trzaskowska, M.; Neffe-Skocinska, K.; Kołozyn-Krajewska, D. Development of Functional High-Protein Organic Bars with the Addition of Whey Protein Concentrate and Bioactive Ingredients. Agriculture 2020, 10, 390. [Google Scholar] [CrossRef]

- Estévez, A.M.; Escobar, B.; Vasquez, M.; Castillo, E.; Araya, E.; Zacarias, I. Cereal and nut bars, nutritional quality and storage stability. Plant Foods Hum. Nutr. 1995, 47, 309–317. [Google Scholar] [CrossRef]

- Passmore, R.; Nicol, B.M.; Narayana, R.M.; Beaton, G.H.; DeMaeyer, E.M. Handbook on Human Nutritional Requirements; World Health Organization: Geneva, Switzerland, 1974. [Google Scholar]

- Salins, S.S.; Siddiqui, S.A.; Reddy, S.V.K.; Kumar, S. Parametric Analysis for Varying Packing Materials and Water Temperatures in a Humidifier. In Proceedings of the 7th International Conference on Fluid Flow, Heat and Mass Transfer (FFHMT’20), Niagara Falls, ON, Canada, 15–17 November 2020; Available online: https://avestia.com/FFHMT2020_Proceedings/files/paper/FFHMT_196.pdf (accessed on 11 March 2021).

- Ibrahim, S.A.; Ayad, A.A.; Williams, L.L.; Ayivi, R.D.; Gyawali, R.; Krastanov, A.; Aljaloud, S.O. Date fruit: A review of the chemical and nutritional compounds, functional effects and food application in nutrition bars for athletes. Int. J. Food Sci. Technol. 2021, 56, 1503–1513. [Google Scholar] [CrossRef]

- Santos, C.T.; Bonomo, R.F.; Fontan, R.C.I.; Bonomo, C.; Veloso, C.M.; Fontan, G.C.R. Characterization and sensorial evaluation of cereal bars with jackfruit. Acta Sci. Technol. 2011, 33, 81–85. [Google Scholar]

- Rios, F.T.; Amaya, A.A.; Lobo, M.O.; Samman, N.C. Design and acceptability of a multi-ingredients snack bar employing regional products with high nutritional value. Proceedings 2020, 53, 14. [Google Scholar] [CrossRef]

| Ingredients | Control Sample | Date Bar with (%) Dates | |||

|---|---|---|---|---|---|

| 40 | 50 | 60 | 70 | ||

| Cashews, % | 20.00 | 20.00 | 16.66 | 13.33 | 10.00 |

| Oatmeal, % | 20.00 | 20.00 | 16.66 | 13.33 | 10.00 |

| Dried cherries % | 20.00 | 20.00 | 16.66 | 13.33 | 10.00 |

| Honey, % | 40.00 | - | - | - | - |

| Dates, % | - | 40.00 | 50.00 | 60.00 | 70.00 |

| Nutritional Facts | Date Bar with (%) Dates | ||||

|---|---|---|---|---|---|

| Control Sample | 40 | 50 | 60 | 70 | |

| Energy, kcal | 378.80 | 372.00 | 362.08 | 352.29 | 342.50 |

| Macronutrients | |||||

| Protein, g | 7.82 | 8.94 | 7.94 | 6.93 | 5.93 |

| Fat, g | 10.16 | 10.35 | 8.70 | 7.05 | 5.41 |

| Carbohydrate, g | 68.76 | 65.68 | 67.10 | 68.55 | 70.00 |

| —Fibre, g | 3.76 | 6.88 | 7.07 | 7.25 | 7.44 |

| Micronutrients | |||||

| Vitamins | |||||

| Thiamin, mg | 0.24 | 0.26 | 0.23 | 0.19 | 0.16 |

| Riboflavin, mg | 0.05 | 0.06 | 0.06 | 0.06 | 0.07 |

| Niacin, mg | 0.46 | 0.92 | 0.98 | 1.04 | 1.10 |

| Pyridoxine, mg | 0.11 | 0.17 | 0.17 | 0.17 | 0.17 |

| Folate, μg | 16.60 | 16.20 | 13.49 | 10.80 | 8.10 |

| Pantothenic Acid, mg | 0.45 | 0.43 | 0.36 | 0.29 | 0.22 |

| Minerals | |||||

| Calcium, mg | 29.70 | 102.10 | 116.24 | 130.40 | 144.55 |

| Iron, mg | 2.58 | 2.82 | 2.52 | 2.22 | 1.92 |

| Magnesium, mg | 94.60 | 153.80 | 153.14 | 152.52 | 151.90 |

| Phosphorus, mg | 224.8 | 234.00 | 199.43 | 164.96 | 130.50 |

| Potassium, mg | 238.60 | 408.32 | 419.58 | 430.94 | 442.31 |

| Sodium, mg | 4.40 | 5.80 | 6.08 | 6.37 | 6.65 |

| Zinc, mg | 2.04 | 2.07 | 1.77 | 1.48 | 1.18 |

| Copper, mg | 0.57 | 0.64 | 0.57 | 0.50 | 0.43 |

| Manganese, mg | 1.34 | 18.51 | 22.59 | 26.67 | 30.76 |

| Selenium, μg | 4.30 | 5.18 | 4.81 | 4.45 | 4.09 |

| Sensory Characteristics 1 | Date Bar with (%) Dates | ||||

|---|---|---|---|---|---|

| Control Sample | 40 | 50 | 60 | 70 | |

| Overall acceptability | 6.68 a ± 0.98 | 5.08 b ± 1.95 | 7.16 c ± 1.21 | 4.44 d ± 0.65 | 2.52 e ± 1.00 |

| Appearance | 5.92 a ± 0.95 | 5.88 a ± 1.05 | 7.28 b ± 0.89 | 6.96 c ± 0.93 | 6.36 d ± 1.07 |

| Flavor | 7.20 a ± 1.04 | 6.6 a ± 1.29 | 8.24 b ± 0.78 | 5.68 c ± 0.63 | 5.80 d ± 0.81 |

| Sweetness | 6.92 a ± 1.18 | 6.84 a ± 0.74 | 8.4 b ± 0.64 | 6.72 c ± 0.61 | 6.12 d ± 0.78 |

| Texture | 6.32 a ± 0.91 | 6.24 a ± 1.09 | 7.12 b ± 0.92 | 6.44 c ± 0.96 | 6.64 d ± 0.81 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibrahim, S.A.; Fidan, H.; Aljaloud, S.O.; Stankov, S.; Ivanov, G. Application of Date (Phoenix dactylifera L.) Fruit in the Composition of a Novel Snack Bar. Foods 2021, 10, 918. https://doi.org/10.3390/foods10050918

Ibrahim SA, Fidan H, Aljaloud SO, Stankov S, Ivanov G. Application of Date (Phoenix dactylifera L.) Fruit in the Composition of a Novel Snack Bar. Foods. 2021; 10(5):918. https://doi.org/10.3390/foods10050918

Chicago/Turabian StyleIbrahim, Salam A., Hafize Fidan, Sulaiman O. Aljaloud, Stanko Stankov, and Galin Ivanov. 2021. "Application of Date (Phoenix dactylifera L.) Fruit in the Composition of a Novel Snack Bar" Foods 10, no. 5: 918. https://doi.org/10.3390/foods10050918

APA StyleIbrahim, S. A., Fidan, H., Aljaloud, S. O., Stankov, S., & Ivanov, G. (2021). Application of Date (Phoenix dactylifera L.) Fruit in the Composition of a Novel Snack Bar. Foods, 10(5), 918. https://doi.org/10.3390/foods10050918