Common Nettle (Urtica dioica L.) as an Active Filler of Natural Rubber Biocomposites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- Elastomer matrix: natural rubber RSS I (NR) provided by Torimex Chemicals (Konstantynów Łódzki, Poland).

- Conventional sulphur curing system consisting of: sulphur (S) (Siarkopol, Tarnobrzeg, Poland), micro-sized zinc oxide (ZnO) (Huta Będzin, Będzin, Poland), mercaptobenzothiazole (MBT) (Sigma-Aldrich, Poznań, Poland), stearin (POCH, Gliwice, Poland).

- Natural filler: common nettle (Urtica dioica L.).

2.2. Preparation of Fillers

2.3. Preparation of Rubber Mixtures

- plasticizing of natural rubber by mixing in a Brabender N50 (Brabender Technologie GmBH & Co. KG, Duisburg, Germany) measuring mixer with process parameters: rotational speed 40 rpm, temperature 40–60 °C, mixing time 4 min,

- dispersing fillers in plasticized natural rubber for 4 min in the same conditions,

- introducing a weighed sulphur curing system for obtained mixtures on a two-roll mill at room temperature.

2.4. Methods

- optimal curing time t90 (min), which occurs at 90% increase in torque;

- increase in torque ΔM (dNm) as a difference of maximum (Mmax) and minimum torque (Mmin) during measurement.

- The day and night segment: 0.78 W/m2;

- Temperature: 60 °C;

- Duration: 72 h.

3. Results and Discussion

3.1. Characterization of Fillers

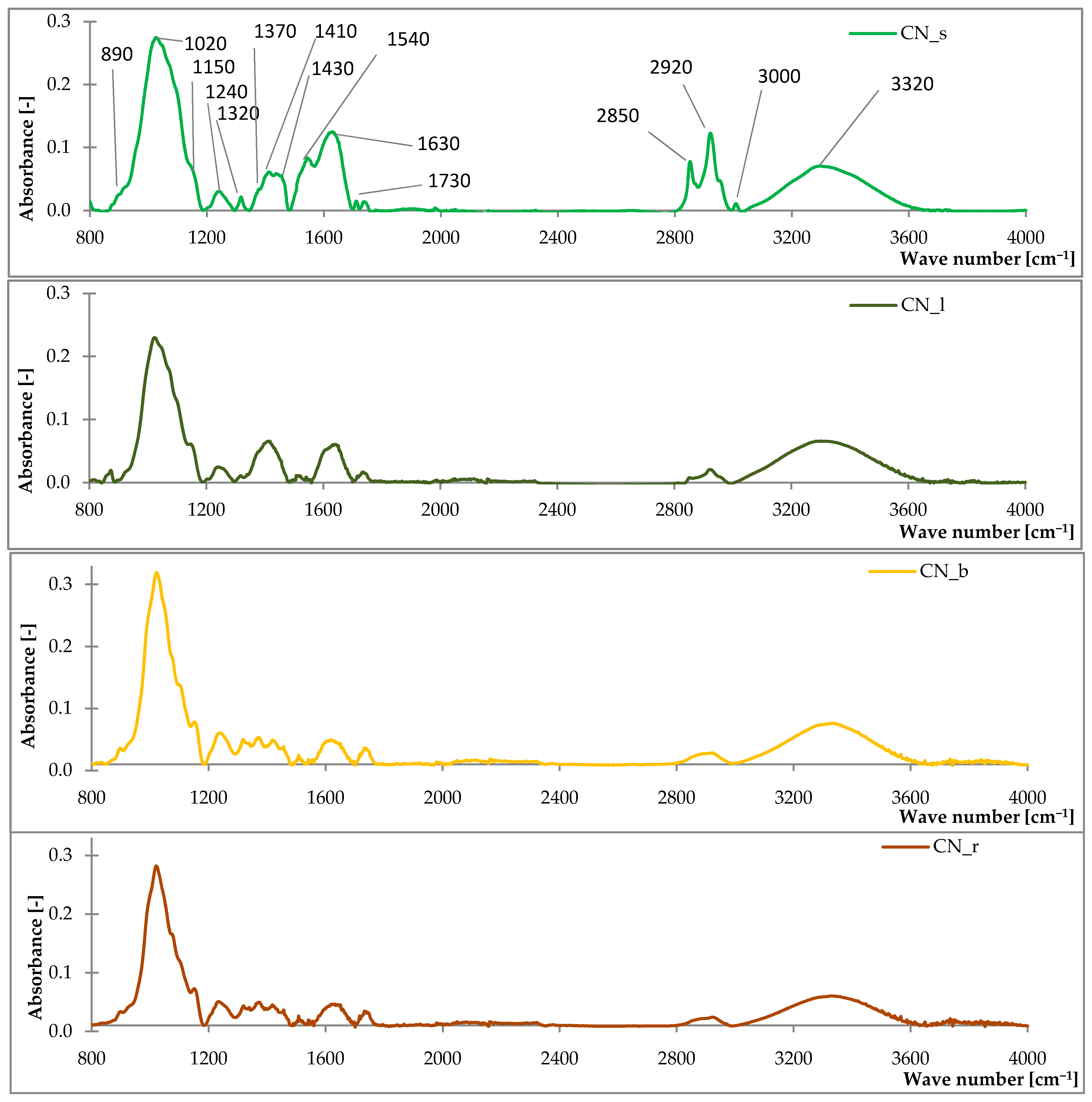

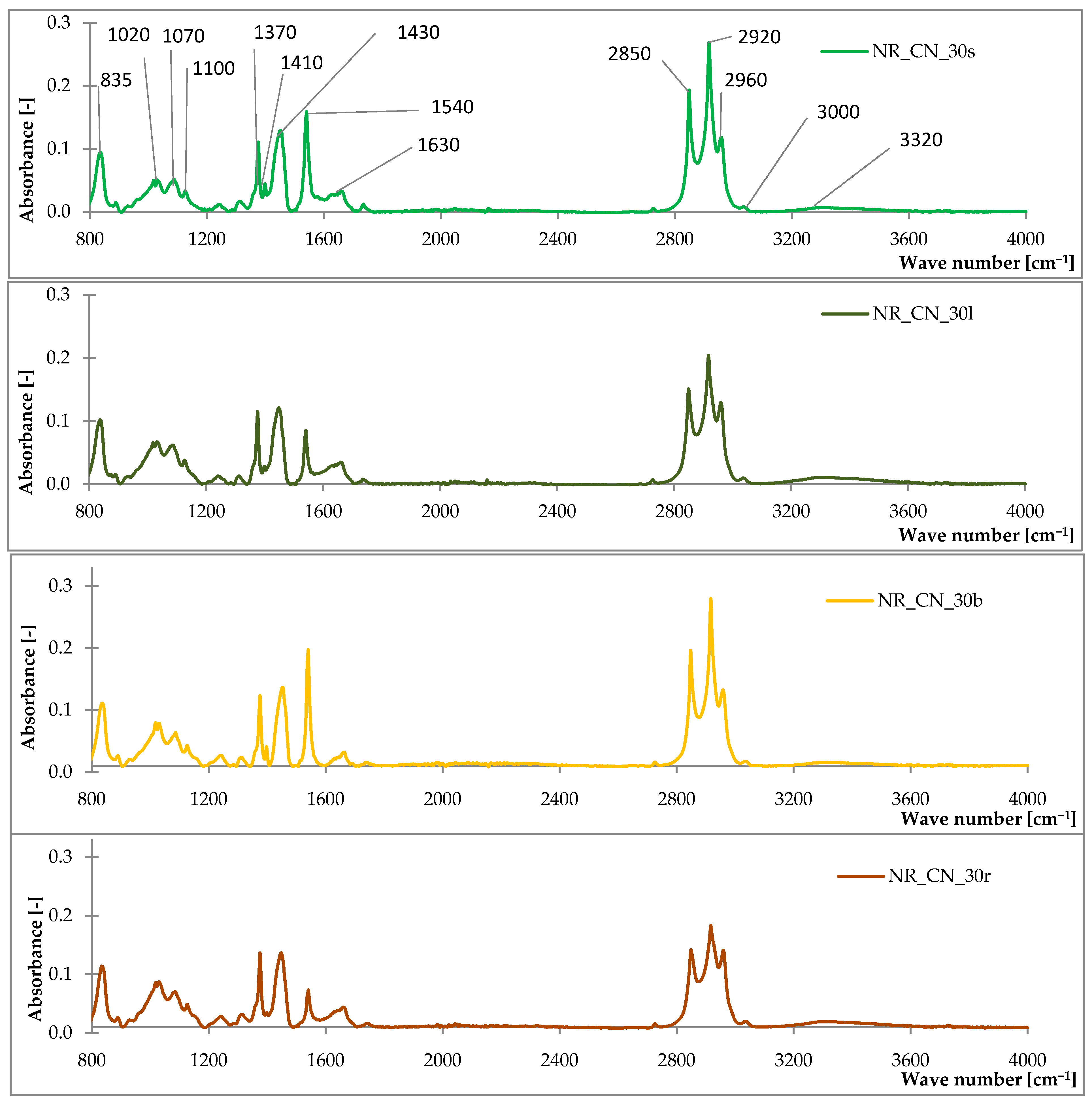

3.1.1. Fourier Transform Infrared Spectroscopy (FTIR) Analysis

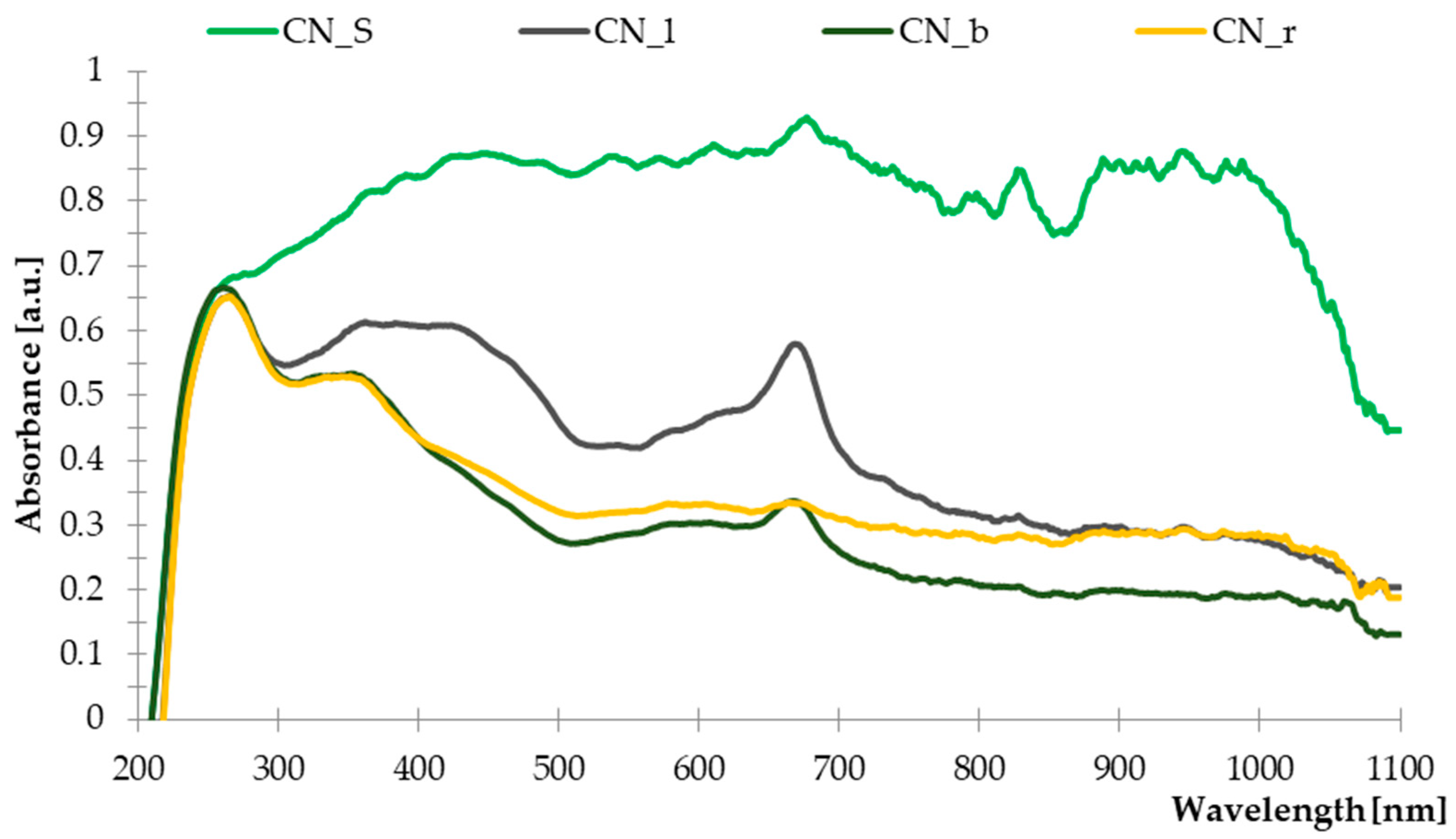

3.1.2. Ultraviolet-Visible Spectroscopy (UV-Vis)

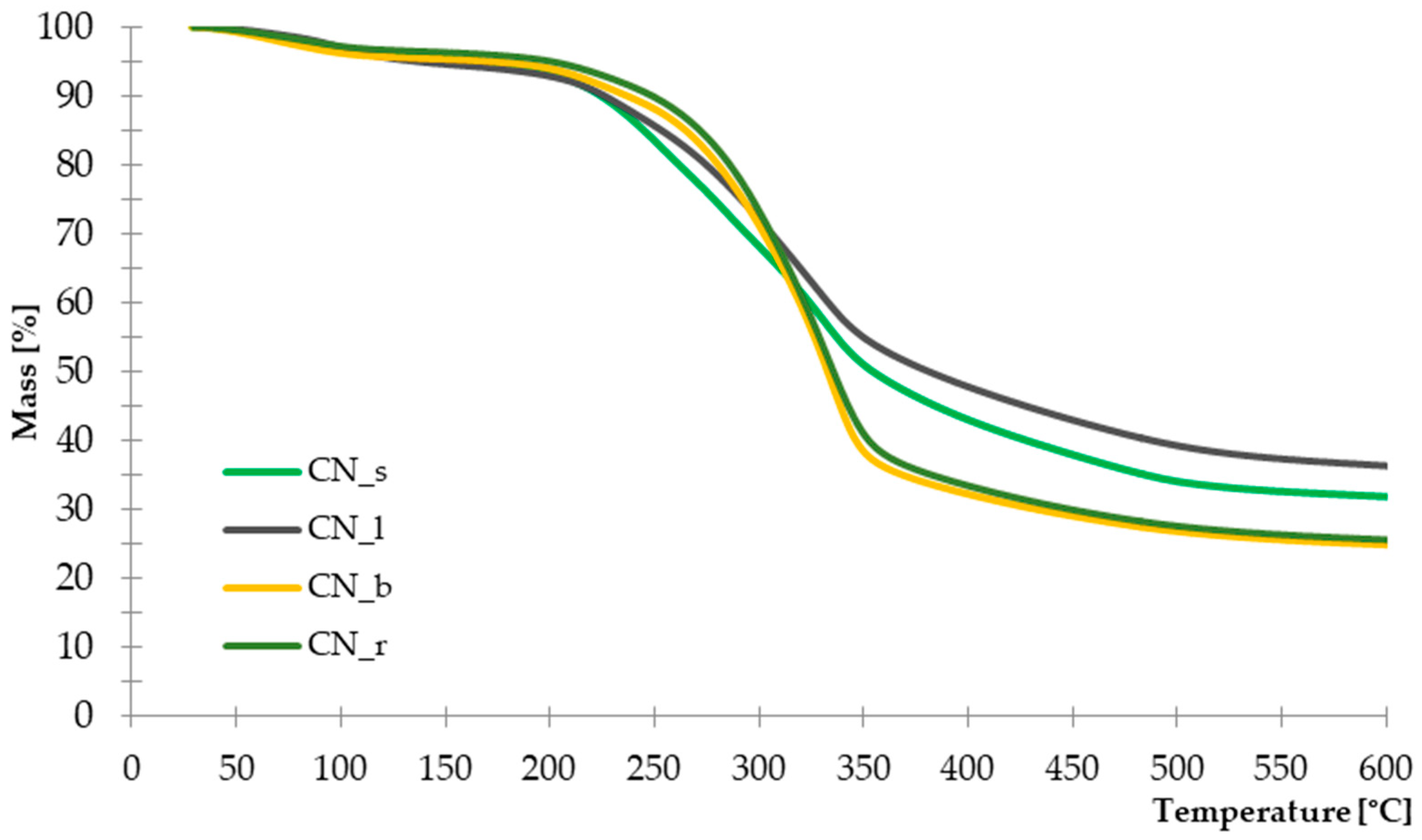

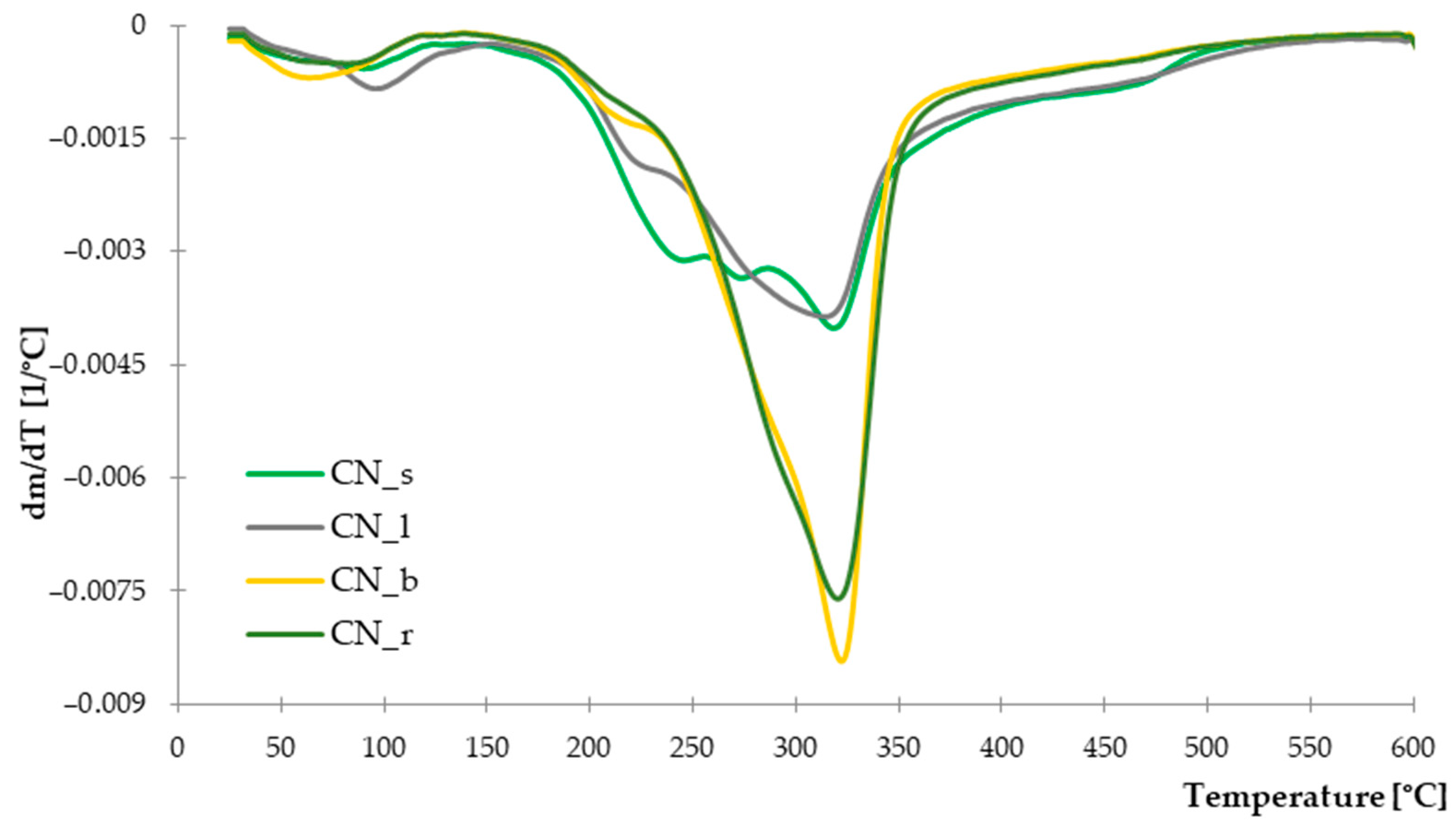

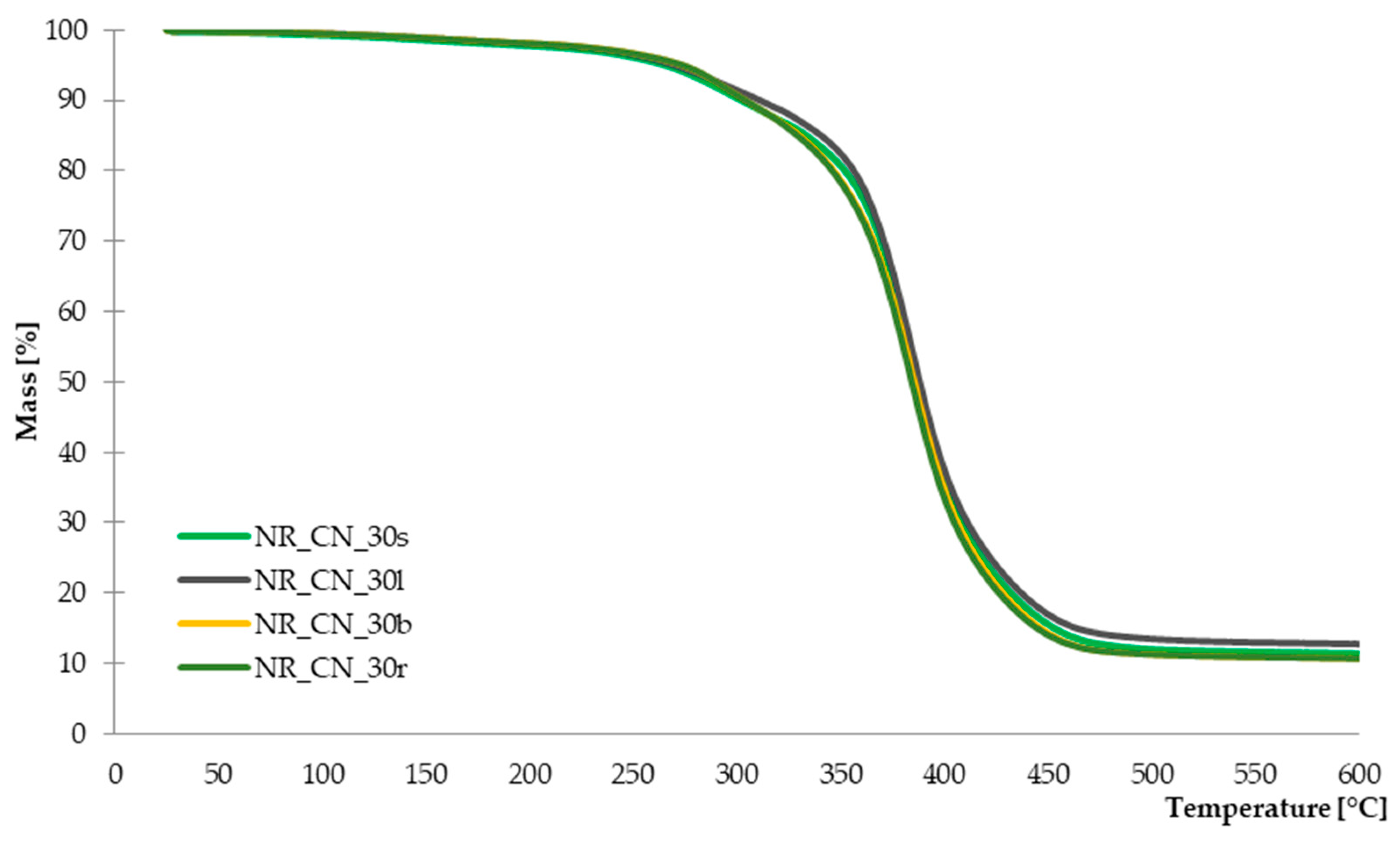

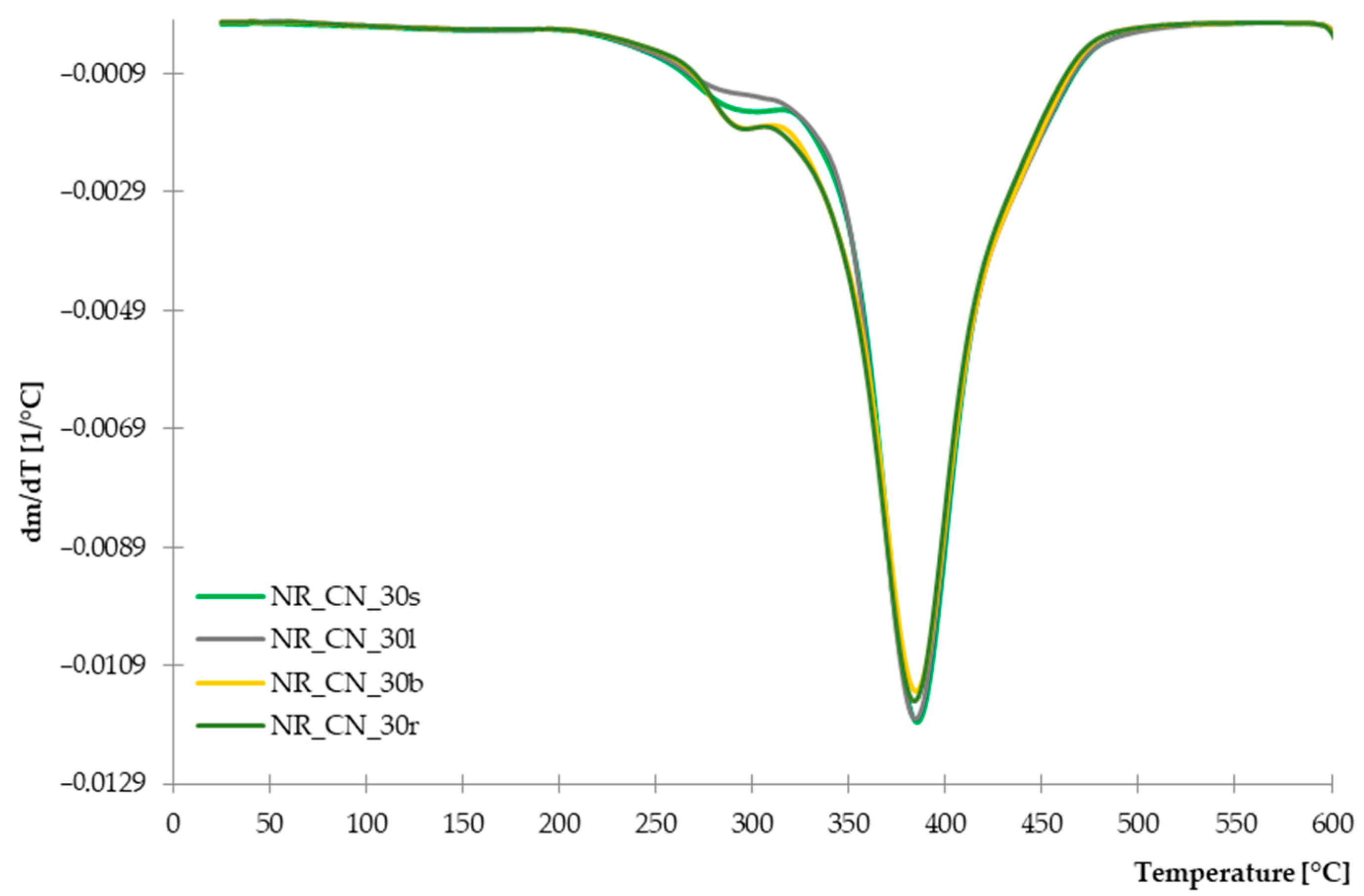

3.1.3. Thermogravimetric Analysis

3.1.4. Wettability and Contact Angle

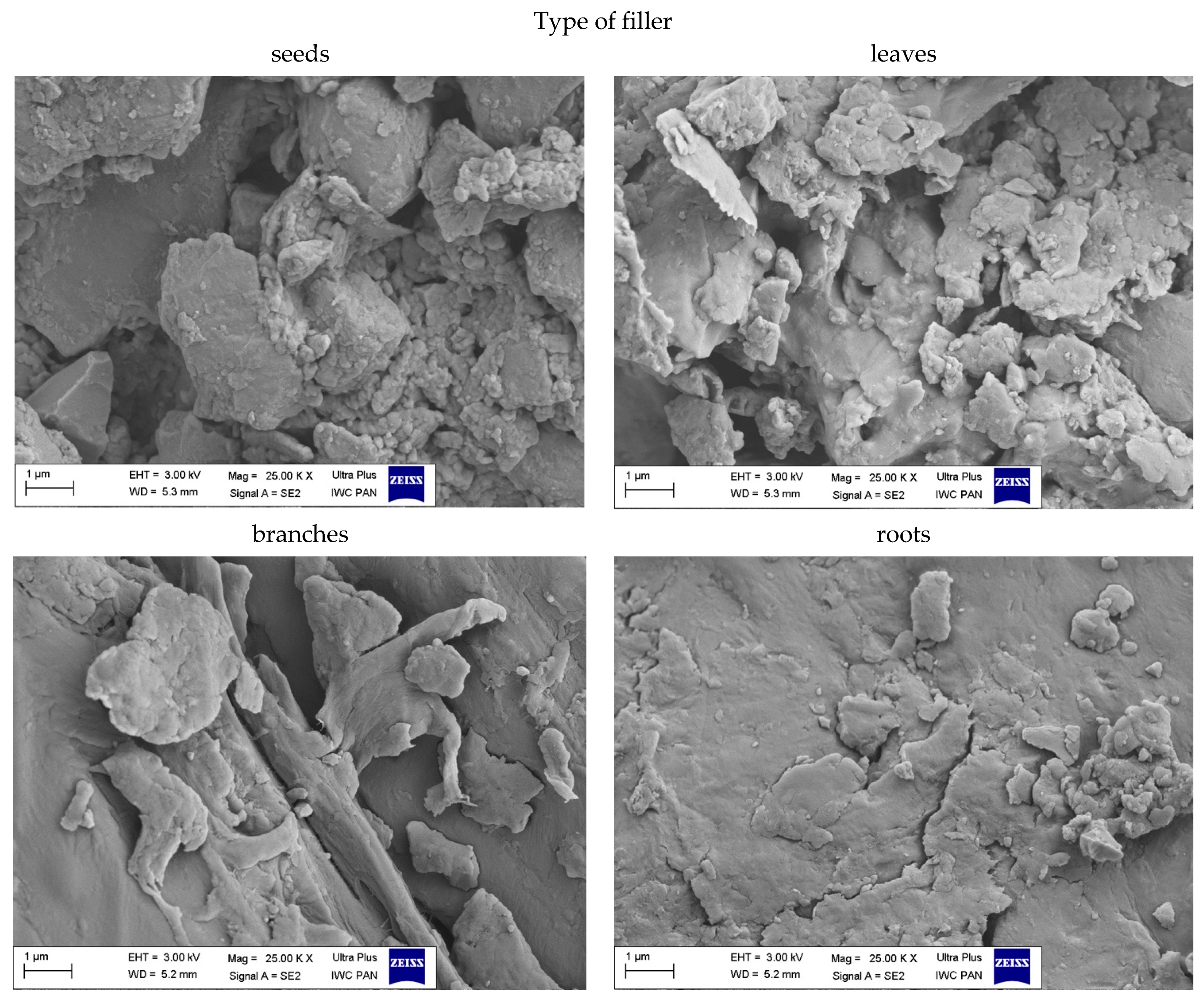

3.1.5. The Morphology of Filler

3.2. Characterization of Composites

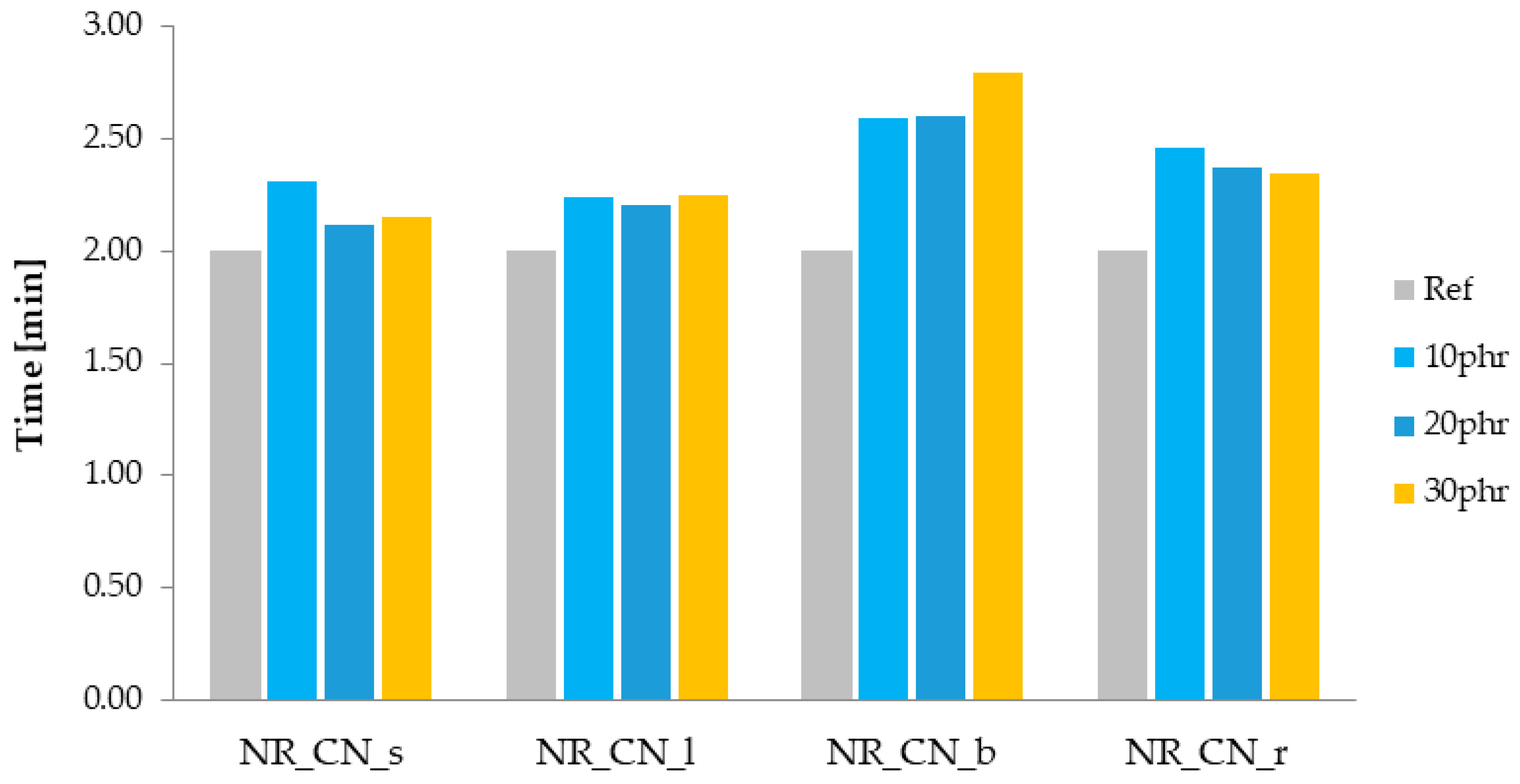

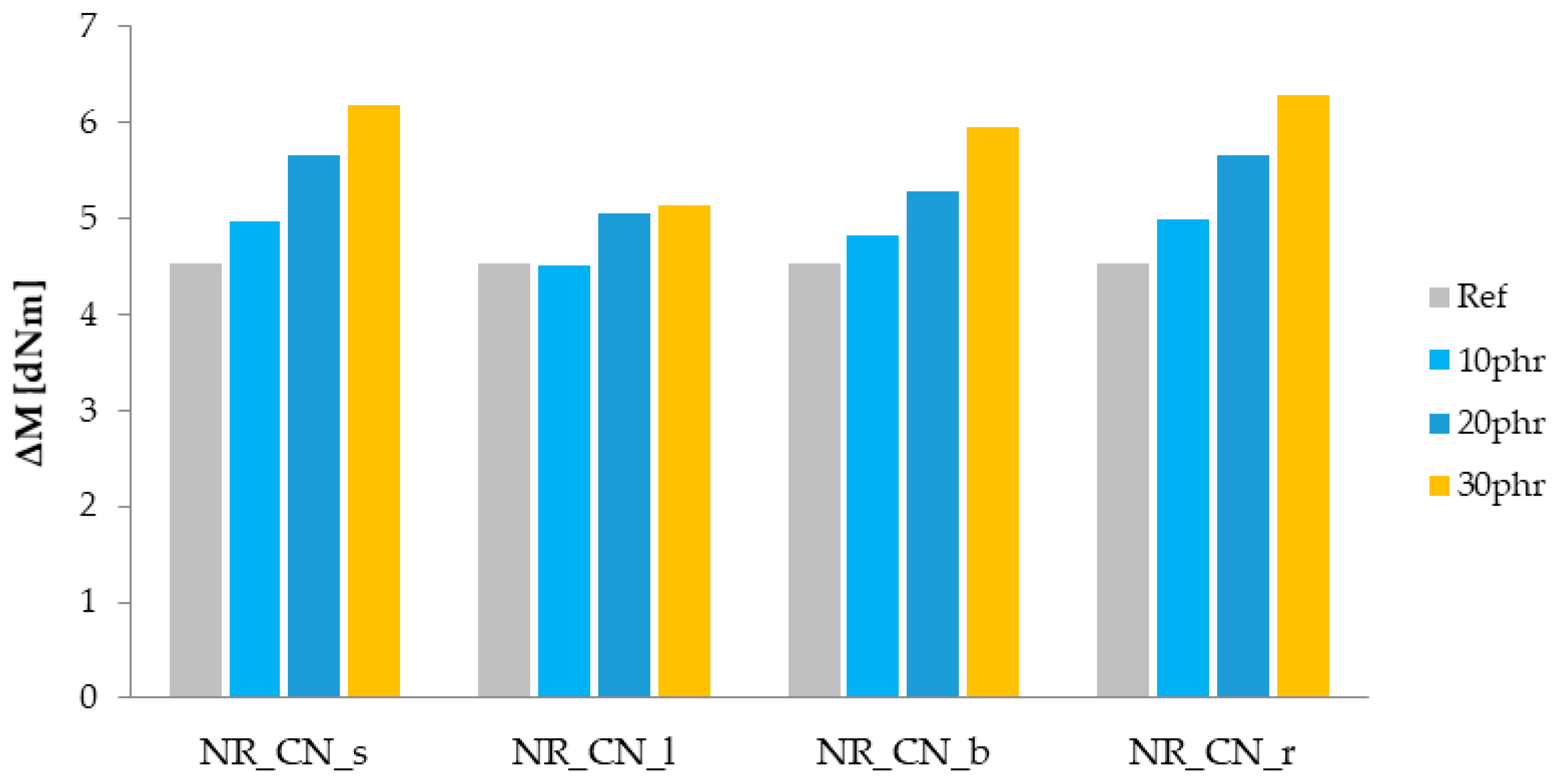

3.2.1. Rheological Properties of Rubber Mixtures

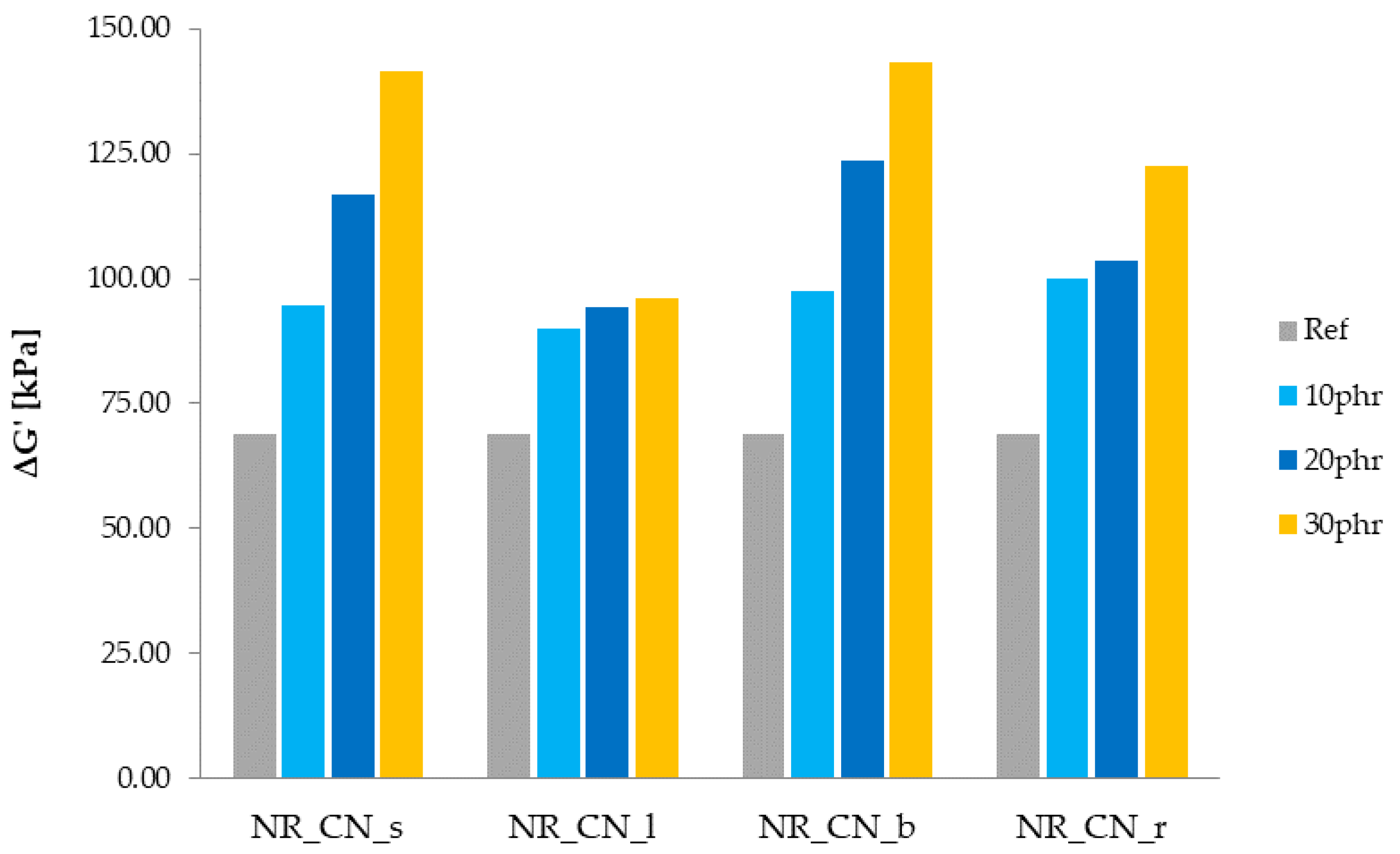

3.2.2. Payne Effect of NR Vulcanizates

3.2.3. Fourier Transform Infrared Spectroscopy (FTIR) Analysis of Composites

3.2.4. Thermal Stability of Composites Determined by TGA

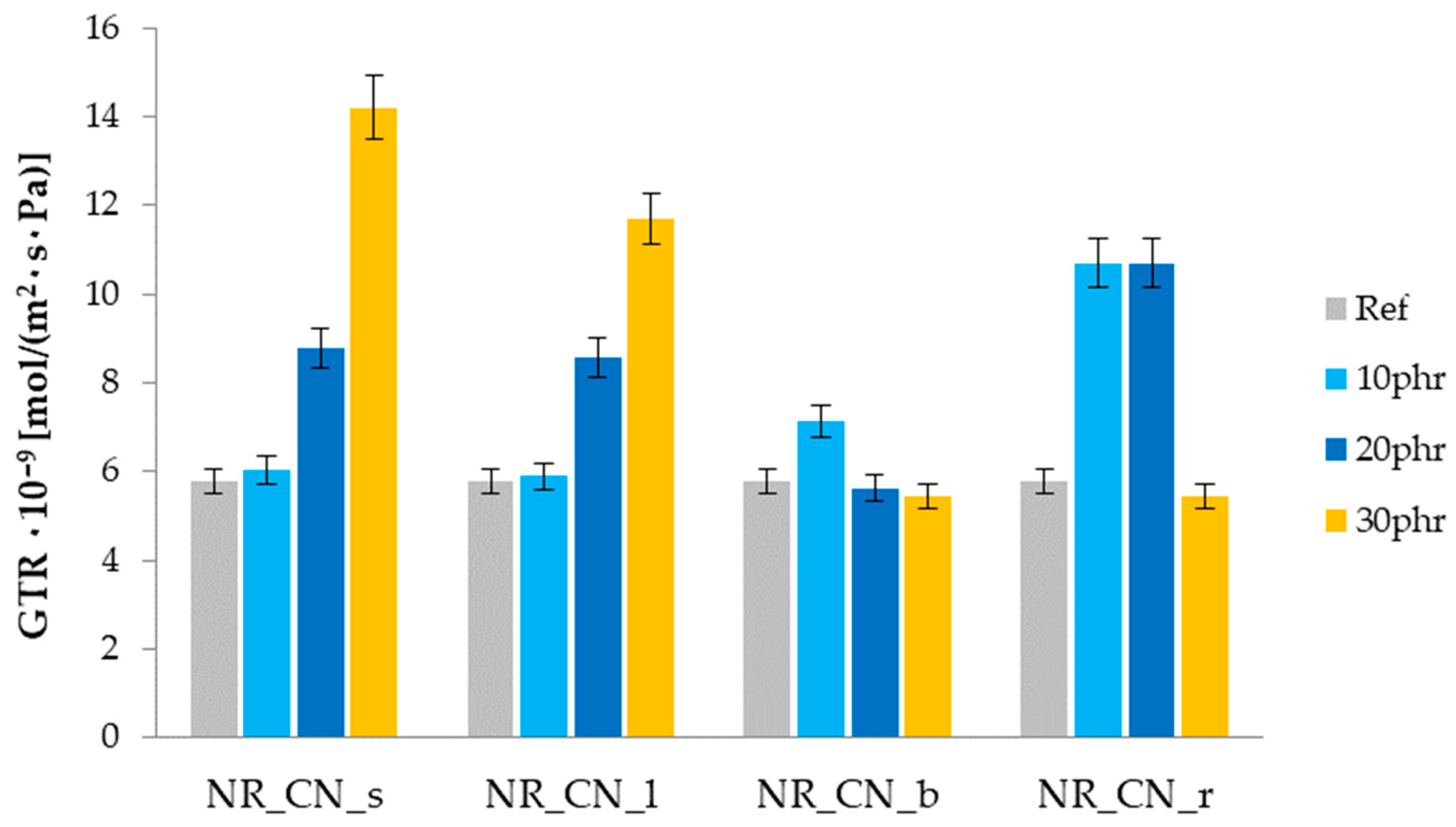

3.2.5. Barrier Properties of the Material

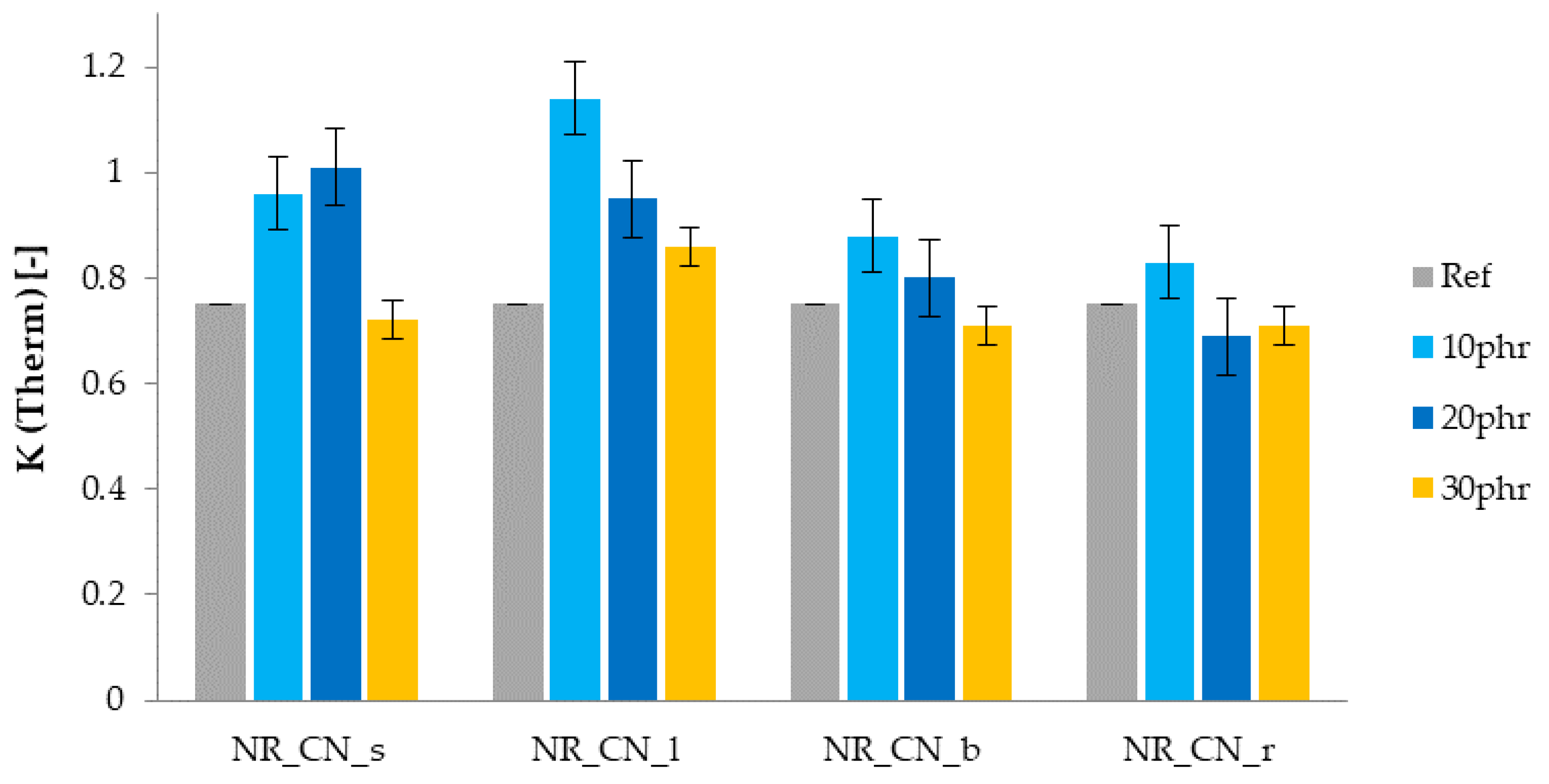

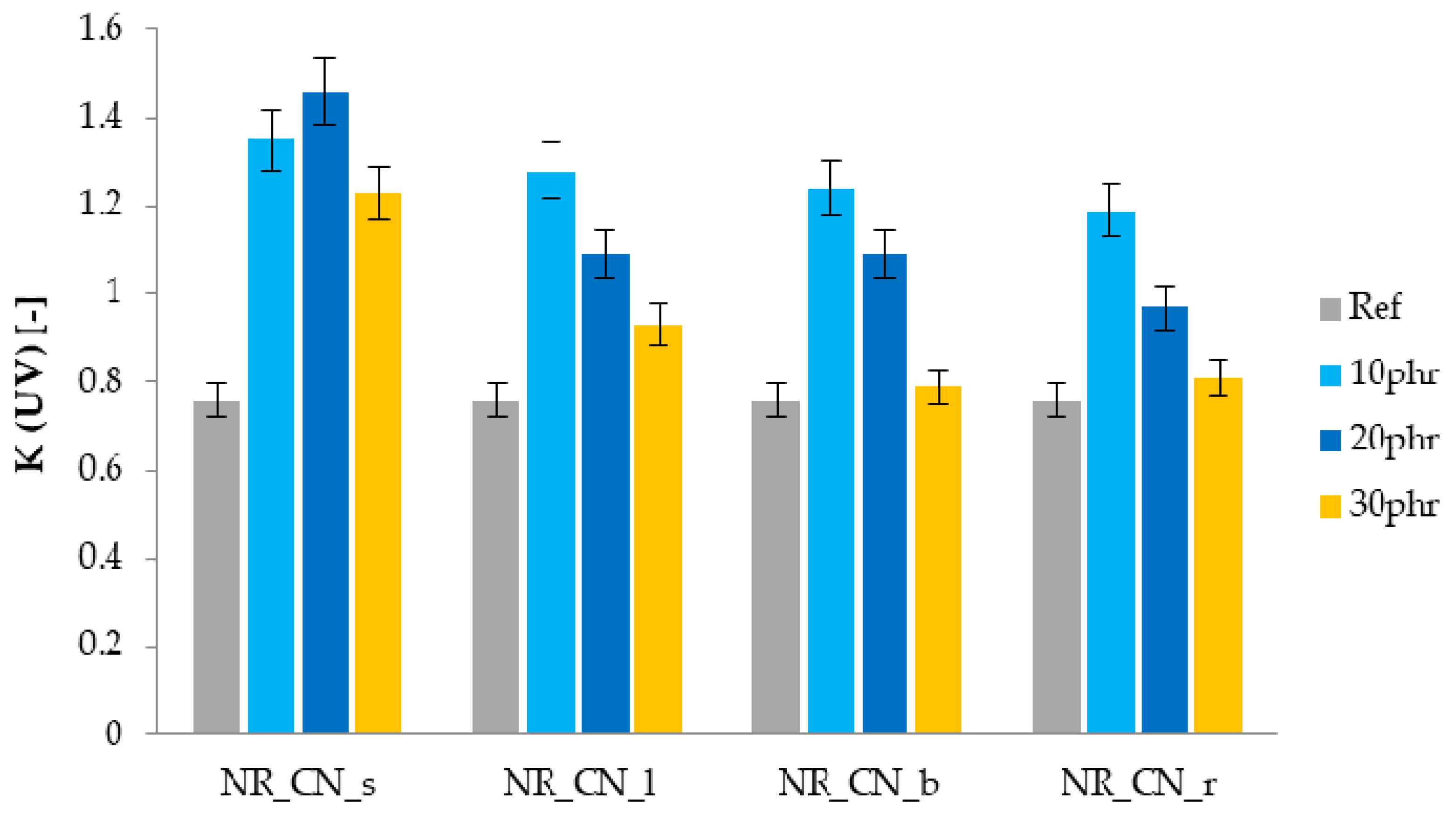

3.2.6. Cross-Linking Density of Biocomposites before and after Aging Processes

3.2.7. Mechanical Properties of Biocomposites before and after Aging Processes

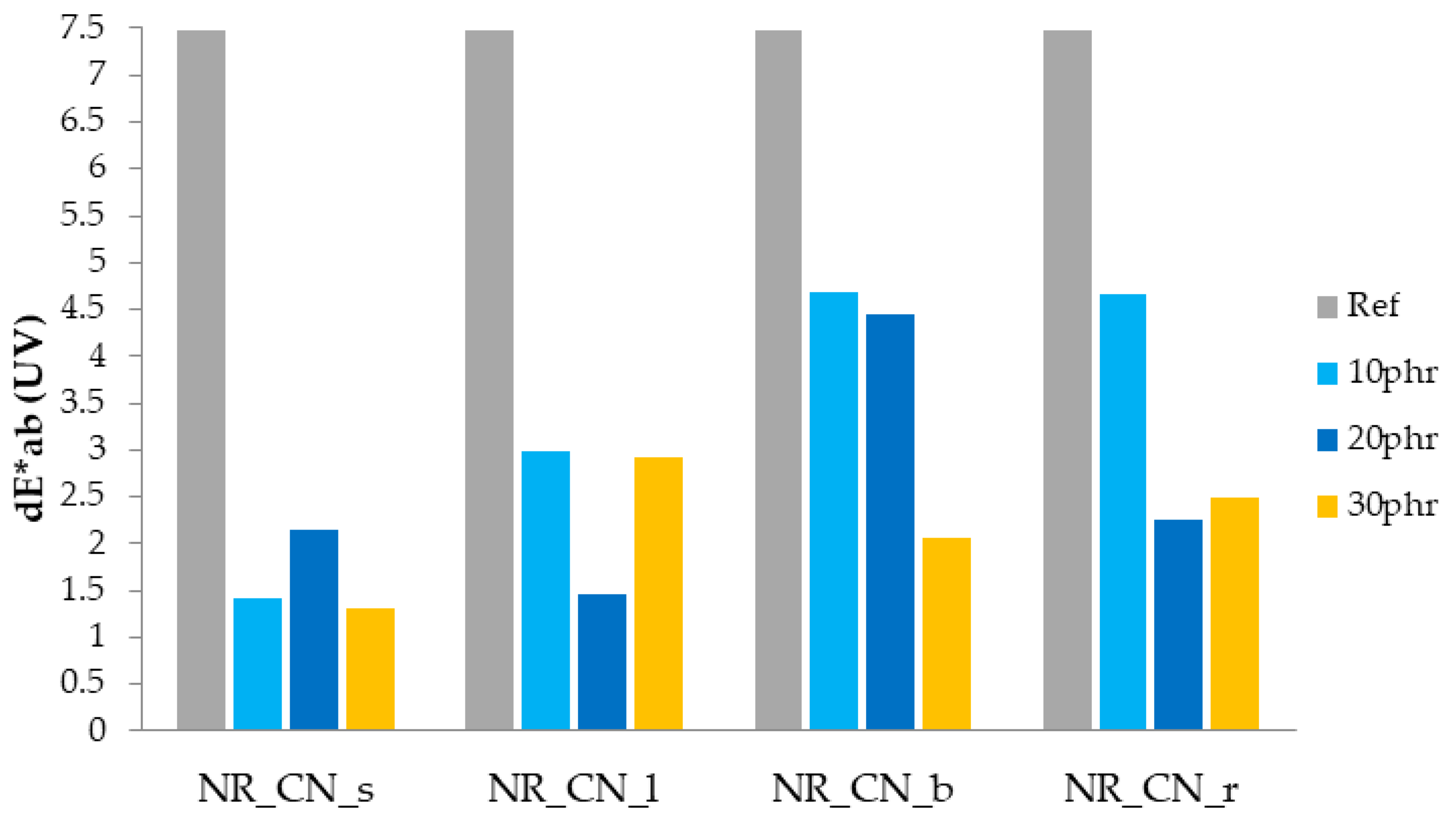

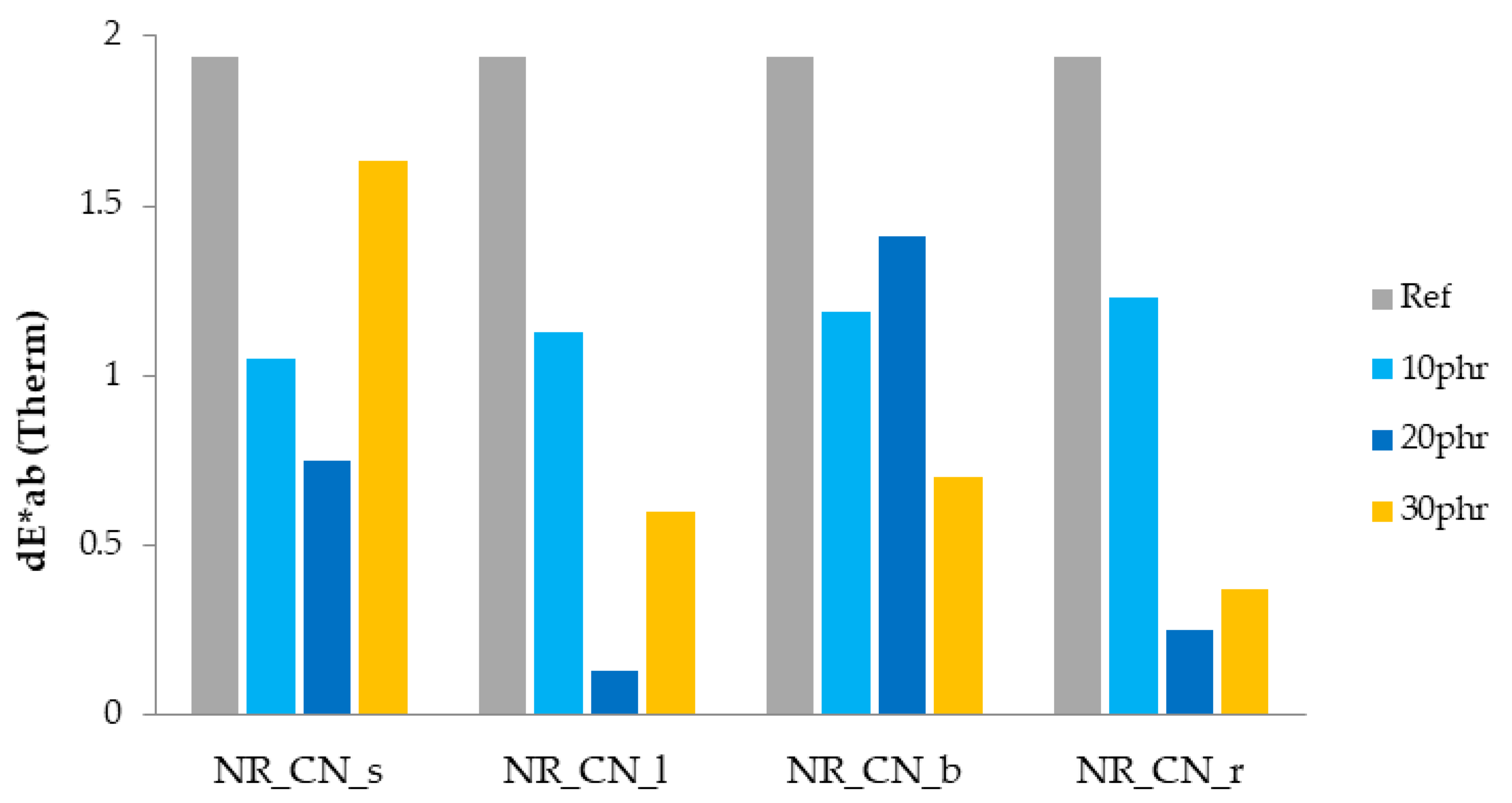

3.2.8. Color Change

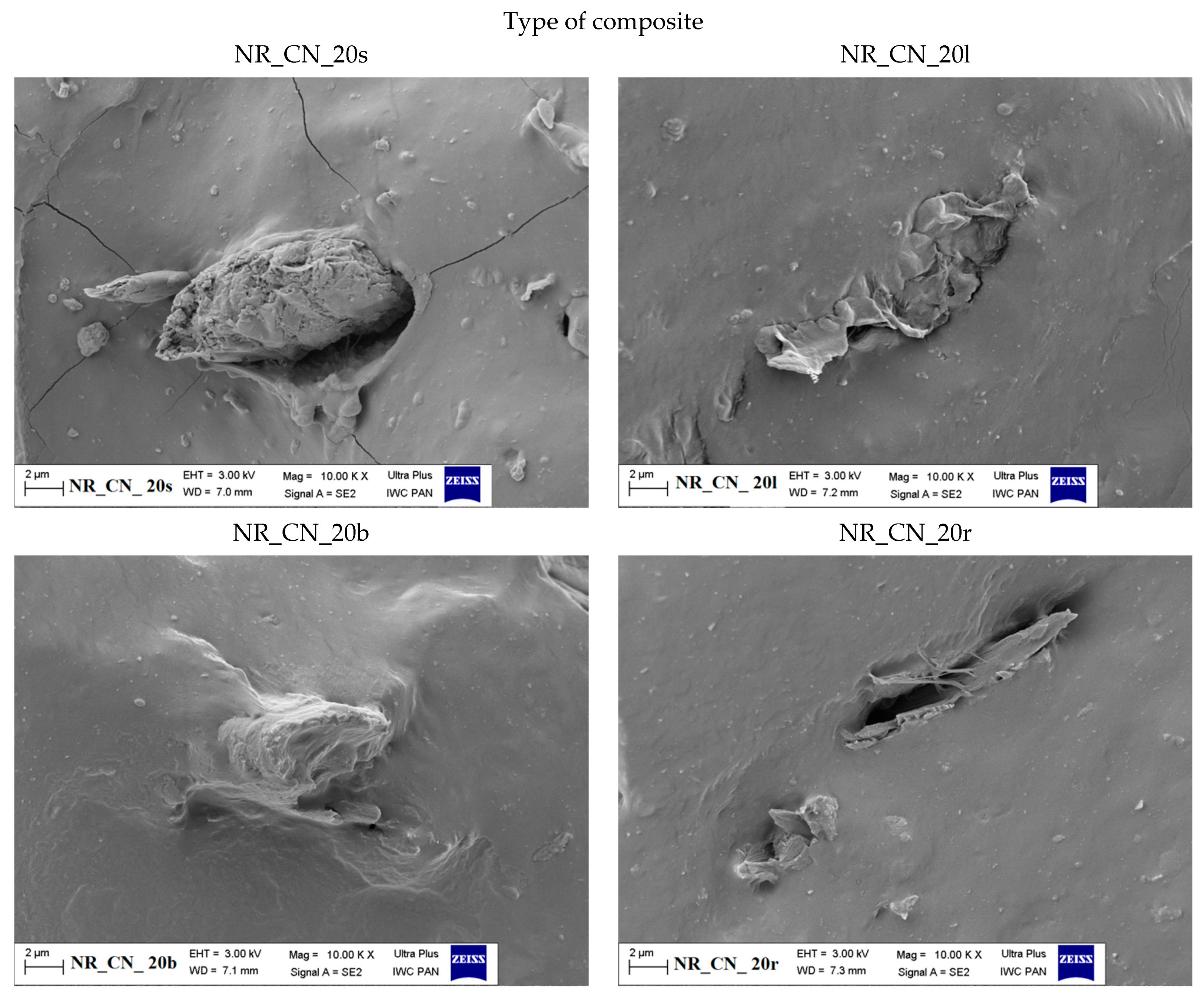

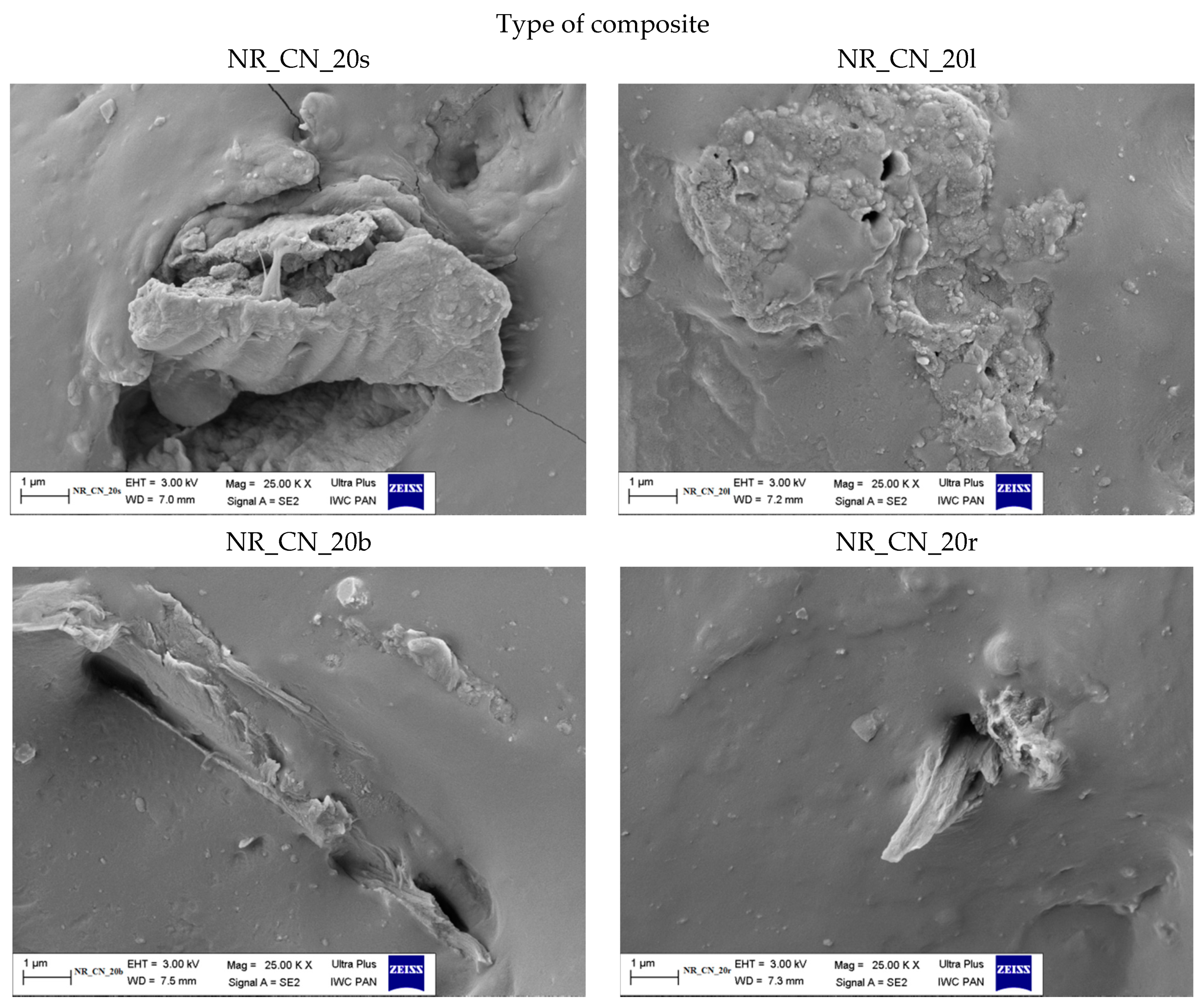

3.2.9. Scanning Electron Microscopy of Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khoo, H.H.; Tan, R.B.H.; Chng, K.W.L. Environmental impacts of conventional plastic and bio-based carrier bags. Int. J. Life Cycle Assess. 2010, 15, 284–293. [Google Scholar] [CrossRef]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 52, 5–25. [Google Scholar] [CrossRef]

- Jasinski, E.; Bounor-Legaré, V.; Taguet, A.; Beyou, E. Influence of halloysite nanotubes onto the fire properties of polymer based composites: A review. Polym. Degrad. Stab. 2021, 183, 109407. [Google Scholar] [CrossRef]

- Gholami, F.; Pakzad, L.; Behzadfar, E. Morphological, interfacial and rheological properties in multilayer polymers: A review. Polymer 2020, 208, 122950. [Google Scholar] [CrossRef]

- Basheer, B.V.; George, J.J.; Siengchin, S.; Parameswaranpillai, J. Polymer grafted carbon nanotubes—Synthesis, properties, and applications: A review. Nanostruct. Nanoobjects 2020, 22, 100429. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, T.; Xie, Z.; Han, J.; Xu, J.; Guo, B. Synthesis and properties of biobased multiblock polyesters containing poly(2,5-furandimethylene succinate) and poly(butylene succinate) blocks. Ind. Eng. Chem. Res. 2017, 56, 3937–3946. [Google Scholar] [CrossRef]

- Quattrosoldi, S.; Soccio, M.; Gazzano, M.; Lotti, N.; Munari, A. Fully biobased, elastomeric and compostable random copolyesters of poly(butylene succinate) containing Pripol 1009 moieties: Structure-property relationship. Polym. Degrad. Stab. 2020, 178, 109189. [Google Scholar] [CrossRef]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Natural rubber composites filled with crop residues as an alternative to vulcanizates with common fillers. Polymers 2019, 11, 972. [Google Scholar] [CrossRef]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. The potential application of cereal straw as a bio-filler for elastomer composites. Polym. Bull. 2020, 77, 2021–2038. [Google Scholar] [CrossRef]

- Kanoth, B.P.; Thomas, T.; Joseph, J.M.; Narayanankutty, S.K. Restructuring of coir to microfibers for enhanced reinforcement in natural rubber. Polym. Compos. 2019, 40, 414–423. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Van Beilen, J.B.; Poirier, Y. Production of renewable polymers from crop plants. Plant J. 2008, 54, 684–701. [Google Scholar] [CrossRef]

- Phakkeeree, T.; Ikeda, Y.; Yokohama, H.; Phinyocheep, P.; Kitano, R.; Kato, A. Network-like structure of lignin in natural rubber matrix to form high performance elastomeric bio-composite. J. Fiber Sci. Technol. 2016, 72, 160–165. [Google Scholar] [CrossRef][Green Version]

- Ichazo, M.; Albano, C.; González, J.; Perera, R.; Candal, M. Polypropylene/wood flour composites: Treatments and properties. Compos. Struct. 2001, 54, 207–214. [Google Scholar] [CrossRef]

- Matuana, L.; Stark, N. The use of wood fibers as reinforcements in composites. In Biofiber Reinforcements in Composite Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 648–688. [Google Scholar]

- Hardinnawirda, K.; SitiRabiatull Aisha, I. Effect of rice husks as filler in polymer matrix composites. J. Mech. Eng. Sci. 2012, 2, 181–186. [Google Scholar] [CrossRef]

- Huang, L.; Mu, B.; Yi, X.; Li, S.; Wang, Q. Sustainable use of coffee husks for reinforcing polyethylene composites. J. Polym. Environ. 2018, 26, 48–58. [Google Scholar] [CrossRef]

- Dong, Y.; Ghataura, A.; Takagi, H.; Haroosh, H.J.; Nakagaito, A.N.; Lau, K.-T. Polylactic acid (PLA) biocomposites reinforced with coir fibres: Evaluation of mechanical performance and multifunctional properties. Compos. Part A Appl. Sci. Manuf. 2014, 63, 76–84. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Yıldızhan, Ş.; Çalik, A.; Özcanlı, M.; Serin, H.; Çalık, A. Bio-composite materials: A short review of recent trends, mechanical and chemical properties, and applications. Eur. Mech. Sci. 2018, 2, 83–91. [Google Scholar] [CrossRef]

- Li, M.C.; Ge, X.; Lim, J.H.; Kim, M.S.; Cho, U.R. Starch/SBR biocomposites prepared by solid blend method: Effect of surface modification and coupling agent. Adv. Mater. Res. 2012, 430-432, 1076–1080. [Google Scholar] [CrossRef]

- Li, M.-C.; Ge, X.; Cho, U.R. Mechanical performance, water absorption behavior and biodegradability of poly(methyl methacrylate)-modified starch/SBR biocomposites. Macromol. Res. 2013, 21, 793–800. [Google Scholar] [CrossRef]

- Sreenivasan, D.P.; Sujith, A.; Rajesh, C. Cure, mechanical and swelling properties of biocomposites from chicken feather fibre and acrylonitrile butadiene rubber. J. Polym. Environ. 2018, 26, 2720–2729. [Google Scholar] [CrossRef]

- Sreenivasan, D.P.; Sujith, A.; Rajesh, C. Cure characteristics and mechanical properties of biocomposites of natural rubber reinforced with chicken feather fibre: Effect of fibre loading, alkali treatment, bonding and vulcanizing systems. Mater. Today Commun. 2019, 20, 100555. [Google Scholar] [CrossRef]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Natural rubber biocomposites containing corn, barley and wheat straw. Polym. Test. 2017, 63, 84–91. [Google Scholar] [CrossRef]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Hybrid straw/perlite reinforced natural rubber biocomposites. J. Bionic Eng. 2019, 16, 1127–1142. [Google Scholar] [CrossRef]

- Vijayaram, T.R. SA technical review on rubber. Int. J. Des. Manuf. Technol. 2009, 3, 25–37. [Google Scholar] [CrossRef]

- Kaczmar, J.; Pach, J.; Kozlowski, R. Use of natural fibres as fillers for polymer composites. Int. Polym. Sci. Technol. 2007, 34, 45–50. [Google Scholar] [CrossRef]

- Ashik, K.P.; Sharma, R.S. A review on mechanical properties of natural fiber reinforced hybrid polymer composites. J. Miner. Mater. Charact. Eng. 2015, 3, 420–426. [Google Scholar] [CrossRef]

- Wei, L.; McDonald, A.G. A review on grafting of biofibers for biocomposites. Materials 2016, 9, 303. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, S.H.; Kim, S.H. Surface alkylation of cellulose nanocrystals to enhance their compatibility with polylactide. Polymers 2020, 12, 178. [Google Scholar] [CrossRef]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Natural rubber composites filled with cereals straw modified with acetic and maleic anhydride: Preparation and properties. J. Polym. Environ. 2018, 26, 4141–4157. [Google Scholar] [CrossRef]

- Miedzianowska, J.; Masłowski, M.; Rybiński, P.; Strzelec, K. Properties of chemically modified (selected silanes) lignocellulosic filler and its application in natural rubber biocomposites. Materials 2020, 13, 4163. [Google Scholar] [CrossRef]

- Ansell, M.P. Wood Composites; Woodhead Publishing: Cambridge, UK, 2015. [Google Scholar]

- Kregiel, D.; Pawlikowska, E.; Antolak, H. Urtica spp.: Ordinary plants with extraordinary properties. Molecules 2018, 23, 1664. [Google Scholar] [CrossRef] [PubMed]

- Skalozubova, T.A.; Reshetova, V.O. Leaves of common nettle (Urtica dioica L.) as a source of ascorbic acid (vitamin C). World Appl. Sci. J. 2013, 28. [Google Scholar] [CrossRef]

- Bojović, B.M.; Jakovljević, D.Z.; Stanković, M.S. Phytotoxic potential of common nettle (Urtica dioica L.) on germination and early growth of cereals and vegetables. Allelopath. J. 2018, 43, 175–186. [Google Scholar] [CrossRef]

- Grauso, L.; De Falco, B.; Lanzotti, V.; Motti, R. Stinging nettle, Urtica dioica L.: Botanical, phytochemical and pharmacological overview. Phytochem. Rev. 2020, 19, 1341–1377. [Google Scholar] [CrossRef]

- Fischer, H.; Werwein, E.; Graupner, N. Nettle fibre (Urtica dioica L.) reinforced poly(lactic acid): A first approach. J. Compos. Mater. 2012, 46, 3077–3087. [Google Scholar] [CrossRef]

- Kumar, N.; Das, D. Fibrous biocomposites from nettle (Girardinia diversifolia) and poly(lactic acid) fibers for automotive dashboard panel application. Compos. Part B Eng. 2017, 130, 54–63. [Google Scholar] [CrossRef]

- Suryawan, I.G.P.A.; Suardana, N.P.G.; Winaya, I.N.S.; Suyasa, I.W.B.; Nindhia, T.G.T. Study of stinging nettle (Urtica dioica L.) Fibers reinforced green composite materials: A review. IOP Conf. Ser. Mater. Sci. Eng. 2017, 201, 012001. [Google Scholar] [CrossRef]

- Şansal, S.; Mıstık, S.I.; Fettahov, R.; Ovalı, S.; Duman, M. Effect of ecological surface treatment method on friction strength properties of nettle (urtica dioica) fibre yarns. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 122010. [Google Scholar] [CrossRef]

- Wu, X.-F.; Dzenis, Y.A. Droplet on a fiber: Geometrical shape and contact angle. Acta Mech. 2006, 185, 215–225. [Google Scholar] [CrossRef]

- Flory, P.J.; Rehner, J. Statistical mechanics of cross-linked polymer networks I. Rubberlike elasticity. J. Chem. Phys. 1943, 11, 512–520. [Google Scholar] [CrossRef]

- Szadkowski, B.; Marzec, A.; Rybiński, P.; Maniukiewicz, W.; Zaborski, M. Aluminum-magnesium hydroxycarbonate/azo dye hybrids as novel multifunctional colorants for elastomer composites. Polymers 2018, 11, 43. [Google Scholar] [CrossRef] [PubMed]

- Maciejewska, M.; Sowińska, A.; Kucharska, J. Organic zinc salts as pro-ecological activators for sulfur vulcanization of styrene–butadiene rubber. Polymers 2019, 11, 1723. [Google Scholar] [CrossRef]

- Marzec, A.; Szadkowski, B.; Rogowski, J.; Rybiński, P.; Maniukiewicz, W. Novel eco-friendly hybrid pigment with improved stability as a multifunctional additive for elastomer composites with reduced flammability and pH sensing properties. Dye. Pigment. 2021, 186, 108965. [Google Scholar] [CrossRef]

- Sandiningtyas, R.D.; Suendo, V. Isolation of chlorophyll a from spinach and its modification using Fe2+ in photostability study. In Proceedings of the Third International Conference on. Mathematics and Natural Sciences (ICMNS 2010), Bandung, Indonesia, 23–25 November 2010. [Google Scholar]

- Zaghdoudi, K.; Ngomo, O.; Vanderesse, R.; Arnoux, P.; Myrzakhmetov, B.; Frochot, C.; Guiavarc’H, Y. Extraction, identification and photo-physical characterization of persimmon (Diospyros kaki L.) carotenoids. Foods 2017, 6, 4. [Google Scholar] [CrossRef] [PubMed]

- Guil-Guerrero, J.; Rebolloso-Fuentes, M.; Isasa, M. Fatty acids and carotenoids from Stinging Nettle (Urtica dioica L.). J. Food Compos. Anal. 2003, 16, 111–119. [Google Scholar] [CrossRef]

- Repajić, M.; Cegledi, E.; Kruk, V.; Pedisić, S.; Çınar, F.; Kovačević, D.B.; Žutić, I.; Dragović-Uzelac, V. Accelerated solvent extraction as a green tool for the recovery of polyphenols and pigments from wild nettle leaves. Processes 2020, 8, 803. [Google Scholar] [CrossRef]

- Pinelli, P.; Ieri, F.; Vignolini, P.; Bacci, L.; Baronti, S.; Romani, A. Extraction and HPLC analysis of phenolic compounds in leaves, stalks, and textile fibers of Urtica dioica L. J. Agric. Food Chem. 2008, 56, 9127–9132. [Google Scholar] [CrossRef]

- Akbay, P.; Basaran, A.A.; Undeger, U.; Basaran, N. In vitro immunomodulatory activity of flavonoid glycosides from Urtica dioica L. Phytother. Res. 2003, 17, 34–37. [Google Scholar] [CrossRef] [PubMed]

- Fan, M.; Naughton, A. Mechanisms of thermal decomposition of natural fibre composites. Compos. Part B Eng. 2016, 88, 1–10. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Ferreira, E.S.; Cranston, E.D.; Rezende, C.A. Naturally hydrophobic foams from lignocellulosic fibers prepared by oven-drying. ACS Sustain. Chem. Eng. 2020, 8, 8267–8278. [Google Scholar] [CrossRef]

- Malas, A. Rubber nanocomposites with graphene as the nanofiller. In Progress in Rubber Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2017; pp. 179–229. [Google Scholar]

- Sowińska, A.; Maciejewska, M.; Guo, L.; Delebecq, E. Effect of SILPs on the vulcanization and properties of ethylene–propylene–diene elastomer. Polymers 2020, 12, 1220. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. A Simulation work for the influences of aggregation/agglomeration of clay layers on the tensile properties of nanocomposites. JOM 2019, 71, 3989–3995. [Google Scholar] [CrossRef]

- Farida, E.; Bukit, N.; Ginting, E.M.; Bukit, B.F. The effect of carbon black composition in natural rubber compound. Case Stud. Therm. Eng. 2019, 16, 100566. [Google Scholar] [CrossRef]

- Stelescu, M.-D.; Manaila, E.; Craciun, G.; Chirila, C. Development and characterization of polymer eco-composites based on natural rubber reinforced with natural fibers. Materials 2017, 10, 787. [Google Scholar] [CrossRef]

- Seidelt, S.; Müller-Hagedorn, M.; Bockhorn, H. Description of tire pyrolysis by thermal degradation behaviour of main components. J. Anal. Appl. Pyrolysis 2006, 75, 11–18. [Google Scholar] [CrossRef]

- Janowska, G.; Kucharska-Jastrząbek, A.; Rybiński, P. Thermal stability, flammability and fire hazard of butadiene-acrylonitrile rubber nanocomposites. J. Therm. Anal. Calorim. 2011, 103, 1039–1046. [Google Scholar] [CrossRef]

- Zeipiņa, S.; Alsina, I.; Lepse, L.; Duma, M. Antioxidant activity in nettle (Urtica dioica l.) and garden orache (Atriplex hortensis L.) leaves during vegetation period. Chem. Technol. 2015, 66. [Google Scholar] [CrossRef]

- Shonte, T.T.; Duodu, K.; De Kock, H.L. Effect of drying methods on chemical composition and antioxidant activity of underutilized stinging nettle leaves. Heliyon 2020, 6, e03938. [Google Scholar] [CrossRef] [PubMed]

| Sample Name | CN | NR | Stearin | ZnO | MBT | Sulphur |

|---|---|---|---|---|---|---|

| (phr 1) | ||||||

| Reference Sample (NR) | 0 | 100 | 1 | 5 | 2 | 2 |

| NR_CN_s10 | 10 | 100 | 1 | 5 | 2 | 2 |

| NR_CN_s20 | 20 | 100 | 1 | 5 | 2 | 2 |

| NR_CN_s30 | 30 | 100 | 1 | 5 | 2 | 2 |

| NR_CN_l10 | 10 | 100 | 1 | 5 | 2 | 2 |

| NR_CN_l20 | 20 | 100 | 1 | 5 | 2 | 2 |

| NR_CN_l30 | 30 | 100 | 1 | 5 | 2 | 2 |

| NR_CN_b10 | 10 | 100 | 1 | 5 | 2 | 2 |

| NR_CN_b20 | 20 | 100 | 1 | 5 | 2 | 2 |

| NR_CN_b30 | 30 | 100 | 1 | 5 | 2 | 2 |

| NR_CN_r10 | 10 | 100 | 1 | 5 | 2 | 2 |

| NR_CN_r20 | 20 | 100 | 1 | 5 | 2 | 2 |

| NR_CN_r30 | 30 | 100 | 1 | 5 | 2 | 2 |

| Fraction [mm] | Sieve Sizes [mm] | Seeds | Leaves | Branches | Roots | ||||

|---|---|---|---|---|---|---|---|---|---|

| (g) | (%) | (g) | (%) | (g) | (%) | (g) | (%) | ||

| 0.500–1.00 | 0.500 | 0.45 | 1.13 | 1.4 | 2.34 | 2.66 | 4.44 | 1.65 | 4.13 |

| 0.250–0.500 | 0.250 | 7.60 | 19.01 | 12.74 | 21.23 | 13.93 | 23.21 | 9.20 | 23.01 |

| 0.125–0.250 | 0.125 | 23.82 | 59.55 | 35.07 | 58.45 | 34.04 | 56.74 | 22.66 | 56.65 |

| 0.065–0.125 | 0.065 | 8.12 | 20.31 | 10.79 | 17.98 | 9.37 | 15.61 | 6.48 | 16.21 |

| Σ | 40 | 100 | 60 | 100 | 60 | 100 | 40 | 100 | |

| Peak Assignments | Type of Vibration | Absorption Ranges [cm−1] |

|---|---|---|

| O-H hydrogen | stretching | 3760 |

| O-H phenols & alcohols | stretching | 3650–3200 |

| C-H vinyl & acrylic | stretching | 3100–3010 |

| C-H aliphatic | stretching | 2970–2800 |

| C=O | stretching | 1730–1690 |

| C=N | stretching | 1750–1500 |

| C=C alkenes | stretching | 1680–1610 |

| C=C aryl | stretching | 1600–1500 |

| C-C aliphatic | stretching | 1500–600 |

| C=C aromatic; | skeletal vibration | 1441 |

| C-H aliphatic | deformation | 1370–1340 |

| C-N | stretching | 1360–1180 |

| C-O, C-C, -C-O-C- | asymmetric & symmetric stretching | 1280–1150 |

| C-O-C | axial deformation | 1060 |

| C-H vinyl | deformation | 995–675 |

| C-H aryl | glucose ring stretching/out of plane deformation | 900–690 |

| Sample Name | T10 1 (°C) | Δm100 2 (%) | Δm335 3 (%) | Residue at 600 °C 4 (%) |

|---|---|---|---|---|

| CN_s | 225.02 | 3.04 | 55.76 | 31.86 |

| CN_l | 226.40 | 2.09 | 59.31 | 36.34 |

| CN_b | 237.40 | 2.78 | 48.13 | 24.88 |

| CN_r | 249.23 | 2.79 | 50.39 | 25.60 |

| Sample Name | T10 1 (°C) | Δm385 2 (%) | Residue at 600 °C 3 (%) |

|---|---|---|---|

| NR_CN_30s | 303.00 | 46.98 | 11.39 |

| NR_CN_30l | 311.00 | 45.93 | 12.76 |

| NR_CN_30b | 304.00 | 49.33 | 10.72 |

| NR_CN_30r | 304.00 | 50.65 | 10.71 |

| Sample Name | Filler Content (phr) | νe × 105 (mol/cm3) | ||

|---|---|---|---|---|

| Ref | UV | Therm | ||

| Ref. Sample (NR) | 0 | 1.78 ± 0.03 | 2.66 ± 0.02 | 2.44 ± 0.03 |

| NR_CN_s | 10 | 2.11 ± 0.03 | 2.43 ± 0.04 | 2.16 ± 0.04 |

| 20 | 2.14 ± 0.03 | 2.55 ± 0.04 | 2.45 ± 0.04 | |

| 30 | 2.25 ± 0.01 | 2.80 ± 0.05 | 2.74 ± 0.05 | |

| NR_CN_l | 10 | 1.97 ± 0.02 | 2.02 ± 0.02 | 2.01 ± 0.02 |

| 20 | 2.03 ± 0.03 | 2.11 ± 0.02 | 2.05 ± 0.03 | |

| 30 | 2.04 ± 0.02 | 2.16 ± 0.02 | 2.08 ± 0.04 | |

| NR_CN_b | 10 | 2.18 ± 0.02 | 2.26 ± 0.02 | 2.25 ± 0.02 |

| 20 | 2.22 ± 0.02 | 2.31 ± 0.03 | 2.37 ± 0.01 | |

| 30 | 2.40 ± 0.03 | 2.78 ± 0.04 | 2.65 ± 0.02 | |

| NR_CN_r | 10 | 2.07 ± 0.03 | 2.35 ± 0.04 | 2.27 ± 0.02 |

| 20 | 2.12 ± 0.01 | 2.50 ± 0.02 | 2.38 ± 0.02 | |

| 30 | 2.53 ± 0.03 | 2.84 ± 0.03 | 2.69 ± 0.13 | |

| Sample Name | Filler Content (phr) | Young Modulus (MPa) | TS (MPa) | Eb (%) |

|---|---|---|---|---|

| Ref. Sample (NR) | 0 | 0.187 ± 0.002 | 11.48 ± 0.05 | 640.05 ± 2.80 |

| NR_CN_s | 10 | 0.193 ± 0.002 | 12.17 ± 0.64 | 677.80 ± 10.83 |

| 20 | 0.204 ± 0.002 | 11.90 ± 0.12 | 645.83 ± 4.91 | |

| 30 | 0.216 ± 0.002 | 11.70 ± 0.41 | 679.85 ± 14.64 | |

| NR_CN_l | 10 | 0.200 ± 0.002 | 12.41 ± 0.28 | 697.4 ± 21.60 |

| 20 | 0.198 ± 0.002 | 14.13 ± 0.10 | 723.27 ± 8.54 | |

| 30 | 0.213 ± 0.002 | 14.22 ± 0.65 | 744.43 ± 8.45 | |

| NR_CN_b | 10 | 0.205 ± 0.002 | 13.42 ± 0.70 | 679.16 ± 13.05 |

| 20 | 0.209 ± 0.002 | 13.18 ± 0.12 | 733.04 ± 8.28 | |

| 30 | 0.285 ± 0.002 | 13.23 ± 0.22 | 718.16 ± 14.93 | |

| NR_CN_r | 10 | 0.201 ± 0.002 | 13.06 ± 0.58 | 738.07 ± 1.00 |

| 20 | 0.214 ± 0.002 | 13.25 ± 1.17 | 700.51 ± 13.36 | |

| 30 | 0.247 ± 0.002 | 13.41 ± 0.41 | 713.07 ± 23.36 |

| Sample Name (Therm) | Filler Content (phr) | TS (MPa) | Eb (%) |

|---|---|---|---|

| Ref. Sample (NR) | 0 | 10.15 ± 0.05 | 543.17 ± 3.04 |

| NR_CN_s | 10 | 12.05 ± 1.91 | 657.28 ± 7.89 |

| 20 | 12.37 ± 0.28 | 625.02 ± 0.71 | |

| 30 | 9.34 ± 0.10 | 614.94 ± 18.98 | |

| NR_CN_l | 10 | 13.57 ± 0.26 | 726.70 ± 9.91 |

| 20 | 13.49 ± 0.44 | 716.44 ± 0.68 | |

| 30 | 13.13 ± 0.09 | 691.45 ± 12.30 | |

| NR_CN_b | 10 | 11.96 ± 0.76 | 673.90 ± 4.61 |

| 20 | 11.42 ± 0.64 | 675.95 ± 5.25 | |

| 30 | 10.08 ± 0.59 | 665.38 ± 13.81 | |

| NR_CN_r | 10 | 11.98 ± 2.86 | 665.91 ± 3.19 |

| 20 | 10.18 ± 1.93 | 628.26 ± 14.76 | |

| 30 | 10.58 ± 0.01 | 643.15 ± 2.62 |

| Sample Name | Filler Content (phr) | TS (MPa) | Eb (%) |

|---|---|---|---|

| Ref. Sample (NR) | 0 | 9.65 ± 0.58 | 578.38 ± 3.75 |

| NR_CN_s | 10 | 14.60 ± 0.46 | 761.47 ± 9.60 |

| 20 | 15.00 ± 0.51 | 750.37 ± 8.24 | |

| 30 | 13.55 ± 0.13 | 724.66 ± 3.02 | |

| NR_CN_l | 10 | 13.68 ± 0.02 | 809.49 ± 1.89 |

| 20 | 14.29 ± 0.87 | 781.61 ± 6.55 | |

| 30 | 12.95 ± 0.32 | 757.11 ± 5.53 | |

| NR_CN_b | 10 | 14.33 ± 0.69 | 788.07 ± 9.62 |

| 20 | 13.81 ± 0.25 | 765.25 ± 3.26 | |

| 30 | 10.71 ± 0.06 | 704.45 ± 3.26 | |

| NR_CN_r | 10 | 14.75 ± 0.13 | 776.27 ± 5.73 |

| 20 | 12.52 ± 0.58 | 717.73 ± 8.26 | |

| 30 | 11.55 ± 0.63 | 668.58 ± 8.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masłowski, M.; Aleksieiev, A.; Miedzianowska, J.; Strzelec, K. Common Nettle (Urtica dioica L.) as an Active Filler of Natural Rubber Biocomposites. Materials 2021, 14, 1616. https://doi.org/10.3390/ma14071616

Masłowski M, Aleksieiev A, Miedzianowska J, Strzelec K. Common Nettle (Urtica dioica L.) as an Active Filler of Natural Rubber Biocomposites. Materials. 2021; 14(7):1616. https://doi.org/10.3390/ma14071616

Chicago/Turabian StyleMasłowski, Marcin, Andrii Aleksieiev, Justyna Miedzianowska, and Krzysztof Strzelec. 2021. "Common Nettle (Urtica dioica L.) as an Active Filler of Natural Rubber Biocomposites" Materials 14, no. 7: 1616. https://doi.org/10.3390/ma14071616

APA StyleMasłowski, M., Aleksieiev, A., Miedzianowska, J., & Strzelec, K. (2021). Common Nettle (Urtica dioica L.) as an Active Filler of Natural Rubber Biocomposites. Materials, 14(7), 1616. https://doi.org/10.3390/ma14071616