Composite Binder Containing Industrial By-Products (FCCCw and PSw) and Nano SiO2

Abstract

1. Introduction

2. Materials and Methods

2.1. Characteristics of Materials

2.2. Methods

3. Results and Discussion

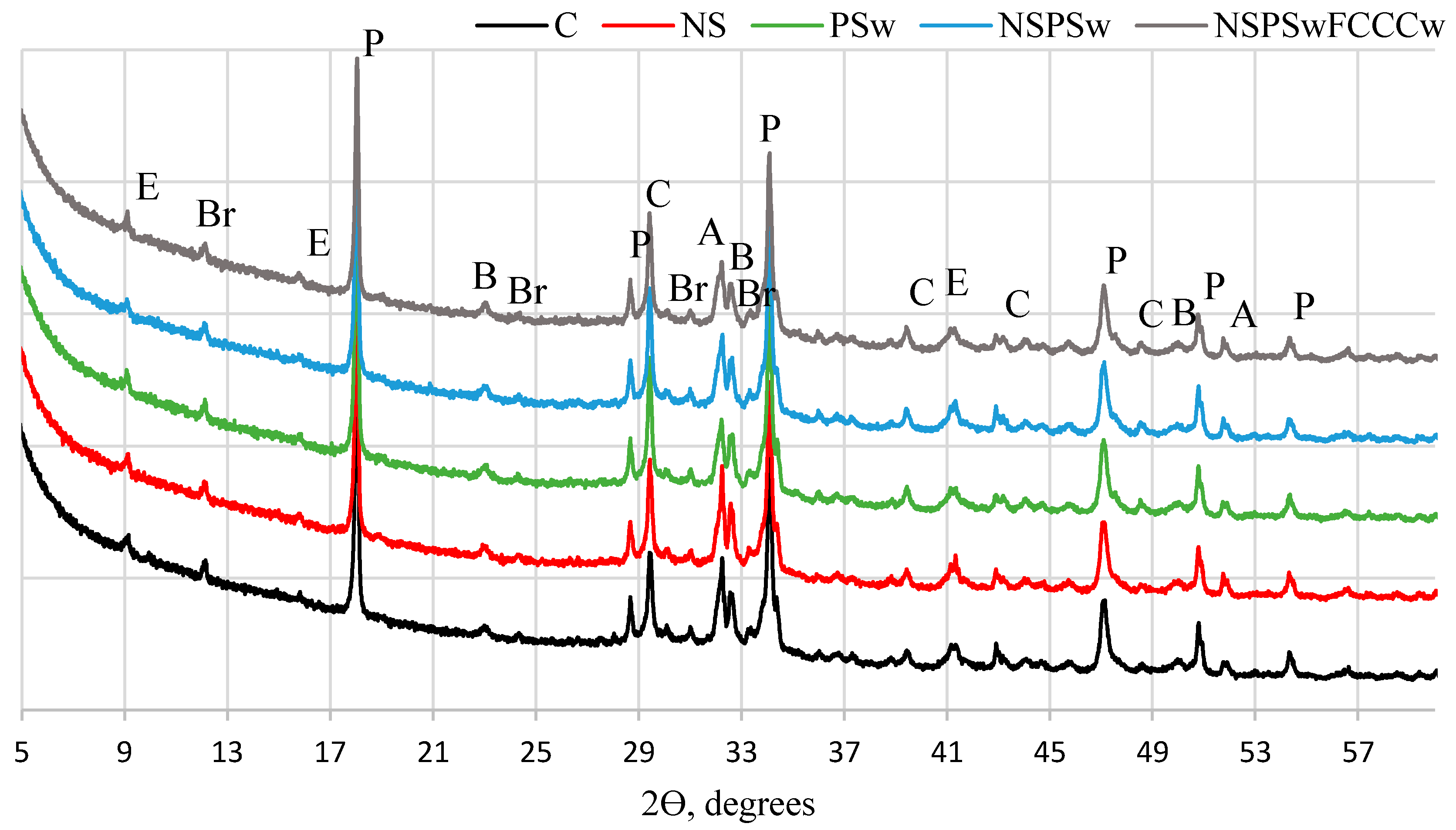

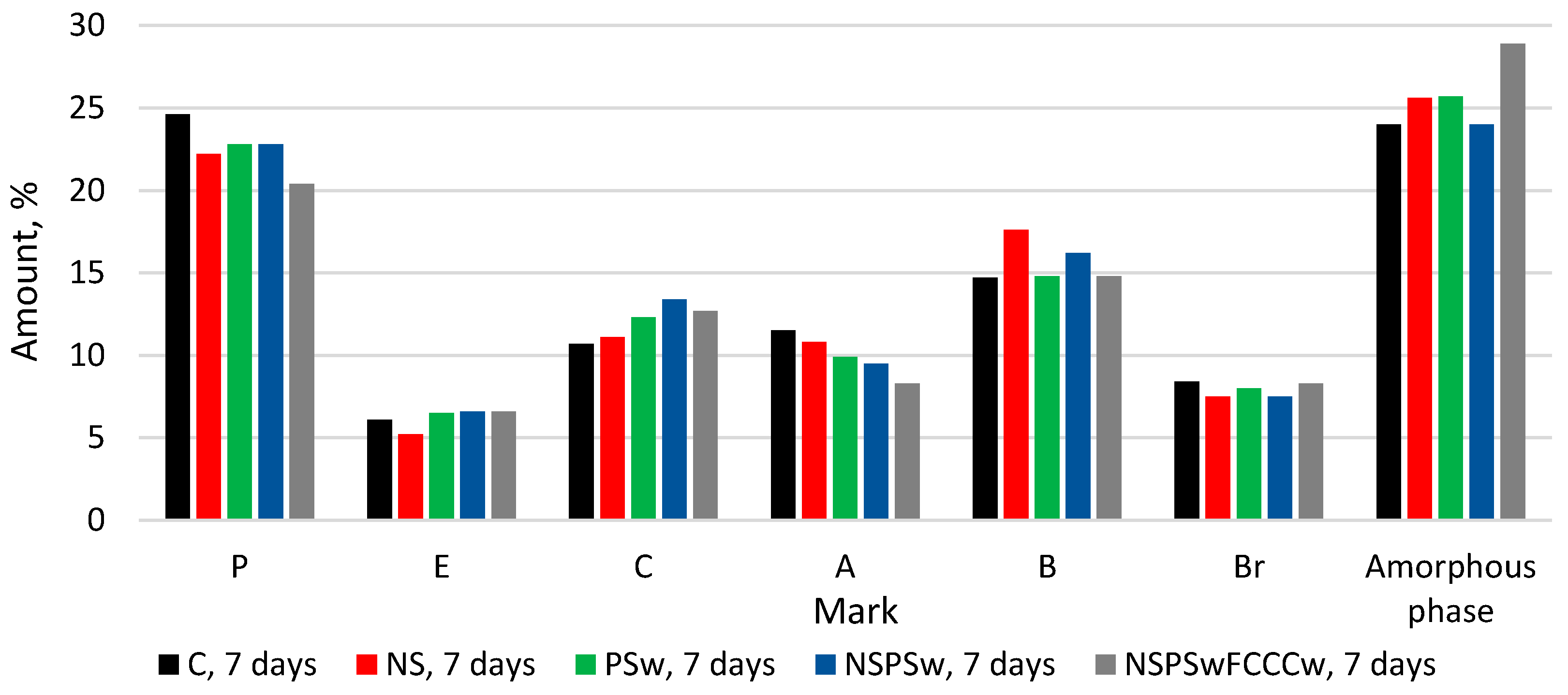

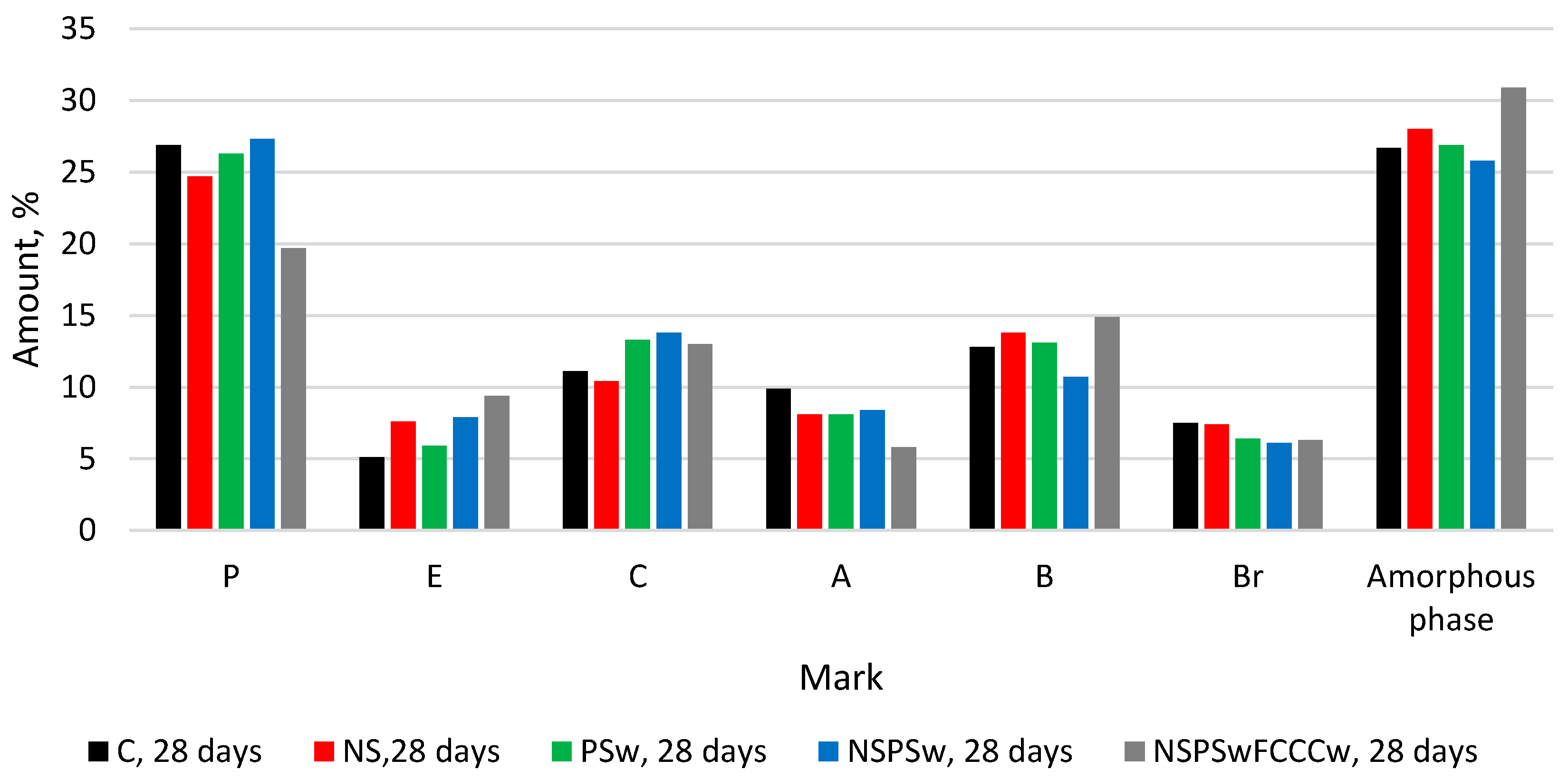

3.1. Results of XRD Analysis

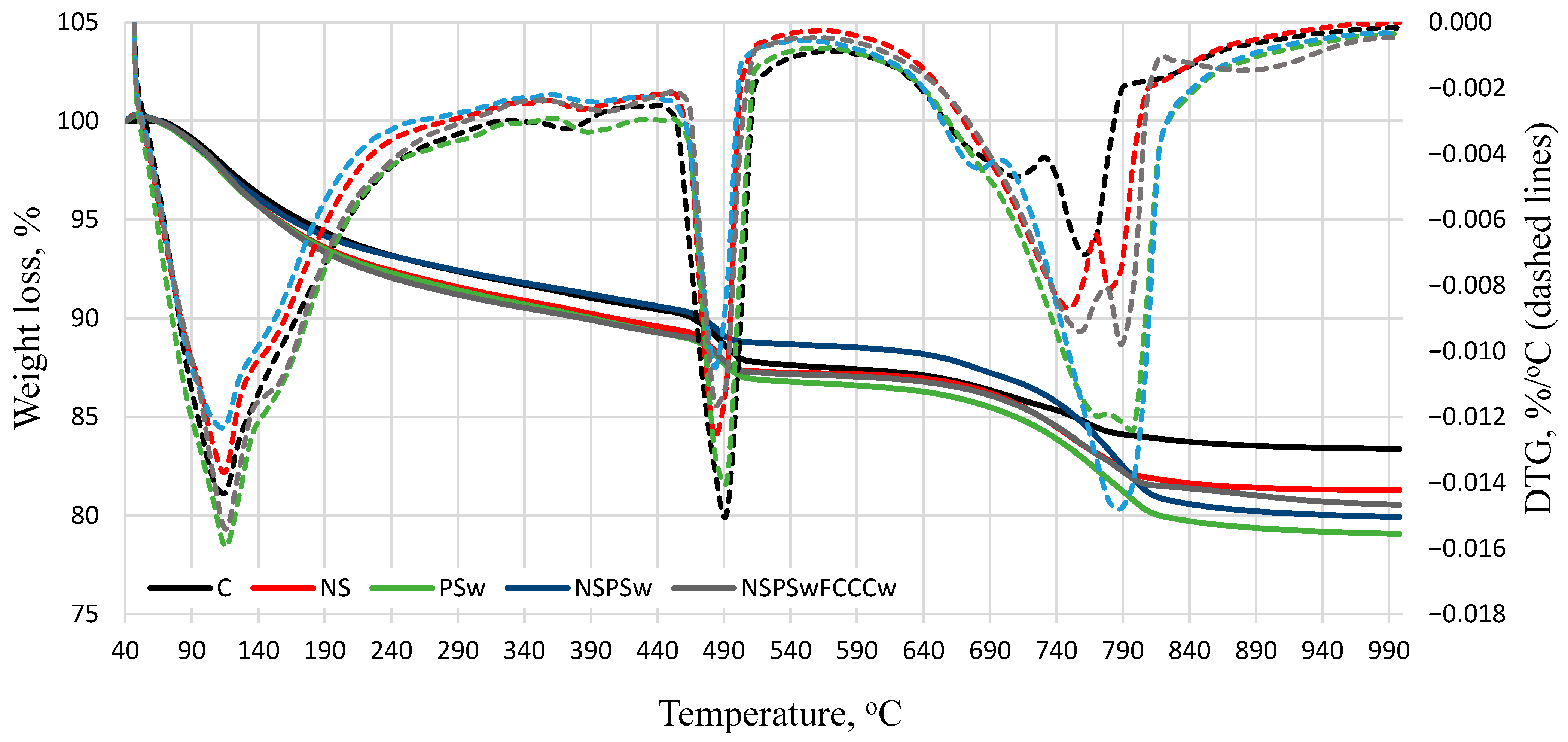

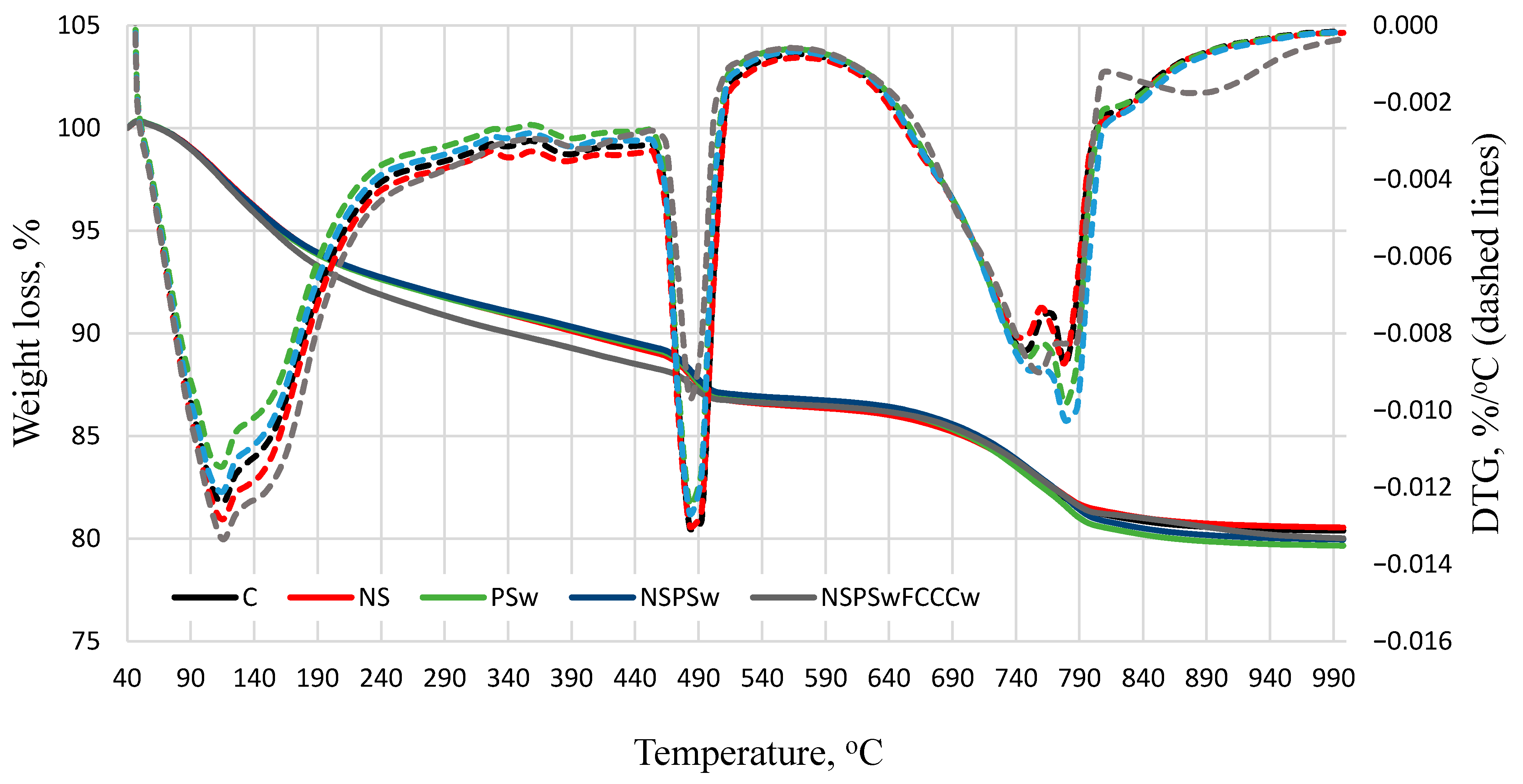

3.2. Results of DTG Analysis

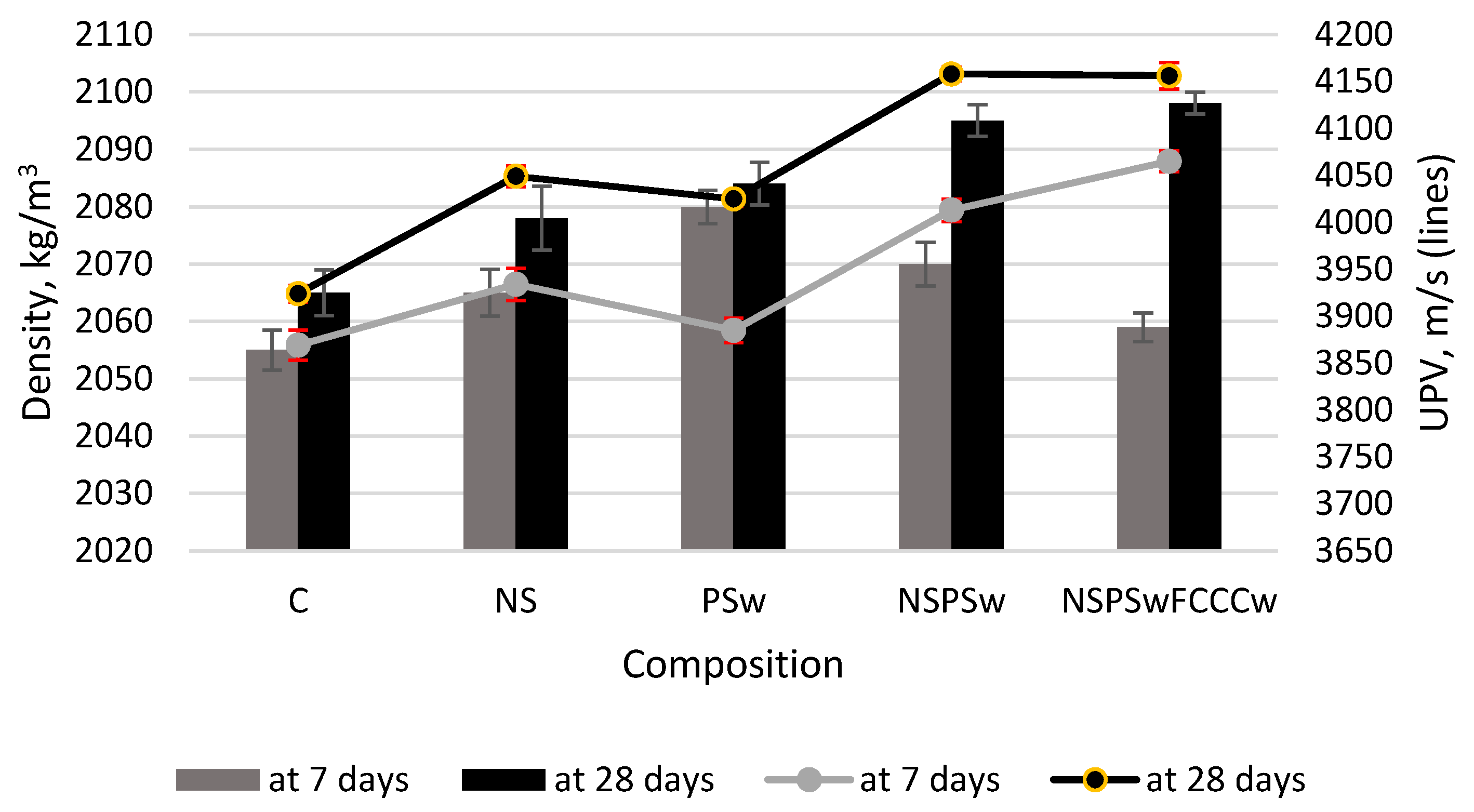

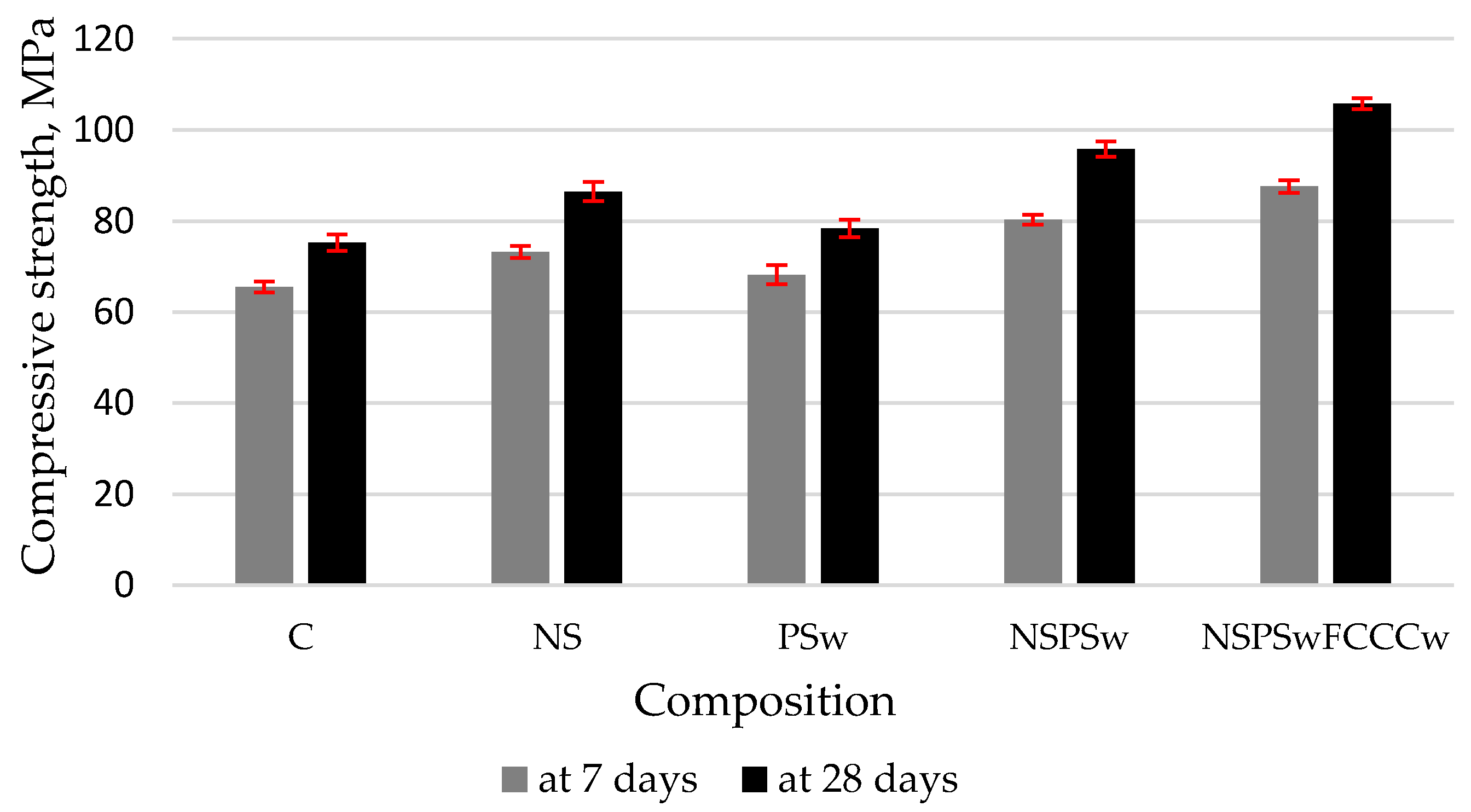

3.3. Results of Physical Mechanical Properties

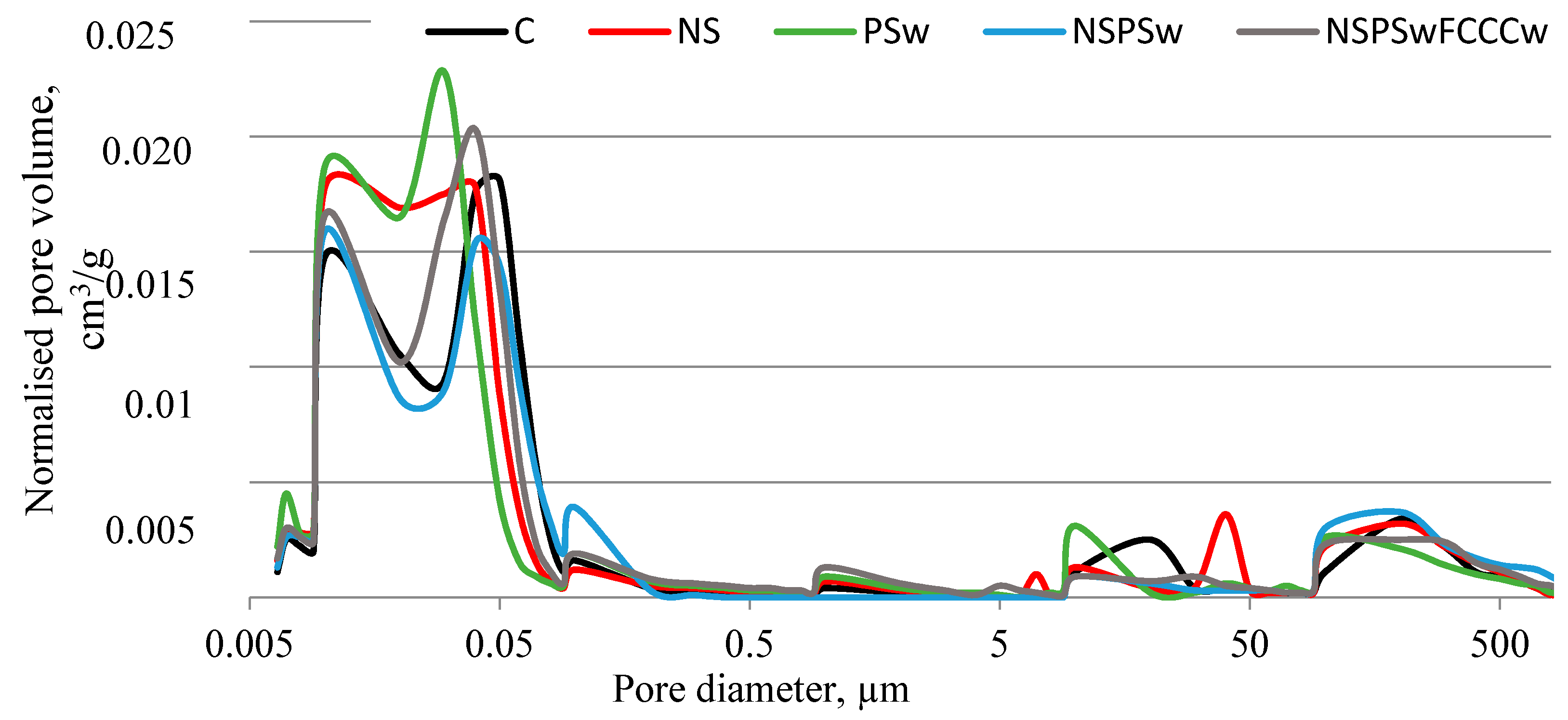

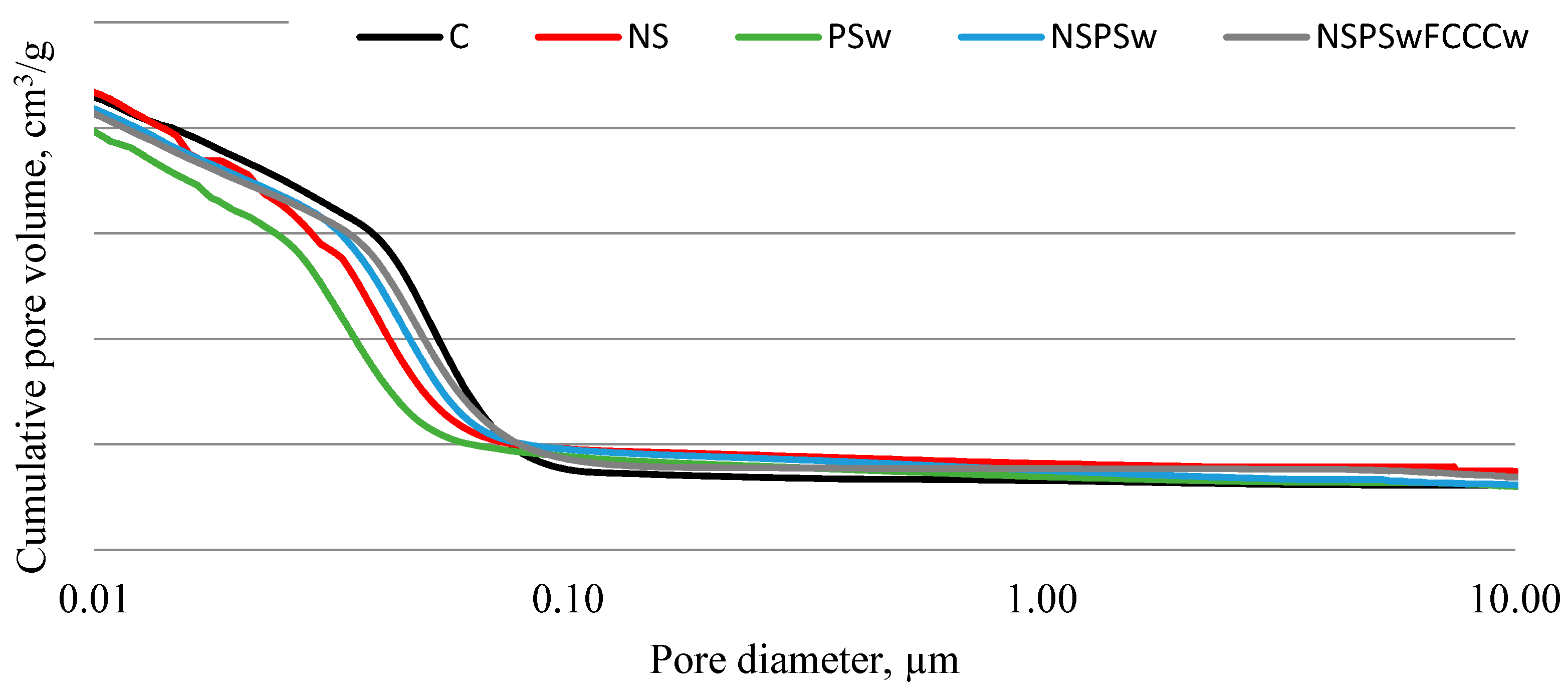

3.4. Results of MIP and SEM Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Abousnina, R.; Manalo, A.; Ferdous, W.; Lokuge, W.; Benabed, B.; Saif Al-Jabri, K. Characteristics, strength development and microstructure of cement mortar containing oil-contaminated sand. Constr. Build. Mater. 2020, 252, 119155. [Google Scholar] [CrossRef]

- Al-Salami, A.E.; Morsy, M.S.; Taha, S.; Shoukry, H. Physico-mechanical characteristics of blended white cement pastes containing thermally activated ultrafine nano clays. Constr. Build. Mater. 2013, 47, 138–145. [Google Scholar] [CrossRef]

- Winter, N.B. Understanding Cement: An Introduction to Cement Production, Cement Hydration and Deleterious Processes in Concrete; WHD Microanalysis Consultants Ltd.: Suffolk, UK, 2012. [Google Scholar]

- Khotbehsara, M.M.; Manalo, A.; Aravinthan, T.; Ferdous, W.; Nguyen, K.T.Q.; Hota, G. Ageing of particulate-filled epoxy resin under hygrothermal conditions. Constr. Build. Mater. 2020, 249, 118846. [Google Scholar] [CrossRef]

- Antonovič, V.; Baltrėnas, P.; Aleknevičius, M.; Pundienė, I.; Stonys, R. Modification of Petrochemical Fluid Catalytic Cracking Catalyst Waste Properties by Treatment in High Temperature. In Proceedings of the 10th International Conference Modern Building Materials, Structures and Techniques, Vilnius, Lithuania, 19–21 May 2010; Selected Papers. Available online: http://dspace.vgtu.lt/handle/1/537 (accessed on 15 January 2021).

- Velázquez, S.; Monzó, J.; Borrachero, M.V.; Soriano, L.; Payá, J. Evaluation of the pozzolanic activity of spent FCC catalyst/fly ash mixtures in Portland cement pastes. Therm. Acta 2016, 632, 29–36. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M.V.; Velázquez, S. Pozzolanic reaction rate of fluid catalytic cracking residue (FC3R) in cement pastes. Adv. Cem. Res. 2013, 25, 112–118. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M.V.; Velázquez, S. Cement equivalence factor evaluations for fluid catalytic cracking catalyst residue. Cem. Concr. Compos. 2013, 39, 12–17. [Google Scholar] [CrossRef]

- Vaiciene, M.; Malaiskiene, J.; Costa, C.; Letenko, D. The Impact of Catalyst Waste on Physical and Mechanical Properties of Cement Materials. In Proceedings of the International conference INEGI-FEUP, Lisbon, Portugal, 6–10 September 2020; pp. 571–582. Available online: https://paginas.fe.up.pt/~irf/Proceedings_IRF2020/ (accessed on 10 December 2020).

- Costa, C.; Ribeiro, M.S.; Brito, N. Effect of Waste Oil-Cracking Catalyst Incorporation on Durability of Mortars. Mater. Sci. Appl. 2014, 5, 905–914. [Google Scholar] [CrossRef]

- Zornoza, E.; Paya, J.; Monzo, J.; Borrachero, M.V.; Garces, P. The carbonation of OPC mortars partially substituted with spent fluid catalytic catalyst (FC3R) and its influence on their mechanical properties. Constr. Build. Mater. 2009, 23, 1323–1328. [Google Scholar] [CrossRef]

- Zornoza, E.; Garces, P.; Monzo, J.; Borrachero, M.V.; Paya, J. Accelerated carbonation of cement pastes partially substituted with fluid catalytic cracking catalyst residue (FC3R). Cem. Concr. Comp. 2009, 31, 134–138. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M.V.; Velázquez, S. Evaluation of the pozzolanic activity of fluid catalytic cracking catalyst residue (FC3R): Thermogravimetric analysis studies on FC3R-Portland cement pastes. Cem. Concr. Res. 2003, 33, 603–609. [Google Scholar] [CrossRef]

- Lin, K.L.; Lo, K.W.; Hung, M.J.; Cheng, T.W.; Chang, Y.M. Recycling of spent catalyst and waste sludge from industry to substitute raw materials in the preparation of Portland cement clinker. Sustain. Environ. Res. 2017, 27, 251–257. [Google Scholar] [CrossRef]

- De Lomas, M.G.; de Rojas, M.I.S.; Frías, M. Pozzolanic reaction of a spent fluid catalytic cracking catalyst in FCC-cement mortars. J. Therm. Anal. Cal. 2007, 90, 443–447. [Google Scholar] [CrossRef]

- Costa, C.; Marques, J.C. Feasibility of Eco-Friendly Binary and Ternary Blended Binders Made of Fly-Ash and Oil-Refinery Spent Catalyst in Ready-Mixed Concrete Production. Sustainability 2018, 10, 3136. [Google Scholar] [CrossRef]

- Allahverdi, A.; Shahrbabaki, M.N.; Ghezelasheghi, M.; Mahinroosta, M. Sulfate resistance of RFCC spent catalyst-blended Portland cement. Bol. Soc. Esp. Cer. Vyd. 2019, 58, 103–114. [Google Scholar] [CrossRef]

- Yongqi, D.; Tingshu, H.; Minhao, W.; Chen, S.; Rongsheng, X.; Renhe, Y. The effect of spent petroleum catalyst powders on the multiple properties in blended cement. Constr. Build. Mater. 2020, 231, 117203. [Google Scholar] [CrossRef]

- Chen, H.L.; Tseng, Y.S.; Hsu, K.C. Spent FCC catalyst as a pozzolanic material for high-performance mortars. Cem. Concr. Comp. 2004, 26, 657–664. [Google Scholar] [CrossRef]

- Monte, M.C.; Fuente, E.; Blanco, A.; Negro, C. Waste management from pulp and paper production in the European Union. Waste Manag. 2009, 29, 293–308. [Google Scholar] [CrossRef]

- Seok, J.H.; Lim, Y.T.; Kang, J.H.; Young, S.S.; Seok, S.H. Influence of calcination and cooling conditions on pozzolanic reactivity of paper mill sludge. Constr. Build. Mater. 2018, 166, 257–270. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Influence of industrial by-products and waste paper sludge ash on properties of recycled aggregate concrete. J. Clean. Prod. 2019, 214, 403–418. [Google Scholar] [CrossRef]

- Malaiskiene, J.; Baneviciene, V.; Boris, R.; Kizinievic, O. Impact of differently prepared paper production waste sludge (PSw) on cement hydration and physical-mechanical properties. In Proceedings of the International conference, Czech 2019 IOP Conference Series, Prague, Czech Republic, 11–13 October 2019. [Google Scholar] [CrossRef]

- De Azevedo, A.E.G.; Alexandre, J.; Pessanha, L.S.P.; Manhães, R.S.T.; Marvila, J.B.M.T. Characterizing the paper industry sludge for environmentally-safe disposal. Waste Manag. 2019, 95, 43–52. [Google Scholar] [CrossRef] [PubMed]

- De Azevedo, A.E.G.; Alexandre, J.; Xavier, G.C.; Pedroti, L.G. Recycling paper industry effluent sludge for use in mortars: A sustainability perspective. J. Clean. Prod. 2018, 192, 335–346. [Google Scholar] [CrossRef]

- Frías, M.; García, R.; Vigil, R.; Ferreiro, S. Calcination of art paper sludge waste for the use as a supplementary cementing material. Appl. Clay Sci. 2008, 42, 189–193. [Google Scholar] [CrossRef]

- Garcıa, R.; de la Villa, R.V.; Vegas, I.; Frıas, M.; de Rojas, M.I.S. The pozzolanic properties of paper sludge waste. Constr. Build. Mater. 2008, 22, 1484–1490. [Google Scholar] [CrossRef]

- Malaiskiene, J.; Kizinievic, O.; Kizinievic, V.; Boris, R. The impact of primary sludge from paper industry on the properties of hardened cement paste and mortar. Constr. Build. Mater. 2018, 172, 553–561. [Google Scholar] [CrossRef]

- Chen, M.; Zheng, Y.; Zhou, X.; Li, L.; Wang, S.; Zhao, P.; Lu, L.; Cheng, X. Recycling of paper sludge powder for achieving sustainable and energy-saving building materials. Constr. Build. Mater. 2019, 229, 116874. [Google Scholar] [CrossRef]

- Adesanya, E.; Ohenoja, K.; Luukkonen, T.; Kinnunen, P.; Illikainen, M. One-part geopolymer cement from slag and pretreated paper sludge. J. Clean. Prod. 2018, 185, 168–175. [Google Scholar] [CrossRef]

- De Azevedo, A.R.G.; Alexandre, J.; Marvila, M.T.; de Castro, G.X.; Monteiro, S.N.; Pedroti, L.G. Technological and environmental comparative of the processing of primary sludge waste from paper industry for mortar. J. Clean. Prod. 2020, 249, 119336. [Google Scholar] [CrossRef]

- Paul, S.C.; van Rooyen, A.S.; van Zijl, G.P.; Petrik, L.F. Properties of cement-based composites using nanoparticles: A comprehensive review. Constr. Build. Mater. 2018, 189, 1019–1034. [Google Scholar] [CrossRef]

- Rong, Z.; Sun, W.; Xiao, H.; Jiang, G. Effects of nano-SiO2 particles on the mechanical and microstructural properties of ultra-high performance cementitious composites. Cem. Concr. Compos. 2015, 56, 25–31. [Google Scholar] [CrossRef]

- Rupasinghe, M.; Nicolas, R.S.; Mendis, P.; Sofi, M.; Ngo, T. Investigation of strength and hydration characteristics in nano-silica incorporated cement paste. Cem. Concr. Compos. 2017, 80, 17–30. [Google Scholar] [CrossRef]

- Du, H.; Pang, S.D. High performance cement composites with colloidal nano-silica. Constr. Build. Mater. 2019, 224, 317–325. [Google Scholar] [CrossRef]

- Li, L.G.; Zheng, J.Y.; Zhu, J.; Kwan, A.K.H. Combined usage of micro-silica and nano-silica in concrete: SP demand, cementing efficiencies and synergistic effect. Constr. Build. Mater. 2018, 168, 622–632. [Google Scholar] [CrossRef]

- Sonebi, M.; Bassuoni, M.T.; Kwasny, J.; Amanuddin, A.K. Effect of nano silica on rheology, fresh properties, and strength of cement-based grouts. J. Mater. Civ. Eng. 2015, 27, 04014145. [Google Scholar] [CrossRef]

- Wang, J.; Cheng, Y.; Yuan, L.; Xu, D.; Du, P.; Hou, P.; Zhou, Z.; Cheng, X.; Liu, S.; Wang, Y. Effect of nano-silica on chemical and volume shrinkage of cement-based composites. Constr. Build. Mater. 2020, 247, 118529. [Google Scholar] [CrossRef]

- Hou, H.; Kawashima, S.; Kong, D.; Corr, D.J.; Qian, J.; Shah, S.P. Modification effects of colloidal nano-SiO2 on cement hydration and its gel property. Compos. B Eng. 2013, 45, 440–448. [Google Scholar] [CrossRef]

- Xu, Z.; Zhou, Z.; Du, P.; Cheng, X. Effects of nano-silica on hydration properties of tricalcium silicate. Constr. Build. Mater. 2016, 125, 1169–1177. [Google Scholar] [CrossRef]

- Singh, L.P.; Bhattacharyya, S.K.; Shah, S.P.; Mishra, G.; Ahalawat, S.; Sharma, U. Studies on early stage hydration of tricalcium silicate incorporating silica nanoparticles: Part I. Constr. Build. Mater. 2015, 74, 278–286. [Google Scholar] [CrossRef]

- Ma, C.; He, J.; Qin, T.; Long, G.; Du, Y.; Xie, Y. A comparison of the influence of micro- and nano-silica on hydration kinetics of Portland cement under different temperatures. Constr. Build. Mater. 2020, 248, 118670. [Google Scholar] [CrossRef]

- Julbe, A.; Drobek, M. Zeolite Y Type. In Encyclopedia of Membranes; Drioli, E., Giorno, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar] [CrossRef]

- Malaiškienė, J.; Banevičienė, V.; Vaičienė, M. The impact of nano SiO2 and superplasticizers on hydration and physical mechanical properties of cement. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 660, pp. 1–9. [Google Scholar]

- Banevičienė, V.; Malaiškienė, J. The Synergistic Effect of Secondary Raw Materials and Nano Additive on the Properties of Cement Matrix. IOP Conf. Ser. Mater. Sci. Eng. 2020, 960, 022038. [Google Scholar] [CrossRef]

- Jansen, D.; Stabler, C.; Goetz-Neunhoeffer, F.; Dittrich, S.; Neubauer, J. Does Ordinary Portland Cement contain amorphous phase? A quantitative study using an external standard method. Powder Diffr. 2011, 26, 31–38. [Google Scholar] [CrossRef]

- Mikhailenko, P.; Cassagnabere, F.; Emam, A.; Lachemi, M. Influence of physico-chemical characteristics on the carbonation of cement paste at high reploacement rates of metakaolin. Constr. Build. Mater. 2018, 158, 164–172. [Google Scholar] [CrossRef]

- Costa, C. Hydraulic binders. In Materials for Construction and Civil Engineering: Science, Processing, and Design; Springer International Publishing: Cham, Switzerland, 2015; pp. 1–52. [Google Scholar] [CrossRef]

| Composition | Cement, % | NS, % | PSw, % | FCCCw, % | Superplasticizer, % (up to 100%) | Water/Binder |

|---|---|---|---|---|---|---|

| Control (C) | 100 | – | – | – | 0.2 | 0.32 |

| nano SiO2 (NS) | 99.98 | 0.02 | – | – | 0.2 | 0.32 |

| paper sludge waste (PSw) | 97.5 | – | 2.5 | – | 0.2 | 0.32 |

| NS/PSw | 97.48 | 0.02 | 2.5 | – | 0.2 | 0.32 |

| NS/PSw/fluidized bed catalytic cracking catalyst waste (FCCCw) | 87.48 | 0.02 | 2.5 | 10.0 | 0.2 | 0.32 |

| Mark | 110 °C–170 °C | 180 °C–350 °C | 430 °C–560 °C | Amount of Dry Basis Portlandite, % | Amount of Cement Basis Portlandite, % | 690 °C–850 °C |

|---|---|---|---|---|---|---|

| C7 | 2.8 | 3.0 | 3.0 | 14.0 | 14.0 | 2.6 |

| NS7 | 3.2 | 3.0 | 2.4 | 11.5 | 11.5 | 4.6 |

| PSw7 | 3.2 | 3.2 | 2.7 | 12.6 | 12.9 | 5.8 |

| NS/PSw7 | 2.8 | 2.7 | 2.3 | 10.9 | 11.2 | 6.7 |

| NS/PSw/FCCCw7 | 3.4 | 3.2 | 2.2 | 10.5 | 11.9 | 4.7 |

| C28 | 3.2 | 3.4 | 2.9 | 14.0 | 14.0 | 4.4 |

| NS28 | 3.2 | 3.4 | 2.9 | 13.8 | 13.8 | 4.2 |

| PSw28 | 3.2 | 3.3 | 2.9 | 13.6 | 13.9 | 5.2 |

| NS/PSw28 | 3.1 | 3.2 | 2.8 | 13.2 | 13.5 | 5.1 |

| NS/PSw/FCCCw28 | 3.6 | 3.7 | 2.0 | 9.7 | 11.0 | 4.4 |

| Characteristic | C | NS | PSw | NS/PSw | NS/PSw/FCCCw |

|---|---|---|---|---|---|

| Average pore diameter, µm | 0.032 | 0.027 | 0.031 | 0.029 | 0.025 |

| Median pore diameter, µm | 0.050 | 0.039 | 0.050 | 0.044 | 0.033 |

| Total pore surface area, m2/g | 15.01 | 17.65 | 15.13 | 16.61 | 18.35 |

| Accessible porosity, % | 19.92 | 19.79 | 18.60 | 19.36 | 18.98 |

| Total porosity, % | 23.02 | 23.73 | 22.47 | 22.70 | 22.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banevičienė, V.; Malaiškienė, J.; Zach, J.; Dvorak, K. Composite Binder Containing Industrial By-Products (FCCCw and PSw) and Nano SiO2. Materials 2021, 14, 1604. https://doi.org/10.3390/ma14071604

Banevičienė V, Malaiškienė J, Zach J, Dvorak K. Composite Binder Containing Industrial By-Products (FCCCw and PSw) and Nano SiO2. Materials. 2021; 14(7):1604. https://doi.org/10.3390/ma14071604

Chicago/Turabian StyleBanevičienė, Vilma, Jurgita Malaiškienė, Jiri Zach, and Karel Dvorak. 2021. "Composite Binder Containing Industrial By-Products (FCCCw and PSw) and Nano SiO2" Materials 14, no. 7: 1604. https://doi.org/10.3390/ma14071604

APA StyleBanevičienė, V., Malaiškienė, J., Zach, J., & Dvorak, K. (2021). Composite Binder Containing Industrial By-Products (FCCCw and PSw) and Nano SiO2. Materials, 14(7), 1604. https://doi.org/10.3390/ma14071604