Abstract

The present study offers a systematic review of the current state of research on lattice structures manufactured by additive technologies for biomedical applications, with the aim of identifying common patterns, such as the use of triply periodic minimal surfaces (TPMS) for bone scaffolds, as well as technological gaps and future research opportunities. Employing the PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) methodology, the review process ensures methodological rigor and replicability across the identification, screening, eligibility, and inclusion phases. Additionally, PRISMA was tailored by prioritizing technical databases and engineering-specific inclusion criteria, thereby aligning the methodology with the scope of this field. In recent years, a substantial surge in interdisciplinary research has underscored the promise of architected porous structures in enhancing mechanical compatibility, fostering osseointegration, and facilitating personalized medicine. A growing body of literature has emerged that explores the optimization of geometric features to replicate the behavior of biological tissues, particularly bone. Additive manufacturing (AM) has played a pivotal role in enabling the fabrication of complex geometries that are otherwise unachievable by conventional methods. The applications of lattice structures range from permanent load-bearing implants, commonly manufactured through selective laser melting (SLM), to temporary scaffolds for tissue regeneration, often produced with extrusion-based processes such as fused filament fabrication (FFF) or direct ink writing (DIW). Notwithstanding these advances, challenges persist in areas such as long-term in vivo validation, standardization of mechanical and biological testing, such as ISO standards for fatigue testing, and integration into clinical workflows.

1. Introduction

In the current context of Industry 4.0, engineering and industrial applications are undergoing a transition towards greater sustainability. This transition involves the design and manufacture of products that require less material, simpler manufacturing processes, and lower energy consumption, without compromising product functionality. Throughout history, humans have consistently turned to nature as a source of inspiration to solve complex design and functionality problems, enabling evolutionarily optimized solutions to be transferred to the field of engineering. In this context, cellular structures—found in bones, corals, and plant tissues—are establishing themselves as a benchmark model by offering an exceptional combination of lightness, mechanical strength, and geometric customization [1,2].

These structures are of particular importance because they represent one of the most effective methodologies for applying topological optimization, which is a design technique that allows material to be redistributed intelligently within certain boundary conditions. The primary objective of this method is to minimize the mass or volume of a component without compromising its functional performance in aspects such as rigidity, strength, or energy absorption capacity. Two primary methodologies can be employed for the removal or distribution of material through topological optimization: generative design and cellular structures. Generative design is a critical component of this process, leveraging advanced computational algorithms to explore a multitude of structural configurations. These algorithms are employed to identify regions of low mechanical demand, thereby enabling the removal of material. Cellular structures contribute to this optimization by redistributing material internally in the form of periodic, gradual, or hierarchical patterns that reproduce highly efficient geometric configurations from a structural point of view [3].

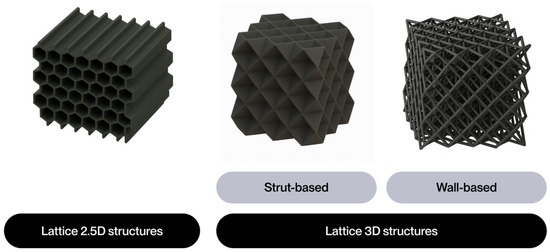

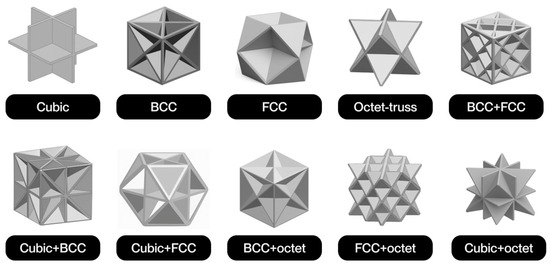

The notion of cellular structure was initially put forward by Gibson and Ashby in the 1980s, drawing upon the analysis of materials exhibiting a porous internal morphology, characterized by a network of cells dispersed throughout the material’s volume [4]. These structures can be categorized into two broad classifications: foams and lattices. Foams are distinguished by a stochastic distribution of cells, which can be either open or closed. These cells are characterized by their high porosity and mechanical behavior, which is dependent on the density and random connectivity of their walls. Conversely, lattice structures are a three-dimensional typology predicated on the periodic repetition of geometrically defined unit cells [5].

Lattice structures are therefore a particularly promising solution due to their controlled and repetitive architecture. A salient feature of these models is their capacity for customization through the utilization of computational modeling tools. This capability enables the manipulation of parameters such as relative density, stress direction, and mass distribution. This enables them to meet the demanding mechanical and functional properties required in today’s most competitive sectors [4]. Furthermore, their architectural design enables the optimization of the strength-to-weight ratio, as well as the incorporation of additional functionalities, such as thermal dissipation, impact absorption, and controlled permeability [6].

For years, the fabrication of cellular structures has been carried out through conventional methodologies, encompassing techniques such as molding, casting, laser cutting of overlapping sheets, profile assembly, and subtractive machining [7]. In essence, these methodologies provided functional solutions; however, they necessitated the compromise of design for technical feasibility. The resulting geometries were, in many cases, repetitive, orthogonal, and topologically simple. Moreover, any effort to modify critical properties such as porosity, element thickness, or internal connectivity resulted in an exponential escalation in process complexity or rendered it directly unfeasible. The result was a discrepancy between the theoretical potential of cellular structures and the actual products that could be produced. Nevertheless, this discrepancy did not impede the progression of scientific research. Throughout the 20th century, particularly in its final decades, there were concerted efforts to enhance the structural and functional performance of these materials. These efforts resulted in the development of optimized solutions, including sintered metal foams, aluminum honeycomb structures, and hybrid combinations of materials with specific functions, such as impact absorption, thermal insulation, or weight reduction. However, these advancements shared a common limitation: they were subject to processes with minimal control over the internal architecture. The advent of additive manufacturing (AM) technologies has profoundly transformed this paradigm [1,7].

AM technologies have effectively eliminated numerous restrictions imposed by conventional manufacturing methods. In contrast to the latter, where geometry was constrained by the capabilities of the available tools, AM inverts the logic, whereby the process adapts to the design. AM, also referred to as “3D printing,” is a term used to describe a set of technologies that construct three-dimensional objects by successively adding layers of material, beginning directly from a digital model. This method, which involves a layering process, eliminates the necessity for conventional tooling, molds, or intricate machining processes. Consequently, it enables the fabrication of components with highly intricate internal geometries, concealed channels, or meticulously detailed cellular structures [4].

Consequently, AM has emerged as the prevailing method for the fabrication of geometrically intricate materials, enabling the integration of internal topological variations without incurring additional costs or complexity. This facilitates the production of components with mechanically adapted properties tailored to their spatial environment. This level of control is particularly relevant for lattice structures, as key parameters such as elastic modulus, compressive strength, energy absorption, and permeability can be controlled by adjusting the geometry of the unit cell and its distribution in the overall volume [8,9]. The integration of lattice structures and AM technologies has exhibited considerable promise across a diverse array of industrial sectors. Within this extensive range of applications, the biomedical sector is particularly noteworthy for its significant advancements in this field, as it is an environment that demands highly specialized structural solutions to meet the intricate demands of functionality, anatomy, and biology [10].

Despite the recent surge in publications concerning the use of additive technologies for manufacturing lattice structures in the biomedical sector, several recent studies concur that there is a paucity of systematic, contemporary compilations that consolidate existing knowledge in this field. Moreover, a significant proportion of extant literature addresses particular case studies or emphasizes specific applications, omitting an overview of the structural types utilized, the manufacturing processes employed, or the design criteria adopted. The absence of a cohesive and interdisciplinary viewpoint on the extant knowledge severely restricts the capacity to delineate unambiguous progress, identify synergies across disciplines, or establish shared design and validation criteria. This predicament is particularly pronounced in a domain where interdisciplinarity is paramount and collaboration between engineering, medicine, and materials science is indispensable.

Research Objective and Contribution

The objective of this review is to address the gap identified in the scientific literature on lattice structures manufactured using additive technologies applied to the biomedical sector, in a critical and systematic manner. In this manner, the AM and lattice structures most widely used or with the greatest potential in the biomedical sector will be explored. The most relevant information to date will be organized and analyzed, allowing not only to clarify the current state of knowledge, but also to detect common patterns and scientific gaps and propose new lines of research. This document is also intended to serve as a useful reference guide for researchers, engineers, and professionals in the biomedical field, providing a structured basis to facilitate the practical application of these technologies and their progressive integration into the design and manufacture of advanced biomedical solutions.

From this initial basis, the procedure for conducting the literature search was defined. The researchers elected to utilize a systematic review methodology based on the PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) guidelines, adapted to the engineering context. This choice enables the process of selecting, analyzing, and classifying information to be structured in a transparent and replicable manner. Finally, once the relevant information has been extracted, the results are presented in a summarized and organized manner, facilitating consultation of key contributions for researchers, professionals, and engineers interested in the design and application of lattice structures in the biomedical field. This facilitates the establishment of possible future lines of research and final conclusions on the state of the art.

2. Materials and Methods

As previously delineated, the PRISMA methodology, adapted to the domain of engineering by prioritizing technical databases and engineering-specific inclusion criteria, will be employed in this state-of-the-art study. This choice is justified by PRISMA’s ability to bring transparency, comprehensiveness, and traceability to the review process. This allows for the systematic identification, selection, and evaluation of the most important literature in the fields searched. Furthermore, PRISMA was initially developed within the domain of health sciences, and its application in engineering studies is becoming increasingly prevalent. This development offers a clear and replicable methodological structure suitable for the critical integration of results in interdisciplinary fields, such as the one addressed in this work. However, it is imperative to acknowledge the inherent limitations of PRISMA. One such limitation pertains to the dependence on the availability and quality of the studies included, which may be contingent upon the scope of the databases consulted or the precision of the terms employed in the search strategy. Furthermore, PRISMA does not provide specific criteria for assessing the methodological validity or relevance of the selected studies, delegating this responsibility to the researcher’s judgment. This may introduce bias if not managed rigorously.

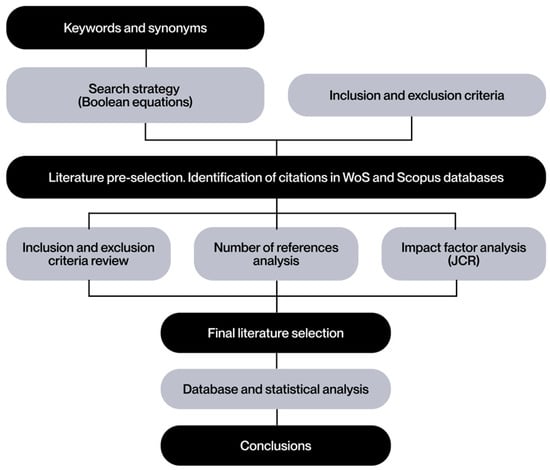

To orient the PRISMA methodology toward the field of engineering, the document published by Blanco et al., 2021 [11] is taken as a reference. This strategy is shown in Figure 1 as a guide for searching and selecting the literature on which the review will be based.

Figure 1.

Literature search strategy based on Blanco et al. [11].

2.1. Inclusion and Exclusion Criteria Used in the Search

The preliminary definition of inclusion and exclusion criteria provides a solid foundation for research and ensures that results align with the stated objectives. These criteria not only delineate the scope of the study but also serve to minimize potential biases and ensure that the selected literature is relevant and representative for further analysis.

As previously indicated, the present analysis focuses on recently published studies. Consequently, the publication period under consideration is limited to the last five years, thereby excluding recent trends in the utilization of additively manufactured lattice structures within the biomedical sector. The selection of studies has been primarily oriented towards journal articles, given their recognition for using rigorous methodologies and presenting reliable results. In addition, the review articles provide a comprehensive overview of the current state of the field, emphasizing the major advancements. The relevance of conference proceedings for presenting the latest progress, innovations, and emerging trends has also been considered. These sources are of particular importance in identifying new approaches in the areas under investigation.

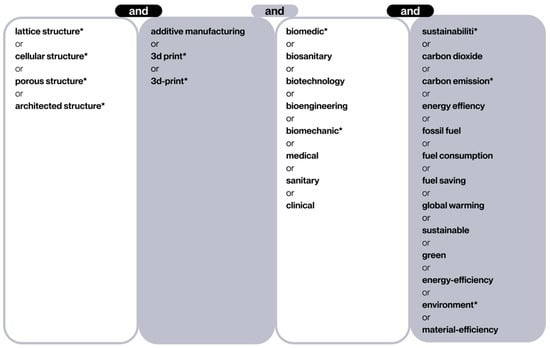

To refine the accuracy of the search within the defined topic, a set of keywords and synonyms has been defined in the form of Boolean equations (see Figure 2). This methodological approach ensures a high level of coverage and accuracy, thereby minimizing the likelihood of omitting relevant studies.

Figure 2.

Terms and synonyms entered in this search. The asterisk (*) serves as an operator that captures any letters that follow it.

The databases selected for this review were Web of Science (WoS) and Scopus. This is attributable to their extensive collection of high-quality, peer-reviewed publications and their advanced search and analysis tools. The WoS database offers access to studies published in leading journals, thereby enhancing the credibility of the review. Scopus is another valuable source due to its multidisciplinary coverage, including a vast number of scientific articles, conference proceedings, and book chapters. The advanced filtering and Boolean search capabilities of both databases facilitate comprehensive and precise bibliographic searches, while their bibliometric tools enable trend analysis and citation tracking. The selection of WoS and Scopus is consistent with PRISMA’s fundamental principles of rigor, transparency, and methodological traceability, thereby ensuring the validity of the review and the inclusion of related studies.

The selection of publications has been limited to those that are open access, with the aim of ensuring their global accessibility and thus promoting collaboration in research. The application of strict quality criteria has been another essential element of the review process. The inclusion of articles has been limited to those peer-reviewed and published in journals classified in the first quartiles (Q1 and Q2), according to the Journal Impact Factor and the Journal Citation Reports. This guarantees a high level of reliability and rigor in the texts analyzed. These criteria are summarized in Table 1.

Table 1.

Inclusion and exclusion criteria used in the search.

2.2. Definition of Search Criteria

The objective of this literature review is to address the main problem previously identified regarding the current situation of additively manufactured lattice structures in the biomedical sector. In accordance with the aforementioned search methodology, a Boolean search strategy was employed, utilizing keywords and their synonyms in structured equations.

The terminology employed during the search process is delineated in Figure 2. The initial column delineates lattice structures, which are a component of cellular structures. The second column restricts the search to the domain of AM technologies, colloquially referred to as “3D printing”. The third column filters the biomedical sector, including different terms in order to cover a broad spectrum of sub-areas in this field, from biomedical engineering to direct clinical applications. Finally, the final column incorporates terms related to sustainability and energy efficiency, with the objective of maintaining a focus on minimizing environmental impact. Given the broad scope of the topic and the anticipated abundance of irrelevant articles, the advanced “exact search” function of WoS was employed to guarantee that each selected document contained at least one term from each column. This function is performed automatically in Scopus searches.

The Boolean equations employed in the search are as follows:

WoS: TS = (lattice structure* OR cellular structure* OR porous structure* OR architected structure*) AND TS = (additive manufacturing OR 3d-print* OR 3D print*) AND TS = (biomedic* OR biosanitary OR biotechnology OR bioengineering OR biomechanic* OR medical OR sanitary OR clinical) AND TS = (sustainabili* OR carbon dioxide OR carbon emission* OR energy efficiency OR fossil fuel OR fuel consumption OR fuel saving OR global warming OR sustainable OR green OR energy-efficiency OR environment* OR material-efficiency)

Scopus: TITLE-ABS-KEY (“lattice structure*” OR “cellular structure*” OR “porous structure*” OR “architected structure*”) AND TITLE-ABS-KEY (“additive manufacturing” OR “3d-print*” OR “3D print*”) AND TITLE-ABS-KEY (“biomedic*” OR “biosanitary” OR “biotechnology” OR “bioengineering” OR “biomechanic*” OR “medical” OR “sanitary” OR “clinical”) AND ALL (“sustainabili*” OR “carbon dioxide” OR “carbon emission*” OR “energy efficiency” OR “fossil fuel” OR “fuel consumption” OR “fuel saving” OR “global warming” OR “sustainable” OR “green” OR “energy-efficiency” OR “environment*” OR “material-efficiency”)

Subsequent to the entry of these Boolean equations into the respective databases, a preliminary selection of 1369 articles was obtained in WoS and 486 in Scopus.

2.3. Literature Selection

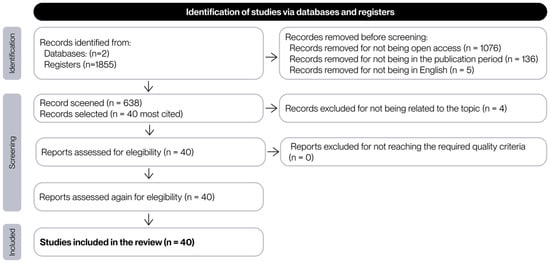

This section delineates the final selection process for the documents obtained in the preceding search. Initially, the inclusion and exclusion criteria enumerated in Table 1 were implemented. The implementation of the filter was executed through the utilization of database search tools, with the selection criteria including exclusively open access documents. This approach led to the exclusion of 809 documents from the WoS database and 267 documents from the Scopus database. Subsequently, the publication date filter was applied, resulting in the exclusion of an additional 108 documents in WoS and 28 in Scopus. Finally, one additional document was excluded from WoS, and four were excluded from Scopus because they were not written in English. This resulted in a final list of 451 documents in WoS and 187 in Scopus for reading.

For the purposes of this project, the reading of 40 documents is considered sufficient. Consequently, the 40 most frequently cited articles were subjected to an initial review to apply the remaining inclusion and exclusion criteria. During this review, documents that did not meet these criteria were discarded, and the next most cited document was selected in its place. The flowchart that summarizes the selection process of the literature found is presented in Figure 3.

Figure 3.

Flow chart of the process of selection of the documents found in the search.

2.4. Synthesis and Analysis of the Documents Included in the Literature Review

The 40 documents selected for review were subjected to an in-depth analysis, encompassing a content analysis with the objective of identifying methodologies, approaches, and findings. This process enabled the detection of recurring patterns, key contributions to the field, and potential gaps in existing research. To ensure proper understanding, the texts were reviewed to extract the data in Table 2.

Table 2.

Main analysis of data from chosen search documents. The symbol ‘X’ indicates that the documents considered refer to or contain content relevant to the specified category.

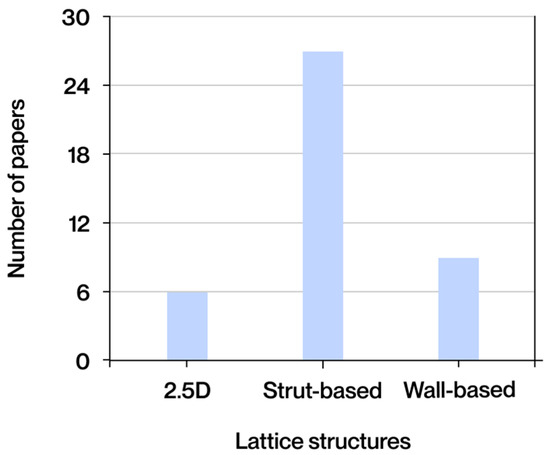

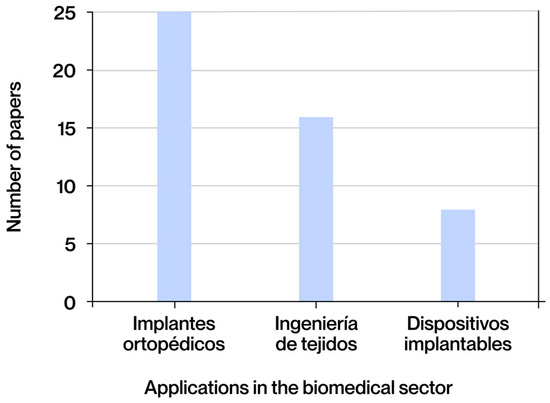

The documents selected for this study were classified according to the type of contribution made, dividing them into three broad categories: state-of-the-art studies, process optimization work, and experimental research. The category with the highest representation is that of state-of-the-art studies, comprising 25 documents (62%), reflecting the community’s interest in consolidating and analyzing recent advances. This is notable despite the consensus among other works on the dearth of updated systematic compilations in this field. Secondly, 14 (35%) of the documents correspond to experimental research, in which biomedical applications have been manufactured and tested to evaluate their most important aspects, allowing the theoretical models or proposed designs to be validated in practice. A total of 10 documents (25%) were classified as process optimization studies, with a focus on the adjustment of design, simulation, or manufacturing parameters to improve the properties or performance of the applications.

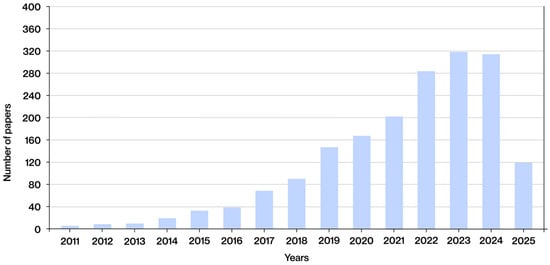

To accurately ascertain the publication date of the articles identified, it is imperative to revert to the literature search in which the inclusion and exclusion criteria were not implemented, resulting in the identification of 1855 documents. The publication date of these documents is displayed in Figure 4, which demonstrates a discernible upward trend in interest in lattice structures manufactured using additive technologies in the biomedical sector in recent years. From 2011 to 2016, the number of publications remained low, exhibiting a gradual upward trend. A more pronounced increase has been observed since 2017, reaching a substantial growth phase since 2019. This increase is particularly pronounced between 2021 and 2023, reaching a peak in 2023, when nearly 320 publications were documented. In 2024, the number remained high, with a slight decrease compared to the previous year, standing at 313 documents. At the time of the search, on 1 June 2025, 120 publications had been identified for that year. While this figure has yet to reach the peak values observed in previous years, it is anticipated that the total number of documents published in 2025 will continue to increase as the year progresses. These data confirm that the topic under investigation is an emerging focus of innovation and application in current manufacturing.

Figure 4.

Date of publication of the documents selected from the search results, without applying the inclusion and exclusion criteria.

With respect to the geographical distribution of the studies, China is the nation with the highest number of publications, with a total of 16 documents (40%), followed by the United States, with 4 (10%). This underscores the profound commitment to development and innovation in this domain, aligning with the historical role of these two nations as leaders in global technological research. Europe has demonstrated a notable level of engagement, with nations such as the Netherlands and England particularly noteworthy, each contributing three publications (8%). Additional contributions have been made by Germany, Switzerland, Italy, Spain, Poland, Ireland, Belgium, and Finland. This commitment is further evidenced by the adoption of initiatives such as the Horizon Europe program, which underscores the region’s dedication to scientific advancement. In addition to China’s leadership, the United Arab Emirates, Pakistan, and Qatar have made significant contributions, highlighting the growing technological advancement of Asian countries. A subsequent investigation yielded a single publication from Australia, a nation with a distinguished technological legacy, notable institutions of higher education, and vibrant innovation hubs.

It is imperative to acknowledge that the identification of knowledge gaps presented in this review is not based on subjective assessments or arbitrary judgments. Rather, it is the result of a systematic procedure applied to the selected studies. In each study, the sections in which the authors themselves outlined the limitations of their work, made recommendations, or proposed future lines of research were analyzed. This analysis demonstrates that, despite the progress achieved, substantial deficiencies persist in the extant literature. These deficiencies include the absence of standardization in mechanical and biological tests, the dearth of long-term in vivo validations, the paucity of consideration for clinical factors in the design of structures, the lack of comparative methodologies that integrate materials, topologies, and manufacturing processes, and the inadequate coverage of certain types of geometries and applications. The aforementioned gaps, which have been repeatedly highlighted by the authors reviewed, underscore the necessity to establish common reference frameworks and to expand research into scenarios and parameters that have remained largely unexplored in the field of lattice structures for biomedical applications.

3. Results

3.1. AM Technologies

As previously stated in the introduction, the field of advanced manufacturing engineering has recently identified the fabrication of complex geometries with high precision and flexibility as a primary focus of research. In contradistinction to conventional subtractive processes, AM enables the fabrication of components through the methodical deposition of material layers, one on top of another, directly from a digital model. This technological advancement has led to the emergence of novel possibilities in the domains of component design and development, particularly for those components characterized by intricate internal structures. These characteristics render it a particularly suitable tool for the fabrication of lattice structures, whose morphology necessitates a high degree of design freedom and the capacity to produce geometries that are challenging to obtain by alternative means [6,12].

The standardization and classification of different AM technologies has been established by the international standard ISO/ASTM 52900:2021, which defines AM as “the process of joining materials to manufacture objects from 3D model data, typically layer by layer, as opposed to traditional subtractive or forming methods.” Consequently, this document serves as the international reference framework for the terminology, general principles, and classification of AM technologies. This classification does not rely on commercial criteria or specific manufacturer designations. Rather, it establishes seven main categories based on physical and operating principles, allowing for clear and standardized identification in any technical or scientific context [1].

The following Table 3 offers a concise overview of the seven categories identified by the standard. Tank photopolymerization, which is further subdivided into the categories of stereolithography (SLA), digital light processing (DLP), and continuous liquid interface production (CLIP), utilizes a liquid photopolymer that is solidified by a controlled light source. In the domain of material jetting, the subcategory of Polyjet and material jet modeling (MJP) involves the precise deposition of microdroplets of photopolymer, which are subsequently cured using UV light. Material extrusion, classified into fused filament fabrication (FFF), and atomic deposition manufacturing (ADAM), involves the melting and deposition of thermoplastic filaments through a nozzle, offering an economical and versatile alternative. Bonding agent jet, comprising binder jetting (BJ), multi-jet fusion (MJF), and selective powder jetting (SPJ), utilizes a liquid that binds the particles of a powder bed. Selective laser sintering (SLS), selective laser melting (SLM), direct metal laser sintering (DMLS), and electron beam melting (EBM) are collectively referred to as powder bed fusion (PBF). Direct energy deposition, comprising laser forming and powder deposition (LENS), electron beam melting with powder or wire feed (EBAM), laser material deposition (LMD), and arc and wire AM (WAAM), facilitates the addition of material in powder or wire form, which is melted by an energy source. Finally, sheet lamination, which is further subdivided into laminated object modeling (LOM) and ultrasonic AM (UAM), involves the superimposition and cutting of adhered or welded sheets [1,7,51].

Table 3.

AM categories according to international standard ISO/ASTM 52900:2021.

In addition to the seven primary categories delineated in the standard, the extant literature has identified manufacturing methodologies that, while not explicitly included in this classification, adhere to the fundamental principle of AM: the generation of geometries through the controlled addition of material layer by layer. These methodologies include techniques such as direct ink writing (DIW), which is based on the direct extrusion of inks with specific rheological properties [13]; biological 3D printing (3DBP), which aims to deposit living cells and biomaterials [14]; and 4D printing (4DP), which incorporates smart materials capable of modifying their shape or properties after manufacture when exposed to external stimuli [15].

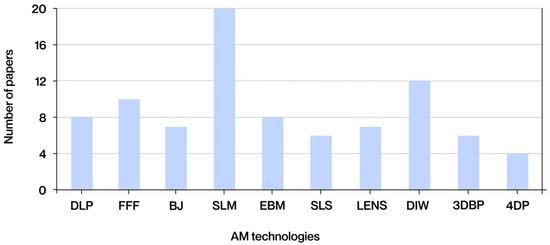

The graph in Figure 5 below illustrates the frequency with which the various AM technologies are mentioned in the analyzed documents.

Figure 5.

Technologies most frequently found in the literature obtained.

In addition to the technologies illustrated in the graph, other manufacturing methodologies have been identified in the extant literature. Despite being mentioned in fewer documents, these methodologies are nevertheless relevant due to their applications in the biomedical sector. These include melt electrowriting (MEW), a hybrid technique combining the principles of 3D printing and electrospinning. MEW enables the precise deposition of molten microfibers, facilitating the fabrication of structured scaffolds for biomedical applications [15]. Another relevant manufacturing technique is layer-by-layer coating, a sequential method that allows the functionalization of surfaces through the alternate deposition of polymeric or bioactive layers. This technique is commonly used to give implants antibacterial properties or to release drugs [16]. In essence, 3D fiber deposition involves the extrusion of fibers to generate three-dimensional structures. A distinguishing feature of this process is its capacity to produce continuous, reinforced fiber networks, which find application in tissue engineering [17]. Despite their exclusion from the ISO/ASTM 52900:2021 standard and their present lack of ubiquity in comparison to other manufacturing processes, these technologies signify research domains with considerable potential for innovative biomedical applications.

3.1.1. DLP

DLP is an AM technology based on the photopolymerization of liquid resins through the controlled projection of structured light. The use of a digital projector enables the emission of ultraviolet or visible light patterns, which solidify entire layers of the photopolymer in a simultaneous manner [18]. This process allows for a substantially higher manufacturing speed in comparison to methods such as SLA, wherein the curing process occurs point-by-point. The utilization of complete two-dimensional images in this manner has been demonstrated to enhance efficiency and ensure high geometric accuracy, particularly in the XY plane resolution [19]. The resins utilized in these processes are typically formulated from acrylate, methacrylate, or epoxy monomers, which are selected based on the desired final properties of the cured polymer [8,18,20].

The primary benefits of DLP include its high resolution, precision in reproducing contours, and capacity to generate complex microstructures with intricate geometries. These characteristics render DLP an ideal technique for obtaining customized architectures with controlled porosity and properties tailored to the needs of tissue engineering applications [21,22]. Furthermore, the simultaneous curing of entire layers results in a substantial reduction in manufacturing times when compared to other point-beam-based technologies, such as SLA or SLS [19]. However, the expenses related to equipment and specialized resins, as well as the necessity for additional post-processing, position this technology within the medium-to-high investment range, particularly in applications necessitating high resolution or complex geometries [20].

Regarding sustainability, the DLP process possesses distinctive characteristics that merit consideration. Its high resolution and curing precision have been demonstrated to minimize the need for rework and reduce the number of rejected parts, resulting in direct savings in resources and energy during production [21]. Furthermore, the utilization of resin deposited in each layer enables low-waste manufacturing, a notable distinction from alternative methods that necessitate the recovery or disposal of excess materials. Additionally, the inherent polymerization speed of DLP technology has been shown to reduce manufacturing times, leading to a comparatively reduced energy consumption per unit of output [18]. However, the sustainability of the process is contingent upon factors such as the management of unpolymerized resins, which necessitate specific treatments to circumvent environmental impacts [18,20].

3.1.2. FFF

FFF is based on the controlled extrusion of a molten thermoplastic filament, which is deposited layer by layer on a build platform following digitally defined trajectories. This process, carried out at carefully controlled temperatures, allows three-dimensional parts to be built directly from computer-aided design (CAD) models, and its simplicity has established it as one of the most widely used technologies in both industry and prototype development [1,23]. FFF supports a wide range of materials, primarily thermoplastic polymers, though composite formulations with short fibers, nanoparticles, or metallic and ceramic fillers that necessitate subsequent sintering are also employed, enabling the adjustment of mechanical, thermal, or electrical properties in accordance with design requirements [6,8].

The primary benefits of this approach include minimal operational expenses, ease of access to equipment and materials, and the capacity to produce functional components with customized geometries without the necessity for specialized tooling. This has led to its extensive utilization in research, development, and short-term production. Despite its comparatively lower resolution, ranging from 100 to 300 µm, as compared to other technologies such as photopolymerization or selective powder melting, it finds application in a wide range of structural projects. In most cases, parts manufactured by FFF can be used without post-processing, except for surface or dimensional adjustments when stricter tolerances are required [1,6,51].

With regard to process sustainability, FFF is distinguished by a straightforward, low-maintenance technical infrastructure, which curtails the consumption of resources linked with equipment preparation and operation. The thermo-mechanical nature of the process, predicated on localized heating of the filament and its layer-by-layer deposition, implies a reduced energy demand in comparison with techniques that necessitate high-power sources, such as lasers [18]. However, the sustainability of FFF may be constrained by the necessity for support structures in complex geometries, which increase the volume of material utilized and the duration of printing processes. Proper process planning, incorporating aspects such as part orientation and the optimization of parameters like layer height and extrusion speed, is imperative to mitigate these effects and curtail both waste and reprints [20].

3.1.3. BJ

BJ is an AM technique that involves the selective deposition of a liquid binder onto a bed of powder, forming successive layers that reproduce the three-dimensional geometry defined by a digital model. A print head, analogous to that of an inkjet printer, deposits the binder in specific areas, causing the particles to adhere locally, while a new layer of powder is spread after each cycle. This technology demonstrates compatibility with a wide variety of powder materials, including metals, ceramics, polymers, and composites, provided these materials exhibit suitable flow and packing density properties. Depending on the type of material and application, the manufactured parts often require heat or infiltration treatments for consolidation [12,24].

The primary benefits of this technology include the capacity to manufacture large-volume components without the need for support structures, due to the inherent properties of the powder, its high manufacturing velocity, and its capability to print multiple components in a simultaneous manner. This technique is particularly well-suited for short production runs and functional prototypes, especially in cases where the materials are challenging to process using alternative additive technologies. The typical resolution of the process is between 50 and 100 µm, allowing for the capture of fine details. However, it does not achieve the precision of methods such as SLM or SLA. The cost of the process is relatively moderate, primarily due to the reuse of unbound powder and the simplicity of the equipment. However, additional costs arising from the post-processing required to achieve the final properties must be taken into account [12,51].

In the context of the BJ process, sustainability is predominantly associated with its capacity to efficaciously employ unconsolidated powder, which can be recovered and reused in subsequent manufacturing cycles, thereby diminishing material waste [22]. Moreover, as it does not necessitate high-intensity energy sources for melting the material, energy consumption per piece is relatively low, placing BJ in an advantageous position from an environmental perspective [23]. However, it is imperative to consider the environmental implications of the use of binding agents, as their handling and disposal can generate chemical waste that necessitates specialized treatment. Moreover, post-processing steps have been shown to increase energy and resource consumption, thereby mitigating some of the initial sustainability benefits [24].

3.1.4. SLM

SLM utilizes a high-energy laser to consolidate metal powders in a localized manner. The process is meticulously executed in a controlled environment, where a roller or scraper distributes fine layers of powder onto the platform. A laser scans and selectively melts the areas defined by the digital model, solidifying the material immediately. Subsequent layers of powder are applied in a descending order, with the platform repeatedly descending to allow for the application of each new layer. This process is repeated until the part is fully completed. This procedure enables the fabrication of components with high density and mechanical properties analogous to those of conventional materials [12,25].

SLM primarily utilizes metal powders, including stainless steels, titanium, and aluminum alloys. These powders must meet stringent criteria concerning fluidity, morphology, and particle size to ensure uniform melting. The primary benefit of this method is its capacity to manufacture components with intricate geometries, exhibiting resolutions ranging from 80 to 250 µm. This renders it well-suited for the fabrication of customized or high-performance functional components. Despite the substantial expense associated with equipment and operational costs, this is counterbalanced by the production of densified metal components that do not necessitate the use of tools or molds. This process reduces development times and facilitates the reuse of unsmelted powder [6,26].

In the SLM process, sustainability is contingent upon the high energy consumption resulting from the utilization of high-power laser sources and the necessity to maintain controlled inert gas atmospheres, which amplifies the environmental impact of the manufacturing cycle [6]. However, a significant advantage from a material point of view is the possibility of reusing a large proportion of the unmelted metal powder in successive cycles, provided that quality controls are applied to ensure the stability of its physical and chemical properties [12]. This enhanced recyclability has been demonstrated to lead to a substantial reduction in material waste. However, it is important to note that this process necessitates the implementation of additional screening and monitoring procedures, which also incur resource consumption [29].

3.1.5. EBM

EBM is a technology in which a concentrated beam of electrons serves as the energy source, enabling the selective melting of layers of metal powder. The process is conducted within a vacuum chamber, a critical component for generating and manipulating the electron beam, and follows a layer-by-layer approach analogous to other powder bed-based methods. A distinguishing feature of EBM is the preheating of the powder bed prior to melting, which reduces thermal gradients and helps minimize residual stresses. This technique is particularly well-suited for the manufacturing of components made of titanium alloys, cobalt-chromium, and nickel superalloys. In this process, powders with spherical morphology, controlled particle size, and high purity are utilized [6,7,12].

The primary benefits of this process include the ability to produce dense and homogeneous metal parts with high mechanical strength and low internal stresses through the use of preheating. Its resolution, ranging from 50 to 100 µm, facilitates the fabrication of functional elements with intricate geometries and regulated metallurgical properties. Furthermore, the utilization of a vacuum environment during the process serves to impede the oxidation of the material. Notwithstanding the exorbitant expenses associated with equipment and operational expenditures, EBM facilitates expeditious manufacturing of medium-sized components and enables concurrent production of multiple parts, rendering it a viable option for applications that prioritize structural integrity and material quality [6,26].

In the context of EBM, the sustainability of the process exhibits distinct characteristics in comparison to other PBF techniques. The utilization of an electron beam as an energy source, under vacuum conditions, facilitates efficient fusion with reduced residual stresses in the component, thereby diminishing the necessity for subsequent heat treatments and, consequently, the energy consumption associated with post-processing [6,12]. Moreover, as in SLM, unconsolidated powder can be recovered and reused to a significant extent, thereby reducing material waste and optimizing resource utilization. However, the process of maintaining a vacuum environment throughout the manufacturing cycle necessitates significant energy consumption. Moreover, the stringent control of process parameters requires a more complex infrastructure, which can lead to an augmented environmental impact [6].

3.1.6. SLS

SLS consolidates fine particles through laser-induced thermal sintering, without achieving complete fusion of the material. The process initiates with the application of powder in layers on a mobile platform. Subsequently, a laser scans each section of the three-dimensional model, generating heat through surface diffusion to bond the particles. The process is repeated until the final part is formed, following a similar pattern to other powder bed-based technologies [25].

The most common materials utilized in SLS are powdered polymers, including polyamides, polyether ketone ketone (PEKK), and polystyrene. However, composites, and in certain instances, metals or ceramics, can also be employed, contingent on specific process adjustments. A primary benefit of this method is the elimination of support structures, as the powder itself functions as a support medium. This characteristic enables significant geometric flexibility, facilitates the creation of internal cavities, and allows for the integration of movable components. Furthermore, it offers a favorable combination of resolution, mechanical properties, and dimensional stability in polymer parts, as well as the possibility of using recyclable materials, making it ideal for advanced prototyping and short runs [6,22].

In the SLS process, as in the two previous processes, sustainability is related to the efficient use of polymer powder. A significant portion of the residual material can be recovered and reused in subsequent cycles, thereby reducing waste [22]. From an energy standpoint, SLS necessitates considerable expenditure due to the preheating of the chamber and the continuous use of high-powered lasers, thereby increasing its environmental impact [22]. Conversely, post-processing activities, such as sandblasting or the elimination of binders, entail augmented energy expenditure and yield by-products that necessitate proper management [25].

3.1.7. LENS

LENS uses a high-power laser to melt metal powder deposited directly through nozzles that direct the flow to a localized melting point. In contrast to powder bed-based processes, the material is fed in real time onto the substrate surface or onto layers that have previously undergone solidification, thereby enabling layer-by-layer construction of the desired geometry. The movement of the laser head and nozzle is guided by the CAD model, while the platform maintains a fixed position or adjusts its height with each layer [25,51].

LENS primarily utilizes metal powders, including steels, titanium alloys, and nickel superalloys, necessitating precise regulation of particle size and fluidity. The primary benefits of this material include its capacity for producing dense, large-volume metal components and its aptitude for repair and coating applications. The potential for modulating the composition of the powder during the process engenders a degree of flexibility in the fabrication of multi-material components or components with functional gradients. Despite its relatively lower typical resolution (250–500 µm) compared to other additive techniques, it is deemed suitable for structural applications. Its high cost is counterbalanced by its versatility and industrial potential [6,24,26].

In the LENS process, sustainability is strongly conditioned by the high energy consumption associated with the use of high-power lasers and the need for inert gas protection systems, factors that increase the environmental footprint [26]. However, the direct additive nature of LENS offers significant advantages in terms of material efficiency. This is due to the fact that the metal powder is deposited only in the necessary areas of the part, which significantly reduces waste compared to subtractive techniques [24]. Moreover, its capacity to repair and re-functionalize damaged metal components is a pivotal aspect from a circular economy perspective, as it prolongs the service life of complex parts and mitigates the necessity to manufacture new components. However, the handling and recovery of unused powder necessitate additional screening and conditioning processes, which are costly in terms of resources and energy [24,26].

3.1.8. DIW

DIW is based on the controlled extrusion of inks or pastes with rheology adapted to maintain their shape after deposition. In contrast to the FFF process, which operates at elevated temperatures, the present method is conducted at ambient or moderate temperatures. This enables the layer-by-layer fabrication of three-dimensional structures using nozzles that follow digital trajectories. The formulation of the ink is pivotal, as it must possess viscoelastic properties that ensure both its extrusion and immediate geometric stability [21,27].

DIW has been demonstrated to exhibit compatibility with a broad array of materials, encompassing ceramic pastes, loaded polymers, hydrogels, bioinks, metal compositions, and intricate functional formulations. The advantages of this method include the ability to process heat-sensitive materials, technical simplicity, low equipment cost, and the possibility of manufacturing customized structures with high geometric freedom. Typically, its resolution is less than 200 µm, a measurement determined by the nozzle diameter and ink properties. The necessity of subsequent consolidation phases, such as drying, sintering, or chemical/thermal curing, is contingent upon the material’s composition [8,15,26,28].

In the case of DIW, the sustainability of the process is linked to its low energy consumption, since the ink extrusion is carried out at relatively moderate pressures and temperatures, without the need for laser sources or vacuum systems with high environmental costs [28]. Furthermore, the process deposits only the volume of ink required for the designed geometry, thereby reducing material waste and increasing resource utilization [8]. However, the sustainability of DIW also depends on the management of unused or surplus inks, which in many cases include solvents or chemical reagents that require proper treatment to minimize their environmental impact [21,26].

3.1.9. 3DBP

3DBP is aimed at creating three-dimensional structures through the controlled deposition of bio-inks composed of hydrogels, biopolymers, cell suspensions, or biomolecules. Its applications include tissue engineering, biomedical research, and pharmacology. In contrast to DIW, 3DBP involves the incorporation of living cells into the printing material, necessitating gentle conditions to ensure their viability. The process can be carried out by pneumatic or piston extrusion, jet injection, or laser-assisted printing. It is based on layer-by-layer deposition guided by digital models [21,22].

This technology facilitates the utilization of a diverse array of natural and synthetic bio-inks, a significant proportion of which have been functionalized with nanoparticles or growth factors. A notable benefit of this approach is its capacity to engineer intricate structures that systematically arrange cells in designated positions. This capability confers a high degree of spatial control, thereby enabling the replication of authentic biological environments. The typical resolution, which is the ability to distinguish between two adjacent points, varies between 50 and 300 µm depending on the method used. The most accurate methods are jet and laser systems. Despite the substantial expense associated with equipment and consumables, their cost-effectiveness in specialized applications is noteworthy. These structures frequently necessitate post-processing procedures, including cross-linking, cultivation under controlled conditions, or functional stabilization [15,29,51].

In the domain of 3DBP, the sustainability of the process is contingent upon its capacity to function under mild conditions, which curtail energy consumption by eschewing high-power sources such as lasers or electron beams [51]. The localized deposition of bioinks enables the highly efficient utilization of material, as only the volume necessary for the construction of the tissue construct is printed, thereby minimizing waste. Furthermore, the additive nature of the process enables the direct fabrication of customized biological scaffolds and models without the need for molds or intermediate processes, thereby reducing waste generation and resource expenditure on tooling [15,51]. Nevertheless, the sustainability of 3DBP is contingent upon the limited shelf life of many bioinks. The handling and storage of bioinks necessitate controlled conditions, which can result in increased energy consumption. Additionally, there is a requirement for auxiliary sterilization and environmental control equipment [29].

3.1.10. 4DP

4DP represents an evolution of AM, incorporating the dimension of time through the use of smart materials capable of modifying their shape, properties, or functionality after printing in response to external stimuli such as temperature, humidity, pH, or magnetic fields. Despite the fact that the manufacturing process is based on conventional techniques such as photopolymerization, extrusion, or ink deposition, the key lies in the use of programmable materials that allow the controlled transformation of printed structures under specific conditions [19].

The materials employed in this study encompass shape memory polymers, sensitive hydrogels, responsive elastomers, composites with functional nanoparticles, and multicomponent systems. The selection of these materials is guided by the anticipated stimulus and the requisite properties. The advent of additive printing technologies, such as FFF and SLA, has led to the adaptation of these processes to a variety of materials. A notable advantage of these materials is their capacity to self-assemble or transform without the need for mechanical intervention, a property that holds significant potential for applications in soft robotics, tissue engineering, and responsive devices. The resolution of the material is contingent upon the fundamental process and the material’s capacity to respond at the micrometer scale. While the initial cost of the equipment is comparable to that of conventional methods, the ongoing expenses associated with material development and research contribute to an elevated operational cost [8,20].

3.1.11. Comparative Summary

Following a thorough analysis of the predominant AM technologies identified in the reviewed literature, Table 4 offers a concise summary, emphasizing their salient characteristics and synthesizing the fundamental aspects of each technology in terms of materials employed, advantages, limitations, achievable resolution, and estimated cost. The objective of this study is to provide a comprehensive overview of the available technologies, facilitating a comparative analysis and serving as a guide for selecting the most appropriate technology according to the specific needs of each application.

Table 4.

Comparison between the characteristics of the most common FA technologies found in the literature. ($ Low cost $$ Medium cost $$$ High cost $$$$ Very high cost).

3.2. Fabrication Materials

The functionality and success of lattice structures in biomedical applications are contingent not only on their geometric design, but also on the materials from which they are manufactured. In the field under consideration, requirements such as biocompatibility, bioactivity, mechanical strength, controlled degradability, and integration with host tissue, among others, impose challenging criteria that cannot be met solely by structural topology. The capacity of additive technologies to process a diverse array of materials has enabled the translation of these designs into practical applications. However, the selection of material remains a pivotal limiting factor. Consequently, the material selected dictates critical properties, including cell response, bone integration velocity, and in vivo dimensional stability [22].

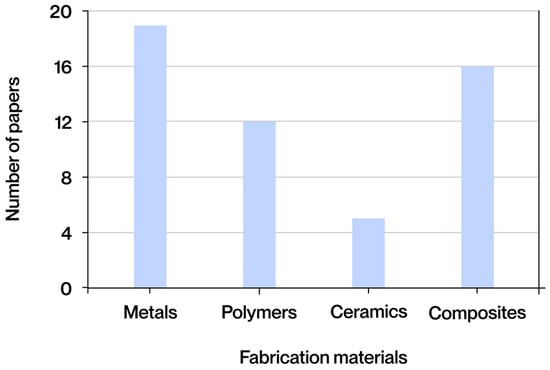

A comprehensive review of the extant literature reveals the identification of four predominant categories of materials that are utilized repeatedly in manufacturing processes that employ additive technologies. The classification system employed in this study is based on the fundamental nature of the materials utilized, with distinctions made according to their base composition. This classification differentiates between metals, polymers, ceramic materials, and composite materials. Each of these possesses a distinct set of properties, applications, and limitations that influence the structural design and functional performance of the manufactured parts. As illustrated in Figure 6, the frequency of occurrence for each material group across diverse documents obtained from the extant literature is depicted.

Figure 6.

Fabrication materials most frequently found in the literature obtained.

Metals, the most common category found in the literature, stand out in AM due to their high mechanical strength, good conductivity, and ability to withstand heavy loads without deformation. They are mainly processed using SLM or EBM. Polymers, widely used for their structural diversity and processability using techniques such as FFF, SLA, or DLP, offer low melting points, compatibility with additives, and great adaptability to required properties. Ceramics, although less common, provide hardness, chemical stability, and thermal resistance, making them useful in demanding contexts despite their fragility, and can be manufactured using BJ or DLP. Finally, composite materials combine matrices (polymeric, metallic, or ceramic) and reinforcements (fibers, particles, or nanoadditives) to optimize rigidity, strength, and functionality, and are processed using techniques such as FFF or DIW for structural and customized applications.

In order to facilitate comparison between the main groups of additive materials, Table 5 summarizes their most relevant characteristics.

Table 5.

Comparison between the characteristics of the most common fabrication materials found in the literature.

While materials can be classified into broad categories based on their composition and predominant behavior, it is crucial to acknowledge that within each category, there exist materials with properties that deviate significantly from the standard for their group. This diversity of properties enables the extension of materials’ applicability to specific functions that may initially appear to be incongruent with their inherent nature. Consequently, the properties enumerated in this table are oriented towards the biomedical sector, which encompasses a diverse array of applications, each with distinct requirements based on the function to be performed. However, there are certain properties that must be met in most cases, regardless of the specific clinical context. These include biomechanical properties, biocompatibility, biodegradability, corrosion resistance, structural porosity, the rheological behavior of the material during processing, and, in some cases, additional functional characteristics such as conductivity or response to stimuli.

The biomechanical properties of materials are determined by their capacity to withstand loads and deformations within the functional environment for which they are intended. In the biomedical field, it is imperative that materials exhibit not only structural stability, but also a mechanical behavior that is as analogous as possible to that of the tissue with which they interact. Excessive stiffness can result in stress shielding, while insufficient strength can compromise load transmission or induce mechanical failure [30]. The disparity between the elastic modulus of the implant and that of the recipient tissue has the potential to induce complications, including interference with regeneration or functional failure of the assembly [31]. Consequently, properties such as tensile strength, compression strength, fatigue strength, fracture toughness, and an elastic modulus suitable for each type of tissue are of particular importance [22]. Lattice structures enable the precise adjustment of these properties without altering the chemical composition of the material. This is achieved by manipulating parameters such as overall stiffness, relative density, or stress distribution. The subsequent section will delve into the intricacies of this geometric control strategy. Table 6 provides a synopsis of the primary mechanical properties of interest, contingent upon the type of fabric.

Table 6.

Mechanical properties, porosity, and density of different human body structures or tissues.

Biocompatibility is a pivotal property in materials intended for biomedical applications, as it dictates their acceptance by the body and their clinical viability. The concept extends beyond mere toxicity, encompassing the prevention of immune responses, the release of deleterious compounds, and the mitigation of inflammation. Additionally, it ensures stable interaction with the physiological environment [30]. This interaction can be classified as either passive or active, depending on whether it facilitates processes such as cell adhesion or functional integration [32]. The requisite level of biocompatibility is contingent upon the intended application, with higher standards applied to permanent devices than to temporary scaffolds [28].

In the context of the biomedical environment, where numerous implants are subjected to prolonged exposure to physiological fluids containing ions, proteins, and pH variations, corrosion resistance is paramount. Uncontrolled corrosion has the potential to compromise the mechanical integrity of the material and result in the release of toxic or immunogenic products [33]. The property in question is contingent upon the chemical composition, surface stability, microstructure, and potential passivation treatments or coatings. It has been demonstrated that even low levels of corrosion can result in failure over time, particularly in areas that experience high levels of stress or that are in contact with sensitive tissues. Consequently, its evaluation should encompass testing in simulated environments and electrochemical analysis under real conditions [28].

Porosity is a pivotal structural property in materials intended for medical applications, particularly when integration with living tissue or biological regeneration is the objective. The promotion of nutrient exchange, oxygenation, cell migration, and vascularization is of particular significance in the context of osseointegration and tissue regeneration [34]. However, it is imperative to note that this process also exerts a significant influence on the mechanical properties of the material. Consequently, meticulous design is essential to ensure a balanced synergy between biological functionality and structural integrity. The manipulation of these parameters, enabled by additive technologies, allows for precise control over the size, distribution, interconnectivity, and total pore percentage of the material, thereby facilitating the desired level of control. Lattice-type structures offer novel possibilities by allowing for regular or gradual porous patterns defined by geometric functions, facilitating spatial modulation adapted to the target tissue and morphological patterns such as those of trabecular bone, cartilage, or partially supported soft tissues [35].

The rheological properties of a material are instrumental in determining its behavior in a fluid or semi-fluid state during the printing process. This is particularly salient in techniques such as 3DBP or the extrusion of pastes and gels. The material must possess sufficient viscosity to ensure precise deposition and rapid solidification, thereby preserving the shape and resolution of the model [32]. This equilibrium is attained by modifying parameters such as shear-dependent viscosity, thixotropy, or viscoelasticity through alterations in concentration, temperature, chemical crosslinking, or additives. Moreover, in biomedical applications, these properties must ensure cell compatibility, biological viability, and mechanical integrity under physiological conditions [29].

In addition to the properties previously delineated, there are other salient characteristics contingent upon the type of tissue, the physiological environment, or the function of the implant. In contexts characterized by elevated heat transfer or the necessity of energy dissipation, thermal conductivity assumes paramount importance [6]. Electrical conductivity is imperative in excitable tissues, such as nerves or muscles, or in electroactive stimulation strategies to promote regeneration [15]. In the domain of 4DP, the focus is on materials that exhibit a response to external stimuli, characterized by alterations in their structural form or functional characteristics following implantation. These properties are obtained through specific formulations, functional nanoparticles, or advanced structural design, and require effective integration between composition, architecture, and environmental engineering [19].

Subsequent to the identification of the properties of the most relevant materials in the biomedical context, the subsequent step is to examine each of the established material categories in greater detail.

3.2.1. Metals

The utilization of metals within the biomedical field is predominantly propelled by the necessity to guarantee mechanical stability in scenarios where alternative materials prove to be inadequate. Their exceptional resistance to cyclic loads, humidity, and fatigue renders them particularly well-suited for implants subjected to prolonged stress. Furthermore, their biological behavior can be modulated through the use of alloys, coatings, or surface treatments [17]. AM technologies enable the optimization of their structures, thereby enhancing biological integration and adjusting properties such as elastic modulus or fatigue resistance [6]. Metals exhibit superior toughness and fatigue tolerance in comparison to other materials, though their rigidity can induce stress shielding. Certain alloys necessitate control of their ionic release for reasons pertaining to biocompatibility [36].

The classification of metals utilized in AM for medical applications is contingent upon their behavior within the biological environment, which can be categorized into two distinct groups: non-biodegradable and biodegradable.

In the biomedical field, the most prevalent non-biodegradable metals are those that possess high mechanical strength, excellent chemical stability, and favorable long-term biocompatibility. The primary objective of the present study is to provide a permanent structural solution that does not require degradation or reabsorption, rendering them suitable for use in joint prostheses, dental implants, or osteosynthesis systems. Among non-biodegradable metals, the most commonly used in the biomedical field are pure titanium and its alloys, cobalt alloys, 316L steel, tantalum, and nickel alloys [17]. These materials are distinguished by their elevated mechanical strength, favorable long-term biocompatibility, and exceptional corrosion resistance, rendering them especially well-suited for permanent implants, including hip prostheses, joint prostheses, and dental implants. However, their high rigidity can result in adverse effects, such as stress shielding. Furthermore, the potential ionic release of elements like cobalt, chromium, or nickel necessitates rigorous control measures [6].

The concept of biodegradable metals represents a more recent development in the field, aimed at applications requiring temporary structural support, with the implant intended to degrade safely within the body over a limited period. This strategy obviates the need for subsequent surgical interventions to excise the material and has the potential to stimulate guided tissue regeneration [23]. Among the metals that have demonstrated the greatest potential are magnesium and its alloys, iron and zinc and their alloys. Among the group of metals that can be biodegraded, magnesium is distinguished by its biocompatibility, osteoinductive effect, and elastic modulus, which is comparable to that of bone [28]. However, its rapid corrosion in physiological environments poses significant structural challenges. Iron offers superior mechanical strength and biological tolerance; however, its slow degradation limits its practical applications. Proposed solutions include manganese alloys and porous designs. Zinc, characterized by intermediate degradability, favorable biocompatibility, and antimicrobial properties, impedes the occurrence of hydrogen during resorption. However, its inherent weakness in terms of strength and ductility necessitates enhancement through alloying processes [37].

The subsequent Table 7 offers a synopsis of the salient properties of the metals previously delineated, with particular emphasis on their characteristics when subjected to the fabrication process utilizing the AM method.

Table 7.

Mechanical properties, biocompatibility, and corrosion resistance of metals manufactured using AM most commonly used in lattice structures in the biomedical sector (* Bad ** Regular *** Good **** Best).

The AM of metals for biomedical applications is predominantly executed through the implementation of PBF techniques, including SLM and EBM. Titanium and its alloys have been identified as materials of choice due to their favorable processability. However, it should be noted that these materials necessitate the implementation of heat treatment to mitigate stresses and avert the formation of cracks [25]. Cobalt and tantalum alloys have also been shown to offer favorable outcomes; however, these results are contingent upon the utilization of high power and scanning strategies to circumvent thermal accumulation or the formation of brittle phases [12]. The processing of nickel alloys is a more intricate process due to their narrow thermal window, which necessitates precise regulation of energy input and environmental factors. However, functional components have been successfully obtained using SLM in small geometries [38]. The utilization of biodegradable metals introduces a set of unique challenges. Magnesium is highly reactive and prone to ignition, zinc tends to evaporate due to its low melting temperature, and iron, although stable, requires strategies to accelerate its degradation. Nevertheless, viable structures have been fabricated under controlled conditions [30].

The sustainability of these materials is contingent upon the procurement of raw materials and the subsequent management of the implant throughout its life cycle. The generation of high-purity metal powders, a prerequisite for processes such as SLM or EBM, entails substantial energy consumption and concomitant emissions [12]. However, the potential for recycling unconsolidated powder and reusing it in multiple cycles has been demonstrated to significantly reduce material waste and improve resource utilization [17]. Concurrently, the emergence of biodegradable alloys, such as Mg, Fe, and Zn, signifies a paradigm shift towards clinical sustainability. The controlled degradation of these alloys within the body obviates the necessity for surgical removal, thereby ensuring cost savings and a reduction in surgical waste generation [33]. Another salient aspect pertains to the durability of non-degradable alloys, which prolongs the useful life of implants and reduces the frequency of replacements, thereby exerting a favorable impact on the cumulative environmental footprint [35].

3.2.2. Polymers

Polymers have become a prevalent material in the field of biomedicine due to their chemical versatility, low density, ease of processing at low temperatures, and good biocompatibility. These materials are composed of long macromolecular chains, which can be either natural or synthetic. The structural integrity of these materials can be adapted to offer different levels of rigidity, elasticity, or degradability. This compositional flexibility enables the design of specific formulations for soft, hard, or temporary tissues, with adjustments to the physiological environment or printing process. Despite their comparatively diminished mechanical strength and thermal stability when compared to metals or ceramics, these materials possess notable applications in fields such as regeneration, controlled release, and temporary scaffolds, thus establishing their importance in biofabrication [21].

The extensive array of polymers available in the biomedical field is attributable not only to their chemical diversity but also to the capacity to adapt them to specific clinical functions. A categorization of these materials based on their application reveals three primary groups: structural polymers for mechanical devices, polymers for tissue regeneration and scaffolding, and polymers formulated as hydrogels or cell matrices for 3DBP.

Structural polymers are utilized in applications that necessitate a specific degree of rigidity, durability, or dimensional stability. Among these, the most notable in the extant literature is polyetheretherketone (PEEK), a semi-crystalline thermoplastic with excellent mechanical strength, high thermal stability, and great chemical resistance, approved for permanent implantable applications. Its elastic modulus, which is comparable to that of cortical bone, renders it a compelling substitute for titanium in spinal, dental, and orthopedic surgery. Other materials, including polyamide 12 (PA12), find application in external prostheses, surgical guides, and support devices. These applications typically involve moderate mechanical requirements, with a focus on printing ease and geometric stability.

Polymers for scaffolding and tissue regeneration are among the most extensively studied in the biomedical field. Notably, polylactic acid (PLA) and polycaprolactone (PCL) have garnered particular attention due to their inherent biodegradability, compatibility with biological systems, and the ease with which they can be printed using the FFF technique. PLA, a more rigid material that rapidly degrades, is employed when structural support is required to be lost within weeks or a few months [21]. PCL, which exhibits enhanced flexibility and gradual degradation, is particularly well-suited for structures that necessitate maintenance of their structural integrity over an extended period, such as in the context of bone or cartilage regeneration. The material’s low melting point and adequate thermal stability enable its processing without causing damage to biological components, thus facilitating its use in hybrid platforms. Copolymers such as poly (lactic-co-glycolic acid) (PLGA) are also employed, as they permit the modulation of degradation rates and the enhancement of interaction with the surrounding environment [29].

Hydrogel polymers play a pivotal role in 3DBP and the design of cell matrices. In contrast to structural polymers, their purpose is to generate biocompatible, moist, and functional microenvironments that house living cells, transport biomolecules, or release drugs in a controlled manner [39]. The materials utilized in this study include GelMA, alginate, collagen, and chitosan, which have demonstrated excellent cell compatibility and rheological properties that are well-suited for AM applications. The formulation of these materials must address three fundamental properties: viscosity, stability, and cell viability. These materials are often combined with nanoparticles, ceramics, or drugs to enhance their functionality. Their capacity to replicate the microarchitecture of tissue renders them indispensable in the development of soft tissue models, the field of controlled release, and the realm of personalized medicine [32].

The subsequent Table 8 offers a synopsis of the most salient properties of the polymers previously delineated that are produced through the utilization of AM.

Table 8.

Mechanical properties, biocompatibility, and corrosion resistance of polymers manufactured using AM most commonly used in lattice structures in the biomedical sector (* Bad ** Regular *** Good **** Best).

The processability of polymers using additive technologies is a significant advantage of these materials. A variety of techniques have been developed to manufacture customized scaffolds using FFF. These techniques allow for the production of customized scaffolds with PLA or PCL, combining the ease of printing with porous geometries adapted to the target tissue. To achieve optimal precision, DLP photopolymerization provides high resolution; however, it necessitates UV-compatible formulations and caution to circumvent residual toxicity. SLS enables the processing of powdered polymers, such as PA12 or thermoplastic polyurethane (TPU), without the need for support structures, thereby favoring the creation of complex internal geometries. However, this method is associated with a reduced range of biocompatible options and a diminished control over porosity or degradation. In bio-inks or soft formulations, systems such as DIW are employed, where viscosity, rheology, and rapid gelation are critical to maintain shape without compromising cell viability. In essence, the selection of printing method and parameters must be adapted to the polymer and the intended function of the device, ensuring precision, stability, and biological compatibility [40].

In the context of polymers, sustainability is predominantly associated with their provenance, processability, and end-of-life management. Some of the polymers previously mentioned, such as PLA and PCL, are derived from renewable resources or are biodegradable, which contributes to a reduction in their environmental impact and facilitates their management following clinical use [18]. This characteristic is particularly advantageous when compared to petroleum-derived synthetic polymers, such as PEKK or PEEK, whose strength and chemical stability make them more difficult to recycle and dispose of. However, the latter option demonstrates high durability in long-term applications, which in turn reduces the need for frequent replacements and may offset their initial environmental impact [32].

3.2.3. Ceramics