Harnessing Deep-Hole Drilling to Fabricate Air-Structured Polymer Optical Fibres

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

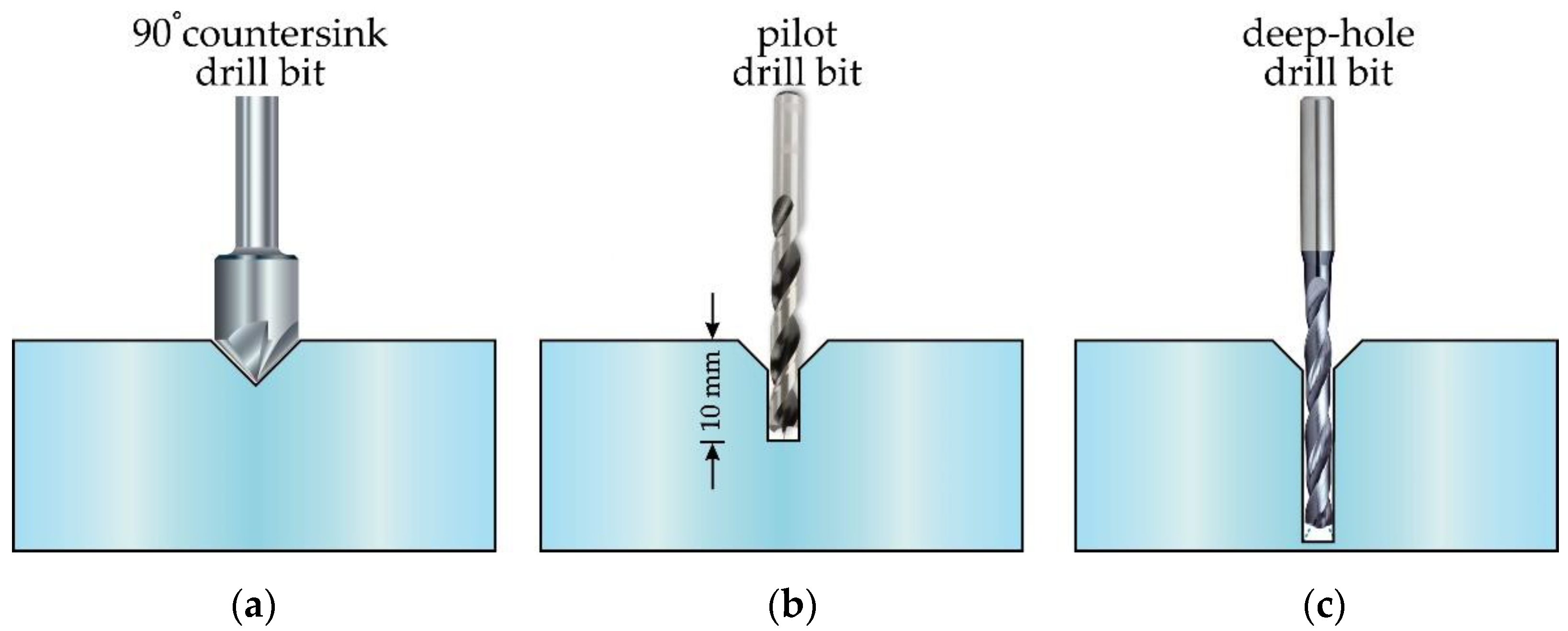

2.2. Drilling Bits

- A standard twist drill of 3 mm diameter and with a length-to-diameter ratio of 40 (HSTD3) [33].

- A through-coolant carbide drill of 3 mm diameter and with a length-to-diameter ratio of 30 (TCCD3) [34].

- A single-lip gundrill of 2 mm diameter and with a length-to-diameter ratio of 50 (SLD2) [35].

- A single-lip gundrill of 3 mm of diameter and with a length-to-diameter ratio of 50 (SLD3) [35].

2.3. Drilling Procedure

2.4. Quality Parameters

2.5. Measurement Technique

3. Results and Discussion

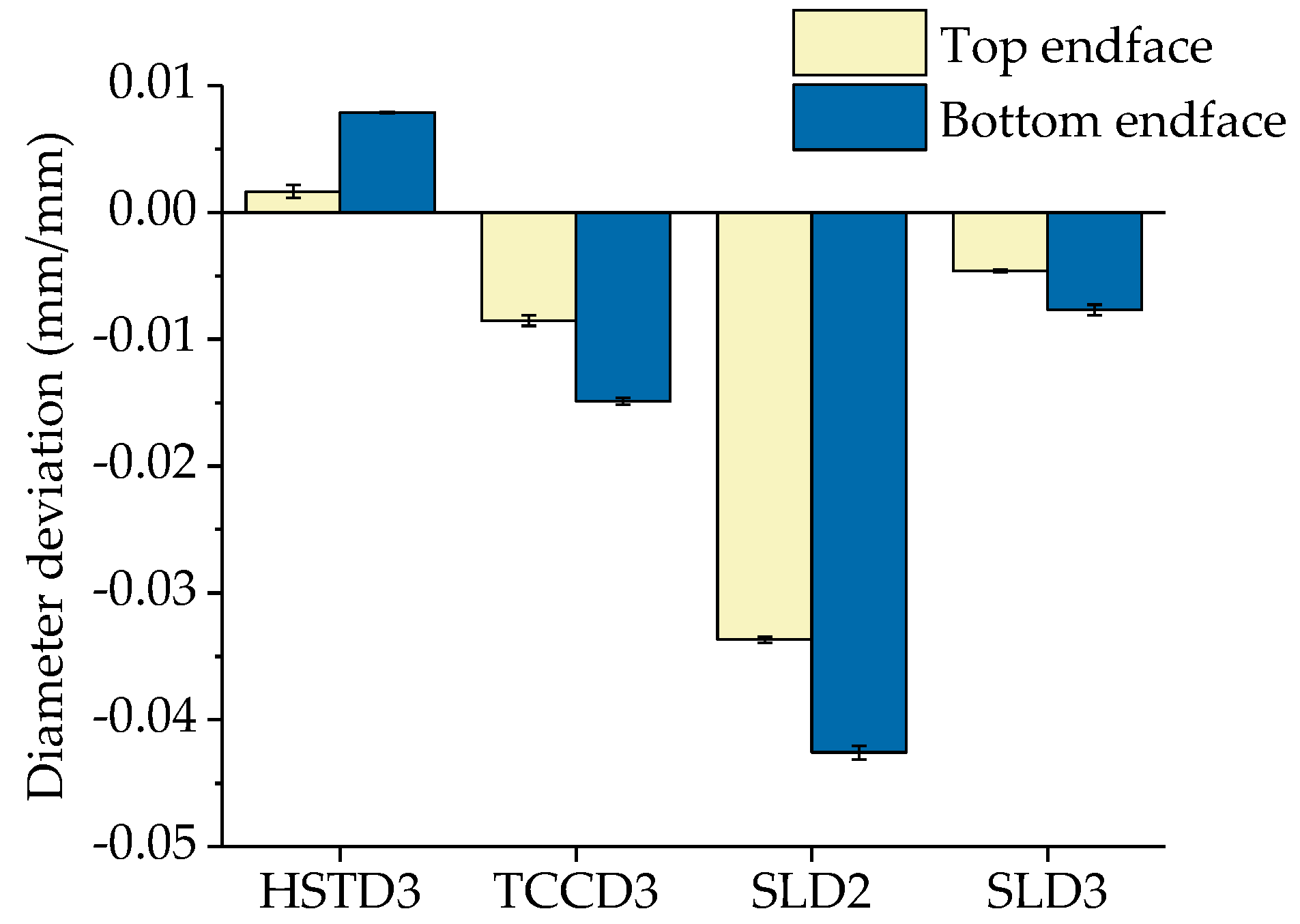

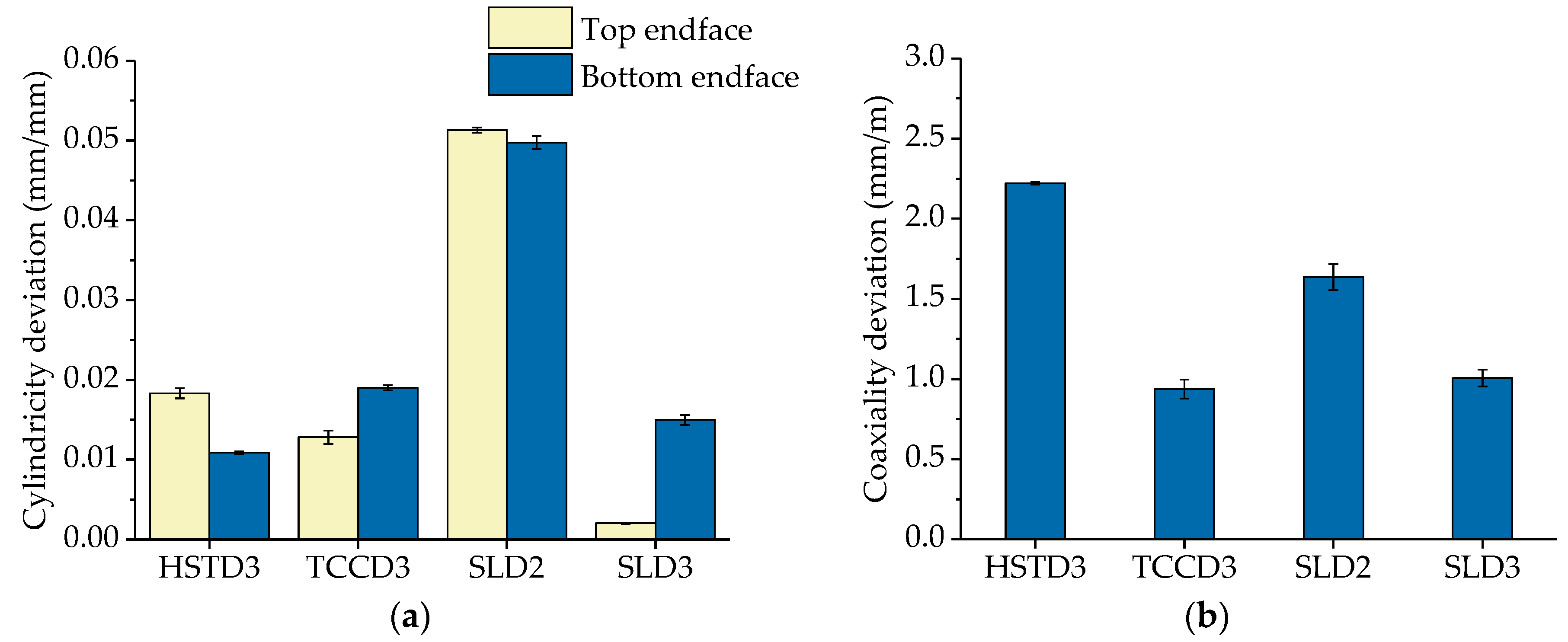

3.1. Experimental Results

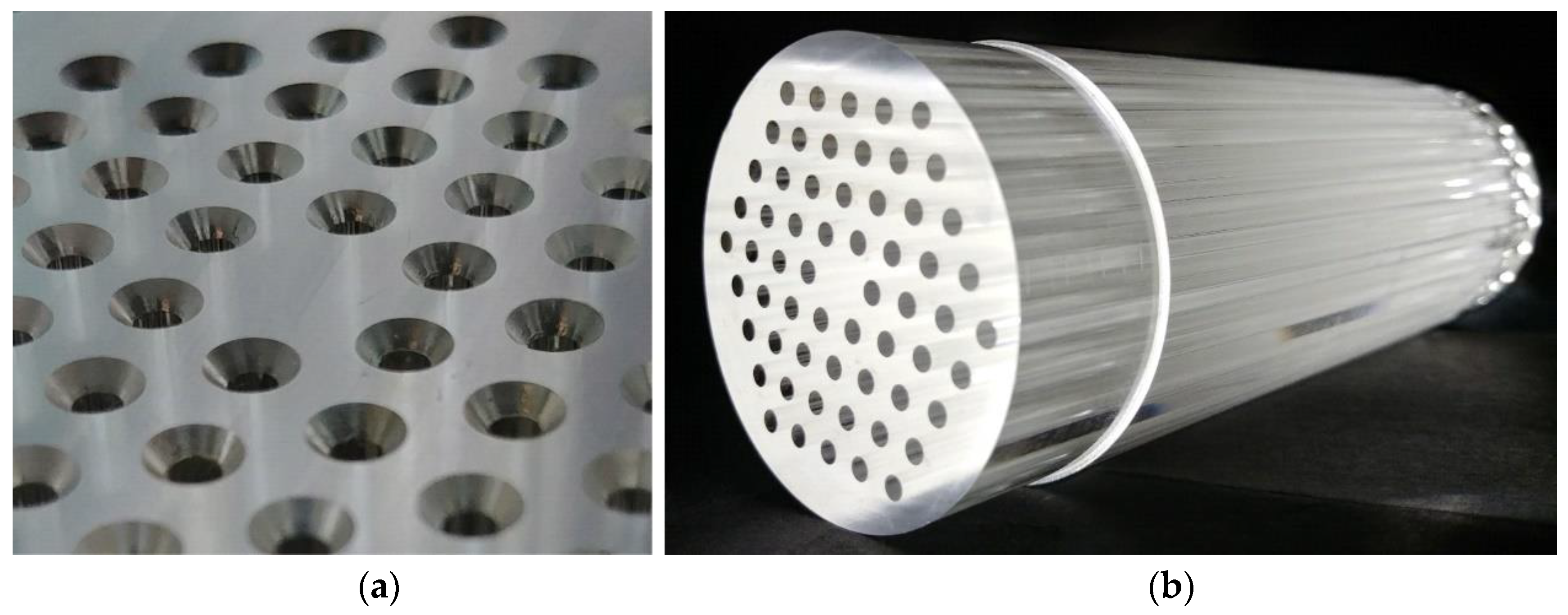

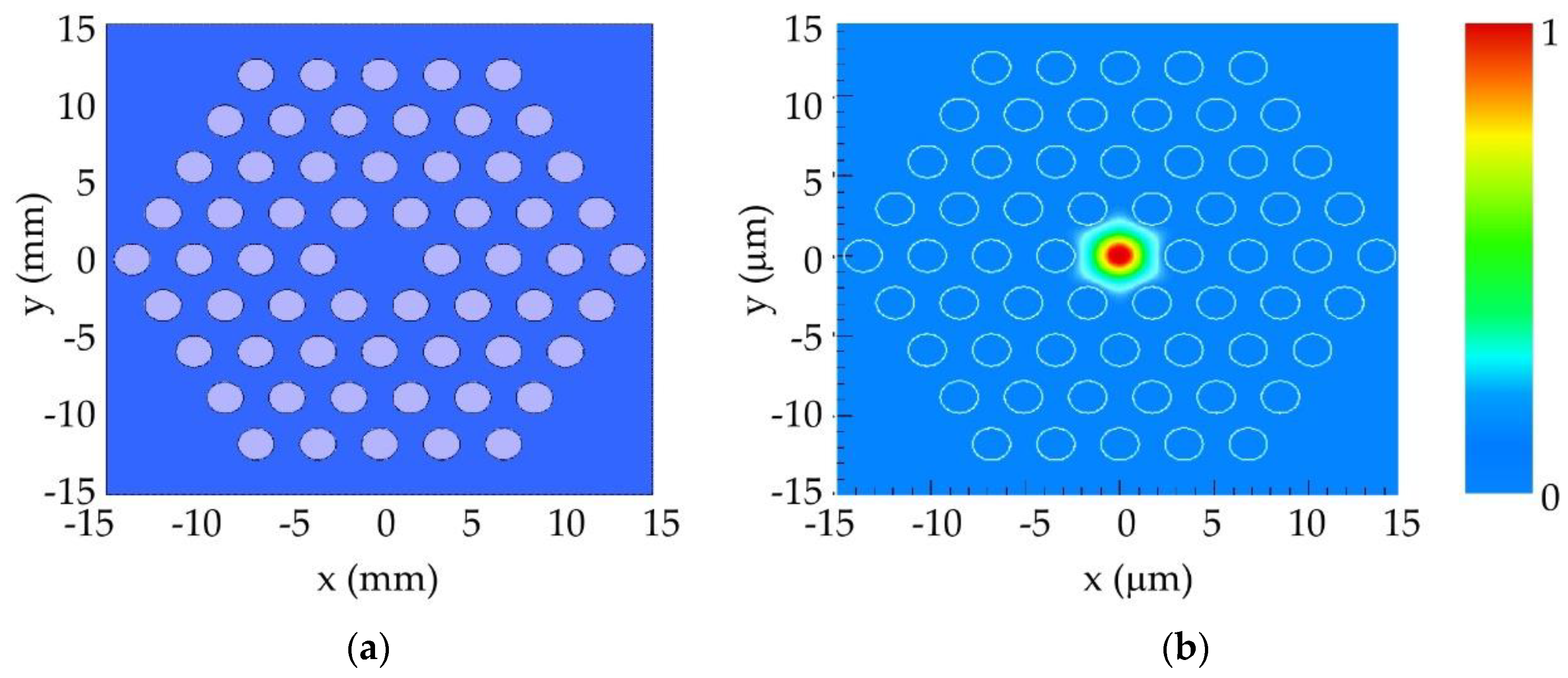

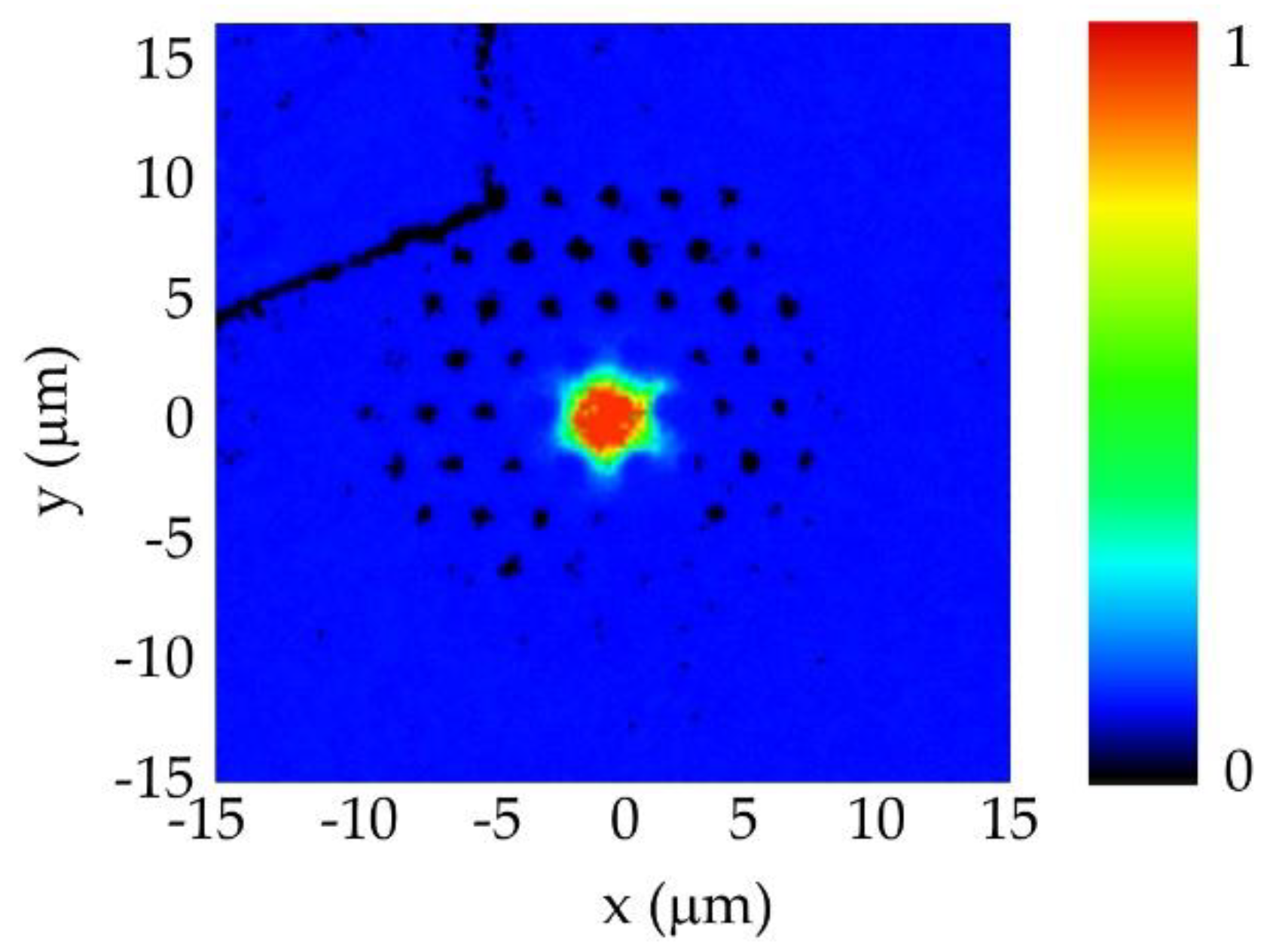

3.2. Fabrication and Assessment of Optical Guidance Properties of the mPOF

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Argyros, A. Microstructured Polymer Optical Fibers. J. Light. Technol. 2009, 27, 1571–1579. [Google Scholar] [CrossRef]

- Barton, G.; van Eijkelenborg, M.A.; Henry, G.; Large, M.C.J.; Zagari, J. Fabrication of Microstructured Polymer Optical Fibres. Opt. Fiber Technol. 2004, 10, 325–335. [Google Scholar] [CrossRef]

- Knight, J.C.; Birks, T.A.; Russell, P.S.J.; Atkin, D.M. All-Silica Single-Mode Optical Fiber with Photonic Crystal Cladding. Opt. Lett. 1996, 21, 1547. [Google Scholar] [CrossRef] [PubMed]

- Russell, P.S.J. Photonic-Crystal Fibers. J. Light. Technol. 2006, 24, 4729–4749. [Google Scholar] [CrossRef]

- Cregan, R.F.; Mangan, B.J.; Knight, J.C.; Birks, T.A.; Russell, P.S.J.; Roberts, P.J.; Allan, D.C. Single-Mode Photonic Band Gap Guidance of Light in Air. Science 1999, 285, 1537–1539. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Large, M.; Poladian, L.; Barton, G.; van Eijkelenborg, M.A. Microstructured Polymer Optical Fibres, 1st ed.; Springer: New York, NY, USA, 2008; ISBN 978-0-38-768617-2. [Google Scholar]

- Large, M.C.J.; Blacket, D.; Bunge, C.A. Microstructured Polymer Optical Fibers Compared to Conventional POF: Novel Properties and Applications. IEEE Sens. J. 2010, 10, 1213–1217. [Google Scholar] [CrossRef]

- Nielsen, K.; Markos, C.; Stefani, A.; Rasmussen, H.K.; Yuan, W.; Bang, O. High-Tg TOPAS MPOF Strain Sensing at 110 Degrees. In Proceedings of the 22nd International Conference on Plastical Optical Fibers, Búzios, Brazil, 11–13 September 2013. [Google Scholar]

- Markos, C.; Stefani, A.; Nielsen, K.; Rasmussen, H.K.; Yuan, W.; Bang, O. High-Tg TOPAS Microstructured Polymer Optical Fiber for Fiber Bragg Grating Strain Sensing at 110 Degrees. Opt. Express 2013, 21, 4758–4765. [Google Scholar] [CrossRef] [PubMed]

- Leal-Junior, A.; Frizera, A.; Pontes, M.J.; Fasano, A.; Woyessa, G.; Bang, O.; Marques, C.A.F. Dynamic Mechanical Characterization with Respect to Temperature, Humidity, Frequency and Strain in MPOFs Made of Different Materials. Opt. Mater. Express 2018, 8, 804. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Frizera, A.; Min, R.; Pontes, M.J.; Fasano, A.; Woyessa, G.T.; Bang, O.; Marques, C. Influence of the Cladding Structure in PMMA MPOFs Mechanical Properties for Strain Sensors Applications. IEEE Sens. J. 2018, 18, 5805–5811. [Google Scholar] [CrossRef]

- Min, R.; Ortega, B.; Marques, C. Fabrication of Tunable Chirped MPOF Bragg Gratings Using a Uniform Phase Mask. Opt. Express 2018, 26, 4411–4420. [Google Scholar] [CrossRef] [PubMed]

- Pysz, D.; Kujawa, I.; Stepien, R.; Klimczak, M.; Filipkowski, A.; Franczyk, M.; Kociszewski, L.; Buzniak, J.; Harasny, K.; Buczynski, R. Stack and Draw Fabrication of Soft Glass Microstructured Fiber Optics. Bull. Polish Acad. Sci. Tech. Sci. 2014, 62, 667–682. [Google Scholar] [CrossRef]

- Lægsgaard, J.; Bjarklev, A. Microstructured Optical Fibers - Fundamentals and Applications. J. Am. Ceram. Soc. 2006, 89, 2–12. [Google Scholar] [CrossRef]

- Bunge, C.-A.; Beckers, M.; Gries, T. Polymer Optical Fibres: Fibre Types, Materials, Fabrication, Characterisation and Applications, 1st ed.; Woodhead Publishing: Cambridge, UK, 2016; ISBN 978-0-08-100056-4. [Google Scholar]

- Cook, K.; Canning, J.; Leon-Saval, S.; Reid, Z.; Hossain, M.A.; Comatti, J.-E.; Luo, Y.; Peng, G.-D. Air-Structured Optical Fiber Drawn from a 3D-Printed Preform. Opt. Lett. 2015, 40, 3966–3969. [Google Scholar] [CrossRef] [PubMed]

- Talataisong, W.; Ismaeel, R.; Marques, T.H.R.; Abokhamis Mousavi, S.; Beresna, M.; Gouveia, M.A.; Sandoghchi, S.R.; Lee, T.; Cordeiro, C.M.B.; Brambilla, G. Mid-IR Hollow-Core Microstructured Fiber Drawn from a 3D Printed PETG Preform. Sci. Rep. 2018, 8. [Google Scholar] [CrossRef] [PubMed]

- Biermann, D.; Bleicher, F.; Heisel, U.; Klocke, F.; Möhring, H.-C.; Shih, A. Deep Hole Drilling. CIRP Ann. 2018, 67, 673–694. [Google Scholar] [CrossRef]

- Hayajneh, M.T. Hole Quality In Deep Hole Drilling. Mater. Manuf. Process. 2001, 16, 147–164. [Google Scholar] [CrossRef]

- Xabier, L.F.; Elangovan, D. Effective Parameters For Improving Deep Hole Drilling Process By Conventional Method—A Review. Int. J. Eng. Res. Technol. 2013, 2, 3. [Google Scholar]

- Biermann, D.; Heilmann, M. Analysis of the Laser Drilling Process for the Combination with a Single-Lip Deep Hole Drilling Process with Small Diameters. Phys. Procedia 2011, 12, 308–316. [Google Scholar] [CrossRef] [Green Version]

- Zabel, A.; Heilmann, M. Deep Hole Drilling Using Tools with Small Diameters—Process Analysis and Process Design. CIRP Ann. 2012, 61, 111–114. [Google Scholar] [CrossRef]

- Van Eijkelenborg, M.A.; Argyros, A.; Barton, G.; Bassett, I.M.; Fellew, M.; Henry, G.; Issa, N.A.; Large, M.C.J.; Manos, S.; Padden, W.; et al. Recent Progress in Microstructured Polymer Optical Fibre Fabrication and Characterisation. Opt. Fiber Technol. 2003. [Google Scholar] [CrossRef]

- Xu, X.; Chen, J.; Zhou, J.; Li, B. Thermal Conductivity of Polymers and Their Nanocomposites. Adv. Mater. 2018, 30, 1705544. [Google Scholar] [CrossRef] [PubMed]

- Upmeier, T.; Biermann, D. Deep Hole Drilling of Thermoplastics. In Proceedings of the 4th International Conference Machining Technology, Pilsen, Check Republic, 25–26 January 2011. [Google Scholar]

- Al Quran, F.M. Machining Accuracy and Stability during Drilling of Thermoplastics. J. Appl. Sci. 2007, 7, 141–144. [Google Scholar] [CrossRef]

- Prado, A.R.; Leal-Junior, A.G.; Marques, C.; Leite, S.; de Sena, G.L.; Machado, L.C.; Frizera, A.; Ribeiro, M.R.N.; Pontes, M.J. Polymethyl Methacrylate (PMMA) Recycling for the Production of Optical Fiber Sensor Systems. Opt. Express 2017, 25, 30051–30060. [Google Scholar] [CrossRef] [PubMed]

- Plexiglas-Shop. Available online: https://www.plexiglas-shop.com/pdfs/en/211-12-PLEXIGLAS-Tubes-Rods-en.pdf (accessed on 27 July 2019).

- Brydson, J.A. Plastics Materials; Elsevier: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Henry, A. Thermal Transport in Polymers. Annu. Rev. Heat Transf. 2014, 17, 485–520. [Google Scholar] [CrossRef]

- Aized, T.; Amjad, M. Quality Improvement of Deep-Hole Drilling Process of AISI D2. Int. J. Adv. Manuf. Technol. 2013, 69, 2493–2503. [Google Scholar] [CrossRef]

- Biermann, D.; Heilmann, M.; Kirschner, M. Analysis of the Influence of Tool Geometry on Surface Integrity in Single-Lip Deep Hole Drilling with Small Diameters. Procedia Eng. 2011, 19, 16–21. [Google Scholar] [CrossRef]

- Walter-Tools. Available online: https://www.walter-tools.com/en-gb/search/pages/default.aspx?m=5062668 (accessed on 27 July 2019).

- Hoffmann-Group. Available online: https://www.hoffmann-group.com/GB/en/houk/Mono-machining/Solid-carbide-drills/Solid-carbide-HPC-deep-hole-drill-plain-shank-DIN-6535-HA-30×D-DLC/p/123595 (accessed on 27 July 2019).

- Botek. Available online: https://www.botek.de/en/single-flute-gundrill (accessed on 27 July 2019).

- White, T.P.; McPhedran, R.C.; de Sterke, C.M.; Botten, L.C.; Steel, M.J. Confinement Losses in Microstructured Optical Fibers. Opt. Lett. 2001, 26, 1660. [Google Scholar] [CrossRef]

- Marques, C.A.F.; Pospori, A.; Demirci, G.; Çetinkaya, O.; Gawdzik, B.; Antunes, P.; Bang, O.; Mergo, P.; André, P.; Webb, D.J. Fast Bragg Grating Inscription in PMMA Polymer Optical Fibres: Impact of Thermal Pre-Treatment of Preforms. Sensors 2017, 17, 891. [Google Scholar] [CrossRef]

- Arrospide, E.; Durana, G.; Azkune, M.; Aldabaldetreku, G.; Bikandi, I.; Ruiz-Rubio, L.; Zubia, J. Polymers beyond Standard Optical Fibres- Fabrication of Microstructured Polymer Optical Fibres. Polym. Int. 2018, 67, 1155–1163. [Google Scholar] [CrossRef]

| Drill | Diameter (mm) | Length-To-Diameter Ratio | Coolant | Feed Speed (mm/min) | Rotation Speed (rpm) | Bit Length (mm) |

|---|---|---|---|---|---|---|

| HSTD3 | 3 | 40 | External | - | 1500 | 120 |

| TCCD3 | 3 | 30 | Internal (40 bars) | 800 | 8000 | 93 |

| SLD2 | 2 | 50 | Internal (40 bars) | 150 | 1500 | 110 |

| SLD3 | 3 | 50 | Internal (40 bars) | 150 | 1500 | 175 |

| Drill | Time (min) | Preform Length (mm) |

|---|---|---|

| HSTD3 | 375 | 120 |

| TCCD3 | 25 | 93 |

| SLD2 | 70 | 110 |

| SLD3 | 100 | 175 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arrospide, E.; Bikandi, I.; Larrañaga, I.; Cearsolo, X.; Zubia, J.; Durana, G. Harnessing Deep-Hole Drilling to Fabricate Air-Structured Polymer Optical Fibres. Polymers 2019, 11, 1739. https://doi.org/10.3390/polym11111739

Arrospide E, Bikandi I, Larrañaga I, Cearsolo X, Zubia J, Durana G. Harnessing Deep-Hole Drilling to Fabricate Air-Structured Polymer Optical Fibres. Polymers. 2019; 11(11):1739. https://doi.org/10.3390/polym11111739

Chicago/Turabian StyleArrospide, Eneko, Iñaki Bikandi, Igor Larrañaga, Xabier Cearsolo, Joseba Zubia, and Gaizka Durana. 2019. "Harnessing Deep-Hole Drilling to Fabricate Air-Structured Polymer Optical Fibres" Polymers 11, no. 11: 1739. https://doi.org/10.3390/polym11111739

APA StyleArrospide, E., Bikandi, I., Larrañaga, I., Cearsolo, X., Zubia, J., & Durana, G. (2019). Harnessing Deep-Hole Drilling to Fabricate Air-Structured Polymer Optical Fibres. Polymers, 11(11), 1739. https://doi.org/10.3390/polym11111739