Purification and Nitrogen Doping of Nanothin Exfoliated Graphite Through RF Thermal Plasma Treatment

Abstract

1. Introduction

2. Experimental Details

2.1. Materials

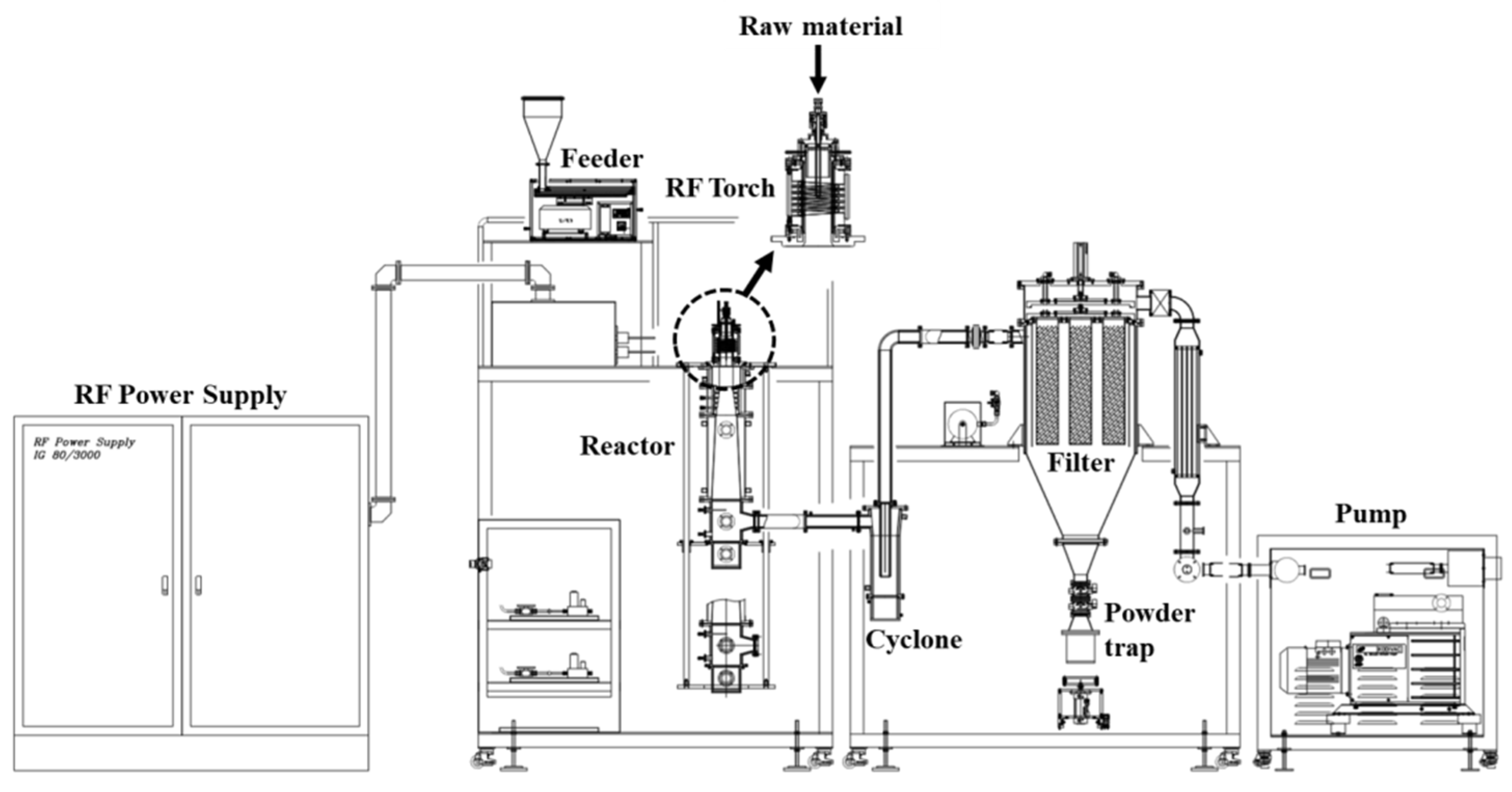

2.2. Configuration of the RF Plasma System

2.3. Synthesis of Nitrogen-Doped NTE Graphite

3. Results and Discussion

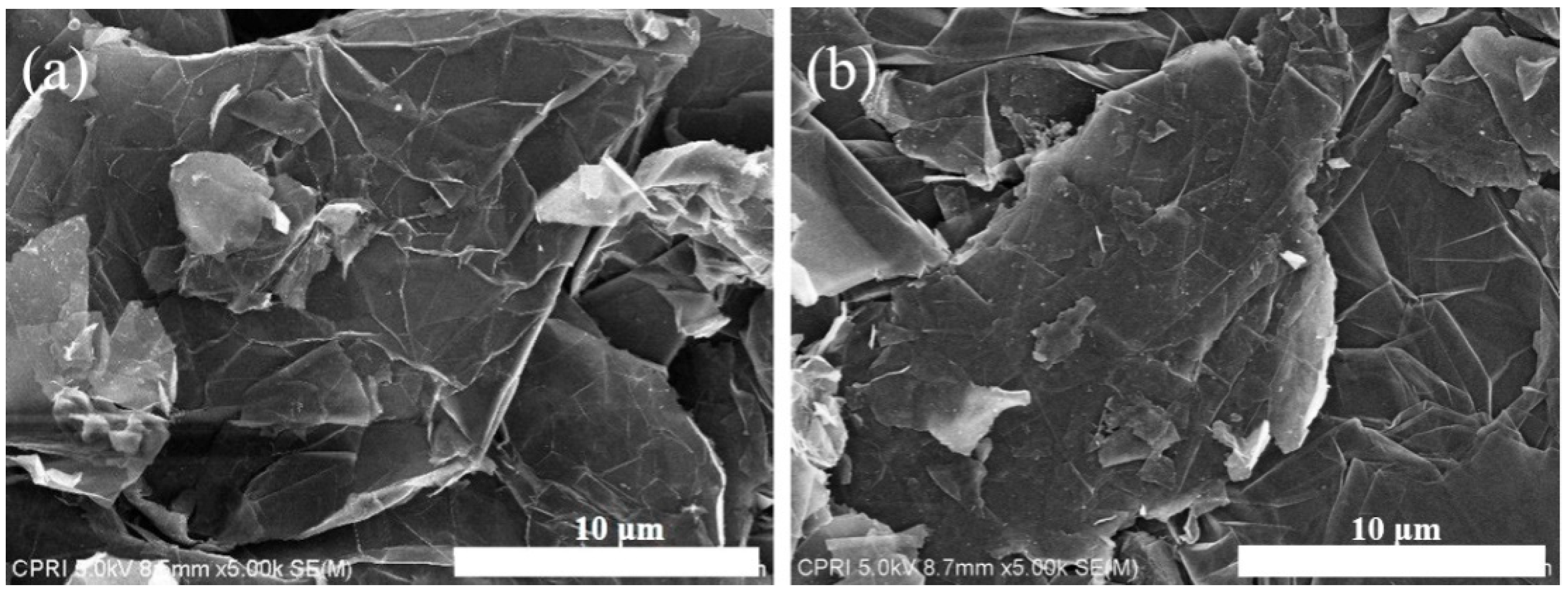

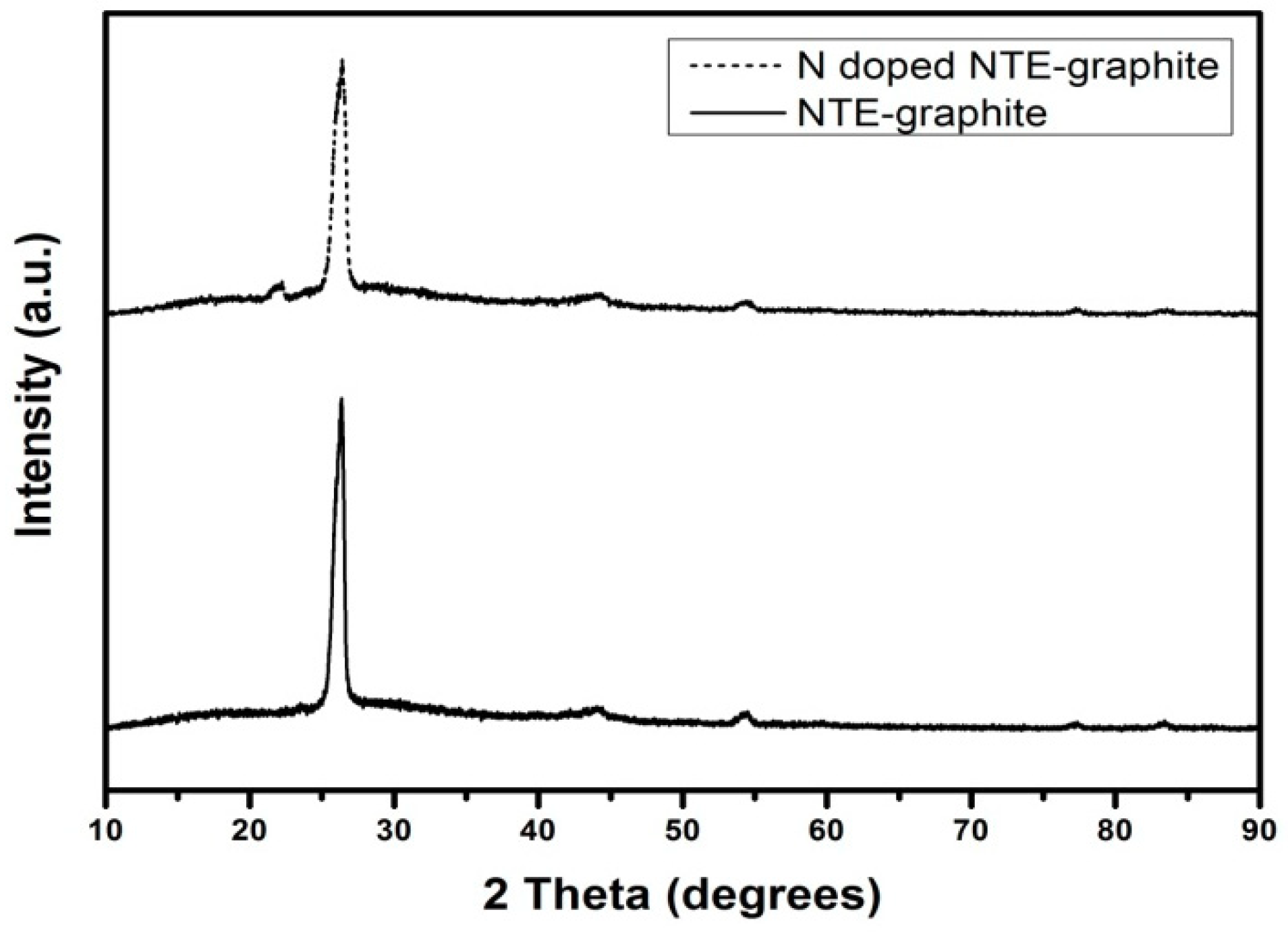

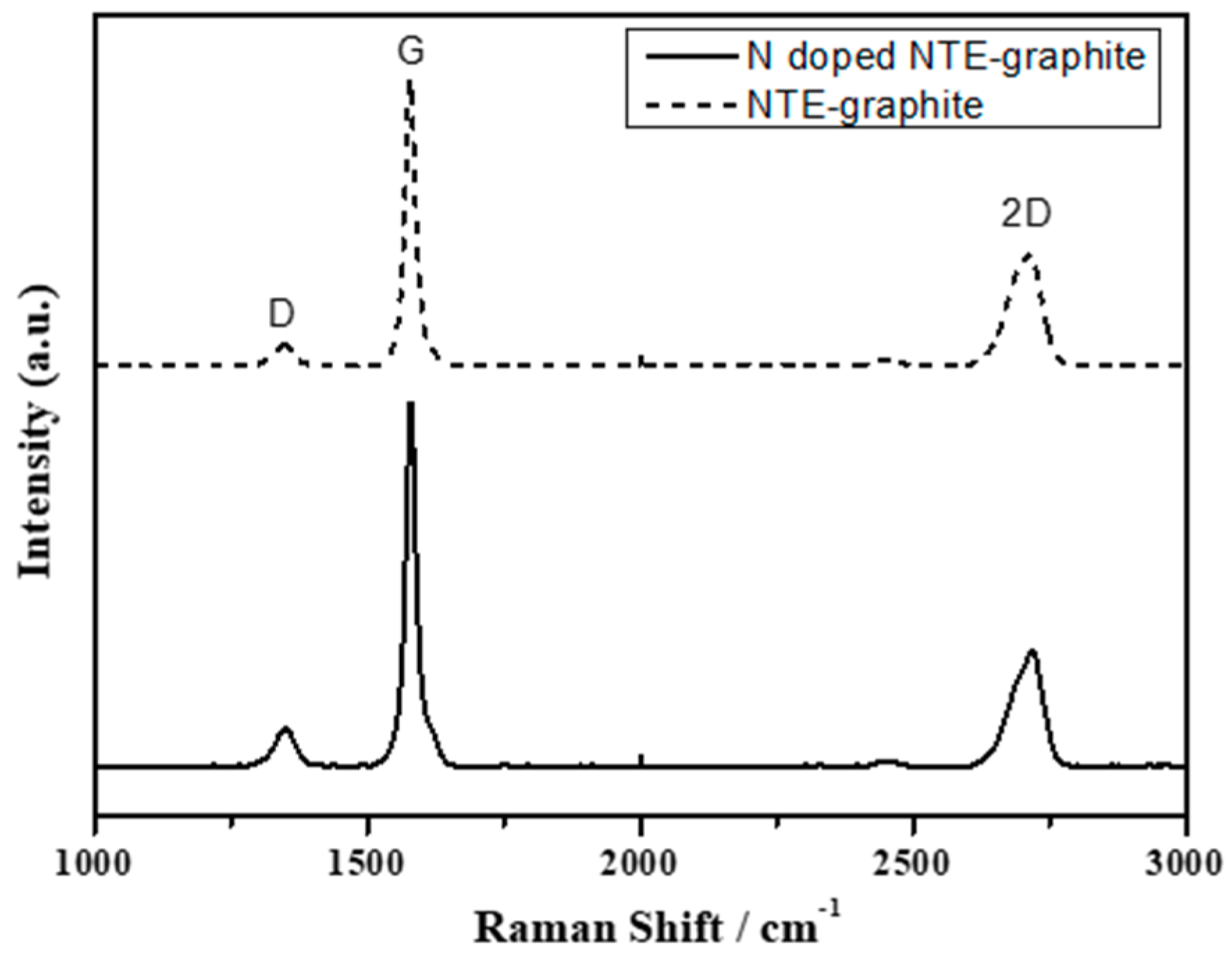

3.1. Analysis of N-Doped NTE Graphite and Untreated NTE Graphite

3.2. Electrical Performance of the N-Doped NTE Graphite Sheet

3.3. N Doping Process in the RF Thermal Plasma System

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Allen, M.J.; Tung, V.C.; Kaner, R.B. Honeycomb carbon: A review of graphene. Chem. Rev. 2010, 110, 132–145. [Google Scholar] [CrossRef] [PubMed]

- Balandin, A.A.; Ghosh, S.; Bao, W.; Calizo, I.; Teweldebrhan, D.; Miao, F.; Lau, C.N. Superior thermal conductivity of single-layer graphene. Nano Lett. 2008, 8, 902–907. [Google Scholar] [CrossRef] [PubMed]

- Stoller, M.D.; Park, S.; Zhu, Y.; An, J.; Ruoff, R.S. Graphene-based ultracapacitors. Nano Lett. 2008, 8, 3498–3502. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.S.; Zhao, Y.; Jang, H.; Lee, S.Y.; Kim, J.M.; Kim, K.S.; Ahn, J.-H.; Kim, P.; Choi, J.-Y.; Hong, B.H. Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 2009, 457, 706–710. [Google Scholar] [CrossRef] [PubMed]

- Obraztsov, A.N.; Obraztsova, E.A.; Tyurnina, A.V.; Zolotukhin, A.A. Chemical vapor deposition of thin graphite films of nanometer thickness. Carbon 2007, 45, 2017–2021. [Google Scholar] [CrossRef]

- Chae, S.J.; Güneş, F.; Kim, K.K.; Kim, E.S.; Han, G.H.; Kim, S.M.; Shin, H.; Yoon, S.-M.; Choi, J.-Y.; Park, M.H.; et al. Synthesis of large-area graphene layers on poly-nickel substrate by chemical vapor deposition: Wrinkle formation. Adv. Mater. 2009, 21, 2328–2333. [Google Scholar] [CrossRef]

- Zheng, G.; Wu, J.; Wang, W.; Pan, C. Characterizations of expanded graphite/polymer composites prepared by in situ polymerization. Carbon 2004, 42, 2839–2847. [Google Scholar] [CrossRef]

- Li, J.; Vaisman, L.; Marom, G.; Kim, J.-K. Br treated graphite nanoplatelets for improved electrical conductivity of polymer composites. Carbon 2007, 45, 744–750. [Google Scholar] [CrossRef]

- George, J.J.; Brandyopadhyay, A.; Bhowmick, A.K. New generation layered nanocomposites derived from ethylene-co-vinyl acetate and naturally occurring graphite. J. Appl. Polym. Sci. 2008, 108, 1603–1616. [Google Scholar] [CrossRef]

- Steurer, P.; Wissert, R.; Thomann, R.; Mülhaupt, R. Functionalized graphenes and thermoplastic nanocomposites based upon expanded graphite oxide. Macromol. Rapid Commun. 2009, 30, 316–327. [Google Scholar] [CrossRef]

- Boscá, A.; Pedrós, J.; Martínez, J.; Palacios, T.; Calle, F. Automatic graphene transfer system for improved material quality and efficiency. Sci. Rep. 2016, 6, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Hummers, W.S.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Staudenmaier, L. Verfahren zur darstellung der graphitsäure. Ber. Dtsch. Chem. Ges. 1898, 31, 1481–1487. [Google Scholar] [CrossRef]

- Ong, B.K.; Poh, H.L.; Chua, C.K.; Pumera, M. Graphenes prepared by hummers, staudenmaier and hofmann methods for analysis of TNT-based nitroaromatic explosives in seawater. Electroanalysis 2012, 24, 2085–2093. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Piner, R.D.; Kohlhaas, K.A.; Kleinhammes, A.; Jia, Y.; Wu, Y.; Nguyen, S.B.T.; Ruoff, R.S. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 2007, 45, 1558–1565. [Google Scholar] [CrossRef]

- Lomeda, J.R.; Doyle, C.D.; Kosynkin, D.V.; Hwang, W.; Tour, J.M. Diazonium functionalization of surfactant-wrapped chemically converted graphene sheets. J. Am. Chem. Soc. 2008, 130, 16201–16206. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.; Shi, Y.; Huang, W.; Chen, P.; Li, L.J. Electrical detection of DNA hybridization with single-base specificity using transistors based on CVD-grown graphene sheets. Adv. Mater. 2010, 22, 1649–1653. [Google Scholar] [CrossRef]

- Suk, J.W.; Kitt, A.; Magnuson, C.W.; Hao, Y.; Ahmed, S.; An, J.; Swan, A.K.; Goldberg, B.B.; Ruoff, R.S. Transfer of CVD-grown monolayer graphene onto arbitrary substrates. ACS Nano 2011, 5, 6916–6924. [Google Scholar] [CrossRef]

- Wang, G.; Yang, J.; Park, J.; Gou, X.; Wang, B.; Liu, H.; Yao, J. Facile synthesis and supercapacitor properties of graphene nanosheets. J. Phys. Chem. 2008, 112, 8192–8195. [Google Scholar]

- Seo, J.H.; Kim, J.S.; Lee, M.Y.; Ju, W.T.; Nam, I.T. Direct synthesis of nano-sized glass powders with spherical shape by RF (radio frequency) thermal plasma. Thin Solid Film. 2011, 519, 7111–7115. [Google Scholar] [CrossRef]

- Oh, S.-M.; Ishigaki, T. Preparation of pure rutile and anatase TiO2 nanopowders using RF thermal plasma. Thin Solid Film. 2004, 457, 186–191. [Google Scholar] [CrossRef]

- Ko, S.-M.; Koo, S.-M.; Cho, W.-S.; Hwnag, K.-T.; Kim, J.-H. Synthesis of SiC nano-powder from organic precursors using RF inductively coupled thermal plasma. Ceram. Int. 2012, 38, 1959–1963. [Google Scholar] [CrossRef]

- Song, S.-K.; Son, B.; Kim, B.; Lee, M.; Sin, M.; Choi, S.; Lee, K.-H.; Kim, S.-I. Development of 80 kW RF thermal plasma torch system for mass production and research of Si nano-powder manufacturing process. J. Korean Vac. Soc. 2013, 22, 66–78. [Google Scholar] [CrossRef]

- Liu, J.; Takeshi, D.; Orejon, D.; Sasaki, K.; Lyth, S.M. Defective nitrogen-doped graphene foam: A metal-free, non-precious electrocatalyst for the oxygen reduction reaction in acid. J. Electrochem. Soc. 2014, 161, F544–F550. [Google Scholar] [CrossRef]

- Cai, M.; Thorpe, D.; Adamson, D.H.; Schniepp, H.C. Methods of graphite exfoliation. J. Mater. Chem. 2012, 22, 24992–25002. [Google Scholar] [CrossRef]

- Mou, Z.; Chen, X.; Du, Y.; Wang, X.; Yang, P.; Wang, S. Forming mechanism of nitrogen doped graphene prepared by thermal solid-state reaction of graphite oxide and urea. Appl. Surf. Sci. 2011, 258, 1704–1710. [Google Scholar] [CrossRef]

- Wang, H.; Maiyalagan, T.; Wang, X. Review on recent progress in nitrogen-doped graphene: Synthesis, characterization, and its potential applications. ACS Catal. 2012, 2, 781–794. [Google Scholar] [CrossRef]

- Granzier-Nakajima, T.; Fujisawa, K.; Anil, V.; Terrones, M.; Yeh, Y.-T. Controlling nitrogen doping in graphene with atomic precision: Synthesis and characterization. Nanomaterials 2019, 9, 425. [Google Scholar] [CrossRef] [PubMed]

- Park, H.J.; Meyer, J.; Roth, S.; Skákalová, V. Growth and properties of few-layer graphene prepared by chemical vapor deposition. Carbon 2010, 48, 1088–1094. [Google Scholar] [CrossRef]

- Kim, K.K.; Reina, A.; Shi, Y.; Park, H.; Li, L.-J.; Lee, Y.H.; Kong, J. Enhancing the conductivity of transparent graphene films via doping. Nanotechnology 2010, 21, 285205. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Wang, L.; Tian, C.; Tan, T.; Xie, Y.; Shi, K.; Li, M.; Fu, H. Nitrogen-doped graphene with high nitrogen level via a one-step hydrothermal reaction of graphene oxide with urea for superior capacitive energy storage. RSC Adv. 2012, 2, 4498–4506. [Google Scholar] [CrossRef]

- Bernhard, A.M.; Peitz, D.; Elsener, M.; Schildhauer, T.; Kröcher, O. Catalytic urea hydrolysis in the selective catalytic reduction of NOx: Catalyst screening and kinetics on anatase TiO2 and ZrO2. Catal. Sci. Technol. 2013, 3, 942–951. [Google Scholar] [CrossRef]

| Plate Power | Plasma Forming Gas | Raw Material | Feeding Rate of Raw Material | Carrier Gas | |

|---|---|---|---|---|---|

| Central Gas | Sheath Gas | ||||

| 30 kW | 30 L/min Ar | 50 L/min Ar | Mixed powder 1 of NTE graphite and CO(NH2)2 | 1 kg/h | 10 L/min Ar |

| Materials | Elements (wt%) | |||

|---|---|---|---|---|

| C | N | H | S | |

| Untreated NTE graphite | 91.73 | 0.83 | 0.29 | 0.59 |

| N-doped NTE graphite | 90.85 | 3.99 | 0.48 | - |

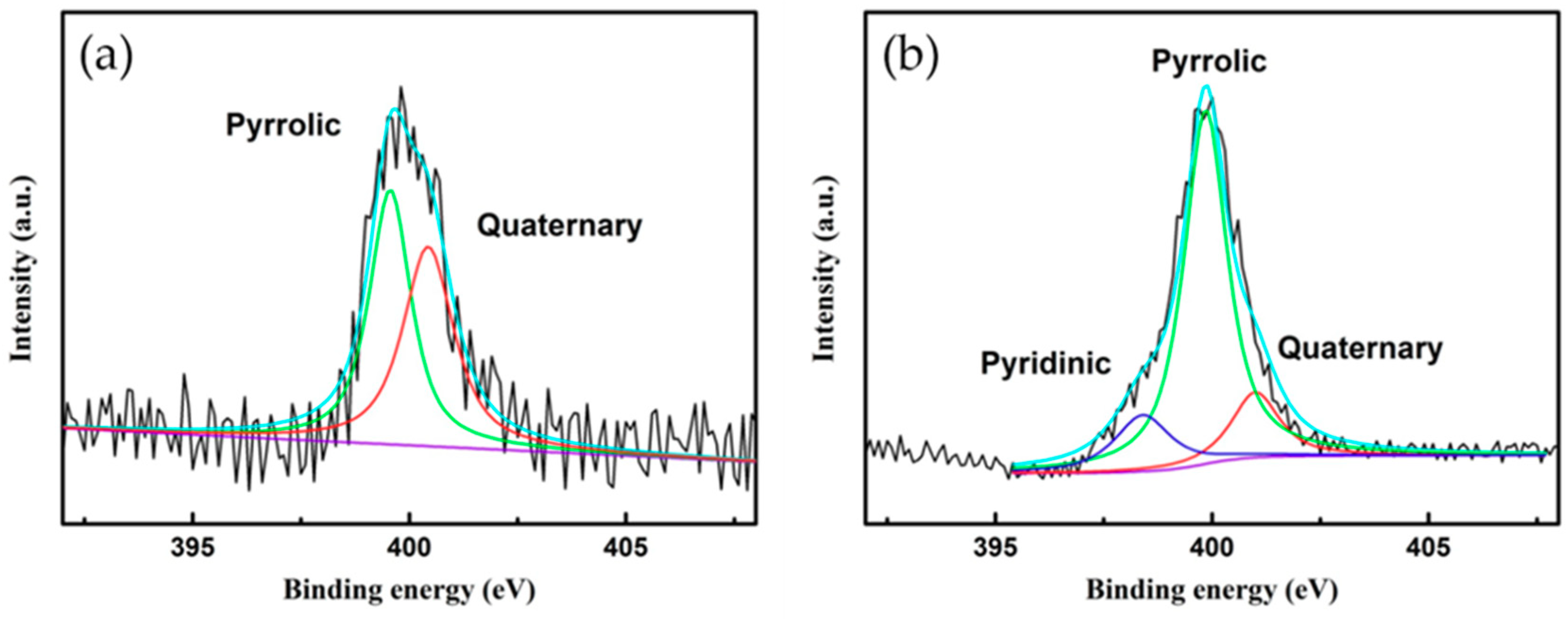

| Materials | Bonding Structure | Total | ||

|---|---|---|---|---|

| Pyrrolic | Pyridinic | Quaternary | ||

| Untreated NTE graphite | 0.18 | - | 0.18 | 0.36 |

| N-doped NTE graphite | 0.26 | 1.28 | 0.26 | 1.79 |

| Materials | Sheet Resistance (Rs, mΩ/sq) | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Untreated NTE Graphite + Hot PRESS | 80.34 | 80.7 | 75.37 | 74.88 | 77.36 | 79.51 | 71.17 | 72.33 |

| N-doped NTE Graphite + Hot PRESS | 58.63 | 62.56 | 65 | 74.48 | 67.34 | 62.23 | 71.68 | 64.48 |

| Untreated NTE Graphite + Roll Process | 78.77 | 75.41 | 74.32 | 76.09 | 79.55 | 80.92 | 72.33 | 82.93 |

| N-doped NTE Graphite + Roll Process | 58.21 | 62.97 | 59.88 | 63.73 | 63.73 | 64.98 | 68.36 | 62.43 |

| Materials | Average Rs (mΩ/sq) | Thickness (μm) | Calibrated Rs (mΩ/sq at 100 μm) | Resistivity (Ω m) | ||||

| Untreated NTE Graphite + Hot PRESS | 76.46 | 113 | 86.40 | 8.63 × 10−6 | ||||

| N-doped NTE Graphite + Hot PRESS | 65.80 | 115.8 | 76.20 | 7.61 × 10−6 | ||||

| Untreated NTE Graphite + Roll Process | 77.54 | 111 | 86.07 | 8.60 × 10−6 | ||||

| N-doped NTE Graphite + Roll Process | 63.04 | 107.5 | 67.76 | 6.77 × 10−6 | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, B.-K.; Lee, K.-H.; Kim, T.-H.; Shin, M.-S.; Choi, S.-Y.; Cho, G. Purification and Nitrogen Doping of Nanothin Exfoliated Graphite Through RF Thermal Plasma Treatment. Nanomaterials 2019, 9, 995. https://doi.org/10.3390/nano9070995

Son B-K, Lee K-H, Kim T-H, Shin M-S, Choi S-Y, Cho G. Purification and Nitrogen Doping of Nanothin Exfoliated Graphite Through RF Thermal Plasma Treatment. Nanomaterials. 2019; 9(7):995. https://doi.org/10.3390/nano9070995

Chicago/Turabian StyleSon, Byung-Koo, Kyu-Hang Lee, Tae-Hee Kim, Myung-Sun Shin, Sun-Yong Choi, and Guangsup Cho. 2019. "Purification and Nitrogen Doping of Nanothin Exfoliated Graphite Through RF Thermal Plasma Treatment" Nanomaterials 9, no. 7: 995. https://doi.org/10.3390/nano9070995

APA StyleSon, B.-K., Lee, K.-H., Kim, T.-H., Shin, M.-S., Choi, S.-Y., & Cho, G. (2019). Purification and Nitrogen Doping of Nanothin Exfoliated Graphite Through RF Thermal Plasma Treatment. Nanomaterials, 9(7), 995. https://doi.org/10.3390/nano9070995