Slicing Ceramics on Material Removed by a Single Abrasive Particle

Abstract

1. Introduction

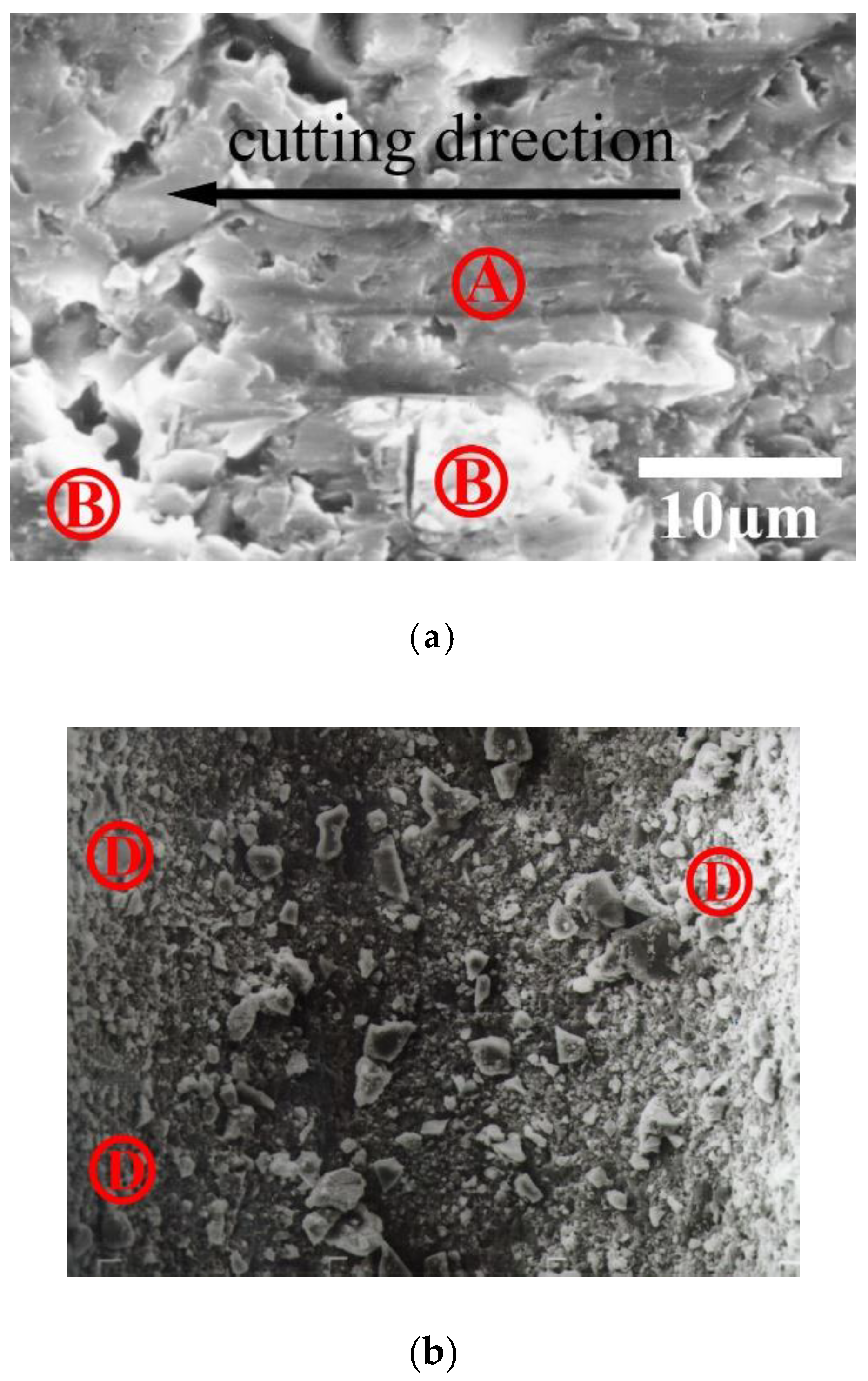

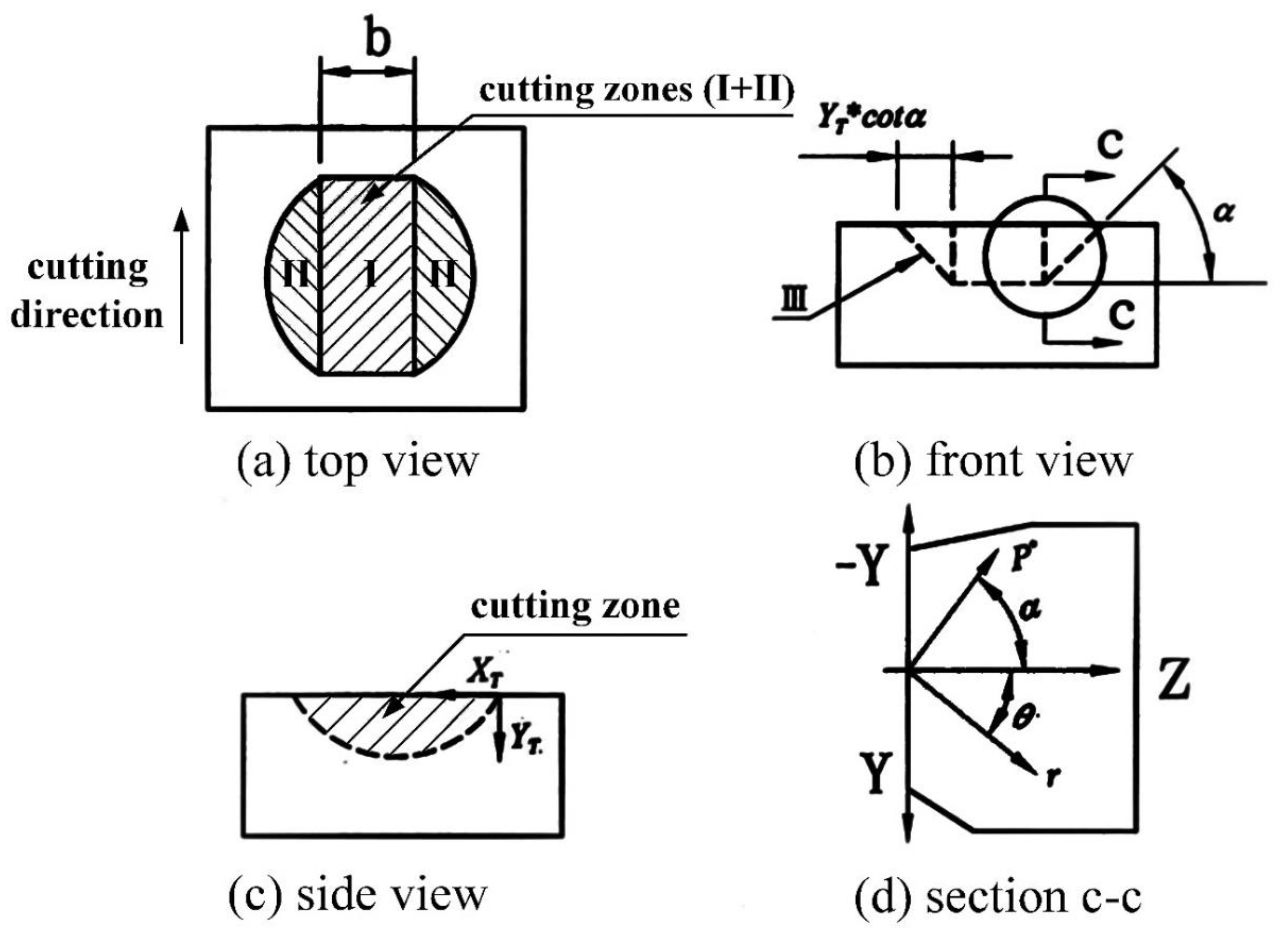

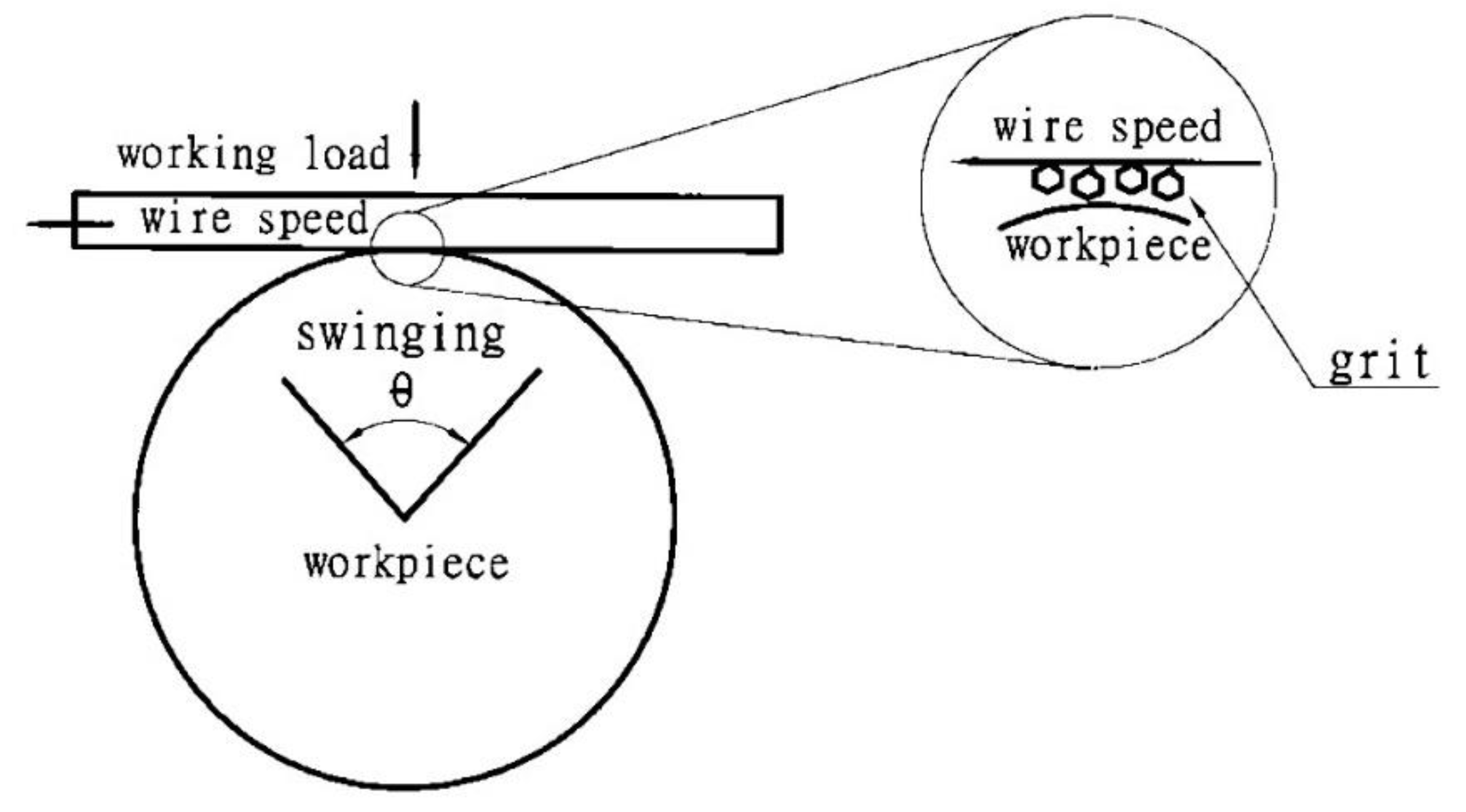

2. Theoretical Derivation Model

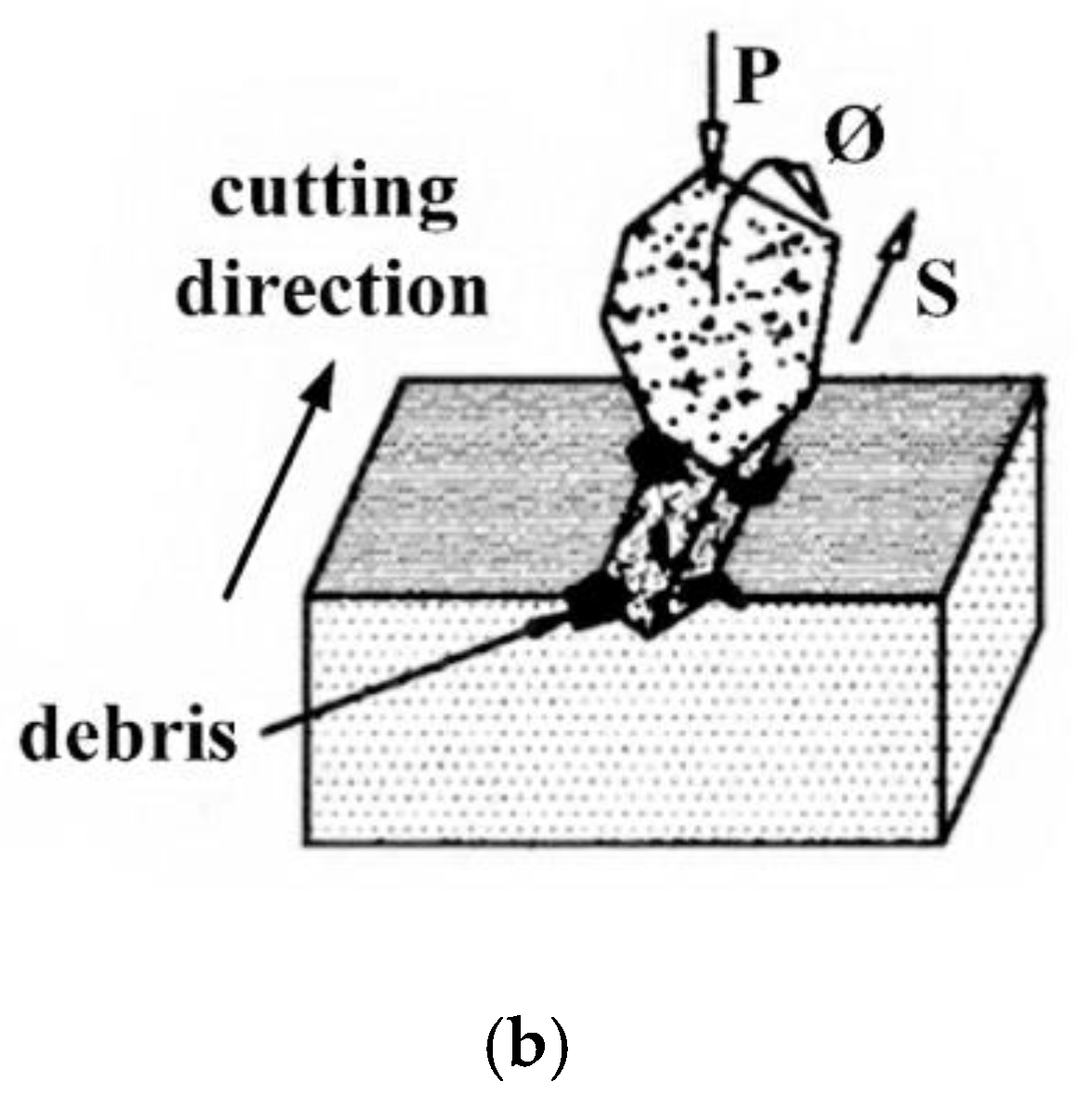

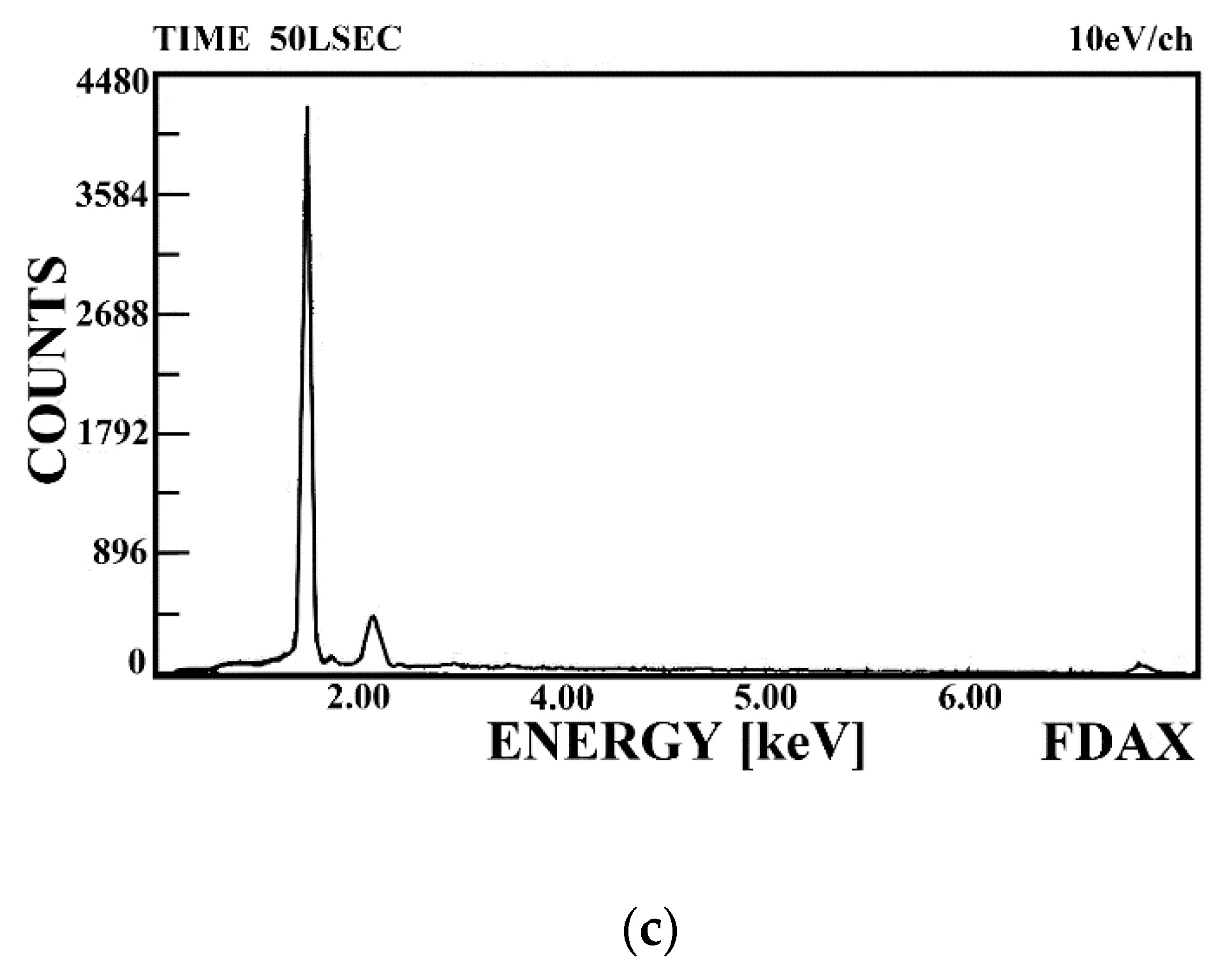

2.1. Removal Mechanism of Hard-Brittle Material

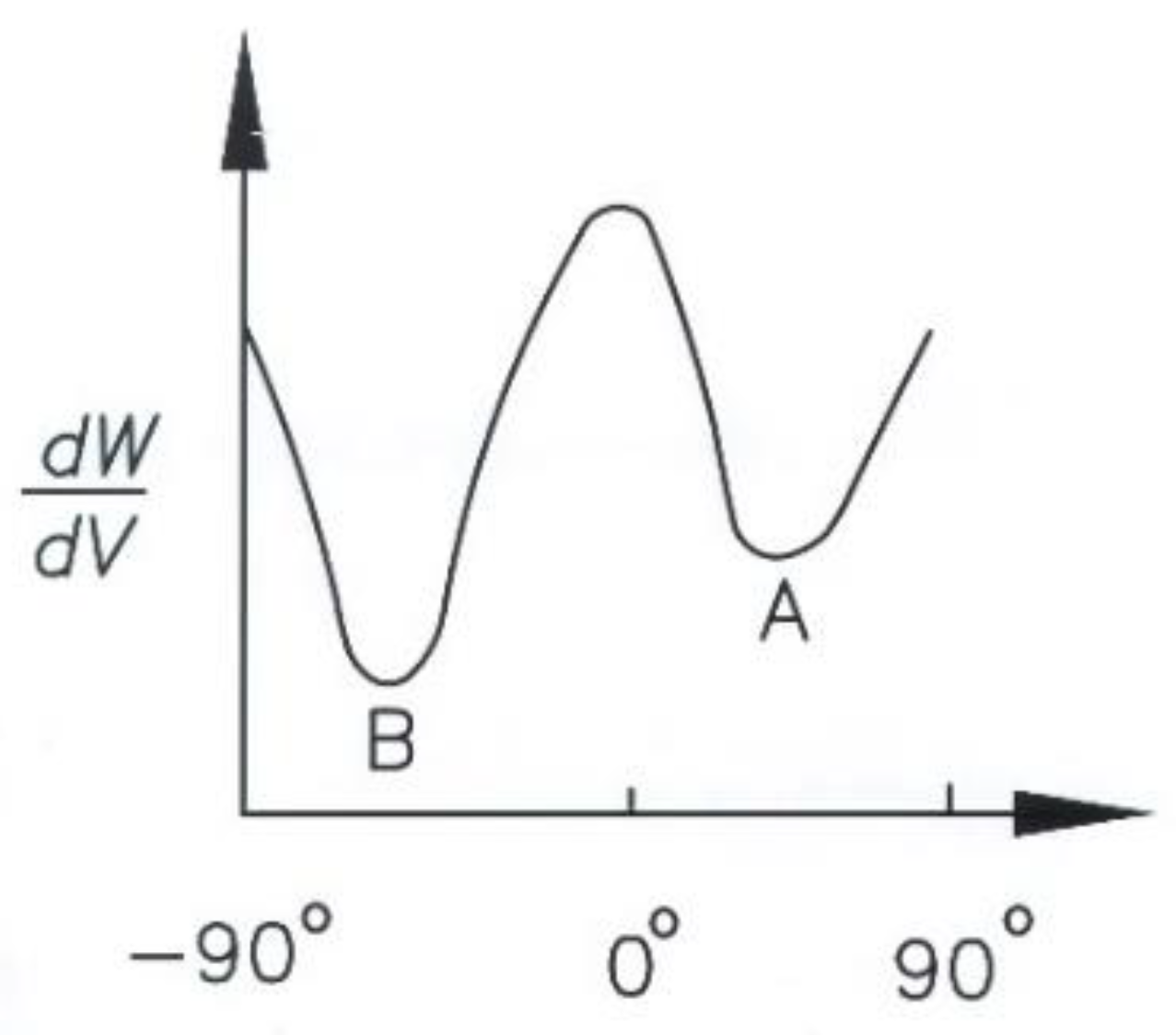

2.2. Brittle Fracture

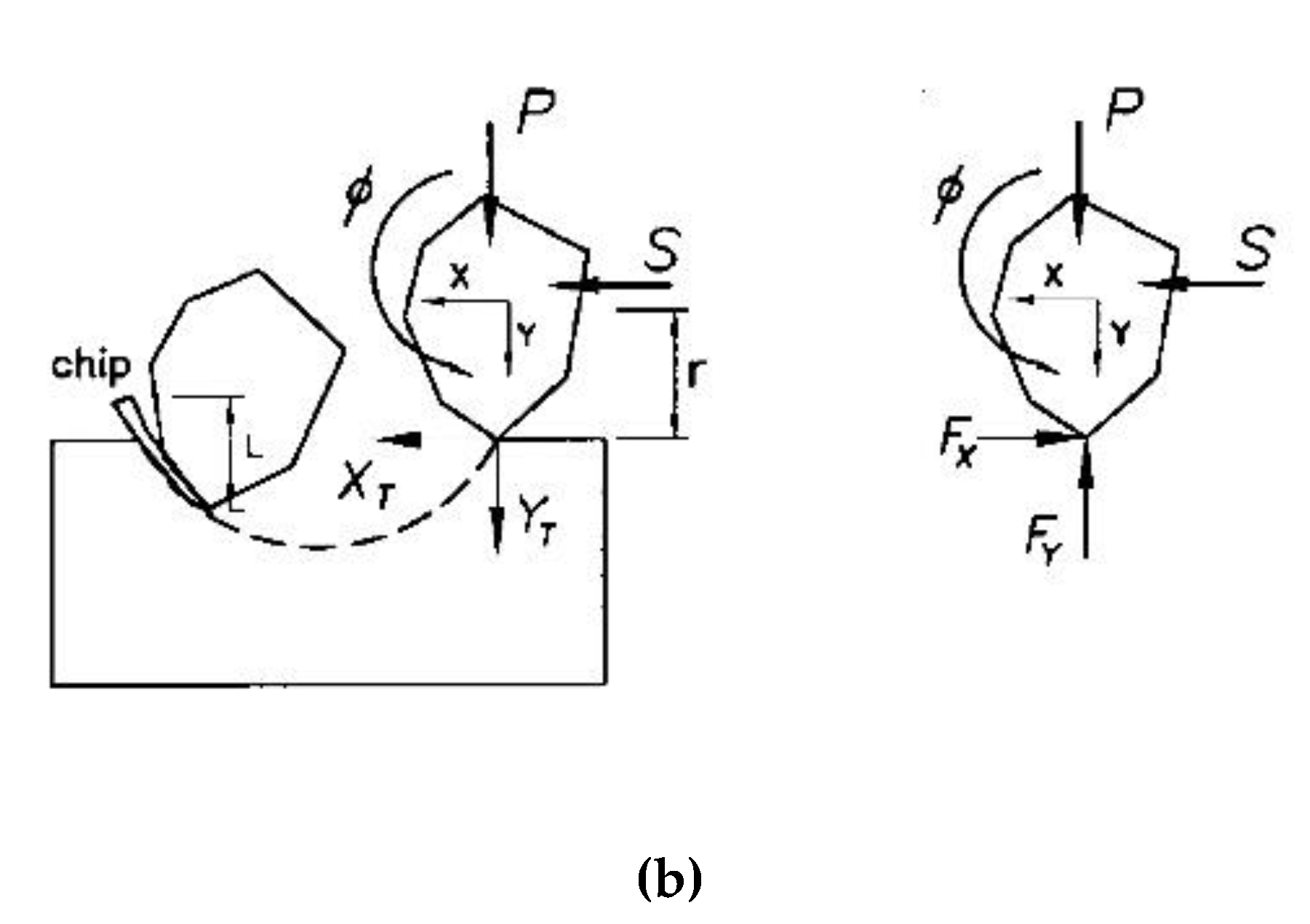

2.3. Plastic Deformation

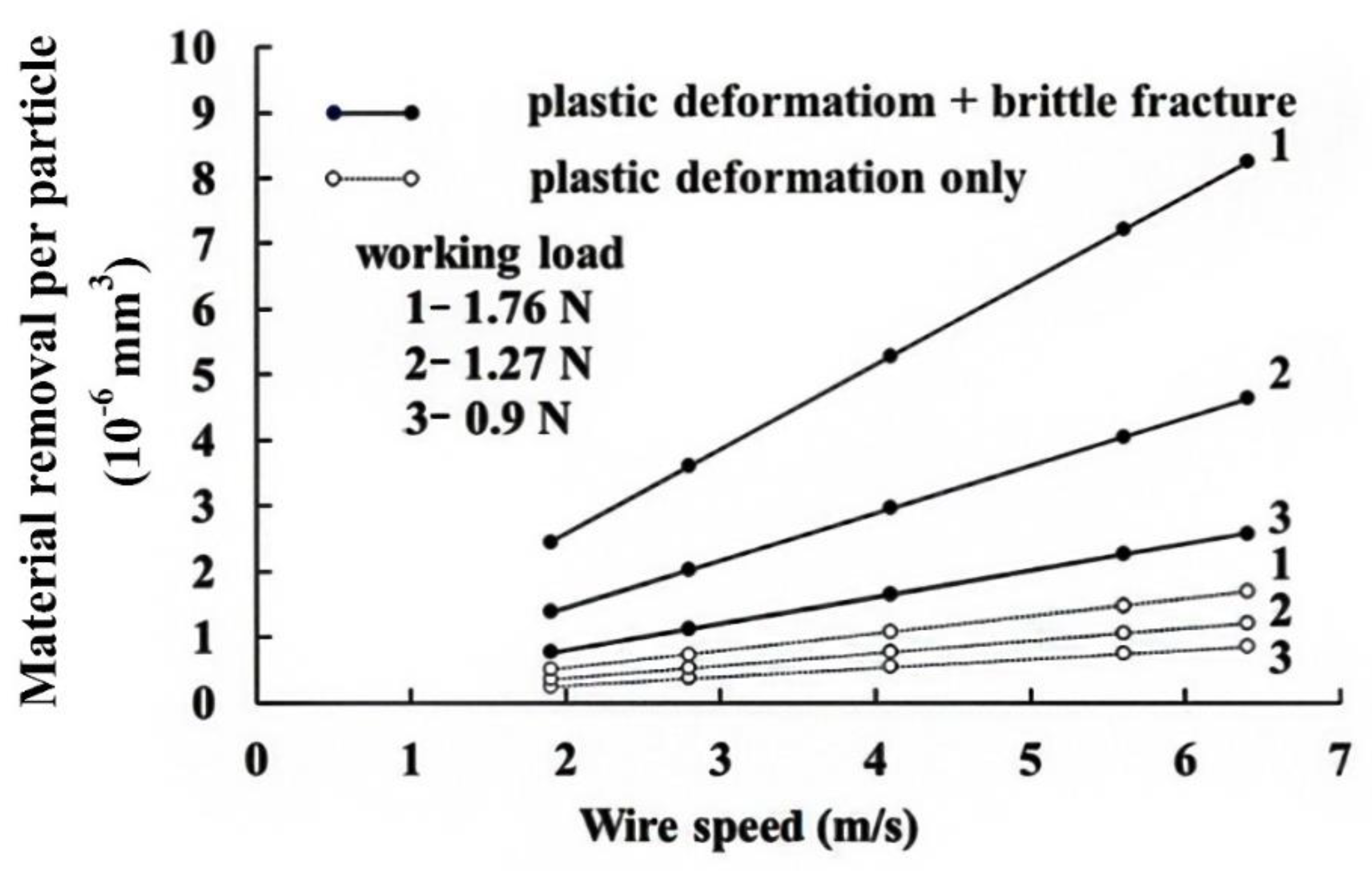

2.4. Material Removed by an Abrasive Particle

3. Experimental Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Total area of the machining zone | |

| b | Cutting width for a single abrasive particle |

| Line width | |

| m | Mass of the abrasive particle |

| Total number of particles | |

| Total number of machining abrasives per unit time | |

| r | Average particle radius |

| Kerf width | |

| Projection area of the contact between the abrasive particle and the chip | |

| Cutting area per unit time | |

| Gap coefficient | |

| Wire speed coefficient | |

| Diameter of a single abrasive particle | |

| Modulus of elasticity | |

| Horizontal cutting force for the tip of an abrasive particle | |

| Vertical cutting force for the tip of an abrasive particle | |

| I | Moment of inertia of a particle about its center of gravity |

| Chip length | |

| Line contact length | |

| Centroid moment | |

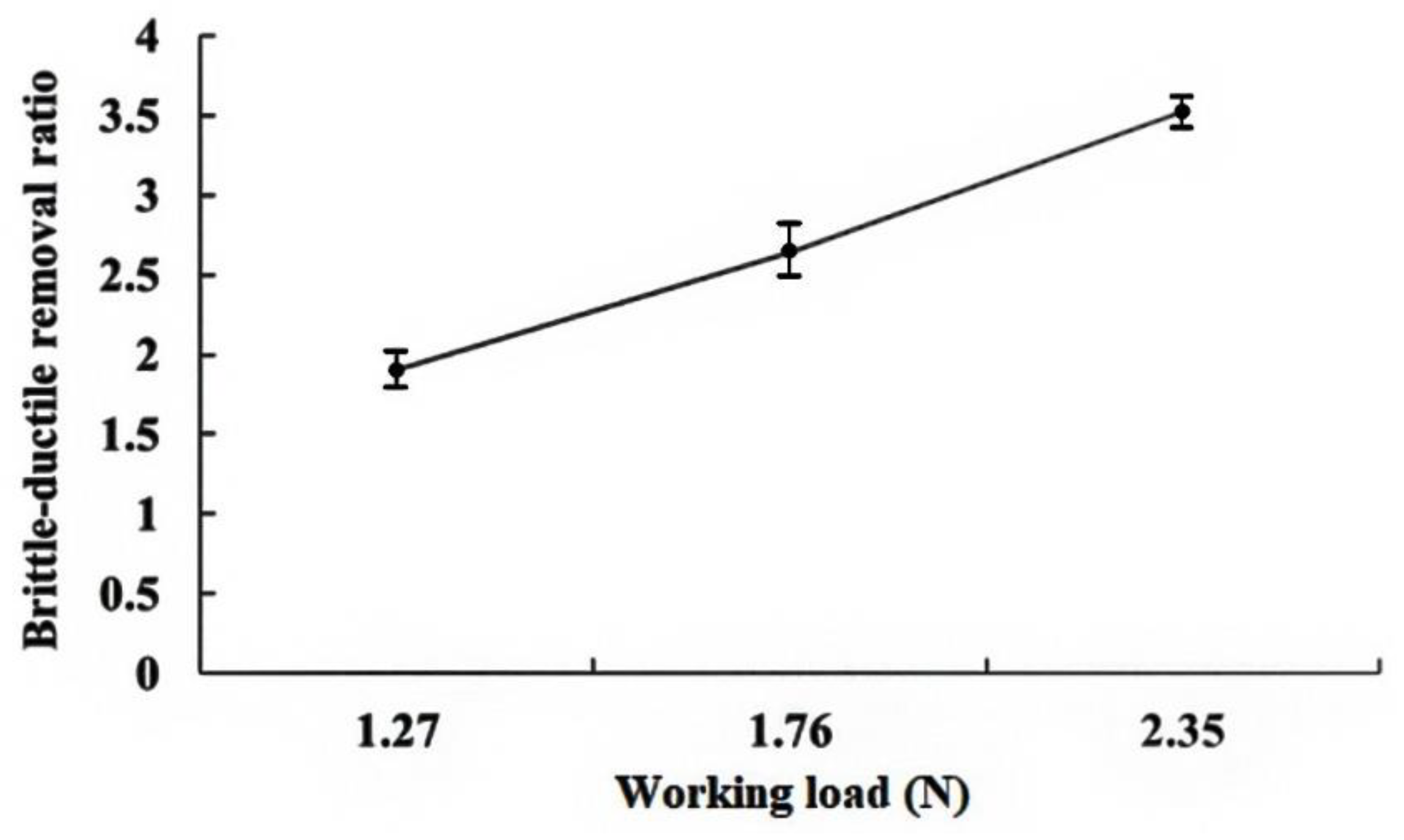

| Working load | |

| P* | Minimum threshold load for lateral cracking |

| Wire speed | |

| Volume of material removed by an abrasive particle | |

| Total volume removed per unit of time | |

| Total energy stored in an element | |

| XT, YT | Locus left by the tip of an abrasive particle cutting into the material surface |

| Strain vector | |

| σ | Plastic flow stress |

| Stress vector | |

| Stress in the Z plane | |

| Ultimate material strength | |

| Coefficient of friction | |

| Poisson’s ratio | |

| Vibration angle | |

| Angle at which occurs | |

| ρ | Density of a single abrasive particle |

References

- Liedke, T.; Kuna, M. Discrete element simulation of micromechanical removal processes during wire sawing. Wear 2013, 304, 77–82. [Google Scholar] [CrossRef]

- Li, X.; Gao, Y.; Ge, P.; Zhang, L.; Bi, W. The effect of cut depth and distribution for abrasives on wafer surface morphology in diamond wire sawing of PV polycrystalline silicon. Mater. Sci. Semicond. Process. 2019, 91, 316–326. [Google Scholar] [CrossRef]

- Xiao, H.; Wang, H.; Yu, N.; Liang, R.; Tong, Z.; Chen, Z.; Wang, J. Evaluation of fixed abrasive diamond wire sawing induced subsurface damage of solar silicon wafers. J. Mater. Process. Technol. 2019, 273, 116267. [Google Scholar] [CrossRef]

- Bidiville, A.; Wasmer, K.; Van Der Meer, M.; Ballif, C. Wire-sawing processes: parametrical study and modeling. Sol. Energy Mater. Sol. Cells 2015, 132, 392–402. [Google Scholar] [CrossRef]

- Zhang, B.; Howes, T.D. Material-Removal Mechanisms in Grinding Ceramics. CIRP Ann. 1994, 43, 305–308. [Google Scholar] [CrossRef]

- Buttery, T.C.; Archard, J.F. Grinding and Abrasive Wear. Proc. Inst. Mech. Eng. 1970, 185, 537–551. [Google Scholar] [CrossRef]

- Finnie, I.; McFadden, D. On the velocity dependence of the erosion of ductile metals by solid particles at low angles of incidence. Wear 1978, 48, 181–190. [Google Scholar] [CrossRef]

- Evans, A.G. Impact damage in ceramic. In Fracture Mechanics of Ceramics; Springer: Boston, MA, USA, 1978; pp. 303–330. [Google Scholar]

- Wang, Z.Y.; Rajurkar, K.P. Dynamic Analysis of the Ultrasonic Machining Process. J. Manuf. Sci. Eng. 1996, 118, 376–381. [Google Scholar] [CrossRef]

- Turchetta, S.; Sorrentino, L.; Bellini, C. A method to optimize the diamond wire cutting process. Diam. Relat. Mater. 2017, 71, 90–97. [Google Scholar] [CrossRef]

- Yilmazkaya, E.; Ozcelik, Y. The Effects of Operational Parameters on a Mono-wire Cutting System: Efficiency in Marble Processing. Rock Mech. Rock Eng. 2015, 49, 523–539. [Google Scholar] [CrossRef]

- Liedke, T.; Kuna, M. A macroscopic mechanical model of the wire sawing process. Int. J. Mach. Tools Manuf. 2011, 51, 711–720. [Google Scholar] [CrossRef]

- Liu, T.; Ge, P.; Bi, W.; Gao, Y. Subsurface crack damage in silicon wafers induced by resin bonded diamond wire sawing. Mater. Sci. Semicond. Process. 2017, 57, 147–156. [Google Scholar] [CrossRef]

- Wang, P.; Ge, P.; Gao, Y.; Bi, W. Prediction of sawing force for single-crystal silicon carbide with fixed abrasive diamond wire saw. Mater. Sci. Semicond. Process. 2017, 63, 25–32. [Google Scholar] [CrossRef]

- Wang, P.; Ge, P.; Ge, M.; Bi, W.; Meng, J. Material removal mechanism and crack propagation in single scratch and double scratch tests of single-crystal silicon carbide by abrasives on wire saw. Ceram. Int. 2019, 45, 384–393. [Google Scholar] [CrossRef]

- Su, Y.-T.; Wang, S.-Y.; Hsiau, J.-S. On machining rate of hydrodynamic polishing process. Wear 1995, 188, 77–87. [Google Scholar] [CrossRef]

- Bifano, T.G.; Dow, T.A.; Scattergood, R.O. Ductile-Regime Grinding: A New Technology for Machining Brittle Materials. J. Eng. Ind. 1991, 113, 184–189. [Google Scholar] [CrossRef]

- Malkin, S.; Hwang, T. Grinding Mechanisms for Ceramics. CIRP Ann. 1996, 45, 569–580. [Google Scholar] [CrossRef]

- Chen, S.Y.; Farris, T.N.; Chandrasekar, S. Sliding Microindentation Fracture of Brittle Materials. Tribol. Trans. 1991, 34, 161–168. [Google Scholar] [CrossRef]

- Sih, G.C. Mechanics of Fracture Initiation and Propagation; Lehigh University: Bethlehem, PA, USA, 1991. [Google Scholar]

- Chao, C.; Chang, R. Crack trajectories influenced by mechanical and thermal disturbance in anisotropic material. Theor. Appl. Fract. Mech. 1992, 17, 177–187. [Google Scholar] [CrossRef]

- Timoshenko, S.P.; Goodier, J.N. Theory of Elasticity; McGraw-Hill: New York, NY, USA, 1970. [Google Scholar]

- Krell, A.; Klaffke, D. Effect of grain size and Humidity on fretting wear in fine-grained alumina, Al2O3/Tic, and Zirconi. J. Am. Ceram. Soc. 1996, 79, 1139–1146. [Google Scholar] [CrossRef]

- Suwabe, H.; Ishikawa, K.I.; Miyashita, T. A study of the processing characteristics of a vibration multi-wire saw-regarding the effects of slurry composition. Int. Conf. Precis. Eng. 1996, 1, 253–256. [Google Scholar]

- Bower, A.; Fleck, N. Brittle fracture under a sliding line contact. J. Mech. Phys. Solids 1994, 42, 1375–1396. [Google Scholar] [CrossRef]

| Item | Specification |

|---|---|

| Workpiece (Diameter) | Al2O3 (ϕ8 mm) |

| Slurry contents | SiC + Water |

| Grains (Diameter) | GC# 600 (27 µm) |

| Concentration (wt.%) | 10 |

| Wire diameter (mm) | ϕ0.24 ± 0.05 (Stainless wire) |

| Wire tension (N) | 18 |

| Wire speed (m/s) | 4.1, 5.6 and 6.4 |

| Working load (N) | 0.60, 0.90, 1.12, 1.27, 1.76 and 1.96 |

| Frequency (Hz) | 0.8 |

| Vibration angle (θ) | 60° |

| P (N) | S (m/s) | V | NX | NY | |

|---|---|---|---|---|---|

| a | 0.6 | 4.1 | 1.31 × 10−7 | 2.325 | 3.550 |

| 0.6 | 5.6 | 1.41 × 10−7 | 2.325 | 2.791 | |

| 0.6 | 6.4 | 1.10 × 10−7 | 2.325 | 2.428 | |

| b | 0.9 | 4.1 | 2.04 × 10−7 | 2.990 | 3.680 |

| 0.9 | 5.6 | 2.08 × 10−7 | 2.990 | 2.750 | |

| 0.9 | 6.4 | 2.14 × 10−7 | 2.990 | 2.480 | |

| c | 1.12 | 4.1 | 2.69 × 10−7 | 3.474 | 3.900 |

| 1.12 | 5.6 | 2.76 × 10−7 | 3.474 | 2.940 | |

| 1.12 | 6.4 | 2.72 × 10−7 | 3.474 | 2.610 | |

| d | 1.27 | 4.1 | 3.20 × 10−7 | 3.805 | 4.100 |

| 1.27 | 5.6 | 3.40 × 10−7 | 3.805 | 3.197 | |

| 1.27 | 6.4 | 3.47 × 10−7 | 3.805 | 2.850 | |

| e | 1.76 | 4.1 | 5.00 × 10−7 | 4.887 | 4.570 |

| 1.76 | 5.6 | 5.10 × 10−7 | 4.887 | 3.880 | |

| 1.76 | 6.4 | 5.10 × 10−7 | 4.887 | 3.040 | |

| f | 1.96 | 4.1 | 5.70 × 10−7 | 5.330 | 4.710 |

| 1.96 | 5.6 | 6.30 × 10−7 | 5.330 | 4.010 | |

| 1.96 | 6.4 | 6.25 × 10−7 | 5.330 | 3.270 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, Y.-Y.; Wu, M.-C.; Liao, Y.-S.; Tsao, C.-C.; Hsu, C.-Y. Slicing Ceramics on Material Removed by a Single Abrasive Particle. Materials 2020, 13, 4324. https://doi.org/10.3390/ma13194324

Tsai Y-Y, Wu M-C, Liao Y-S, Tsao C-C, Hsu C-Y. Slicing Ceramics on Material Removed by a Single Abrasive Particle. Materials. 2020; 13(19):4324. https://doi.org/10.3390/ma13194324

Chicago/Turabian StyleTsai, Yao-Yang, Ming-Chang Wu, Yunn-Shiuan Liao, Chung-Chen Tsao, and Chun-Yao Hsu. 2020. "Slicing Ceramics on Material Removed by a Single Abrasive Particle" Materials 13, no. 19: 4324. https://doi.org/10.3390/ma13194324

APA StyleTsai, Y.-Y., Wu, M.-C., Liao, Y.-S., Tsao, C.-C., & Hsu, C.-Y. (2020). Slicing Ceramics on Material Removed by a Single Abrasive Particle. Materials, 13(19), 4324. https://doi.org/10.3390/ma13194324