Rolling Bearing Fault Diagnosis Using Hybrid Neural Network with Principal Component Analysis

Abstract

:1. Introduction

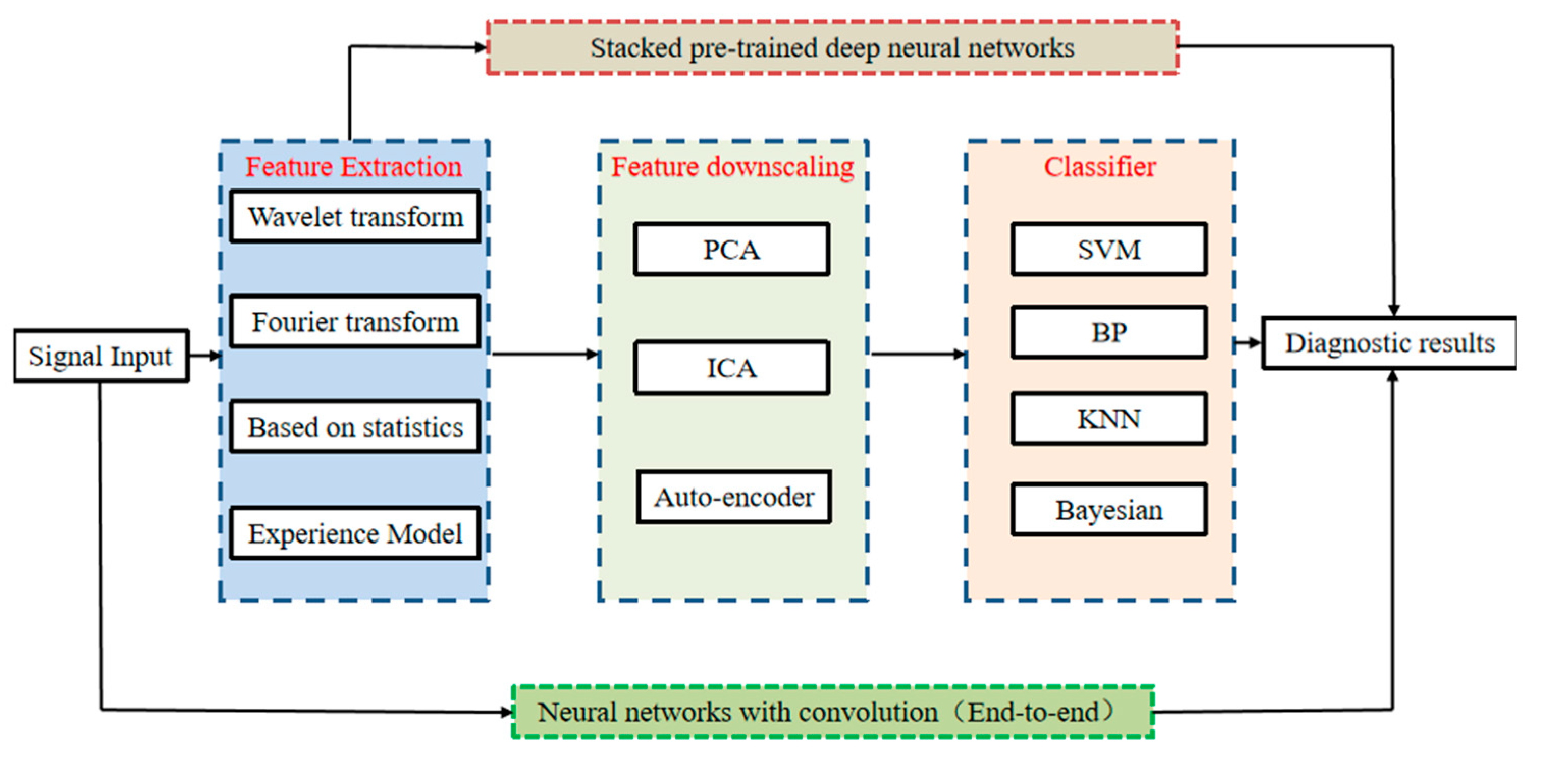

2. Related Works

3. Introduction to Theory and Methodology

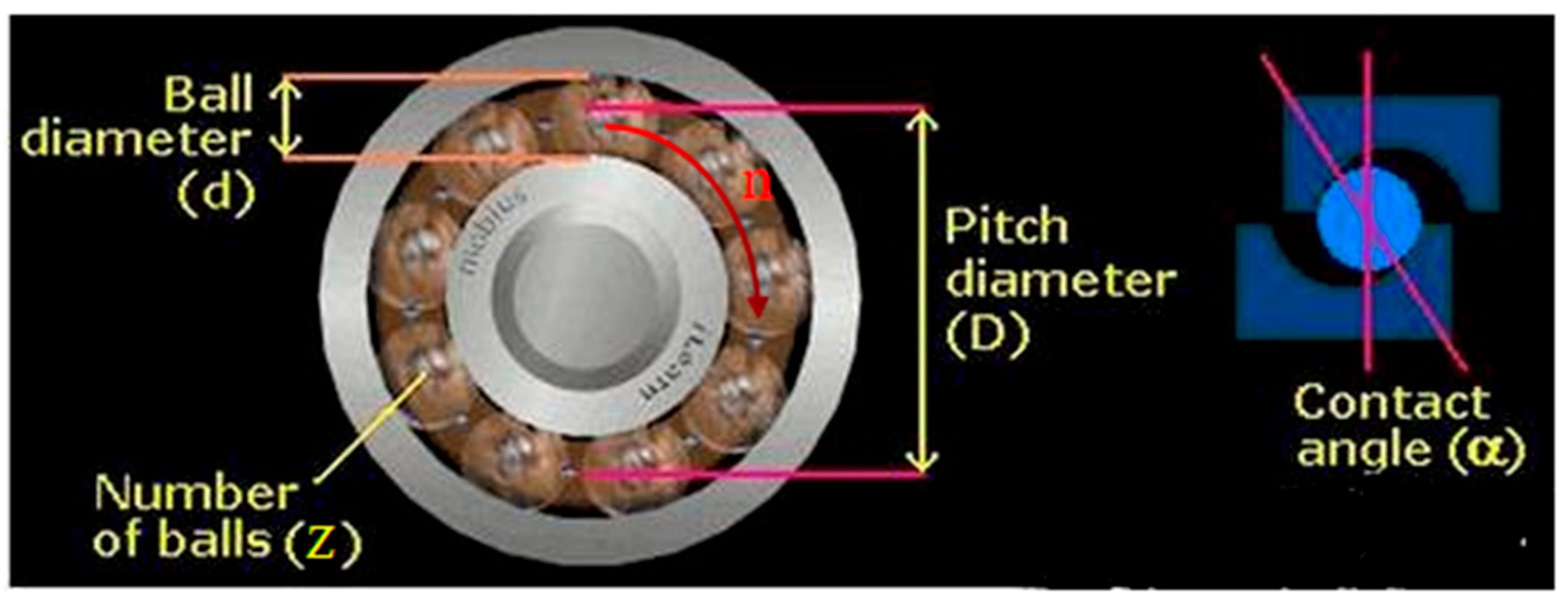

3.1. Level I: Fault Generation of Rolling Bearings

3.2. Level II: Fault Diagnosis Methods

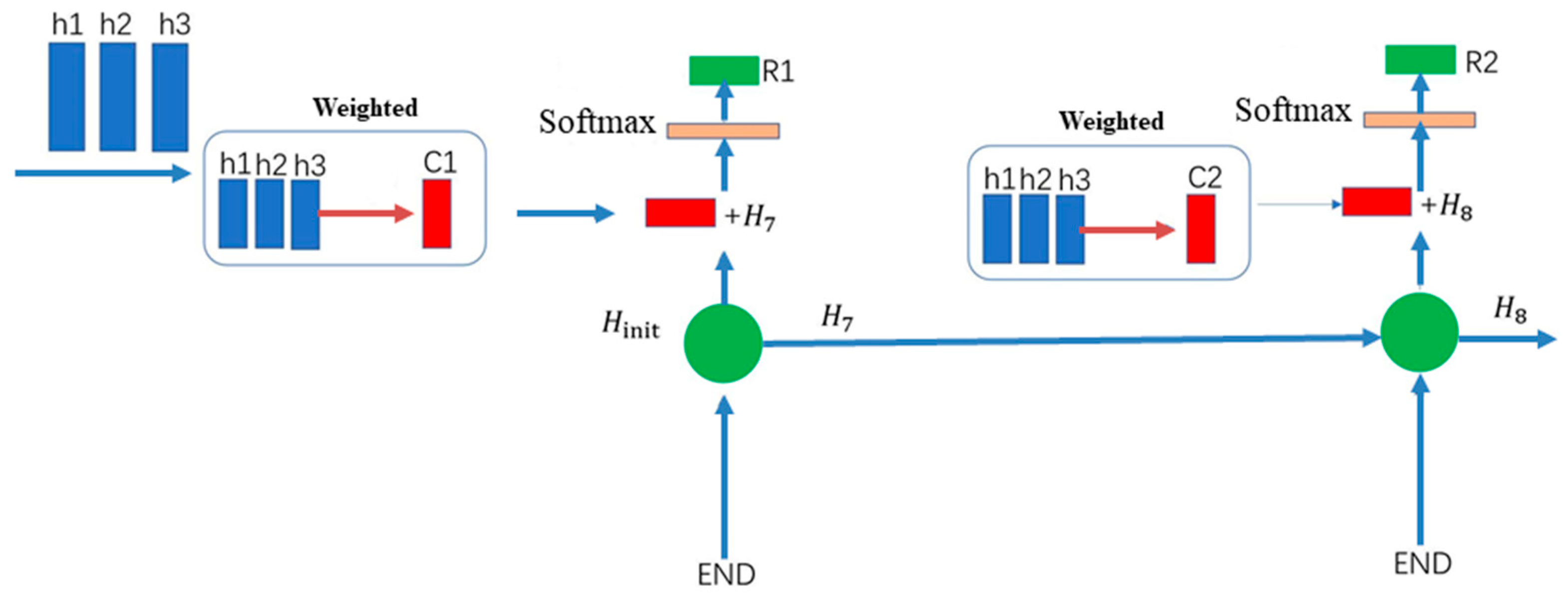

3.3. Level III: The Proposed Hybrid Neural Network Fault Diagnosis Method with PCA

3.3.1. Data Pre-Processing with PCA

- (1)

- Normalization of the data, i.e.,

- (2)

- Calculating the covariance matrix C of the normalized data.

- (3)

- Computing the eigenvalues (λ1, λ2,…, λm) of the covariance matrix C.

- (4)

- Calculating the cumulative contribution of the first k principal components. When the cumulative contribution rate ≥ 90%, only the first k feature vectors can be extracted as sample features, and the larger the cumulative contribution rate is, the more original information is included.

- (5)

- Deriving the principal component feature vector Y with reduced dimensional.

3.3.2. End-to-End Hybrid Neural Network Fault Diagnosis Method

4. Bearing Diagnostic Performance Verification of the Proposed Model

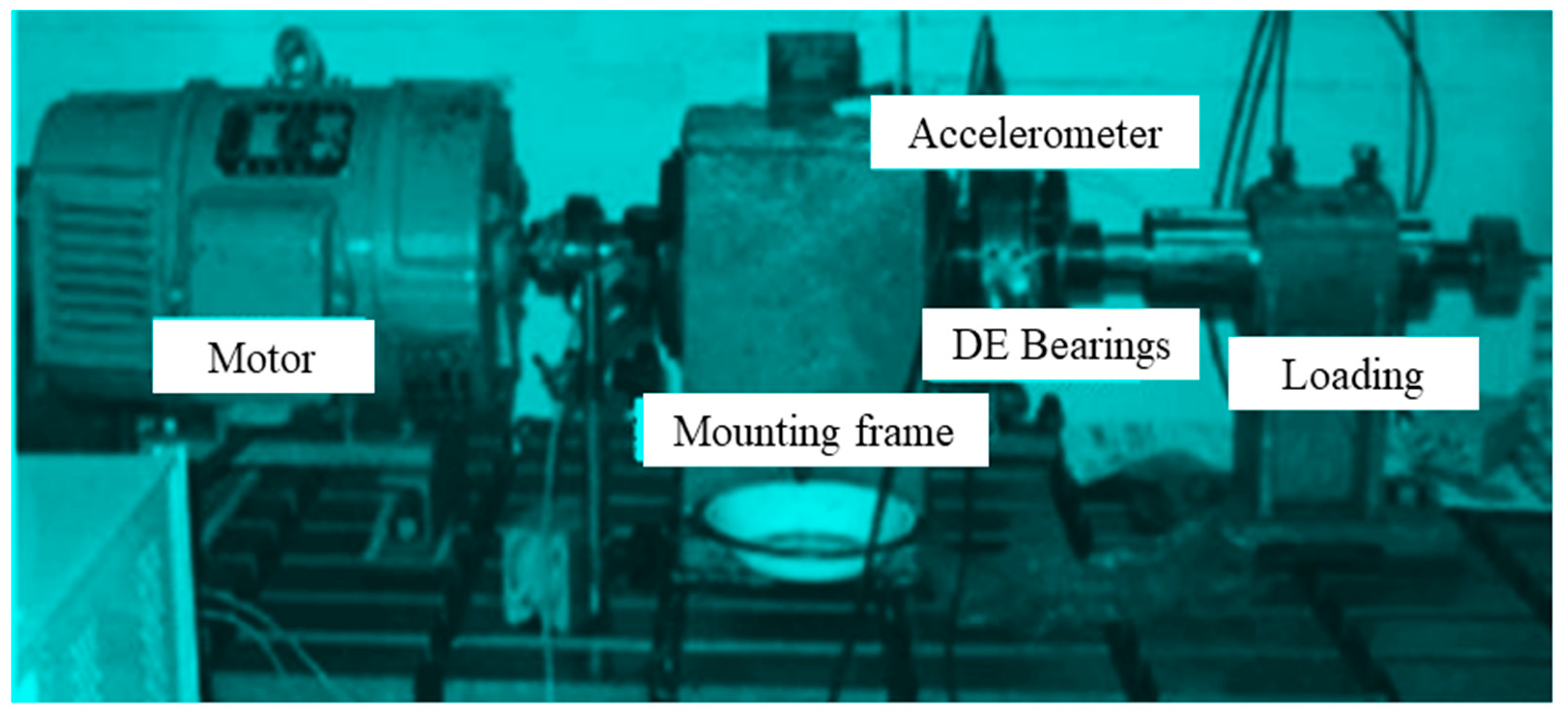

4.1. Level I: Introduction to the Conditions and Data Set of the Experiment

4.2. Level II: Training Results of the Model and Testing under Different Load Cases

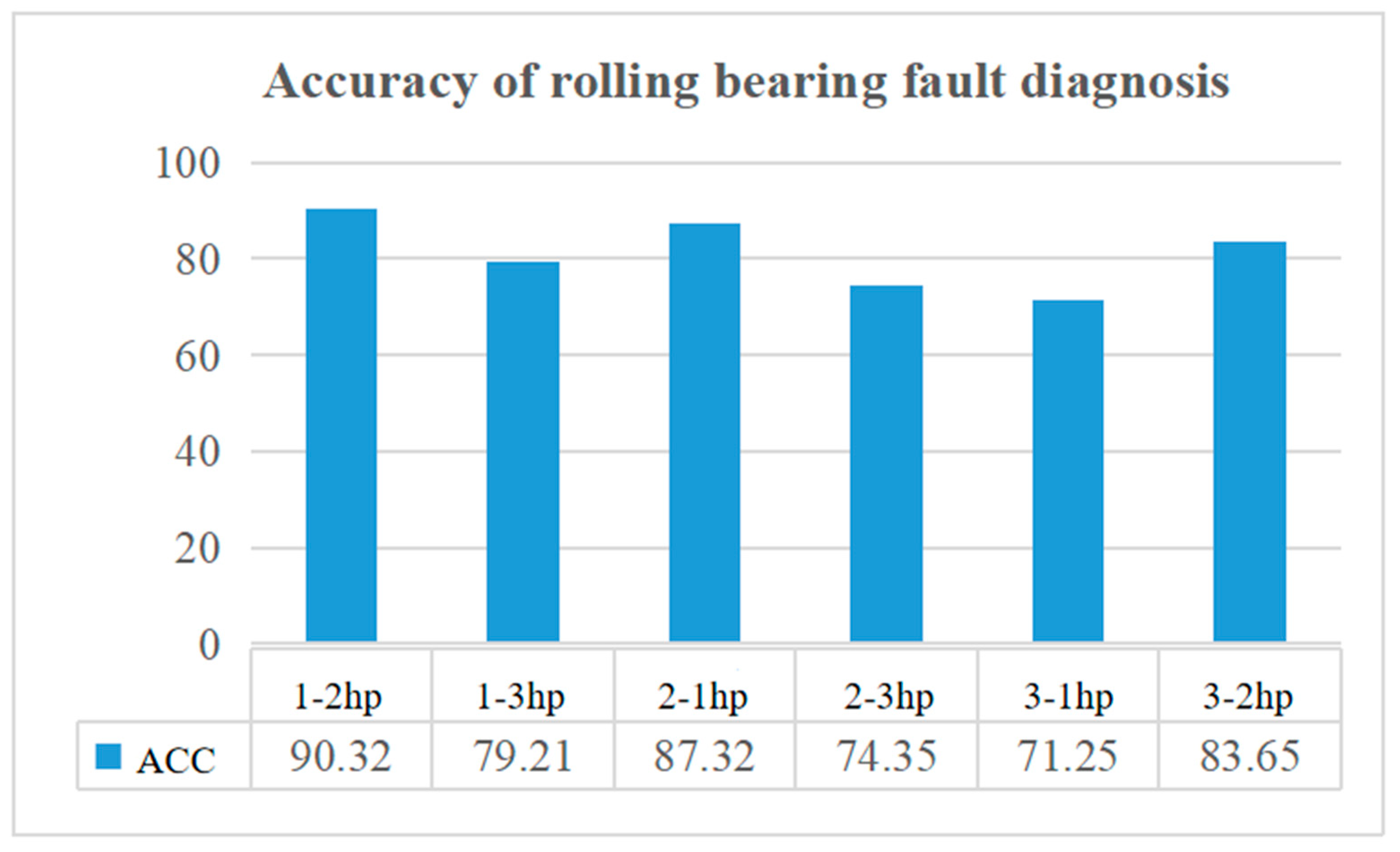

4.3. Level III: Diagnostic Performance Verification with Load Variation by Practical Testing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lanham, C. Understanding the Tests That Are Recommended for Electric Motor Predictive Maintenance; Baker Instrument Company: New York, NY, USA, 2002; Energy Publication. [Google Scholar]

- Hoang, D.-T.; Kang, H.-J. A survey on Deep Learning based bearing fault diagnosis. Neurocomputing 2019, 335, 327–335. [Google Scholar] [CrossRef]

- Wu, H.; Li, J.; Zhang, Q.; Tao, J.; Meng, Z. Intelligent fault diagnosis of rolling bearings under varying operating conditions based on domain-adversarial neural network and attention mechanism. ISA Trans. 2022, 130, 477–489. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Tao, H.; Wu, L.; Guan, Y. Transfer Learning with Neural Networks for Bearing Fault Diagnosis in Changing Working Conditions. IEEE Access 2017, 5, 14347–14357. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, F.; Li, S. A Cross Working Condition Multiscale Recursive Feature Fusion Method for Fault Diagnosis of Rolling Bearing in Multiple Working Conditions. IEEE Access 2022, 10, 78502–78518. [Google Scholar] [CrossRef]

- ISO 15243; Rolling Bearings: Damage and Failures—Terms, Characteristics and Causes. International Organization for Standardization: Geneva, Switzerland, 2004.

- Liu, R.; Yang, B.; Zio, E.; Chen, X. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Process. 2018, 108, 33–47. [Google Scholar] [CrossRef]

- Ambrozkiewicz, B.; Litak, G.; Georgiadis, A.; Syta, A.; Meier, N.; Gassner, A. Effect of Radial Clearance on Ball Bearing’s Dynamics Using a 2-DOF Model. Int. J. Simul. Model. 2021, 20, 513–524. [Google Scholar] [CrossRef]

- Wang, P.; Yang, Y.; Ma, H.; Hongyang, X.; Xu, L.; Zhong, L.; Bangchun, W. Vibration characteristics of rotor-bearing system with angular misalignment and cage fracture: Simulation and experiment. Mech. Syst. Signal Process. 2023, 182, 109545. [Google Scholar] [CrossRef]

- Khan, S.; Yairi, T. A review on the application of deep learning in system health management. Mech. Syst. Signal Process. 2018, 107, 241–265. [Google Scholar] [CrossRef]

- Cerrada, M.; Sánchez, R.-V.; Li, C.; Pacheco, F.; Cabrera, D.; de Oliveira, J.V.; Vásquez, R.E. A review on data-driven fault severity assessment in rolling bearings. Mech. Syst. Signal Process. 2018, 99, 169–196. [Google Scholar] [CrossRef]

- Zhao, R.; Yan, R.; Chen, Z.; Mao, K.; Wang, P.; Gao, R.X. Deep learning and its applications to machine health monitoring. Mech. Syst. Signal Process. 2019, 115, 213–237. [Google Scholar] [CrossRef]

- Huo, Z.; Martinez-Garcia, M.; Zhang, Y.; Shu, L. A Multisensor Information Fusion Method for High-Reliability Fault Diagnosis of Rotating Machinery. IEEE Trans. Instrum. Meas. 2021, 71, 1–12. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, S.; Wang, B.; Habetler, T.G. Deep Learning Algorithms for Bearing Fault Diagnostics—A Comprehensive Review. In Proceedings of the 2019 IEEE 12th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Toulouse, France, 27–30 August 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Soualhi, A.; Taleb, S. Data Fusion for Fault Severity Estimation of Ball Bearings. In Proceedings of the 2018 IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 20–22 February 2018; pp. 2105–2110. [Google Scholar] [CrossRef]

- Wu, J.; Wu, C.; Cao, S.; Or, S.W.; Deng, C.; Shao, X. Degradation Data-Driven Time-To-Failure Prognostics Approach for Rolling Element Bearings in Electrical Machines. IEEE Trans. Ind. Electron. 2019, 66, 529–539. [Google Scholar] [CrossRef]

- Hu, Q.; Qin, A.; Zhang, Q.; He, J.; Sun, G. Fault Diagnosis Based on Weighted Extreme Learning Machine With Wavelet Packet Decomposition and KPCA. IEEE Sens. J. 2018, 18, 8472–8483. [Google Scholar] [CrossRef]

- Kang, S.; Cui, L.; Wang, Y.; Li, F.; Mikulovich, V.I. Method of assessing the multi-state of a rolling bearing based on CFOA-HSVM two measures combination. In Proceedings of the 2017 Prognostics and System Health Management Conference (PHM-Harbin), Harbin, China, 9–12 July 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Jallepalli, D.; Kakhki, F.D. Data-Driven Fault Classification Using Support Vector Machines. Intell. Hum. Syst. Integr. 2021, 1322, 316–322. [Google Scholar] [CrossRef]

- Nayana, B.R.; Geethanjali, P. Analysis of Statistical Time-Domain Features Effectiveness in Identification of Bearing Faults From Vibration Signal. IEEE Sens. J. 2017, 17, 5618–5625. [Google Scholar] [CrossRef]

- Awadallah, M.; Morcos, M. Application of AI tools in fault diagnosis of electrical machines and drives-an overview. IEEE Trans. Energy Convers. 2003, 18, 245–251. [Google Scholar] [CrossRef]

- Nandi, S.; Toliyat, H.; Li, X. Condition monitoring and fault diagnosis of electrical motors—A review. IEEE Trans. Energy Convers. 2005, 20, 719–729. [Google Scholar] [CrossRef]

- Chow, M.-Y.; Mangum, P.; Yee, S. A neural network approach to real-time condition monitoring of induction motors. IEEE Trans. Ind. Electron. 1991, 38, 448–453. [Google Scholar] [CrossRef]

- Malhi, A.; Gao, R. PCA-Based Feature Selection Scheme for Machine Defect Classification. IEEE Trans. Instrum. Meas. 2004, 53, 1517–1525. [Google Scholar] [CrossRef]

- Xue, X.; Zhou, J. A hybrid fault diagnosis approach based on mixed-domain state features for rotating machinery. ISA Trans. 2017, 66, 284–295. [Google Scholar] [CrossRef]

- Ettefagh, M.M.; Ghaemi, M.; Asr, M.Y. Bearing fault diagnosis using hybrid genetic algorithm K-means clustering. In Proceedings of the 2014 IEEE International Symposium on Innovations in Intelligent Systems and Applications (INISTA) Proceedings, Alberobello, Italy, 23–25 June 2014; pp. 84–89. [Google Scholar] [CrossRef]

- Teotrakool, K.; Devaney, M.J.; Eren, L. Bearing Fault Detection in Adjustable Speed Drives via a Support Vector Machine with Feature Selection using a Genetic Algorithm. In Proceedings of the 2008 IEEE Instrumentation and Measurement Technology Conference, Victoria, BC, Canada, 12–15 May 2008; pp. 1129–1133. [Google Scholar] [CrossRef]

- Liu, H.; You, K. Optimization of dewatering process of concentrate pressure filtering by support vector regression. Sci. Reports 2022, 12, 7135. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Zhang, B.; Vachtsevanos, G. Prediction of Machine Health Condition Using Neuro-Fuzzy and Bayesian Algorithms. IEEE Trans. Instrum. Meas. 2011, 61, 297–306. [Google Scholar] [CrossRef]

- Li, W.; Zhang, S.; He, G. Semisupervised distance-preserving self-organizing map for machine-defect detection and classification. IEEE Trans. Instrum. Meas. 2013, 62, 869–879. [Google Scholar] [CrossRef]

- Tong, Q.; Cao, J.; Han, B.; Zhang, X.; Nie, Z.; Wang, J.; Lin, Y.; Zhang, W. A Fault Diagnosis Approach for Rolling Element Bearings Based on RSGWPT-LCD Bilayer Screening and Extreme Learning Machine. IEEE Access 2017, 5, 5515–5530. [Google Scholar] [CrossRef]

- Shen, F.; Chen, C.; Yan, R.; Gao, R.X. Bearing fault diagnosis based on SVD feature extraction and transfer learning classification. In Proceedings of the 2015 Prognostics and System Health Management Conference (PHM), Beijing, China, 21–23 October 2015. [Google Scholar]

- Zhao, X.; Jia, M. Fault diagnosis of rolling bearing based on feature reduction with global-local margin Fisher analysis. Neurocomputing 2018, 315, 447–464. [Google Scholar] [CrossRef]

- Cococcioni, M.; Lazzerini, B.; Volpi, S.L. Robust Diagnosis of Rolling Element Bearings Based on Classification Techniques. IEEE Trans. Ind. Inform. 2012, 9, 2256–2263. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Q.; Xiong, J.; Xiao, M.; Sun, G.; He, J. Fault Diagnosis of a Rolling Bearing Using Wavelet Packet Denoising and Random Forests. IEEE Sens. J. 2017, 17, 5581–5588. [Google Scholar] [CrossRef]

- Yang, T.; Pen, H.; Wang, Z.; Chang, C.S. Feature Knowledge Based Fault Detection of Induction Motors Through the Analysis of Stator Current Data. IEEE Trans. Instrum. Meas. 2016, 65, 549–558. [Google Scholar] [CrossRef]

- He, D.; Li, R.; Zhu, J. Plastic Bearing Fault Diagnosis Based on a Two-Step Data Mining Approach. IEEE Trans. Ind. Electron. 2012, 60, 1. [Google Scholar] [CrossRef]

- Chen, C.; Shen, F.; Yan, R. Topic Correlation Analysis for Bearing Fault Diagnosis Under Variable Operating Conditions. J. Phys. Conf. Ser. 2017, 842, 12045. [Google Scholar] [CrossRef] [Green Version]

- Wei, Z.; Wang, Y.; He, S.; Bao, J. A novel intelligent method for bearing fault diagnosis based on affinity propagation clustering and adaptive feature selection. Knowl. Based Syst. 2017, 116, 1–12. [Google Scholar] [CrossRef]

- Lu, Y.; Xie, R.; Liang, S.Y. Adaptive online dictionary learning for bearing fault diagnosis. Int. J. Adv. Manuf. Technol. 2018, 101, 195–202. [Google Scholar] [CrossRef] [PubMed]

- Janssens, O.; Slavkovikj, V.; Vervisch, B.; Stockman, K.; Loccufier, M.; Verstockt, S.; Van de Walle, R.; Van Hoecke, S. Convolutional Neural Network Based Fault Detection for Rotating Machinery. J. Sound Vib. 2016, 377, 331–345. [Google Scholar] [CrossRef]

- Guo, X.; Chen, L.; Shen, C. Hierarchical adaptive deep convolutionneural network and its application to bearing fault diagnosis. Measurement 2016, 93, 490–502. [Google Scholar] [CrossRef]

- Wen, L.; Li, X.; Gao, L.; Zhang, Y. A New Convolutional Neural Network-Based Data-Driven Fault Diagnosis Method. IEEE Trans. Ind. Electron. 2017, 65, 5990–5998. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, F.; Chen, W.; Jiang, Y.; Song, D. Fault State Recognition of Rolling Bearing Based Fully Convolutional Network. Comput. Sci. Eng. 2019, 21, 55–63. [Google Scholar] [CrossRef]

- Zhuang, Z.; Wei, Q. Intelligent fault diagnosis of rolling bearing using one-dimensional multi-scale deep convolutional neural network based health state classification. In Proceedings of the 2018 IEEE 15th International Conference on Networking, Sensing and Control (ICNSC), Zhuhai, China, 27–29 March 2018; pp. 1–6. [Google Scholar]

- Guo, S.; Yang, T.; Gao, W.; Zhang, C.; Zhang, Y. An Intelligent Fault Diagnosis Method for Bearings with Variable Rotating Speed Based on Pythagorean Spatial Pyramid Pooling CNN. Sensors 2018, 18, 3857. [Google Scholar] [CrossRef] [Green Version]

- Qian, W.; Li, S.; Wang, J.; An, Z.; Jiang, X. An intelligent fault diagnosis framework for raw vibration signals: Adaptive overlapping convolutional neural network. Meas. Sci. Technol. 2018, 29, 095009. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, H.; Zhao, H.; Wang, F. A novel deep autoencoder feature learning method for rotating machinery fault diagnosis. Mech. Syst. Signal Process. 2017, 95, 187–204. [Google Scholar] [CrossRef]

- Chen, Z.; Li, W. Multisensor Feature Fusion for Bearing Fault Diagnosis Using Sparse Autoencoder and Deep Belief Network. IEEE Trans. Instrum. Meas. 2017, 66, 1693–1702. [Google Scholar] [CrossRef]

- Abed, W.; Sharma, S.; Sutton, R.; Motwani, A. A Robust Bearing Fault Detection and Diagnosis Technique for Brushless DC Motors Under Non-stationary Operating Conditions. J. Control. Autom. Electr. Syst. 2015, 26, 241–254. [Google Scholar] [CrossRef] [Green Version]

- Xie, Y.; Zhang, T. Imbalanced Learning for Fault Diagnosis Problem of Rotating Machinery Based on Generative Adversarial Networks. In Proceedings of the 2018 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018. [Google Scholar] [CrossRef]

- Pan, H.; He, X.; Tang, S.; Meng, F. An improved bearing fault diagnosis method using one-dimensional CNN and LSTM. J. Mech. Eng. 2018, 64, 443–452. [Google Scholar]

- Zhang, W.; Li, C.; Peng, G.; Chen, Y.; Zhang, Z. A deep convolutional neural network with new training methods for bearing fault diagnosis under noisy environment and different working load. Mech. Syst. Signal Process. 2018, 100, 439–453. [Google Scholar] [CrossRef]

- Li, T.; Zhou, Z.; Li, S.; Sun, C.; Yan, R.; Chen, X. The emerging graph neural networks for intelligent fault diagnostics and prognostics: A guideline and a benchmark study. Mech. Syst. Signal Process. 2021, 168, 108653. [Google Scholar] [CrossRef]

- Chen, Z.; Yang, J.; Chen, L.; Jiao, H. Garbage classification system based on improved shufflenet v2. Resour. Conserv. Recycling 2022, 178, 106090. [Google Scholar] [CrossRef]

- Lv, H.; Chen, J.; Pan, T.; Zhang, T.; Feng, Y.; Liu, S. Attention mechanism in intelligent fault diagnosis of machinery: A review of technique and application. Measurement 2022, 199, 111594. [Google Scholar] [CrossRef]

- Case Western Reserve University (CWRU) Bearing Data Center, December 2018. Available online: https://engineering.case.edu/bearingdatacenter (accessed on 11 September 2022).

- Smith, W.A.; Randall, R.B. Rolling element bearing diagnostics using the Case Western Reserve University data: A benchmark study. Mech. Syst. Signal Process. 2015, 64, 100–131. [Google Scholar] [CrossRef]

| Sampling Position | Bearing Type | Sampling Frequency | Load | Single-Point Loss Diameter |

|---|---|---|---|---|

| Drive end(DE) 6 o’clock | SKF6205 | 48 KHZ | 0–2.205 N·m/s | 0.007 mm, 0.014 mm, 0.021 mm |

| Sample Type | Sample Number | Sample Length | Training Sets | Test Set | Category Marker |

|---|---|---|---|---|---|

| Normal | 1000 | 470 | 700 | 300 | 0 |

| Outer ring fault (07 in) | 1000 | 470 | 700 | 300 | 1 |

| Outer ring fault (14 in) | 1000 | 470 | 700 | 300 | 2 |

| Outer ring fault (21 in) | 1000 | 470 | 700 | 300 | 3 |

| Inner ring fault (07 in) | 1000 | 470 | 700 | 300 | 4 |

| Inner ring fault (14 in) | 1000 | 470 | 700 | 300 | 5 |

| Inner ring fault (21 in) | 1000 | 470 | 700 | 300 | 6 |

| Rolling body fault (07 in) | 1000 | 470 | 700 | 300 | 7 |

| Rolling body fault (14 in) | 1000 | 470 | 700 | 300 | 8 |

| Rolling body fault (21 in) | 1000 | 470 | 700 | 300 | 9 |

| Fault Diagnosis Model | Classifier | Percentage of Training Samples | Average Accuracy |

|---|---|---|---|

| ADCNN | Softmax | 50% | 97.9% |

| CNN | Softmax | 90% | 92.6% |

| LeNet-5-CNN | FC layer | 83% | 99.79% |

| IDS-CNN | Softmax | 80% | 98.92% |

| PSPP-CNN | Softmax | 67% | 99.19% |

| AOCNN | Softmax | 50% | 99.19% |

| SAE | ELM | 50% | 99.61 |

| DBN | Softmax | N/A | 98.8% |

| CNN-LSTM | Softmax | 83% | 99.6% |

| DC-GAN | SVM | 96% | 86.33% |

| GAAN-SDAE | Softmax | 78% | 99.2% |

| The proposed | Softmax | 70% | 99.98% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, K.; Qiu, G.; Gu, Y. Rolling Bearing Fault Diagnosis Using Hybrid Neural Network with Principal Component Analysis. Sensors 2022, 22, 8906. https://doi.org/10.3390/s22228906

You K, Qiu G, Gu Y. Rolling Bearing Fault Diagnosis Using Hybrid Neural Network with Principal Component Analysis. Sensors. 2022; 22(22):8906. https://doi.org/10.3390/s22228906

Chicago/Turabian StyleYou, Keshun, Guangqi Qiu, and Yingkui Gu. 2022. "Rolling Bearing Fault Diagnosis Using Hybrid Neural Network with Principal Component Analysis" Sensors 22, no. 22: 8906. https://doi.org/10.3390/s22228906

APA StyleYou, K., Qiu, G., & Gu, Y. (2022). Rolling Bearing Fault Diagnosis Using Hybrid Neural Network with Principal Component Analysis. Sensors, 22(22), 8906. https://doi.org/10.3390/s22228906