Removal of Volatile Organic Compounds (VOCs) from Air: Focus on Biotrickling Filtration and Process Modeling

Abstract

:1. Air Pollution with VOCs: Problem and Treatment Strategies

2. Review Methodology

3. Biotrickling Filtration for the Removal of VOCs from Air: Background, Current Problems, and Research Overview

| VOC | Bioreactor Dimensions: din × H [m]; V [dm3] | Packing Material | Inoculum | Process Parameters | Interesting Outcomes | Reference |

|---|---|---|---|---|---|---|

| n-Butanol | 0.08 × 0.68; 2.5 | Peat & perlite, ceramic Raschig rings | No additional inoculation | EBRT: 60 s, Cin: 100–800 ppm | The extent of reduction in VOCs concentration in gas phase is not quantitatively equivalent to odor reduction | [63] |

| Triethylamine | 0.21 × 1; 52 | Lava rocks | Sludge from WWTP | EBRT: 31–312 s Cin: 600 mg m−3 | Increasing of the gas flow rate is more cost-effective than increasing EBRT | [64] |

| Trimethylamine | 0.077 × 1.7; 5.6 | Polyurethane rings | Aminobacter aminovorans | EBRT: 85, 170 s IL: 0.2–12 g·m−3·h−1 | H2S only slightly affected the removal efficiency of trimethylamine | [65] |

| Ethyl acetate | 0.2 × 0.14 (two sections) | Anode materials: carbon coke or carbide porous ceramic rings (CPCR) | Activated sludge from WWTP | EBRT: 60–120 s Cin: 0.54–3.23 g m−3 | The use of CPCR resulted in higher removal efficiency of ethyl acetate that carbon coke | [61] |

| Methyl acrylate | 0.12 × 1.1; 6.44 | Ceramic particles | Activated sludge from WWTP | EBRT: 200–400 s Cin: 120–7505 mg m−3 | Three-layer BTF was applied and it was the 1st packing layer that mainly reduced methyl acrylate concentrations in air | [1] |

| Chloroform | 0.076 × 1.3; 5.89 | Celite (pelletized diatomaceous earth) | Filamentous fungi | EBRT: 344 s Cin = 5 ppm | The application of ethanol as a co-metabolite; acidic conditions enhanced the fungi growth | [66] |

| 0.076 × 1.3; 5.89 | Pelletized diatomaceous earth | Bacteria from WWTP | EBRT: 344 s Cin: 200 ppm | Aerobic and anaerobic conditions (with methanogenic bacteria) were investigated | [67] | |

| Ethylbenzene | 0.1 × 0.78; 6.1 | Polyurethane sponge | Activated sludge from WWTP | EBRT: 30 s Cin: 2.5 g m−3 | The addition of saponins to the liquid phase resulted in enhanced removal of ethylbenzene | [52] |

| 0.1 × 0.8 (2 sections); 12.56 | Polyurethane sponge | Fresh biological from WWTP | EBRT: 30 s Cin: 1 g m−3 | The high removal of ethylbenzene due to addition of biosurfactant (from piggery wastewater) to liquid phase | [68] | |

| Styrene | 0.144 × 1.63; 20 | Polypropylene Ralu rings | Pseudomonas sp. E-93486 | EBRT: 62 s IL: 1 g m−3 h−1 | A three-phase dynamic mathematical model was proposed | [69] |

| Six rectangular sections with total packing volume of 50 dm3 | Fern or plastic chips | Activated sludge from WWTP | EBRT: 21 s Cin: 2.39 g m−3 | The study provides a comparison of packing materials, presenting the superior performance of plastic over fern chips during styrene removal from air | [70] | |

| 0.08 × 1.5; 3.77 | Ceramic Raschig rings | Activated sludge from cooking plant | EBRT: 68 s IL = 180 g m−3 h−1 | The removal of styrene from air is enhanced by the acclimatization of a biotrickling filter to toluene-styrene mixture | [71] | |

| Toluene | 0.12 × 0.78; 4.27 | Ceramic pellets | Fungi from activated sludge (e.g., Fusarium) | EBRT: 55 s IL = 100.3 g m−3 h−1 | A fungi-based biotrickling filter was applied to efficiently remove toluene from air | [72] |

| 0.1 × 0.6 (approx.); 4.56 | Ceramsite particles | Fungi (Fusarium) | EBRT: 59 s Cin: 1.053 g m−3 | The effects of bed porosity on pressure drop and its maintenance during biotrickling filtration process were studied | [73] | |

| Differential biotrickling filter with a packing volume of 0.4 dm3 | Glass beads | Inoculum from previously working biotrickling filter | EBRT: 28 s IL: 472 g m−3 h−1 | A differential biotrickling filter was proposed in opposition to popular integral-column bioreactors | [74] | |

| Cyclohexane | 0.318 × 1; 52 | Polyurethane foam | Acidovorax sp. CHX 100 | EBRT: 37 s Cin: 720 mg dm−3 | A proposal for the removal of cyclohexane from air in a biotrickling filter using Acidovorax sp. | [75] |

| Hexane | 0.07 × 1; 2.4 | Perlite | Fusarium solani | EBRT: 78 s Cin: 7400 mg dm−3 | The addition of different carbon sources to the trickling liquid may shorten the start-up period | [76] |

| 0.076 × 1.3; 2.7 | Pellets of diatomaceous earth (Celite) | Fungi with dominant Cladosporium and Rhodotorula species (genus) | EBRT: 120 s Cin: 125 ppmv | The effects of pH and methanol addition on the removal of hexane were studied; low pH was favorable for enhanced removal of hexane | [77] | |

| 0.1 × 0.65; 5.1 | Reticular polyurethane sponge | Filamentous bacteria | EBRT: 30 s IL: 124 g m−3 h−1 | The intermittent mode of spraying and reticulated packing configuration, enhancing the mass transfer, enabled high removal of hexane | [78] |

| VOCs Mixture | Bioreactor Dimensions (din x H; V) | Packing Material | Inoculum | Process Parameters | Outcomes | Reference |

|---|---|---|---|---|---|---|

| Acetone, toluene, trichloroethylene | 0.07 × 0.6; 1.9 (bioreactor organized in 2 segments) | Granular activated carbon | Acclimated microbial seeds from industrial WWTP | EBRT: 155 s Cin (of each VOC): 10–800 ppmv | Relative concentrations of VOCs in treated gas mixture as a crucial parameter for the functioning of microbes during biofiltration | [79] |

| Trichloroethylene, perchloroethylene | 0.07 × 0.6; 3 | Granular activated carbon | Mixed microbial consortium from soil and activated sludge | EBRT: 6–36s Cin: 35.4 ppmv (PCE) and 46.7 ppmv (TCE) | The application of photooxidation enhanced the removal of target pollutants in biotrickling filter, and various removal mechanisms in a biofilter were identified (hydrolysis, adsorption, biodegradation) | [80] |

| Hydrogen sulfide, methyl mercaptan, ammonia, VOCs mixture, dimethyl sulfide | 3.2 × 13 | OdourTeQ vessels | Thiobacillus for H2S removal, heterotrophic microbes for VOCs removal | EBRT: 17 s | Industrial application | [81] |

| Methanol, ethanol, acetone, toluene, chloroform | 0.054 × 1; 1.7 | Polyvinyl chloride particles | Microbial consortium taken from previously operating bioreactors | EBRT: 25–68.6 s Cin: 1–4 g m−3 (VOCs); 0.05–1 g m−3 (chloroform) | High removal of target air pollutants and resistance to intermittent loadings | [82] |

| Methyl mercaptan, toluene, alpha-pinene and hexane | 0.08 × 1; 4 | Polyurethane foam cubes | Acclimated activated sludge | RE up to about 99% for hydrophilic and about 80% for hydrophobic VOCs at inlet concentrations of order of mg m−3 for EBRT = 7 s | The addition of silicone oil enhanced and stabilized biofiltration performance; high overall mass transfer coefficients reported for polyurethane foam | [83] |

| Ethyl acetate, toluene, ethyl benzene, xylene, ethyl toluene, trimethylbenzene | 2 × 2 × 4 (rectangular bioreactor); 6 m3 | Ceramic particles, hollow plastic balls, Raschig rings | Enriched activated sludge from WWTP | EBRT: 7.2 s Cin: up to 150 mg m−3 (sum of VOCs) | BTF combined with photocatalytic oxidation revealed high performance for VOC removal from air | [84] |

| Acetone, methyl ethyl ketone (MEK), toluene, styrene | Field-scale stainless steel BTF: 1.5 × 1.5 × 1.8 [m] | Pall rings | Activated sludge from the local paint and coating plant wastewater treatment plant | EBRT: 14 s Total inlet loading of VOCs mixture: 30.5 m m−3 h−1 RE from 67 to 99 % | Mixed VOCs from paint and coating plant; higher removal of acetone and MEK than toluene and styrene; shutdown periods diminished BTF performance, especially for hydrophobic VOCs | [85] |

| Methanol, n-hexane | 0.076 × 1.3; 2.72 | Pelletized diatomaceous earth (Celite) | Aerobic microbial culture from secondary clarifier of an activated sludge system at Cincinnati municipal wastewater treatment plant | EBRT: 120 s RE of methanol about 99% regardless process conditions; RE of n-hexane decreased from about 98% to 60% when inlet loading increased from 1 to 13.2 g m−3 h−1 | Methanol significantly increased the removal of hexane in the BTF; switching of flow directions (co- and counter-current) was applied to ensure uniform biofilm formation across the packing; decrease in BTF performance was observed after bed backwashing due to high biomass loss; high methanol concentrations may have inhibited n-hexane biodegradation, as it is a more accessible carbon source | [50] |

| Hydrogen sulfide, methanol, α-pinene | 0.094 × 0.7; 4.55 | Polypropylene pall rings | Autotrophic H2S-degrading culture and pure strains of Candida boidinii, Rhodococcus erythropolis, and Ophiostoma stenoceras | EBRT: 26 s Maximum elimination capacities of methanol, α-pinene and H2S were 302, 175, and 191 g m−3 h−1, respectively | The α-pinene degraders developed more slowly than degraders for methanol and H2S; diversified microbial population within the filter bed offered promising VOCs removal for industrial applications | [57] |

| Butanone, toluene, α-pinene, hexane | 0.08 × 1; 4 | Kaldness K1 rings | Activated sludge from Valladolid WWTP | EBRT: 6 s RE for inlet concentrations of butanone (3 mg m−3); toluene (1.4 mg m−3); α-pinene (1.4 mg m−3) and hexane (1.3 mg m−3) were about 99%, 98%, 97% and 65%, respectively | A two-phase BTF showed better performance and supported a richer as well as more uniform microbial community in the biofilter bed than a single-phase BTF | [86] |

| Methanol, n-hexane | 0.076 × 1.3; 2.72 | Pelletized diatomaceous earth (Celite) | Activated sludge from WWTP as reported in [50] | EBRT: 120 s; 3:1 and 5:1 ratios of methanol to n-hexane; maximum elimination capacity for n-hexane was 11.2 g m−3 h−1 for its inlet loading of 13.2 g m−3 h−1 when lower ratio of methanol was tested | Removal of methanol and hexane was favored in acidic conditions and offered high removal efficiencies; degradation of methanol was not affected by n-hexane | [87] |

| Pelletized diatomaceous earth support media (Celite) | From previously working BTF From previously working BTF | EBRT: 120 s Acclimation with intermittent loading of methanol Inlet loading of hexane from 21.5 to 47.7 g m−3 h−1 | Acidic conditions (pH = 4) with a dominant fungi consortium offered higher performance than the process realized at pH = 7; a change in the inlet loading of VOCs may affect the microbial community, especially for high VOC loads | [88] | ||

| EBRT: 120 s Inlet loading: hexane 13.2, methanol 37.7 g m−3 h−1 | Methanol introduction ameliorated the removal of hexane from air, a high reaction rate constant for hexane biofiltration was obtained for the alternate strategy of treatment air polluted with either hexane or its mixture with methanol; the reintroduction of methanol increased the removal of hexane, due to an increase in hexane bioavailability | [89] | ||||

| n-Hexane, benzene, methanol | 0.076 × 1.3; 2.72 | Pelletized diatomaceous earth support media | From previously working BTF, pH = 4 favors fungal growth | EBRT: 120 s Total inlet loading of VOCs between 96.4 and 117.7 g m−3 h−1; | Results showed that the top section of BTF was the most active part of a biofilter where competition among VOC degraders took place; VOCs concentrations played a role in the recovery of biofilter performance after shut-down periods, as well as affected the removal efficiency of resistant hydrophobic VOCs, such as hexane | [90] |

| Benzene, toluene | Pilot plant; 2.76 × 1; 6000 | Blue mussel shells | Natural from blue mussel shells and WWTP effluent used as a trickling liquid | Gas flow: 0.9 m3 h−1; inlet concentrations of benzene and toluene were 0.4–56 and 1.6–22.8 mg m−3, respectively | The two-stage process combining a water scrubber and BTF resulted in a high purification degree of air from WWTP | [91] |

| Styrene, acetone | 0.15 × 1.5; 17.6 | Polypropylene pall rings | Mixed culture from previously working biofilter | EBRT: 53 s | Investigated system combined a BTF with a downstream conventional biofilter; acetone accumulated in the trickling liquid and hindered the biodegradation; recovery of the BTF performance was possible when acetone in liquid was degraded; a proposed two-stage biofiltration system is promising for the smoothing variation of concentrations or for the overloading of a biofilter unit | [92] |

| Methanol, toluene, trichloroethylene (TCE) | 0.076 × 1.3; 2.72 | Celite | Fungi; from previously working BTF | pH = 4 EBRT: 120 s Inlet loading: TCE (10–40 g m−3 h−1), methanol (22–237 g m−3 h−1), toluene (17–101 g m−3 h−1) | The elevated inlet loading of a primary substrate (i.e. carbon source like methanol) inhibited TCE removal; biofilters with lower ratios of methanol and toluene to TCE resulted in better removal of TCE, as well as better responses to increased TCE loads | [93] |

| Trichloro- ethylene (TCE), methanol | 0.076 × 1.3; 2.72 | Celite | Fungi; from previously working BTF | pH = 4 EBRT: 120 s Inlet concentrations: TCE (28–80 ppmv), methanol (103–711 ppmv) | Higher concentrations of methanol in the inlet stream allowed for the higher removal of TCE, but only for methanol concentrations below the inhibition level; TCE was more bioavailable for higher methanol concentrations; preferential degradation of hydrophilic over hydrophobic substrate was observed; elimination efficiency of methanol was not affected by variations in TCE concentration | [94] |

| Benzene, toluene, ethylbenzene, xylene | 0.084 × 0.45; 2 | Kaldnes rings | Activated sludge from denitrification-nitrification section from Valladolid WWTP | EBRT: 30 min Inlet loading of xylene, toluene and ethylebenze was 1.4 g m−3 h−1 for each and 1.5 g m−3 h−1 for benzene | Oxygen-free conditions of biodegradation were applied; REs above 90% were noted for toluene and ethylbenzene (relative ease of biodegradation compared to benzene and xylene); removal of xylene was limited due to mass transfer limitations; benzene removal was poor due to toxic intermediate products of biodegradation which were overcome by the application of UV to trickling liquid; the coupling of BTF with a UV gas pre-treatment didn’t increase the removal of BTEX in the system; low similarity of inoculum and developed microbial community composition was detected | [95] |

| Cyclohexane, methyl acetate | 0.11 × 1; 4.75 | Volcanic rock and ceramsite | Activated sludge from the secondary sedimentation tank from Beijing Gaobeidian WWTP | EBRT: 88.3 s Inlet concentrations of cyclohexane and methyl acetate are up to 250 and 800 mg m−3 | REs of over 90% for both investigated VOCs | [96] |

| Toluene, formaldehyde, benzo-a-pyrene | 0.079 × 1.05 | Vermiculite | Fusarium solani B1 (fungi) and Rhodococcus erythropolis DSM 43066 | EBRT: 31 s Inlet loadings: benzo-a-pyrene (373 g m−3 h−1), toluene (33.5 g m−3 h−1), formaldehyde (34.8 g m−3 h−1) | Elimination capacities for benzo-a-pyrene, toluene, and formaldehyde reached 215, 31, and 22.5 g m-3 h-1, respectively, for conditions indicated in reference conditions given to the left; the biofilter was divided into three sections, and the first stage was preferentially colonized mainly by fungi, while the other two were colonized with bacteria | [39] |

| Chloroform, dichlorobromo-methane, ethanol | 0.076 × 1.3; 2.72 | Celite | From previously working BTF | EBRT: 5 min Inlet concentrations of trihalomethanes (total) 14 ppmv, inlet concentration of ethanol 25–200 ppm | The application of a co-metabolite (ethanol) resulted in a similar increase in the elimination of trihalomethanes as the use of a surfactant; natural surfactant was found to be more efficient in aiding the BTF performance than the synthetic one | [97] |

| Toluene, ethyl benzene, p-xylene, m-xylene, o-xylene | 0.1 × 0.38; 3 | Ceramic particles | Mixed acclimated microbial consortia from petroleum polluted soil | EBRT: 60 s Inlet concentrations of each VOC from 50 to 160 mg m−3 | Continuous and discontinuous BTF feeding strategies were compared; continuous feeding resulted in the higher removal of VOCs than the discontinuous mode, while switching from discontinuous to continuous resulted in a great increase in process efficiency | [98] |

| n-Butanol, cyclohexane | 0.08 × 0.68; 2.5 | Peat, perlite, ceramic Raschig rings | No additional inoculation (only microbes naturally occurring in peat material) | EBRT: 46–60 s Inlet loading of n-butanol (19.8–99 g m−3 h−1) and cyclohexane (45–180 g m−3 h−1) | Presence of butanol increased the removal efficiency of cyclohexane, starvation episodes slightly decreased biofiltration performance, and the longer the starvation period, the longer time that was needed for the recovery of removal efficiency | [99] |

| Ethanol, hexane | 0.08 × 0.68; 2.5 | Peat, perlite, ceramic Raschig rings | No additional inoculation (only microbes naturally occurring in peat material) | EBRT: 60 s Inlet loading of ethanol (18.45–38.5 g m−3 h−1) and hexane (25–140 g m−3 h−1) | The presence of ethanol increased the removal efficiency of hexane; ethanol starvation caused only a slight decrease in removal efficiency of hexane; a lower than previously reported volume by volume ratio of ethanol ensured the efficient biofiltration of hexane | [100] |

| Cyclohexane, ethanol | 0.08 × 0.68; 2.5 | Polyurethane foam | Candida albicans, Candida subhashii | EBRT: 60 s Inlet loadings of VOCs in the range from 36 to 90 g m−3 h−1 | Feeding a BTF with a mixture of ethanol and cyclohexane resulted in the higher removal of cyclohexane compared to when ethanol was added to the gas stream polluted with cyclohexane only; negligible concentrations of VOCs were detected in the liquid phase in steady-state conditions | [101] |

| n-Hexane, dichloromethane | No information | Bamboo charcoal based polyurethane foam | Activated sludge from the pharmaceutical factory WWTP | EBRT: 20–150 s Inlet concentrations of n-hexane (100 mg m−3) and dichloromethane (150 mg m−3) | The applied packing material offered large and uniform pores, thus improving the mass transfer from gas to liquid phase; further, the modification of polyurethane foam with charcoal increased its porosity, resulting in greater surface area available for biofilm development; the packing offered higher resistance to transient conditions | [42] |

| m-Xylene, toluene | 0.0885 × 0.7; 2.4 | Diatomaceous earth pellets | Acclimated activated sludge | EBRT: 25–60 s Inlet concentrations of m-xylene (250–1500 mg m−3) and toluene (250 mg m−3) | The mechanisms of synergistic removal of m-xylene in the presence of toluene were discussed in terms of toxicity effects, co-metabolism, and suitable concentration proportions (1:2 for toluene to m-xylene) | [49] |

| Toluene, hexane, α-pinene, trichloroethylene (TCE) | 0.1 × 0.34; | Polyurethane foam | Candida subhashii | EBRT: 30 s Inlet concentrations of VOCs in the range from 200 to 450 mg m−3; removal efficiency in the range 20–45% | A biodegradation pattern for investigated VOCs was found: toluene > n-hexane > α-pinene > TCE; this sequence was discussed in terms of Hansen solubility parameters; biotrickling filter configuration proved to be more efficient in biodegradation of VOCs than the conventional biofilter | [102] |

4. Modeling of Biofiltration and Biotrickling Filtration Processes

4.1. Modeling of Conventional Biofiltration

- target compounds (i.e., compounds removed from air in biofiltration system) are transported within the biofilm layer via diffusion, described by an effective diffusion coefficient;

- the biofilm thickness is much smaller that the diameter of a bed particle;

- the biodegradation of target compounds in the biofilter can be described by the Michaelis–Menten equation;

- the flow of the gas phase is a plug flow;

- mass transfer resistance at the gas side in the gas-biofilm interface is negligibly small.

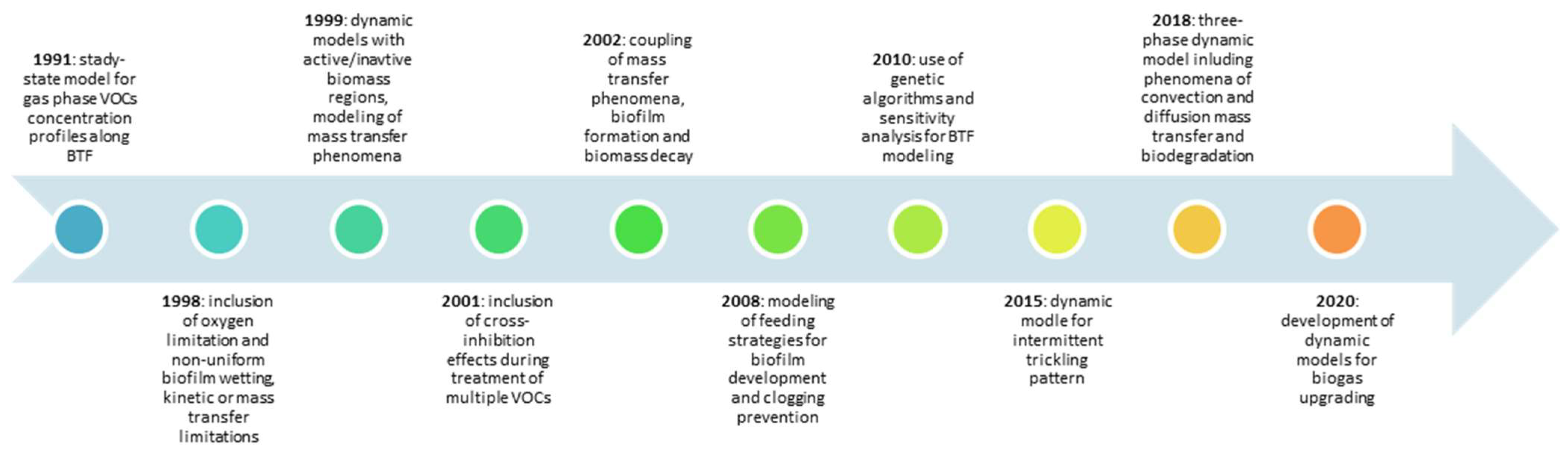

4.2. Modeling of Biotrickling Filtration

4.3. Problems and Challenges for Modeling of Biotrickling Filtration

- non-uniform wetting of the packing and biofilm

- oxygen limitation

- biokinetic or mass transfer and diffusion limitations, depending on the substrate type

- stripping of pollutants at the top of the biotrickling filter (in the vicinity of a trickling liquid sprayer)

- existence of active and inactive biomass zones

- determination or estimation of the gas-biofilm/liquid interface area

- the need to include gas–liquid / gas–liquid–biofilm mass transfer as well as adsorption of VOCs in the solid phases; however, problems with adsorption may be only relevant for rare package materials, as most materials are made of plastics with low adsorption capacity

- interactions between target compounds.

| Target Compound (s) | Biofilter Parameters | Model Description | Reference |

|---|---|---|---|

| Dichlorobenzene | Vertical Perspex pipe (din = 0.29 m; H = 1 m) packed with polypropylene elements (Filterpack) inoculated with adopted dichloromethane degrading microorganisms | Simulation of the biotrickling filter as a series of perfectly stirred interconnected reactors; computer software was used for calculating dichloromethane conversion using immobilized biocatalysts; the modeling gave surprisingly good results when compared to experimental data, however no mass transfer resistance between liquid and biofilm was included | [134] |

| Dichloromethane | Ceramic saddles | Steady-state model with the assumption of zeroth order kinetics; negligible resistance for the mass transfer of VOCs from gas to liquid phase; the model allowed for determining concentration profiles along co- and counter-current biofilter | [133,153] |

| Theoretical model | No experimental verification; modeling study | The model incorporates simplified equations describing the gas flow and biodegradation; the model indicated two aspects of biotrickling filtration: the inclusion of both stripping in counter-current operation, and the influence of absorption/biodegradation in the liquid phase | [154] |

| Toluene | Stainless-steel biotrickling filter packed with Celite (pelletized diatomaceous earth) inoculated with activated sludge | A modification of a conventional model for synthetic-media biotrickling filters using one substrate, uniform biomass, and one type of microbial population; uniform pollutant concentrations in the gas phase are assumed; only gaseous and biofilm phases are considered | [155] |

| m-Chlorobenzene | Glass column (din = 0.152 m; H = 0.74 m) packed with Intalox ceramic saddles inoculated with a stable microbial consortium | The model incorporates oxygen limitation, non-uniform wetting of biofilm, and step-wise mass transfer of pollutants from the gas to liquid to biofilm phase; reactions occur only in the effective biolayer; no anaerobic degradation of VOCs is assumed; constant density of the biofilm is assumed | [135] |

| Pentane, izobutene | A biotrickling filter (din = 0.0508 m; H = 0.5 m) packed with a structured polyethylene packing inoculated with microbial consortium taken from previous studies | Steady-state model assuming a biofilm covered with a liquid phase; a two-step approach of modeling, including dependence on mass transfer and then biodegradation kinetics is proposed; results of the modeling suggest both kinetic and mass transfer limitations during the biotrickling filtration of pentane and izobutene | [156] |

| Acetone, toluene | Stainless-steel bioreactor packed with pelletize diatomaceous earth particles (H = 1.14 m) | Conceptual model incorporating active and inactive regions of biomass as well as the simultaneous growth and detachment of biofilm; modeling results indicated high mass transfer resistance for the liquid phase | [157] |

| Diethyl ether | Glass BTF divided into 7 sections, din = 0.076 m and total height of packing H = 0.61 m; packing material: Celite (porous ceramic particles); inoculation with enriched microbial culture from activated sludge | The model is a development of [157]; Glass BTF is divided into 7 sections, din = 0.076 m, and total height of packing H = 0.61 m; packing material: Celite (porous ceramic particles); assumes inoculation with enriched microbial culture from activated sludge | [137] |

| Dichloromethane | Glass fiber enforced plastic column, din = 0.396 m and H = 2.7 m; packed with a corrugated sheet 60° PVC cross-flow cooling packing, inoculated with a biomass suspension of Hyphomicrobium sp. GJ21 | A dynamic model assuming the development of active (i.e. dichloromethane-degrading microorganisms) as well as inactive biomass; dicholormethane undergoes mass transfer from the gas to liquid phase to biofilm phase; a model for the biodegradation of acidifying VOCs; the model predicts process performance and related gasphase and liquid VOC concentration profiles, as well as the effects of initial VOC concentration increases in a treated gas, like bed clogging | [136] |

| Carbon disulfide | Acrylic tube of din = 0.29 m and height of packing H = 1.2 m; packed with Pastdec 12060 structured PVC packing; inoculation with Thiobacilii consortia | Modeling of mass transfer from the gas to liquid to biofilm phase; a single criterion was proposed for identifying the rate-limiting step of biotrickling filtration; a model for describing substrate gas-phase and liquid concentrations and their effects on mass transfer; low substrate concentration in the liquid phase illustrates mass transfer limitations, while higher concentrations suggest kinetic limitation in the biofilm; two-parameter steady-state, one-species, one-directional and heterogeneous model; the model predicts substrate concentration profiles for co- and counter-current modes | [158] |

| Diethyl ether | A four-section BTF packed to the total height H = 0.122 m with Celite (pelletized diatomaceous earth), inoculated with ethyl ether acclimated and enriched aerobic culture, originating from activated sludge | Conceptual model incorporating the reduction of the gas–liquid interface area and the increase in liquid velocity occurring during biomass growth and biofilm development; the paper presents very clear assumptions for the model; a dynamic model for biotrickling filtration was developed, with a focus on nutrient addition and the removal of clogging overgrowing biomass; the model included two effects of backwashing, i.e. biomass thickness reduction and related changes in the reactor specific surface area; the model allows for qualitative description of the biotrickling filtration process | [159] |

| Chlorobenzene, ortho-chlorobenzene | Glass BTF column of din = 0.152 m and H = 0.79 m packed with Intalox ceramic saddles, inoculated with microbial community from previous studies | The model is a development of [135] and includes cross-inhibition effects during the biofiltration of a mixture of chlorobenzene (with kinetic competition for biodegradation) | [160] |

| Hydrogen sulfide | Pilot scale biofilter—insulated vertical fiberglass cylinder with din = 0.608 m and H = 1.8 m, packed with lava rock particles, inoculum from activated sludge | Conceptual model incorporating detailed mass transfer phenomena, biofilm formation, and biomass decay; a dynamic model for biofiltration of real waste air streams from wastewater treatment plants | [161] |

| Differential biotrickling filter filled with a open-pore polyurethane foam cube (side wall of 0.04 m) with already developed biofilm from previous processes | Conceptual model for predicting mass transfer phenomena; the model considers the wetting of packing, as well as gas/liquid/biofilm mass transfer issues; uniform biofilm thickness, non-uniform biofilm wetting, plug flow for gas phase; no reaction in the liquid is assumed; the model proved that the biofiltration of H2S may be highly limited by the external mass transfer | [138] | |

| Mono-chlorobenzene | Perspex tube (din = 0.05 m; H = 1 m); coal particles on acrylic plastic mesh; inoculation with activated sludge | The model utilizes Monod kinetics for the description of biodegradation; biodegradation is evaluated solely as an aerobic process; the plug flow of gas phase and negligible axial dispersion are assumed, the biofilter is regarded isothermic; the model predicts the concentration profile of the VOC in the gas phase, in the biofilm, and in the trickling liquid retained on solid particles; the model follows first-order kinetics | [162] |

| Dimethyl sulfide and methanol | PMMA biofilter (din = 0.101 m; H = 0.33 m); Packed with Nova inert i.e. porous silica packing, inoculated with activated sludge | Model assumptions: plug flow of gas phase, no mass transfer resistance, rectangular geometry for biofilm, methanol and DMS are the only growth substrates for microbes, microbial species degrading both substrates are the same; the model incorporates competitive and activation functions of methanol on DMS biofiltration and sets the basis for the description and modeling of VOC mixtures, and successfully predicted the feeding strategies for enhanced biofiltration performance | [139] |

| Styrene | Glass biofilter (din = 0.005 m, H = 0.41 m) packed with coconut coir inoculated with Pseudomonas putida | Model assumptions include: negligible internal and external mass transfer resistance, plug flow bioreactor, uniform distribution of microorganisms throughout the biofilter packing, equilibrium at gas–liquid/liquid–solid interfaces; a deterministic model based on the kinetic parameters is proposed for describing biofiltration behavior for styrene abatement | [163] |

| CO2 as a model compound for absorption studies | Typical packing for biofilters and biotrickling filters, including: porous ceramic rings, Pall rings, polyurethane foam, Lava rock, compost mixture | The paper presents an approach for determining and setting the reference values of mass transfer coefficients for various packing materials used in biofiltration/biotrickling filtration; the approach and obtained values are useful for modeling purposes for a broad range of biofilter configurations; this is an important contribution to further studies of biofiltration modeling | [164,165] |

| Ammonia and hydrogen sulfide | Acrylic tube (din = 0.1 m; H = 0.61 m); polypropylene, polystyrene or PVC packing elements | The model combines the models described in [153,154]; the model describes co- and counter -current biotrickling filtration for the simultaneous treatment of gas and liquid contaminants; the model assumptions include a plug flow, no oxygen or nutrient limitation, constant biofilm density, substrate concentration at the liquid-biofilm interface is the same as in the bulk liquid, and adsorption, as well as direct transfer of substrate to the biofilm, are insignificant | [143] |

| Methane | Feasibility study—no single experimental verification of the model | Modeling of biotrickling filtration using methanotrophic bacteria; a general, theoretical model for the estimation of methane removal is proposed; the assumptions of model are taken from [155] | [166] |

| Ethyl acetate, toluene (separately) and their mixture | Biofilter with intermittently supplied liquid solution; biofilter (din = 0.136 m, H = 0.95 m) packed with fibrous peat inoculated with pre-acclimated activated sludge | A dynamic model with the following assumptions: plug flow of gas phase, mass transfer is limited by the diffusion resistance in the liquid phase, adsorption phenomena are negligible, biofilm develops only on the surface of packing elements, inhibition in biodegradation is accounted for; cross-inhibition of ethyl acetate on the toluene removal is confirmed | [140] |

| Ethylene | Theoretical approach | Modeling with the use of genetic algorithms; inverse modeling is used to estimate values of biofiltration parameters | [167] |

| TRS (total reduced sulfur) | Theoretical approach | Sensitivity analysis on the mathematical model for biotrickling filtration of TRS revealed that biofilm properties and kinetics had the most important influence on the model behavior | [168] |

| Hexane | PVC column (din = 0.083 m, H = 0.53 m); abiotic conditions were tested for determining mass transfer from gas to liquid phase | Modeling resulting in an isomorphous equation describing the maximum fraction of VOC that can be transferred from the gas to liquid phase within the comparison of three types of bioreactors; the biotrickling filter working as a two-liquid phase system exhibited the highest mass transfer performance | [141] |

| Hydrogen sulfide | Pilot scale biotrickling filter (din = 0.3 m, H = 1.1 m) packed with polyurethane foam cubes inoculated with WWTP activated sludge | A model describing biomass accumulation (the production of solids) related to the pressure head loss increase due to the occurrence of solids by sulfur transformations; the growth rate of biomass, measurements of pressure drops, biomass increase, effluent COD, and total solids were successfully modeled | [169] |

| Nitric oxide | A plexiglass cylinder (din = 0.08 m, H = 0.3 m) packed with porous ceramic particles inoculated with Chelatococcus daeguensis TAD 1 | The model incorporates gaseous chemical oxidation for NO removal during biotrickling filtration, which is novel in biotrickling filtration modeling; the assumptions include plug glow of a gas phase, planar geometry of the biofilm, NO as a single rate-limiting substrate, no excessive biomass and uniform distribution of the biofilm; Monod-type kinetics and mass transfer in the gas–biofilm interface are exploited | [170] |

| Ethyl acetate | Plexiglass column (din = 0.062 m, H = 1 m) packed with walnut shell, inoculated with Pseudomonas putida PTCC 1694 | Experimental model based on zeroth order kinetics with diffusion limitation, assuming gas plug flow, constant biofilm thickness, and diffusion following Fick’s law; paper presents optimal results of various model results for the experimental data | [171] |

| Benzene, toluene, ethylbenzene, o-xylene (BTEX) | Perspex pipe (din = 0.14 m, H = 0.6 m) packed with corn-cobs, inoculated with Bacillus sphaericus | CDR (convection–diffusion reactor) model was used to generate VOC concentration profiles along the biofilter | [172] |

| Hydrogen sulfide | A theoretical model | A dynamic model as an extension of a differential reactor model by Kim and Deshusses [138]; the model includes mass balances in gas, liquid, wetted, and non-wetted biofilm; biotrickling filtration performance is mostly affected by H2S concentration and gas flow rate | [144] |

| Isopropanol | Methacrylate column (din = 0.144 m, H = 1.2 m); two packing materials were compared: random and structured polymeric media | A model aimed at describing mass transfer properties in biotrickling filters for a hydrophilic compound, including the mass transfer of oxygen, which is a limiting factor in such conditions; the results showed that global mass transfer coefficients describes the mass transfer phenomena in biotrickling filters with the highest accuracy | [146] |

| Hydrogen sulfide | Differential biotrickling filter | A dynamic model for describing the biotrickling filtration of high loads of H2S; assumptions of the model include: biofilm is completely covered with a liquid, adsorption phenomena are negligible, biofilm is uniformly distributed over packing elements, biomass contains active and non-active parts; gas–liquid mass transfer is described by the gas–liquid mass transfer coefficient, the biodegradation kinetics of hydrogen sulfide follow the Haldane equation; the model reveals a high dependence of H2S biofiltration on oxygen mass transfer | [173] |

| Hydrophilic VOCs: ethanol, ethyl acetate, 1-ethoxy-2-propanol | Two systems were investigated: a laboratory biotrickling filter (din = 0.144 m, H = 1 m) and an industrial biotrickling filter (packing volume: 49 m3) filled with polypropylene rings inoculated with activated sludge | A dynamic model for biotrickling filtration with intermittent trickling patterns; the liquid phase is considered mobile during spraying episodes and considered stagnant for non-spraying periods; it makes similar assumptions to [173], except for: biodegradation kinetics follow a Monod equation, the presence of biomass in the biofilter increases the resistance for mass transfer from the gas to liquid phase, oxygen limitation is assumed; the model predicts performance, outlet emission peaks, and decreases in concentrations of outlet gases after trickling stops | [103] |

| Methane | PVC column (din = 0.153 m, H = 1.2 m) packed with polyethylene rings inoculated with methanotrophic bacteria, i.e., Methylomicrobium album (ATCC 33003) and Methylocystis sp. (ATCC 49242) | A dynamic mathematical model based on mass transfer and kinetic parameters; the model assumptions include: plug flow of gas phase with no axial dispersion, gas–biofilm equilibrium follows Henry’s law, diffusion is described by Fick’s law, biofilm develops only on the outer surface of packing elements, the surface properties of the biofilm are the same as those for water, uniform distribution and no accumulation of biomass, no adsorption of the pollutant | [174] |

| Styrene | Laboratory (din = 0.144 m, H = 1.23 m) and industrial biofilters (volume of packing: 0.6 m3), packed with polypropylene rings and structured packing, respectively | A three-phase dynamic model accounting for the convection, mass transfer, diffusion, and biodegradation phenomena of a biotrickling filtration process; the model is based on mass balances of the above-listed phenomena; the model assumes gas phase plug flow, a negligible share of adsorption and axial dispersion pertaining to biofiltration performance, that biodegradation takes place only within the biofilm; a numerical solution to the model by Matlab software; a limiting factor for the biotrickling filtration of hydrophobic compounds is their water solubility | [69] |

| Styrene | Pilot-scale stainless-steel biotrickling filter (din = 1.084 m, H = 3.51 m) packed with polypropylene Ralu rings inoculated with microorganisms (E-93486 strain) | Simple one substrate model was proposed; the paper presents verification of a two-substrate and one-substrate model for styrene removal from air; oxygen is not a limiting factor for the biotreatment of styrene-polluted air; the simple one-substrate model gave the lowest values of mean relative error, and can be used for predicting the performance of styrene biotrickling filtration | [145] |

| Hydrogen sulfide | A full-scale SULPHUS system was applied using a structured packing media (din = 3m, H = 5 m) | The paper revises and restates selected models for biodegradation kinetics in biofilms, as well as proposes novel assumptions to be included in the biofilter models; a broad set of data is fit to the existing models, and the most appropriate models for various ranges of H2S inlet concentrations are proposed | [147] |

| Biogas upgrading | PVC column (din = 0.03 m, H = 1 m) packed with open pore polyurethane foam inoculated with hydrogenotrophic methanogens (Methanospirillum hungatei and additional biomass suspension) | The developed conceptual model includes the transport of hydrogen from the gas to wetted and non-wetted biofilm fractions; the model assumptions include: the uniform spread and thickness of biofilm, biofilm thickness remains constant and cannot be not fully wetted, dynamic variations in biofilm and adsorption on packing material are neglected, diffusion in the biofilm is described by Fick’s law, axial dispersion is considered (e.g., due to high substrate concentration), the most sensitive parameters of the model are the gas flow rate, specific surface area, biofilm thickness, and maximum reaction rate; the model can be used for the optimization of biotrickling filters for biogas upgrading, | [172] |

| Toluene and methanol | Glass column (din = 0.065 m, H = 0.8 m) packed with a mixture of pumice grains and HDPE pall rings inoculated with a consortium of microorganisms, including Pandoraea pnomenusa DSM 16536 and Ralstonia eutrohpa PTCC1615 | Dynamic model based on mass transfer through gas, liquid, and biofilm phases is developed; assumptions include neglected physical adsorption, plug flow for gas phase, no axial dispersion, planar biofilm geometry, neglected methanol stripping from liquid, and no oxygen limitation; the model was calibrated and validated; the model indicated the fractions of a biofilm / biotrickling filter that are active in the degradation of either toluene or methanol; sensitivity analyses were performed; model can predict the dynamics of VOC biotrickling filtration, together with the determination of kinetic constants | [142] |

| Hydrogen sulfide (biogas upgrading) | A laboratory-scale biotrickling filter (din = 0.0714 m, H = 0.7 m) packed with polypropylene Pall rings, inoculated with aerobic sludge | Liquid–gas mass transfer correlations are provided; a dynamic model for predicting physio-chemical and biological process during biogas desulfurization using a biotrickling filter; the model is a three-phase model that can describe biotrickling filter operation for variable H2S inlet loading | [173] |

5. Concluding Remarks and Future Perspectives

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, H.; Yin, Z.; Quan, Y.; Fang, Y.; Yin, C. Removal of methyl acrylate by ceramic-packed biotrickling filter and their response to bacterial community. Bioresour. Technol. 2016, 209, 237–245. [Google Scholar] [CrossRef] [PubMed]

- Anand, S.S.; Philip, B.K.; Mehendale, H.M. Volatile Organic Compounds. Encycl. Toxicol. Third Ed. 2014, 967–970. [Google Scholar] [CrossRef] [Green Version]

- Sbai, S.E.; Mejjad, N.; Norelyaqine, A.; Bentayeb, F. Air quality change during the COVID-19 pandemic lockdown over the Auvergne-Rhône-Alpes region, France. Air Qual. Atmos. Health 2021, 14, 617–628. [Google Scholar] [CrossRef] [PubMed]

- Conticini, E.; Frediani, B.; Caro, D. Can atmospheric pollution be considered a co-factor in extremely high level of SARS-CoV-2 lethality in Northern Italy? Environ. Pollut. 2020, 261, 114465. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Deng, J.; Xie, S.; Wang, Z.; Dai, H. Catalytic removal of volatile organic compounds using ordered porous transition metal oxide and supported noble metal catalysts. Cuihua Xuebao/Chin. J. Catal. 2016, 37, 1193–1205. [Google Scholar] [CrossRef]

- Li, Y.; Chang, H.; Yan, H.; Tian, S.; Jessop, P.G. Reversible Absorption of Volatile Organic Compounds by Switchable-Hydrophilicity Solvents: A Case Study of Toluene with N, N-Dimethylcyclohexylamine. ACS Omega 2021, 6, 253–264. [Google Scholar] [CrossRef]

- Gil, R.R.; Ruiz, B.; Lozano, M.S.; Martín, M.J.; Fuente, E. VOCs removal by adsorption onto activated carbons from biocollagenic wastes of vegetable tanning. Chem. Eng. J. 2014, 245, 80–88. [Google Scholar] [CrossRef]

- Gupta, V.K.; Verma, N. Removal of volatile organic compounds by cryogenic condensation followed by adsorption. Chem. Eng. Sci. 2002, 57, 2679–2696. [Google Scholar] [CrossRef]

- Song, M.; Kim, K.; Cho, C.; Kim, D. Reduction of Volatile Organic Compounds (VOCs) Emissions from Laundry Dry-Cleaning by an Integrated Treatment Process of Condensation and Adsorption. Processes 2021, 9, 1658. [Google Scholar] [CrossRef]

- Poddar, T.K.; Majumdar, S.; Sirkar, K.K. Removal of VOCs from air by membrane-based absorption and stripping. J. Memb. Sci. 1996, 120, 221–237. [Google Scholar] [CrossRef]

- Bai, B.; Qiao, Q.; Li, J.; Hao, J. Progress in research on catalysts for catalytic oxidation of formaldehyde. Cuihua Xuebao/Chin. J. Catal. 2016, 37, 102–122. [Google Scholar] [CrossRef]

- Dobslaw, D.; Engesser, K.H.; Störk, H.; Gerl, T. Low-cost process for emission abatement of biogas internal combustion engines. J. Clean. Prod. 2019, 227, 1079–1092. [Google Scholar] [CrossRef]

- Wang, C.; Xi, J.Y.; Hu, H.Y.; Yao, Y. Effects of UV pretreatment on microbial community structure and metabolic characteristics in a subsequent biofilter treating gaseous chlorobenzene. Bioresour. Technol. 2009, 100, 5581–5587. [Google Scholar] [CrossRef] [PubMed]

- Sivachandiran, L.; Thevenet, F.; Rousseau, A. Isopropanol removal using MnXOY packed bed non-thermal plasma reactor: Comparison between continuous treatment and sequential sorption/regeneration. Chem. Eng. J. 2015, 270, 327–335. [Google Scholar] [CrossRef]

- Liang, Z.; Wang, J.; Zhang, Y.; Han, C.; Ma, S.; Chen, J.; Li, G.; An, T. Removal of volatile organic compounds (VOCs) emitted from a textile dyeing wastewater treatment plant and the attenuation of respiratory health risks using a pilot-scale biofilter. J. Clean. Prod. 2020, 253, 120019. [Google Scholar] [CrossRef]

- Rybarczyk, P.; Szulczyński, B.; Gębicki, J.; Hupka, J. Treatment of malodorous air in biotrickling filters: A review. Biochem. Eng. J. 2019, 141, 146–162. [Google Scholar] [CrossRef]

- Dobslaw, D.; Ortlinghaus, O. Biological Waste Air and Waste Gas Treatment: Overview, Challenges, Operational Efficiency, and Current Trends. Sustain. 2020, 12, 8577. [Google Scholar] [CrossRef]

- Barbusiński, K.; Urbaniec, K.; Kasperczyk, D.; Thomas, M. Biofilters versus bioscrubbers and biotrickling filters: State-of-the-art biological air treatment. In From Biofiltration to Promising Options in Gaseous Fluxes Biotreatment: Recent Developments, New Trends, Advances, and Opportunities; Elsevier: Amsterdam, The Netherlands, 2020; pp. 29–51. ISBN 9780128190647. [Google Scholar]

- Runye, Z.; Kennes, C.; Zhuowei, C.; Lichao, L.; Jianming, Y.; Jianmeng, C. Styrene removal in a biotrickling filter and a combined UV–biotrickling filter: Steady- and transient-state performance and microbial analysis. Chem. Eng. J. 2015, 275, 168–178. [Google Scholar] [CrossRef]

- Helbich, S.; Dobslaw, D.; Schulz, A.; Engesser, K.-H. Styrene and Bioaerosol Removal from Waste Air with a Combined Biotrickling Filter and DBD–Plasma System. Sustainability 2020, 12, 9240. [Google Scholar] [CrossRef]

- Cheng, Z.W.; Zhang, L.L.; Chen, J.M.; Yu, J.M.; Gao, Z.L.; Jiang, Y.F. Treatment of gaseous alpha-pinene by a combined system containing photo oxidation and aerobic biotrickling filtration. J. Hazard. Mater. 2011, 192, 1650–1658. [Google Scholar] [CrossRef]

- Zeng, P.; Li, J.; Liao, D.; Tu, X.; Xu, M.; Sun, G. Performance of a combined system of biotrickling filter and photocatalytic reactor in treating waste gases from a paint-manufacturing plant. Environ. Technol. (United Kingd.) 2016, 37, 237–244. [Google Scholar] [CrossRef]

- Barbusinski, K.; Kalemba, K.; Kasperczyk, D.; Urbaniec, K.; Kozik, V. Biological methods for odor treatment—A review. J. Clean. Prod. 2017, 152, 223–241. [Google Scholar] [CrossRef]

- Rene, E.R.; Špačková, R.; Veiga, M.C.; Kennes, C. Biofiltration of mixtures of gas-phase styrene and acetone with the fungus Sporothrix variecibatus. J. Hazard. Mater. 2010, 184, 204–214. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cox, H.H.J.; Deshusses, M.A. Biotrickling Filters; Springer: Dordrecht, The Netherlands, 2001; pp. 99–131. [Google Scholar]

- Deshusses, M.A.; Gabriel, D. Bio trickling filter technology. In Biotechnology for Odor and Air Pollution Control; Springer: Berlin/Heidelberg, Germany, 2005; pp. 147–168. ISBN 3540233121. [Google Scholar]

- Sheoran, K.; Siwal, S.S.; Kapoor, D.; Singh, N.; Saini, A.K.; Alsanie, W.F.; Thakur, V.K. Air Pollutants Removal Using Biofiltration Technique: A Challenge at the Frontiers of Sustainable Environment. ACS Eng. Au 2022, 2, 378–396. [Google Scholar] [CrossRef] [PubMed]

- Lamprea Pineda, P.A.; Demeestere, K.; Toledo, M.; Van Langenhove, H.; Walgraeve, C. Enhanced removal of hydrophobic volatile organic compounds in biofilters and biotrickling filters: A review on the use of surfactants and the addition of hydrophilic compounds. Chemosphere 2021, 279, 130757. [Google Scholar] [CrossRef]

- Meena, M.; Sonigra, P.; Yadav, G. Biological-based methods for the removal of volatile organic compounds (VOCs) and heavy metals. Environ. Sci. Pollut. Res. 2020, 28, 2485–2508. [Google Scholar] [CrossRef] [PubMed]

- Schiavon, M.; Ragazzi, M.; Rada, E.C.; Torretta, V. Air pollution control through biotrickling filters: A review considering operational aspects and expected performance. Crit. Rev. Biotechnol. 2016, 36, 1143–1155. [Google Scholar] [CrossRef] [PubMed]

- Pachaiappan, R.; Cornejo-Ponce, L.; Rajendran, R.; Manavalan, K.; Femilaa Rajan, V.; Awad, F. A review on biofiltration techniques: Recent advancements in the removal of volatile organic compounds and heavy metals in the treatment of polluted water. Bioengineered 2022, 13, 8432–8477. [Google Scholar] [CrossRef]

- Lee, S.-H.; Kurade, M.B.; Jeon, B.-H.; Kim, J.; Zheng, Y.; Salama, E.-S. Water condition in biotrickling filtration for the efficient removal of gaseous contaminants. Crit. Rev. Biotechnol. 2021, 41, 1279–1296. [Google Scholar] [CrossRef]

- Kraakman, N.J.R.; Rocha-Rios, J.; Van Loosdrecht, M.C.M. Review of mass transfer aspects for biological gas treatment. Appl. Microbiol. Biotechnol. 2011, 91, 873–886. [Google Scholar] [CrossRef]

- Yang, C.; Qian, H.; Li, X.; Cheng, Y.; He, H.; Zeng, G.; Xi, J. Simultaneous Removal of Multicomponent VOCs in Biofilters. Trends Biotechnol. 2018, 36, 673–685. [Google Scholar] [CrossRef]

- Gomez, M.; De Oca, M.; Danila, V.; Zagorskis, A.; Januševičius, T. Effects of Water Content and Irrigation of Packing Materials on the Performance of Biofilters and Biotrickling Filters: A Review. Processes 2022, 10, 1304. [Google Scholar] [CrossRef]

- Marycz, M.; Brillowska-Dąbrowska, A.; Muñoz, R.; Gębicki, J. A state of the art review on the use of fungi in biofiltration to remove volatile hydrophobic pollutants. Rev. Environ. Sci. Biotechnol. 2022, 21, 225–246. [Google Scholar] [CrossRef]

- Gabriel, D.; Deshusses, M.A. Retrofitting existing chemical scrubbers to biotrickling filters for H2S emission control. Proc. Natl. Acad. Sci. USA 2003, 100, 6308–6312. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ferdowsi, M.; Avalos Ramirez, A.; Jones, J.P.; Heitz, M. Elimination of mass transfer and kinetic limited organic pollutants in biofilters: A review. Int. Biodeterior. Biodegrad. 2017, 119, 336–348. [Google Scholar] [CrossRef]

- Vergara-Fernández, A.; Yánez, D.; Morales, P.; Scott, F.; Aroca, G.; Diaz-Robles, L.; Moreno-Casas, P. Biofiltration of benzo[A]pyrene, toluene and formaldehyde in air by a consortium of Rhodococcus erythropolis and Fusarium solani: Effect of inlet loads, gas flow and temperature. Chem. Eng. J. 2018, 332, 702–710. [Google Scholar] [CrossRef]

- Guo, J.; Gao, Q. Enhancement of ethylbenzene removal from contaminated gas and corresponding mechanisms in biotrickling filters by a biosurfactant from piggery wastewater. J. Environ. Manage. 2021, 277, 111411. [Google Scholar] [CrossRef]

- Zhanga, Y.; Denga, W.; Qina, Y.; Yanga, Z.; Liua, J.; Lia, J. Research on Simultaneous Removal of Cyclohexane and Methyl Acetate in Biotrickling Filters. In Proceedings of the 2nd International Conference of Recent Trends in Environmental Science and Engineering (RTESE’18), Niagara Falls, ON, Canada, 10–12 June 2018; Available online: https://avestia.com/RTESE2018_Proceedings/files/paper/RTESE_107.pdf (accessed on 31 October 2021).

- Zhao, M.; Hu, L.; Dai, L.; Wang, Z.; He, J.; Wang, Z.; Chen, J.; Hrynsphan, D.; Tatsiana, S. Bamboo charcoal powder-based polyurethane as packing material in biotrickling filter for simultaneous removal of n-hexane and dichloromethane. Bioresour. Technol. 2022, 345, 126427. [Google Scholar] [CrossRef]

- Sempere, F.; Gabaldón, C.; Martínez-Soria, V.; Marzal, P.; Penya-roja, J.M.; Javier Álvarez-Hornos, F. Performance evaluation of a biotrickling filter treating a mixture of oxygenated VOCs during intermittent loading. Chemosphere 2008, 73, 1533–1539. [Google Scholar] [CrossRef] [PubMed]

- Jiménez, L.; Arriaga, S.; Muñoz, R.; Aizpuru, A. Effect of extended and daily short-term starvation/shut-down events on the performance of a biofilter treating toluene vapors. J. Environ. Manage. 2017, 203, 68–75. [Google Scholar] [CrossRef] [PubMed]

- Mudliar, S.; Giri, B.; Padoley, K.; Satpute, D.; Dixit, R.; Bhatt, P.; Pandey, R.; Juwarkar, A.; Vaidya, A. Bioreactors for treatment of VOCs and odours—A review. J. Environ. Manage. 2010, 91, 1039–1054. [Google Scholar] [CrossRef] [PubMed]

- Dobslaw, D.; Woiski, C.; Winkler, F.; Engesser, K.H.; Dobslaw, C. Prevention of clogging in a polyurethane foam packed biotrickling filter treating emissions of 2-butoxyethanol. J. Clean. Prod. 2018, 200, 609–621. [Google Scholar] [CrossRef]

- Baltzis, B.C.; Wojdyla, S.M.; Zarook, S.M. Modeling Biofiltration of VOC Mixtures under Steady-State Conditions. J. Environ. Eng. 1997, 123, 599–605. [Google Scholar] [CrossRef]

- Yao, X.; Shi, Y.; Wang, K.; Wang, C.; He, L.; Li, C.; Yao, Z. Highly efficient degradation of hydrogen sulfide, styrene, and m-xylene in a bio-trickling filter. Sci. Total Environ. 2022, 808, 152130. [Google Scholar] [CrossRef]

- Dou, X.; Liu, J.; Qi, H.; Li, P.; Lu, S.; Li, J. Synergistic removal of m-xylene and its corresponding mechanism in a biotrickling filter. Process Biochem. 2022, 118, 404–412. [Google Scholar] [CrossRef]

- Zehraoui, A.; Hassan, A.A.; Sorial, G.A. Effect of methanol on the biofiltration of n-hexane. J. Hazard. Mater. 2012, 219–220, 176–182. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Li, X.; Liu, H.; Yang, C.; Wu, S.; Du, C.; Nie, L.; Zhong, Y. Effect of presence of hydrophilic volatile organic compounds on removal of hydrophobic n-hexane in biotrickling filters. Chemosphere 2020, 252, 126490. [Google Scholar] [CrossRef] [PubMed]

- Qian, H.; Cheng, Y.; Yang, C.; Wu, S.; Zeng, G.; Xi, J. Performance and biofilm characteristics of biotrickling filters for ethylbenzene removal in the presence of saponins. Environ. Sci. Pollut. Res. 2017 2530 2017, 25, 30021–30030. [Google Scholar] [CrossRef] [PubMed]

- Karre, A.; Jones, K.; Boswell, J.; Paca, J. Evaluation of VOC emissions control and opacity removal using a biological sequential treatment system for forest products applications. J. Chem. Technol. Biotechnol. 2012, 87, 797–805. [Google Scholar] [CrossRef]

- Jiade, W.; Jianmeng, C. Removal of dichloromethane from waste gases with a bio-contact oxidation reactor. Chem. Eng. J. 2006, 123, 103–107. [Google Scholar] [CrossRef]

- Dobslaw, D.; Schöller, J.; Krivak, D.; Helbich, S.; Engesser, K.H. Performance of different biological waste air purification processes in treatment of a waste gas mix containing tert-butyl alcohol and acetone: A comparative study. Chem. Eng. J. 2019, 355, 572–585. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.; Xing, H.; Li, J. Performance and fungal diversity of bio-trickling filters packed with composite media of polydimethylsiloxane and foam ceramics for hydrophobic VOC removal. Chemosphere 2020, 256, 127093. [Google Scholar] [CrossRef] [PubMed]

- López, M.E.; Rene, E.R.; Malhautier, L.; Rocher, J.; Bayle, S.; Veiga, M.C.; Kennes, C. One-stage biotrickling filter for the removal of a mixture of volatile pollutants from air: Performance and microbial community analysis. Bioresour. Technol. 2013, 138, 245–252. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.H.; Shih, J.C.; Lin, C.W. Continuous production of power using microbial fuel cells with integrated biotrickling filter for ethyl acetate-contaminated air stream treatment. Int. J. Hydrog. Energy 2016, 41, 21945–21954. [Google Scholar] [CrossRef]

- Liu, S.H.; Fu, S.H.; Chen, C.Y.; Lin, C.W. Enhanced processing of exhaust gas and power generation by connecting mini-tubular microbial fuel cells in series with a biotrickling filter. Renew. Energy 2020, 156, 342–348. [Google Scholar] [CrossRef]

- Valdebenito-Rolack, E.; Díaz, R.; Marín, F.; Gómez, D.; Hansen, F. Markers for the Comparison of the Performances of Anoxic Biotrickling Filters in Biogas Desulphurisation: A Critical Review. Processes 2021, 9, 567. [Google Scholar] [CrossRef]

- Liu, S.H.; Tsai, S.L.; Lai, Y.R.; Lin, C.W.; Huang, Y.W. Improving the performance of biotrickling filter microbial fuel cells in treating exhaust gas by adjusting the oxygen content of the anode tank. Chemosphere 2021, 278, 130390. [Google Scholar] [CrossRef] [PubMed]

- Korth, B.; Pous, N.; Hönig, R.; Haus, P.; Corrêa, F.B.; Nunes da Rocha, U.; Puig, S.; Harnisch, F. Electrochemical and Microbial Dissection of Electrified Biotrickling Filters. Front. Microbiol. 2022, 13, 1512. [Google Scholar] [CrossRef] [PubMed]

- Szulczyński, B.; Rybarczyk, P.; Gospodarek, M.; Gębicki, J. Biotrickling filtration of n-butanol vapors: Process monitoring using electronic nose and artificial neural network. Mon. Fur Chem. 2019, 150, 1667–1673. [Google Scholar] [CrossRef] [Green Version]

- Mirmohammadi, M.; Sotoudeheian, S.; Bayat, R. Triethylamine removal using biotrickling filter (BTF): Effect of height and recirculation liquid rate on BTFs performance. Int. J. Environ. Sci. Technol. 2017, 14, 1615–1624. [Google Scholar] [CrossRef]

- Aguirre, A.; Bernal, P.; Maureira, D.; Ramos, N.; Vásquez, J.; Urrutia, H.; Gentina, J.C.; Aroca, G. Biofiltration of trimethylamine in biotrickling filter inoculated with Aminobacter aminovorans. Electron. J. Biotechnol. 2018, 33, 63–67. [Google Scholar] [CrossRef]

- Palanisamy, K.; Mezgebe, B.; Sorial, G.A.; Sahle-Demessie, E. Biofiltration of Chloroform in a Trickle Bed Air Biofilter Under Acidic Conditions. Water Air Soil Pollut. 2016, 227, 478. [Google Scholar] [CrossRef] [PubMed]

- Mezgebe, B.; Palanisamy, K.; Sorial, G.A.; Sahle-Demessie, E.; Hassan, A.A.; Lu, J. Comparative Study on the Performance of Anaerobic and Aerobic Biotrickling Filter for Removal of Chloroform. Environ. Eng. Sci. 2018, 35, 462–471. [Google Scholar] [CrossRef]

- San-Valero, P.; Dorado, A.D.; Martínez-Soria, V.; Gabaldón, C. Biotrickling filter modeling for styrene abatement. Part 1: Model development, calibration and validation on an industrial scale. Chemosphere 2018, 191, 1066–1074. [Google Scholar] [CrossRef] [PubMed]

- Chuang, F.-J.; Chou, M.-S.; Chang, H.-Y. Biotrickling filtration of airborne styrene: A comparison of filtration media. J. Air Waste Manag. Assoc. 2018, 68, 369–376. [Google Scholar] [CrossRef]

- Li, K.; Zhou, J.; Wang, L.; Mao, Z.; Xu, R. The styrene purification performance of biotrickling filter with toluene-styrene acclimatization under acidic conditions. J. Air Waste Manag. Assoc. 2019, 69, 944–955. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Liu, J.; Qin, Y.; Yang, Z.; Cao, J.; Xing, Y.; Li, J. Performance and microbial community evolution of toluene degradation using a fungi-based bio-trickling filter. J. Hazard. Mater. 2019, 365, 642–649. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.; Li, J.; Yue, T. Effects of filler voidage on pressure drop and microbial community evolution in fungal bio-trickling filters. Chemosphere 2021, 273, 129710. [Google Scholar] [CrossRef]

- De Vela, R.J.L.; Gostomski, P.A. Design and Performance of a Toluene-Degrading Differential Biotrickling Filter as an Alternative Research Tool to Column Reactors. J. Environ. Eng. 2020, 147, 04020159. [Google Scholar] [CrossRef]

- Salamanca, D.; Dobslaw, D.; Engesser, K.-H. Removal of cyclohexane gaseous emissions using a biotrickling filter system. Chemosphere 2017, 176, 97–107. [Google Scholar] [CrossRef]

- Vergara-Fernández, A.; Hernández, S.; Revah, S. Elimination of hydrophobic volatile organic compounds in fungal biofilters: Reducing start-up time using different carbon sources. Biotechnol. Bioeng. 2011, 108, 758–765. [Google Scholar] [CrossRef] [PubMed]

- Botros, M.M.; Hassan, A.A.; Sorial, G.A.; Botros, M.M.; Hassan, A.A.; Sorial, G.A. Role of Fungal Biomass in N-Hexane Biofiltration. Adv. Microbiol. 2017, 7, 673–688. [Google Scholar] [CrossRef] [Green Version]

- Yu, G.; Wang, G.; Wang, S.; Yang, C.; Chen, H.; Zhu, Y.; Yu, L.; Li, J.; Kazemian, H. Performance promotion and its mechanism for n-hexane removal in a lab-scale biotrickling filter with reticular polyurethane sponge under intermittent spraying mode. Process Saf. Environ. Prot. 2021, 152, 654–662. [Google Scholar] [CrossRef]

- Den, W.; Huang, C.; Li, C.H. Effects of cross-substrate interaction on biotrickling filtration for the control of VOC emissions. Chemosphere 2004, 57, 697–709. [Google Scholar] [CrossRef] [PubMed]

- Den, W.; Ravindran, V.; Pirbazari, M. Photooxidation and biotrickling filtration for controlling industrial emissions of trichloroethylene and perchloroethylene. Chem. Eng. Sci. 2006, 61, 7909–7923. [Google Scholar] [CrossRef]

- Lakey, M.; Manager Victoria, G.; Pitt, M. 36th Annual Qld Water Industry Operations Workshop, Dual Phase Biotrickling Filter Treatment of H2S & VOC’S; 2011. In Proceedings of the 36th Annual Qld Water Industry Operations Workshop, Clive Berghofer Recreation Centre, USQ, Toowoomba, Australia, 31 May–2 June 2011; Available online: http://www.wioa.org.au/conference_papers/2011_qld/documents/Matthew_Lakey.pdf (accessed on 19 June 2022).

- Balasubramanian, P.; Philip, L.; Murty Bhallamudi, S. Biotrickling filtration of complex pharmaceutical VOC emissions along with chloroform. Bioresour. Technol. 2012, 114, 149–159. [Google Scholar] [CrossRef]

- Lebrero, R.; Rodríguez, E.; Estrada, J.M.; García-Encina, P.A.; Muñoz, R. Odor abatement in biotrickling filters: Effect of the EBRT on methyl mercaptan and hydrophobic VOCs removal. Bioresour. Technol. 2012, 109, 38–45. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Li, J.; Chen, J.; Chen, Z.; Li, G.; Sun, G.; An, T. Treatment of organic waste gas in a paint plant by combined technique of biotrickling filtration with photocatalytic oxidation. Chem. Eng. J. 2012, 200–202, 645–653. [Google Scholar] [CrossRef]

- Li, J.; Ye, G.; Sun, D.; An, T.; Sun, G.; Liang, S. Performance of a biotrickling filter in the removal of waste gases containing low concentrations of mixed VOCs from a paint and coating plant. Biodegradation 2012, 23, 177–187. [Google Scholar] [CrossRef] [PubMed]

- Lebrero, R.; Rodríguez, E.; Pérez, R.; García-Encina, P.A.; Muñoz, R. Abatement of odorant compounds in one- and two-phase biotrickling filters under steady and transient conditions. Appl. Microbiol. Biotechnol. 2013, 97, 4627–4638. [Google Scholar] [CrossRef] [PubMed]

- Zehraoui, A.; Hassan, A.A.; Sorial, G.A. Biological treatment of n-hexane and methanol in trickle bed air biofilters under acidic conditions. Biochem. Eng. J. 2013, 77, 129–135. [Google Scholar] [CrossRef]

- Zehraoui, A.; Wendell, D.; Sorial, G.A. Treatment of hydrophobic VOCs in trickling bed air biofilter: Emphasis on long-term effect of initial alternate use of hydrophilic VOCs and microbial species evolution. J. Air Waste Manage. Assoc. 2014, 64, 1102–1111. [Google Scholar] [CrossRef] [Green Version]

- Zehraoui, A.; Kapoor, V.; Wendell, D.; Sorial, G.A. Impact of alternate use of methanol on n-hexane biofiltration and microbial community structure diversity. Biochem. Eng. J. 2014, 85, 110–118. [Google Scholar] [CrossRef]

- Zehraoui, A.; Wendell, D.; Sorial, G.A. Biodegradation of a ternary mixture of hydrophobic and hydrophilic VOCs in trickle bed air biofilters. Water. Air. Soil Pollut. 2014, 225, 1–14. [Google Scholar] [CrossRef]

- Viotti, P.; Schiavon, M.; Gavasci, R.; Capodaglio, A.G. Remoção de benzeno e tolueno de um efluente de refinaria por absorção e filtração "biotrickling". Rev. Ambient. E Agua 2015, 10, 720–727. [Google Scholar] [CrossRef] [Green Version]

- Vanek, T.; Halecky, M.; Paca, J.; Zapotocky, L.; Gelbicova, T.; Vadkertiova, R.; Kozliak, E.; Jones, K. A two-stage combined trickle bed reactor/biofilter for treatment of styrene/acetone vapor mixtures. J. Environ. Sci. Health—Part A Toxic/Hazard. Subst. Environ. Eng. 2015, 50, 1148–1159. [Google Scholar] [CrossRef]

- Chheda, D.; Sorial, G.A. Effect of a Ternary Mixture of Volatile Organic Compounds on Degradation of TCE in Biotrickling Filter Systems. Water. Air. Soil Pollut. 2016, 227, 1–11. [Google Scholar] [CrossRef]

- Chheda, D.; Sorial, G.A. Evaluation of co-metabolic removal of trichloroethylene in a biotrickling filter under acidic conditions. J. Environ. Sci. (China) 2017, 57, 54–61. [Google Scholar] [CrossRef] [Green Version]

- Akmirza, I.; Pascual, C.; Carvajal, A.; Pérez, R.; Muñoz, R.; Lebrero, R. Anoxic biodegradation of BTEX in a biotrickling filter. Sci. Total Environ. 2017, 587–588, 457–465. [Google Scholar] [CrossRef]

- Mezgebe, B.; Sorial, G.; Wendell, D.; Sahle-Demessie, E. Effectiveness of biosurfactant for the removal of trihalomethanes by biotrickling filter. Eng. Rep. 2019, 1, e12031. [Google Scholar] [CrossRef]

- Feng, R.; Xu, M.; Li, J.; Huang, S.; Zhao, G.; Tu, X.; Sun, G.; Guo, J. Structure and predictive functional profiling of microbial communities in two biotrickling filters treated with continuous/discontinuous waste gases. AMB Express 2019, 9, 2. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rybarczyk, P.; Szulczyński, B.; Gospodarek, M.; Gębicki, J. Effects of n-butanol presence, inlet loading, empty bed residence time and starvation periods on the performance of a biotrickling filter removing cyclohexane vapors from air. Chem. Pap. 2019, 74, 1039–1047. [Google Scholar] [CrossRef] [Green Version]

- Rybarczyk, P.; Szulczyński, B.; Gębicki, J. Simultaneous Removal of Hexane and Ethanol from Air in a Biotrickling Filter—Process Performance and Monitoring Using Electronic Nose. Sustainability 2020, 12, 387. [Google Scholar] [CrossRef] [Green Version]

- Rybarczyk, P.; Marycz, M.; Szulczyński, B.; Brillowska-Dąbrowska, A.; Rybarczyk, A.; Gębicki, J. Removal of cyclohexane and ethanol from air in biotrickling filters inoculated with Candida albicans and Candida subhashii. Arch. Environ. Prot. 2021, 47, 26–34. [Google Scholar] [CrossRef]

- Marycz, M.; Rodríguez, Y.; Gębicki, J.; Muñoz, R. Systematic comparison of a biotrickling filter and a conventional filter for the removal of a mixture of hydrophobic VOCs by Candida subhashii. Chemosphere 2022, 306, 135608. [Google Scholar] [CrossRef]

- San-Valero, P.; Penya-Roja, J.M.; Javier Álvarez-Hornos, F.; Marzal, P.; Gabaldón, C. Dynamic Mathematical Modelling of the Removal of Hydrophilic VOCs by Biotrickling Filters. OPEN ACCESS Int. J. Environ. Res. Public Health 2015, 12, 746–766. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deshusses, M.A.; Shareefdeen, Z. Modeling of Biofilters and Biotrickling Filters for Odor and VOC Control Applications. Biotechnol. Odor Air Pollut. Control 2005, 213–231. [Google Scholar] [CrossRef]

- Kucharska, K.; Hołowacz, I.; Konopacka-Łyskawa, D.; Rybarczyk, P.; Kamiński, M. Key issues in modeling and optimization of lignocellulosic biomass fermentative conversion to gaseous biofuels. Renew. Energy 2018, 129, 384–408. [Google Scholar] [CrossRef]

- Fedailaine, M.; Moussi, K.; Khitous, M.; Abada, S.; Saber, M.; Tirichine, N. Modeling of the Anaerobic Digestion of Organic Waste for Biogas Production. Procedia Comput. Sci. 2015, 52, 730–737. [Google Scholar] [CrossRef] [Green Version]

- Lebrero, R.; Rodríguez, E.; Collantes, M.; De Juan, C.; Norden, G.; Rosenbom, K.; Muñoz, R.; Maria, L.; Capelli, T.; Invernizzi, M. Comparative Performance Evaluation of Commercial Packing Materials for Malodorants Abatement in Biofiltration Comparative Performance Evaluation of Commercial Packing Materials for Malodorants Abatement in. Biofiltration. Appl. Sci 2021, 2021, 2966. [Google Scholar] [CrossRef]

- Devinny, J.S.; Ramesh, J. A phenomenological review of biofilter models. Chem. Eng. J. 2005, 113, 187–196. [Google Scholar] [CrossRef]

- Shareefdeen, Z.; Singh, A. Biotechnology for Odor and Air Pollution Control; Springer: Berlin/Heidelberg, Germany, 2005; ISBN 3540233121. [Google Scholar]

- Ottengraf, S.P.P.; Oever, A.H.C. Van Den Kinetics of organic compound removal from waste gases with a biological filter. Biotechnol. Bioeng. 1983, 25, 3089–3102. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deshusses, M.A.; Hamer, G. Bioprocess Engineering The removal of volatile ketone mixtures from air in biofilters. Bioprocess Eng. 1993, 9, 141–146. [Google Scholar] [CrossRef]

- Shareefdeen, Z.; Baltzis, B.C. Biofiltration of toluene vapor under steady-state and transient conditions: Theory and experimental results. Chem. Eng. Sci. 1994, 49, 4347–4360. [Google Scholar] [CrossRef]

- Świsłowski, M. Removal of organic substances vapors from air in a biofilter with natural packings (in Polish). Ph.D. Dissertation, Gdansk University of Technology, Gdansk, Poland, 2002. [Google Scholar]

- Dupasquier, D.; Revah, S.; Auria, R. Biofiltration of methyl tert-butyl ether vapors by cometabolism with pentane: Modeling and experimental approach. Environ. Sci. Technol. 2002, 36, 247–253. [Google Scholar] [CrossRef]

- Hodge, D.S.; Devinny, J.S. Modeling Removal of Air Contaminants by Biofiltration. J. Environ. Eng. 1995, 121, 21–32. [Google Scholar] [CrossRef]

- Deshusses, M.A.; Hamer, G.; Dunn, I.J. Behavior of Biofilters for Waste Air Biotreatment. 1. Dynamic Model Development. Environ. Sci. Technol 1995, 29, 1048–1058. [Google Scholar] [CrossRef]

- Amanullah, M.; Farooq, S.; Viswanathan, S. Modeling and Simulation of a Biofilter. Ind. Eng. Chem. Res. 1999, 38, 2765–2774. [Google Scholar] [CrossRef]

- Ozis, F.; Bina, A.; Devinny, J.S. Biofilm Growth-Percolation Models and Channeling in Biofilter Clogging. J. Air Waste Manage. Assoc. 2007, 57, 882–892. [Google Scholar] [CrossRef] [Green Version]

- Optimization of Biofiltration for Odor Control: Model Calibration, Validation, and Applications on JSTOR. Available online: https://www.jstor.org/stable/25045568 (accessed on 18 August 2022).

- Xi, J.; Kang, I.; Hu, H.; Zhang, X. A biofilter model for simultaneous simulation of toluene removal and bed pressure drop under varied inlet loadings. Front. Environ. Sci. Eng. 2014 93 2014, 9, 554–562. [Google Scholar] [CrossRef]

- Vaiškūnaitė, R.; Zagorskis, A. Modelling of a biofiltration process of volatile organic compound mixtures in a biofilter. Biotechnol. Biotechnol. Equip. 2016, 30, 1217–1222. [Google Scholar] [CrossRef] [Green Version]

- Süß, M.; Visscher, A. De Experimental and numerical study of steady state stability in a toluene biodegrading biofilter. Sci. Rep. 2022, 12, 12510. [Google Scholar] [CrossRef]

- Shareefdeen, Z.; Baltzis, B.C.; Oh, Y.-S.; Bartha, R. Biofiltration of methanol vapor. Biotechnol. Bioeng. 1993, 41, 512–524. [Google Scholar] [CrossRef] [PubMed]

- Shareefdeen, Z.; Baltzis, B.C. Biological Removal of Hydrophobic Solvent Vapors from Airstreams. Adv. Bioprocess Eng. 1994, 397–404. [Google Scholar] [CrossRef]

- Deshusses, M.A.; Hamer, G.; Dunn, I.J. Behavior of Biofilters for Waste Air Biotreatment 2. Experimental Evaluation of a Dynamic Model. Environ. Sci. Technol 1995, 29, 1059–1068. [Google Scholar] [CrossRef] [PubMed]

- Zarook, S.M.; Shaikh, A.A.; Ansar, Z. Development, experimental validation and dynamic analysis of a general transient biofilter model. Chem. Eng. Sci. 1997, 52, 759–773. [Google Scholar] [CrossRef]

- Mohseni, M.; Allen, D.G. Biofiltration of mixtures of hydrophilic and hydrophobic volatile organic compounds. Chem. Eng. Sci. 2000, 55, 1545–1558. [Google Scholar] [CrossRef]

- Raghuvanshi, S.; Babu, B.V. Modeling and Simulation of Biofilters Operated in Periodic Mode. Available online: https://www.researchgate.net/publication/252695298_Modeling_and_Simulation_of_Biofilters_Operated_in_Periodic_Mode (accessed on 19 June 2022).

- Rene, E.R.; Veiga, M.C.; Kennes, C. Experimental and neural model analysis of styrene removal from polluted air in a biofilter. J. Chem. Technol. Biotechnol. 2009, 84, 941–948. [Google Scholar] [CrossRef] [Green Version]

- Ranjbar, S.; Ghaemi, A. Mathematical Modeling for Volatile Organic Compounds Removal in a Biofilter: Model Validation and Sensitivity Analysis. Iran. J. Chem. Eng. 2013, 10, 77. [Google Scholar]

- Meena, V.; Rajendran, L.; Kumar, S.; Jansi Rani, P.G. Mathematical modeling of gas phase and biofilm phase biofilter performance. Egypt. J. Basic Appl. Sci. 2016, 3, 94–105. [Google Scholar] [CrossRef] [Green Version]

- Salih, M.; Shareefdeen, Z.; Khouri, S. A novel approach to the solution of a steady state biofilter model. Environ. Eng. Res. 2020, 25, 779–787. [Google Scholar] [CrossRef]

- Diks, R.M.M.; Ottengraf, S.P.P. Verification studies of a simplified model for the removal of dichloromethane from waste gases using a biological trickling filter. Bioprocess Eng. 1991, 6, 93–99. [Google Scholar] [CrossRef] [Green Version]

- Hartmans, S.; Tramper, J. Dichloromethane removal from waste gases with a trickle-bed bioreactor. Bioprocess Eng. 1991, 6, 83–92. [Google Scholar] [CrossRef]

- Mpanias, C.J.; Baltzis, B.C. An Experimental and Modeling Study on the Removal of Mono-Chlorobenzene Vapor in Biotrickling Filters. Biotechnol Bioeng 1998, 59, 328–343. [Google Scholar] [CrossRef]

- Okkerse, W.J.H.; Ottengraf, S.P.P.; Osinga-Kuipers, B.; Okkerse, M. Biomass Accumulation and Clogging in Biotrickling Filters for Waste Gas Treatment. Evaluation of a Dynamic Model Using Dichloromethane as a Model Pollutant. 1999, 63, 418–430. [Google Scholar] [CrossRef]

- Zhu, X.; Alonso, C.; Suidan, M.T.; Cao, H.; Kim, B.J.; Kim, B.R. The effect of liquid phase on VOC removal in trickle-bed biofilters. Water Sci. Technol. 1998, 38, 315–322. [Google Scholar] [CrossRef]

- Kim, S.; Deshusses, M.A. Development and experimental validation of a conceptual model for biotrickling filtration of H2S. Environ. Prog. 2003, 22, 119–128. [Google Scholar] [CrossRef]

- Zhang, Y.; Liss, S.N.; Allen, D.G. Modeling the Biofiltration of Dimethyl Sulfide in the Presence of Methanol in Inorganic Biofilters at Steady State. Biotechnol. Prog. 2008, 24, 845–851. [Google Scholar] [CrossRef] [PubMed]

- Álvarez-Hornos, F.J.; Gabaldón, C.; Martínez-Soria, V.; Marzal, P.; Penya-roja, J.M. Mathematical modeling of the biofiltration of ethyl acetate and toluene and their mixture. Biochem. Eng. J. 2009, 43, 169–177. [Google Scholar] [CrossRef]

- Hernández, M.; Quijano, G.; Muñoz, R.; Bordel, S. Modeling of VOC mass transfer in two-liquid phase stirred tank, biotrickling filter and airlift reactors. Chem. Eng. J. 2011, 172, 961–969. [Google Scholar] [CrossRef]

- Kalantar, M.; Zamir, S.M.; Ferdowsi, M.; Shojaosadati, S.A. Removal of toluene in a biotrickling filter in the presence of methanol vapors: Experimental study, mathematical modeling, and kinetic parameters optimization. J. Environ. Chem. Eng. 2021, 9, 104617. [Google Scholar] [CrossRef]

- Sharvelle, S.; Arabi, M.; McLamore, E.; Banks, M.K. Model Development for Biotrickling Filter Treatment of Graywater Simulant and Waste Gas. I. J. Environ. Eng. 2008, 134, 813–825. [Google Scholar] [CrossRef]

- Ahmed, W.; Shareefdeen, Z.M.; Jabbar, N.A. Dynamic modeling and analysis of biotrickling filters in continuous operation for H2S removal. Clean Technol. Environ. Policy 2014, 16, 1757–1765. [Google Scholar] [CrossRef]

- Gąszczak, A.; Bartelmus, G.; Burghardt, A.; Rotkegel, A.; Sarzyński, R. Experiments and modelling of a biotrickling filter (BTF) for removal of styrene from airstreams. J. Chem. Technol. Biotechnol. 2018, 93, 2659–2670. [Google Scholar] [CrossRef]

- San-Valero, P.; Penya-Roja, J.M.; Álvarez-Hornos, F.J.; Gabaldón, C. Modelling mass transfer properties in a biotrickling filter for the removal of isopropanol. Chem. Eng. Sci. 2014, 108, 47–56. [Google Scholar] [CrossRef] [Green Version]

- Beigi, B.H.M.; Thorpe, R.B.; Ouki, S.; Winter, P.; Waalkens, A. Hydrogen sulphide and VOC removal in biotrickling filters: Comparison of data from a full-scale, low-emission unit with kinetic models. Chem. Eng. Sci. 2019, 208, 115033. [Google Scholar] [CrossRef]

- Dallinger, A.; Duldhardt, I.; Kabisch, J.; Schlüter, R.; Schauer, F. Biotransformation of cyclohexane and related alicyclic hydrocarbons by Candida maltosa and Trichosporon species. Int. Biodeterior. Biodegrad. 2016, 107, 132–139. [Google Scholar] [CrossRef]

- Dewidar, A.A.; Sorial, G.A. Effect of surfactin on removal of semi-volatile organic compound: Emphasis on enhanced biofiltration performance. Environ. Res. 2021, 193, 110532. [Google Scholar] [CrossRef] [PubMed]

- López, L.R.; Bezerra, T.; Mora, M.; Lafuente, J.; Gabriel, D. Influence of trickling liquid velocity and flow pattern in the improvement of oxygen transport in aerobic biotrickling filters for biogas desulfurization. J. Chem. Technol. Biotechnol. 2016, 91, 1031–1039. [Google Scholar] [CrossRef]

- López, L.R.; Dorado, A.D.; Mora, M.; Gamisans, X.; Lafuente, J.; Gabriel, D. Modeling an aerobic biotrickling filter for biogas desulfurization through a multi-step oxidation mechanism. Chem. Eng. J. 2016, 294, 447–457. [Google Scholar] [CrossRef] [Green Version]

- Taha, A.; Patón, M.; Rodríguez, J. Model-based design and operation of biotrickling filters for foul air H2S removal at wastewater networks. J. Environ. Chem. Eng. 2022, 10, 107372. [Google Scholar] [CrossRef]

- Diks, R.M.M.; Ottengraf, S.P.P. Bioproeess Engineering Verification studies of a simplified model for the removal of dichloromethane from waste gases using a biological trickling filter (Part II). Bioprocess Eng. 1991, 6, 131–140. [Google Scholar] [CrossRef]

- Ockeloen, H.F.; Overcamp, T.J.; Grady, C.P.L., Jr. Engineering Model for Fixed-Film Bioscrubbers. J. Environ. Eng. 1996, 122, 191–197. [Google Scholar] [CrossRef]

- Alonso, C.; Suidan, M.T.; Sorial, G.A.; Smith, F.L.; Biswas, P.; Smith, P.J.; Brenner, R.C. Gas Treatment in Trickle-Bed Biofilters: Biomass, How Much Is Enough? Biotechnol Bioeng 1997, 54, 583–594. [Google Scholar] [CrossRef]

- Barton, J.W.; Hartz, S.M.; Klasson, K.T.; Davison, B.H. Microbial Removal of Alkanes From Dilute Gaseous Waste Streams: Mathematical Modeling of Advanced Bioreactor Systems. 93è98 J. Chem. T Echnol. Biotechnol 1998, 72, 93–98. [Google Scholar] [CrossRef]

- Alonso, C.; Suidan, M.T.; Kim, B.R.; Kim, B.J. Dynamic mathematical model for the diodegradation of VOCs in a biofilter: Biomass accumulation study. Environ. Sci. Technol. 1998, 32, 3118–3123. [Google Scholar] [CrossRef]

- Lobo, R.; Revah, S.; Viveros-García, T. An Analysis of a Trickle-Bed Bioreactor: Carbon Disulfide Removal. Biotechnol. Bioeng. 1999, 63, 98–109. [Google Scholar] [CrossRef]

- Alonso, C.; Zhu, X.; Suidan, M.T.; Kim, B.R.; Kim, B.J. Mathematical Model of Biofiltration of VOCs: Effect of Nitrate Concentration and Backwashing. J. Environ. Eng. 2001, 127, 655–664. [Google Scholar] [CrossRef]