Natural Materials—Interesting Candidates for Carbon Nanomaterials

Abstract

1. Introduction

2. Natural Materials as a Catalyst for Carbon Nanomaterials

2.1. Garnet

2.2. Forsterite, Disposide, Quartz, Magnesite, and Brucite

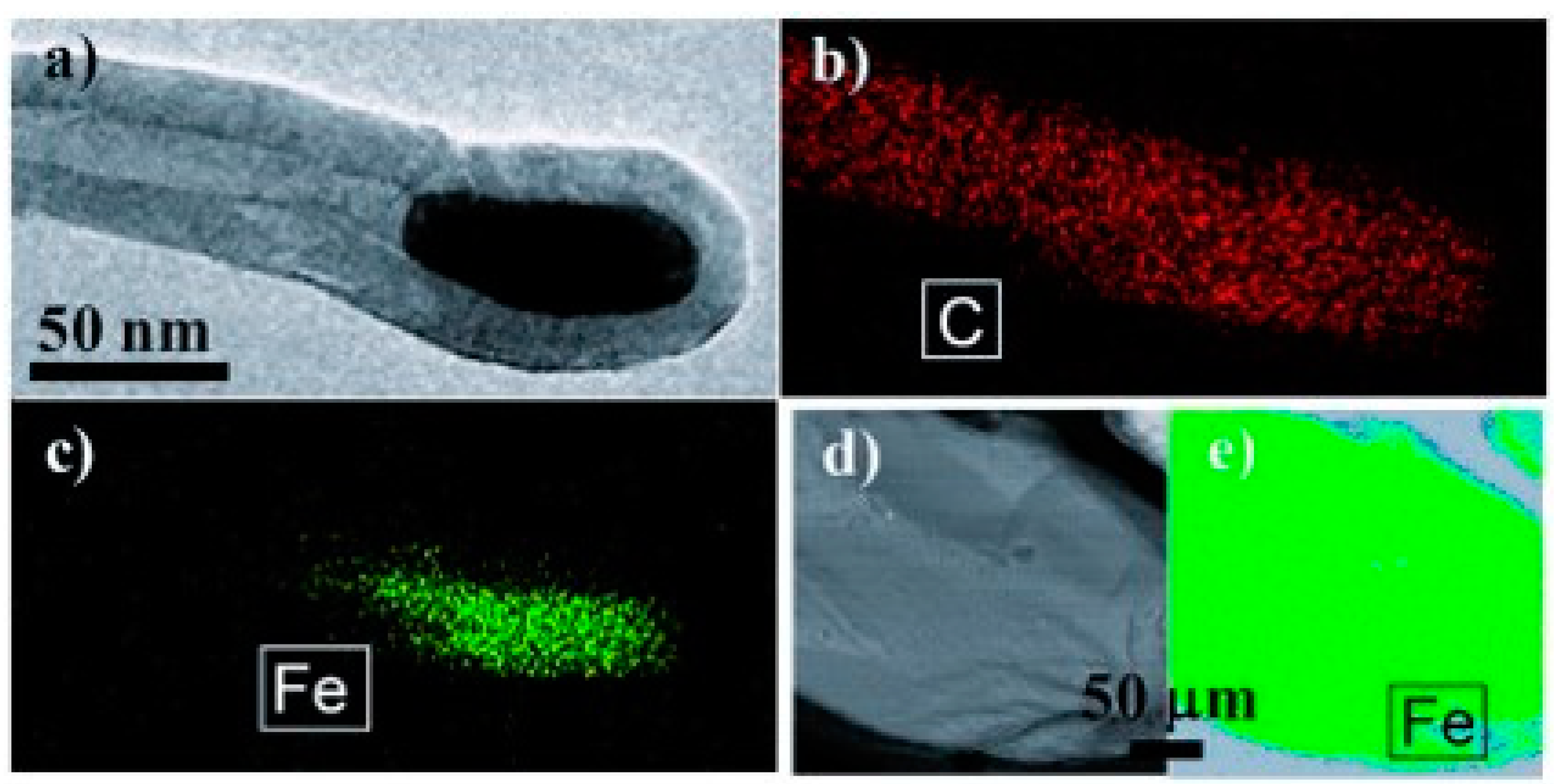

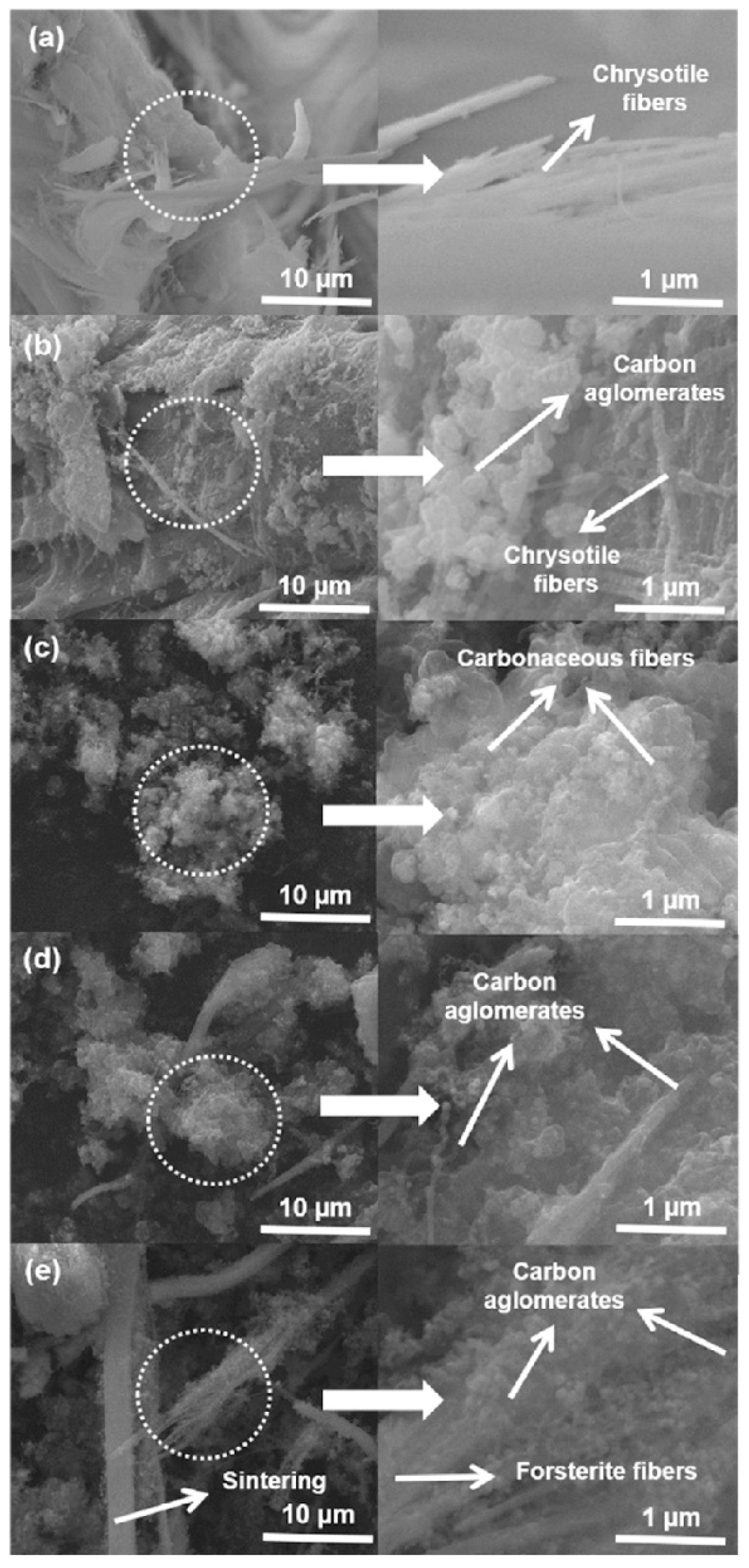

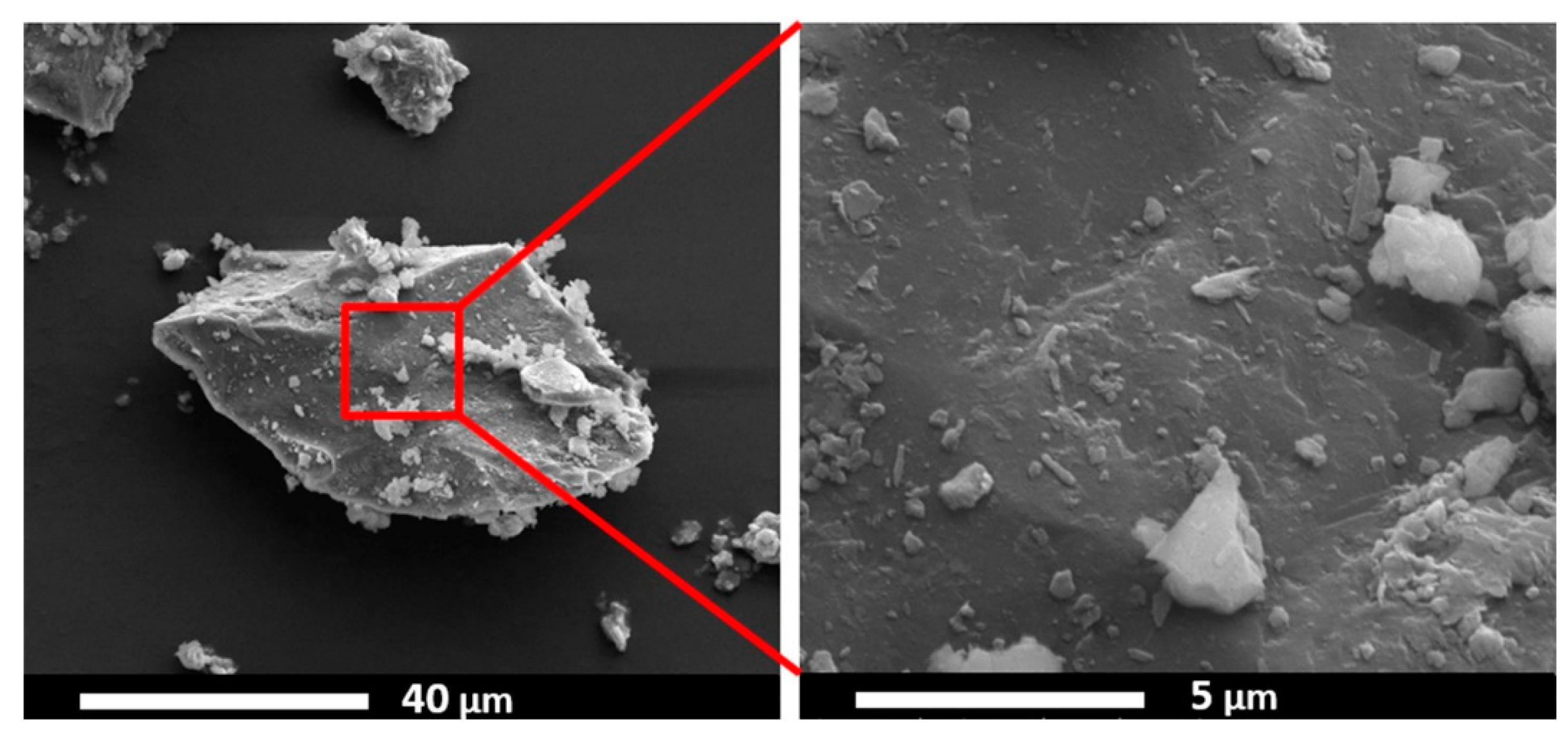

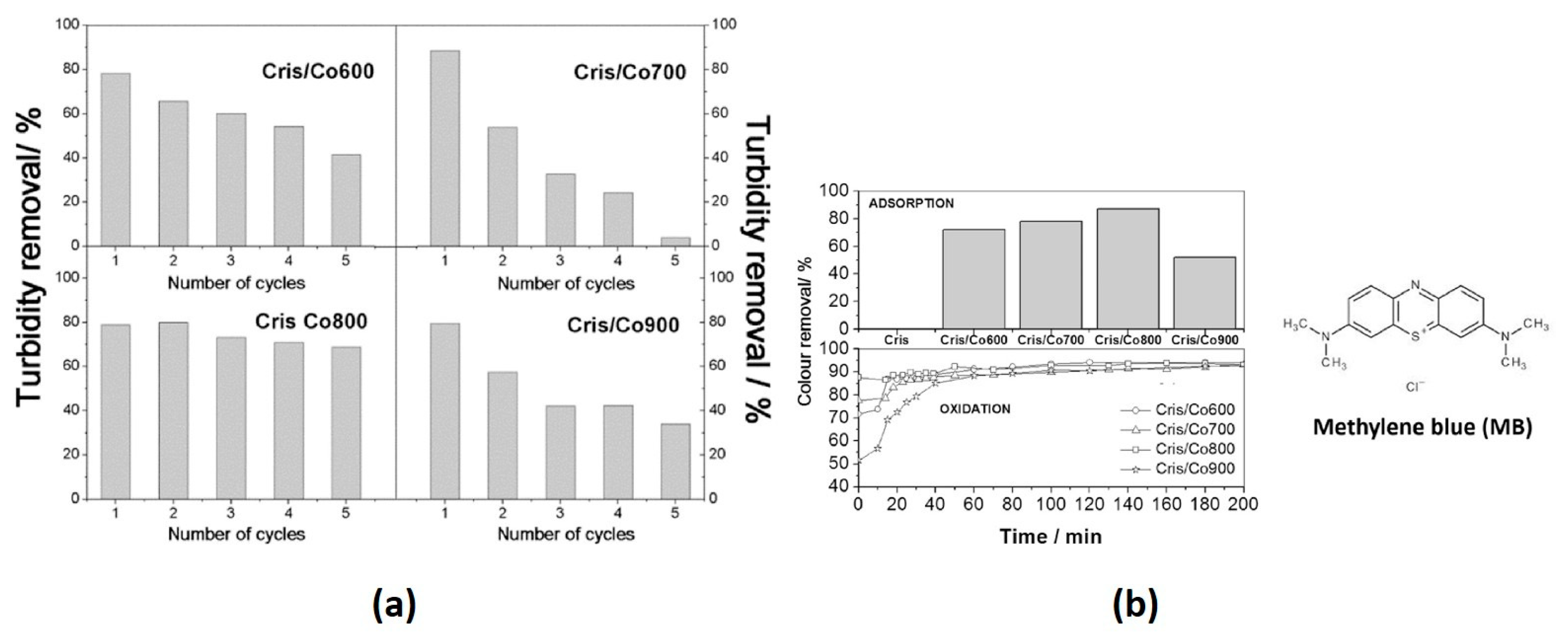

2.3. Chrysotile

2.4. Bentonite—Montmorillonite, Zeolite

2.5. Natural Laterite

2.6. Siliceous Breccia

2.7. Vermiculite

2.8. Natural Lava

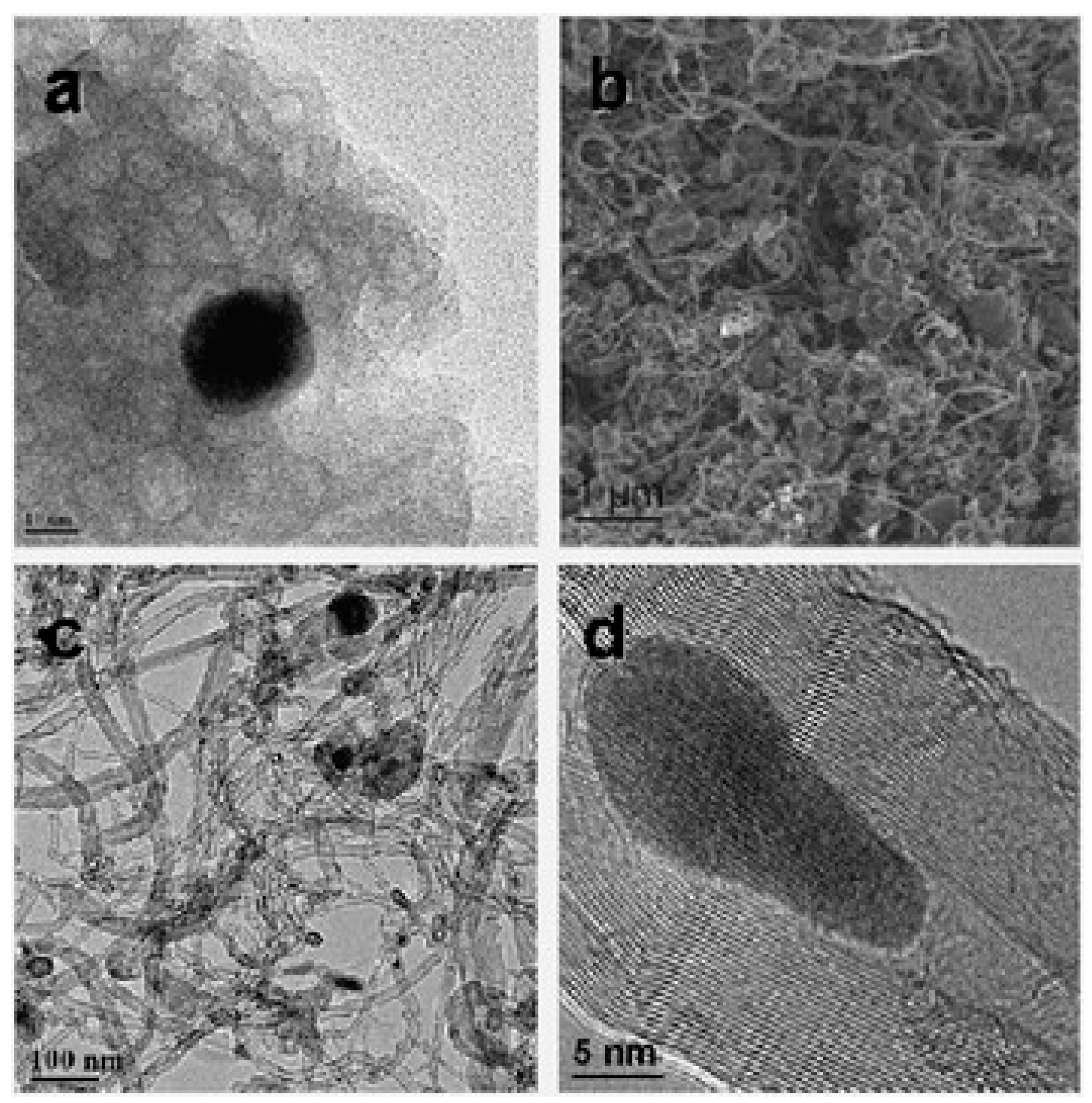

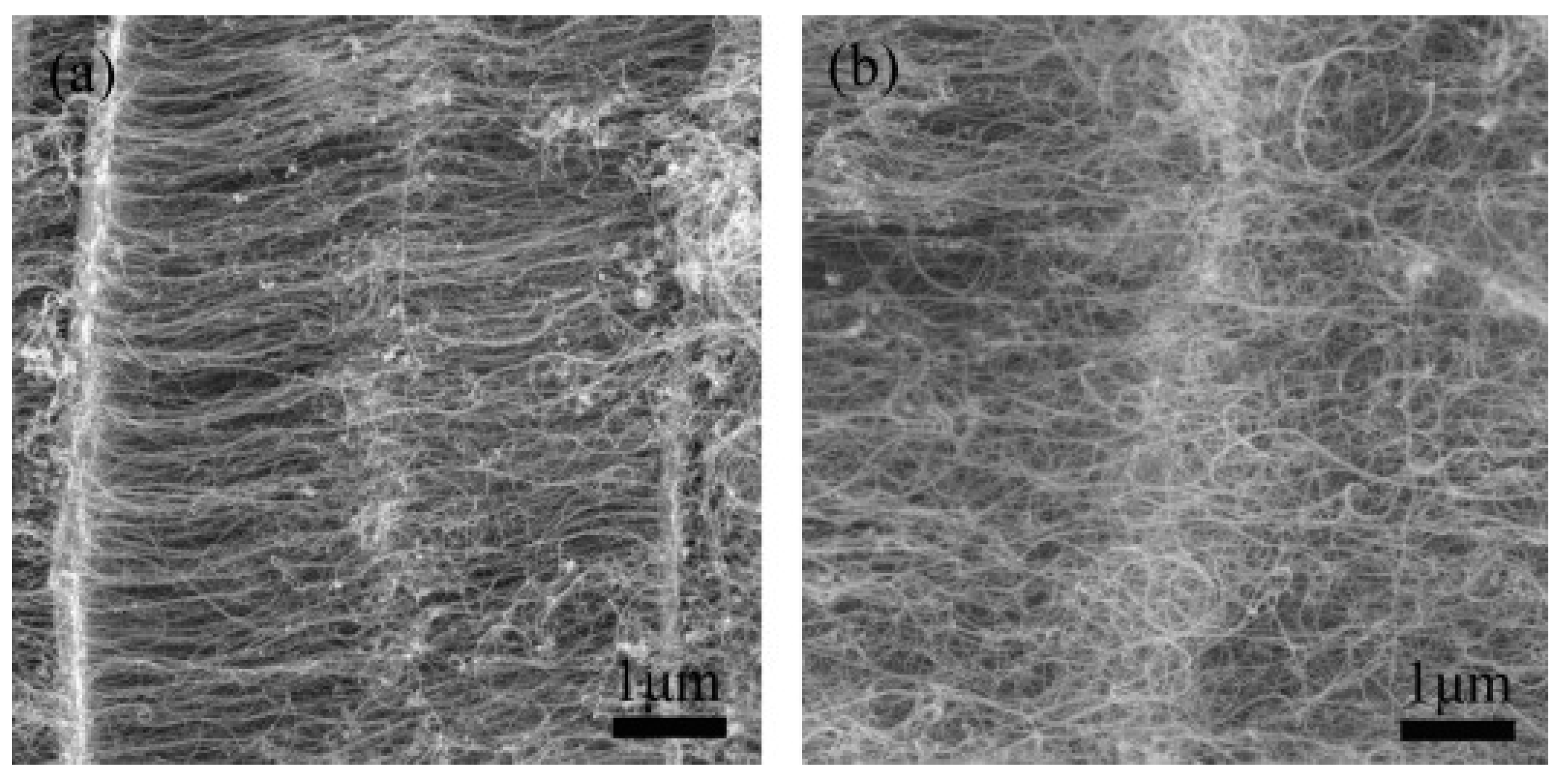

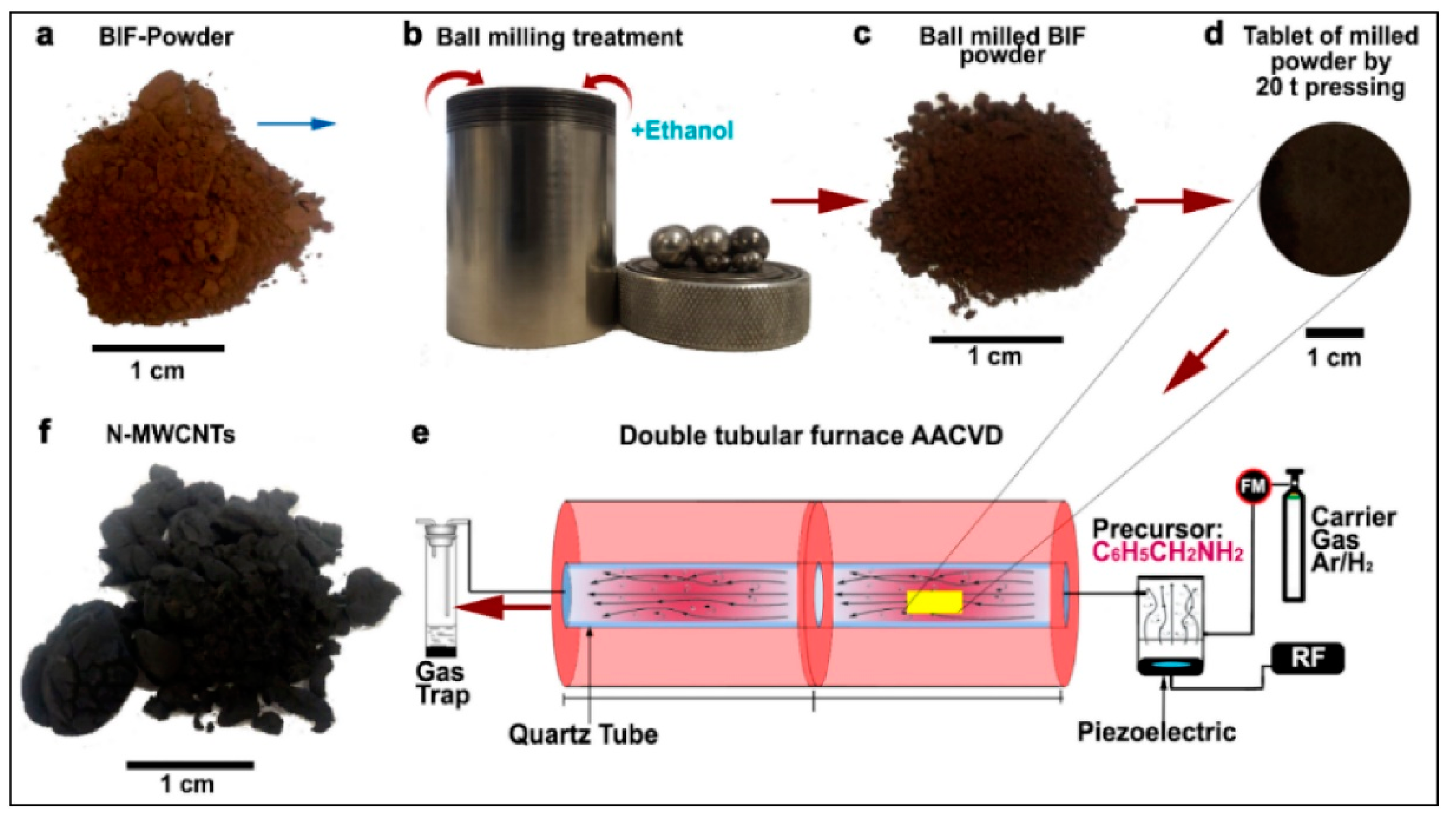

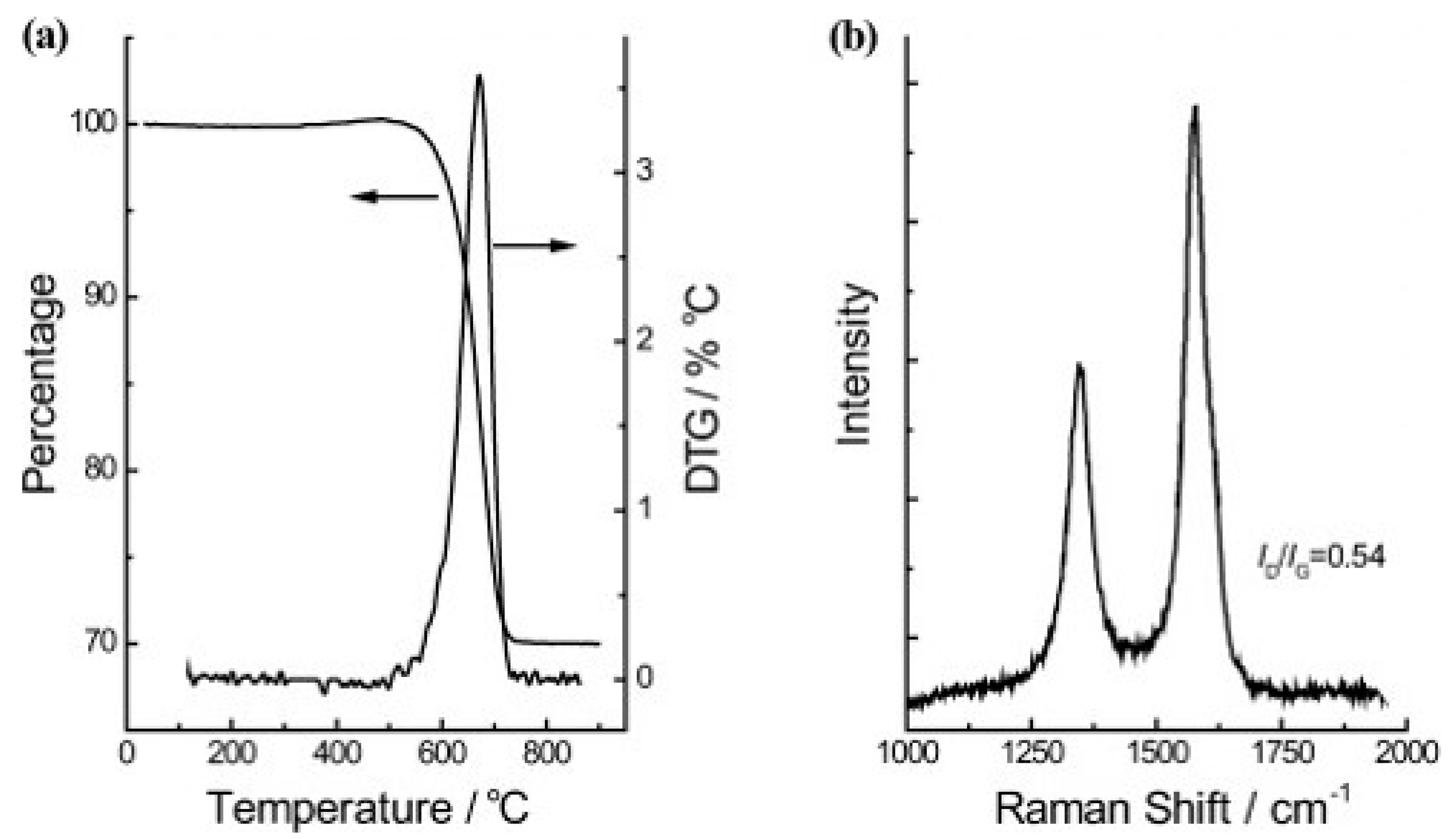

2.9. Blended Iron Formation (BIF)

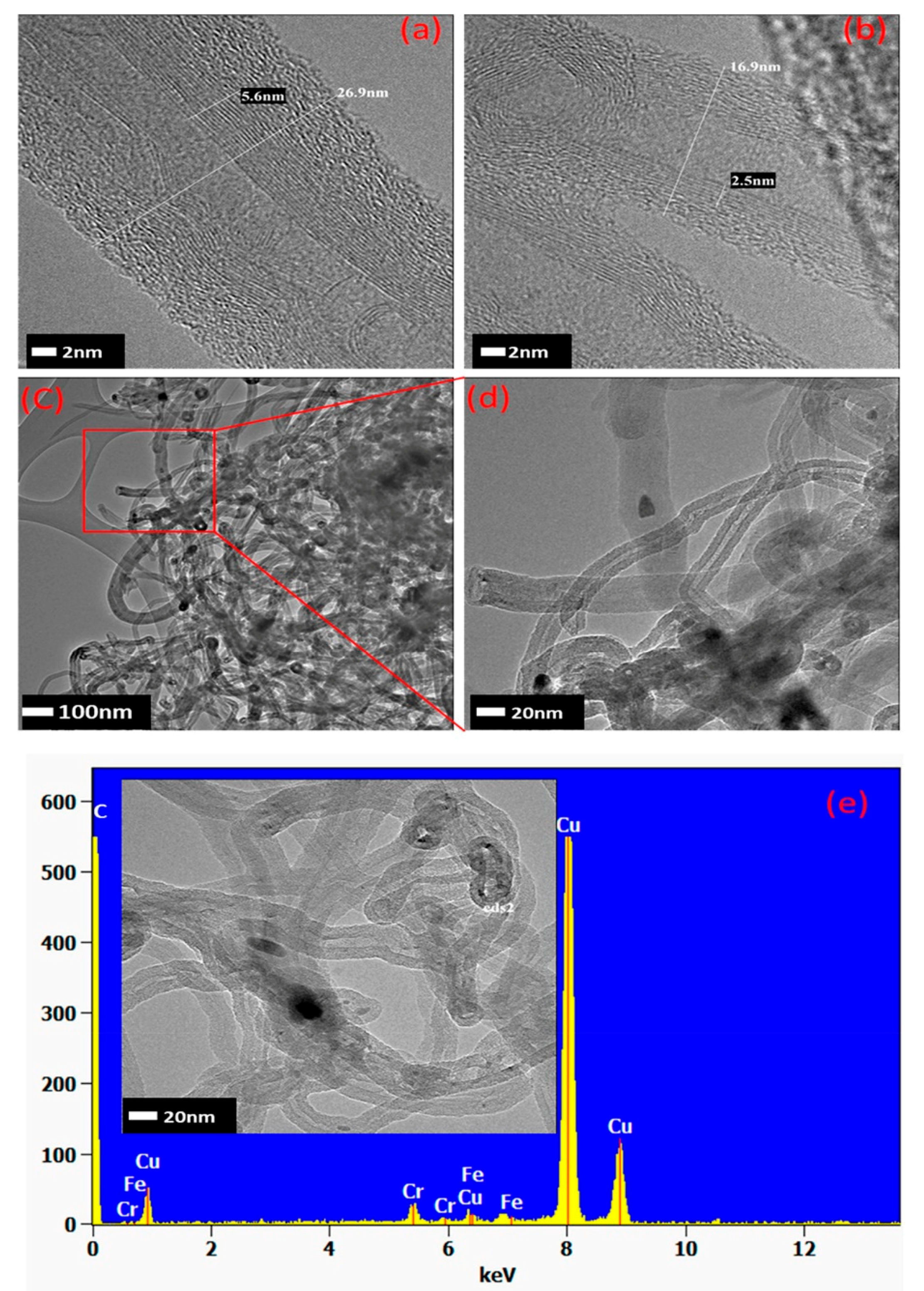

2.10. Wollastonite

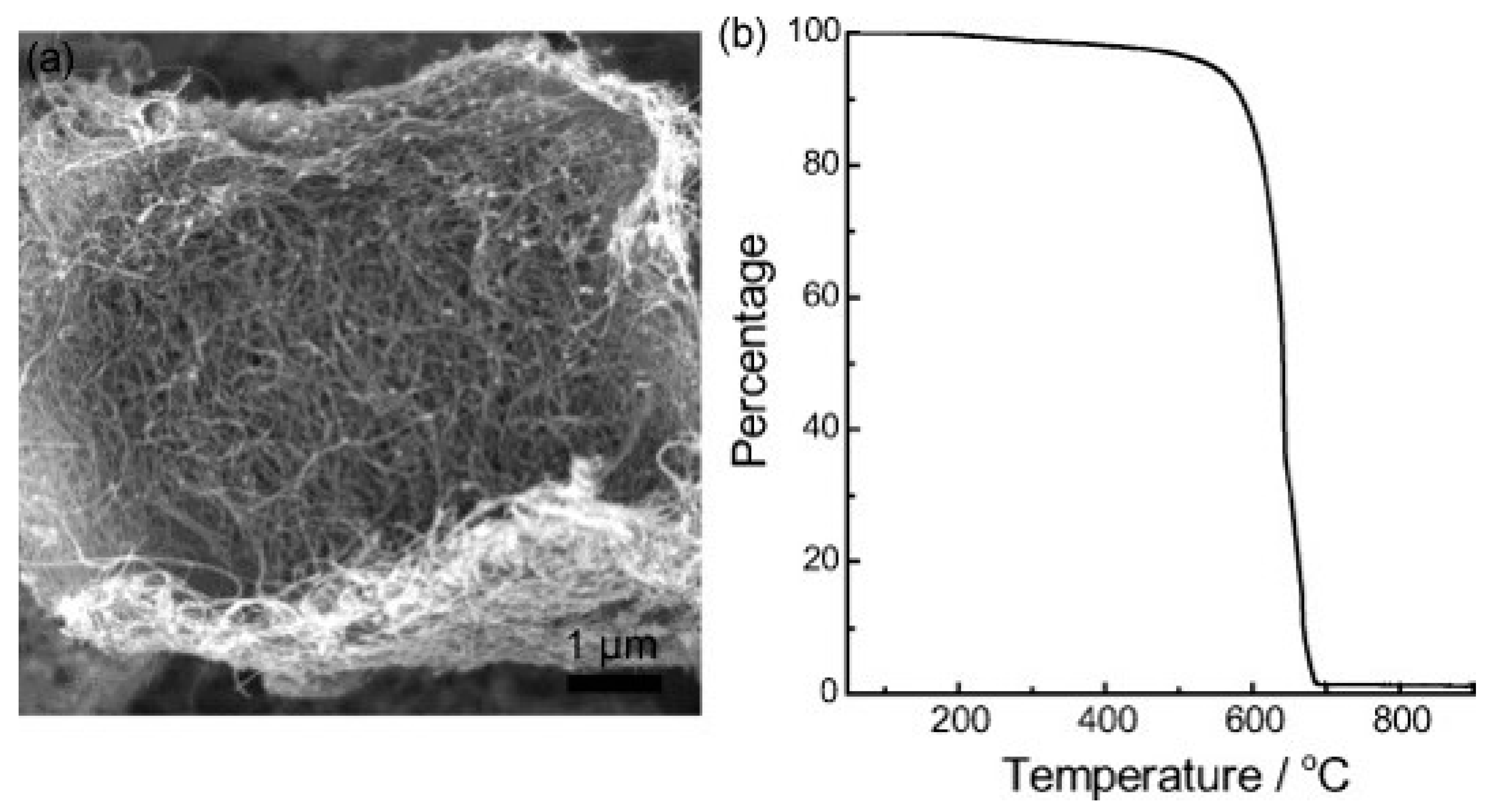

2.11. Kaolinite, Nontronite, and Sepiolite

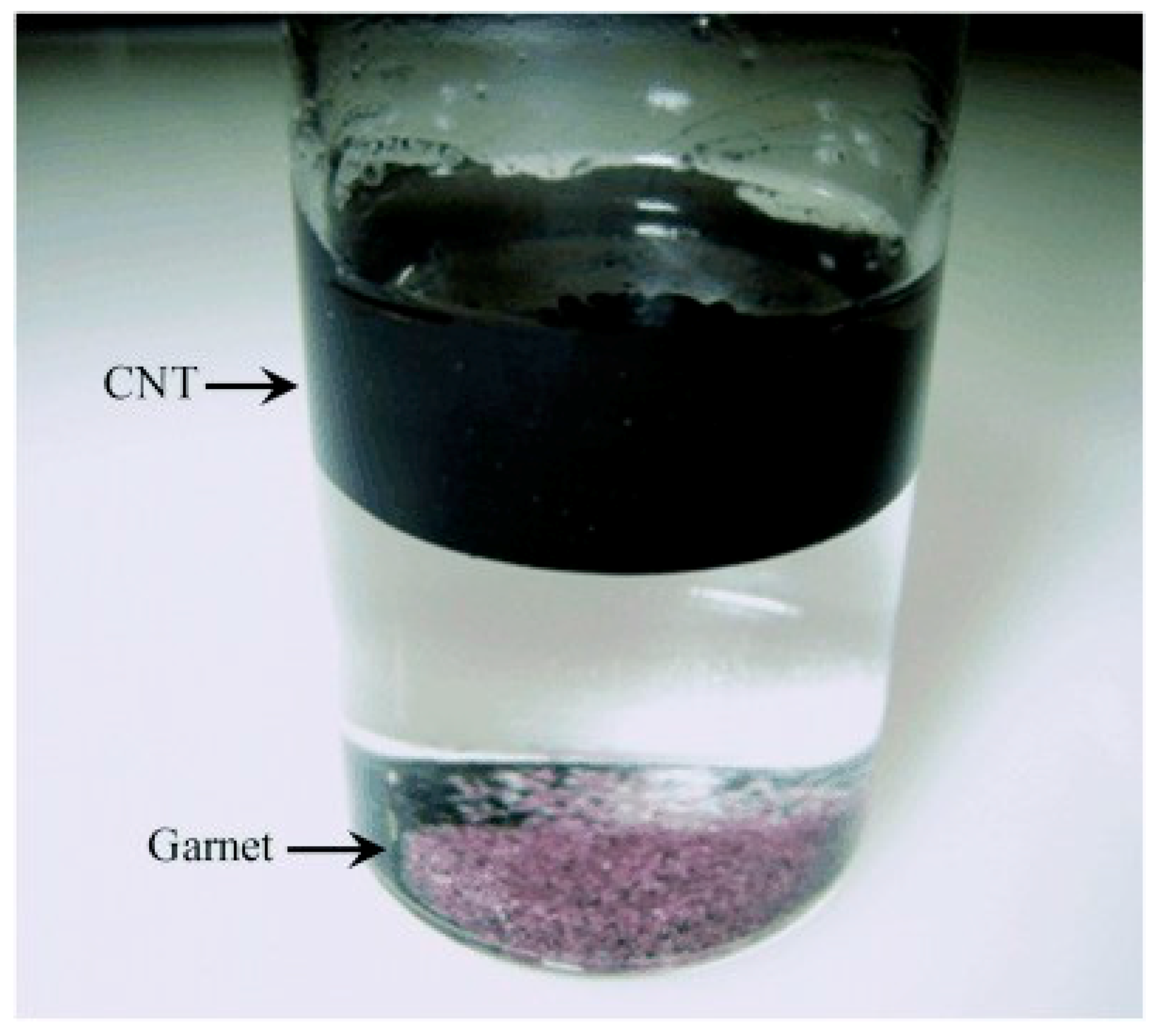

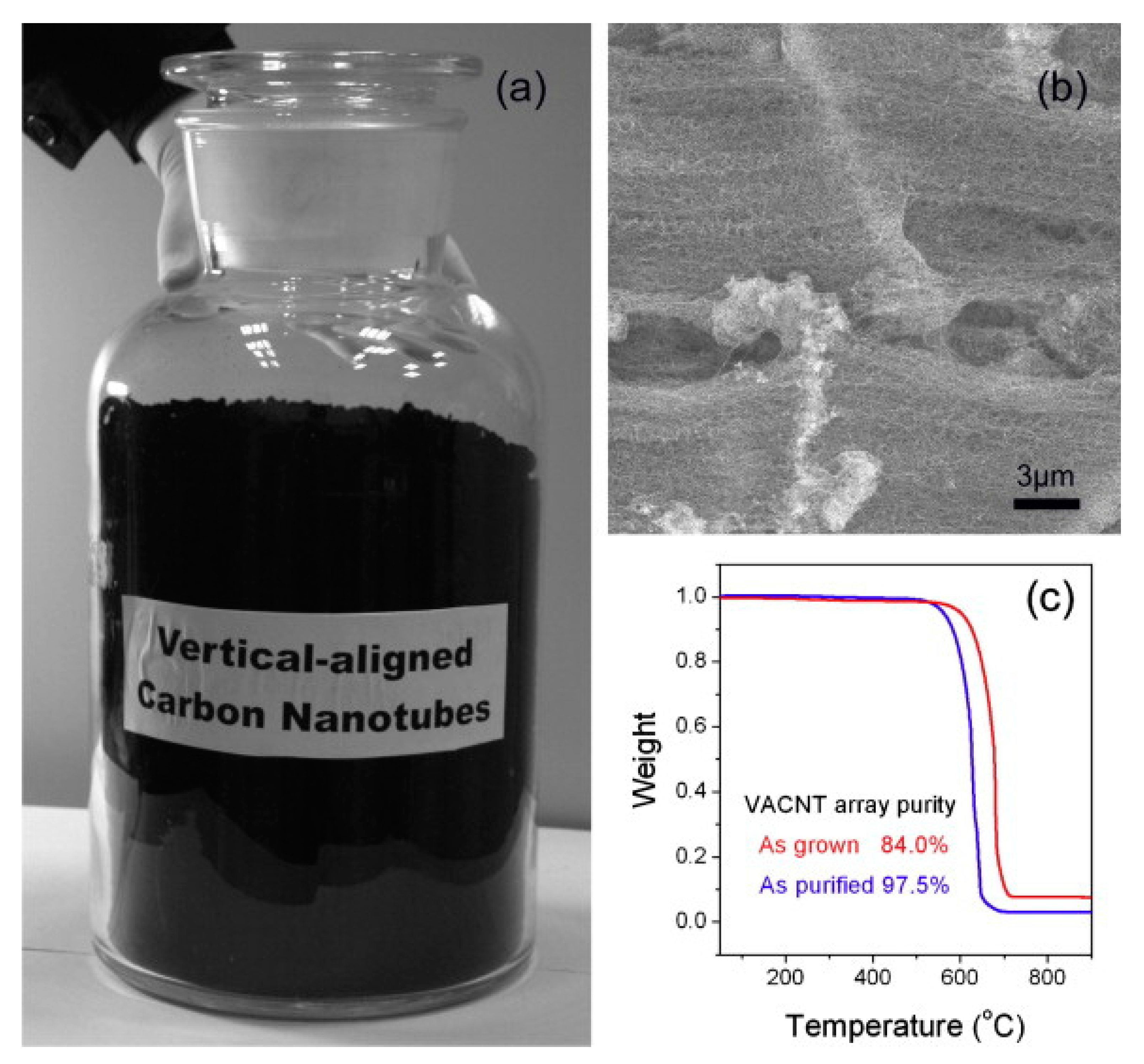

3. Purification: The Bridge between Synthesized CNTs and Applications

4. Application of the Carbon Nanomaterials Produced through Natural Materials

5. Conclusions and Prospective Outlook

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Reibold, M.; Paufler, P.; Levin, A.A.; Kochmann, W.; Pätzke, N.; Meyer, D.C. Materials: Carbon nanotubes in an ancient Damascus sabre. Nature 2006, 444. [Google Scholar] [CrossRef] [PubMed]

- Kokarneswaran, M.; Selvaraj, P.; Ashokan, T.; Perumal, S.; Sellappan, P.; Murugan, K.D.; Ramalingam, S.; Mohan, N.; Chandrasekaran, V. Discovery of Carbon nanotubes in 6th Century BC potteries from Keeladi, India. Sci. Rep. 2020, 10, 339–343. [Google Scholar] [CrossRef] [PubMed]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991. [Google Scholar] [CrossRef]

- Che, J.; Çaǧin, T.; Goddard, W.A. Thermal conductivity of carbon nanotubes. Nanotechnology 2000, 11, 65. [Google Scholar] [CrossRef]

- Hone, J.; Llaguno, M.C.; Biercuk, M.J.; Johnson, A.T.; Batlogg, B.; Benes, Z.; Fischer, J.E. Thermal properties of carbon nanotubes and nanotube-based materials. Appl. Phys. A Mater. Sci. Process. 2002, 74, 339–343. [Google Scholar] [CrossRef]

- Han, Z.; Fina, A. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: A review. Prog. Polym. Sci. 2011, 36, 914–944. [Google Scholar] [CrossRef]

- Kumanek, B.; Janas, D. Thermal conductivity of carbon nanotube networks: A review. J. Mater. Sci. 2019, 54, 7397–7427. [Google Scholar] [CrossRef]

- Nejad, S.M.; Srivastava, R.; Bellussi, F.M.; Thielemann, H.C.; Asinari, P.; Fasano, M. Nanoscale thermal properties of carbon nanotubes/epoxy composites by atomistic simulations. Int. J. Therm. Sci. 2021, 159, 106588. [Google Scholar] [CrossRef]

- Fischer, J.E.; Johnson, A.T. Electronic properties of carbon nanotubes. Curr. Opin. Solid State Mater. Sci. 1999, 4, 28–33. [Google Scholar] [CrossRef]

- Janas, D.; Milowska, K.Z.; Bristowe, P.D.; Koziol, K.K.K. Improving the electrical properties of carbon nanotubes with interhalogen compounds. Nanoscale 2017, 9, 3212–3222. [Google Scholar] [CrossRef]

- Barnett, C.J.; Gowenlock, C.E.; Welsby, K.; White, A.O.; Barron, A.R. Spatial and Contamination-Dependent Electrical Properties of Carbon Nanotubes. Nano Lett. 2018, 18, 695–700. [Google Scholar] [CrossRef] [PubMed]

- Mathur, R.B.; Pande, S.; Singh, B.P.; Dhami, T.L. Electrical and mechanical properties of multi-walled carbon nanotubes reinforced PMMA and PS composites. Polym. Compos. 2008, 29, 717–727. [Google Scholar] [CrossRef]

- Salvetat, J.P.; Bonard, J.M.; Thomson, N.B.; Kulik, A.J.; Forró, L.; Benoit, W.; Zuppiroli, L. Mechanical properties of carbon nanotubes. Appl. Phys. A Mater. Sci. Process. 1999, 69, 255–260. [Google Scholar] [CrossRef]

- Ruoff, R.S.; Qian, D.; Liu, W.K. Mechanical properties of carbon nanotubes: Theoretical predictions and experimental measurements. C. R. Phys. 2003, 4, 993–1008. [Google Scholar] [CrossRef]

- Coleman, J.N.; Khan, U.; Blau, W.J.; Gun’ko, Y.K. Small but strong: A review of the mechanical properties of carbon nanotube-polymer composites. Carbon 2006, 44, 1624–1652. [Google Scholar] [CrossRef]

- Lei, X.; Natsuki, T.; Shi, J.; Ni, Q.Q. Analysis of carbon nanotubes on the mechanical properties at atomic scale. J. Nanomater. 2011, 2011, 805313. [Google Scholar] [CrossRef]

- Tans, S.J.; Devoret, M.H.; Dai, H.; Thess, A.; Smalley, R.E.; Geerligs, L.J.; Dekker, C. Individual single-wall carbon nanotubes as quantum wires. Nature 1997, 386, 474–477. [Google Scholar] [CrossRef]

- Sinitsyn, N.I.; Gulyaev, Y.V.; Torgashov, G.V.; Chernozatonskii, L.A.; Kosakovskaya, Z.Y.; Zakharchenko, Y.F.; Kiselev, N.A.; Musatov, A.L.; Zhbanov, A.I.; Mevlyut, S.T.; et al. Thin films consisting of carbon nanotubes as a new material for emission electronics. Appl. Surf. Sci. 1997, 111, 145–150. [Google Scholar] [CrossRef]

- Tans, S.J.; Verschueren, A.R.M.; Dekker, C. Room-temperature transistor based on a single carbon nanotube. Nature 1998, 393, 49–52. [Google Scholar] [CrossRef]

- Sharma, P.; Ahuja, P. Recent advances in carbon nanotube-based electronics. Mater. Res. Bull. 2008, 43, 2517–2526. [Google Scholar] [CrossRef]

- Peng, L.M.; Zhang, Z.; Wang, S. Carbon nanotube electronics: Recent advances. Mater. Today 2014, 17, 433–442. [Google Scholar] [CrossRef]

- Si, J.; Xu, L.; Zhu, M.; Zhang, Z.; Peng, L.M. Advances in High-Performance Carbon-Nanotube Thin-Film Electronics. Adv. Electron. Mater. 2019, 5, 1900122. [Google Scholar] [CrossRef]

- Xiong, C.; Li, M.; Zhao, W.; Duan, C.; Ni, Y. Flexible N-Doped reduced graphene oxide/carbon Nanotube-MnO2 film as a Multifunctional Material for High-Performance supercapacitors, catalysts and sensors. J. Mater. 2020, 6, 523–531. [Google Scholar] [CrossRef]

- Xiong, C.; Lin, X.; Liu, H.; Li, M.; Li, B.; Jiao, S.; Zhao, W.; Duan, C.; Dai, L.; Ni, Y. Fabrication of 3D Expanded Graphite-Based (MnO 2 Nanowalls and PANI Nanofibers) Hybrid as Bifunctional Material for High-Performance Supercapacitor and Sensor. J. Electrochem. Soc. 2019, 166, A3965–A3971. [Google Scholar] [CrossRef]

- Zaporotskova, I.V.; Boroznina, N.P.; Parkhomenko, Y.N.; Kozhitov, L.V. Carbon nanotubes: Sensor properties. A review. Mod. Electron. Mater. 2016, 2, 95–105. [Google Scholar] [CrossRef]

- Schroeder, V.; Savagatrup, S.; He, M.; Lin, S.; Swager, T.M. Carbon nanotube chemical sensors. Chem. Rev. 2019, 119, 599–663. [Google Scholar] [CrossRef]

- Hwang, S.I.; Star, A. Picking Flowers with Carbon Nanotube Sensors. ACS Cent. Sci. 2020, 6, 461–463. [Google Scholar] [CrossRef]

- Xiong, C.; Li, M.; Zhao, W.; Duan, C.; Dai, L.; Shen, M.; Xu, Y.; Ni, Y. A smart paper@polyaniline nanofibers incorporated vitrimer bifunctional device with reshaping, shape-memory and self-healing properties applied in high-performance supercapacitors and sensors. Chem. Eng. J. 2020, 396, 125318. [Google Scholar] [CrossRef]

- Bianco, A.; Kostarelos, K.; Prato, M. Applications of carbon nanotubes in drug delivery. Curr. Opin. Chem. Biol. 2005, 9, 674–679. [Google Scholar] [CrossRef]

- Bhirde, A.A.; Patel, V.; Gavard, J.; Zhang, G.; Sousa, A.A.; Masedunskas, A.; Leapman, R.D.; Weigert, R.; Gutkind, J.S.; Rusling, J.F. Targeted killing of cancer cells in vivo and in vitro with EGF-directed carbon nanotube-based drug delivery. ACS Nano 2009, 3, 307–316. [Google Scholar] [CrossRef]

- Tangboriboon, N. Carbon and Carbon Nanotube Drug Delivery and Its Characterization, Properties, and Applications. In Nanocarriers for Drug Delivery; Elsevier: Amsterdam, The Netherlands, 2019; pp. 451–467. [Google Scholar]

- Cheng, H.M.; Yang, Q.H.; Liu, C. Hydrogen storage in carbon nanotubes. Carbon 2001, 39, 1447–1454. [Google Scholar] [CrossRef]

- Doğan, E.E.; Tokcan, P.; Kizilduman, B.K. Storage of Hydrogen in Activated Carbons and Carbon Nanotubes. Adv. Mater. Sci. 2019, 18, 5–16. [Google Scholar] [CrossRef]

- Tripathi, P.; Bhatnagar, A.; Ramesh, A.; Vishwakarma, A.K.; Singh, S.; Bailmare, D.B.; Deshmukh, A.D.; Gupta, B.K.; Srivastava, O.N. Radially aligned CNTs derived carbon hollow cylinder architecture for efficient energy storage. Electrochim. Acta 2020, 354, 136650. [Google Scholar] [CrossRef]

- Xia, X.; Zhang, Y.; Fan, Z.; Chao, D.; Xiong, Q.; Tu, J.; Zhang, H.; Fan, H.J. Novel Metal@CARBON spheres core-shell arrays by controlled self-assembly of carbon nanospheres: A stable and flexible supercapacitor electrode. Adv. Energy Mater. 2015, 5. [Google Scholar] [CrossRef]

- Sun, L.; Wang, X.; Wang, Y.; Zhang, Q. Roles of carbon nanotubes in novel energy storage devices. Carbon 2017, 122, 462–474. [Google Scholar] [CrossRef]

- Yu, D.; Goh, K.; Wang, H.; Wei, L.; Jiang, W.; Zhang, Q.; Dai, L.; Chen, Y. Scalable synthesis of hierarchically structured carbon nanotube-graphene fibres for capacitive energy storage. Nat. Nanotechnol. 2014, 9, 555–562. [Google Scholar] [CrossRef]

- Lu, Z.; Raad, R.; Safaei, F.; Xi, J.; Liu, Z.; Foroughi, J. Carbon nanotube based fiber supercapacitor as wearable energy storage. Front. Mater. 2019, 6, 138. [Google Scholar] [CrossRef]

- Xiong, C.; Li, B.; Liu, H.; Zhao, W.; Duan, C.; Wu, H.; Ni, Y. A smart porous wood-supported flower-like NiS/Ni conjunction with vitrimer co-effect as a multifunctional material with reshaping, shape-memory, and self-healing properties for applications in high-performance supercapacitors, catalysts, and sensors. J. Mater. Chem. A 2020, 8, 10898–10908. [Google Scholar] [CrossRef]

- Xiong, C.; Li, M.; Nie, S.; Dang, W.; Zhao, W.; Dai, L.; Ni, Y. Non-carbonized porous lignin-free wood as an effective scaffold to fabricate lignin-free Wood@Polyaniline supercapacitor material for renewable energy storage application. J. Power Sources 2020, 471, 228448. [Google Scholar] [CrossRef]

- Castillejos, E.; Serp, P. Carbon Nanotubes for Catalytic Applications. In Carbon Nanotubes and Related Structures; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2010; pp. 321–347. [Google Scholar]

- Esteves, L.M.; Oliveira, H.A.; Passos, F.B. Carbon nanotubes as catalyst support in chemical vapor deposition reaction: A review. J. Ind. Eng. Chem. 2018, 65, 1–12. [Google Scholar] [CrossRef]

- Harrison, B.S.; Atala, A. Carbon nanotube applications for tissue engineering. Biomaterials 2007, 28, 344–353. [Google Scholar] [CrossRef] [PubMed]

- Baughman, R.H.; Zakhidov, A.A.; De Heer, W.A. Carbon nanotubes—The route toward applications. Science 2002, 297, 787–792. [Google Scholar] [CrossRef] [PubMed]

- Kaushik, B.K.; Majumder, M.K. Carbon nanotube: Properties and applications. In Carbon Nanotube Based VLSI Interconnects; Springer: New Delhi, India, 2015; pp. 17–37. [Google Scholar] [CrossRef]

- Zhai, P.; Isaacs, J.A.; Eckelman, M.J. Net energy benefits of carbon nanotube applications. Appl. Energy 2016, 173, 624–634. [Google Scholar] [CrossRef]

- Venkataraman, A.; Amadi, E.V.; Chen, Y.; Papadopoulos, C. Carbon Nanotube Assembly and Integration for Applications. Nanoscale Res. Lett. 2019, 14, 1–47. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, J.Q.; Zhao, M.Q.; Qian, W.Z.; Wei, F. Carbon nanotube mass production: Principles and processes. ChemSusChem 2011, 4, 864–889. [Google Scholar] [CrossRef]

- Kumar, M.; Ando, Y. Chemical vapor deposition of carbon nanotubes: A review on growth mechanism and mass production. J. Nanosci. Nanotechnol. 2010, 10, 3739–3758. [Google Scholar] [CrossRef]

- Ghaemi, F.; Ali, M.; Yunus, R.; Othman, R.N. Synthesis of carbon nanomaterials using catalytic chemical vapor deposition technique. In Synthesis, Technology and Applications of Carbon Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–27. ISBN 9780128157572. [Google Scholar]

- See, C.H.; Harris, A.T. A review of carbon nanotube synthesis via fluidized-bed chemical vapor deposition. Ind. Eng. Chem. Res. 2007, 46, 997–1012. [Google Scholar] [CrossRef]

- Danafar, F.; Fakhru’l-Razi, A.; Salleh, M.A.M.; Biak, D.R.A. Fluidized bed catalytic chemical vapor deposition synthesis of carbon nanotubes—A review. Chem. Eng. J. 2009, 155, 37–48. [Google Scholar] [CrossRef]

- Ayre, G.N.; Uchino, T.; Mazumder, B.; Hector, A.L.; Hutchison, J.L.; Smith, D.C.; Ashburn, P.; De Groot, C.H. On the mechanism of carbon nanotube formation: The role of the catalyst. J. Phys. Condens. Matter 2011, 23, 394201. [Google Scholar] [CrossRef]

- Gao, J.; Zhong, J.; Bai, L.; Liu, J.; Zhao, G.; Sun, X. Revealing the role of catalysts in carbon nanotubes and nanofibers by scanning transmission X-Ray microscopy. Sci. Rep. 2014, 4, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Liu, X.; Zhao, X.; Yang, F.; Wang, X.; Li, Y. Metallic Catalysts for Structure-Controlled Growth of Single-Walled Carbon Nanotubes. Top. Curr. Chem. 2017, 375, 1–43. [Google Scholar] [CrossRef]

- Yahyazadeh, A.; Khoshandam, B. Carbon nanotube synthesis via the catalytic chemical vapor deposition of methane in the presence of iron, molybdenum, and iron–molybdenum alloy thin layer catalysts. Results Phys. 2017, 7, 3826–3837. [Google Scholar] [CrossRef]

- Homma, Y.; Kobayashi, Y.; Ogino, T.; Takagi, D.; Ito, R.; Jung, Y.J.; Ajayan, P.M. Role of transition metal catalysts in single-walled carbon nanotube growth in chemical vapor deposition. J. Phys. Chem. B 2003, 107, 12161–12164. [Google Scholar] [CrossRef]

- Ur Rashid, H.; Yu, K.; Naveed Umar, M.; Naveed Anjum, M.; Khan, K.; Ahmad, N.; Tariq Jan, M. Catalyst role in chemical vapor deposition (CVD) process: A review. Rev. Adv. Mater. Sci. 2015, 40, 235–248. [Google Scholar]

- Hoecker, C.; Smail, F.; Pick, M.; Boies, A. The influence of carbon source and catalyst nanoparticles on CVD synthesis of CNT aerogel. Chem. Eng. J. 2017, 314, 388–395. [Google Scholar] [CrossRef]

- Endo, M.; Takeuchi, K.; Kim, Y.A.; Park, K.C.; Ichiki, T.; Hayashi, T.; Fukuyo, T.; Iinou, S.; Su, D.S.; Terrones, M.; et al. Simple synthesis of multiwalled carbon nanotubes from natural resources. ChemSusChem 2008, 1, 820–822. [Google Scholar] [CrossRef]

- Kawasaki, S.; Shinoda, M.; Shimada, T.; Okino, F.; Touhara, H. Single-walled carbon nanotubes grown on natural minerals. Carbon 2006, 44, 2139–2141. [Google Scholar] [CrossRef]

- Lemos, B.R.S.; Soares, A.R.; Teixeira, A.P.C.; Ardisson, J.D.; Fernandez-Outon, L.E.; Amorim, C.C.; Lago, R.M.; Moura, F.C.C. Growth of carbon structures on chrysotile surface for organic contaminants removal from wastewater. Chemosphere 2016, 159, 602–609. [Google Scholar] [CrossRef]

- Bakandritsos, A.; Simopoulos, A.; Petridis, D. Iron changes in natural and Fe(III) loaded montmorillonite during carbon nanotube growth. Nanotechnology 2006, 17, 1112–1117. [Google Scholar] [CrossRef]

- Kadlečíková, M.; Breza, J.; Jesenák, K.; Pastorková, K.; Luptáková, V.; Kolmačka, M.; Vojačková, A.; Michalka, M.; Vávra, I.; Križanová, Z. The growth of carbon nanotubes on montmorillonite and zeolite (clinoptilolite). Appl. Surf. Sci. 2008, 254, 5073–5079. [Google Scholar] [CrossRef]

- Zhang, W.D.; Phang, I.Y.; Liu, T. Growth of carbon nanotubes on clay: Unique nanostructured filler for high-performance polymer nanocomposites. Adv. Mater. 2006, 18, 73–77. [Google Scholar] [CrossRef]

- Rinaldi, A.; Zhang, J.; Mizera, J.; Girgsdies, F.; Wang, N.; Hamid, S.B.A.; Schlögl, R.; Su, D.S. Facile synthesis of carbon nanotube/natural bentonite composites as a stable catalyst for styrene synthesis. Chem. Commun. 2008, 6528–6530. [Google Scholar] [CrossRef]

- Huseynov, A.; Israfilov, A.; Mammadova, S.; Abdullayeva, S.; Sokolov, S.; Goryunkov, A.; Guliyev, A. Fabrication and characterization of MWCNT/natural Azerbaijani bentonite electroconductive ceramic composites. J. Compos. Mater. 2019, 53, 3909–3923. [Google Scholar] [CrossRef]

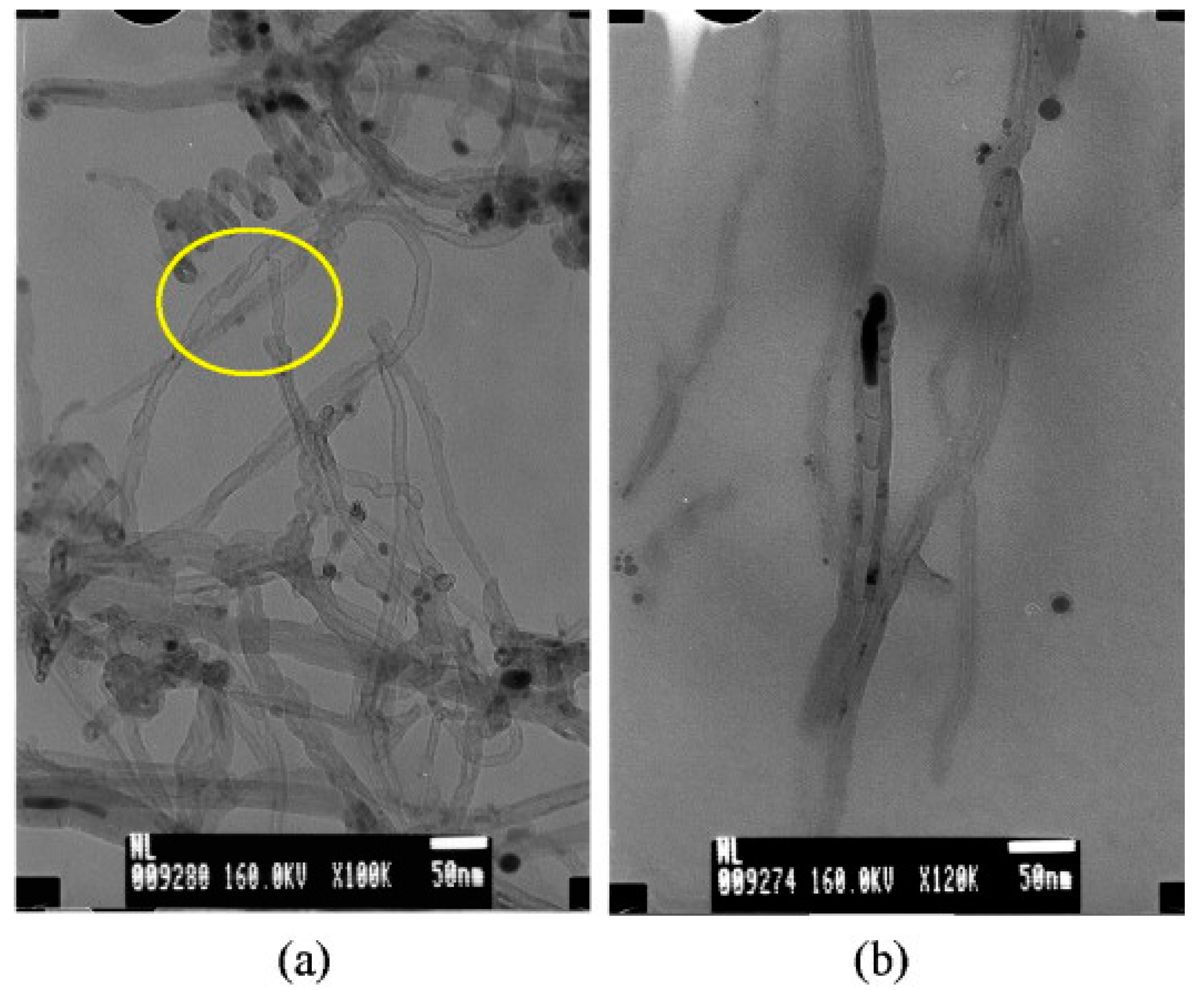

- Kumar, A.; Kostikov, Y.; Orberger, B.; Nessim, G.D.; Mariotto, G. Natural Laterite as a Catalyst Source for the Growth of Carbon Nanotubes and Nanospheres. ACS Appl. Nano Mater. 2018, 1, 6046–6054. [Google Scholar] [CrossRef]

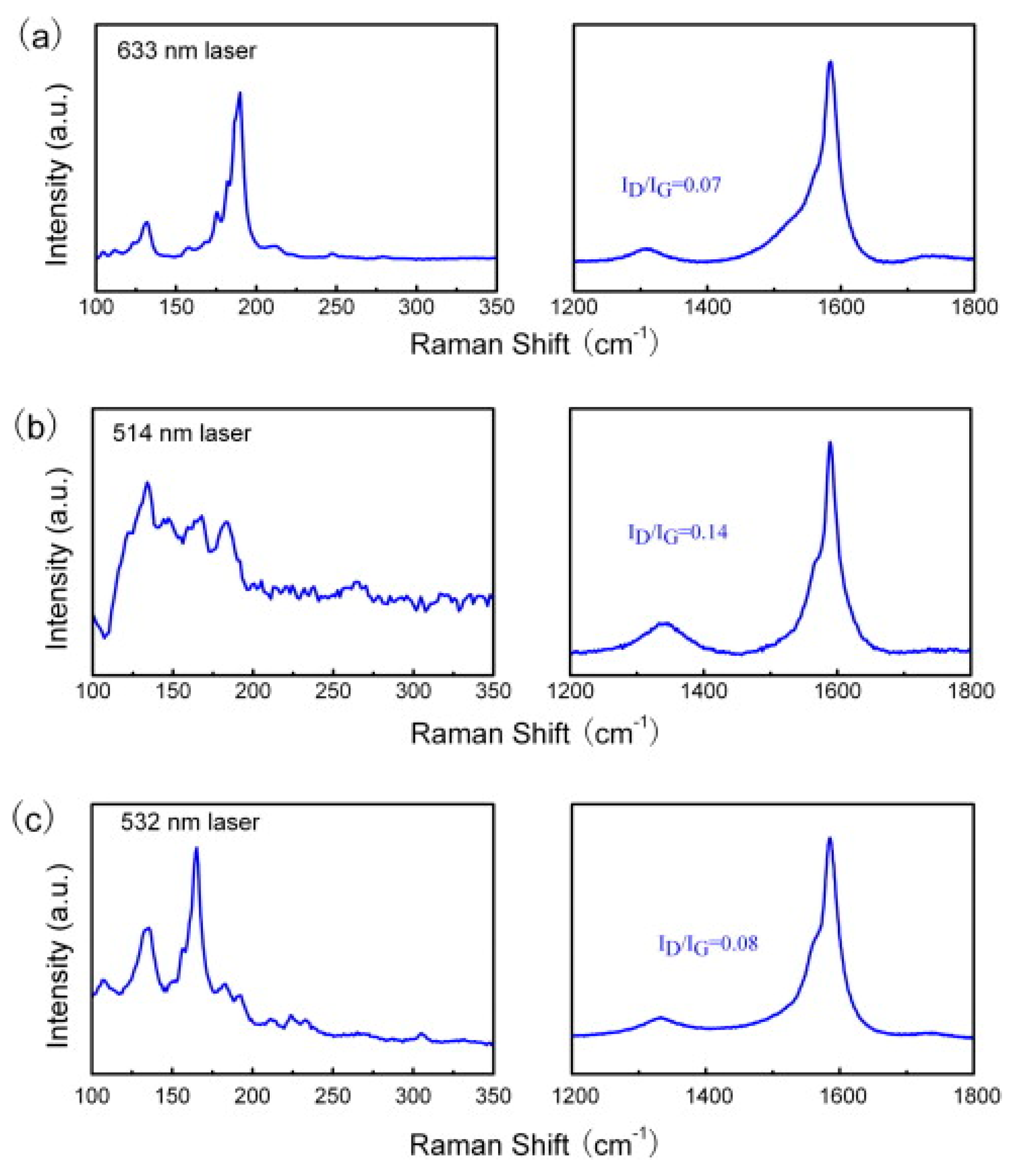

- Secchi, M.; Zanatta, M.; Borovin, E.; Bortolotti, M.; Kumar, A.; Giarola, M.; Sanson, A.; Orberger, B.; Daldosso, N.; Gialanella, S.; et al. Mineralogical investigations using XRD, XRF, and Raman spectroscopy in a combined approach. J. Raman Spectrosc. 2018, 49, 1023–1030. [Google Scholar] [CrossRef]

- Duée, C.; Maubec, N.; Laperche, V.; Capar, L.; Bourguignon, A.; Bourrat, X.; Mendili, Y.E.; Chateigner, D.; Gascoin, S.; Mariotto, G.; et al. Combined mineralogy and chemistry on drill cores: Challenging for on-line-real-time analyses. In Proceedings of the 14th Biennial SGA Meeting, Quebéc, QC, Canada, 20–23 August 2017; Volume 3, pp. 1241–1244. [Google Scholar]

- Kumar, A.; Kostikov, Y.; Zanatta, M.; Sorarù, G.D.; Orberger, B.; Nessim, G.D.; Mariotto, G. Carbon nanotubes synthesis using siliceous breccia as a catalyst source. Diam. Relat. Mater. 2019, 97, 107433. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhao, M.Q.; Huang, J.Q.; Liu, Y.; Wang, Y.; Qian, W.Z.; Wei, F. Vertically aligned carbon nanotube arrays grown on a lamellar catalyst by fluidized bed catalytic chemical vapor deposition. Carbon 2009, 47, 2600–2610. [Google Scholar] [CrossRef]

- Wei, F.; Zhang, Q.; Qian, W.Z.; Yu, H.; Wang, Y.; Luo, G.H.; Xu, G.H.; Wang, D.Z. The mass production of carbon nanotubes using a nano-agglomerate fluidized bed reactor: A multiscale space-time analysis. Powder Technol. 2008, 183, 10–20. [Google Scholar] [CrossRef]

- Dang, S.S.; Chen, X.W. Natural lavas as catalysts for efficient production of carbon nanotubes and nanofibers. Angew. Chemie Int. Ed. 2007, 46, 1823–1824. [Google Scholar] [CrossRef]

- Su, D.S.; Rinaldi, A.; Frandsen, W.; Weinberg, G. Nanocarbons: Efficient synthesis using natural lava as supported catalyst. Phys. Status Solidi 2007, 244, 3916–3919. [Google Scholar] [CrossRef]

- Katsuta, N.; Shimizu, I.; Helmstaedt, H.; Takano, M.; Kawakami, S.; Kumazawa, M. Major element distribution in Archean banded iron formation (BIF): Influence of metamorphic differentiation. J. Metamorph. Geol. 2012, 30, 457–472. [Google Scholar] [CrossRef]

- Jimenez-Ramirez, L.E.; Kashina, S.; Galindo, R.; Fuentes-Ramirez, R.; Verma, S.K.; Fajardo-Diaz, J.L.; López-Urías, F.; Muñoz-Sandoval, E. Synthesis, morphology, magnetic and electrochemical studies of nitrogen-doped multiwall carbon nanotubes fabricated using banded iron-formation as catalyst. J. Alloy. Compd. 2020, 835, 155200. [Google Scholar] [CrossRef]

- Zhao, M.Q.; Zhang, Q.; Huang, J.Q.; Nie, J.Q.; Wei, F. Advanced materials from natural materials: Synthesis of aligned carbon nanotubes on wollastonites. ChemSusChem 2010, 3, 453–459. [Google Scholar] [CrossRef] [PubMed]

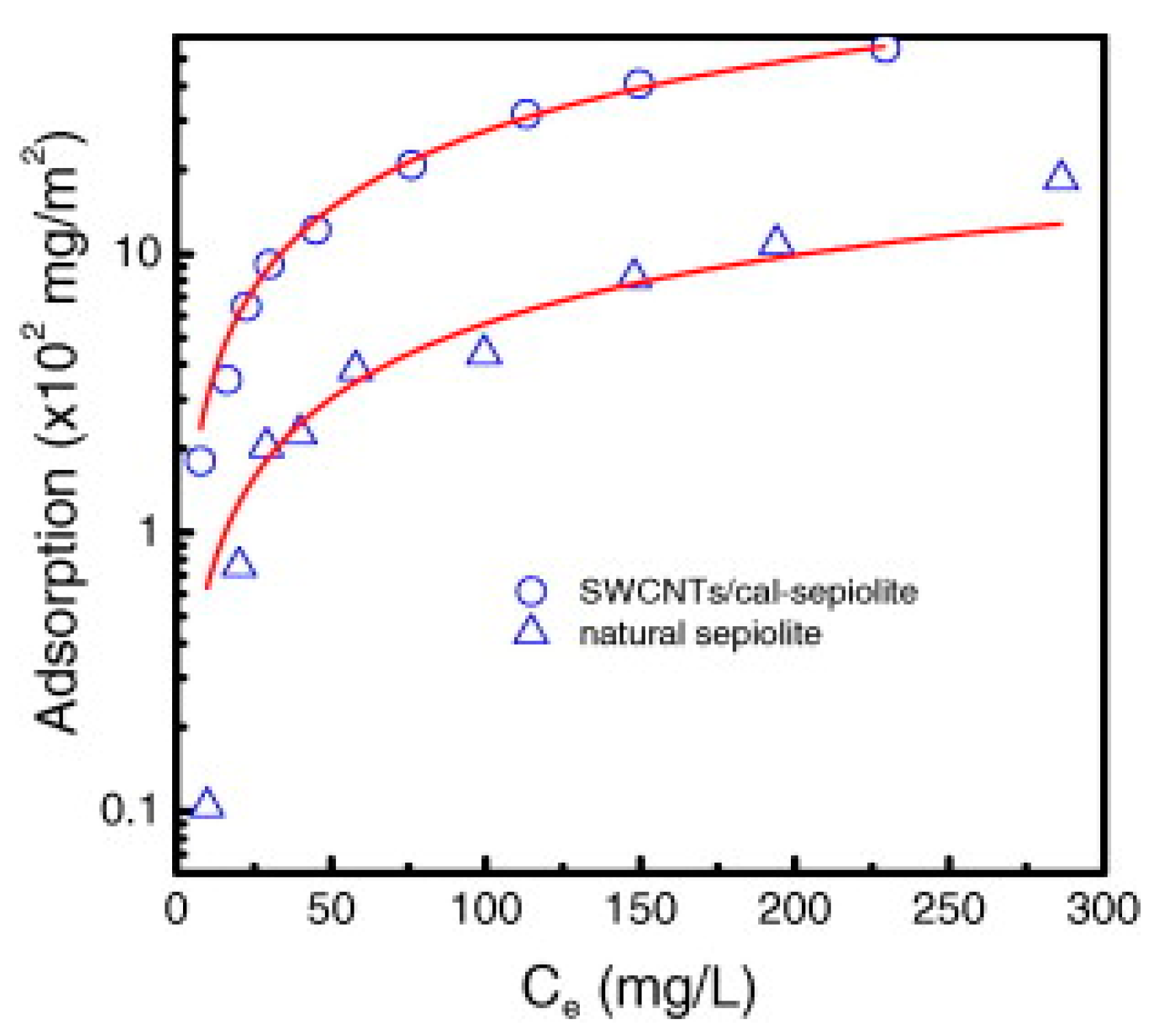

- Nie, J.Q.; Zhang, Q.; Zhao, M.Q.; Huang, J.Q.; Wen, Q.; Cui, Y.; Qian, W.Z.; Wei, F. Synthesis of high quality single-walled carbon nanotubes on natural sepiolite and their use for phenol absorption. Carbon 2011, 49, 1568–1580. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Dresselhaus, G.; Saito, R.; Jorio, A. Raman spectroscopy of carbon nanotubes. Phys. Rep. 2005, 409, 47–99. [Google Scholar] [CrossRef]

- Pastorková, K.; Jesenák, K.; Kadlečíková, M.; Breza, J.; Kolmačka, M.; Čaplovičová, M.; Lazišťan, F.; Michalka, M. The growth of multi-walled carbon nanotubes on natural clay minerals (kaolinite, nontronite and sepiolite). Appl. Surf. Sci. 2012, 258, 2661–2666. [Google Scholar] [CrossRef]

- Behmel, S.; Damour, M.; Ludwig, R.; Rodriguez, M.J. Water quality monitoring strategies—A review and future perspectives. Sci. Total Environ. 2016, 571, 1312–1329. [Google Scholar] [CrossRef]

- Salari, M.; Dehghani, M.H.; Azari, A.; Motevalli, M.D.; Shabanloo, A.; Ali, I. High performance removal of phenol from aqueous solution by magnetic chitosan based on response surface methodology and genetic algorithm. J. Mol. Liq. 2019, 285, 146–157. [Google Scholar] [CrossRef]

- Du, W.; Sun, J.; Zan, Y.; Zhang, Z.; Ji, J.; Dou, M.; Wang, F. Biomass-derived nitrogen-doped hierarchically porous carbon networks as efficient absorbents for phenol removal from wastewater over a wide pH range. RSC Adv. 2017, 7, 46629–46635. [Google Scholar] [CrossRef]

- Fu, Y.; Shen, Y.; Zhang, Z.; Ge, X.; Chen, M. Activated bio-chars derived from rice husk via one- and two-step KOH-catalyzed pyrolysis for phenol adsorption. Sci. Total Environ. 2019, 646, 1567–1577. [Google Scholar] [CrossRef] [PubMed]

- Ethaib, S.; Erabee, I.K. Abdulsahib 2018 Removal of Methylene Blue Dye from Synthetic Wastewater using Kenaf Core and Activated Carbon. Int. J. Eng. Technol. 2018, 7, 909. [Google Scholar] [CrossRef]

- Arumugam, N.; Chelliapan, S.; Kamyab, H.; Thirugnana, S.; Othman, N.; Nasri, N. Treatment of Wastewater Using Seaweed: A Review. Int. J. Environ. Res. Public Health 2018, 15, 2851. [Google Scholar] [CrossRef]

- Bao, Y.; Zhang, G. Study of adsorption characteristics of methylene blue onto activated carbon made by salix psammophila. In Proceedings of the Energy Procedia; Elsevier Ltd.: Amsterdam, The Netherlands, 2012; Volume 16, pp. 1141–1146. [Google Scholar]

- Pathania, D.; Sharma, S.; Singh, P. Removal of methylene blue by adsorption onto activated carbon developed from Ficus carica bast. Arab. J. Chem. 2017, 10, S1445–S1451. [Google Scholar] [CrossRef]

- Ahmad, I.; Yazdani, B.; Zhu, Y. Recent Advances on Carbon Nanotubes and Graphene Reinforced Ceramics Nanocomposites. Nanomaterials 2015, 5, 90–114. [Google Scholar] [CrossRef]

- Sorarù, G.D.; Kacha, G.; Campostrini, R.; Ponzoni, A.; Donarelli, M.; Kumar, A.; Mariotto, G. The effect of B-doping on the electrical conductivity of polymer-derived Si(B)OC ceramics. J. Am. Ceram. Soc. 2017, 100, 4611–4621. [Google Scholar] [CrossRef]

- Delbari, S.A.; Nayebi, B.; Ghasali, E.; Shokouhimehr, M.; Shahedi Asl, M. Spark plasma sintering of TiN ceramics codoped with SiC and CNT. Ceram. Int. 2019, 45, 3207–3216. [Google Scholar] [CrossRef]

- Popov, O.; Vleugels, J.; Huseynov, A.; Vishnyakov, V. Reactive sintering of TiB2-SiC-CNT ceramics. Ceram. Int. 2019, 45, 22769–22774. [Google Scholar] [CrossRef]

- Bernstein, D.; Dunnigan, J.; Hesterberg, T.; Brown, R.; Antonio, J.; Velasco, L.; Barrera, R.; Hoskins, J.; Gibbs, A. Health risk of chrysotile revisited. Crit. Rev. Toxicol. 2013, 43, 154–183. [Google Scholar] [CrossRef]

| Natural Material | Origin | Carbon Source | Process | Temperature (°C) | Type of Carbon Nanomaterial | Ref. |

|---|---|---|---|---|---|---|

| Garnet | Japan | City Gas | CVD | 1000 | MWCNT | [60] |

| Lava | Italy | Ethylene | CVD | 700 | CNF | [74] |

| Bentonite | Germany | Ethylene | CVD | 650 | MWCNT | [66] |

| Forsterite | USA | Methane | CVD | 800–900 | Amorphous carbon | [61] |

| Diopside | Pakistan | Methane | CVD | 800–900 | Amorphous carbon | [61] |

| Quartz | Japan | Methane | CVD | 800–900 | Amorphous carbon | [61] |

| Magnesite | Brazil | Methane | CVD | 800–900 | SWCNT, MWCNT | [61] |

| Brucite | USA | Methane | CVD | 800–900 | SWCNT, MWCNT | [61] |

| Bentonite | Greece | Acetylene | CVD | 700 | CNF | [63] |

| Sepiolite | China | Methane | CVD | 9000 | CNT | [79] |

| Natural Laterite | New Caledonia | Ethylene | CVD | 700–900 | CNT, CNS | [68] |

| Siliceous Breccia | New Caledonia | Ethylene | CVD | 700 | CNT | [71] |

| Vermiculite | China | Ethylene, Propylene, Liquefied Petroleum Gas | CVD | 600–800 | MWCNT | [72] |

| Chrysotile | Brazil | Ethanol | CVD | 600–900 | CNT, CNF, amorphous carbon | [62] |

| Blended Iron Formation | India | Benzylamine | AACCVD | - | N-MWCNT | [77] |

| Wollastonite | China | Ethylene | CVD | 700 | CNT | [78] |

| Nontronite | USA | Methane | HFCVD | CNT | [81] | |

| Sepiolite | China | Methane | CVD | 900 | SWCNT | [81] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, A. Natural Materials—Interesting Candidates for Carbon Nanomaterials. Physchem 2021, 1, 4-25. https://doi.org/10.3390/physchem1010002

Kumar A. Natural Materials—Interesting Candidates for Carbon Nanomaterials. Physchem. 2021; 1(1):4-25. https://doi.org/10.3390/physchem1010002

Chicago/Turabian StyleKumar, Arun. 2021. "Natural Materials—Interesting Candidates for Carbon Nanomaterials" Physchem 1, no. 1: 4-25. https://doi.org/10.3390/physchem1010002

APA StyleKumar, A. (2021). Natural Materials—Interesting Candidates for Carbon Nanomaterials. Physchem, 1(1), 4-25. https://doi.org/10.3390/physchem1010002