Fundamental Technologies and Recent Advances of Cell-Sheet-Based Tissue Engineering

Abstract

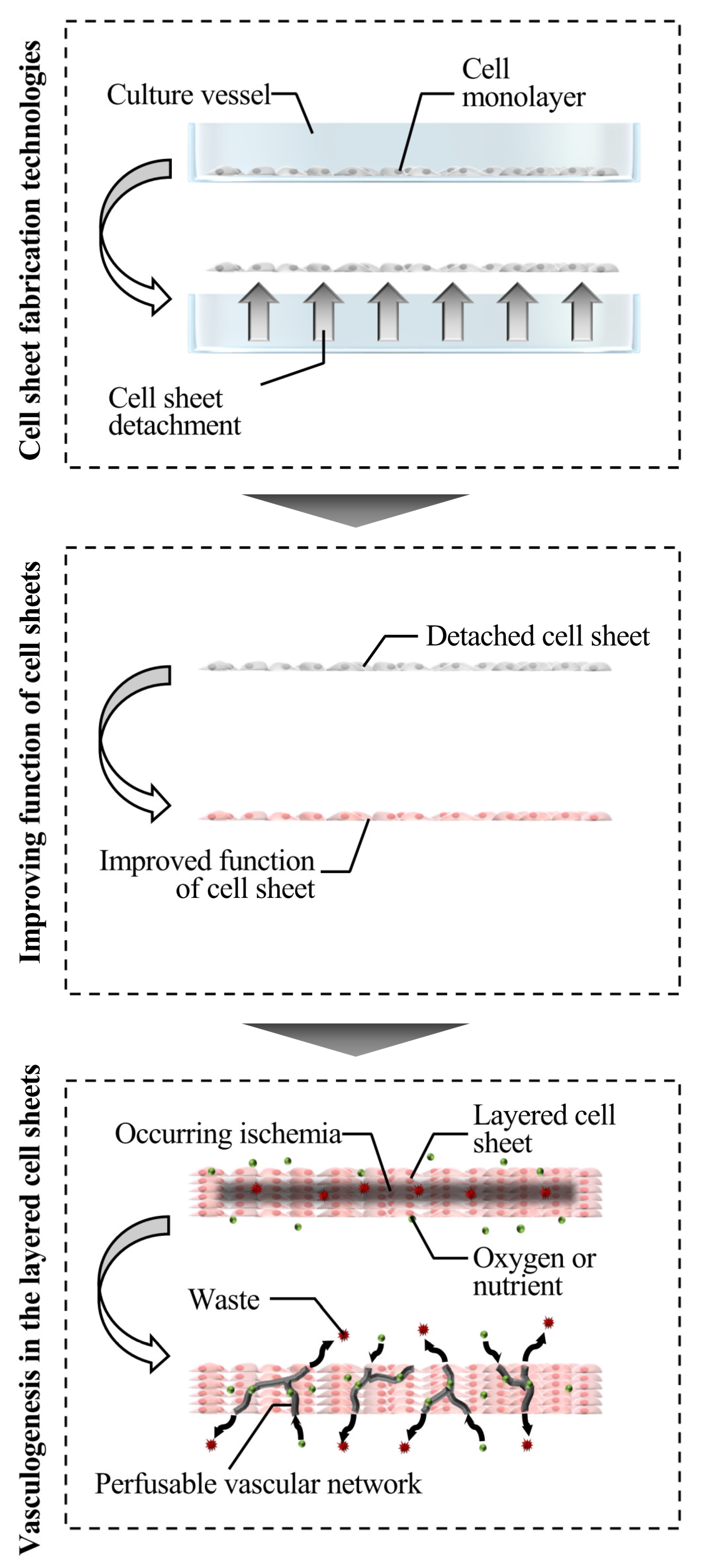

1. Introduction

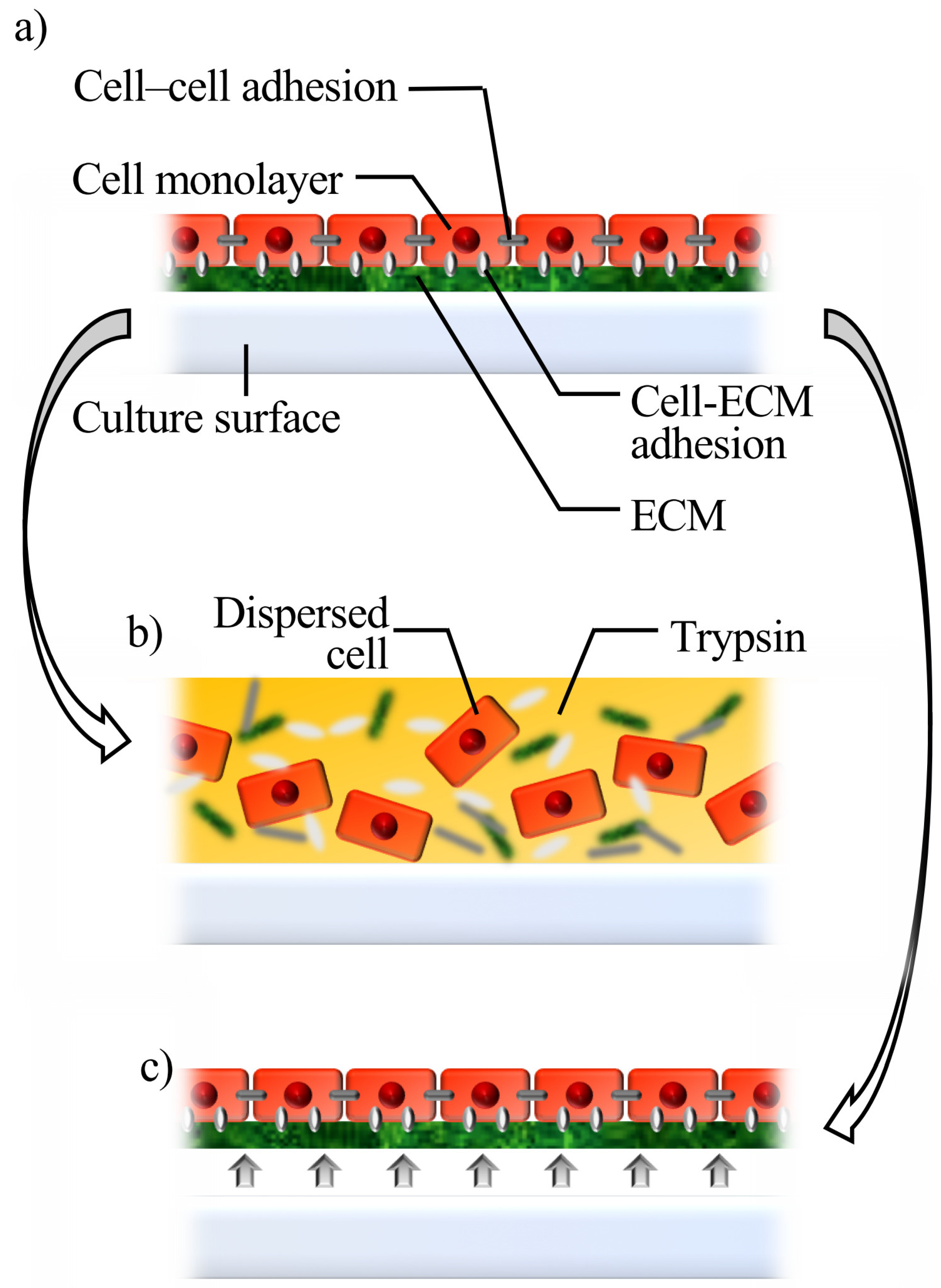

2. Cell Sheet Fabrication Technologies

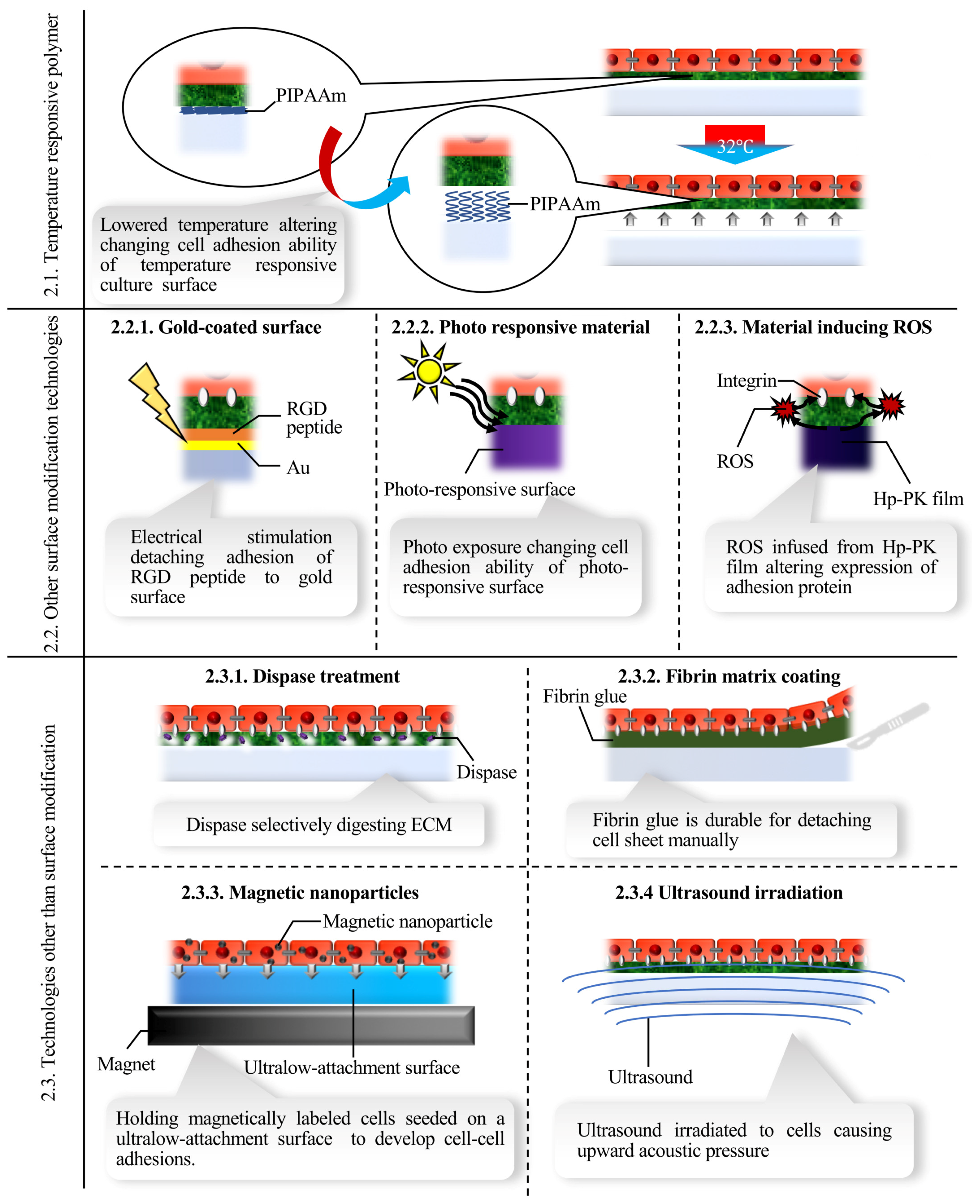

2.1. Temperature-Responsive Culture Surface

2.2. Other Surface-Modification Technologies

2.2.1. Gold-Coated Surface

2.2.2. Photo-Responsive Material

2.2.3. Materials Inducing Reactive Oxygen Species (ROS) Production

2.3. Technologies other Than Surface Modification

2.3.1. Dispase Treatment

2.3.2. Fibrin Matrix Coating

2.3.3. Magnetic Nanoparticles

2.3.4. Ultrasound Irradiation

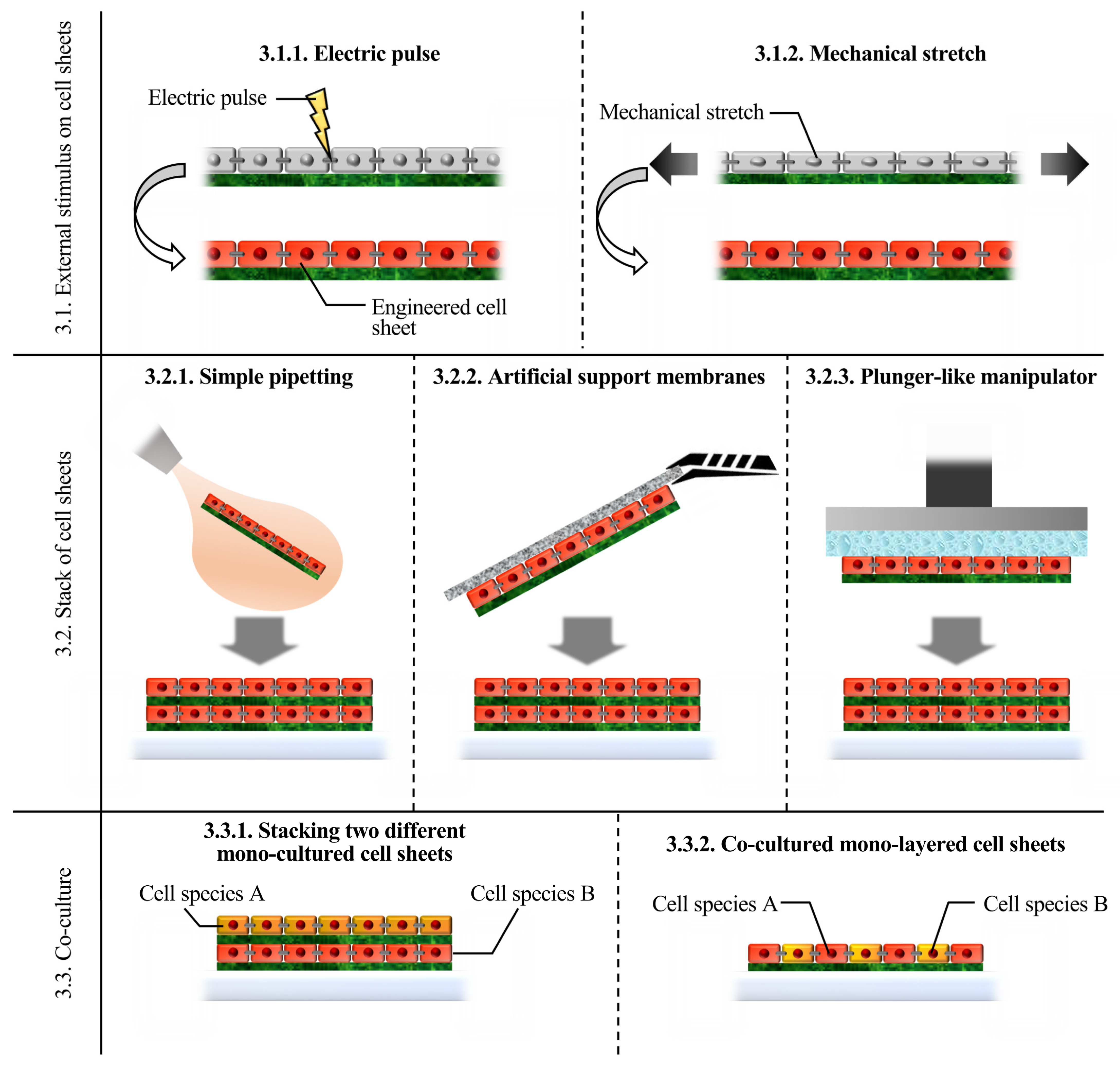

3. Improving the Function of Cell Sheets

3.1. External Stimulus on Cell Sheets

3.1.1. Electric Pulse

3.1.2. Mechanical Stretch

3.2. Stack of Cell Sheets

3.2.1. Simple Pipetting

3.2.2. Artificial Support Membranes

3.2.3. Plunger-Like Manipulator

3.3. Co-Culture

3.3.1. Stacking Two Different Mono-Cultured Cell Sheets

3.3.2. Co-Cultured Mono-Layered Cell Sheets

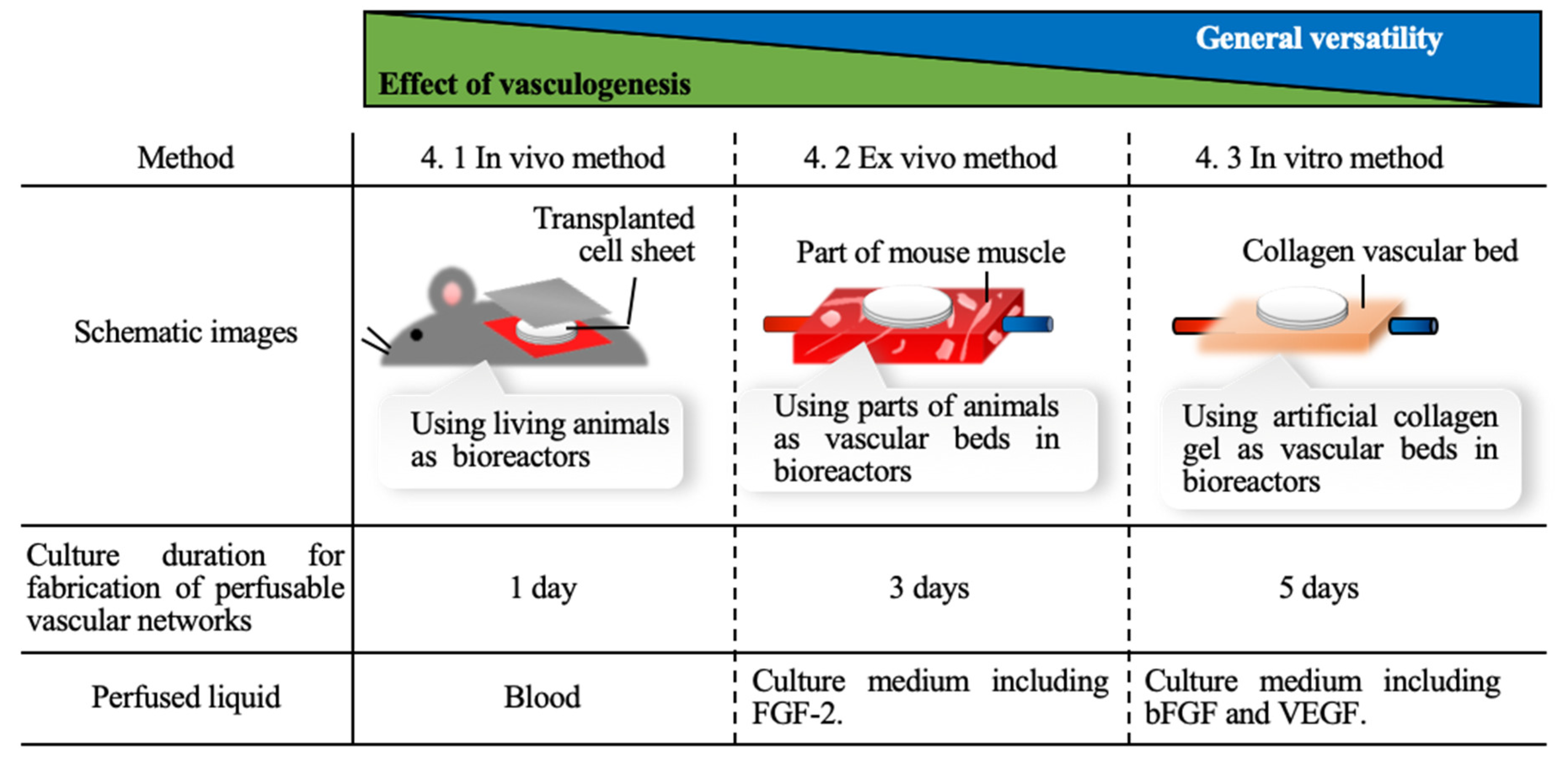

4. Vasculogenesis in the Layered Cell Sheets

4.1. In Vivo Method

4.2. Ex Vivo Method

4.3. In Vitro Method

5. Conclusions

Funding

Conflicts of Interest

References

- Yang, J.; Zhao, S.; Ji, Y.; Zhao, L.; Kong, Q.; Zhang, Q. Cell sheet-based multilayered liver tumor models for anti-cancer drug screening. Biotechnol. Lett. 2018, 40, 427–435. [Google Scholar] [CrossRef]

- Zhang, G.; Zhao, X.; Li, X.; Du, G.; Zhou, J.; Chen, J. Challenges and possibilities for bio-manufacturing cultured meat. Trends Food Sci. Technol. 2020, 97, 443–450. [Google Scholar] [CrossRef]

- Masuda, S.; Shimizu, T. Three-dimensional cardiac tissue fabrication based on cell sheet technology. Adv. Drug Deliv. Rev. 2016, 96, 103–109. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Bou-Ghannam, S.; Okano, T. Cell sheet tissue engineering for scaffold-free three-dimensional (3D) tissue reconstruction, 1st ed.Elsevier Inc.: Amsterdam, The Netherlands, 2020; Volume 157, ISBN 9780128201749. [Google Scholar] [CrossRef]

- Uesugi, K.; Sakuma, Y.; Akiyama, Y.; Akiyama, Y.; Iwabuchi, K.; Okano, T.; Morishima, K. Temperature-responsive culture surfaces for insect cell sheets to fabricate a bioactuator. Adv. Robot. 2019, 33, 219–231. [Google Scholar] [CrossRef]

- Akimoto, J.; Takagi, S.; Nakayama, M.; Arauchi, A.; Yamato, M.; Okano, T. Transplantation of cancerous cell sheets effectively generates tumour-bearing model mice. J. Tissue Eng. Regen. Med. 2016, 10, E510–E517. [Google Scholar] [CrossRef] [PubMed]

- Akimoto, J.; Nakayama, M.; Takagi, S.; Okano, T. Improved in vivo subcutaneous tumor generation by cancer cell sheet transplantation. Anticancer Res. 2018, 38, 671–676. [Google Scholar] [CrossRef] [PubMed]

- Abulaiti, M.; Yalikun, Y.; Murata, K.; Sato, A.; Sami, M.M. Establishment of a heart - on - a - chip microdevice based on human iPS cells for the evaluation of human heart tissue function. Sci. Rep. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Yamada, N.; Okano, T.; Sakai, H.; Karikusa, F.; Sawasaki, Y.; Sakurai, Y. Thermo-responsive polymeric surfaces; control of attachment and detachment of cultured cells. Die Makromol. Chem. Rapid Commun. 1990, 11, 571–576. [Google Scholar] [CrossRef]

- Yamamoto, R.; Miyagawa, S.; Toda, K.; Kainuma, S.; Yoshioka, D.; Yoshikawa, Y.; Hata, H.; Ueno, T.; Kuratani, T.; Sawa, Y. Long-Term Outcome of Ischemic Cardiomyopathy After Autologous Myoblast Cell-Sheet Implantation. Ann. Thorac. Surg. 2019, 108, e303–e306. [Google Scholar] [CrossRef]

- Hayashi, R.; Ishikawa, Y.; Katori, R.; Sasamoto, Y.; Taniwaki, Y.; Takayanagi, H.; Tsujikawa, M.; Sekiguchi, K.; Quantock, A.J.; Nishida, K. Coordinated generation of multiple ocular-like cell lineages and fabrication of functional corneal epithelial cell sheets from human iPS cells. Nat. Protoc. 2017, 12, 683–696. [Google Scholar] [CrossRef]

- Yamaguchi, N.; Isomoto, H.; Kobayashi, S.; Kanai, N.; Kanetaka, K.; Sakai, Y.; Kasai, Y.; Takagi, R.; Ohki, T.; Fukuda, H.; et al. Oral epithelial cell sheets engraftment for esophageal strictures after endoscopic submucosal dissection of squamous cell carcinoma and airplane transportation. Sci. Rep. 2017, 7, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Narita, T.; Shintani, Y.; Ikebe, C.; Kaneko, M.; Campbell, N.G.; Coppen, S.R.; Uppal, R.; Sawa, Y.; Yashiro, K.; Suzuki, K. The use of scaffold-free cell sheet technique to refine mesenchymal stromal cell-based therapy for heart failure. Mol. Ther. 2013, 21, 860–867. [Google Scholar] [CrossRef] [PubMed]

- Fukumori, K.; Akiyama, Y.; Yamato, M.; Okano, T. A facile method for preparing temperature-responsive cell culture surfaces by using a thioxanthone photoinitiator immobilized on a polystyrene surface. ChemNanoMat 2016, 2, 454–460. [Google Scholar] [CrossRef]

- Sakuma, M.; Kumashiro, Y.; Nakayama, M.; Tanaka, N.; Haraguchi, Y.; Umemura, K.; Shimizu, T.; Yamato, M.; Okano, T. Preparation of thermoresponsive nanostructured surfaces for tissue engineering. J. Vis. Exp. 2016, 2016, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Nakayama, M.; Toyoshima, Y.; Chinen, H.; Kikuchi, A.; Yamato, M.; Okano, T. Water stable nanocoatings of poly( N-isopropylacrylamide)-based block copolymers on culture insert membranes for temperature-controlled cell adhesion. J. Mater. Chem. B 2020, 8, 7812–7821. [Google Scholar] [CrossRef] [PubMed]

- Dzhoyashvili, N.A.; Thompson, K.; Gorelov, A.V.; Rochev, Y.A. Film Thickness Determines Cell Growth and Cell Sheet Detachment from Spin-Coated Poly(N-Isopropylacrylamide) Substrates. ACS Appl. Mater. Interfaces 2016, 8, 27564–27572. [Google Scholar] [CrossRef] [PubMed]

- Akiyama, Y.; Matsuyama, M.; Yamato, M.; Takeda, N.; Okano, T. Poly(N-isopropylacrylamide)-Grafted Polydimethylsiloxane Substrate for Controlling Cell Adhesion and Detachment by Dual Stimulation of Temperature and Mechanical Stress. Biomacromolecules 2018, 19, 4014–4022. [Google Scholar] [CrossRef]

- Hama, T.; Yamamoto, K.; Yaguchi, Y.; Murakami, D.; Sasaki, H.; Yamato, M.; Okano, T.; Kojima, H. Autologous human nasal epithelial cell sheet using temperature-responsive culture insert for transplantation after middle ear surgery. J. Tissue Eng. Regen. Med. 2017, 11, 1089–1096. [Google Scholar] [CrossRef]

- Ebara, M.; Yamato, M.; Hirose, M.; Aoyagi, T.; Kikuchi, A.; Sakai, K.; Okano, T. Copolymerization of 2-carboxyisopropylacrylamide with N-isopropylacrylamide accelerates cell detachment from grafted surfaces by reducing temperature. Biomacromolecules 2003, 4, 344–349. [Google Scholar] [CrossRef]

- Oh, H.K.; Kikuchi, A.; Yamato, M.; Okano, T. Accelerated cell sheet recovery by co-grafting of PEG with PIPAAm onto porous cell culture membranes. Biomaterials 2003, 24, 1223–1232. [Google Scholar]

- Lu, Y.; Zhang, W.; Wang, J.; Yang, G.; Yin, S.; Tang, T.; Yu, C.; Jiang, X. Recent advances in cell sheet technology for bone and cartilage regeneration: From preparation to application. Int. J. Oral Sci. 2019, 11, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Inaba, R.; Khademhosseini, A.; Suzuki, H.; Fukuda, J. Electrochemical desorption of self-assembled monolayers for engineering cellular tissues. Biomaterials 2009, 30, 3573–3579. [Google Scholar] [CrossRef] [PubMed]

- Enomoto, J.; Kageyama, T.; Myasnikova, D.; Onishi, K.; Kobayashi, Y.; Taruno, Y.; Kanai, T.; Fukuda, J. Gold cleaning methods for preparation of cell culture surfaces for self-assembled monolayers of zwitterionic oligopeptides. J. Biosci. Bioeng. 2018, 125, 606–612. [Google Scholar] [CrossRef] [PubMed]

- Enomoto, J.; Mochizuki, N.; Ebisawa, K.; Osaki, T.; Kageyama, T.; Myasnikova, D.; Nittami, T.; Fukuda, J. Engineering thick cell sheets by electrochemical desorption of oligopeptides on membrane substrates. Regen. Ther. 2016, 3, 24–31. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Cordonier, C.E.J.; Noda, Y.; Nagase, F.; Enomoto, J.; Kageyama, T.; Honma, H.; Maruo, S.; Fukuda, J. Tailored cell sheet engineering using microstereolithography and electrochemical cell transfer. Sci. Rep. 2019, 9, 1–8. [Google Scholar] [CrossRef]

- Kim, J.D.; Heo, J.S.; Park, T.; Park, C.; Kim, H.O.; Kim, E. Photothermally induced local dissociation of collagens for harvesting of cell sheets. Angew. Chem. Int. Ed. 2015, 54, 5869–5873. [Google Scholar] [CrossRef]

- Patel, N.G.; Zhang, G. Responsive systems for cell sheet detachment. Organogenesis 2013, 9, 93–100. [Google Scholar] [CrossRef]

- Long, X.; Yi, Y.; Wang, X.; Duan, X.; Sun, Y.; Wu, C.; Weng, W.; Xu, B.; Cheng, K.; Wang, H.; et al. Gr/TiO2 Films with Light-Controlled Positive/Negative Charge for Cell Harvesting Application. ACS Biomater. Sci. Eng. 2020, 6, 2020–2028. [Google Scholar] [CrossRef]

- Na, J.; Heo, J.S.; Han, M.; Lim, H.; Kim, H.O.; Kim, E. Harvesting of Living Cell Sheets by the Dynamic Generation of Diffractive Photothermal Pattern on PEDOT. Adv. Funct. Mater. 2017, 27, 1604260. [Google Scholar] [CrossRef]

- Zhou, Y.; Dong, L.; Liu, C.; Lin, Y.; Yu, M.; Ma, L.; Zhang, B.; Cheng, K.; Weng, W.; Wang, H. Engineering prevascularized composite cell sheet by light-induced cell sheet technology. RSC Adv. 2017, 7, 32468–32477. [Google Scholar] [CrossRef]

- You, J.; Heo, J.S.; Kim, J.; Park, T.; Kim, B.; Kim, H.S.; Choi, Y.; Kim, H.O.; Kim, E. Noninvasive photodetachment of stem cells on tunable conductive polymer nano thin films: Selective harvesting and preserved differentiation capacity. ACS Nano 2013, 7, 4119–4128. [Google Scholar] [CrossRef] [PubMed]

- Kolesnikova, T.A.; Kohler, D.; Skirtach, A.G.; Möhwald, H. Laser-induced cell detachment, patterning, and regrowth on gold nanoparticle functionalized surfaces. ACS Nano 2012, 6, 9585–9595. [Google Scholar] [CrossRef] [PubMed]

- Song, H.; Cha, M.J.; Song, B.W.; Kim, I.K.; Chang, W.; Lim, S.; Choi, E.J.; Ham, O.; Lee, S.Y.; Chung, N.; et al. Reactive oxygen species inhibit adhesion of mesenchymal stem cells implanted into ischemic myocardium via interference of focal adhesion complex. Stem Cells 2010, 28, 555–563. [Google Scholar] [CrossRef] [PubMed]

- Koo, M.A.; Lee, M.H.; Kwon, B.J.; Seon, G.M.; Kim, M.S.; Kim, D.; Nam, K.C.; Park, J.C. Exogenous ROS-induced cell sheet transfer based on hematoporphyrin-polyketone film via a one-step process. Biomaterials 2018, 161, 47–56. [Google Scholar] [CrossRef] [PubMed]

- Green, H.; Kehinde, O.; Thomas, J. Growth of cultured human epidermal cells into multiple epithelia suitable for grafting. Proc. Natl. Acad. Sci. USA 1979, 76, 5665–5668. [Google Scholar] [CrossRef] [PubMed]

- Osada, A.; Sekine, H.; Soejima, K.; Sakurai, H.; Shimizu, T. Harvesting epithelial keratinocyte sheets from temperature-responsive dishes preserves basement membrane proteins and improves cell survival in a skin defect model. J. Tissue Eng. Regen. Med. 2017, 11, 2516–2524. [Google Scholar] [CrossRef]

- Hyun, D.W.; Kim, Y.H.; Koh, A.Y.; Lee, H.J.; Wee, W.R.; Jeon, S.; Kim, M.K. Characterization of biomaterial-free cell sheets cultured from human oral mucosal epithelial cells. J. Tissue Eng. Regen. Med. 2017, 11, 743–750. [Google Scholar] [CrossRef]

- Bardag-Gorce, F.; Oliva, J.; Wood, A.; Hoft, R.; Pan, D.; Thropay, J.; Makalinao, A.; French, S.W.; Niihara, Y. Carrier-free cultured autologous oral mucosa epithelial cell sheet (CAOMECS) for corneal epithelium reconstruction: A histological study. Ocul. Surf. 2015, 13, 150–163. [Google Scholar] [CrossRef]

- Rovere, M.R.; Rousselle, P.; Haftek, M.; Charleux, B.; Kocaba, V.; Auxenfans, C.; Nataf, S.; Damour, O. Preserving Basement Membranes during Detachment of Cultivated Oral Mucosal Epithelial Cell Sheets for the Treatment of Total Bilateral Limbal Stem Cell Deficiency. Cell Transplant. 2018, 27, 264–274. [Google Scholar] [CrossRef]

- Ronfard, V.; Broly, H.; Mitchell, V.; Galizia, J.P.; Hochart, D.; Chambon, E.; Pellerin, P.; Huart, J.J. Use of human keratinocytes cultured on fibrin glue in the treatment of burn wounds. Burns 1991, 17, 181–184. [Google Scholar] [CrossRef]

- Itabashi, Y.; Miyoshi, S.; Kawaguchi, H.; Yuasa, S.; Tanimoto, K.; Furuta, A.; Shimizu, T.; Okano, T.; Fukuda, K.; Ogawa, S. A new method for manufacturing cardiac cell sheets using fibrin-coated dishes and its electrophysiological studies by optical mapping. Artif. Organs 2005, 29, 95–103. [Google Scholar] [CrossRef] [PubMed]

- Ito, A.; Hayashida, M.; Honda, H.; Hata, K.I.; Kagami, H.; Ueda, M.; Kobayashi, T. Construction and harvest of multilayered keratinocyte sheets using magnetite nanoparticles and magnetic force. Tissue Eng. 2004, 10, 873–880. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, A.I.; Rodrigues, M.T.; Gomes, M.E. Tissue-engineered magnetic cell sheet patches for advanced strategies in tendon regeneration. Acta Biomater. 2017, 63, 110–122. [Google Scholar] [CrossRef] [PubMed]

- Imashiro, C.; Kurashina, Y.; Takemura, K. Cell Patterning Method Using Resonance Vibration of a Metallic Cell Cultivation Substrate. Adv. Biomed. Eng. 2016, 5, 142–148. [Google Scholar] [CrossRef]

- Kurashina, Y.; Hirano, M.; Imashiro, C.; Totani, K.; Komotori, J.; Takemura, K. Enzyme-free cell detachment mediated by resonance vibration with temperature modulation. Biotechnol. Bioeng. 2017, 114, 2279–2288. [Google Scholar] [CrossRef] [PubMed]

- Kang, B.; Shin, J.; Park, H.-J.; Rhyou, C.; Kang, D.; Lee, S.-J.; Yoon, Y.; Cho, S.-W.; Lee, H. High-resolution acoustophoretic 3D cell patterning to construct functional collateral cylindroids for ischemia therapy. Nat. Commun. 2018, 9, 1–13. [Google Scholar] [CrossRef]

- Nakao, M.; Kurashina, Y.; Imashiro, C.; Takemura, K. A method for collecting single cell suspensions using an ultrasonic pump. IEEE Trans. Biomed. Eng. 2017, 65, 224–231. [Google Scholar] [CrossRef]

- Enomoto, U.; Imashiro, C.; Takemura, K. Collective cell migration of fibroblasts is affected by horizontal vibration of the cell culture dish. Eng. Life Sci. 2020, 20, 402–411. [Google Scholar] [CrossRef]

- Imashiro, C.; Kurashina, Y.; Kuribara, T.; Hirano, M.; Totani, K.; Takemura, K. Cell Patterning Method on a Clinically Ubiquitous Culture Dish Using Acoustic Pressure Generated From Resonance Vibration of a Disk-Shaped Ultrasonic Transducer. IEEE Trans. Biomed. Eng. 2019, 66, 111–118. [Google Scholar] [CrossRef]

- Inui, T.; Kurashina, Y.; Imashiro, C.; Takemura, K. Method of localized removal of cells using a bolt-clamped Langevin transducer with an ultrasonic horn. Eng. Life Sci. 2019, 19, 575–583. [Google Scholar] [CrossRef]

- Tauchi, H.; Imashiro, C.; Kuribara, T.; Fujii, G.; Kurashina, Y.; Totani, K.; Takemura, K. Effective and Intact Cell Detachment from a Clinically Ubiquitous Culture Flask by Combining Ultrasonic Wave Exposure and Diluted Trypsin. Biotechnol. Bioprocess Eng. 2019, 24, 536–543. [Google Scholar] [CrossRef]

- Kurashina, Y.; Imashiro, C.; Hirano, M.; Kuribara, T.; Totani, K.; Ohnuma, K.; Friend, J.; Takemura, K. Enzyme-free release of adhered cells from standard culture dishes using intermittent ultrasonic traveling waves. Commun. Biol. 2019, 2, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Imashiro, C.; Hirano, M.; Morikura, T.; Fukuma, Y.; Ohnuma, K.; Kurashina, Y.; Miyata, S.; Takemura, K. Detachment of cell sheets from clinically ubiquitous cell culture vessels by ultrasonic vibration. Sci. Rep. 2020, 10, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Nakao, M.; Imashiro, C.; Kuribara, T.; Kurashina, Y.; Totani, K.; Takemura, K. Formation of Large Scaffold-Free 3-D Aggregates in a Cell Culture Dish by Ultrasound Standing Wave Trapping. Ultrasound Med. Biol. 2019, 45, 1306–1315. [Google Scholar] [CrossRef]

- Soares, C.P.; Midlej, V.; Mewd, O.; Benchimol, M.; Costa, M.L. 2D and 3D-Organized Cardiac Cells Shows Differences in Cellular Morphology, Adhesion Junctions, Presence of Myofibrils and Protein Expression. PLoS One 2012, 7, e38147. [Google Scholar] [CrossRef]

- Sakaguchi, K.; Takahashi, H.; Tobe, Y.; Sasaki, D.; Matsuura, K.; Iwasaki, K.; Shimizu, T.; Umezu, M. Measuring the Contractile Force of Multilayered Human Cardiac Cell Sheets. Tissue Eng. Part C Methods 2020, 26, 485–492. [Google Scholar] [CrossRef]

- Ruan, J.L.; Tulloch, N.L.; Razumova, M.V.; Saiget, M.; Muskheli, V.; Pabon, L.; Reinecke, H.; Regnier, M.; Murry, C.E. Mechanical Stress Conditioning and Electrical Stimulation Promote Contractility and Force Maturation of Induced Pluripotent Stem Cell-Derived Human Cardiac Tissue. Circulation 2016, 134, 1557–1567. [Google Scholar] [CrossRef]

- Roberts, E.G.; Kleptsyn, V.F.; Roberts, G.D.; Mossburg, K.J.; Feng, B.; Domian, I.J.; Emani, S.M.; Wong, J.Y. Development of a bio-MEMS device for electrical and mechanical conditioning and characterization of cell sheets for myocardial repair. Biotechnol. Bioeng. 2019, 116, 3098–3111. [Google Scholar] [CrossRef]

- Berger, H.J.; Prasad, S.K.; Davidoff, A.J.; Pimental, D.; Ellingsen, O.; Marsh, J.D.; Smith, T.W.; Kelly, R.A. Continual electric field stimulation preserves contractile function of adult ventricular myocytes in primary culture. Am. J. Physiol. Hear. Circ. Physiol. 1994, 266, H341–H349. [Google Scholar] [CrossRef]

- Godier-Furnémont, A.F.G.; Tiburcy, M.; Wagner, E.; Dewenter, M.; Lämmle, S.; El-Armouche, A.; Lehnart, S.E.; Vunjak-Novakovic, G.; Zimmermann, W.H. Physiologic force-frequency response in engineered heart muscle by electromechanical stimulation. Biomaterials 2015, 60, 82–91. [Google Scholar] [CrossRef]

- Sasaki, D.; Matsuura, K.; Seta, H.; Haraguchi, Y.; Okano, T.; Shimizu, T. Contractile force measurement of human induced pluripotent stem cell-derived cardiac cell sheet-tissue. PLoS ONE 2018, 13, e0198026. [Google Scholar] [CrossRef] [PubMed]

- Tsuruyama, S.; Matsuura, K.; Sakaguchi, K.; Shimizu, T. Pulsatile tubular cardiac tissues fabricated by wrapping human iPS cells-derived cardiomyocyte sheets. Regen. Ther. 2019, 11, 297–305. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, H.; Shimizu, T.; Okano, T. Engineered Human Contractile Myofiber Sheets as a Platform for Studies of Skeletal Muscle Physiology. Sci. Rep. 2018, 8, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Bansai, S.; Morikura, T.; Onoe, H.; Miyata, S. Effect of cyclic stretch on tissue maturation in myoblast-laden hydrogel fibers. Micromachines 2019, 10, 399. [Google Scholar] [CrossRef]

- Liu, Y.; Ojima, Y.; Horie, M.; Nagamori, E.; Fujita, H. Design and fabrication of devices for investigating cell-sheet stretch. Biochip J. 2017, 11, 173–179. [Google Scholar] [CrossRef]

- Homma, J.; Shimizu, S.; Sekine, H.; Matsuura, K.; Shimizu, T. A novel method to align cells in a cardiac tissue-like construct fabricated by cell sheet-based tissue engineering. J. Tissue Eng. Regen. Med. 2020, 944–954. [Google Scholar] [CrossRef]

- Morita, Y.; Matsubara, F.; Toku, Y.; Ju, Y. Use of a tendon/ligament cell sheet with mesenchymal stem cells and cyclic stretch stimulus for tendon/ligament tissue restoration. J. Mech. Eng. 2018, 5, 1–11. [Google Scholar]

- Haraguchi, Y.; Kagawa, Y.; Hasegawa, A.; Kubo, H.; Shimizu, T. Rapid fabrication of detachable three-dimensional tissues by layering of cell sheets with heating centrifuge. Biotechnol. Prog. 2018, 34, 692–701. [Google Scholar] [CrossRef]

- Iwata, T.; Yamato, M.; Tsuchioka, H.; Takagi, R.; Mukobata, S.; Washio, K.; Okano, T.; Ishikawa, I. Periodontal regeneration with multi-layered periodontal ligament-derived cell sheets in a canine model. Biomaterials 2009, 30, 2716–2723. [Google Scholar] [CrossRef]

- Nagamoto, Y.; Takayama, K.; Ohashi, K.; Okamoto, R.; Sakurai, F.; Tachibana, M.; Kawabata, K.; Mizuguchi, H. Transplantation of a human iPSC-derived hepatocyte sheet increases survival in mice with acute liver failure. J. Hepatol. 2016, 64, 1068–1075. [Google Scholar] [CrossRef]

- Tsuda, Y.; Shimizu, T.; Yamato, M.; Kikuchi, A.; Sasagawa, T.; Sekiya, S.; Kobayashi, J.; Chen, G.; Okano, T. Cellular control of tissue architectures using a three-dimensional tissue fabrication technique. Biomaterials 2007, 28, 4939–4946. [Google Scholar] [CrossRef] [PubMed]

- Asakawa, N.; Shimizu, T.; Tsuda, Y.; Sekiya, S.; Sasagawa, T.; Yamato, M.; Fukai, F.; Okano, T. Pre-vascularization of in vitro three-dimensional tissues created by cell sheet engineering. Biomaterials 2010, 31, 3903–3909. [Google Scholar] [CrossRef] [PubMed]

- Sakai, Y.; Yamanouchi, K.; Ohashi, K.; Koike, M.; Utoh, R.; Hasegawa, H.; Muraoka, I.; Suematsu, T.; Soyama, A.; Hidaka, M.; et al. Vascularized subcutaneous human liver tissue from engineered hepatocyte/fibroblast sheets in mice. Biomaterials 2015, 65, 66–75. [Google Scholar] [CrossRef] [PubMed]

- Sakai, Y.; Koike, M.; Hasegawa, H.; Yamanouchi, K.; Soyama, A.; Takatsuki, M.; Kuroki, T.; Ohashi, K.; Okano, T.; Eguchi, S. Rapid Fabricating Technique for Multi-Layered Human Hepatic Cell Sheets by Forceful Contraction of the Fibroblast Monolayer. PLoS ONE 2013, 8, e70970. [Google Scholar] [CrossRef]

- Gao, B.; Sakaguchi, K.; Matsuura, K.; Ogawa, T.; Kagawa, Y.; Kubo, H.; Shimizu, T. In Vitro Production of Human Ballooned Hepatocytes in a Cell Sheet-based Three-dimensional Model. Tissue Eng. Part A 2020, 26, 93–101. [Google Scholar] [CrossRef]

- Tsuda, Y.; Kikuchi, A.; Yamato, M.; Nakao, A.; Sakurai, Y.; Umezu, M.; Okano, T. The use of patterned dual thermoresponsive surfaces for the collective recovery as co-cultured cell sheets. Biomaterials 2005, 26, 1885–1893. [Google Scholar] [CrossRef]

- Sharma, D.; Ross, D.; Wang, G.; Jia, W.; Kirkpatrick, S.J.; Zhao, F. Upgrading prevascularization in tissue engineering: A review of strategies for promoting highly organized microvascular network formation. Acta Biomater. 2019, 95, 112–130. [Google Scholar] [CrossRef]

- Chiu, L.L.Y.; Montgomery, M.; Liang, Y.; Liu, H.; Radisic, M. Perfusable branching microvessel bed for vascularization of engineered tissues. Proc. Natl. Acad. Sci. USA 2012, 109. [Google Scholar] [CrossRef]

- Shimizu, T.; Sekine, H.; Yang, J.; Isoi, Y.; Yamato, M.; Kikuchi, A.; Kobayashi, E.; Okano, T. Polysurgery of cell sheet grafts overcomes diffusion limits to produce thick, vascularized myocardial tissues. FASEB J. 2006, 20, 708–710. [Google Scholar] [CrossRef]

- Sekine, H.; Shimizu, T.; Sakaguchi, K.; Dobashi, I.; Wada, M.; Yamato, M.; Kobayashi, E.; Umezu, M.; Okano, T. In vitro fabrication of functional three-dimensional tissues with perfusable blood vessels. Nat. Commun. 2013, 4, 1–10. [Google Scholar] [CrossRef]

- Sakaguchi, K.; Shimizu, T.; Horaguchi, S.; Sekine, H.; Yamato, M.; Umezu, M.; Okano, T. In vitro engineering of vascularized tissue surrogates. Sci. Rep. 2013, 3, 1316. [Google Scholar] [CrossRef] [PubMed]

- Villasante, A.; Sakaguchi, K.; Kim, J.; Cheung, N.K.; Nakayama, M.; Parsa1, H.; Okano, T.; Shimizu, T.; Vunjak-Novakovic, G. Vascularized tissue-engineered model for studying drug resistance in neuroblastoma. Theranostics 2017, 7, 4099. [Google Scholar] [CrossRef] [PubMed]

- Takehara, H.; Sakaguchi, K.; Sekine, H.; Okano, T.; Shimizu, T. Microfluidic vascular-bed devices for vascularized 3D tissue engineering: Tissue engineering on a chip. Biomed. Microdevices 2020, 22, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, H.; Okano, T. Cell Sheet-Based Tissue Engineering for Organizing Anisotropic Tissue Constructs Produced Using Microfabricated Thermoresponsive Substrates. Adv. Healthc. Mater. 2015, 4, 2388–2407. [Google Scholar] [CrossRef]

- Chen, M.; Xu, Y.; Zhang, T.; Ma, Y.; Liu, J.; Yuan, B.; Chen, X.; Zhou, P.; Zhao, X.; Pang, F.; et al. Mesenchymal stem cell sheets: A new cell-based strategy for bone repair and regeneration. Biotechnol. Lett. 2019, 41, 305–318. [Google Scholar] [CrossRef]

| Feature | Special Equipment | Triger of Detachment | Possible Residual Substances | ||

|---|---|---|---|---|---|

| 2.1. Temperature responsive polymer | Commercially available and clinically reliable. | Low-temperature incubator | Temperature reduction | - | |

| 2.2. Other surface modification technologies | 2.2.1. Gold-coated surface | Implementation of 3D-shaped cell sheets. | Potentiostat | Electric stimulus | RGD peptide |

| 2.2.2. Photo responsive material | Good temporal and spatial controllability. | Illumination device | Photo exposure | - | |

| 2.2.3. Material inducing ROS | The ease of transplantation owing to flexible substrate. | Illumination device | Photo exposure | ROS | |

| 2.3. Technologies other than surface modification | 2.3.1. Dispase treatment | Simple method to just add an enzyme. | - | Adding enzyme | Dispase |

| 2.3.2. Fibrin matrix coating | Long-term durability for handling and good adhesion properties | - | Manual handling | Fibrin | |

| 2.3.3. Magnetic nanoparticles | Potential in regenerative therapy was confirmed by in vivo experiments | Magnet | Remove of magnetic field | Magnetic nanoparticles | |

| 2.3.4. Ultrasound irradiation | High biocompatibility and low running cost | Ultrasound transducer | Ultrasound irradiation | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Imashiro, C.; Shimizu, T. Fundamental Technologies and Recent Advances of Cell-Sheet-Based Tissue Engineering. Int. J. Mol. Sci. 2021, 22, 425. https://doi.org/10.3390/ijms22010425

Imashiro C, Shimizu T. Fundamental Technologies and Recent Advances of Cell-Sheet-Based Tissue Engineering. International Journal of Molecular Sciences. 2021; 22(1):425. https://doi.org/10.3390/ijms22010425

Chicago/Turabian StyleImashiro, Chikahiro, and Tatsuya Shimizu. 2021. "Fundamental Technologies and Recent Advances of Cell-Sheet-Based Tissue Engineering" International Journal of Molecular Sciences 22, no. 1: 425. https://doi.org/10.3390/ijms22010425

APA StyleImashiro, C., & Shimizu, T. (2021). Fundamental Technologies and Recent Advances of Cell-Sheet-Based Tissue Engineering. International Journal of Molecular Sciences, 22(1), 425. https://doi.org/10.3390/ijms22010425