Tracking Control for Piezoelectric Actuators with Advanced Feed-Forward Compensation Combined with PI Control †

Abstract

:1. Introduction

2. Methods

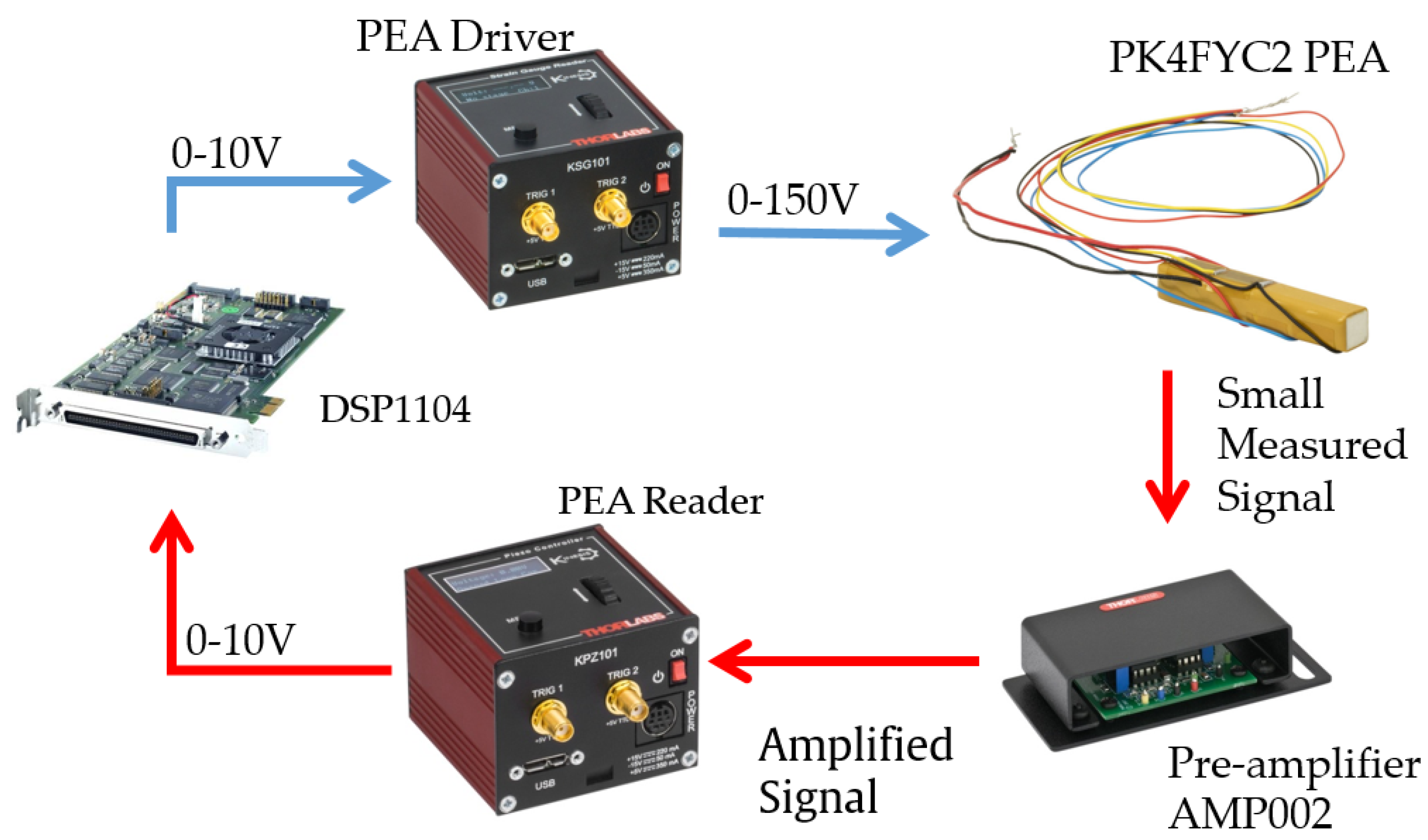

2.1. Hardware Description

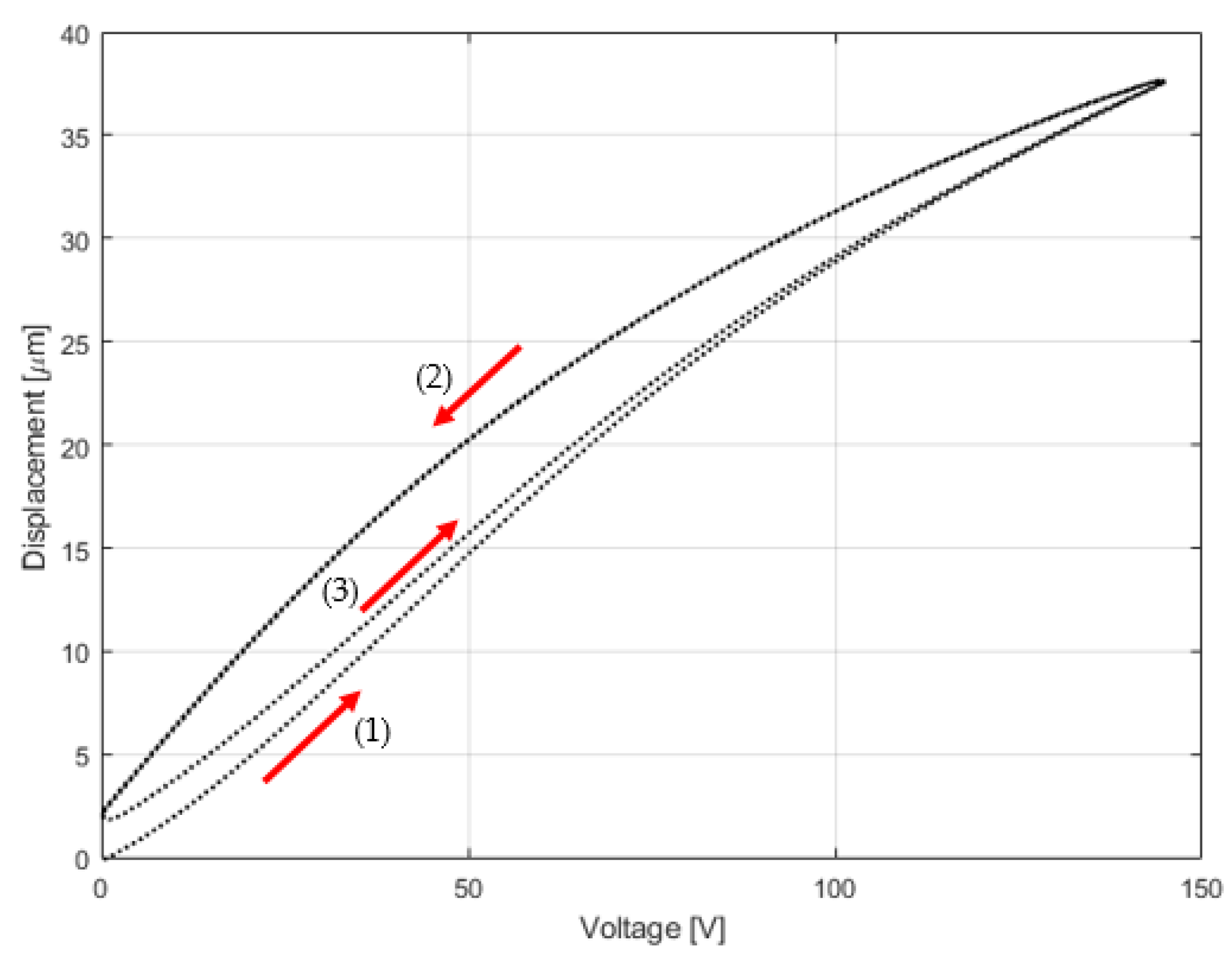

2.2. PEA Hysteresis

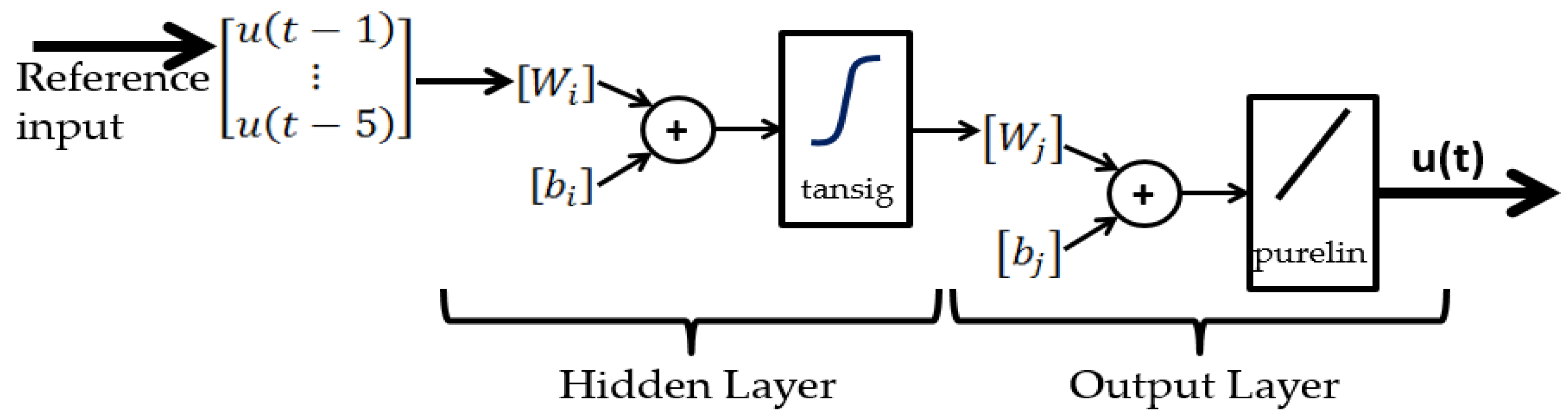

2.3. ANN Configuration

2.4. Hammerstein–Wiener Configuration

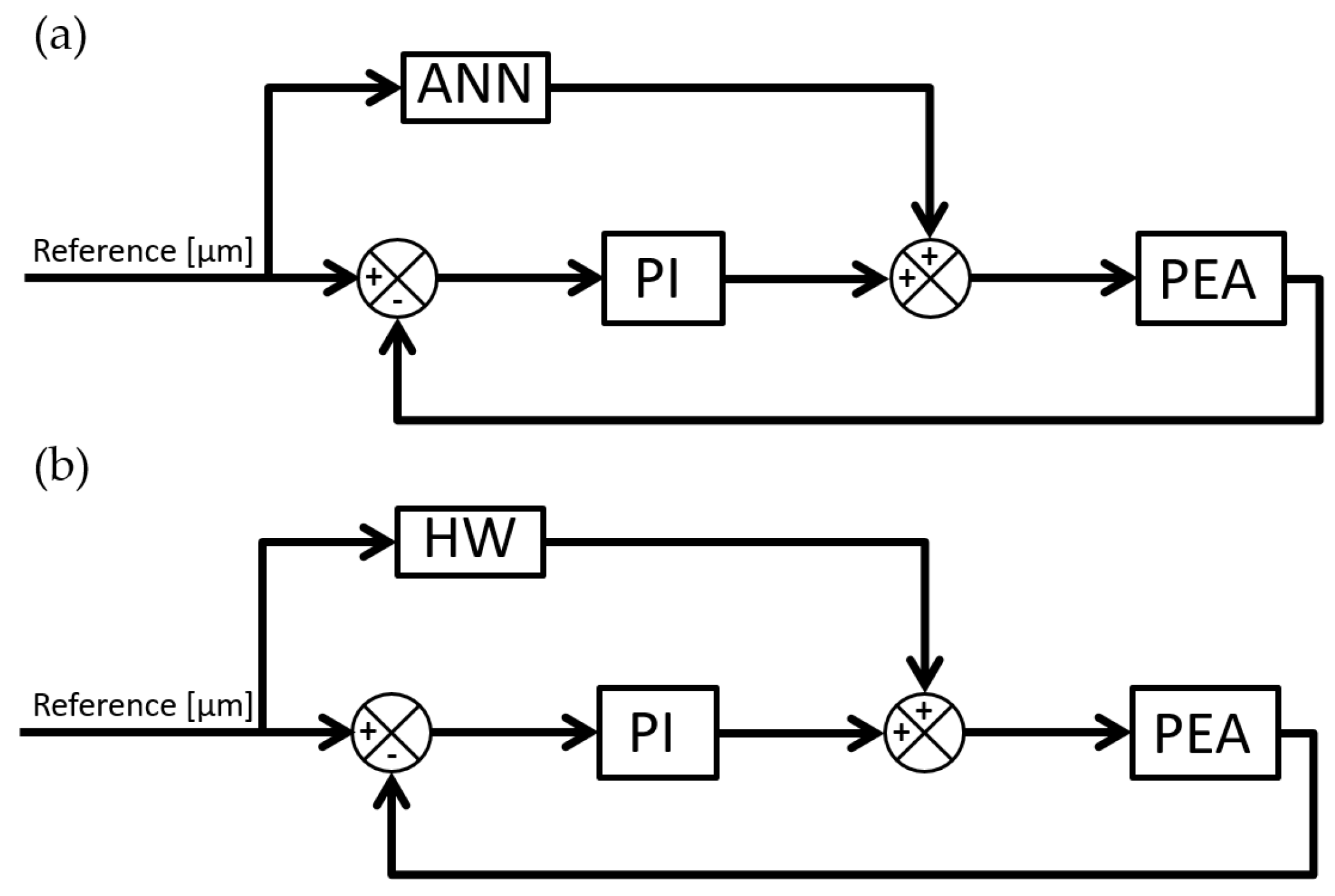

2.5. Control Structure

3. Results and Discussion

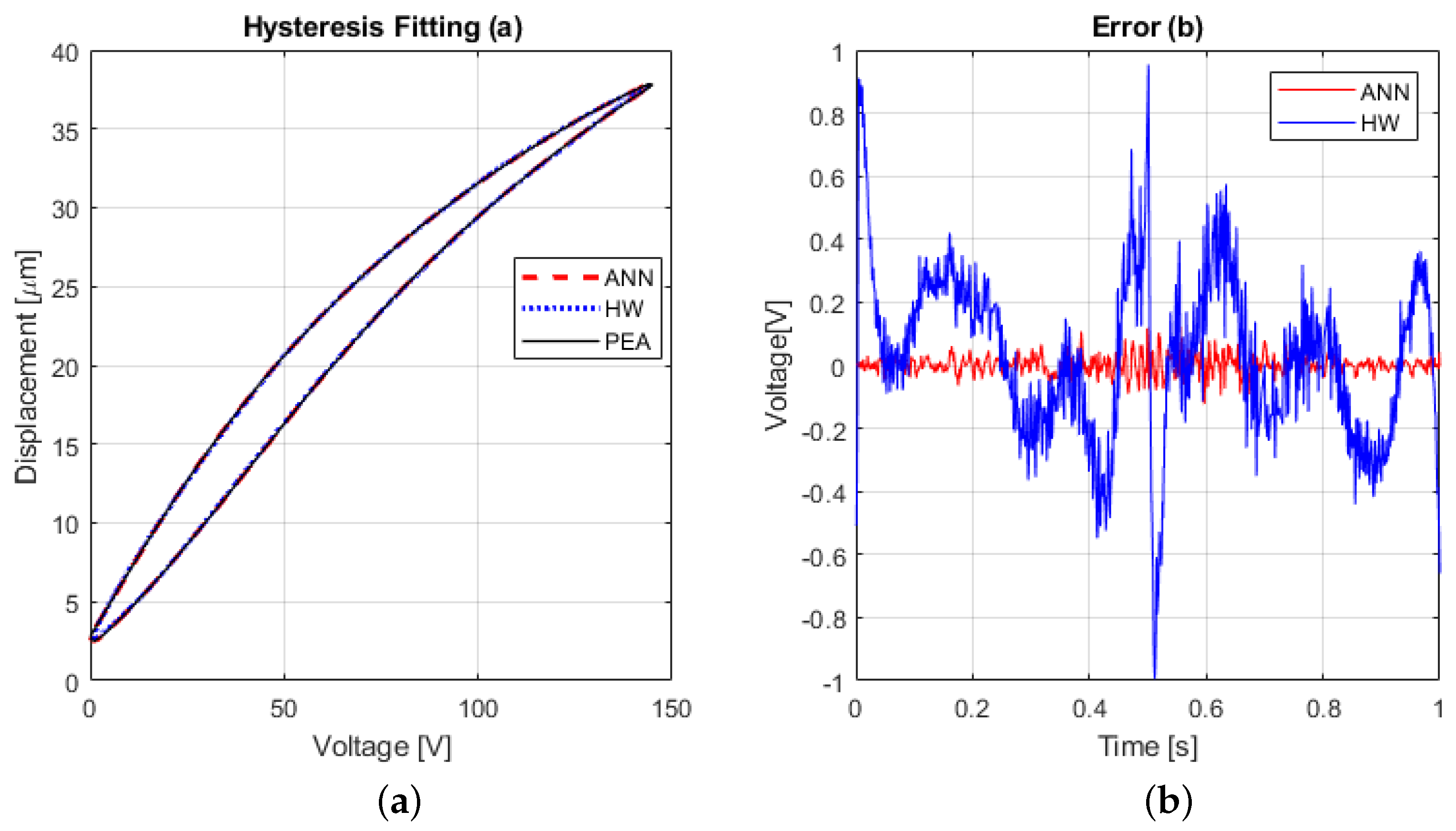

3.1. Hysteresis Fitting Results

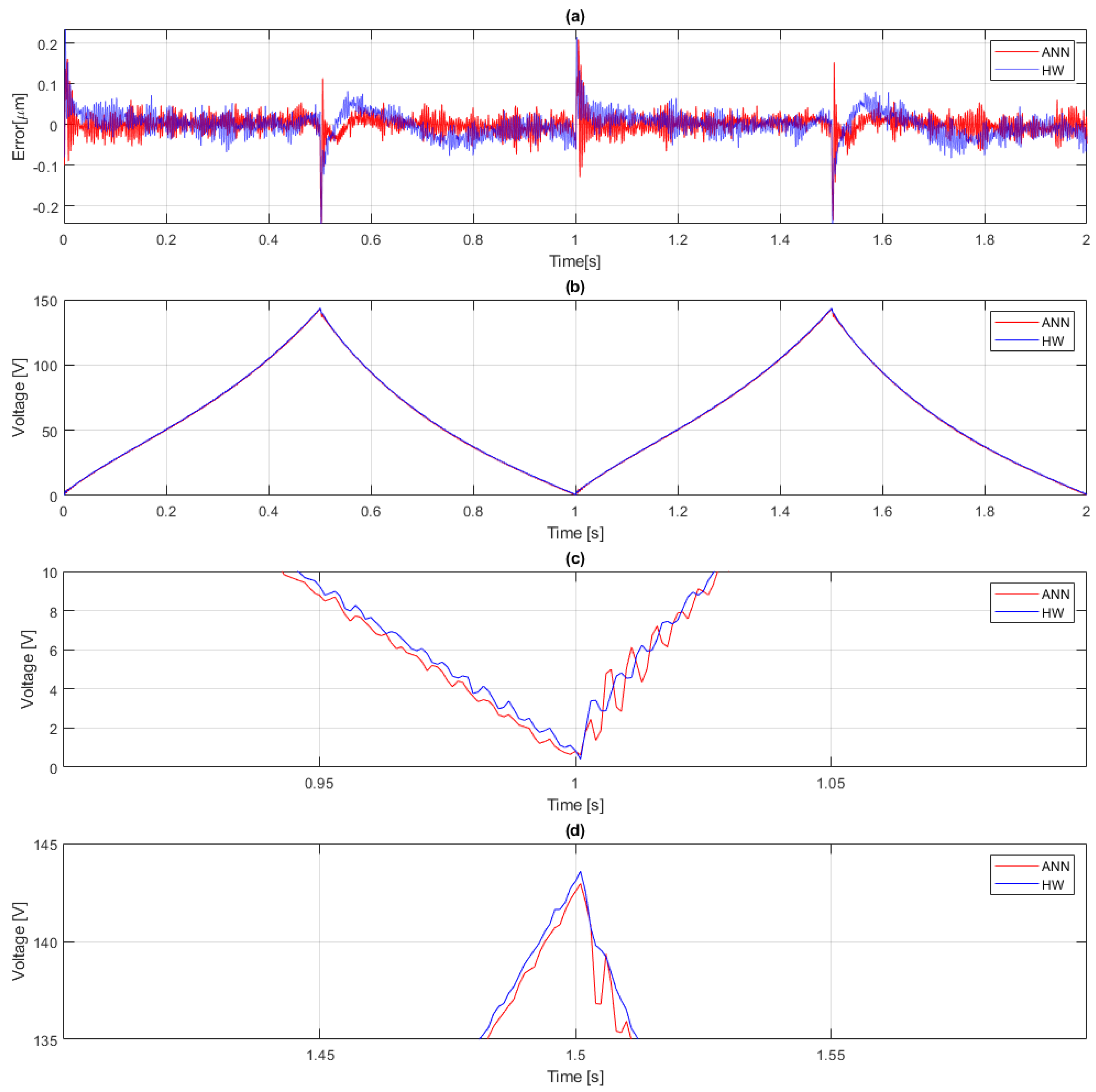

3.2. Guidance Control Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| PEA | Piezoelectric Actuator |

| FF | Feed-Forward |

| PI | Proportional-Integral |

| IAE | Integral of the Absolute Error |

| SMC | Sliding Mode Control |

| BW | Bouc–Wen |

| BB | Black-box |

| ANN | Artificial Neural Networks |

| HW | Hammerstein–Wiener |

| TDNN | Time Delay Neural Network |

| LM | Levenberg–Marquardt |

| MSE | Mean Squared Error |

References

- Gäbel, G.; Millitzer, J.; Atzrodt, H.; Herold, S.; Mohr, A. Development and Implementation of a Multi-Channel Active Control System for the Reduction of Road Induced Vehicle Interior Noise. Actuators 2018, 7, 52. [Google Scholar] [CrossRef]

- Toledo, J.; Ruiz-Díez, V.; Hernando-García, J.; Sánchez-Rojas, J.L. Piezoelectric Actuators for Tactile and Elasticity Sensing. Actuators 2020, 9, 21. [Google Scholar] [CrossRef]

- Ai, R.; Monteiro, L.L.S.; Monteiro, P.C.C., Jr.; Pacheco, P.M.C.L.; Savi, M.A. Piezoelectric Vibration-Based Energy Harvesting Enhancement Exploiting Nonsmoothness. Actuators 2019, 8, 25. [Google Scholar] [CrossRef]

- Hunstig, M. Piezoelectric Inertia Motors—A Critical Review of History, Concepts, Design, Applications, and Perspectives. Actuators 2017, 6, 7. [Google Scholar] [CrossRef]

- Huang, Y.; Xia, Y.X.; Lin, D.H.; Lim, L.-C. High-Bending-Stiffness Connector (HBSC) and High-Authority Piezoelectric Actuator (HAPA) Made of Such. Actuators 2018, 7, 61. [Google Scholar] [CrossRef]

- Bertotti, G.; Mayergoyz, I.; Damjanoivc, D. Hysteresis in Piezoelectric and Ferroelectric Materials. In The Science of Hysteresis; Elsevier: Riverport Lane, MD, USA, 2006; Volume 3, pp. 338–448. [Google Scholar]

- Frederik, F.; Minorowicz, N. Open loop control of piezoelectric tube transducer. Mech. Technol. Mater. 2018, 38, 23–28. [Google Scholar]

- Velasco, J.; Barambones, O.; Calvo, I.; Zubia, J.; Ocariz, I.; Chouza, A. Sliding Mode Control with Dynamical Correction for Time-Delay Piezoelectric Actuactor Systems. Materials 2019, 13, 132. [Google Scholar] [CrossRef] [PubMed]

- Chouza, A.; Barambones, O.; Calvo, I.; Velasco, J. Sliding Mode-Based Robust Control for Piezoelectric Actuators with Inverse Dynamics Estimation. Energies 2019, 12, 943. [Google Scholar] [CrossRef]

- Song, J.; Der Kiureghian, A. Generalized Bouc–Wen Model for Highly Asymmetric Hysteresis. J. Eng. Mech. 2006, 132, 610–618. [Google Scholar] [CrossRef]

- Tan, X.; Iyer, R.; Krishnaprasad, P.S. Control of hysteresis: Theory and experimental results. Proc. SPIE 2001, 4326, 101–112. [Google Scholar]

- Peng, J.; Chen, J. A Survey of Modeling and Control of Piezoelectric Actuators. Mod. Mech. Eng. 2013, 3, 1–20. [Google Scholar] [CrossRef]

- Sjöberg, J.; Zhang, Q.; Ljung, L.; Benveniste, A.; Delyon, B.; Glorennec, P.; Hjalmarsson, H.; Juditsky, A. Nonlinear black-box modeling in system identification: A unified overview. Automatica 1995, 31, 1691–1724. [Google Scholar] [CrossRef]

- Napole, C.; Barambones, O.; Calvo, I.; Velasco, J. Feedforward Compensation Analysis of Piezoelectric Actuators Using Artificial Neural Networks with Conventional PID Controller and Single-Neuron PID Based on Hebb Learning Rules. Energies 2020, 13, 3929. [Google Scholar] [CrossRef]

- Wills, A.; Schön, T.; Ljung, L.; Ninness, B. Identification of Hammerstein–Wiener Models. Automatica 2012, 49, 70–81. [Google Scholar] [CrossRef]

- Wang, Y.; Ho, J.; Jiang, Y. A self-positioning linear actuator based on a piezoelectric slab with multiple pads. Mech. Syst. Signal Process. 2021, 150, 107245. [Google Scholar] [CrossRef]

- Qin, Y.; Duan, H. Single-Neuron Adaptive Hysteresis Compensation of Piezoelectric Actuator Based on Hebb Learning Rules. Micromachines 2020, 11, 84. [Google Scholar] [CrossRef] [PubMed]

- Waibel, A.; Hanazana, T.; Hinton, G.; Shikano, K.; Lang, K.J. Phoneme recognition using time delay neural networks. IEEE Trans. Acoust. Speech Signal Process 1989, 37, 328–339. [Google Scholar] [CrossRef]

| Properties | Values | Units |

|---|---|---|

| Physical dimensions | 7.3 × 7.3 × 36 | mm |

| Nominal max displacement | 38.5 | m |

| Max force | 1000 | N |

| Drive voltage range | 0–150 | V |

| Error due to hysteresis | 15 | % |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Napole, C.; Barambones, O.; Derbeli, M.; Silaa, M.Y.; Calvo, I.; Velasco, J. Tracking Control for Piezoelectric Actuators with Advanced Feed-Forward Compensation Combined with PI Control. Proceedings 2020, 64, 29. https://doi.org/10.3390/IeCAT2020-08481

Napole C, Barambones O, Derbeli M, Silaa MY, Calvo I, Velasco J. Tracking Control for Piezoelectric Actuators with Advanced Feed-Forward Compensation Combined with PI Control. Proceedings. 2020; 64(1):29. https://doi.org/10.3390/IeCAT2020-08481

Chicago/Turabian StyleNapole, Cristian, Oscar Barambones, Mohamed Derbeli, Mohammed Yousri Silaa, Isidro Calvo, and Javier Velasco. 2020. "Tracking Control for Piezoelectric Actuators with Advanced Feed-Forward Compensation Combined with PI Control" Proceedings 64, no. 1: 29. https://doi.org/10.3390/IeCAT2020-08481