Effect of Soil Loading and Unloading on Its Acoustic Behavior †

Abstract

:1. Introduction

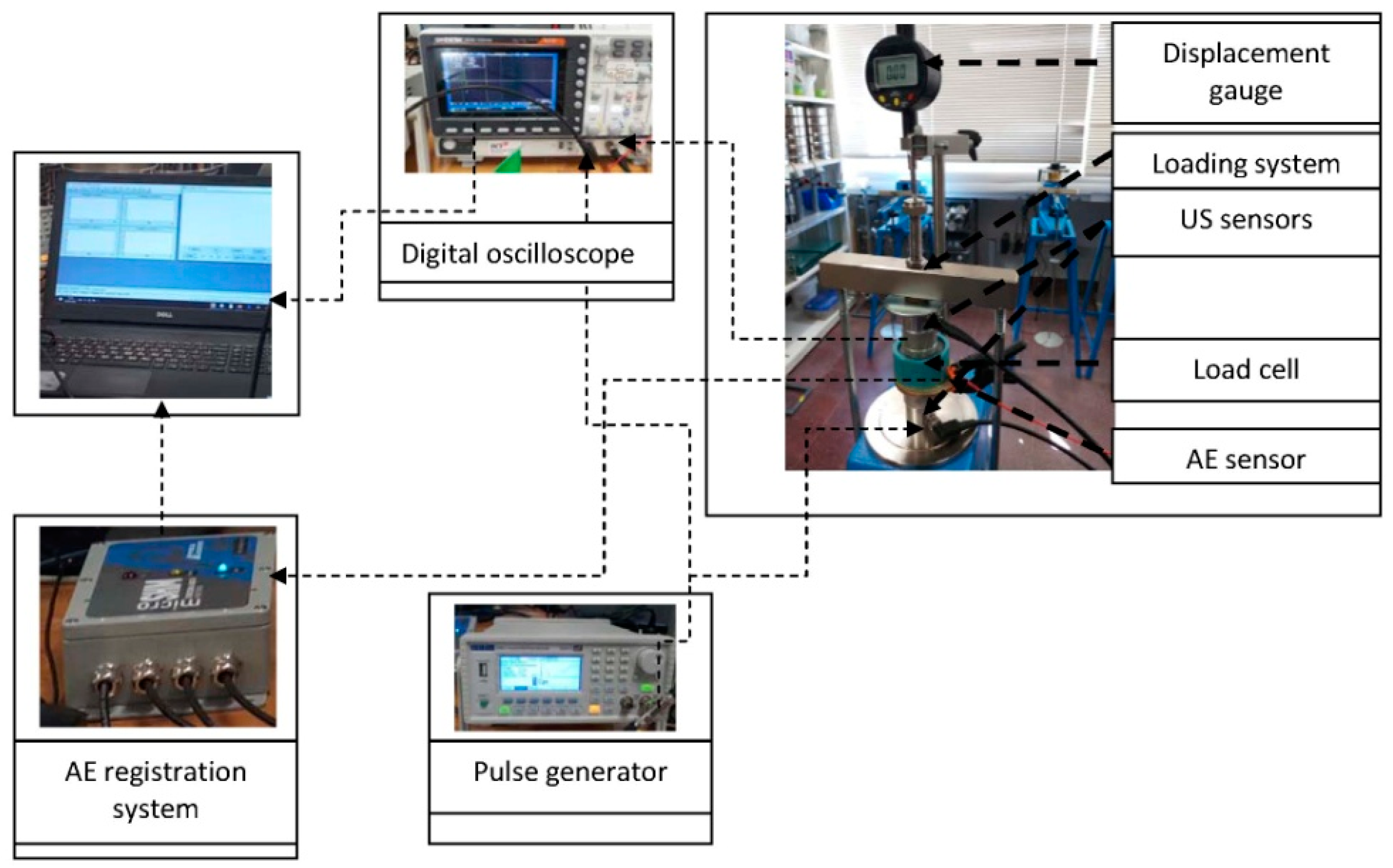

2. Materials and Methods

3. Results

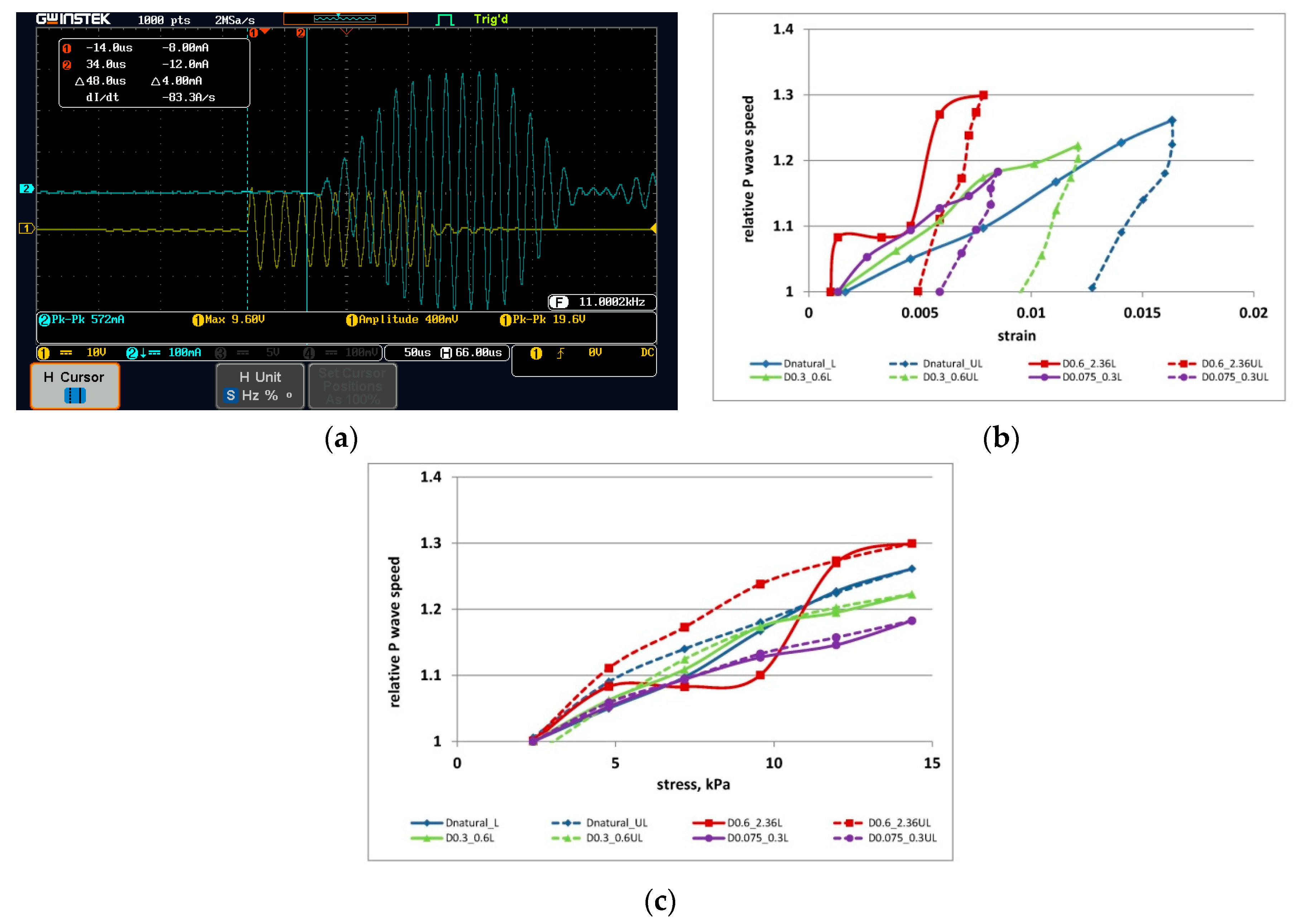

3.1. The Results of US Measurements

3.2. The Results of AE Measurements

4. Discussion

5. Conclusions

- In the stress increase branch: gradual increase in US-wave speed and sharp excitation of AE activity.

- In the stress relaxation branch: abrupt decrease in US-wave speed and minor excitation of AE signals.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Lockner, D. The role of acoustic emission in the study of rock fracture. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1993, 30, 883–899. [Google Scholar] [CrossRef]

- Grosse, C.U.; Ohtsu, M. Acoustic Emission Testing; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Anders, M.H.; Laubach, S.E.; Scholz, C.H. Microfractures: A review. J. Struct. Geol. 2014, 69, 377–394. [Google Scholar] [CrossRef]

- Manthei, G.; Plenkers, K. Review on in situ Acoustic Emission Monitoring in the Context of Structural Health Monitoring in Mines. Appl. Sci. 2018, 8, 1595. [Google Scholar] [CrossRef]

- Khoshouei, M.; Bagherpour, R. Application of Acoustic Emission (AE) in mining and earth sciences: A review. Min. Geol. Pet. Eng. Bull. 2019, 34, 19–32. [Google Scholar] [CrossRef]

- Nejati, H.R.; Nazerigivi, A.; Imani, M.; Karrech, A. Monitoring of fracture propagation in brittle materials using acoustic emission techniques-A review. Comput. Concr. 2020, 25, 15–27. [Google Scholar]

- Michlmayr, G.; Cohen, D.; Or, D. Sources and characteristics of acoustic emissions from mechanically stressed. Earth-Sci. Rev. 2012, 112, 97–114. [Google Scholar] [CrossRef]

- Smith, A.; Dixon, N.; Meldrum, P.; Haslam, E.; Chambers, J. Acoustic emission monitoring of a soil slope: Comparisons with continuous deformation measurements. Géotech. Lett. 2014, 4, 255–261. [Google Scholar] [CrossRef]

- Smith, A.; Dixon, N.; Fowmes, G.J. Early detection of first-time slope failures using acoustic emission measurements: Large-scale physical modeling. Géotechnique 2017, 67, 138–152. [Google Scholar] [CrossRef]

- Hu, W.; Scaringi, G.; Xu, Q.; Huang, R. Acoustic emissions and microseismicity in granular slopes prior to failure and flow-like motion: The potential for early warning. Geophys. Res. Lett. 2018, 45, 10406–10415. [Google Scholar] [CrossRef]

- Deng, L.; Yuan, H.; Chen, J.; Sun, Z.; Fu, M.; Zhou, Y.; Yan, S.; Zhang, Z.; Chen, T. Experimental investigation on progressive deformation of soil slope using acoustic emission monitoring. Eng. Geol. 2019, 261, 105295. [Google Scholar] [CrossRef]

- Lin, W.; Liu, A.; Mao, W.; Koseki, J. Acoustic emission characteristics of a dry sandy soil subjected to drained triaxial compression. Acta Geotech. 2020. [Google Scholar] [CrossRef]

- Naderi-Boldaji, M.; Bahrami, M.; Keller, T.; Or, D. Characteristics of acoustic emissions from soil subjected to confined uniaxial compression. Vadose Zone J. 2017, 16. [Google Scholar] [CrossRef]

- ASTMD2845-08. 2008 Standard Test Method for Laboratory Determination of Pulse Velocities and Ultrasonic Elastic Constants of Rock; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Stephenson, R.W. Ultrasonic testing for Determination Dynamic Soil Mocduli, Dynamic Geotechnical Testing; ASTM STP 654; American Society for Testing and Materials: West Conshohocken, PA, USA, 1978; pp. 179–195. [Google Scholar]

- Zimmer, M.A.; Prasad, M.; Mavko, G.; Nur, A. Seismic velocities of unconsolidated sands: Part 1—Pressure trends from 0.1 to 20 MPa. Geophysics 2007, 72, E1–E13. [Google Scholar] [CrossRef]

- Chen, Y.; Irfan, M.; Uchimura, T. Estimation of elastic wave velocity through unsaturated soil slope as function of water content and shear deformation. Soils Found. 2019, 59, 2180–2194. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frid, V.; Potirakis, S.M.; Shulov, S. Effect of Soil Loading and Unloading on Its Acoustic Behavior. Proceedings 2020, 67, 20. https://doi.org/10.3390/ASEC2020-07516

Frid V, Potirakis SM, Shulov S. Effect of Soil Loading and Unloading on Its Acoustic Behavior. Proceedings. 2020; 67(1):20. https://doi.org/10.3390/ASEC2020-07516

Chicago/Turabian StyleFrid, Vladimir, Stelios M. Potirakis, and Semen Shulov. 2020. "Effect of Soil Loading and Unloading on Its Acoustic Behavior" Proceedings 67, no. 1: 20. https://doi.org/10.3390/ASEC2020-07516

APA StyleFrid, V., Potirakis, S. M., & Shulov, S. (2020). Effect of Soil Loading and Unloading on Its Acoustic Behavior. Proceedings, 67(1), 20. https://doi.org/10.3390/ASEC2020-07516