Effect of Surface Ultrasonic Rolling Treatment on Rolling Contact Fatigue Life of D2 Wheel Steel

Abstract

:1. Introduction

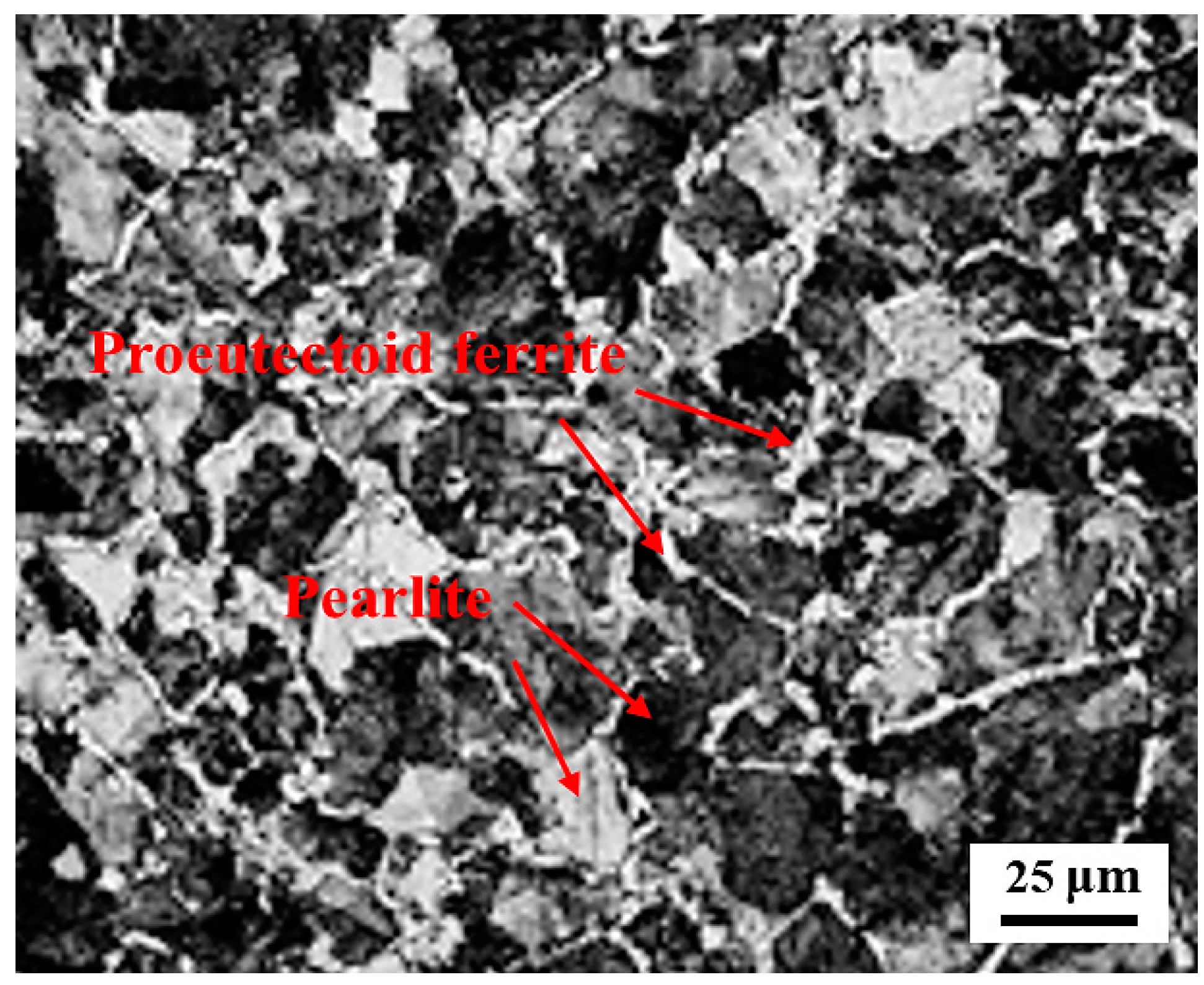

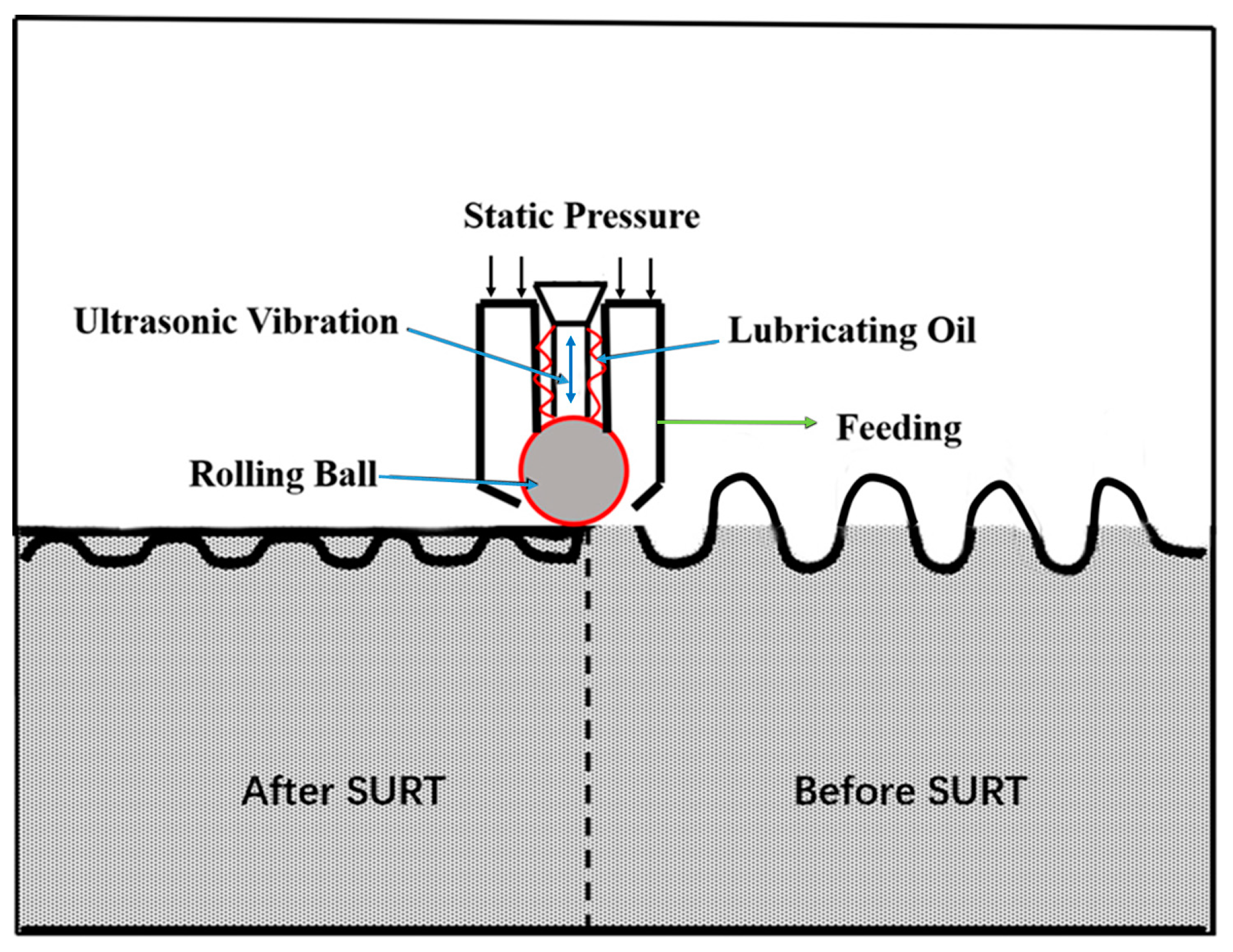

2. Experimental Methods

3. Results

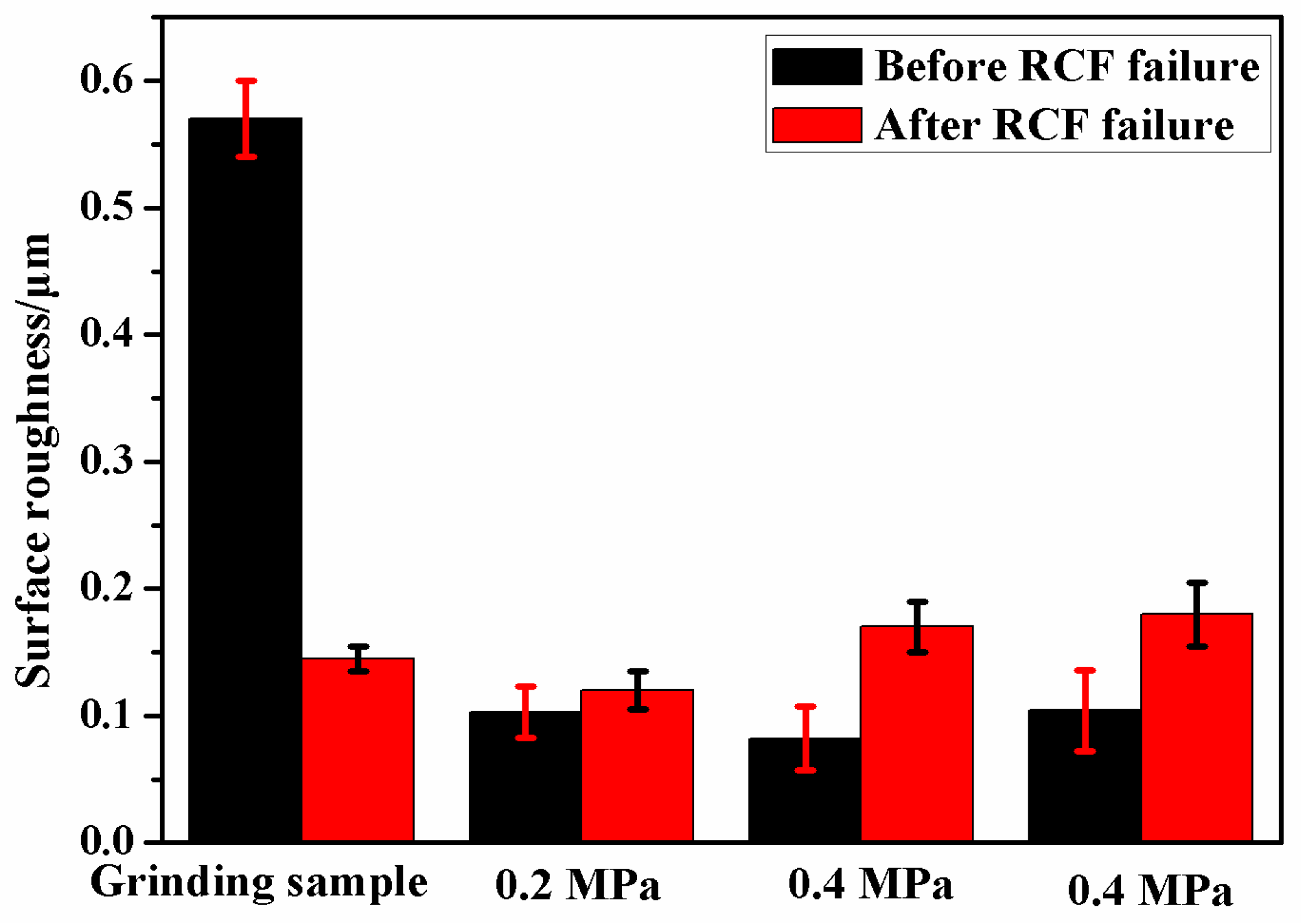

3.1. Rolling Contact Fatigue Life

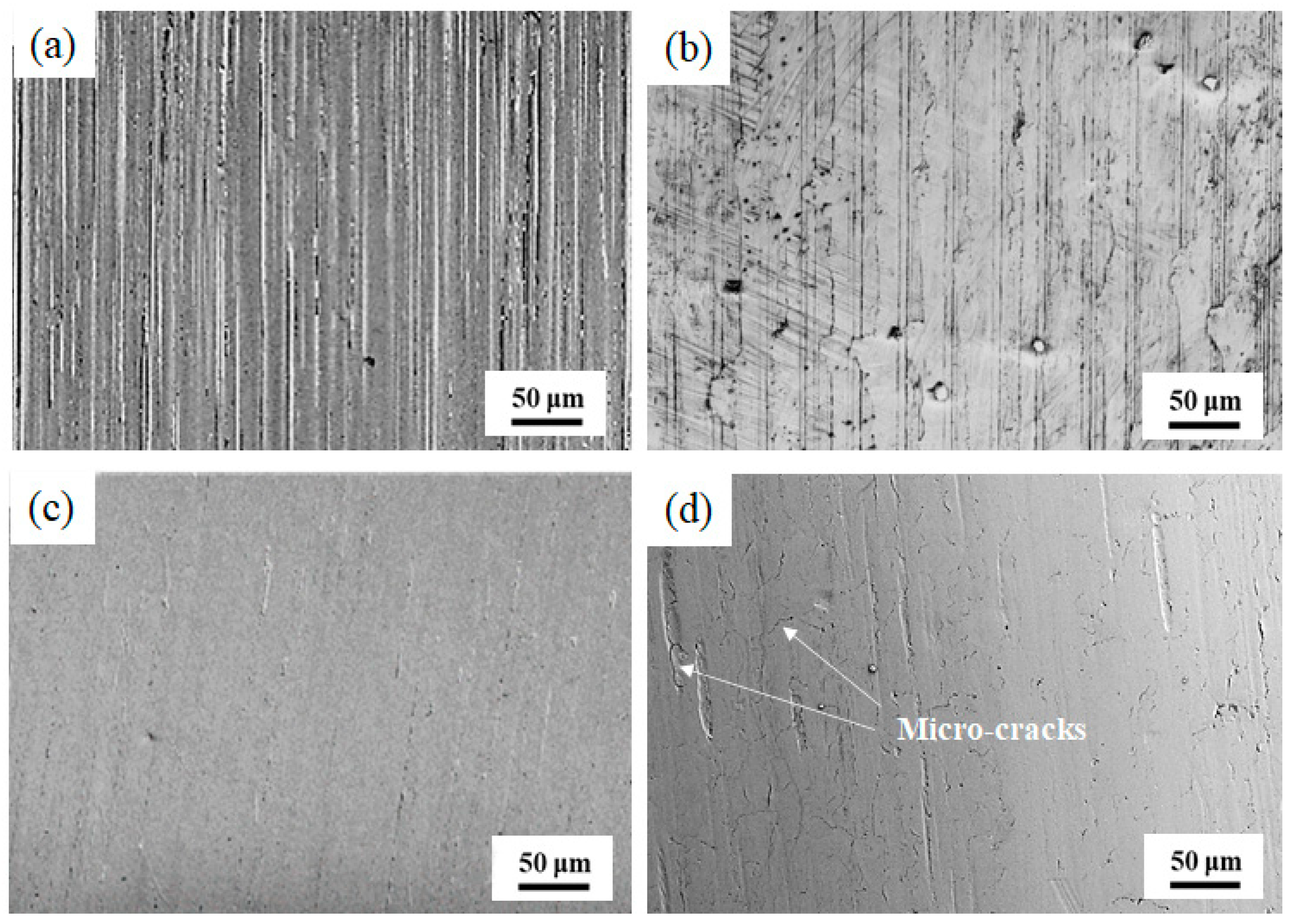

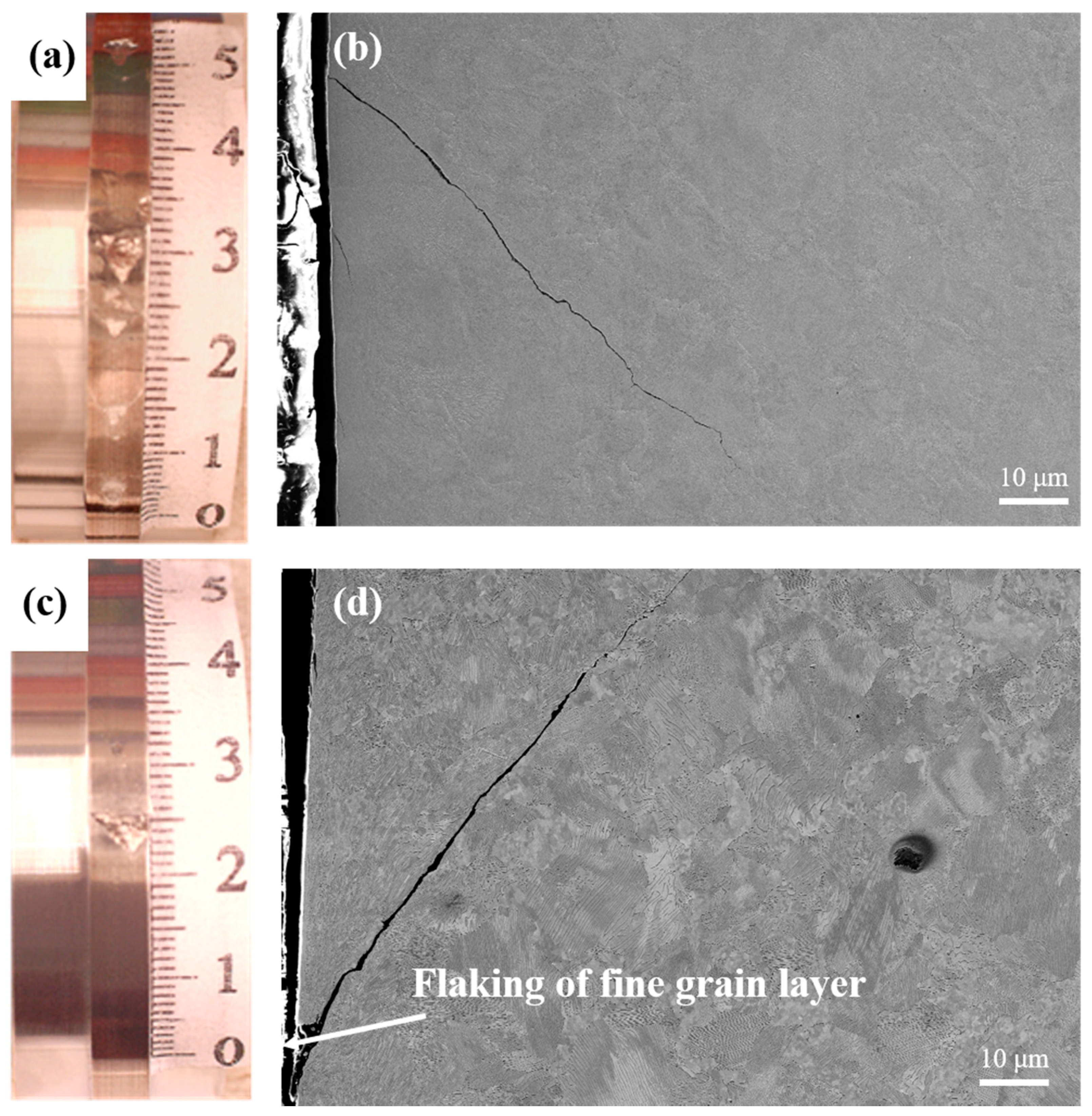

3.2. Surface Morphology after SURT

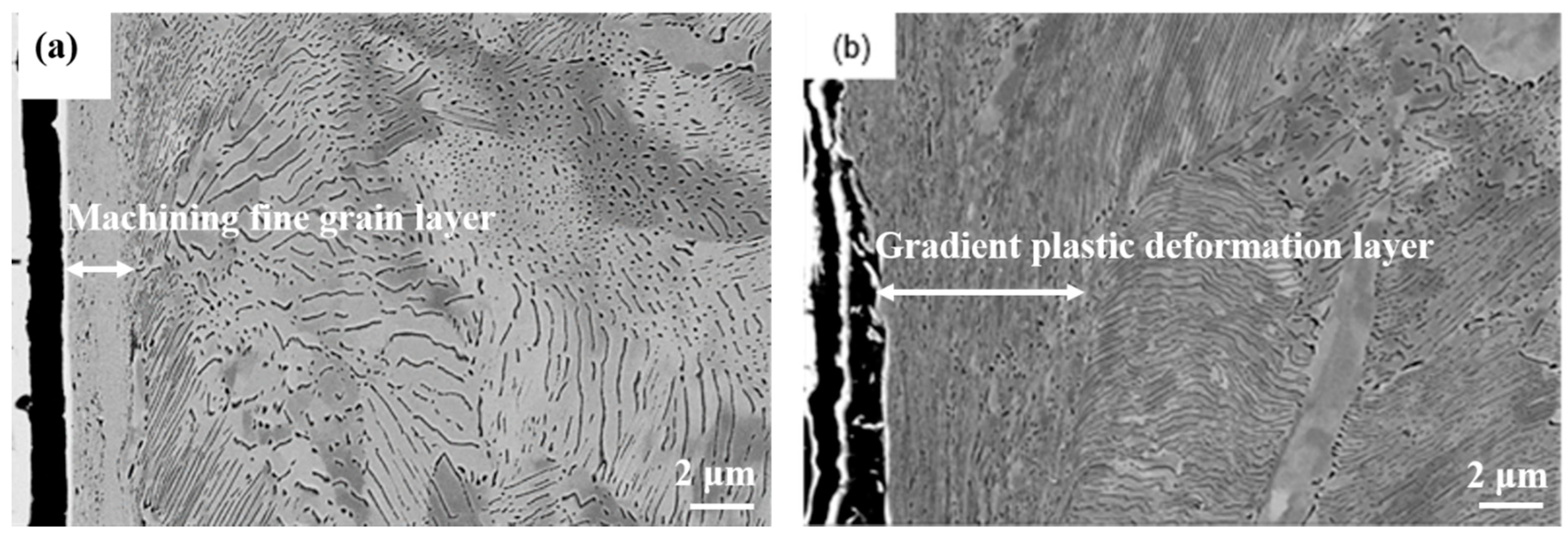

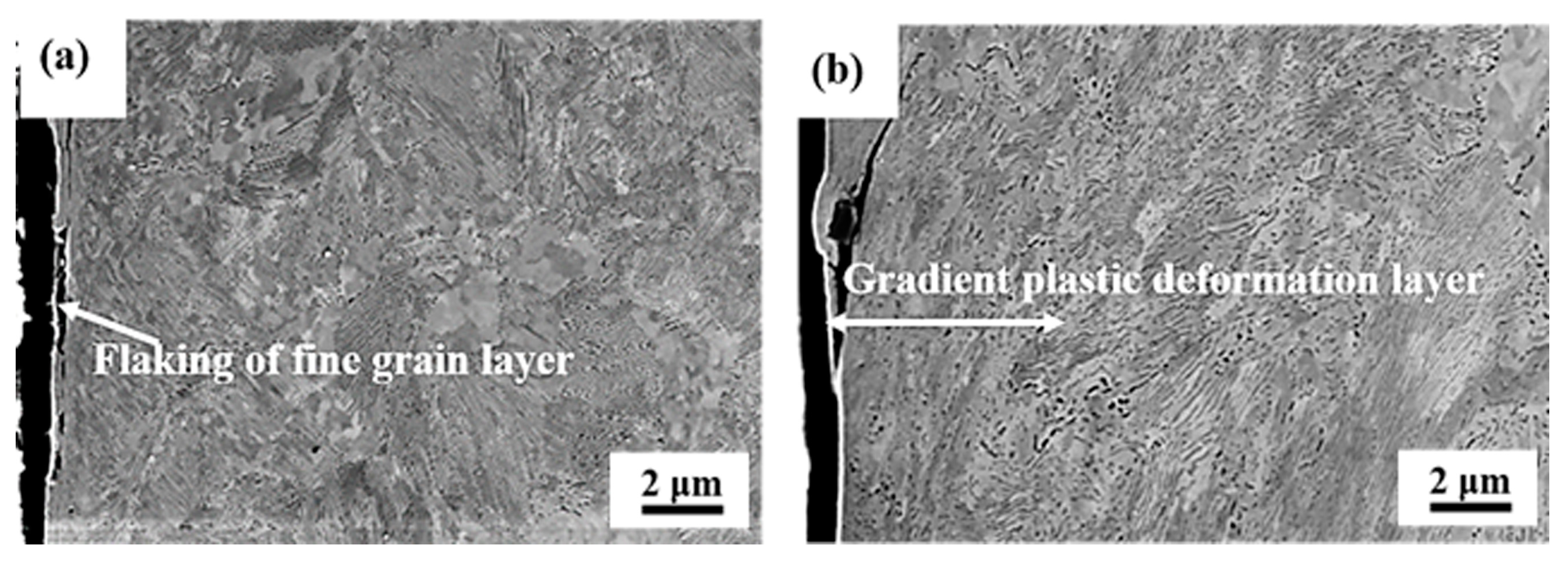

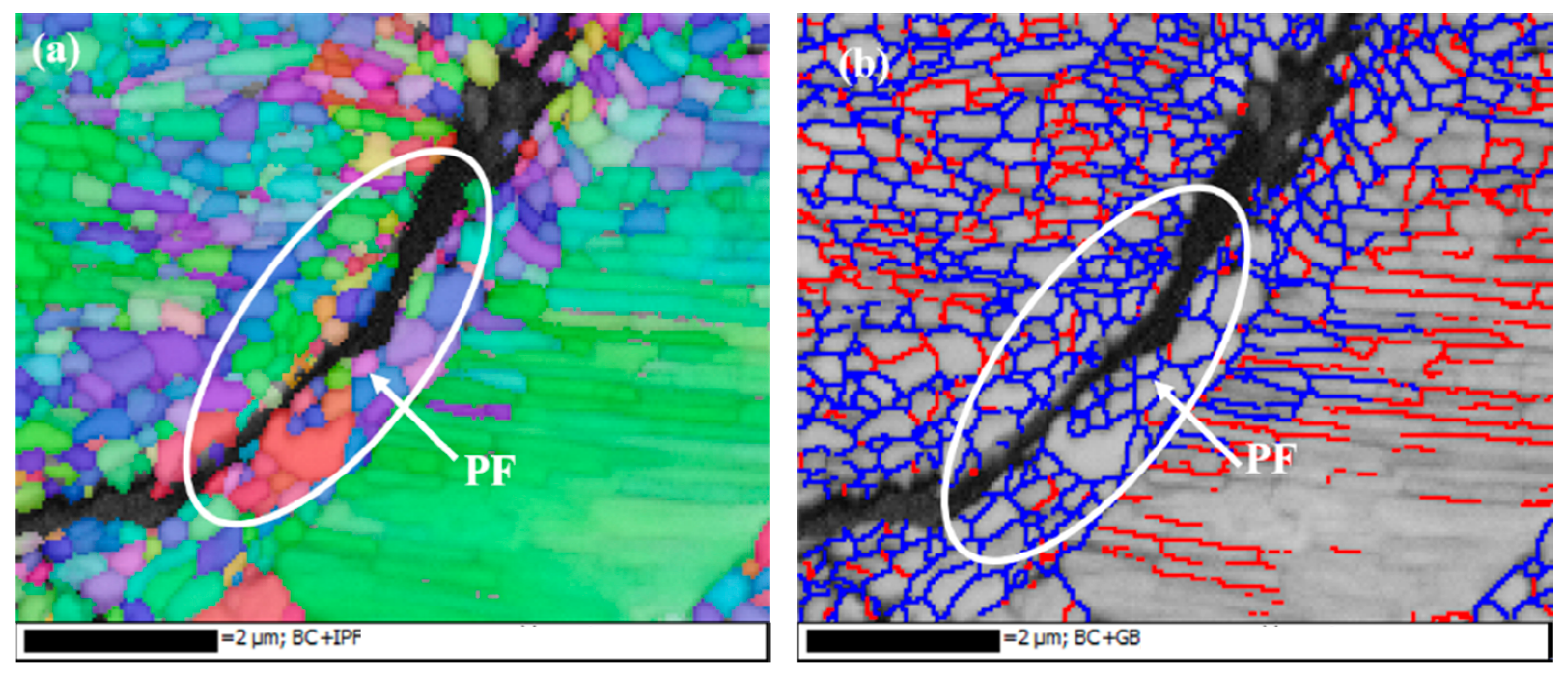

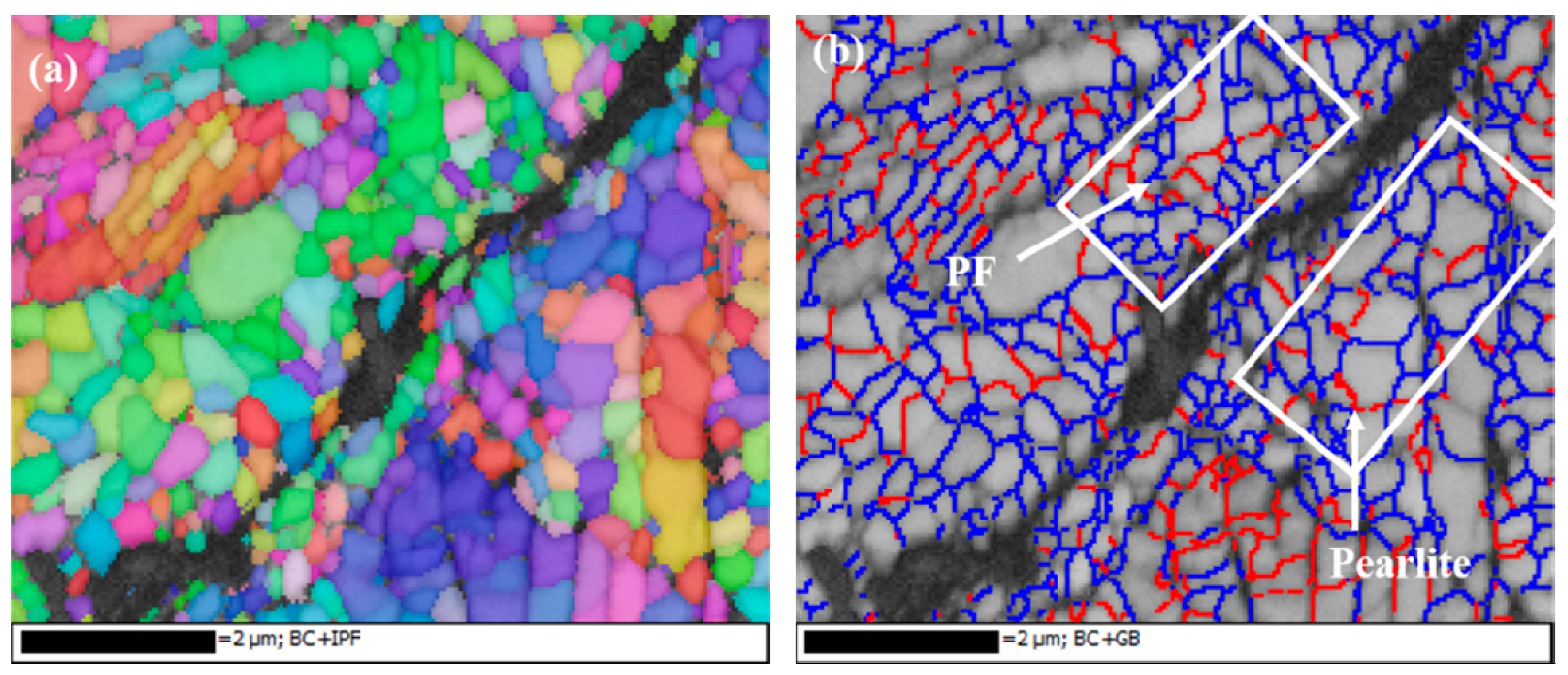

3.3. Surface Microstructure

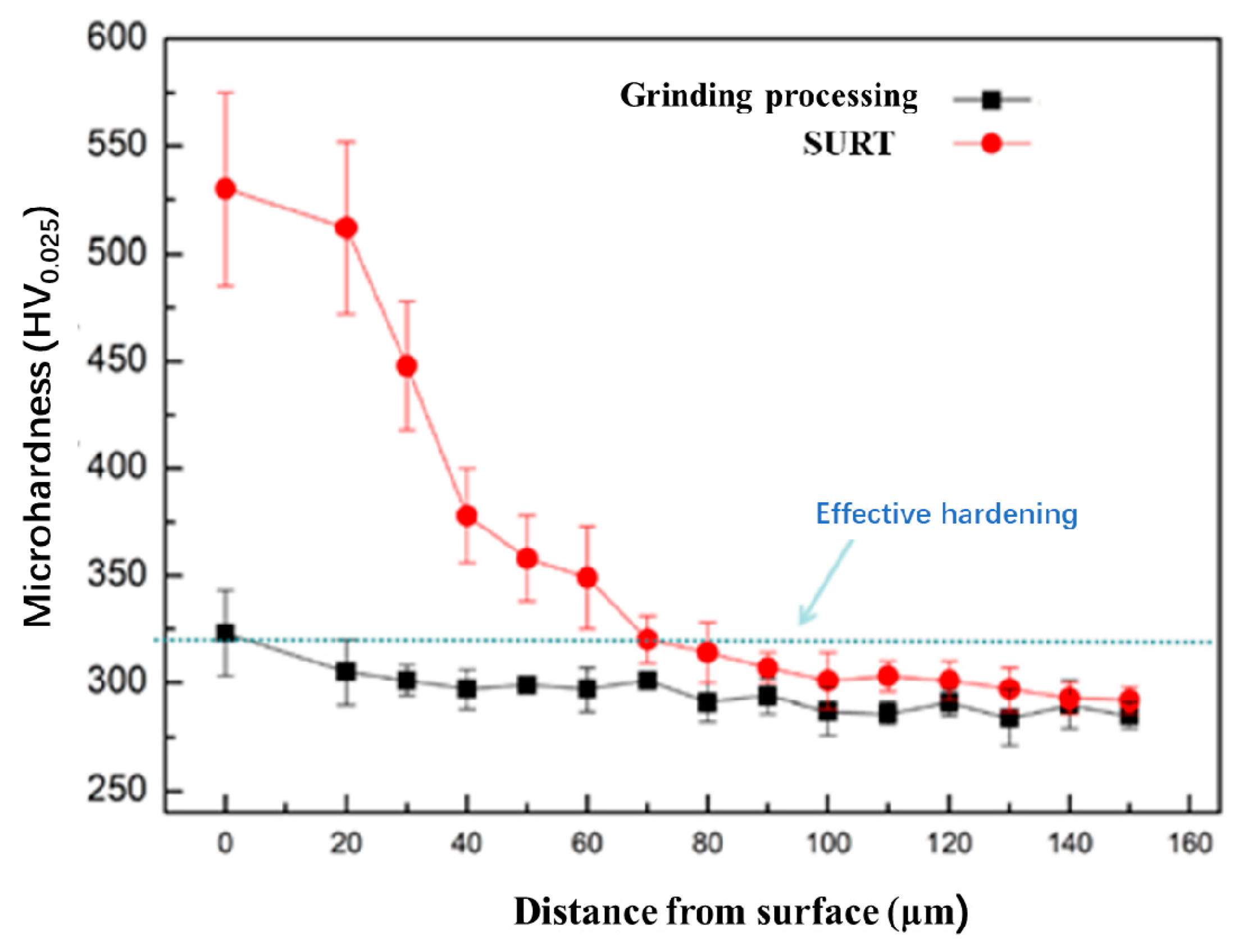

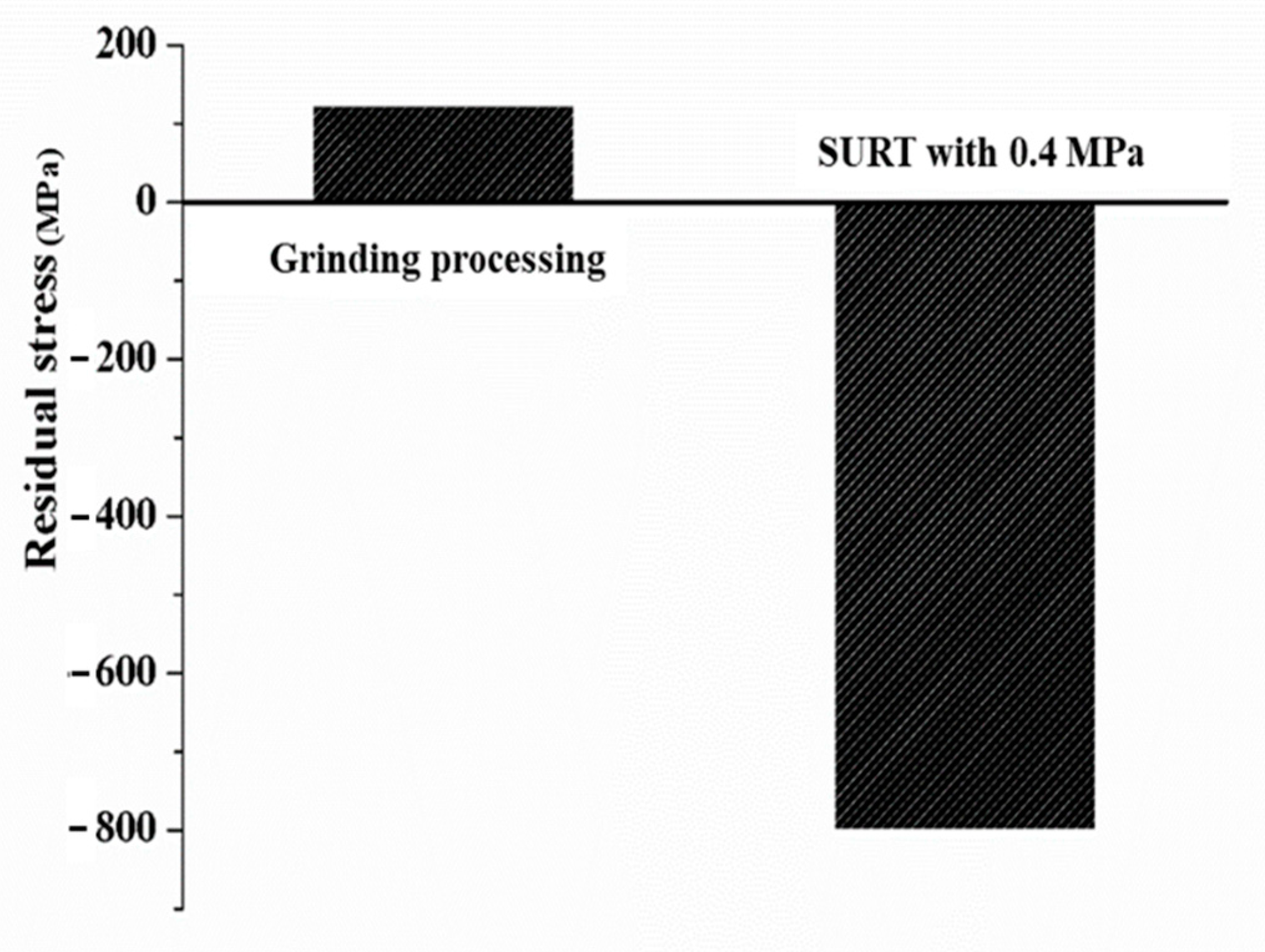

3.4. Surface Hardness and Residual Stress

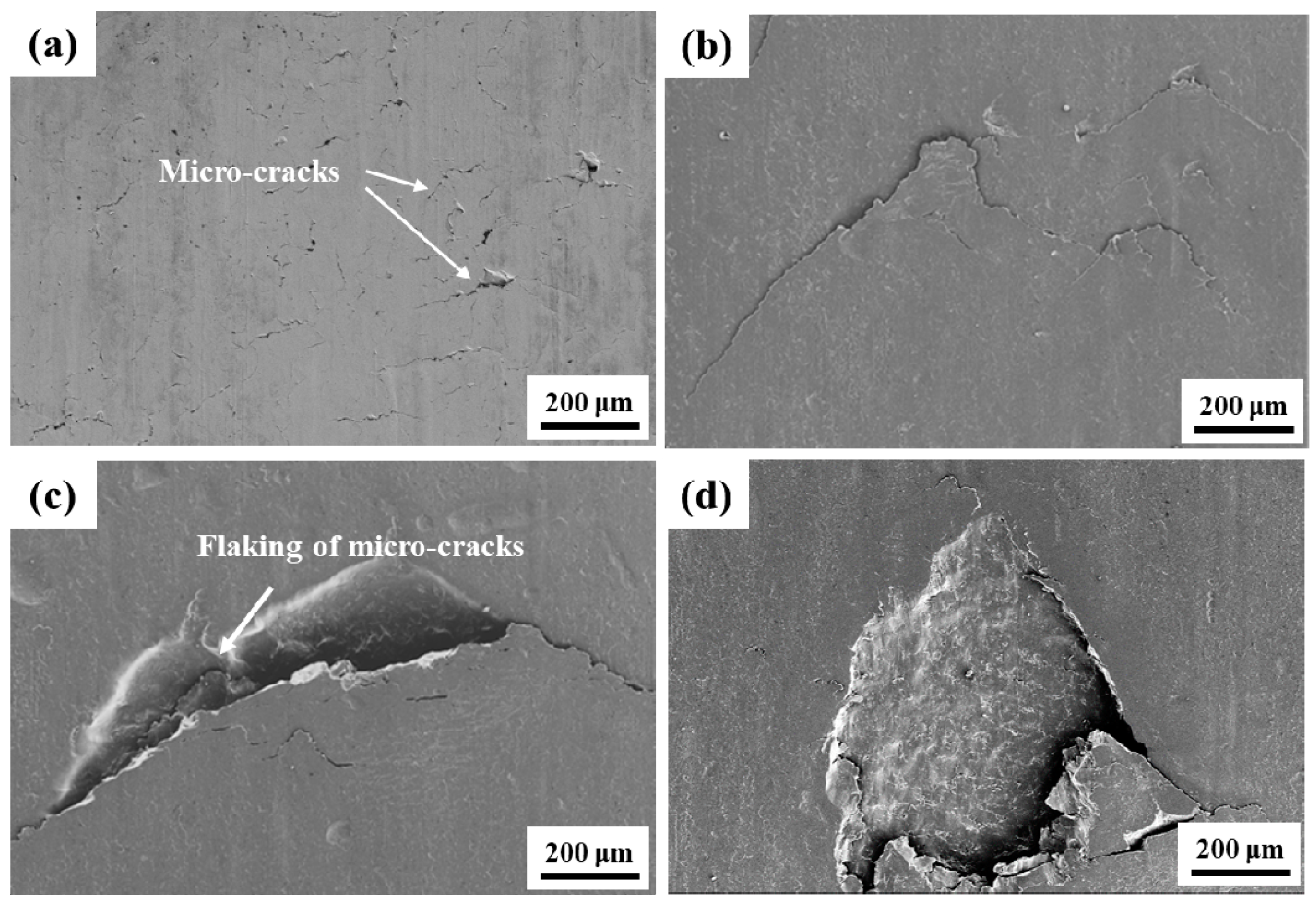

3.5. Rolling Contact Fatigue Cracks

4. Discussion

5. Conclusions

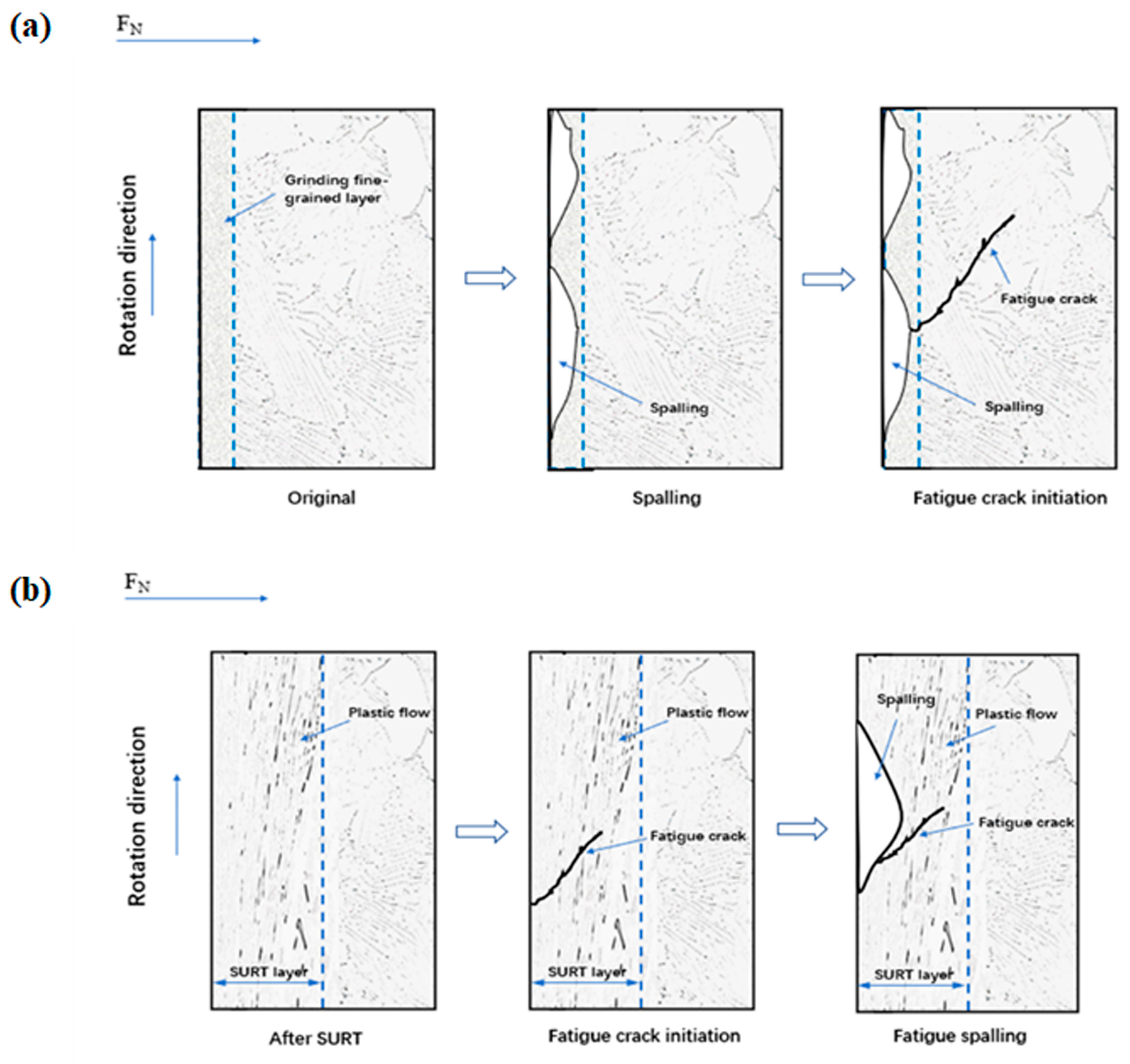

- For the grinding processing sample, the interface between the fine ferrite grain layer and the core microstructure causes the flaking of the fine grain layer. The flaking of the fine grain layer accelerates the formation of RCF cracks.

- SURT can lead to a decrease of the surface roughness, a gradient hardening layer, and a residual compressive layer at the sample surface to enhance the RCF life before micro-cracks are produced at the sample surface during SURT process.

- When the micro-crack is formed during SURT, it becomes a source of the RCF crack, accelerating RCF crack initiation and causing an obvious reduction of RCF life.

Author Contributions

Funding

Conflicts of Interest

References

- Yan, G.C.; He, Q.F.; Gao, Y.G. Study of rolling contact fatigue of wheels. Railw. Locomot. Car 2002, 4, 17–20. [Google Scholar]

- Bevan, A.; Molyneux-Berry, P.; Eickhoff, B.; Burstow, M. Development and validation of a wheel wear and rolling contact fatigue damage model. Wear 2013, 307, 100–111. [Google Scholar] [CrossRef] [Green Version]

- Knothe, K.; Liebelt, S. Determination of temperatures for sliding contact with applications for wheel-rail systems. Wear 1995, 189, 91–99. [Google Scholar] [CrossRef]

- Jin, X.S.; Zhang, J.Y.; Wen, Z.F.; Li, F. Overview of phenomena of rolling contact fatigue of wheel/rail. J. Mech. Strength 2002, 24, 250–257. [Google Scholar]

- Huang, Y.B.; He, C.G.; Ma, L.; Zhao, X.J.; Wang, W.J.; Liu, Q.Y. Experimental study on initiation of fatigue crack of wheel material under dry condition. Tribology 2016, 36, 194–200. [Google Scholar]

- Kapoor, A.; Franklin, F.; Wong, S.; Ishida, M. Surface roughness and plastic flow in rail wheel contact. Wear 2002, 253, 257–264. [Google Scholar] [CrossRef]

- Kato, T.; Sugeta, A.; Nakayama, E. Investigation of influence of white layer geometry on spalling property in rail wheel steel. Wear 2011, 271, 400–407. [Google Scholar] [CrossRef]

- Zhong, W.; Hu, J.; Li, Z.; Liu, Q.; Zhou, Z. A study of rolling contact fatigue crack growth in U75V and U71Mn rails. Wear 2011, 271, 388–392. [Google Scholar] [CrossRef]

- Fletcher, D.I.; Beynon, J. The effect of intermittent lubrication on the fatigue life of pearlitic rail steel in rolling-sliding contact. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2000, 214, 145–158. [Google Scholar] [CrossRef]

- Liu, P.T.; Wang, J.; Liu, C.P.; Zhao, X.J.; Ren, R.M. Experimental investigation on effect different machining process on rolling contact fatigue life of D2 wheel steel. Tribol. Trans. 2020, 986–995. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, X.; Liu, P.; Pan, J.; Chen, C.; Ren, R. Investigation of the Relation between Rolling Contact Fatigue Property and Microstructure on the Surface Layer of D2 Wheel Steel. Mater. Sci. Appl. 2019, 10, 509–526. [Google Scholar] [CrossRef] [Green Version]

- Jiao, F.; Lan, S.-L.; Zhao, B.; Wang, Y. Theoretical calculation and experiment of the surface residual stress in the plane ultrasonic rolling. J. Manuf. Process. 2020, 50, 573–580. [Google Scholar] [CrossRef]

- Yang, J.; Liu, D.; Zhang, X.; Liu, M.; Zhao, W.; Liu, C. The effect of ultrasonic surface rolling process on the fretting fatigue property of GH4169 superalloy. Int. J. Fatigue 2020, 133, 105373. [Google Scholar] [CrossRef]

- Liu, P.; Yu, R.; Gao, X.; Zhang, G. Influence of Surface Ultrasonic Rolling on Microstructure and Corrosion Property of T4003 Ferritic Stainless Steel Welded Joint. Metals 2020, 10, 1081. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, P.; Ding, Y.; Jiang, B.; Liu, X.; Zhang, M.; Chen, G. An Investigation on Wear Behavior of ER8 and SSW-Q3R Wheel Steel under Pure Rolling Condition. Metals 2020, 10, 513. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.-P.; Liu, P.-T.; Pan, J.-Z.; Chen, C.-H.; Ren, R.-M. Effect of pre-wear on the rolling contact fatigue property of D2 wheel steel. Wear 2020, 442–443, 203154. [Google Scholar] [CrossRef]

- Izotov, V.I.; Pozdnyakov, V.A.; Luk’yanenko, E.V.; Yu, O.; Sanova, U.; Filippov, G.A. Influence of the pearlite fineness on the mechanical properties, deformation behavior, and fracture characteristics of carbon steel. Phys. Met. Metallogr. 2007, 103, 519–529. [Google Scholar] [CrossRef]

- Huang, H.; Wang, Z.; Lu, J.; Lu, K. Fatigue behaviors of AISI 316L stainless steel with a gradient nanostructured surface layer. Acta Mater. 2015, 87, 150–160. [Google Scholar] [CrossRef]

- Liu, C.-P.; Ren, R.-M.; Liu, D.-Y.; Zhao, X.-J.; Chen, C.-H. An EBSD Investigation on the Evolution of the Surface Microstructure of D2 Wheel Steel During Rolling Contact Fatigue. Tribol. Lett. 2020, 68, 1–11. [Google Scholar] [CrossRef]

- Garnham, J.E.; Davis, C.L. The role of deformed rail microstructure on rolling contact fatigue initiation. Wear 2008, 265, 1363–1372. [Google Scholar] [CrossRef]

- Urashima, C.; Nishida, S. Fatigue crack initiation and propagation behavior in pearlite structures, Fatigue’96. Sixth Int. Fatigue Congr. 1996, 1, 319–324. [Google Scholar]

- Tanaka, K.; Mura, T. A Dislocation Model for Fatigue Crack Initiation. J. Appl. Mech. 1981, 48, 97–103. [Google Scholar] [CrossRef]

- Wagner, L.; Muller, C.; Gregory, J.K. Effect of Surface Rolling and Shot Peening on Notched Fatigue Strength in Al 2024; GKSS-Forschungszentrum Geesthacht GmbH: Bremen, Germany, 1993; pp. 181–186. [Google Scholar]

- Batista, A.C.; Dias, A.M.; Lebrun, J.L.; le Flour, J.C.; Inglebert, G. Contact fatigue of automotive gears: Evolution and effects of residual stresses introduced by surface treatments. Fatigue Fract. Eng. Mater. Struct. 2000, 23, 217–228. [Google Scholar] [CrossRef]

- Song, P.S.; Wen, C.C. Crack closure and crack growth behavior in shot peened fatigued specimen. Eng. Fract. Mech. 1999, 63, 295–304. [Google Scholar] [CrossRef]

- Mirzazadeh, M.M.; Plumtree, A. High cycle fatigue behavior of shot-peened steels. Metall. Mater. Trans. A 2012, 43, 2777–2784. [Google Scholar] [CrossRef]

- Horstman, R.; Peters, K.; Meltzer, R.; Vieth, M.; Fuchs, H. The Effect of Self Stresses on High Cycle Fatigue. J. Test. Eval. ASTM 1982, 10, 168. [Google Scholar] [CrossRef]

- Harris, W.J. Metallic Fatigue; Pergamon Press: New York, NY, USA, 1961. [Google Scholar]

| Samples | C | Si | Mn | S | P |

|---|---|---|---|---|---|

| D2 | 0.50–0.56 | 0.90–1.10 | 0.90–1.10 | ≤0.010 | ≤0.015 |

| U71Mn | 0.65–0.77 | 0.15–0.35 | 1.00–1.40 | ≤0.03 | ≤0.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Lin, Z.; Liu, C.; Zhao, X.; Ren, R. Effect of Surface Ultrasonic Rolling Treatment on Rolling Contact Fatigue Life of D2 Wheel Steel. Materials 2020, 13, 5438. https://doi.org/10.3390/ma13235438

Liu P, Lin Z, Liu C, Zhao X, Ren R. Effect of Surface Ultrasonic Rolling Treatment on Rolling Contact Fatigue Life of D2 Wheel Steel. Materials. 2020; 13(23):5438. https://doi.org/10.3390/ma13235438

Chicago/Turabian StyleLiu, Pengtao, Zilong Lin, Chunpeng Liu, Xiujuan Zhao, and Ruiming Ren. 2020. "Effect of Surface Ultrasonic Rolling Treatment on Rolling Contact Fatigue Life of D2 Wheel Steel" Materials 13, no. 23: 5438. https://doi.org/10.3390/ma13235438