Development of an Artificial Intelligence Powered TIG Welding Algorithm for the Prediction of Bead Geometry for TIG Welding Processes using Hybrid Deep Learning

Abstract

:1. Introduction

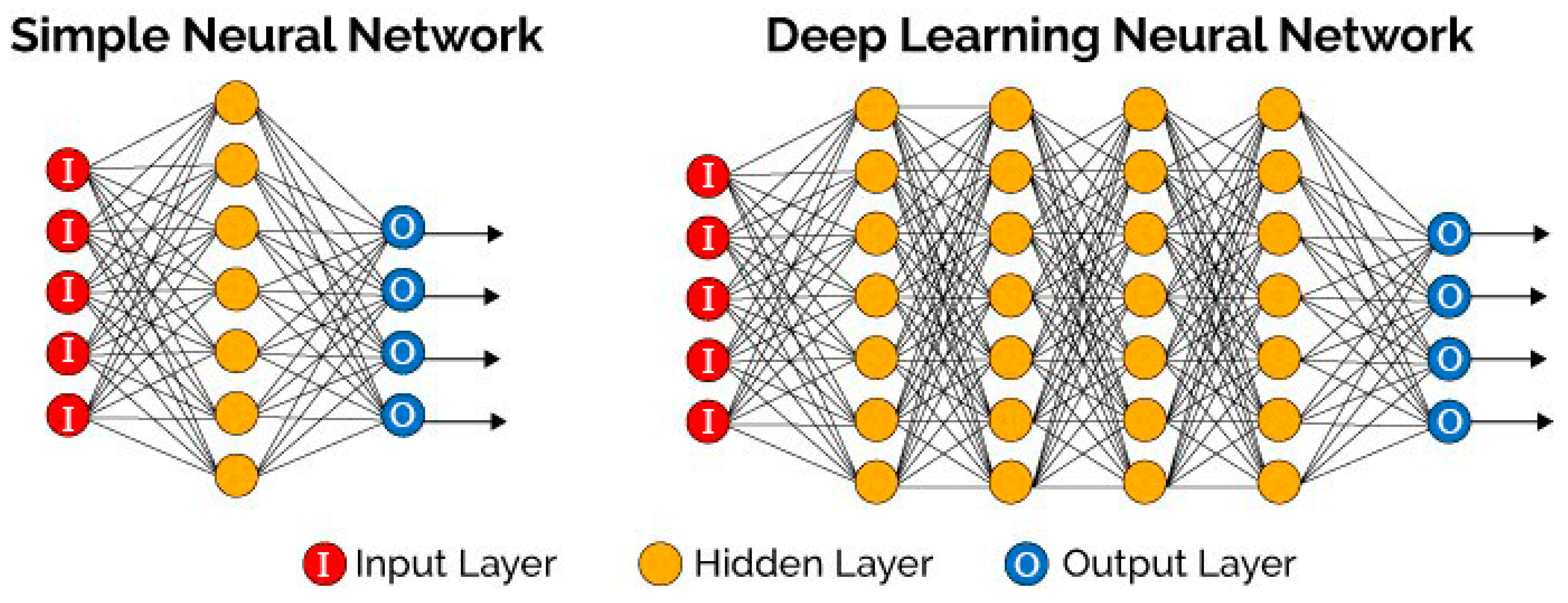

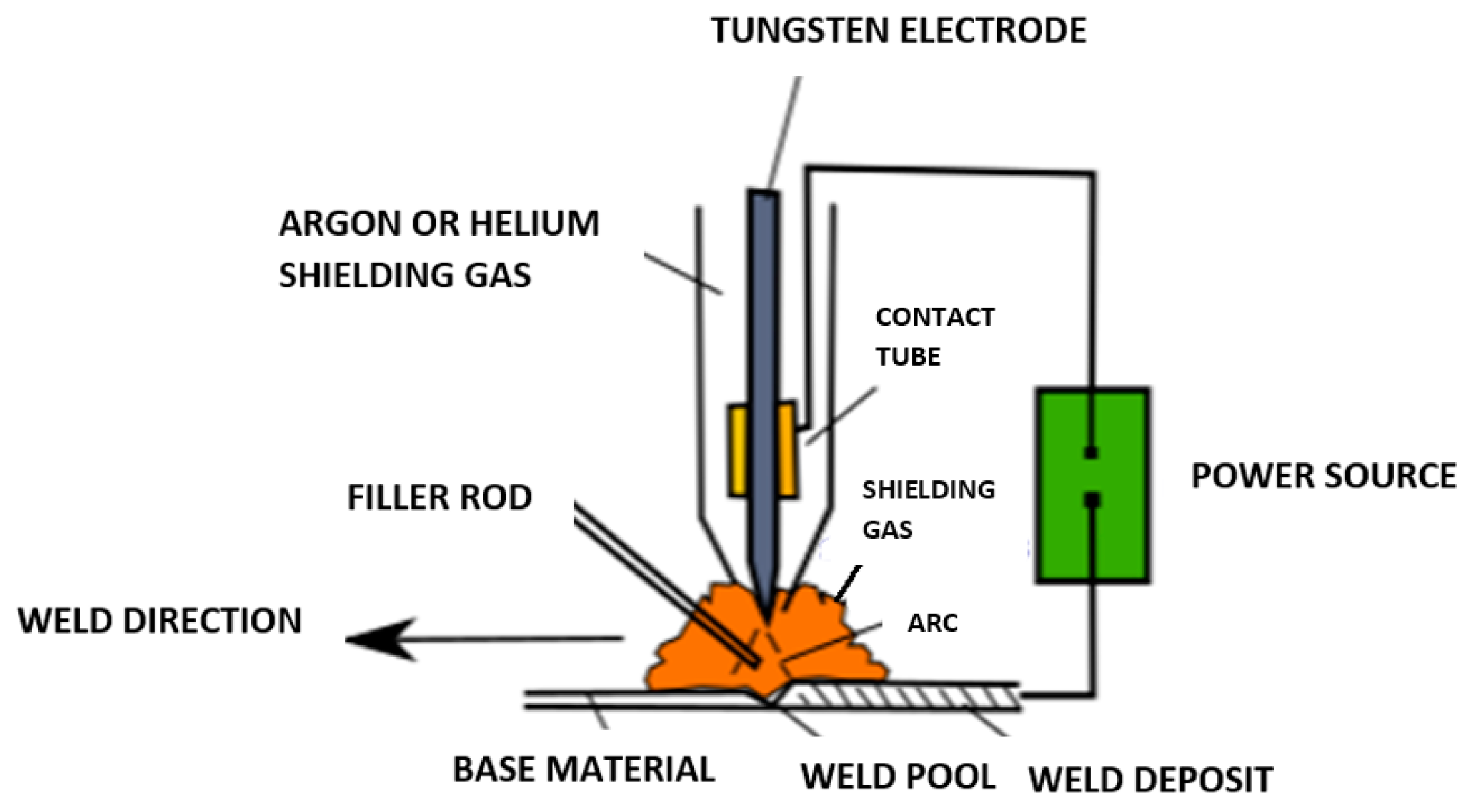

2. TIG Welding Process

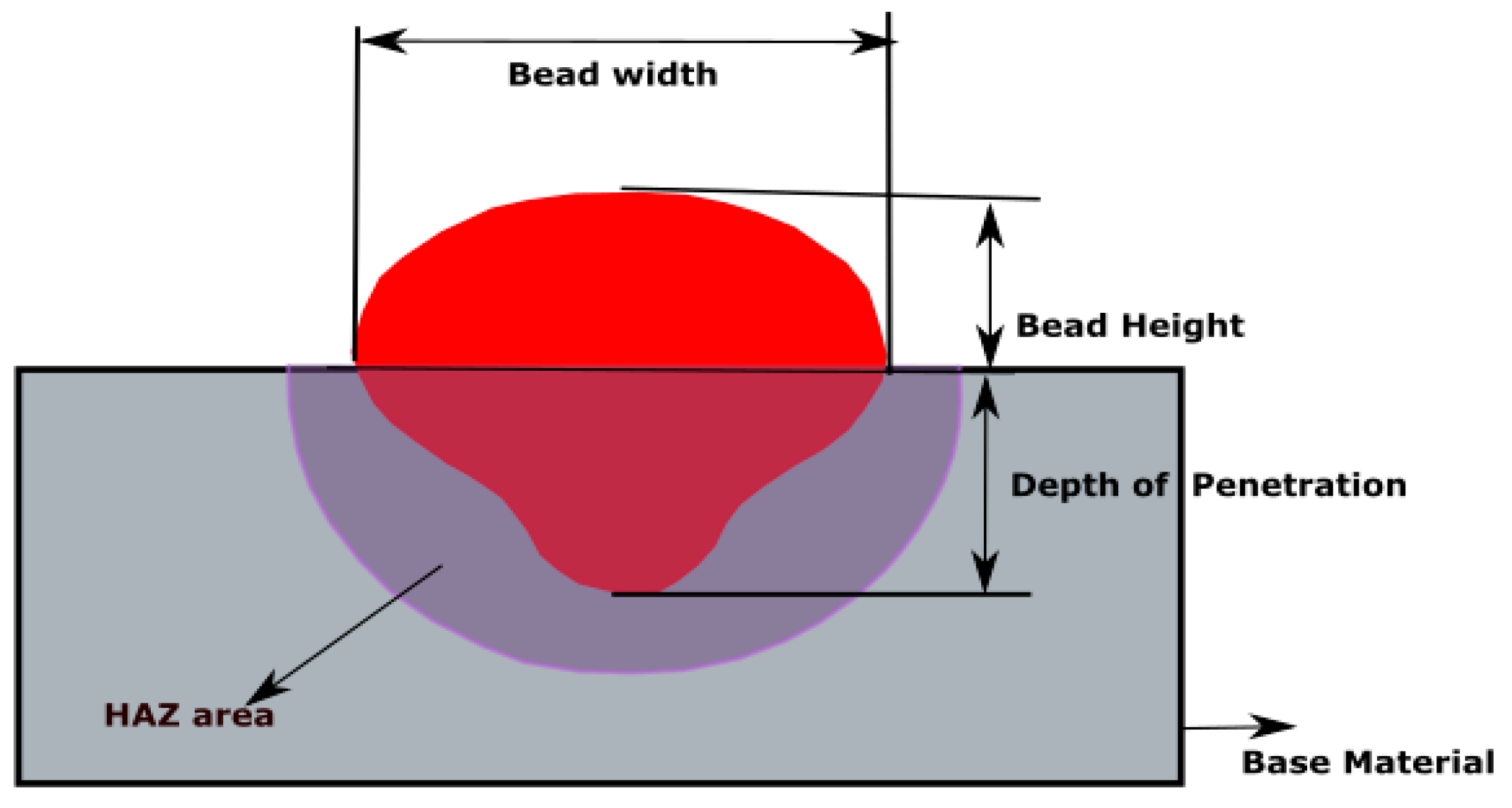

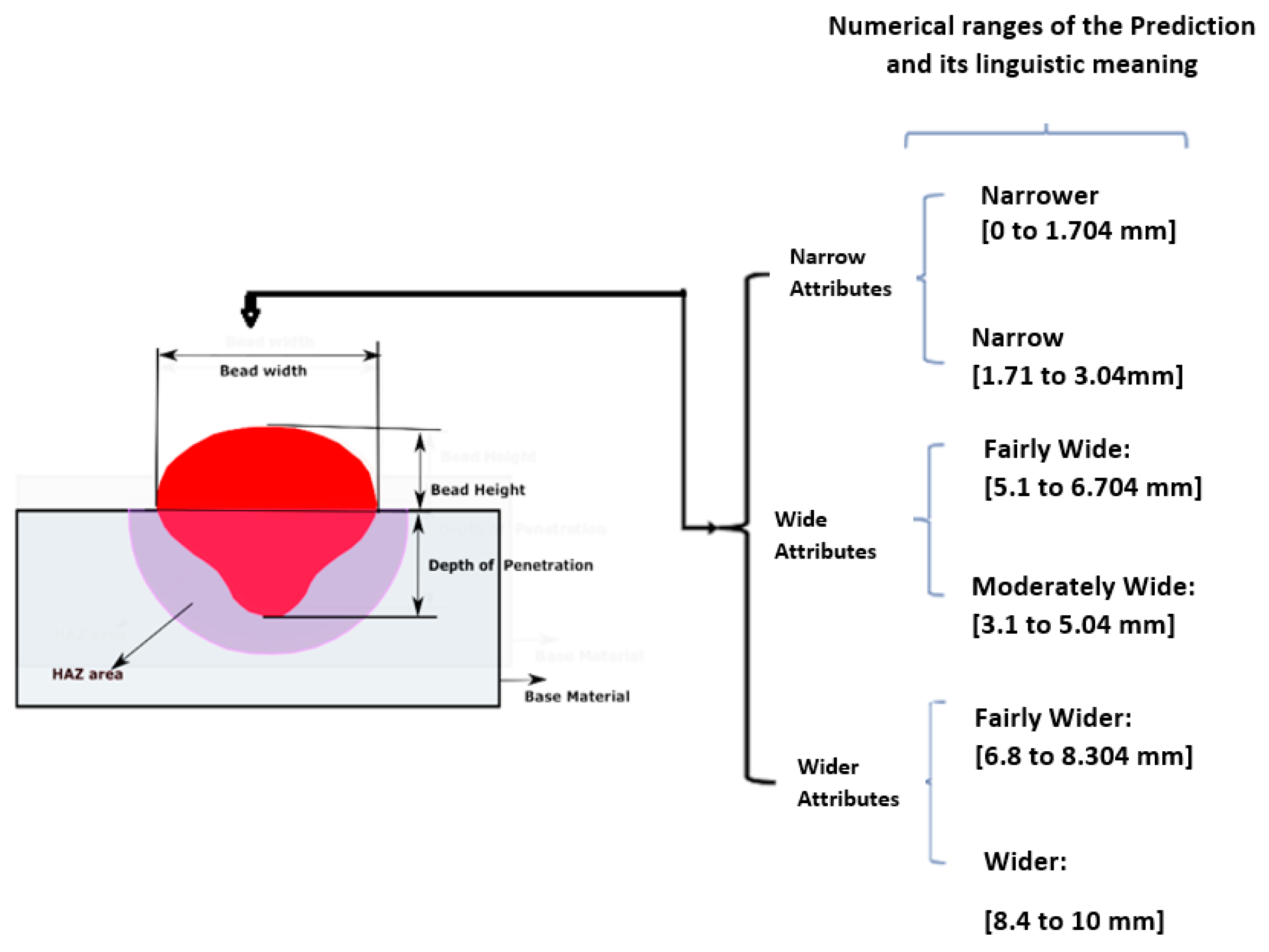

Characteristics of Weld Bead Geometry

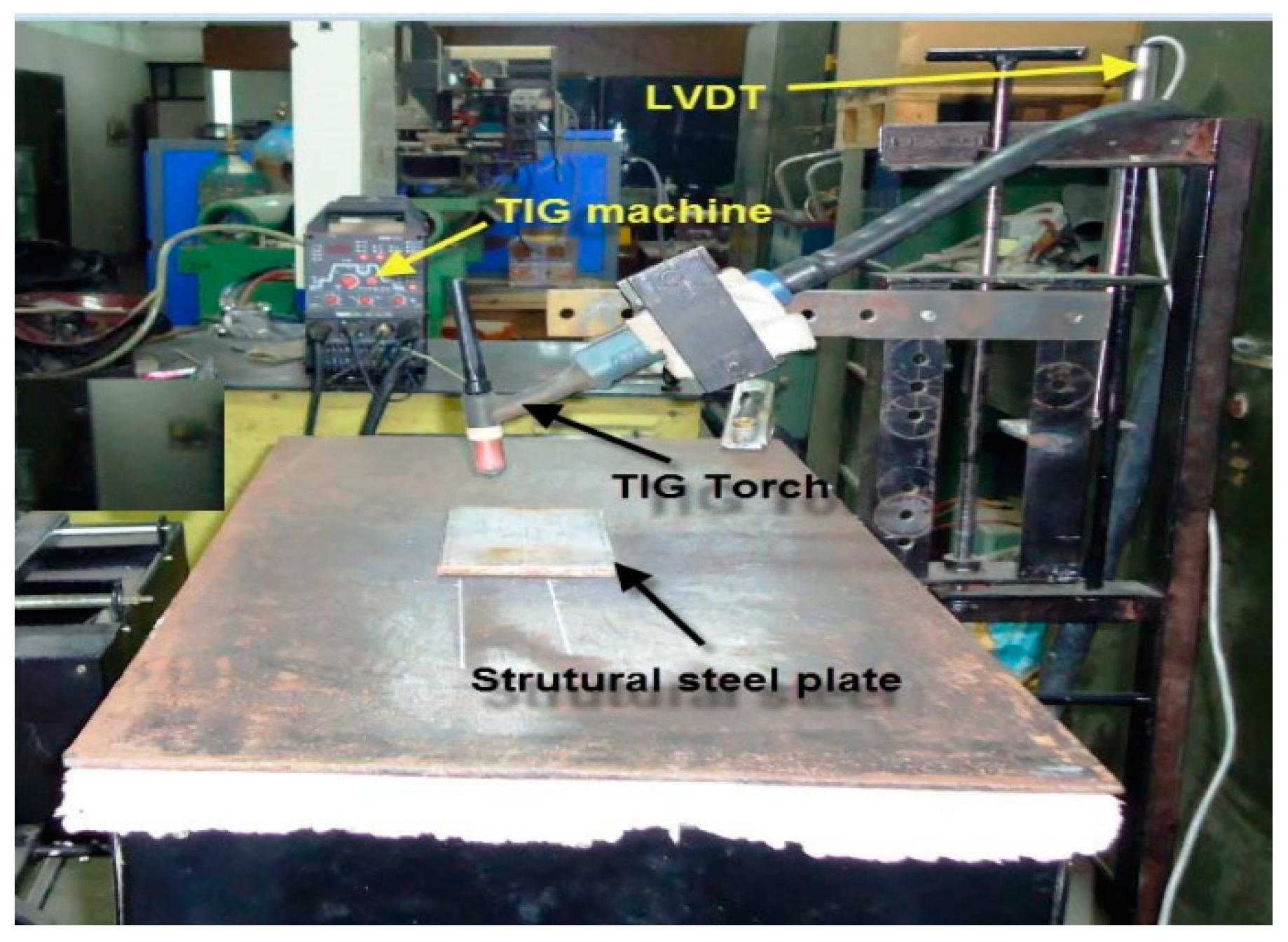

3. Simulation Experiments

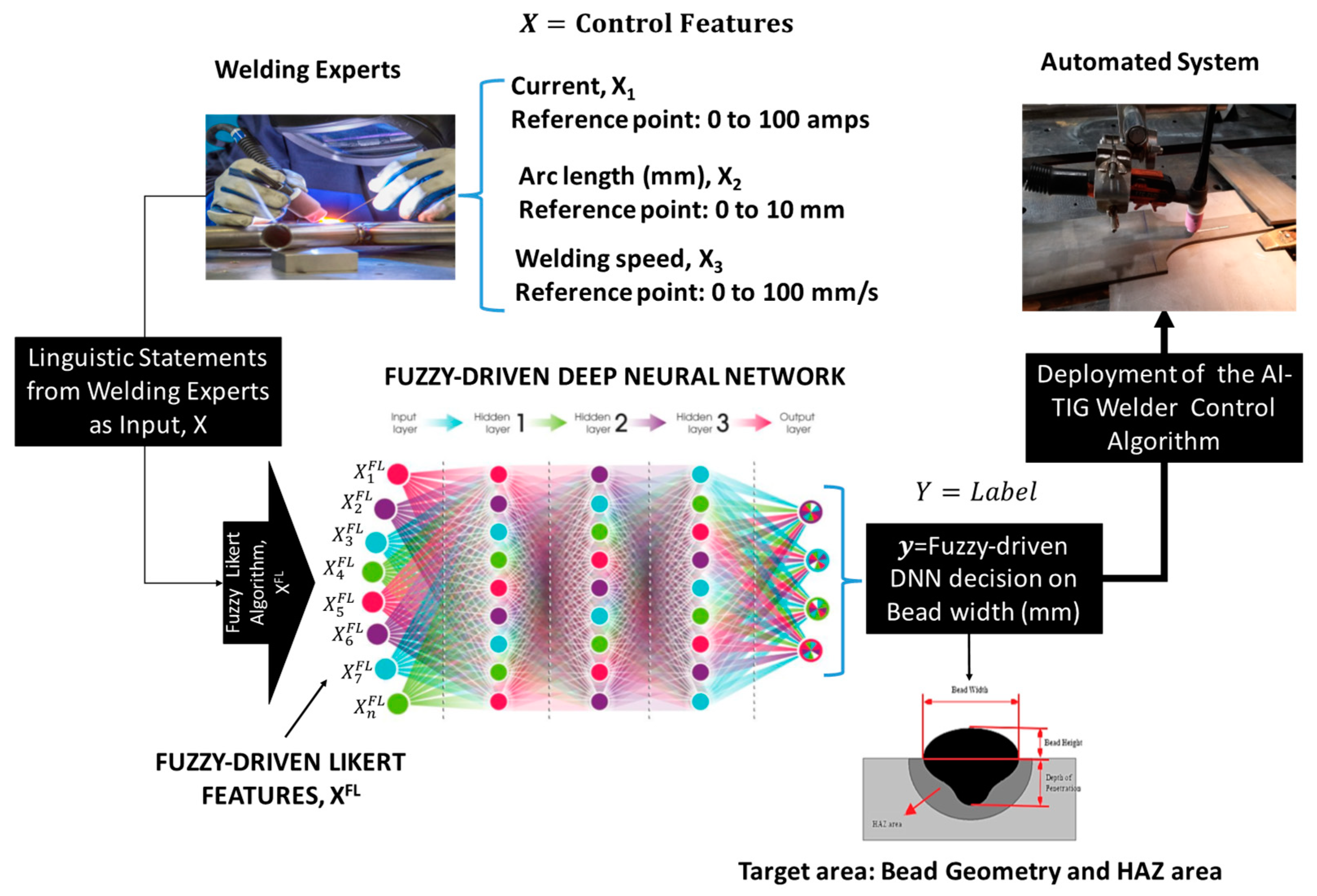

3.1. Building the AI TIG Welding Control Algorithm and Datasets

3.1.1. Feature Selection and Measurement using a Fuzzy Mathematical Technique

3.1.2. Training, Validating and Testing the Fuzzy-Driven DNN Model

3.2. Objective Evaluation of the AI TIG Welding Algorithm

4. Result and Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Harold, F.; Giles, Jr.; John, R.; Wagner, Jr. Extrusion: The Definitive Processing Guide, 2nd ed.; Willian Andrews Publications: Wayne, PA, USA, 2014. [Google Scholar]

- Yung, W.K.C.; Ralph, B.; Lee, W.B.; Fenn, R. An investigation into welding parameters affecting the tensile properties of titanium welds. J. Mater. Process. Technol. 1997, 63, 759–764. [Google Scholar] [CrossRef]

- Dutta, P.; Pratihar, D.K. Modeling of TIG welding process using conventional regression analysis and neural network-based approaches. J. Mater. Process. Technol. 2007, 184, 56–68. [Google Scholar] [CrossRef]

- Buah, E.; Linnanen, L.; Wu, H. Emotional responses to energy projects: A new method for modeling and prediction beyond self-reported emotion measure. Energy 2020, 190, 116210. [Google Scholar] [CrossRef]

- Torrisi, M.; Pollastri, G.; Le, Q. Deep learning methods in protein structure prediction. Comput. Struct. Biotechnol. J. 2020, 521, 436–444. [Google Scholar] [CrossRef]

- Deng, L.; Yu, D. Deep Learning: Methods and Applications. Found. Trends Signal Process. 2014, 7, 197–387. [Google Scholar] [CrossRef] [Green Version]

- Goodfellow, I. Deep Learning. Book in Preparation for MIT Press. 2016. Available online: http://www.deeplearningbook.org (accessed on 20 March 2020).

- Deng, Y.; Bao, F.; Kong., Y.; Ren, Z.; Dai., Q. Deep direct reinforcement learning for financial signal representation and trading. IEEE Trans. Neural Network Learn. Syst. 2017, 28, 653–664. [Google Scholar] [CrossRef] [PubMed]

- Deep Learning in Digital Pathology. Available online: http://www.global-engage.com/life-science/deep-learning-in-digital-pathology/ (accessed on 24 March 2020).

- The Welding Institute. Available online: https://www.twi-global.com/technical-knowledge/job-knowledge/tungsten-inert-gas-tig-or-gta-welding-006 (accessed on 18 March 2020).

- Larry, F.J. Welding Principles and Applications; Cengage Learning: Boston, MA, USA, 2002. [Google Scholar]

- Larry, F.J. Welding and Metal Fabrication; Cengage Learning: Boston, MA, USA, 2002. [Google Scholar]

- Azar, A.S.; Ås, S.; Akselsen, O.M. Determination of welding heat source parameters from actual bead shape. Comput. Mater. Sci. 2012, 54, 176–182. [Google Scholar] [CrossRef]

- Dey, V.; Pratihar, D.K.; Datta, G.; Jha, M.N.; Saha, T.; Bapat, A. Optimization of bead geometry in electron beam welding using a Genetic Algorithm. J. Mater. Process. Technol. 2009, 209, 1151–1157. [Google Scholar] [CrossRef]

- Anbarasan, N.; Oyyaravelu, R.; Kuppan, P. Effect of GMAW process parameters on the influence of bead geometry and HAZ area on ASTM A516 grade 70 Low alloy Pressure vessel steel. Int. J. Technol. Chem. Res. 2015, 1, 1–10. [Google Scholar]

- Deshmukh, A.; Venkatachalam, G.; Divekar, H.; Saraf, M. Effect of Weld Penetration on Fatigue Life. Procedia Eng. 2014, 97, 783–789. [Google Scholar] [CrossRef] [Green Version]

- Zadeh, L. The concept of a linguistic variable and its application to approximate reasoning—II. Inf. Sci. 1975, 8, 301–357. [Google Scholar] [CrossRef]

- Bonanno, D.; Nock, K.; Smith, L.; Elmore, P.; Petry, F. An approach to explainable deep learning using fuzzy inference. Next-Generation Analyst V. Proc. SPIE 2017, 10207, 102070D. [Google Scholar]

- Shorten, C.; Khoshgoftaar, T.M. A survey on Image Data Augmentation for Deep Learning. J. Big Data 2019, 6, 60. [Google Scholar] [CrossRef]

- Narang, H.; Singh, U.; Mahapatra, M.; Jha, P. Prediction of the weld pool geometry of TIG arc welding by using fuzzy logic controller. Int. J. Eng. Sci. Technol. 2011, 3, 77–85. [Google Scholar] [CrossRef] [Green Version]

| Control Parameters | Scale Range of Controlled Parameters, X on Psychometric Scale (Likert) | Corresponding Fuzzy Scale Range |

|---|---|---|

| Current | 0 to 100 amps | 0 to 1 |

| Arc length | 0 to 10 mm | 0 to 1 |

| Speed | 0 to 100 mm/s | 0 to 1 |

| Bead width | 0 to 10 mm | 0 to 1 |

| Rules and Variables | IF…(Premise) | THEN (Conclusion) | ||

|---|---|---|---|---|

| Parameters | Current | Arc Length | Speed | Bead Width |

| Rule: 1 | Low | Decrease | Very High | Narrow |

| Rule: 2 | Very High | Decrease greatly | Very High | Wilder |

| Rule: 3 | Low | Increase greatly | Very High | Fairly Wide |

| Rule: 4 | Medium High | Decrease greatly | Very High | Narrow |

| Rule: 5 | Very Low | Decrease greatly | Very High | Narrower |

| Rule: 6 | Very Low | Increase greatly | Very High | Fairly Wide |

| Rule: 7 | Very High | Decrease greatly | Very Low | Fairly Wider |

| Rule: 8 | Very High | Increase greatly | Very Low | Wider |

| Rule: 9 | Low | Decrease | Very High | Fairly Wide |

| Rule: 10 | Low | Increase greatly | Very High | Fairly Wide |

| Rule: 11 | Very High | Increase greatly | Low | Wider |

| Rule: 12 | Very High | Decrease greatly | Low | Moderately Wide |

| Rule: 13 | Low | Decrease | High | Narrower |

| Features and Labels | Linguistic Terms for Parameters | Fuzzy Likert Range, | Likert Value, X | Corresponding Fuzzy Range of Fuzzy Likert, XFL |

|---|---|---|---|---|

| Current (A) 0 to 100 A | Very Low | 0 | 0 | 0–0.1704 |

| Low | 17.1–30.4 | 23.75 | 0.171–0.304 | |

| Medium Low | 31.0–50.4 | 40.7 | 0.31–0.504 | |

| Medium High | 51.0–67.04 | 59.02 | 0.51–0.6704 | |

| High | 68.0–83.04 | 75.52 | 0.68–0.8304 | |

| Very High | 84.0–100 | 100 | 0.84–1 | |

| Arc Length (mm) 0 to 10 mm | Decrease greatly | 0–1.704 | 0 | 0–0.1704 |

| Decrease | 1.71–3.04 | 2.375 | 0.171–0.304 | |

| Slightly decrease | 3.1–5.04 | 4.07 | 0.31–0.504 | |

| Slightly Increase | 5.1–6.704 | 5.902 | 0.51–0.6704 | |

| Increase | 6.8–8.304 | 7.552 | 0.68–0.8304 | |

| Increase Greatly | 8.4–10 | 10 | 0.84–1 | |

| Speed (mm/s) 0 to 100 mm/s | Very Low | 0 | 0 | 0–0.1704 |

| Low | 17.1–30.4 | 23.75 | 0.171–0.304 | |

| Medium Low | 31.0–50.4 | 40.7 | 0.31–0.504 | |

| Medium High | 51.0–67.04 | 59.02 | 0.51–0.6704 | |

| High | 68.0–83.04 | 75.52 | 0.68–0.8304 | |

| Very High | 84.0–100 | 100 | 0.84–1 | |

| Bead Width (mm) 0 to 10 mm | Narrower | 0–1.704 | 0 | 0–0.1704 |

| Narrow | 1.71–3.04 | 2.375 | 0.171–0.304 | |

| Fairly Wide | 3.1–5.04 | 4.07 | 0.31–0.504 | |

| Moderately Wide | 5.1–6.704 | 5.902 | 0.51–0.6704 | |

| Fairly Wide | 6.8–8.304 | 7.552 | 0.68–0.8304 | |

| Wider | 8.4–10 | 10 | 0.84–1 |

| Rules and Variables | If…(Premise) | Then (Conclusion) | ||

|---|---|---|---|---|

| Parameters | Current | Arc Length | Speed | Bead Width |

| Rule:1 → X | Low | Decrease | Very High | Narrow |

| Rule:1 → XFL | 17.1–30.4 | 1.71–3.04 | 84.0–100 | Narrow (2.375) |

| Learner Type | Neural Networks |

|---|---|

| Number of output nodes | 3 classes with 6 sub-classes (see Figure 6 and Table 3) |

| Loss function | Categorical cross-entropy |

| Hidden layer | 8-layer network with 6 hidden layers Total number of neurons: 188 |

| Maximum number of training iterations | Epochs: 176 and Batch size: 122 |

| Activation function | Rectified linear unit (ReLu) |

| Optimization algorithm | Stochastic gradient descent |

| Early stopping rule | Manual stopping by observation in loss in generality |

| Pre-training | No pre-trained model. The models were trained from scratch |

| Regularization | Dropout Dropout was applied to 6th and 7th layer with 0.05 and 0.55, respectively |

| Dataset for training and validation | Training sample: 14,407 Validation sample: 9593 Data split rule: 60/40 |

| Dataset for testing: objective evaluation | 27 experiments |

| Learning rate | 0.003 |

| C % | Si % | Mn % | P % | S % | Ni % | Cr % | Fe % |

|---|---|---|---|---|---|---|---|

| 0.16 | 0.178 | 0.45 | 0.18 | 0.07 | 0.13 | 0.016 | 98.84 |

| Serial Number (S.N) | Current (A) | Arc Length (mm) | Welding Speed (mm/s) | Bead Width (mm) | Depth of Penetration (mm) | Depth of HAZ (mm) | Width of HAZ (mm) |

|---|---|---|---|---|---|---|---|

| 1 | 55 | 2 | 15 | 5.46 | 1.59 | 1.73 | 1.83 |

| 2 | 55 | 2 | 30 | 4.71 | 1.25 | 1.19 | 1.35 |

| 3 | 55 | 2 | 45 | 4.16 | 1.04 | 1.02 | 1.13 |

| 4 | 55 | 2.5 | 15 | 5.77 | 1.76 | 1.94 | 2.20 |

| 5 | 55 | 2.5 | 30 | 4.93 | 1.38 | 1.33 | 1.63 |

| 6 | 55 | 2.5 | 45 | 4.46 | 1.18 | 1.16 | 1.33 |

| 7 | 55 | 3 | 15 | 6.09 | 1.91 | 2.13 | 2.45 |

| 8 | 55 | 3 | 30 | 5.03 | 1.42 | 1.51 | 1.84 |

| 9 | 55 | 3 | 45 | 4.55 | 1.23 | 1.23 | 1.46 |

| 10 | 75 | 2 | 15 | 6.12 | 1.99 | 2.48 | 2.25 |

| 11 | 75 | 2 | 30 | 5.13 | 1.39 | 1.46 | 1.72 |

| 12 | 75 | 2.5 | 45 | 4.59 | 1.16 | 1.22 | 1.39 |

| 13 | 75 | 2.5 | 15 | 6.59 | 2.06 | 2.65 | 2.41 |

| 14 | 75 | 2.5 | 30 | 5.26 | 1.50 | 1.65 | 1.89 |

| 15 | 75 | 2.5 | 45 | 4.85 | 1.32 | 1.34 | 1.57 |

| 16 | 75 | 3 | 15 | 7.07 | 2.18 | 2.72 | 2.79 |

| 17 | 75 | 3 | 30 | 5.45 | 1.65 | 1.86 | 2.02 |

| 18 | 75 | 3 | 45 | 5.16 | 1.45 | 1.58 | 1.79 |

| 19 | 95 | 2 | 15 | 6.65 | 2.17 | 3.04 | 2.7 |

| 20 | 95 | 2 | 30 | 5.38 | 1.51 | 1.81 | 1.94 |

| 21 | 95 | 2 | 45 | 4.75 | 1.23 | 1.49 | 1.52 |

| 22 | 95 | 2.5 | 15 | 7.19 | 2.23 | 3.32 | 2.89 |

| 23 | 95 | 2.5 | 30 | 6.16 | 1.63 | 1.97 | 2.15 |

| 24 | 95 | 2.5 | 45 | 5.2 | 1.32 | 1.56 | 1.75 |

| 25 | 95 | 3 | 15 | 7.64 | 2.51 | 3.21 | 3.15 |

| 26 | 95 | 3 | 30 | 6.31 | 1.74 | 2.15 | 2.70 |

| 27 | 95 | 3 | 45 | 5.11 | 1.41 | 1.74 | 2.16 |

| S.N | Observed Values of Bead Width in LAB | Class Label of Observed Value in Fuzzy Likert Terms | Fuzzy Linguistic Terms for Observed Values | Predicted Value of Bead Width with the AI TIG Welding | Class Label of Predicted Values in Fuzzy Likert Terms |

|---|---|---|---|---|---|

| 1 | 5.46 | 5.1–6.704 | Fairly wide | 5.1–6.704 | Fairly wide |

| 2 | 4.71 | 3.1–5.04 | Moderately wide | 3.1–5.04 | Moderately wide |

| 3 | 4.16 | 3.1–5.04 | Moderately wide | 3.1–5.04 | Moderately wide |

| 4 | 5.77 | 5.1–6.704 | Fairly wide | 5.1–6.704 | Fairly wide |

| 5 | 4.93 | 3.1–5.04 | Moderately wide | 3.1–5.04 | Moderately wide |

| 6 | 4.46 | 3.1–5.04 | Moderately wide | 3.1–5.04 | Moderately wide |

| 7 | 6.09 | 5.1–6.704 | Fairly wide | 5.1–6.704 | Fairly wide |

| 8 | 5.03 | 3.1–5.04 | Moderately wide | 3.1–5.04 | Moderately wide |

| 9 | 4.55 | 3.1–5.04 | Moderately wide | 3.1–5.04 | Moderately wide |

| 10 | 6.12 | 5.1–6.704 | Fairly wide | 5.1–6.704 | Fairly wide |

| 11 | 5.13 | 5.1–6.704 | Fairly wide | 5.1–6.704 | Fairly wide |

| 12 | 4.59 | 3.1–5.04 | Moderately wide | 3.1–5.04 | Moderately wide |

| 13 | 6.59 | 5.1–6.704 | Fairly wide | 5.1–6.704 | Fairly wide |

| 14 | 5.26 | 5.1–6.704 | Fairly wide | 5.1–6.704 | Fairly wide |

| 15 | 4.85 | 3.1–5.04 | Moderately wide | 3.1–5.04 | Moderately wide |

| 16 | 7.07 | 6.8–8.304 | Fairly wider | 6.8–8.304 | Fairly wider |

| 17 | 5.45 | 5.1–6.704 | Fairly wide | 5.1–6.704 | Fairly wide |

| 18 | 5.16 | 5.1–6.705 | Fairly wide | 3.1–5.04 | Moderately wide |

| 19 | 6.65 | 5.1–6.706 | Fairly wide | 6.8–8.304 | Fairly wider |

| 20 | 5.38 | 5.1–6.704 | Fairly wide | 5.1–6.704 | Fairly wide |

| 21 | 4.75 | 3.1–5.04 | Moderately wide | 3.1–5.04 | Moderately wide |

| 22 | 7.19 | 6.8–8.304 | Fairly wider | 6.8–8.304 | Fairly wider |

| 23 | 6.16 | 5.1–6.704 | Fairly wide | 5.1–6.704 | Fairly wide |

| 24 | 5.2 | 5.1–6.704 | Fairly wide | 5.1–6.704 | Fairly wide |

| 25 | 7.64 | 6.8–8.304 | Fairly wider | 6.8–8.304 | Fairly wider |

| 26 | 6.31 | 5.1–6.704 | Fairly wide | 5.1–6.704 | Fairly wide |

| 27 | 5.11 | 5.1–6.704 | Fairly wide | 5.1–6.704 | Fairly wide |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kesse, M.A.; Buah, E.; Handroos, H.; Ayetor, G.K. Development of an Artificial Intelligence Powered TIG Welding Algorithm for the Prediction of Bead Geometry for TIG Welding Processes using Hybrid Deep Learning. Metals 2020, 10, 451. https://doi.org/10.3390/met10040451

Kesse MA, Buah E, Handroos H, Ayetor GK. Development of an Artificial Intelligence Powered TIG Welding Algorithm for the Prediction of Bead Geometry for TIG Welding Processes using Hybrid Deep Learning. Metals. 2020; 10(4):451. https://doi.org/10.3390/met10040451

Chicago/Turabian StyleKesse, Martin A., Eric Buah, Heikki Handroos, and Godwin K. Ayetor. 2020. "Development of an Artificial Intelligence Powered TIG Welding Algorithm for the Prediction of Bead Geometry for TIG Welding Processes using Hybrid Deep Learning" Metals 10, no. 4: 451. https://doi.org/10.3390/met10040451