Challenges for Wood–Plastic Composites: Increasing Wood Content and Internal Compatibility †

Abstract

1. Introduction

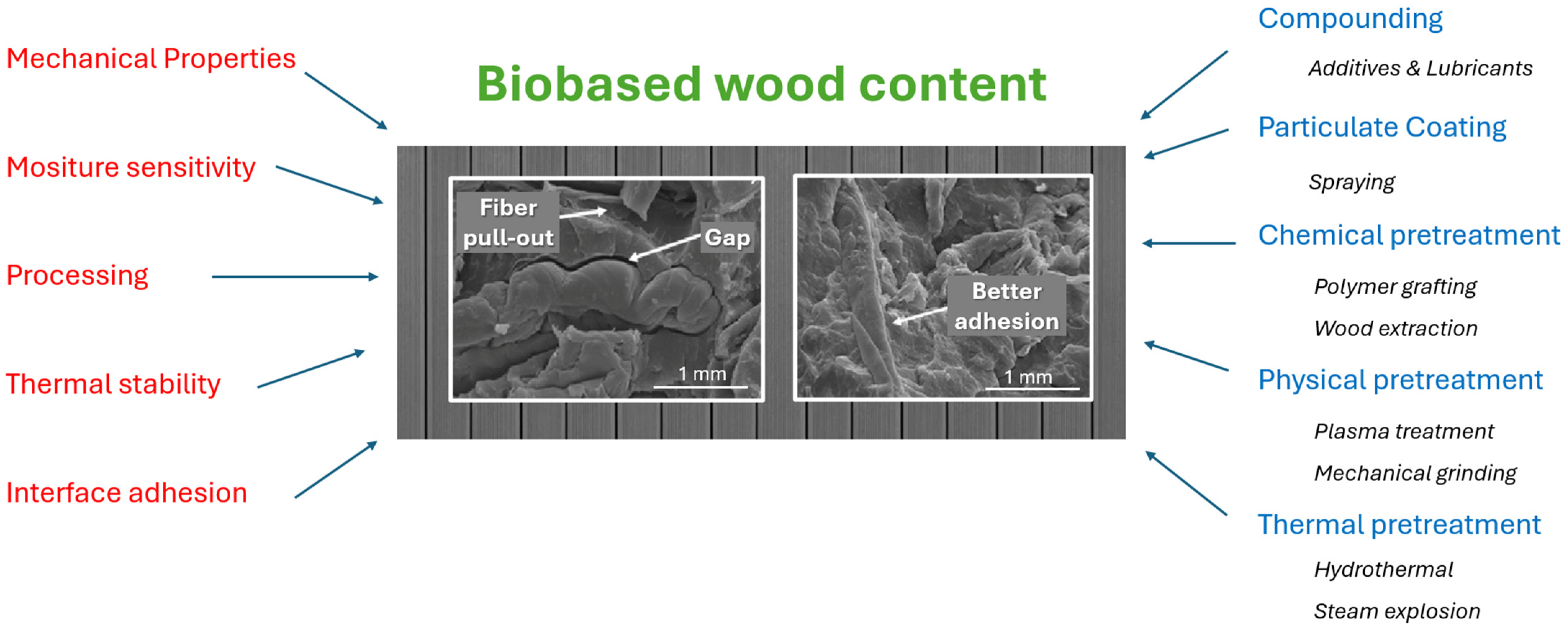

2. Technical Challenges

2.1. Limitations in Biobased Filler Content

2.2. Performance with High Wood Filler Content

- Mechanical Properties: It is noticed that the high wood filler content can enhance certain properties like the stiffness, tensile strength and thermal stability, but it may reduce other properties, such as impact resistance, flexibility and toughness [7].

- Moisture Sensitivity: The moisture absorption of hydrophilic wood fillers can lead to local swelling, warping and reduced dimensional stability. Particularly at high filler content, the formation of a continuous network with contacting wood particles enhances the pathways for the diffusion of water and moisture throughout the composite [8].

- Processing: The viscosity of the melt increases at high wood filler content, making processing techniques like extrusion and injection molding more challenging [9].

- Thermal Stability: As wood fillers are thermally less stable and can degrade at temperatures of around 220 °C, high processing temperatures should be avoided, and the types of plastics that can be used under these processing conditions become limited.

- Interface Adhesion: The poor adhesion between the hydrophilic wood fibers and the hydrophobic polymer matrix may lead to weak interfaces and reduced strength [10].

3. Remediation Strategies

3.1. Compounding with Compatibilizers and Additives

| Polymer Matrix | Filler | Compatibilizer | Reference |

|---|---|---|---|

| PE | wood flour | polyethylene-co-glycidyl methacrylate | [16] |

| wood chips | aliphatic copolyamide | [17] | |

| PE, PP | wood flour | anhydride-modified ethylene copolymer, ethylene elastomer, anhydride-modified polyethylene and ethylene copolymer | [18] |

| PP | saw dust (Scots pine) | hardwood distillate (pyrolysis liquid) | [15] |

| PE, PP, PVC | wood veneer | methylenediphenyl-4,4′-diisocyanate | [19] |

| wood flour Phragmites karka | exfoliated nanoclay (evt. + polyethylene-co-glycidyl methacrylate) | [20] | |

| PVC | bamboo particles | fatty acid, glycerol ester, PE wax | [21] |

| olive pit flour | chlorinated polyethylene | [22] | |

| wood flour | chlorinated polyethylene | [23] | |

| wood flour | poly-1,4-butylene glycol adipate diol, polyurethane prepolymer | [13] | |

| wood flour | terpolymers (P(MAA-BA-MMA)) of methyl acrylate, butyl acrylate and methyl methacrylate | [24] | |

| wood flour | chitosan (evt. + nano calcium carbonate (NCC) + activated carbon (AC)) | [14,25] | |

| alfa fibers | maleic anhydride–poly(vinyl chloride) | [26] | |

| wood sawdust | silanes: chlorosilanes, aminopropyltrimethoxysilanes | [27] |

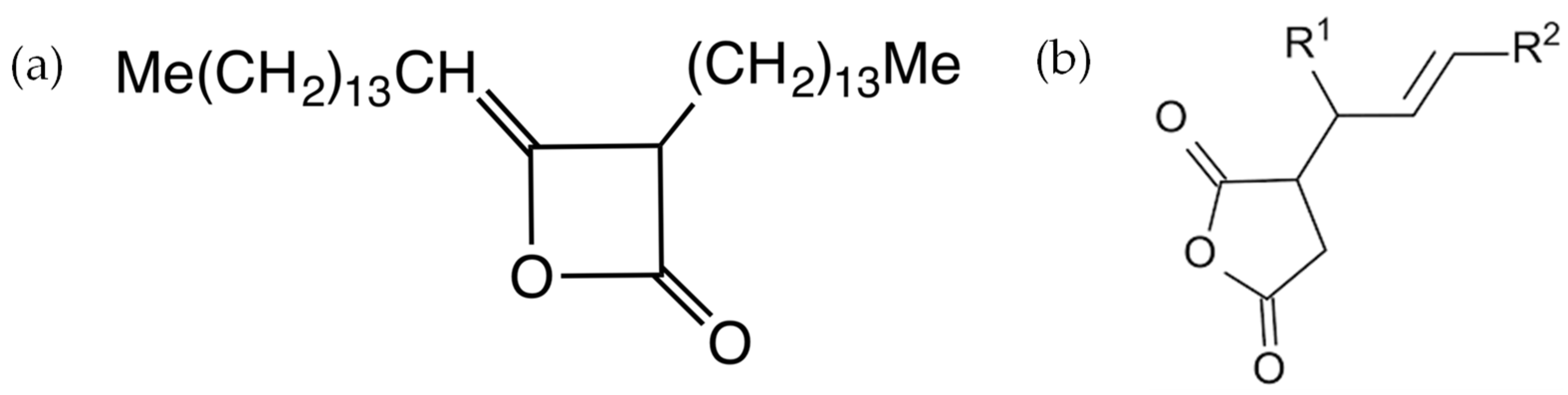

3.2. Particulate Coating

3.3. Chemical Pretreatment

3.4. Physical Pretreatment

3.5. Thermal Pretreatment

4. Industrial Feasibility and Patent Review

5. Conclusions

- The following techniques are the most straightforward: the spray coating of individual wood chips (natural oils, wax, ASA, AKD), the use of copolymer additives (PHA, maleated styrene/acrylonitrile copolymer, chlorinated PE) and the addition of selected compatibilizing agents (chitosan/chitin, acrylic-based terpolymers) in the compound.

- The thermal pretreatment of the wood seems efficient, but it requires collaboration over the processing chain and long-term development.

- The chemical pretreatment of the wood particles seems efficient, but it requires the extensive testing and optimization of the processes. The removal of hemicellulose fractions seems critical in improving the water resistance.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schwarzkopf, M.J.; Burnard, M.D. Wood-plastic composites—Performance and environmental impacts. In Environmental Impacts of Traditional and Innovative Forest-Based Bioproducts; Kutnar, A., Muthu, S., Eds.; Springer: Singapore, 2016. [Google Scholar]

- Kamau-Devers, K.; Millmer, S.A. The environmental attributes of wood fiber composites with bio-based or petroleum-based plastics. Int. J. Life Cycle Assess. 2020, 25, 1145–1159. [Google Scholar] [CrossRef]

- Fuchigami, Y.; Kojiro, K.; Furuta, Y. Quantification of greenhouse gas emissions from wood-plastic recycled composite (wprc) and verification of the effect of reducing emissions through multiple recycling. Sustainability 2020, 12, 2449. [Google Scholar] [CrossRef]

- Leu, S.Y.; Yang, T.H.; Lo, S.F.; Yang, T.H. Optimized material composition to improve the physical and mechanical properties of extruded wood–plastic composites (WPCs). Construct. Build. Mater. 2012, 29, 120–127. [Google Scholar] [CrossRef]

- Bhaskar, K.; Jayabalakrishnan, D.; Kumar, M.V.; Sendilvelan, S.; Prabhahar, M. Analysis on mechanical properties of wood plastic composite. Mater. Today Proc. 2021, 45, 5886–5891. [Google Scholar] [CrossRef]

- Walinder, M.; Segerholm, K.; Söderström, O. Water sorption properties and dimensional changes of high wood-content WPC: Effect of acetylation and heat-treated wood components. In Proceedings of the 5th Meeting Nordic Baltic Notwork in Wood Material Science and Engineering, Copenhagen, Denmark, 1–2 October 2009; pp. 153–160. [Google Scholar]

- Yadav, R.; Singh, M.; Shelhawat, D.; Lee, S.Y.; Park, S.J. The role of fillers to enhance the mechanical, thermal, and wear characteristics of polymer composite materials: A review. Comp. A 2023, 175, 107775. [Google Scholar] [CrossRef]

- Mitalova, Z.; Mital, D.; Berladir, K. A concise review of the components and properties of wood–plastic composites. Polymers 2024, 16, 1556. [Google Scholar] [CrossRef]

- Lewandowki, K.; Piszcszek, K.; Skorczewska, K.; Mirowksi, J.; Zajchowski, S.; Wilczewski, S. Rheological properties of wood polymer composites at high shear rates. Comp. A 2022, 154, 106804. [Google Scholar] [CrossRef]

- Huang, S.; Fu, Q.; Yan, L.; Kasal, B. Characterization of interfacial properties between fibre and polymer matrix in composite materials—A critical review. J. Mater. Res. Technol. 2021, 13, 1441–1484. [Google Scholar] [CrossRef]

- Jiang, H.; Kamdem, D.P. Development of poly(vinyl chloride)/wood composites: A literature review. J. Vinyl Add. Technol. 2004, 10, 59–69. [Google Scholar] [CrossRef]

- Hejna, A.; Przybysz-Romatowska, M.; Kosmela, P.; Zedler, L.; Korol, J.; Formela, K. Recent advances in compatibilization strategies of wood-polymer composites by isocyanates. Wood Sci. Technol. 2020, 54, 1091–1119. [Google Scholar] [CrossRef]

- Xu, Z.; Yu, Z.; Daixing, J.; Mei, Z.; Qiangxian, W. A novel interface structure for preparing compatible wood/polyvinyl chloride composites. J. Biobased Mater. Bioenergy 2015, 9, 155–162. [Google Scholar]

- Ge, S.; Zuo, S.; Zhang, M.; Luo, Y.; Yang, R.; Wu, Y.; Zhang, Y.; Li, J.; Xia, C. Utilization of decayed wood for polyvinyl chloride/wood flour composites: Use of chitosan as compatibilizer. J. Mater. Res. Technol. 2021, 12, 862–869. [Google Scholar] [CrossRef]

- Väisänen, T.; Heikkinen, J.; Tomppo, L.; Lappalainen, R. Improving the properties of wood–plastic composite through addition of hardwood pyrolysis liquid. J. Thermoplast. Comp. Mater. 2016, 29, 1587–1598. [Google Scholar] [CrossRef]

- Deka, B.K.; Maji, T. Effect of coupling agent and nanoclay on properties of HDPE, LDPE, PP, PVC blend and Phargamites karka nanocomposite. Comp. Sci. Technol. 2010, 70, 1755–1761. [Google Scholar] [CrossRef]

- Zanoaga, M.; Tanasa, F.; Mamunya, Y. Compatibilized green composites based on wood chips and thermoplastic polymer waste matrices. Cell Chem. Technol. 2016, 50, 637–648. [Google Scholar]

- Martikka, O.; Karki, T.; Puurtinen, A. Improving durability of wood-mixed waste plastic composites with compatibilizers. IOP Conf. Ser. Mater. Sci. Eng. 2019, 490, 022001. [Google Scholar] [CrossRef]

- Shen, Z.; Ye, Z.; Li, K.; Qi, C. Effects of coupling agent and thermoplastic on the interfacial bond strength and the mechanical properties of oriented wood strand–thermoplastic composites. Polymers 2021, 13, 4260. [Google Scholar] [CrossRef]

- Deka, B.K.; Maji, T.K. Effect of TiO2 and nanoclay on the properties of wood polymer nanocomposite. Compos. A 2011, 42, 2117–2125. [Google Scholar] [CrossRef]

- Bahari, S.A.; Grigsby, W.; Krause, A. Thermal stability of processed PVC/bamboo blends: Effect of compounding procedures. Eur. J. Wood Prod. 2017, 75, 147–159. [Google Scholar] [CrossRef]

- Ali, S.F.A.; Althobaiti, I.O.; El-Rafey, E.; Gad, E.S. Wooden polymer composites of poly(vinyl chloride), olive pits flour, and precipitated bio-calcium carbonate. ACS Omega 2021, 6, 23924–23933. [Google Scholar]

- Guffey, V.O.; Sabbagh, A.B. PVC/wood-flour composites compatibilized with chlorinated polyethylene. J. Vinyl Add. Technol. 2002, 8, 259–263. [Google Scholar] [CrossRef]

- Zhu, D.; Sheng, Y.; Liu, X.; Chen, Q. Effects of a novel acrylic-based compatibilizer on the mechanical properties, contact angle, water absorption, density and processibility of polyvinyl chloride/wood flour composite. J. Reinf. Plast. Comp. 2012, 31, 1025–1036. [Google Scholar] [CrossRef]

- Shah, B.L.; Matuana, L.M.; Heiden, P. Novel coupling agents for PVC/wood-flour composites: Chitin/chitosan. J. Vinyl Add. Technol. 2005, 11, 160–165. [Google Scholar] [CrossRef]

- Hammiche, D.; Boukerrou, A.; Guermazi, N.; Arrakhiz, F.E. Effects of types of PVC-g-MA on wettability and dynamical behavior of polyvinyl Chloride/Alfa composites. Mater. Today Proc. 2021, 36, 10–15. [Google Scholar] [CrossRef]

- Sombatsompop, N.; Chaochanchaikul, K. Average mixing torque, tensile and impact properties, and thermal stability of poly(vinyl chloride)/sawdust composites with different silane coupling agents. J. Appl. Polym. Sci. 2005, 96, 213–221. [Google Scholar] [CrossRef]

- Janesh, J.; Gusenbauer, C.; Mautner, A.; Gindl-Altmutter, W.; Hansmann, C. Efficient wood hydrophobization exploiting natural roughness using minimum amounts of surfactant-free plant oil emulsions. ACS omega 2021, 6, 22202–22212. [Google Scholar] [CrossRef]

- Samyn, P.; Rastogi, V.K. Stabilization of an Aqueous Bio-Based Wax Nano-Emulsion through Encapsulation. Nanomaterials 2022, 13, 4329. [Google Scholar] [CrossRef]

- Yue, X.; Chen, F.; Zhou, X. Synthesis of lignin-g-MMA and the utilization of the copolymer in PVC/wood composites. J. Macromol. Sci. B 2011, 51, 242–254. [Google Scholar] [CrossRef]

- Hundhausen, U.; Militz, H.; Mai, C. Treatment of particleboard chips with alkenyl succinic anhydride. Wood Res. 2010, 55, 25–37. [Google Scholar]

- Zhang, H. Effect of a novel coupling agent, alkyl ketene dimer, on mechanical properties of wood/polypropylene composites. Mater. Design 2014, 59, 130–134. [Google Scholar] [CrossRef]

- Müller, M.; Radovanovic, I.; Grüneberg, T.; Militz, H.; Krause, A. Influence of various wood modifications on the properties of polyvinyl chloride/wood flour composites. J. Appl. Polym. Sci. 2011, 125, 308–312. [Google Scholar] [CrossRef]

- Pintiaux, T.; Laourine, F.; Vacamedina, G.; Rouilly, A.; Peydecastaing, J. Hydrophobic cellulose-based materials obtained by uniaxial high-pressure compression: In-situ esterification with fatty acids and anhydrides. Bioresources 2015, 10, 4626–4640. [Google Scholar] [CrossRef]

- Hietala, M.; Samuelsson, E.; Niinimäli, J.; Oksman, K. The effect of pre-softened wood chips on wood fibre aspect ratio and mechanical properties of wood–polymer composites. Comp. A 2011, 42, 2110–2116. [Google Scholar] [CrossRef]

- Bendjaouahdou, C.; Aidaoui, K. Synthesis and characterization of polyvinyl chloride/wood flour/organoclay ternary composites. Polym. Polym. Comp. 2021, 29, S949–S958. [Google Scholar] [CrossRef]

- Wang, Q.; Xiao, S.; Shi, S.Q.; Cai, L. Effect of light-delignification on mechanical, hydrophobic, and thermal properties of high-strength molded fiber materials. Nat. Sci. Rep. 2018, 8, 995. [Google Scholar] [CrossRef] [PubMed]

- Shen, T.; Li, M.; Zhang, B.; Zhong, L.; Lin, X.; Yang, P.; Li, M.; Zhuang, W.; Zhu, C.; Ying, H. Enhanced mechanical properties of polyvinyl chloride-based wood–plastic composites with pretreated corn stalk. Front. Bioeng. Biotechnol. 2022, 9, 829821. [Google Scholar] [CrossRef]

- Jaunslavietis, J.; Shulga, G.; Ozolins, J.; Neiberte, B.; Verovkins, A.; Vitolina, S.; Betkers, T. Hydrophilic-Hydrophobic Characteristics of Wood-Polymer Composites Filled with Modified Wood Particles. Key Eng. Mater. 2018, 762, 176–181. [Google Scholar] [CrossRef]

- Toriz, G.; Wendel, A.; Martinez-Gomez, A. Highly hydrophobic wood surfaces prepared by treatment with atmospheric pressure dielectric barrier discharges. J. Adhes. Sci. Technol. 2008, 22, 2059–2078. [Google Scholar] [CrossRef]

- Kociszewski, M.; Gozdecki, C.; Wilczynshi, A.; Zajchowski, S.; Mirowski, J. Effect of industrial wood particle size on mechanical properties of wood-polyvinyl chloride composites. Eur. J. Wood Wood Prod. 2012, 70, 113–118. [Google Scholar] [CrossRef]

- Esteves, B.M.; Pereira, H.M. Wood modification by heat treatment: A review. Bioresources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Hosseinihashemi, S.K.; Arwinfar, F.; Najafi, A.; Nemli, G.; Ayrilmis, N. Long-term water absorption behavior of thermoplastic composites produced with thermally treated wood. Measurement 2016, 86, 202–208. [Google Scholar] [CrossRef]

- Arwinfar, F.; Hosseinihashemi, S.K.; Latibari, A.J.; Lashgari, A.; Ayrilmis, N. Mechanical properties and morphology of wood plastic composites produced with thermally treated beech wood. Bioresources 2016, 11, 1494–1504. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kwon, J.H.; Han, T.H. Effect of wood chip size on hemicellulose extraction and technological properties of flakeboard. Turk. J. Agricult. Forest. 2017, 41, 331–337. [Google Scholar] [CrossRef]

- Pelaez-Samaniego, M.R.; Yadama, V.; Lowell, E.; Amidon, T.E.; Chaffee, T.L. Hot water extracted wood fiber for production of wood plastic composites (WPCs). Holzforschung 2013, 67, 193–200. [Google Scholar] [CrossRef]

- Brandt, J.R.; Taylor, W.G.; Miller, J.M. Balanced Cooling of Extruded Synthetic Wood Material. U.S. Patent 5827462, 27 October 1998. [Google Scholar]

- Zehner, B.E.; Brandt, J.R. Renewable Surface for Extruded Synthetic Wood Material. U.S. Patent 5866264, 2 February 1999. [Google Scholar]

- Zehner, B.E. Vinyl Based Cellulose Reinforced Composite. U.S. Patent 6011091, 1 April 2000. [Google Scholar]

- Brandt, J.R. Extrusion of Synthetic Wood Material. U.S. Patent 6117924, 12 September 2000. [Google Scholar]

- Woodhams, R.T. Oriented Thermoplastic and Particulate Matter Composite Material. U.S. Patent 5474722, 12 December 1995. [Google Scholar]

- Goettler, L.A. Treated Fibers and Bonded Composites of Cellulose Fibers in Vinyl Chloride Polymer Characterized by an Isocyanate Bonding Agent. U.S. Patent 4376144, 8 August 1983. [Google Scholar]

- Hopperdietzel, S. Use of Cellulose Fibers for Structurally Modifying Polyvinyl Chloride Articles. U.S. Patent 4851458, 25 July 1989. [Google Scholar]

- Ronden, C.P.; Morin, J.C. Process for the Production of Composites of Co-Mingled Thermoset Resin Bonded Wood Waste Blended with Thermoplastic Polymers. U.S. Patent 5981631, 9 November 1999. [Google Scholar]

- Clarke, J.A. Wood Particle Board and a Method of Making the Same. U.S. Patent 3245867, 12 April 1966. [Google Scholar]

- Frenkel, P.; Ma, Q.; Stott, P.; Weer, J.; Krainer, E. Compatibilizers for Composites of PVC and Cellulosic Materials. U.S. Patent 20070259995, 8 November 2007. [Google Scholar]

| Patent | Assignee | Title | Compatibilizer | Reference |

|---|---|---|---|---|

| US 5,827,462 US 5,866,264 US 6,011,091 US 6,117,924 | CPG International LLC | Balanced cooling of extruded synthetic wood material Renewable surface for extruded synthetic wood material Vinyl based cellulose reinforced composite Extrusion of synthetic wood material | lubricants (zinc stearate or calcium stearate) | [47] [48] [49] [50] |

| US 5,474,722 | Eovations LLC | Oriented thermoplastic and particulate matter composite material | polyurethane | [51] |

| US 4,376,144 | Flexsys America LP | Treated fibers and bonded composites of cellulose fibers in vinyl chloride polymer characterized by an isocyanate bonding agent | isocyanate | [52] |

| US 4,851,458 | Rehau AG | Use of cellulose fibers for structurally modifying polyvinyl chloride articles | undisclosed structure | [53] |

| US 5,981,631 | Wood Composite Technologies | Process for the production of composites of co-mingled thermoset resin bonded wood waste blended with thermoplastic polymers | fatty acid, rosin | [54] |

| US 3,245,867 | Dow Chemical | Wood particle board and a method of making the same | magnesium chloride, bromide, sulfate | [55] |

| US 2007/0259995 | Galata Chemicals LLC | Compatibilizers for composites of PVC and cellulosic materials | maleated styrene/acrylonitrile copolymer | [56] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samyn, P. Challenges for Wood–Plastic Composites: Increasing Wood Content and Internal Compatibility. Environ. Earth Sci. Proc. 2024, 31, 1. https://doi.org/10.3390/eesp2024031001

Samyn P. Challenges for Wood–Plastic Composites: Increasing Wood Content and Internal Compatibility. Environmental and Earth Sciences Proceedings. 2024; 31(1):1. https://doi.org/10.3390/eesp2024031001

Chicago/Turabian StyleSamyn, Pieter. 2024. "Challenges for Wood–Plastic Composites: Increasing Wood Content and Internal Compatibility" Environmental and Earth Sciences Proceedings 31, no. 1: 1. https://doi.org/10.3390/eesp2024031001

APA StyleSamyn, P. (2024). Challenges for Wood–Plastic Composites: Increasing Wood Content and Internal Compatibility. Environmental and Earth Sciences Proceedings, 31(1), 1. https://doi.org/10.3390/eesp2024031001