Development of Cryogenic Structural Steels for Magnetic Confinement Fusion

Abstract

1. Introduction

2. Austenitic Stainless Steels for the ITER Superconducting Magnets

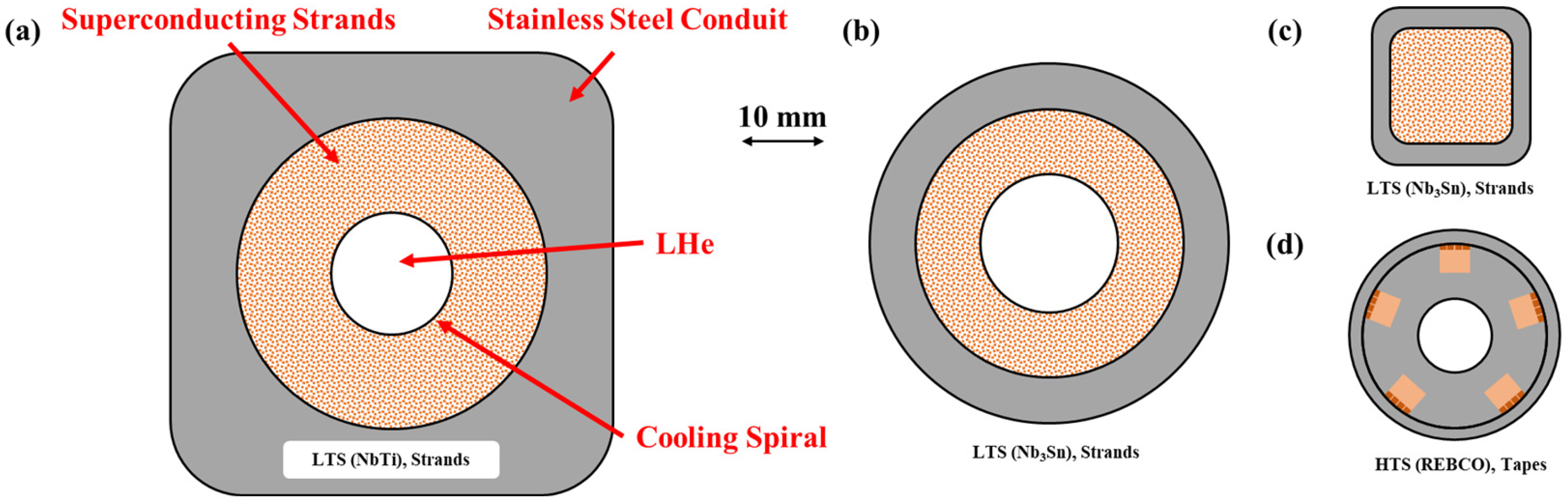

2.1. Jackets of the CICCs of Coils

| TF | CS | PF1&6 | PF2–5 | CC | ||

|---|---|---|---|---|---|---|

| Assignment proportion (%) | CN | 7.5 | 100 | 100 | ||

| EU | 20.2 | 39.8 | ||||

| JA | 25.0 | 60.2 | ||||

| KO | 20.2 | |||||

| RF | 19.3 | |||||

| US | 7.8 | 100 |

| TF | CS | PF1&6 | PF2–5 | CC | |||

|---|---|---|---|---|---|---|---|

| Material types | Modified 316LN | JK2LB | Modified 316L | AISI 316L | |||

| Chemical compositions (wt%) | C | <0.015 | <0.02 | ≤0.03 | ≤0.03 | ||

| Si | <0.75 | <0.28 | ≤0.75 | ≤0.75 | |||

| Mn | <2.0 | 20.50–22.50 | ≤2.00 | ≤2.00 | |||

| P | <0.04 | <0.008 | ≤0.03 | ≤0.045 | |||

| S | <0.03 | <0.008 | ≤0.01 | ≤0.030 | |||

| Cr | 16.0–18.0 | 12.00–14.00 | 16.00–18.50 | 16.0–18.0 | |||

| Ni | 11.0–14.0 | 8.0–10.0 | 11.0–14.0 | 10.0–14.0 | |||

| Mo | 2.0–3.0 | 0.5–1.5 | 2.00–2.50 | 2.00–3.00 | |||

| N | 0.14–0.18 | 0.09–0.15 | 0.1–0.16 | ||||

| B | 0.001–0.004 | ||||||

| Co | <0.1 | <0.1 | ≤0.1 | ||||

| Coil shapes | Circle | Circle in square | Circle in square | Square | |||

| Coil sizes (mm) | Outer diameter | 43.7 | 49.0 | 53.8 | 51.9 | 19.2 | |

| Inner diameter | 39.7 | 32.6 | 37.7 | 35.3 | 14.8 | ||

| Modified 316LN | JK2LB | Modified 316L | 316L | CHN01 | ||

|---|---|---|---|---|---|---|

| Yield strength (Rp0.2) (MPa) | 4.2 K | >950 (1165) | >850 (1076) | >700 (797) | >700 (813) | >1500 (1600) |

| 300 K | (530) | >700 (800) | >173 (494) | >173 (512) | 547 | |

| Tensile strength (Rm) (MPa) | 4.2 K | (1537) | >1150 (1450) | >1000 (1525) | >1000 (1582) | >1800 (1930) |

| 300 K | (746) | >1000 (1550) | >483 (626) | >483 (615) | >480 (776) | |

| Young’s modulus (E) (GPa) | 4.2 K | (202) | (201) | >205 (209) | (202) | (216) |

| 300 K | (195) | >180 (192) | >190 (193) | >190 (194) | (184) | |

| Elongation (e) (%) | 4.2 K | >20 (34) | >25 (43) | >40 (45) | >30 (39) | >25 (34) |

| 300 K | (38) | >30 (44) | >35 (51) | >35 (45) | >35 (50) | |

| Fracture toughness (K(J)Ic) (MPa·m1/2) | 4.2 K | >150 (300) | >130 (209) | >150 (278) | >130 (265) | |

| Pre-test processing | Compaction 3.5%; Tensile 2.5%; 650 °C (200 h) | Compaction 3.5%; Tensile 2.5%; 650 °C (200 h) | Compaction 5%; Bending (radius 2 m); Straightening | Compaction 3.5%; Tension 2.5% | Compaction 5%; Bending (radius 2 m); Straightening; 665 °C (50 h) | |

2.2. Cases of the TF and CC Coils

| CASE of TF | CASE of CC | |||||||

|---|---|---|---|---|---|---|---|---|

| Assignment proportions (%) | CN | 100% | ||||||

| JA | 100% | |||||||

| Material types | JJ1 | Filler material | 316LNH | 316LNM | 316LNL | 316LN | Filler material | |

| Chemical compositions | C | <0.03 | 0.016 | <0.03 | <0.03 | <0.03 | <0.03 | 0.018 |

| Si | <0.75 | 0.52 | <0.75 | <0.75 | <0.75 | <1.0 | 0.46 | |

| Mn | 9.0–11.0 | 10.17 | <2.0 | <2.0 | <2.0 | <2.0 | 7.01 | |

| P | <0.035 | 0.004 | <0.03 | <0.03 | <0.03 | <0.04 | 0.017 | |

| S | <0.015 | 0.004 | <0.02 | <0.02 | <0.02 | <0.03 | 0.003 | |

| Cr | 11.0–13.0 | 12.27 | 16.0–18.5 | 16.0–18.5 | 16.0–18.5 | 16.0–18.0 | 20.59 | |

| Ni | 11.0–13.0 | 14.16 | 10.0–14.0 | 10.0–14.0 | 10.0–14.0 | 10.0–14.0 | 15.37 | |

| Mo | 4.0–6.0 | 4.97 | 2.0–3.0 | 2.0–3.0 | 2.0–3.0 | 2.00–3.00 | 2.83 | |

| N | 0.21–0.27 | 0.162 | 0.17–0.22 | 0.12–0.17 | 0.10–0.12 | <0.18 | 0.156 | |

| JJ1 | 316LNH | 316LNM | 316LNL | 316LN | ||

|---|---|---|---|---|---|---|

| Yield strength (Rp0.2) (MPa) | 4.2 K | >1000 (1126) | >900 (1093) | >700 (868) | >500 (713) | >700 (1080) |

| 300 K | (330) | (355) | (289) | (263) | >250 (318) | |

| Tensile strength (Rm) (MPa) | 4.2 K | (1319) | (1444) | (1348) | (1313) | >1000 (1430) |

| 300 K | (665) | (666) | (590) | (557) | >480 (642) | |

| Elongation (e) (%) | 4.2 K | (42) | >35 | |||

| 300 K | (65) | >40 | ||||

| Fracture toughness (K(J)Ic) (MPa·m1/2) | 4.2 K | >200 (366) | >200 | >180 (213) | ||

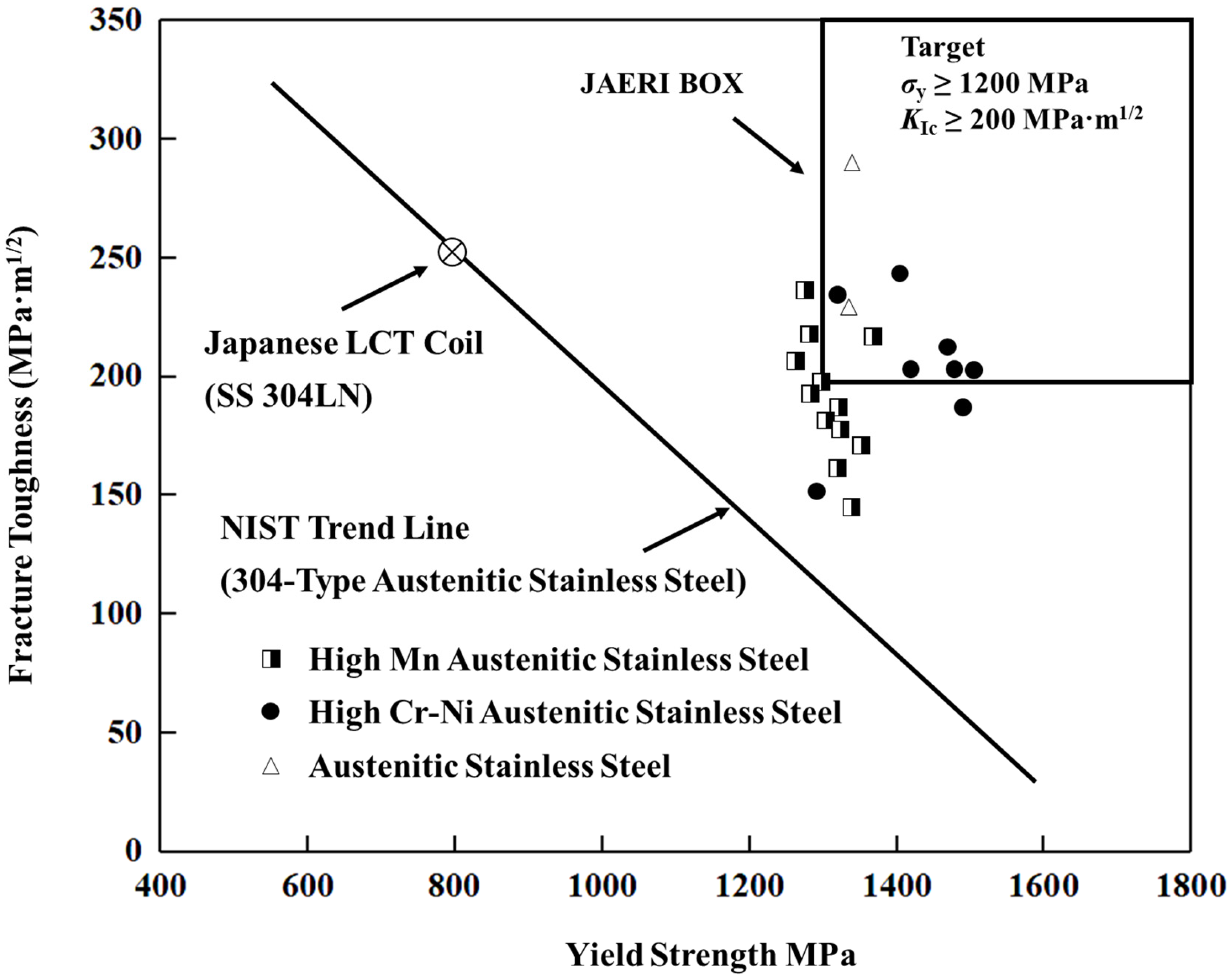

3. Historical Development of Cryogenic Structural Steels in Japan and the United States

3.1. Japan

3.2. The United States of America

4. Recent Advances in Austenitic Stainless Steels for Next-Generation MCF Devices

4.1. Japan

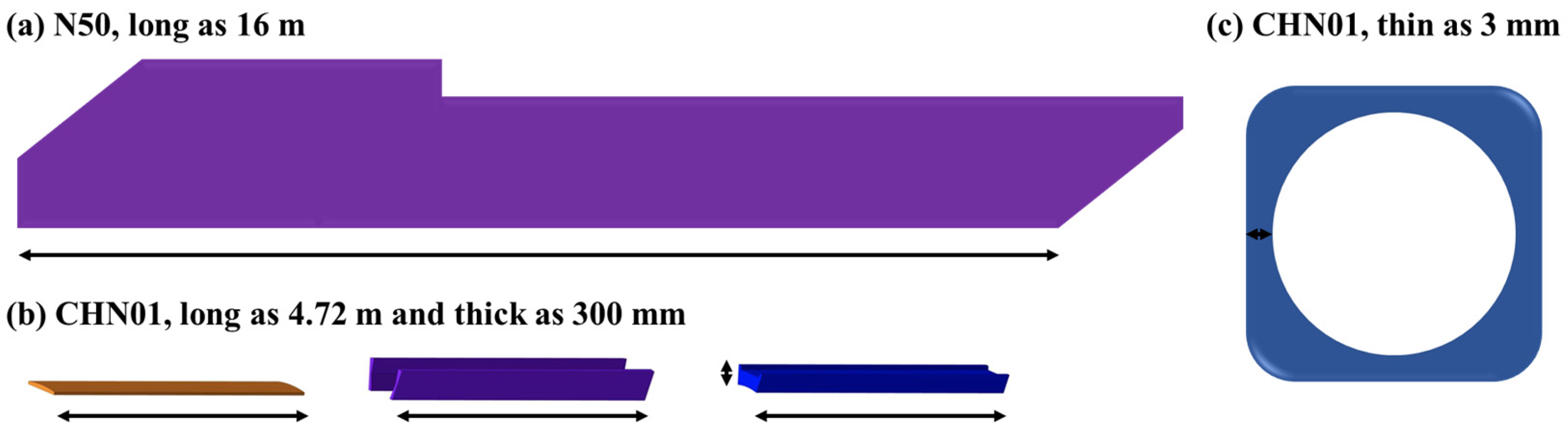

4.2. China

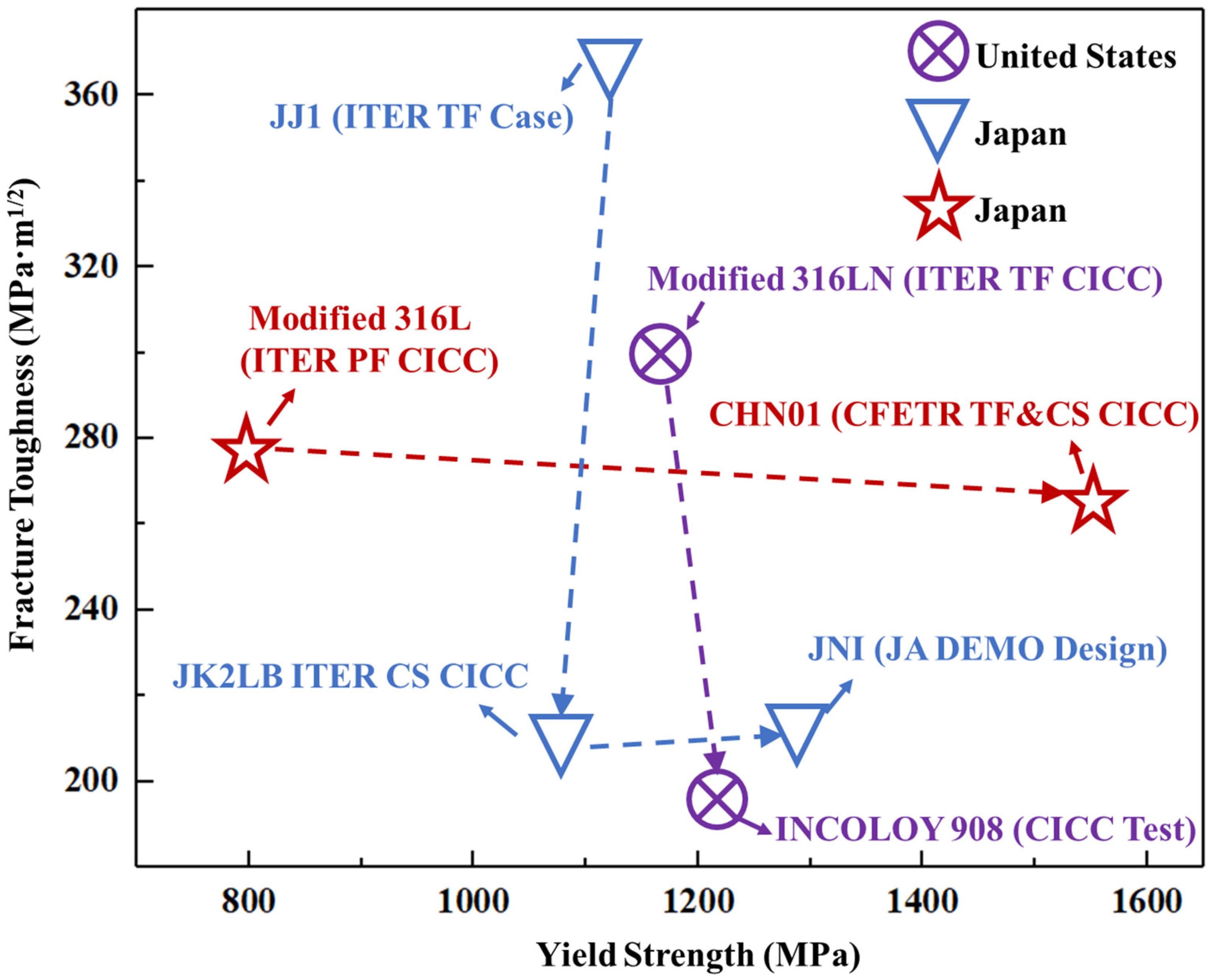

5. Comparative Analysis and Future Perspectives

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| e | Elongation |

| K(J)Ic | Fracture Toughness |

| Rm | Ultimate Tensile Strength |

| Rp0.2 | Yield Strength |

| AE | Acoustic Emission |

| ASS | Austenitic Stainless Steel |

| BEST | Burning Experimental Superconducting Tokamak |

| BM | Base Metal |

| CC | Correction Coil |

| CFETR | China Fusion Engineering Test Reactor |

| CICC | Cable-In-Conduit Conductor |

| CS | Central Solenoid |

| DRX | Dynamic Recrystallization |

| DIC | Digital Image Correlation |

| EAST | Experimental Advanced Superconducting Tokamak |

| EBSD | Electron Backscatter Diffraction |

| ECT | Eddy Current Testing |

| EDS | Energy Dispersive Spectroscopy |

| ENEA | European Nuclear Energy Agency |

| FCC | Face-Centered Cubic |

| FCGR | Fatigue Crack Growth Rate |

| FS | Ferritic Steel |

| HAZ | Heat Affected Zone |

| HFML | High Field Magnet Laboratory |

| HMAS | High-Mn Austenitic Steel |

| HMASS | High-Mn Austenitic Stainless Steel |

| HTS | High Temperature Superconductivity |

| INC | International Nickel Corporation |

| ITER | International Thermonuclear Experimental Reactor |

| JA-DEMO | Japan Demonstration |

| JAEA | Japan Atomic Energy Agency |

| JAERI | Japan Atomic Energy Research Institute |

| JCS | Japanese Cryogenic Steel |

| JK2LB | JK2-Low C-B-added |

| JT-60SA | Japan Torus-60-Super Advanced |

| LBW | Laser Beam Welding |

| LEFM | Linear Elastic Fracture Mechanics |

| MIT | Massachusetts Institute of Technology |

| NAFASSY | National Facility for Superconducting Systems |

| NDE | Non-Destructive Examination |

| NG-MIGW | Narrow-Gap Metal Inert Gas Weld |

| PAUT | Phased Array Ultrasonic Testing |

| PF | Polar Field |

| QST | Quantum Science and Technology |

| SAGBO | Stress Accelerated Grain Boundary Oxidation |

| SEM | Scanning Electron Microscope |

| SFE | Stacking Fault Energy |

| SHR | Strain Hardening Rate |

| TEM | Transmission Electron Microscope |

| TIGW | Tungsten Inert Gas Weld |

| TF | Toroidal Field |

| TFTR | Toroidal Fusion Test Reactor |

| VEBW | Vacuum Electron Beam Weld |

| WZ | Weld Zone |

References

- International Fusion Research Council (IFRC). Status report on fusion research. Nucl. Fusion 2005, 45, A1. [Google Scholar] [CrossRef]

- Holdren, J.P. Safety and Environmental Aspects of Fusion Energy. Annu. Rev. Environ. Resour. 1991, 16, 235–258. [Google Scholar] [CrossRef]

- Sborchia, C.; Soto, E.B.; Batista, R.; Bellesia, B.; Oliva, A.B.; Rebollo, E.B.; Boutboul, T.; Bratu, E.; Caballero, J.; Cornelis, M.; et al. Overview of ITER magnet system and European contribution. In Proceedings of the 2011 IEEE/NPSS 24th Symposium on Fusion Engineering, Chicago, IL, USA, 26–30 June 2011; pp. 1–8. [Google Scholar] [CrossRef]

- Reinders, L.J. The Big Tokamaks: TFTR, JET, JT-60. In The Fairy Tale of Nuclear Fusion; Reinders, L.J., Ed.; Springer International Publishing: Cham, Germany, 2021; pp. 183–217. [Google Scholar] [CrossRef]

- Tobita, K.; Asakura, N.; Hiwatari, R.; Someya, Y.; Utoh, H.; Katayama, K.; Nishimura, A.; Sakamoto, Y.; Homma, Y.; Kudo, H.; et al. Design Strategy and Recent Design Activity on Japan’s DEMO. Fusion Sci. Technol. 2017, 72, 537–545. [Google Scholar] [CrossRef]

- Kwon, S.; Im, K.; Hong, S.-H.; Lee, H.; Rognlien, T.D.; Meyer, W.; Kim, K. Recent progress in the design of the K-DEMO divertor. Fusion Eng. Des. 2020, 159, 111770. [Google Scholar] [CrossRef]

- Zheng, J.; Song, Y.; Liu, X.; Lu, K.; Qin, J. Overview of the Design Status of the Superconducting Magnet System of the CFETR. IEEE. Trans. Appl. Supercond. 2018, 28, 1–5. [Google Scholar] [CrossRef]

- Song, Y.; Li, J.; Wan, Y.; Liu, Y.; Wang, X.; Wan, B.; Fu, P.; Weng, P.; Wu, S.; Duan, X.; et al. Engineering design of the CFETR machine. Fusion Eng. Des. 2022, 183, 113247. [Google Scholar] [CrossRef]

- Jin, H.; Qin, J.G.; Zhou, C.; Liu, H.J.; Liu, F.; Gao, P.; Xiao, G.Y.; Ma, H.J.; Li, J.G.; Wu, Y.; et al. The performance of first CORC cable solenoid insert for development of CFETR high-field magnet. Nucl. Fusion 2020, 60, 096028. [Google Scholar] [CrossRef]

- Dai, C.; Wu, Y.; Li, J.; Guo, Z.; Qin, J.; Long, F.; Nijhuis, A.; Bruzzone, P.; Stepanov, B.; Shi, Y.; et al. Performance test and analysis of the first large-scale cable-in-conduit conductor with high Jc Nb3Sn strand for fusion reactor. Nucl. Fusion 2021, 61, 036044. [Google Scholar] [CrossRef]

- Watson, J. Mechanical Properties of High-Strength 301 Stainless Steel Sheet at 70, −320, and −423 °F in the Base Metal and Welded Joint Configurations. In Advances in Cryogenic Engineering: Proceedings of the 1959 Cryogenic Engineering Conference University of California, Berkeley, California September 2–4, 1959; Springer: Boston, MA, USA, 1960. [Google Scholar]

- Libeyre, P.; Bessette, D.; Devred, A.; Jong, C.; Mitchell, N.; Sgobba, S. Conductor jacket development to meet the mechanical requirements of the ITER central solenoid coils. Fusion Eng. Des. 2011, 86, 1553–1557. [Google Scholar] [CrossRef]

- Reed, R.P. Trends and Advances in Cryogenic Materials. In Cryogenic Engineering; Timmerhaus, K.D., Reed, R.P., Eds.; Springer: New York, NY, USA, 2007; pp. 52–83. [Google Scholar] [CrossRef]

- Mitchell, N.; Devred, A. The ITER magnet system: Configuration and construction status. Fusion Eng. Des. 2017, 123, 17–25. [Google Scholar] [CrossRef]

- Devred, A.; Backbier, I.; Bessette, D.; Bevillard, G.; Gardner, M.; Jong, C.; Lillaz, F.; Mitchell, N.; Romano, G.; Vostner, A. Challenges and status of ITER conductor production. Supercond. Sci. Technol. 2014, 27, 044001. [Google Scholar] [CrossRef]

- Wu, Y.; Qin, J.G.; Liu, B.; Liu, F.; Liu, H.J.; Long, F.; Jin, H.; Jin, J.; Yang, Z.Y.; Pang, Y.C.; et al. Status of the ITER Conductors in China. IEEE Trans. Appl. Supercond. 2016, 26, 1–5. [Google Scholar] [CrossRef]

- Huguet, M.; Team, I.J.C.; Teams, I.H. Key engineering features of the ITER-FEAT magnet system and implications for the R&D programme. Nucl. Fusion 2001, 41, 1503. [Google Scholar] [CrossRef]

- Xin, J.; Zhang, H.; Sun, W.; Wang, W.; Wu, D.; Lyu, B.; Shen, F.; Fang, Z.; Huang, C.; Li, L. Microstructure evolution of austenitic stainless steels under high-cycle-fatigue loading at deep cryogenic temperature. Scr. Mater. 2023, 226, 115223. [Google Scholar] [CrossRef]

- Li, L.F.; Yang, K.; Rong, L.J. Strengthening mechanism of 316LN stainless steel at cryogenic temperatures. Adv. Cryog. Eng. ICMC 2002, 614, 165–169. [Google Scholar] [CrossRef]

- Fernández-Pisón, P.; Rodríguez-Martínez, J.A.; García-Tabarés, E.; Avilés-Santillana, I.; Sgobba, S. Flow and fracture of austenitic stainless steels at cryogenic temperatures. Eng. Fract. Mech. 2021, 258, 108042. [Google Scholar] [CrossRef]

- Sas, J.; Weiss, K.P.; Jung, A. The Mechanical and material properties of 316LN austenitic stainless steel for the fusion application in cryogenic temperatures. IOP Conf. Ser. Mater. Sci. Eng. 2015, 102, 012003. [Google Scholar] [CrossRef]

- Han, W.; Liu, Y.; Wan, F.; Liu, P.; Yi, X.; Zhan, Q.; Morrall, D.; Ohnuki, S. Deformation behavior of austenitic stainless steel at deep cryogenic temperatures. J. Nucl. Mater. 2018, 504, 29–32. [Google Scholar] [CrossRef]

- Ishio, K.; Hamada, K.; Nakajima, H. Effects of nitrogen, niobium, phosphorous and carbon on the mechanical properties of aged 316LN stainless steels at the cryogenic temperature, 4K. Tetsu Hagane-J. Iron Steel Inst. Jpn. 2006, 92, 30–35. [Google Scholar] [CrossRef][Green Version]

- Walsh, R.P.; Toplosky, V.J.; McRae, D.; Han, K.; Martovetsky, N.N. Cold Work Study on a 316ln Modified Alloy for the Iter tf Coil Conduit. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2012; Volume 1435, pp. 63–69. [Google Scholar][Green Version]

- Kim, J.H.; Feng, J. The 4K mechanical properties of modified SS316LN for jacket materials in superconducting fusion magnets. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2008; Volume 54, pp. 92–99. [Google Scholar][Green Version]

- Park, S.H.; Kim, J.Y.; Park, W.W.; Choi, H.; Ma, Y.J.; Kwon, S.P.; Kim, K.; Kang, S.C.; Lee, D.H. The Effect of Plastic Deformation on Low Temperature Mechanical and Magnetic Properties of Austenite 316LN Tube for ITER TF Conductor. IEEE Trans. Appl. Supercond. 2012, 22, 7800204. [Google Scholar] [CrossRef]

- Jin, H.; Wu, Y.; Liu, H.; Han, Q. Mechanical Properties of 316LN Stainless Steel Tube for ITER TF Jacket. J. Iron Steel Res. 2012, 24, 34–38. [Google Scholar]

- Huang, C.; Li, L.; Wu, Z.; Huang, R.; Li, J.; Li, S.; Qin, J.; Liu, H.; Wu, Y. Effect of Solution Annealing Treatment on the Cryogenic Elongation of ITER TF jacket Material-316LN. Chin. J. Low Temp. Phys. 2013, 35, 117–121. [Google Scholar]

- Summers, L.T.; Walsh, R.P.; Miller, J.R. The Cryogenic Tensile and Fracture Toughness Properties of Austenitic Steels Given Low Temperature, Short-Time Nb3Sn Reaction Heat Treatments. In Advances in Cryogenic Engineering Materials; Summers, L.T., Ed.; Springer: Boston, MA, USA, 1997; pp. 339–344. [Google Scholar] [CrossRef]

- Vostner, A.; Pong, I.; Bessette, D.; Devred, A.; Sgobba, S.; Jung, A.; Weiss, K.P.; Jewell, M.C.; Liu, S.; Yu, W.; et al. Benchmarking of Mechanical Test Facilities Related to ITER CICC Steel Jackets. IEEE Trans. Appl. Supercond. 2013, 23, 9500705. [Google Scholar] [CrossRef]

- Dornfeld, D. Application of acoustic emission techniques in manufacturing. NDT E Int. 1992, 25, 259–269. [Google Scholar] [CrossRef]

- Wu, S.; Xin, J.; Xie, W.; Zhang, H.; Huang, C.; Wang, W.; Zhou, Z.; Zhou, Y.; Li, L. Mechanical properties and microstructure evolution of cryogenic pre-strained 316LN stainless steel. Cryogenics 2022, 121, 103388. [Google Scholar] [CrossRef]

- Anashkin, O.P.; Keilin, V.E.; Krivykh, A.V.; Diev, D.N.; Dinisilov, A.S.; Shcherbakov, V.I.; Tronza, V.I. Tensile Tests of ITER TF Conductors Jacket Materials. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2012; Volume 1435, pp. 117–124. [Google Scholar] [CrossRef]

- Vogt, J.B.; Foct, J.; Regnard, C.; Robert, G.; Dhers, J. Low-temperature fatigue of 316L and 316LN austenitic stainless steels. Metall. Trans. A. 1991, 22, 2385–2392. [Google Scholar] [CrossRef]

- Ogawa, Y.; Okazaki, S.; Takakuwa, O.; Matsunaga, H. The roles of internal and external hydrogen in the deformation and fracture processes at the fatigue crack tip zone of metastable austenitic stainless steels. Scr. Mater. 2018, 157, 95–99. [Google Scholar] [CrossRef]

- Gao, S.; Bai, Y.; Zheng, R.; Tian, Y.; Mao, W.; Shibata, A.; Tsuji, N. Mechanism of huge Lüders-type deformation in ultrafine grained austenitic stainless steel. Scr. Mater. 2019, 159, 28–32. [Google Scholar] [CrossRef]

- Yang, W.H.; Cheng, P.M.; Li, Y.; Wang, R.; Liu, G.; Xin, L.; Zhang, J.Y.; Sun, J. Ratcheting-induced twinning/de-twinning behaviors in a 316LN austenitic stainless steel. Mater. Sci. Eng. A 2022, 851, 143648. [Google Scholar] [CrossRef]

- Yang, H.H.; Wu, Z.X.; Huang, C.J.; Huang, R.J.; Li, S.P.; Li, L.F. Stress-induced Martensitic Transformation During Tensile Test of Full-size TF Conductor Jacket Tube at 4.2 K. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2014; Volume 1574, pp. 48–53. [Google Scholar] [CrossRef]

- Yang, H.; Zhang, H.; Xu, X.; Liu, Q.; Li, L. Analysis on full-size ITER TF jacked tubes after tensile test at 300, 77 and 4.2 K. In Proceedings of the 25th International Cryogenic Engineering Conference and International Cryogenic Materials Conference 2014, Enschede, the Netherlands, 7–11 July 2014; Volume 67, pp. 1022–1027. [Google Scholar] [CrossRef]

- Devred, A.; Backbier, I.D.; Bessette, G.; Bevillard, M.; Gardner, M.; Jewell, N.; Mitchell, I.P.; Vostner, A. Status of ITER Conductor Development and Production. IEEE Trans. Appl. Supercond. 2012, 22, 4804909. [Google Scholar] [CrossRef]

- Li, X.B.; Jin, H.; Qin, J.G.; Wu, Y.; Li, L.; Wang, K.; Ji, H.; Liu, S. Mechanical Properties of ITER CICC Jacket in China. IEEE Trans. Appl. Supercond. 2018, 28, 1–5. [Google Scholar] [CrossRef]

- Wang, W.; Jin, J.; Wu, L.; Deng, M.; Shi, J.; Jin, H.; Huang, C.; Yuan, Y.; Liu, K.; Wang, S.; et al. Study on the welding properties of modified N50 CICC jacket for future fusion applications. J. Mater. Res. Technol. 2023, 27, 6094–6103. [Google Scholar] [CrossRef]

- Saito, T.; Kawano, K.; Yamazaki, T.; Ozeki, H.; Isono, T.; Hamada, K.; Devred, A.; Vostner, A. Mechanical properties of high manganese austenitic stainless steel JK2LB for ITER central solenoid jacket material. In Proceedings of the 25th International Cryogenic Engineering Conference and International Cryogenic Materials Conference 2014, Enschede, The Netherlands, 7–11 July 2014; Volume 67, pp. 1016–1021. [Google Scholar] [CrossRef]

- Sgobba, S.; Dalin, J.-M.; Libeyre, P.; Marcinek, D.J.; Nyilas, A. Progress in Production and Qualification of Stainless Steel Jacket Material for the Conductor of the ITER Central Solenoid. IEEE Trans. Appl. Supercond. 2012, 22, 7800104. [Google Scholar] [CrossRef]

- Sgobba, S.; Libeyre, P.; Marcinek, D.J.; Nyilas, A. A comparative assessment of metallurgical and mechanical properties of two austenitic stainless steels for the conductor jacket of the ITER Central Solenoid. Fusion Eng. Des. 2013, 88, 2484–2487. [Google Scholar] [CrossRef]

- Walsh, R.P.; Han, K.; Toplosky, V.J.; Martovetsky, N.N.; Mann, T.L., Jr.; Miller, J.R. Mechanical Properties of Modified JK2LB for Nb3sn CICC Applications. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2010; Volume 1219, pp. 17–24. [Google Scholar] [CrossRef]

- Feng, J.; Kim, J.; Ballinger, R.G.; Minervini, J.V. Mechanical Properties of JK2LB at 4K. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2006; Volume 824, pp. 192–199. [Google Scholar] [CrossRef]

- Hamada, K.; Nakajima, H.; Kawano, K.; Takano, K.; Tsutsumi, F.; Seki, S.; Okuno, K.; Fujitsuna, N.; Mizoguchi, M. Demonstration of JK2LB jacket fabrication for ITER Central Solenoid. IEEE Trans. Appl. Supercond. 2006, 16, 787–790. [Google Scholar] [CrossRef]

- Ozeki, H.; Saito, T.; Kawano, K.; Takahashi, Y.; Nunoya, Y.; Yamazaki, T.; Isono, T. Effect of Change of Aging Heat Treatment Pattern on the JK2LB Jacket for the ITER Central Solenoid. Phys. Procedia. 2015, 67, 1010–1015. [Google Scholar] [CrossRef][Green Version]

- Nakajima, H.; Hamada, K.; Takano, K.; Okuno, K.; Fujitsuna, N. Development of low carbon and boron added 22Mn-13Cr-9Ni-1Mo-0.24N steel (JK2LB) for jacket which undergoes Nb/sub 3/Sn heat treatment. IEEE Trans. Appl. Supercond. 2004, 14, 1145–1148. [Google Scholar] [CrossRef]

- Hamada, K.; Nakajima, H.; Kawano, K.; Takano, K.; Tsutsumi, F.; Okuno, K.; Suzuki, T.; Fujitsuna, N. Optimization of JK2LB chemical composition for ITER Central Solenoid conduit material. Cryogenics 2007, 47, 174–182. [Google Scholar] [CrossRef]

- Ishio, K.; Nakajima, H.; Kawasaki, T.; Uehara, S.; Shimamoto, S. Mechanical properties of 110mm thick hot rolled plates of JJ1 and JK2 for ITER TF coil. Proc. Inter. Conf. Magnet Tech. 1997, 989–992. Available online: https://jopss.jaea.go.jp/search/servlet/search?2001518&language=1 (accessed on 10 October 2025).

- Libeyre, P.; Mitchell, N.; Bessette, D.; Gribov, Y.; Jong, C.; Lyraud, C. Detailed design of the ITER central solenoid. Fusion Eng. Design 2009, 84, 1188–1191. [Google Scholar] [CrossRef]

- Walsh, R.P.; McRae, D.M.; Han, K.; Martovetsky, N.N. Tensile and fatigue qualification testing of ITER-CS conduit alloy JK2LB. IOP Conf. Ser. Mater. Sci. Eng. 2015, 102, 012002. [Google Scholar] [CrossRef]

- Lu, J.; Walsh, R.P.; Han, K. Low temperature physical properties of a high Mn austenitic steel JK2LB. Cryogenics 2009, 49, 133–137. [Google Scholar] [CrossRef]

- Takahashi, Y.; Suwa, T.; Nabara, Y.; Ozeki, H.; Hemmi, T.; Nunoya, Y.; Isono, T.; Matsui, K.; Kawano, K.; Oshikiri, M.; et al. Non-Destructive Examination of Jacket Sections for ITER Central Solenoid Conductors. IEEE Trans. Appl. Supercond. 2015, 25, 1–4. [Google Scholar] [CrossRef]

- Ozeki, H.; Hamada, K.; Takahashi, Y.; Nunoya, Y.; Kawano, K.; Oshikiri, M.; Saito, T.; Teshima, O.; Matsunami, M. Establishment of Production Process of JK2LB Jacket Section for ITER CS. IEEE Trans. Appl. Supercond. 2014, 24, 1–4. [Google Scholar] [CrossRef]

- Lim, B.; Simon, F.; Ilyin, Y.; Gung, C.Y.; Smith, J.; Hsu, Y.H.; Luongo, C.; Jong, C.; Mitchell, N. Design of the ITER PF Coils. IEEE Trans. Appl. Supercond. 2011, 21, 1918–1921. [Google Scholar] [CrossRef]

- Qin, J.; Weiss, K.-P.; Wu, Y.; Wu, Z.; Li, L.; Liu, S. Fatigue tests on the ITER PF jacket. Cryogenics 2012, 52, 486–490. [Google Scholar] [CrossRef]

- Liu, H.J.; Wu, Y.; Han, Q.Y.; Wu, Z.X.; Li, L.F. Mechanical tests on the ITER PF 316L jacket after compaction. Cryogenics 2011, 51, 234–236. [Google Scholar] [CrossRef]

- Huang, C.; Huang, R.; Li, L. Mechanical property tests on structural materials for ITER magnet system at low temperatures in China. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2014; Volume 1574, pp. 346–353. [Google Scholar] [CrossRef]

- Liu, X.; Wu, Y.; Qin, J.; Li, L.; Deng, M.; Wang, W.; Pedrosa, N.M.; Sousa, J.P.; Vostner, A.; Devred, A. Developments of Nondestructive Test Method of Jacket Section for ITER Poloidal Field Coils. IEEE Trans. Appl. Supercond. 2016, 26, 1–4. [Google Scholar] [CrossRef]

- Peng, J.; Wu, Y.; Liu, H.; Shi, Y.; Chen, J.; Ren, Z. The cryogenic system for ITER CC superconducting conductor test facility. Cryogenics 2011, 51, 62–67. [Google Scholar] [CrossRef]

- Qin, J.; Weiss, K.-P.; Wu, Y.; Liao, G.; Wu, Z.; Li, L.; Li, H.; Niu, E. Mechanical test on the ITER CC and Feeder jacket. Fusion Eng. Des. 2013, 88, 151–155. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar] [CrossRef]

- Mitchell, N.; Alekseev, A.; Gallix, R.; Holland, D.; Meyder, R.; Panin, A.; Shimada, M.; Wong, F.; Zapretelina, E. Magnet Safety Assessment for ITER. J. Fusion Energy 1997, 16, 25–35. [Google Scholar] [CrossRef]

- Wong, F.M.G.; Mitchell, N.A. Selection of Tokamak Toroidal Field Coil Case Structural Materials. In Advances in Cryogenic Engineering Materials; Balachandran, U.B., Gubser, D.G., Hartwig, K.T., Reed, R.P., Warnes, W.H., Bardos, V.A., Eds.; Springer: Boston, MA, USA, 1998; pp. 65–72. [Google Scholar] [CrossRef]

- Iguchi, M.; Sakurai, T.; Nakhira, M.; Koizumi, N.; Nakajima, H. Cryogenic Structural Materials of the ITER Toroidal Field Coil Structure. In Fourth International Workshop on Structural Materials for Innovative Nuclear Systems (SMINS-4); The Nuclear Energy Agency: Paris, France, 2017. [Google Scholar]

- Iguchi, M.; Sakurai, T.; Hisashige, T.; Nakahira, M. Evaluation of Mass Production Results of Cryogenic Structural Stainless Steels for ITER Toroidal Field Coils. IEEE Trans. Appl. Supercond. 2022, 32, 1–5. [Google Scholar] [CrossRef]

- Iguchi, M.; Saito, T.; Kawano, K.; Takano, K.; Tsutsumi, F.; Chida, Y.; Nakajima, H. Estimation of Tensile Strengths at 4K of 316LN Forging and Hot Rolled Plate for the ITER Toroidal Field Coils. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2012; Volume 1435, pp. 70–77. [Google Scholar] [CrossRef]

- Iguchi, M.; Saito, T.; Kawano, K.; Chida, Y.; Nakajima, H.; Ogawa, T.; Katayama, Y.; Ogata, H.; Minemura, T.; Tokai, D.; et al. Mechanical properties of full austenitic welding joint at cryogenic temperature for the ITER toroidal field coil structure. Fusion Eng. Des. 2013, 88, 2520–2524. [Google Scholar] [CrossRef]

- Ishio, K.; Nakajima, H.; Nunoya, Y.; Miura, Y.; Kawasaki, T.; Tsuji, H. Trial Fabrication of Heavy Section Base Metals and Welded Joints for ITER TF Coil. In Advances in Cryogenic Engineering Material; Balachandran, U.B., Gubser, D.G., Hartwig, K.T., Reed, R.P., Warnes, W.H., Bardos, V.A., Eds.; Springer: Boston, MA, USA, 1998; pp. 73–80. [Google Scholar] [CrossRef]

- Onozuka, M.; Shimizu, K.; Urata, K.; Kimura, M.; Kadowaki, H.; Okamoto, M.; Nakajima, H.; Hamada, K.; Okuno, K. Basic analysis of weldability and machinability of structural materials for ITER Toroidal Field coils. Fusion Eng. Des. 2007, 82, 1431–1436. [Google Scholar] [CrossRef]

- Shindo, Y.; Kobori, T.; Horiguchi, K.; Yamada, E.; Nakajima, H.; Tsuji, H. Fracture toughness and temperature rise during crack propagation in forged JJ1 type austenitic stainless steel plate at 4.2 K. Nippon. Kinzoku Gakkaishi (J. Jpn. Inst. Met.) 1995, 59, 793–798. [Google Scholar][Green Version]

- Shindo, Y.; Takahashi, T.; Horiguchi, K.; Sanada, K.; Kobori, T. Cryogenic fracture toughness and temperature rise of thick section weldments in forged JJ1 type austenitic stainless steel plate. Weld. Int. 1998, 12, 360–365. [Google Scholar] [CrossRef]

- Hamada, K.; Nakajima, H.; Kawano, K.; Takano, K.; Tsutsumi, F.; Okuno, K. Demonstration of full scale JJ1 and 316LN fabrication for ITER TF coil structure. Fusion Eng. Des. 2007, 82, 1481–1486. [Google Scholar] [CrossRef]

- Hamada, K.; Nakajima, H.; Takano, K.; Kudo, Y.; Tsutsumi, F.; Okuno, K.; Jong, C. Fatigue assessment of the ITER TF coil case based on JJ1 fatigue tests. Fusion Eng. Des. 2005, 75, 87–91. [Google Scholar] [CrossRef]

- Fang, C.; Song, Y.; Wei, J.; Xin, J.; Wu, H.; Handroos, H.; Salminen, A.; Li, H.; Libeyre, P.; Dolgetta, N. Microstructural characteristics of the laser welded joint of ITER correction coil sub case. Fusion Eng. Des. 2015, 98–99, 1960–1963. [Google Scholar] [CrossRef]

- Foussat, A.; Wu, W.; Li, H.; Dolgetta, N.; Libeyre, P.; Mitchell, N. Qualification Phase of Key Technologies for ITER Correction Coils. IEEE Trans. Appl. Supercond. 2012, 22, 4201205. [Google Scholar] [CrossRef]

- Xin, J.; Fang, C.; Song, Y.; Wei, J.; Huang, C.; Libeyre, P.; Simon, F.; Sgobba, S. Microstructure and Mechanical Properties of ITER Correction Coil Case Material. IEEE Trans. Appl. Supercond. 2017, 27, 1–8. [Google Scholar] [CrossRef]

- Foussat, A.; Wu, W.; Jing, W.; Du, S.; Sgobba, S.; Li, H.; Libeyre, P.; Jong, C.; Klofac, K.; Mitchell, N. Mechanical design and construction qualification program on ITER correction coils structures. Nucl. Eng. Des. 2014, 269, 116–124. [Google Scholar] [CrossRef][Green Version]

- Wei-yue, W. Structure analysis of correction coils for ITER. Nucl. Fusion Plasma Phys. 2009, 29, 264. [Google Scholar][Green Version]

- Foussat, A.; Dolgetta, N.; Jong, C.; Libeyre, P.; Mitchell, N.; Wu, W.; Liu, L.; Du, S.; Liu, X.; Yu, X.; et al. From Design to Development Phase of the ITER Correction Coils. IEEE Trans. Appl. Supercond. 2011, 21, 1960–1963. [Google Scholar] [CrossRef]

- Foussat, A.; Libeyre, P.; Mitchell, N.; Gribov, Y.; Jong, C.T.J.; Bessette, D.; Gallix, R.; Bauer, P.; Sahu, A. Overview of the ITER Correction Coils Design. IEEE Trans. Appl. Supercond. 2010, 20, 402–406. [Google Scholar] [CrossRef]

- Fang, C.; Song, Y.; Wu, W.; Wei, J.; Zhang, S.; Li, H.; Dolgetta, N.; Libeyre, P.; Cormany, C.; Sgobba, S. The Laser Welding with Hot Wire of 316LN Thick Plate Applied on ITER Correction Coil Case. J. Fusion Energy 2014, 33, 752–758. [Google Scholar] [CrossRef]

- Huang, C.; Xin, J.; Wei, J.; Zhang, H.; Huang, R.; Xu, D.; Liu, S.; Li, L. Assessment of Mechanical Properties of Welding Joints for ITER Correction Coils Cases at Cryogenic Temperature. IEEE Trans. Appl. Supercond. 2021, 31, 1–5. [Google Scholar] [CrossRef]

- Zhou, Z.; Wu, W.; Wei, J.; Du, S.; Han, S.; Liu, L.; Yu, X.; Li, H.; Foussat, A.; Libeyre, P. Research on Manufacture and Enclosure Welding of ITER Correction Coils Cases. IEEE Trans. Appl. Supercond. 2012, 22, 4202603. [Google Scholar] [CrossRef]

- De Cooman, B.C. 11-High Mn TWIP steel and medium Mn steel. In Automotive Steels; Rana, R., Singh, S.B., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 317–385. [Google Scholar] [CrossRef]

- Lu, J.; Hultman, L.; Holmström, E.; Antonsson, K.H.; Grehk, M.; Li, W.; Vitos, L.; Golpayegani, A. Stacking fault energies in austenitic stainless steels. Acta Mater. 2016, 111, 39–46. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.T. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater. 2010, 58, 5129–5141. [Google Scholar] [CrossRef]

- Shimamoto, S.; Nakajima, H.; Yoshida, K.; Tada, E. Requirements for Structural Alloys for Superconducting Magnet Cases. In Advances in Cryogenic Engineering Materials; Reed, R.P., Clark, A.F., Eds.; Springer: Boston, MA, USA, 1986; pp. 23–32. [Google Scholar] [CrossRef]

- Umezawa, O. Review of the Mechanical Properties of High-Strength Alloys at Cryogenic Temperatures. Mater. Perform. Charact. 2021, 10, 20200138. [Google Scholar] [CrossRef]

- Nakajima, H.; Yoshida, K.; Shimamoto, S. Development of the Fusion of New Cryogenic Steels Experimental Reactor for the Superconducting Magnets. ISIJ Int. 2001, 30, 567–578. [Google Scholar] [CrossRef]

- Hwang, I.S.; Ballinger, R.G.; Morra, M.M.; Steeves, M.M. Mechanical Properties of Incoloy 908—An Update. In Materials; Fickett, F.R., Reed, R.P., Eds.; Springer: Boston, MA, USA, 1992; pp. 1–10. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, C.; Jin, J.; Shi, J.; Tu, Z.; Chen, X.; Huang, C.; Li, L.; Li, J.; Qin, J. The research on high-strength CICC jackets with YS > 1500 MPa at 4.2 K for future fusion applications. Nucl. Mater. Energy 2023, 36, 101474. [Google Scholar] [CrossRef]

- Yong-Hwan, K.; Sang-He, K.; Young-Hwan, K.; Han-Sung, K.; Kie-Hyung, C. Mechanical analysis of the KSTAR CS model coil. IEEE Trans. Appl. Supercond. 1999, 9, 228–231. [Google Scholar] [CrossRef]

- Lim, B.S.; Lee, S.-I.; Kim, K.; Choi, J.Y. Fabrication of the KSTAR superconducting CICC. IEEE Trans. Appl. Supercond. 2002, 12, 591–594. [Google Scholar] [CrossRef]

- Libeyre, P.; Brosset, C.; Decool, P.; Rubino, M.; Bevilacqua, G.; Laurenti, A.; Pesenti, P.; Ursuleac, M.; Valle, N.; Nyilas, A. Risks and benefits of Incoloy 908. Fusion Eng. Des. 2001, 58–59, 129–134. [Google Scholar] [CrossRef]

- Okano, K.; Kasada, R.; Ikebe, Y.; Ishii, Y.; Oba, K.; Kashiwagi, M.; Sakamoto, R.; Sawa, N.; Takenaga, H.; Nishimura, A.; et al. An action plan of Japan toward development of demo reactor. Fusion Eng. Des. 2018, 136, 183–189. [Google Scholar] [CrossRef]

- Tobita, K.; Utoh, H.; Hiwatari, R.; Miyoshi, Y.; Tokunaga, S.; Sakamoto, Y.; Someya, Y.; Asakura, N.; Homma, Y.; Nakajima, N.; et al. Conceptual design of Japan’s fusion DEMO reactor (JADEMO) and superconducting coil issues. J. Phys. Conf. Ser. 2019, 1293, 012078. [Google Scholar] [CrossRef]

- Nakajima, H.; Yoshida, K.; Shimamoto, S. Development of New Cryogenic Steels for the Superconducting Magnets of the Fusion Experimental Reactor. ISIJ Int. 1990, 30, 567–578. [Google Scholar] [CrossRef]

- Nakajima, H.; Takano, K.; Tsutsumi, F.; Kawano, K.; Hamada, K.; Okuno, K. Qualification of Cryogenic Structural Materials for the ITER Toroidal Field Coils. In Proceedings of the ASME 2009 Pressure Vessels and Piping Conference, Prague, Czech Republic, 26–30 July 2009; pp. 789–797. [Google Scholar] [CrossRef]

- Nakajima, H.; Hamada, K.; Okuno, K.; Hada, K.; Tada, E. New cryogenic material and design for ITER superconducting magnet system. In Proceedings of the 10th International Conference on Nuclear Engineering, Arlington, VA, USA, 14–18 April 2002; pp. 591–598. [Google Scholar]

- Utoh, H.; Sakamoto, Y.; Miura, H.; Arakawa, H.; Echizenya, D.; Matsuda, T.; Hasegawa, M.; Nomoto, K. Design study of superconducting coil system for JA DEMO. Fusion Eng. Des. 2024, 202, 114345. [Google Scholar] [CrossRef]

- Zhuang, G.; Li, G.Q.; Li, J.; Wan, Y.X.; Liu, Y.; Wang, X.L.; Song, Y.T.; Chan, V.; Yang, Q.W.; Wan, B.N.; et al. Progress of the CFETR design. Nucl. Fusion. 2019, 59, 112010. [Google Scholar] [CrossRef]

- Yao, C.; Ma, Y. Superconducting materials: Challenges and opportunities for large-scale applications. iScience. 2021, 24, 102541. [Google Scholar] [CrossRef]

- Zheng, J.; Song, Y.; Liu, F.; Liu, X.; Lu, K.; Zhu, L.; Xu, W.; Shen, G.; Fang, C.; Li, C.; et al. Progress in engineering design of CFETR toroidal field superconducting magnet. Fusion Eng. Des. 2022, 177, 113063. [Google Scholar] [CrossRef]

- Langeslag, S.A.E.; Sgobba, S.; Libeyre, P.; Marcinek, D.J.; Zhang, Z. Extensive characterisation of advanced manufacturing solutions for the ITER Central Solenoid pre-compression system. Fusion Eng. Des. 2015, 98–99, 2015–2019. [Google Scholar] [CrossRef]

- McRae, D.M.; Walsh, R.P.; Dalder, E.N.C.; Litherland, S.; Trosen, M.; Kuhlmann, D.J. Fatigue and fracture properties of a super-austenitic stainless steel at 295 K and 4 K. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2014; Volume 1574, pp. 59–66. [Google Scholar] [CrossRef]

- Libeyre, P.; Cormany, C.; Dolgetta, N.; Gaxiola, E.; Jong, C.; Lyraud, C.; Reiersen, W.; Everitt, D.; Martovetsky, N.; Rosenblad, P.; et al. Status of design and manufacturing of the ITER Central Solenoid and Correction Coils. In Proceedings of the 2015 IEEE 26th Symposium on Fusion Engineering (SOFE), Austin, TX, USA, 31 May–4 June 2015; pp. 1–8. [Google Scholar] [CrossRef]

- Zhai, R.; Zhang, H.; Xu, B.; Liu, S.; Xie, B.; Sun, M. Elimination of δ-ferrite in N50 steel and its effect on cryogenic mechanical properties. Cryogenics 2022, 126, 103522. [Google Scholar] [CrossRef]

- Zhai, R.; Zhang, H.; Liu, S.; Sun, M.; Sheng, S.; Xu, B. Influence of carbon content on the microstructure and cryogenic tensile properties of N50 austenitic stainless steel after aging treatment. J. Nucl. Mater. 2022, 571, 154023. [Google Scholar] [CrossRef]

- Zhai, R.; Zhang, H.; Pan, S.; Xu, B.; Liu, S.; Sun, M. Effect of boron addition on the microstructure and cryogenic mechanical properties of N50 stainless steel after aging treatment. Mater. Sci. Eng. A. 2023, 881, 145372. [Google Scholar] [CrossRef]

- Zhai, R.; Zhang, H.; Qi, X.; Wang, W.; Chen, X.; Xu, B.; Sun, M. Fabrication and performance evaluation of CICC jacket based on modified N50 austenitic steel for CFETR magnet. J. Mater. Res. Technol. 2024, 28, 3435–3448. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, C.; Jin, H.; Huang, C.; Li, L.; Tu, Z.; Xu, B.; Zhai, R.; Li, J.; Qin, J. Mechanical properties evaluation of ReBCO CICC jacket based on super-austenitic stainless steel for CFETR high-field magnet. Nucl. Mater. Energy. 2023, 34, 101344. [Google Scholar] [CrossRef]

- Dai, J.; Xie, L.; Wang, W.; Xin, J.; Li, B.; Bao, R.; Huang, Y.; Huang, C.; Sun, W.; Wang, W.; et al. Evaluation of localized mechanical properties of modified N50 welded joints at cryogenic temperature through a digital image correlation technique. Cryogenics 2024, 143, 103960. [Google Scholar] [CrossRef]

- Pan, B. Recent Progress in Digital Image Correlation. Exp. Mech. 2011, 51, 1223–1235. [Google Scholar] [CrossRef]

- Zhang, B.; Bao, R.; Dai, J.; Sun, W.; Huang, C.; Shi, L.; Zhao, Y.; Zhou, H.; Zheng, W.; Li, L.; et al. Recognition of fracture stages of CHN01 austenitic stainless steel by acoustic emission at cryogenic temperature. Cryogenics 2025, 150, 104154. [Google Scholar] [CrossRef]

- Moorthy, V.; Jayakumar, T.; Raj, B. Acoustic emission behaviour during stage II fatigue crack growth in an AISI type 316 austenitic stainless steel. Bull. Mater. Sci. 1994, 17, 699–715. [Google Scholar] [CrossRef]

- Sawan, H.A.; Walter, M.E.; Marquette, B. Unsupervised learning for classification of acoustic emission events from tensile and bending experiments with open-hole carbon fiber composite samples. Compos. Sci. Technol. 2015, 107, 89–97. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R.E. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Seol, J.B.; Bae, J.W.; Kim, J.G.; Sung, H.; Li, Z.; Lee, H.H.; Shim, S.H.; Jang, J.H.; Ko, W.-S.; Hong, S.I.; et al. Short-range order strengthening in boron-doped high-entropy alloys for cryogenic applications. Acta. Mater. 2020, 194, 366–377. [Google Scholar] [CrossRef]

- Uranga, P.; Shang, C.J.; Senuma, T.; Yang, J.R.; Guo, A.M.; Mohrbacher, H. Molybdenum alloying in high-performance flat-rolled steel grades. Adv. Manuf. 2020, 8, 15–34. [Google Scholar] [CrossRef]

- Miyazaki, T.; Sasaki, T. X-Ray Residual Stress Measurement of Austenitic Stainless Steel Based on Fourier Analysis. Nucl. Technol. 2016, 194, 111–116. [Google Scholar] [CrossRef]

- Kim, J.S.; Kim, M.W.; Yang, J.S. Investigation on effect of thermal aging embrittlement on residual stresses of austenitic stainless steel repair welds in nuclear components subject to seismic loads. J. Mech. Sci. Technol. 2020, 34, 2821–2831. [Google Scholar] [CrossRef]

- Weng, Z.; Gu, K.; Wang, K.; Liu, X.; Wang, J. The reinforcement role of deep cryogenic treatment on the strength and toughness of alloy structural steel. Mater. Sci. Eng. A 2020, 772, 138698. [Google Scholar] [CrossRef]

- Weng, Z.; Liu, X.; Gu, K.; Guo, J.; Cui, C.; Wang, J. Modification of residual stress and microstructure in aluminium alloy by cryogenic treatment. Mater. Sci. Technol. 2020, 36, 1547–1555. [Google Scholar] [CrossRef]

- Kalia, S. Cryogenic Processing: A Study of Materials at Low Temperatures. J. Low Temp. Phys. 2010, 158, 934–945. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Muñoz-Escalona, P.; Newman, S.T. State-of-the-art cryogenic machining and processing. Int. J. Comput. Integr. Manuf. 2013, 26, 616–648. [Google Scholar] [CrossRef]

- Cui, C.; Gu, K.; Qiu, Y.; Weng, Z.; Zhang, M.; Wang, J. The effects of post-weld aging and cryogenic treatment on self-fusion welded austenitic stainless steel. J. Mater. Res. Technol. 2022, 21, 648–661. [Google Scholar] [CrossRef]

- Cui, C.; Weng, Z.; Gu, K.; Zhang, M.; Wang, J.; Zhang, Y. The strengthening role of post-welded cryogenic treatment on the performance and microstructure of 304 austenitic stainless steel weldments. J. Mater. Res. Technol. 2024, 29, 5576–5584. [Google Scholar] [CrossRef]

| Steps | Experiments | Requirements | Number of Test Steels at 4.2 K | Time | ||||

|---|---|---|---|---|---|---|---|---|

| ASS | HMASS | HMSS | FS | Total | ||||

| 1 | Tensile | Rp0.2 ≥ 1200 MPa and CVN ≥ 100 J | 31 | 40 | 14 | 4 | 89 | 1982 |

| 2 | Charpy Impact | 31 | 35 | 12 | 3 | 81 | 1984 | |

| Next candidate materials | 10 | 12 | 22 | 1986 | ||||

| 3 | Fracture toughness | KIc ≥ 200 MPa·m1/2 | 10 | 12 | 22 | 1988 | ||

| 4 | Fatigue properties | ~316LN | 3 | 2 | 5 | 1990 | ||

| ITER candidate materials | 1 | 1 | 2 | |||||

| JCS | C | Si | Mn | P | S | Ni | Cr | Mo | N | Cu | V |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CSUS-JN1 | 0.026 | 0.99 | 4.2 | 0.026 | 0.002 | 14.74 | 24.2 | 0.34 | 0.70 | 0.30 | |

| CSUS-JKA1 | 0.023 | 0.42 | 0.49 | 0.006 | 0.001 | 14.0 | 25.0 | 0.68 | 0.268 | ||

| CSUS-JN2 | 0.050 | 0.34 | 22.4 | 0.010 | 0.002 | 3.22 | 13.4 | 0.70 | 0.24 | ||

| CSUS-JK2 | 0.05 | 0.36 | 21.79 | 0.013 | 0.005 | 4.94 | 12.82 | 0.212 | |||

| CSUS-JJ1 | 0.046 | 0.44 | 9.74 | 0.020 | 0.002 | 11.92 | 12.21 | 4.89 | 0.203 |

| Fe | Ni | Cr | Nb | Ti | Al | N | Mn | C | Co |

|---|---|---|---|---|---|---|---|---|---|

| 40.7 | 49 | 3.98 | 2.92 | 1.74 | 0.93 | 0.002 | 0.041 | 0.01 | <0.1 |

| Yield Strength (Rp0.2) (MPa) | Tensile Strength (Rm) (MPa) | Young’s Modulus (E) (GPa) | Elongation (e) (%) | Fracture Toughness (KIc) (MPa·m1/2) | |

|---|---|---|---|---|---|

| 4.2 K | 1216 | 1694 | 177 | 22 | 196 |

| 300 K | 1110 | 1302 | 171 | 22 | 196 |

| ITER | JA-DEMO | |

|---|---|---|

| SC Strand | Nb3Sn | Nb3Sn |

| Number of TFC | 18 | 16 |

| Bmax | 11.8 T | 13.9 T |

| Conductor current | 68 kA | 83 kA |

| Number of turns per TFC | 134 | 192 |

| Design stress | 667 MPa | 800 MPa |

| Total magnetic energy | 41 GJ | 153 GJ |

| Width/Height of TFC | 8/12.6 m | 12/19 m |

| C | N | Cr | Ni | Mn | Mo | Nb | V | Si | |

|---|---|---|---|---|---|---|---|---|---|

| N50 (XM-19) | 0.058 | 0.30 | 23.23 | 13.5 | 4.81 | 2.08 | 0.22 | 0.25 | 0.67 |

| CHN01 | 0.008 | 0.31 | 22.3 | 14.6 | 5.18 | 2.1 | 0.09 | 0.19 | 0.30 |

| CHN01 Base Material | CHN01 Welded Joint | |||||

|---|---|---|---|---|---|---|

| 300 K | 77 K | 4.2 K | 300 K | 77 K | 4.2 K | |

| Yield strength (Rp0.2) (MPa) | 546.5 | 1193.5 | 1600.0 | 514.5 | 1103.0 | 1335.5 |

| Tensile strength (Rm) (MPa) | 776.0 | 1550.0 | 1930.0 | 699.5 | 1339.0 | 1622.5 |

| Young’s modulus (E) (GPa) | 184.0 | 196.5 | 215.5 | 218.5 | 185.0 | 219.5 |

| Elongation (e) (%) | 49.2 | 38.5 | 33.8 | 29.0 | 14.5 | 19.1 |

| Fracture toughness (K(J)Ic) (MPa·m1/2) | 264.5 | 209.0 | ||||

| Japan | United States | China | |||||

|---|---|---|---|---|---|---|---|

| Material | JK2LB | JJ1 | JN1 | Modified 316LN | INCOLOY 908 | Modified 316L | CHN01 |

| Application | ITER CS | ITER TF | JA-DEMO (Design) | ITER TF | CICC Test | ITER PF | CFETR (Design) |

| Development time | 2000s | 1990s | 2010s | 1990s | 1990s | 2010s | 2018 |

| Fracture toughness (MPa·m1/2) | 209 | 366 | 210 | 300 | 196 | 278 | 265 |

| Yield Strength (MPa) | 1076 | 1126 | 1288 | 1165 | 1216 | 797 | 1550 |

| Manufacturability | ◊◊◊ | ◊◊ | ◊◊ | ◊◊◊◊ | ◊ | ◊◊◊◊ | ◊◊ |

| Weldability |     |  |    |      |  |     |   |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, J.; Huang, C. Development of Cryogenic Structural Steels for Magnetic Confinement Fusion. Cryo 2025, 1, 13. https://doi.org/10.3390/cryo1040013

Dai J, Huang C. Development of Cryogenic Structural Steels for Magnetic Confinement Fusion. Cryo. 2025; 1(4):13. https://doi.org/10.3390/cryo1040013

Chicago/Turabian StyleDai, Jingjing, and Chuanjun Huang. 2025. "Development of Cryogenic Structural Steels for Magnetic Confinement Fusion" Cryo 1, no. 4: 13. https://doi.org/10.3390/cryo1040013

APA StyleDai, J., & Huang, C. (2025). Development of Cryogenic Structural Steels for Magnetic Confinement Fusion. Cryo, 1(4), 13. https://doi.org/10.3390/cryo1040013