Preparation of Gazpacho Assisted by Pulsed Electric Fields: A Preliminary Study

Abstract

1. Introduction

Gazpacho

2. Materials and Methods

2.1. Preparation of Gazpacho

2.2. PEF Pretreatment of Vegetables

2.3. Evaluation of Vegetable and Gazpacho Parameters After PEF Treatments

2.3.1. Vegetable Firmness

2.3.2. Water Holding Capacity (WHC) of Vegetables

2.3.3. Consistency of Tomato Juice and Gazpacho

2.3.4. Color Measurement

2.3.5. Sensory Analysis

2.4. Statistical Analysis

3. Results and Discussion

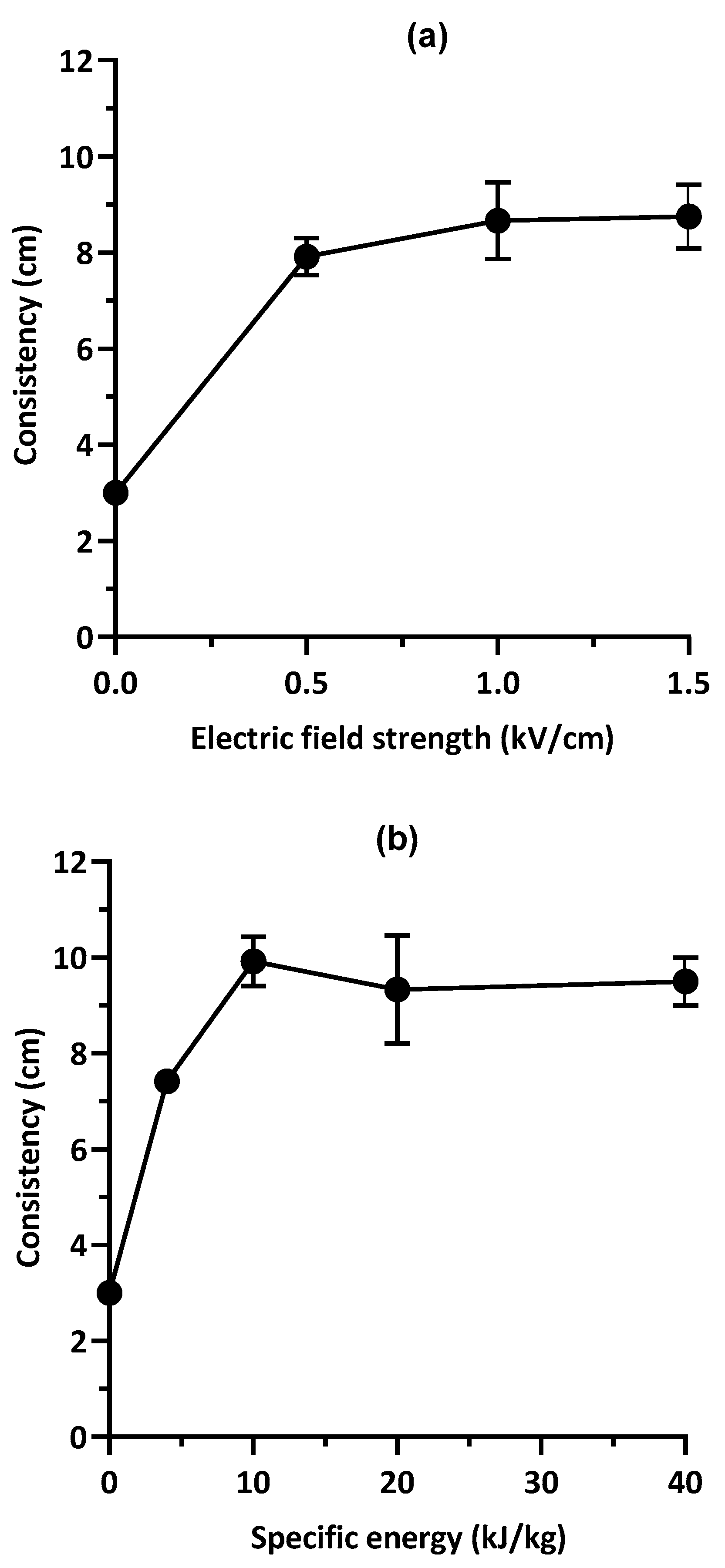

3.1. Influence of PEF Treatments on Cherry Tomato Juice Consistency

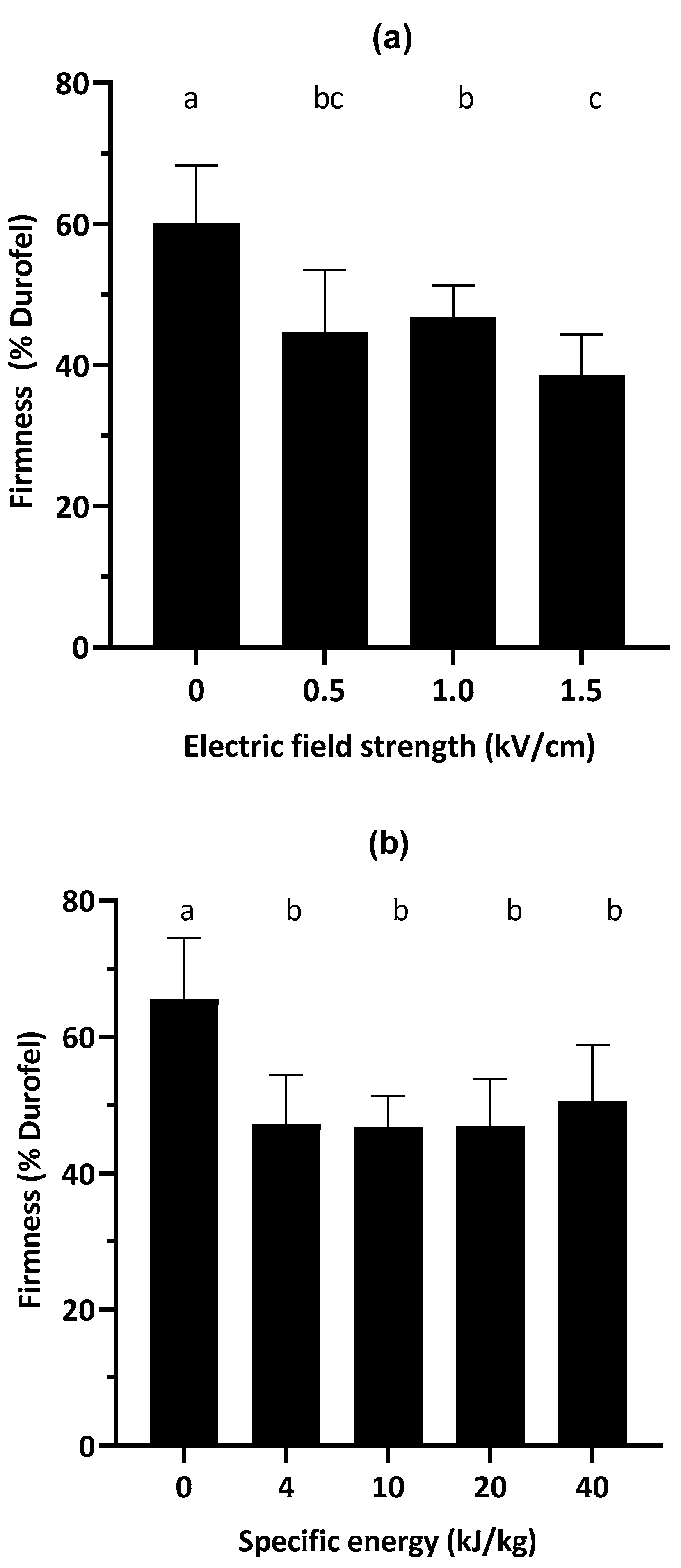

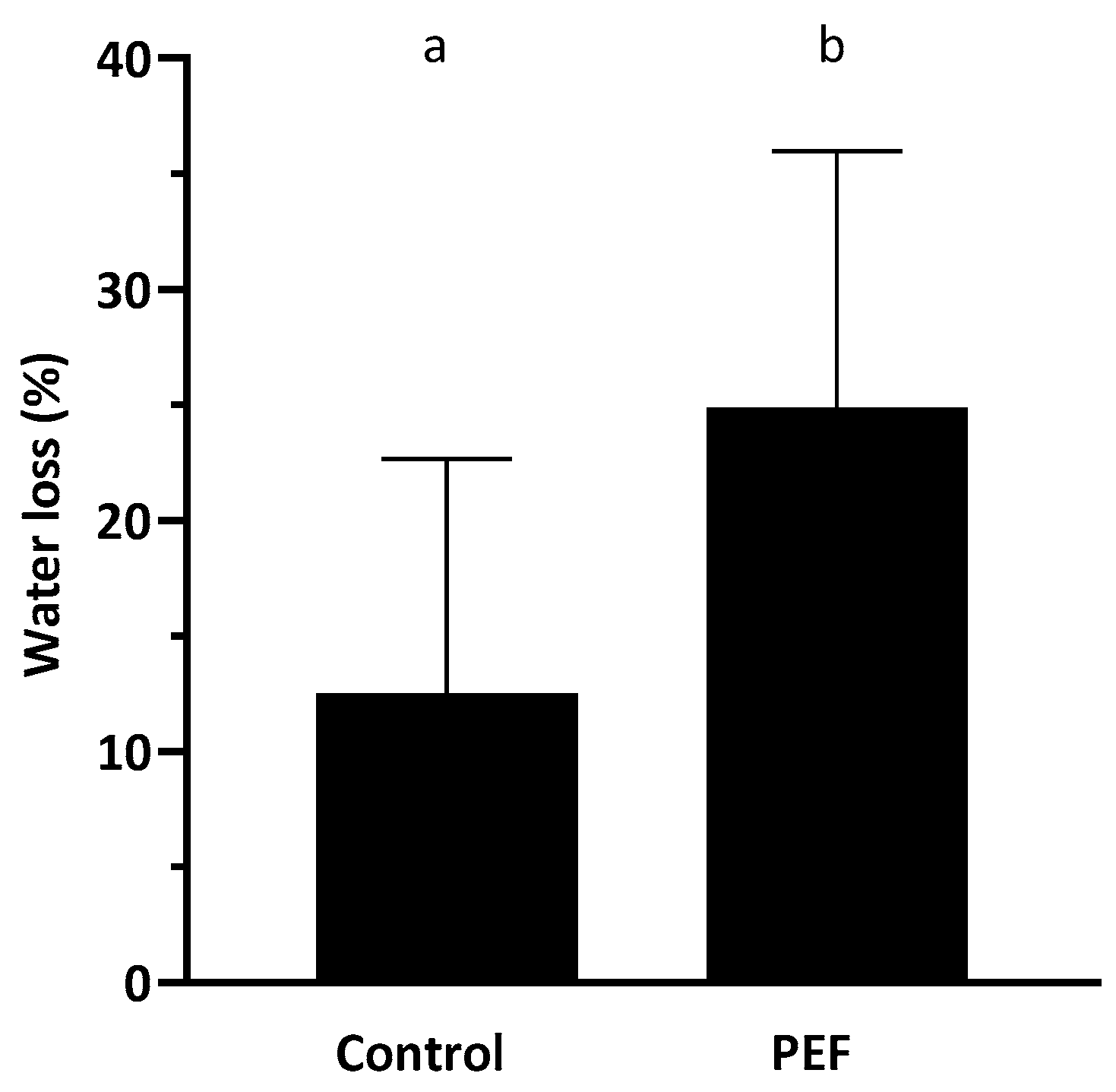

3.2. Influence of PEF Treatments on Cherry Tomatoes

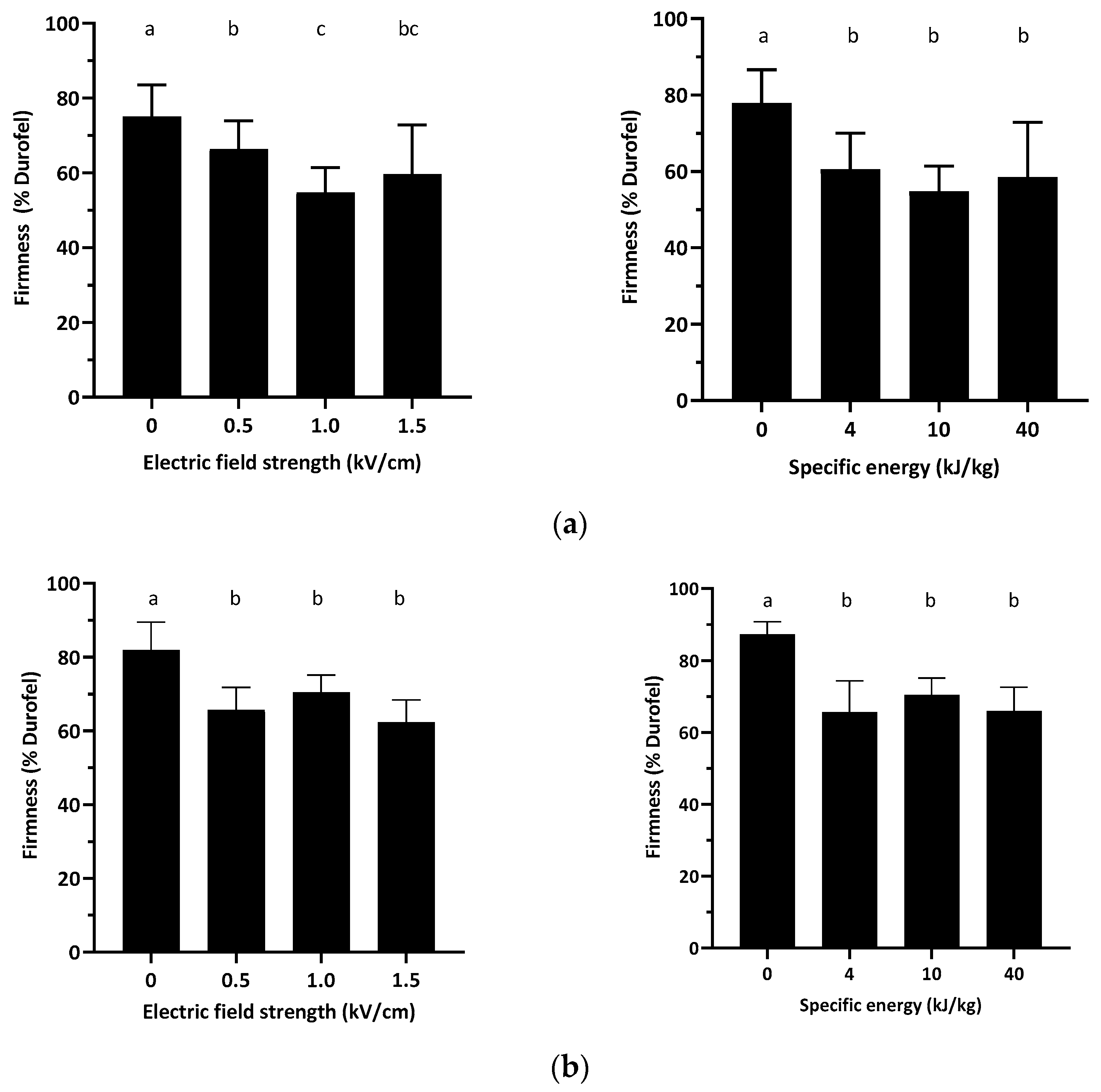

3.3. Effect of PEF on the Firmness of Red Pepper and Cucumber

3.4. Effect of PEF Gazpacho Characteristics

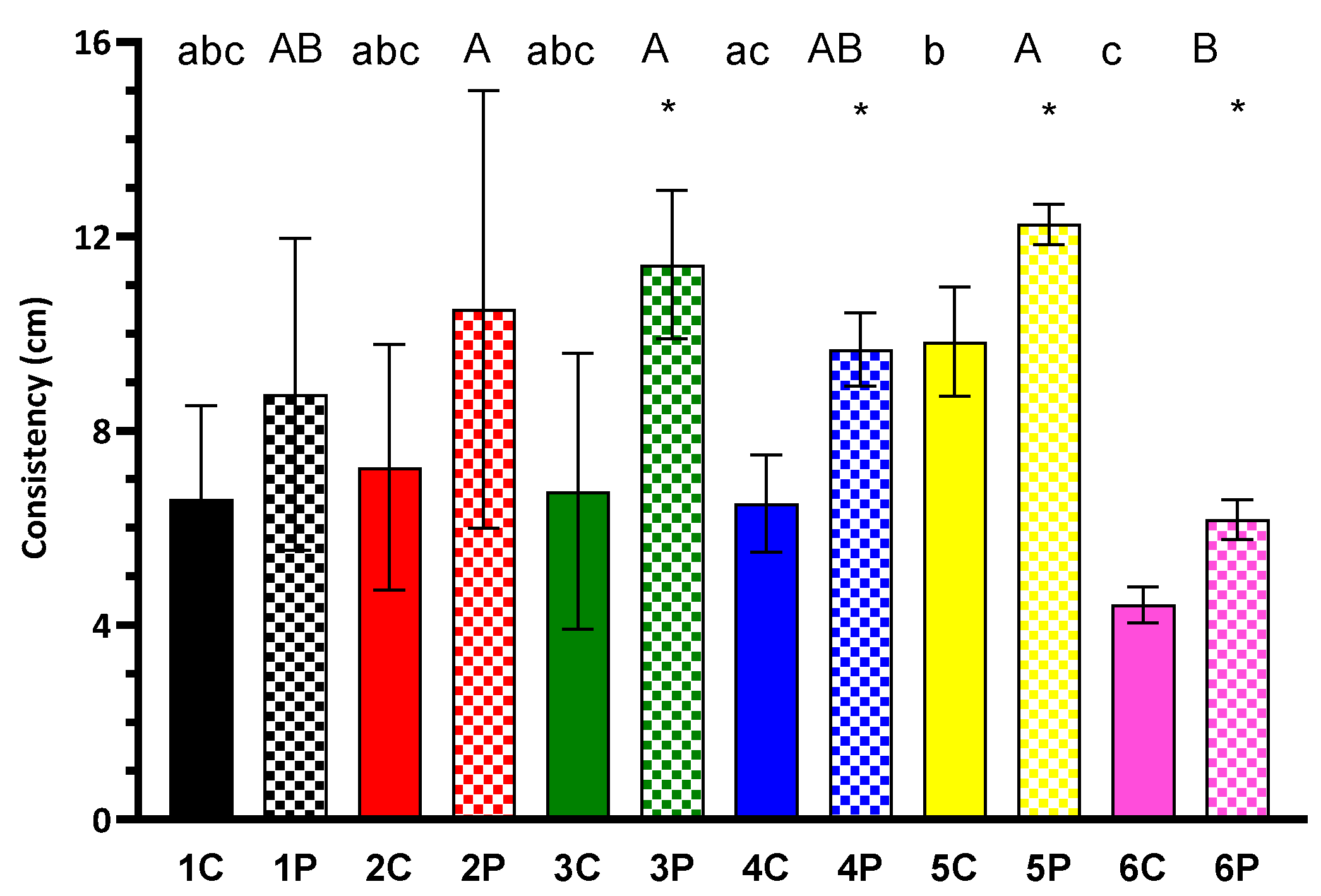

3.4.1. Consistency

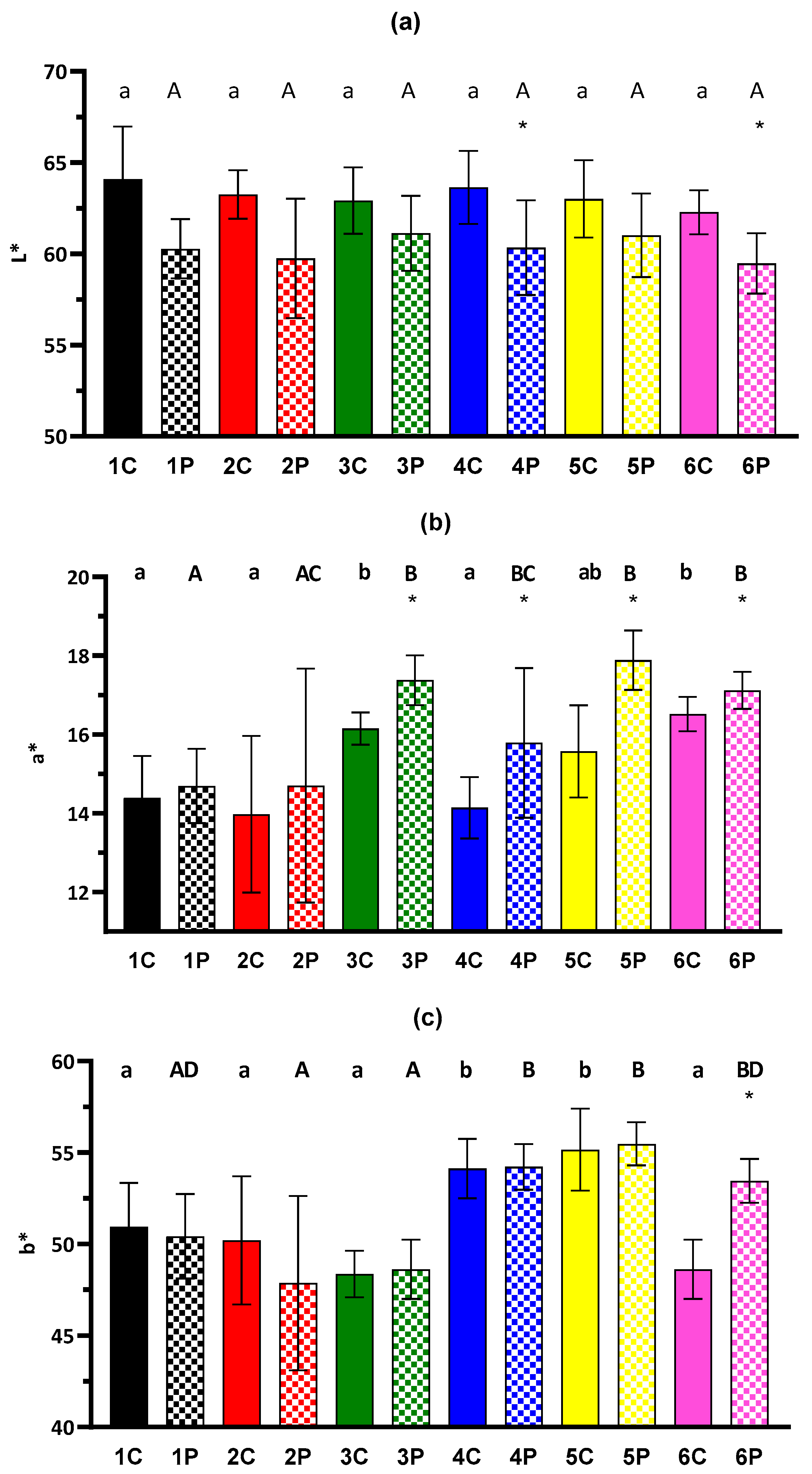

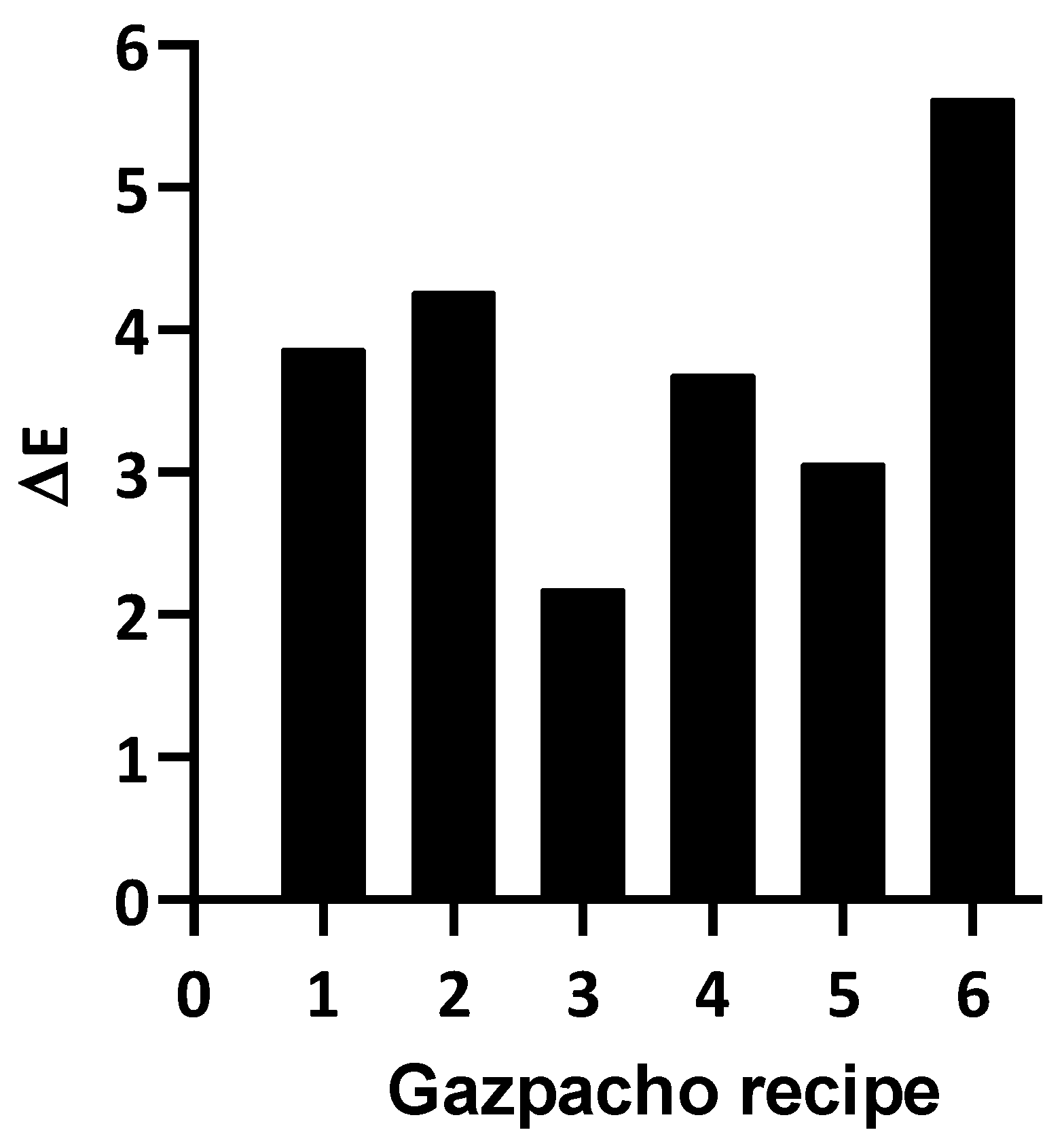

3.4.2. Color

3.4.3. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Agencia Española de Nutrición y Seguridad Alimentación (AESAN). Available online: https://www.consumo.gob.es/sites/consumo.gob.es/files/consumo_masinfo/Informe_Gazpacho.pdf (accessed on 29 April 2024).

- Ministerio de Agricultura, Pesca y Alimentación (MAPA). Available online: https://www.mapa.gob.es/es/prensa/ultimas-noticias/el-consumo-de-gazpacho-y-salmorejo-preparados-aumenta-un-101-en-2023-con-una-facturaci%C3%B3n-de-17896-millones-de-euros/tcm:30-658958 (accessed on 21 May 2024).

- Zumos y Gazpachos de España. Available online: https://www.zumosygazpachos.com/es/ (accessed on 14 May 2024).

- Elez-Martínez, P.; Soliva-Fortuny, R.; Martín-Belloso, O. Impact of high-intensity pulsed electric fields on bioactive compounds in Mediterranean plant-based foods. Nat. Prod. Commun. 2009, 4, 741–746. [Google Scholar] [CrossRef] [PubMed]

- Elez-Martínez, P.; Martín-Belloso, O. Effects of high intensity pulsed electric field processing conditions on vitamin C and antioxidant capacity of orange juice and gazpacho, a cold vegetable soup. Food Chem. 2007, 102, 201–209. [Google Scholar] [CrossRef]

- Plaza, L.; Sánchez-Moreno, C.; De Ancos, B.; Cano, M.P. Carotenoid content and antioxidant capacity of Mediterranean vegetable soup (gazpacho) treated by highpressure/ temperature during refrigerated storage. Eur. Food Res. Technol. 2006, 223, 210–215. [Google Scholar] [CrossRef]

- Devlieghere, F.; Vermeiren, L.; Debevere, J. New preservation technologies: Possibilities and limitations. Inter. Dairy J. 2004, 14, 273–285. [Google Scholar] [CrossRef]

- Raso, J.; Heinz, V.; Álvarez, I.; Toepfl, S. Pulsed Electric Fields Technology for the Food Industry, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Teissié, J.; Eynard, N.; Vernhes, M.C.; Bénichou, A.; Ganeva, V.; Galutzov, B.; Cabanez, P.A. Recent biotechnological developments of electropulsation. A prospective review. Bioelectrochem 2002, 55, 107–112. [Google Scholar] [CrossRef]

- Hill, K.; Ostermeier, R.; Töepfl, S.; Heinz, V. PEF in the Potato Industry. In Pulsed Electric Fields Technology for the Food Industry, 2nd ed.; Raso, J., Heinz, V., Alvarez, I., Toepfl, S., Eds.; Springer: Cham, Switzerland, 2022; pp. 325–335. [Google Scholar]

- Ignat, A.; Manzocco, L.; Brunton, P.N.; Nicoli, M.C.; Lyng, J.G. The effect of pulsed electric field pre-treatments prior to deep-fat frying on quality aspects of potato fries. Innov. Food Sci. Emerg. Technol. 2015, 29, 65–69. [Google Scholar] [CrossRef]

- Andreou, V.; Dimopoulos, G.; Dermesonlouoglou, E.; Taoukis, P. Application of pulsed electric fields to improve product yield and waste valorization in industrial tomato processing. J. Food Eng. 2020, 270, 109778. [Google Scholar] [CrossRef]

- Arnal, A.J.; Royo, P.; Pataro, G.; Ferrari, G.; Ferreira, V.J.; López-Sabirón, A.M.; Ferreira, G.A. Implementation of PEF Treatment at Real-Scale Tomatoes Processing Considering LCA Methodology as an Innovation Strategy in the Agri-Food Sector. Sustainability 2018, 10, 979. [Google Scholar] [CrossRef]

- Martínez-Beamonte, R.; Ripalda, M.; Herrero-Continente, T.; Barranquero, C.; Dávalos, A.; López de las Hazas, M.C.; Álvarez-Lanzarote, I.; Sánchez-Gimeno, A.C.; Raso, J.; Arnal, C.; et al. Pulsed electric field increases the extraction yield of extra virgin olive oil without loss of its biological properties. Front. Nutr. 2022, 9, 1065543. [Google Scholar] [CrossRef]

- Vorobiev, E.; Lebovka, N.I. Cell Membrane Permeabilization by PEF for Efficient Extraction of Intercellular Components from Foods. In Pulsed Electric Fields Technology for the Food Industry, 2nd ed; Raso, J., Heinz, V., Alvarez, I., Toepfl, S., Eds.; Springer: Cham, Switzerland, 2022; pp. 209–262. [Google Scholar]

- Zare, F.; Ghasemi, N.; Bansal, N.; Garg, A.; Hosano, H. Increasing the Production Yield of White Oyster Mushrooms With Pulsed Electric Fields. IEEE Trans. Plasma Sci. 2021, 49, 805–812. [Google Scholar] [CrossRef]

- Sjöblom, J.; Mhatre, S.; Simon, S.; Skartlien, R.; Sørland, G. Emulsions in external electric fields. Adv. Colloid Interface Sci. 2021, 294, 102455. [Google Scholar] [CrossRef] [PubMed]

- Taha, A.; Casanova, F.; Šimonis, P.; Stankevič, V.; Gomaa, M.A.E.; Stirkė, A. Pulsed Electric Field: Fundamentals and Effects on the Structural and Techno-Functional Properties of Dairy and Plant Proteins. Foods 2022, 11, 1556. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Xiao, S.; Wang, L.; Niu, D.; Gao, W.; Zeng, X.; Woo, M.; Han, Z.; Wang, R. Pulsed electric field enhances glucose glycation and emulsifying properties of bovine serum albumin: Focus on polarization and ionization effects at a high reaction temperature. Int. J. Biol. Macromol. 2024, 257, 128509. [Google Scholar] [CrossRef]

- López-Gámez, G.; Elez-Martínez, P.; Martín-Belloso, O.; Soliva-Fortuny, R. Applying Pulsed Electric Fields to Whole Carrots Enhances the Bioaccessibility of Carotenoid and Phenolic Compounds in Derived Products. Foods 2021, 10, 1321. [Google Scholar] [CrossRef] [PubMed]

- Canelli, G.; Kuster, I.; Jaquenod, L.; Buchmann, L.; Murciano Martínez, P.; Rohfritsch, Z.; Dionisi, F.; Bolten, C.J.; Nanni, P.; Mathys, A. Pulsed electric field treatment enhances lipid bioaccessibility while preserving oxidative stability in Chlorella vulgaris. Innov. Food Sci. Emerg. Technol. 2022, 75, 102897. [Google Scholar] [CrossRef]

- López-Gámez, G.; Elez-Martínez, P.; Martín-Belloso, O.; Soliva-Fortuny, R. Pulsed electric field treatment strategies to increase bioaccessibility of phenolic and carotenoid compounds in oil-added carrot purees. Food Chem. 2021, 364, 130377. [Google Scholar] [CrossRef]

- Astráin-Redín, L.; Raso, J.; Álvarez, I.; Kirkhus, B.; Meisland, A.; Borge, G.I.A.; Cebrián, G. New pulsed electric fields approach to improve the blanching of carrots. LWT 2023, 189, 115468. [Google Scholar] [CrossRef]

- Pataro, G.; Carullo, D.; Ferrari, G. Effect of PEF Pre-Treatment and Extraction Temperature on the Recovery of Carotenoids from Tomato Wastes. Chem. Eng. Trans. 2019, 75, 139. [Google Scholar]

- Eslami, E.; Carpentieri, S.; Pataro, G.; Ferrari, G. A Comprehensive Overview of Tomato Processing By-Product Valorization by Conventional Methods versus Emerging Technologies. Foods 2023, 12, 166. [Google Scholar] [CrossRef]

- Luengo, E.; Álvarez, I.; Raso, J. Improving carotenoid extraction from tomato waste by pulsed electric fields. Front. Nutr. 2014, 1, 12. [Google Scholar] [CrossRef]

- Navarro, A.; Ruiz-Méndez, M.V.; Sanz, C.; Martínez, M.; Rego, D.; Pérez, A.G. Application of Pulsed Electric Fields to Pilot and Industrial Scale Virgin Olive Oil Extraction: Impact on Organoleptic and Functional Quality. Foods 2022, 11, 2022. [Google Scholar] [CrossRef]

| Formulation Name | 1C | 1P | 2C | 2P | 3C | 3P | 4C | 4P | 5C | 5P | 6C | 6P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PEF treatment | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes | No | Yes |

| Sieving | No | No | No | Yes | Yes | Yes | ||||||

| % water | 100 | 100 | 50 | 100 | 100 | 50 | ||||||

| Cucumber peel | Yes | No | Yes | Yes | No | Yes | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cegoñino, M.; Abad, V.; Ruiz-Comeras, R.; Luengo, E.; Raso, J.; Cebrián, G.; Álvarez-Lanzarote, I. Preparation of Gazpacho Assisted by Pulsed Electric Fields: A Preliminary Study. Gastronomy 2025, 3, 5. https://doi.org/10.3390/gastronomy3010005

Cegoñino M, Abad V, Ruiz-Comeras R, Luengo E, Raso J, Cebrián G, Álvarez-Lanzarote I. Preparation of Gazpacho Assisted by Pulsed Electric Fields: A Preliminary Study. Gastronomy. 2025; 3(1):5. https://doi.org/10.3390/gastronomy3010005

Chicago/Turabian StyleCegoñino, María, Vanesa Abad, Raúl Ruiz-Comeras, Elisa Luengo, Javier Raso, Guillermo Cebrián, and Ignacio Álvarez-Lanzarote. 2025. "Preparation of Gazpacho Assisted by Pulsed Electric Fields: A Preliminary Study" Gastronomy 3, no. 1: 5. https://doi.org/10.3390/gastronomy3010005

APA StyleCegoñino, M., Abad, V., Ruiz-Comeras, R., Luengo, E., Raso, J., Cebrián, G., & Álvarez-Lanzarote, I. (2025). Preparation of Gazpacho Assisted by Pulsed Electric Fields: A Preliminary Study. Gastronomy, 3(1), 5. https://doi.org/10.3390/gastronomy3010005