Abstract

This study intends to understand the effect of annealing behavior on the microstructure and mechanical and magnetic properties of cold-rolled extra-low-carbon steel. Deformed steel samples are annealed at temperature ranges of 200–690 °C followed by air-cooling. As part of this study, Magnetic Hysteresis loop (MHL) and Barkhausen emission (MBE) measurements are carried out for non-destructive evaluation (NDE) of the mechanical properties that are altered during annealing, viz. recovery and recrystallization. At low annealing temperature ranges 200 < T < 550 °C, the recovery causes no substantial variations in microstructure, hardness value from 191–185 HV, and tensile strength 456–452 MPa, while magnetic coercivity decreases from 293–275 A/m for cold-rolled annealed steels. The microstructural changes due to recovery and recrystallization are examined using transmission electron microscopy and orientation imaging microscopy (OIM) through electron backscattered diffraction (EBSD). Recrystallization is found after annealing at T > 550 °C, confirmed by the lowering of the microstructural KAM value from 0.81° to 0.65° and a hardness drop from 190.02 to 98 HV for cold-rolled extra-low-carbon steel.

1. Introduction

Extra-low-carbon steel, applied in packaging and other applications, shows an excellent combination of drawability and a high degree of formability, associating with a strong <111>//ND recrystallization texture [1,2]. This occurs through an optimum annealing treatment for removing cold-rolling stress and restoring ductility. Due to annealing treatment, the cold-rolled steel possesses three distinct stages, viz. recovery, recrystallization, and grain growth. The recovery involves the annihilation and rearrangement of dislocations with the thermally activated motion of point defects and dislocations. Recrystallization is concerned with new strain-free grain nucleation and the consequent motion of high-angle grain boundaries [3]. Due to continuous changes in microstructural behavior and resultant mechanical properties, it is necessary to control the processing parameters during the multi-step cold rolling and annealing treatment. The well-known destructive techniques, like X-ray diffraction [4], optical and electron microscopy [5,6,7], and hardness and tensile testing, are widely used for the evaluation of microstructural and mechanical behaviors after post-annealing treatment [8]. Due to the lengthy characterization time for the aforementioned destructive techniques, several non-destructive electromagnetic (EM) techniques have been developed for the characterization of cold-rolled annealed steel [9,10].

In the EM technique, a cyclic magnetic field is applied to the ferromagnetic samples, and the consequential induced magnetization results in a magnetic hysteresis loop (MHL), which represents some important parameters, such as coercivity, permeability, magnetic flux intensity, and remanence [11]. There are microscopic small steps near the coercive field of the MHL, creating another signal, known as magnetic Barkhausen emission (MBE), which is quantified as r.m.s. voltage, peak amplitude, pulse height distribution, etc. Amongst them, the EM parameters of coercivity and r.m.s. voltage have shown credibility for assessing microstructural features and mechanical properties of steel components. These parameters are generated with the restriction of magnetic domain wall (DW) movement in the restraining sites, such as inclusion, dislocations, grain boundary, second phase particles, etc. [12,13,14,15,16]. Due to the pinning effect by these microstructural features, the mean free path of magnetic DW movement impacts on MHL under cyclic magnetization, causing a synergistic influence on the magnetic behaviors of steels. The magnetic coercivity (Hc) has been found to have a linear relationship with dislocation density (Hc √ρ, where ρ is the dislocation density) [17], resulting in an indirect relation to the strength and hardness behavior of steels [18,19,20,21]. Gurruchaga et al. explained that dislocations are key factors to hindering the DW movement during the recovery of low-carbon cold-rolled steel [22]. Upon recrystallization, the specific texture diminishes in low-carbon steel, and it becomes isotropic, indicating dislocation density as a dominating factor for controlling DW movement [23]. The lower dislocation density in recrystallized grains leads to a single-domain structure compared to the multi-domain in substructured regions. This causes an easier DW movement in recrystallized grains than the substructures, creating a weaker MBE signal in former grain structures. Moreover, the martensite phase fraction and grain size of DP steels are also well characterized by nondestructive electromagnetic parameters of coercivity and r.m.s. voltage [24]. The MBE voltage (Vr.m.s.) is found to be higher after cold-rolling deformation than in annealed and hot-rolled non-oriented electrical (0.88 wt% Si) steel [25]. Upon increasing annealing temperature, grain size, and recrystallization fractions increase progressively, causing a small change in MBE voltage at the initial temperature (T < 650 °C) and a sudden drop at high-temperature ranges of 650–750 °C. This occurs due to the combined effect of dislocation rearrangement (recovery) and subsequently the generation of strain-free grain structures. Martinez et al. discussed the influence of annealing treatment on MBE voltages of cold-rolled low-carbon steel [26]. They reported the occurrence of partial recovery and recrystallization with increasing annealing temperature and time, leading to a sudden decrease in the integral MBE energy upon recrystallization onset. Extra-low-carbon and microalloyed steels indicate magnetic softening due to recovery and mechanical softening for recrystallization [22,27]. Blaow et al. also discussed this technique for distinguishing different annealing stages of low-carbon hot-rolled steels. They stated that a decrease in dislocation structures is leading during the recovery and recrystallization stages of low-carbon steel and, consequently, these stages are well observed by the MBE technique [28]. Therefore, the recrystallization behavior of cold-rolled ferritic steel is found to have a good relation to mechanical and magnetic properties. The resultant recrystallized microstructure is justified through hardness values and microstructural parameters of misorientation angle and recrystallized volume fractions [29]. Moreover, the EBSD techniques of grain boundary misorientation mapping and Kernel Average Misorientation (KAM) mapping clearly distinguish the recrystallized fraction from non-recrystallized microstructures [30,31]. Accordingly, the electromagnetic NDE technique is an alternative characterizing technique for monitoring ferromagnetic material behaviors during processing and in-service states. Some researchers reported the application of multi-frequency electromagnetic sensors for the characterization of microstructures and mechanical behaviors of steels on the basis of microstructural phase transformation [32,33,34]. In contrast, magnetic coercivity (Hc) and magnetic Barkhausen voltage (Vr.m.s.) are more effective in assessing the microstructural changes owing to the changes in dislocation density.

The reported literature mostly highlighted the change in the microstructure and mechanical behaviors upon deformation and annealing treatment, which are evaluated by analyzing its effect on EM-NDE parameters. In this study, we have correlated the parameters of microstructure and mechanical and magnetic properties through a single curve, which will be beneficial to presume, the material behaviors during its processing. For this purpose, a portable NDE device is utilized, which is workable under an industrial atmosphere without much surface treatment of the tested materials.

2. Aims and Objectives

The present research focused on assessing the microstructural and mechanical behaviors of cold-rolled and annealed extra-low-carbon steel through non-destructive electromagnetic parameters, such as magnetic coercivity (Hc) and magnetic Barkhausen voltage (Vr.m.s.). To achieve this target, 50% of the cold-rolled steel sheets are annealed at different temperatures between 200–690 °C, and their microstructures and mechanical properties are evaluated by scanning and transmission electron microscopy and hardness measurement, respectively. The microstructural and mechanical parameters are monitored by a correlation to the electromagnetic parameters.

3. Materials and Methods

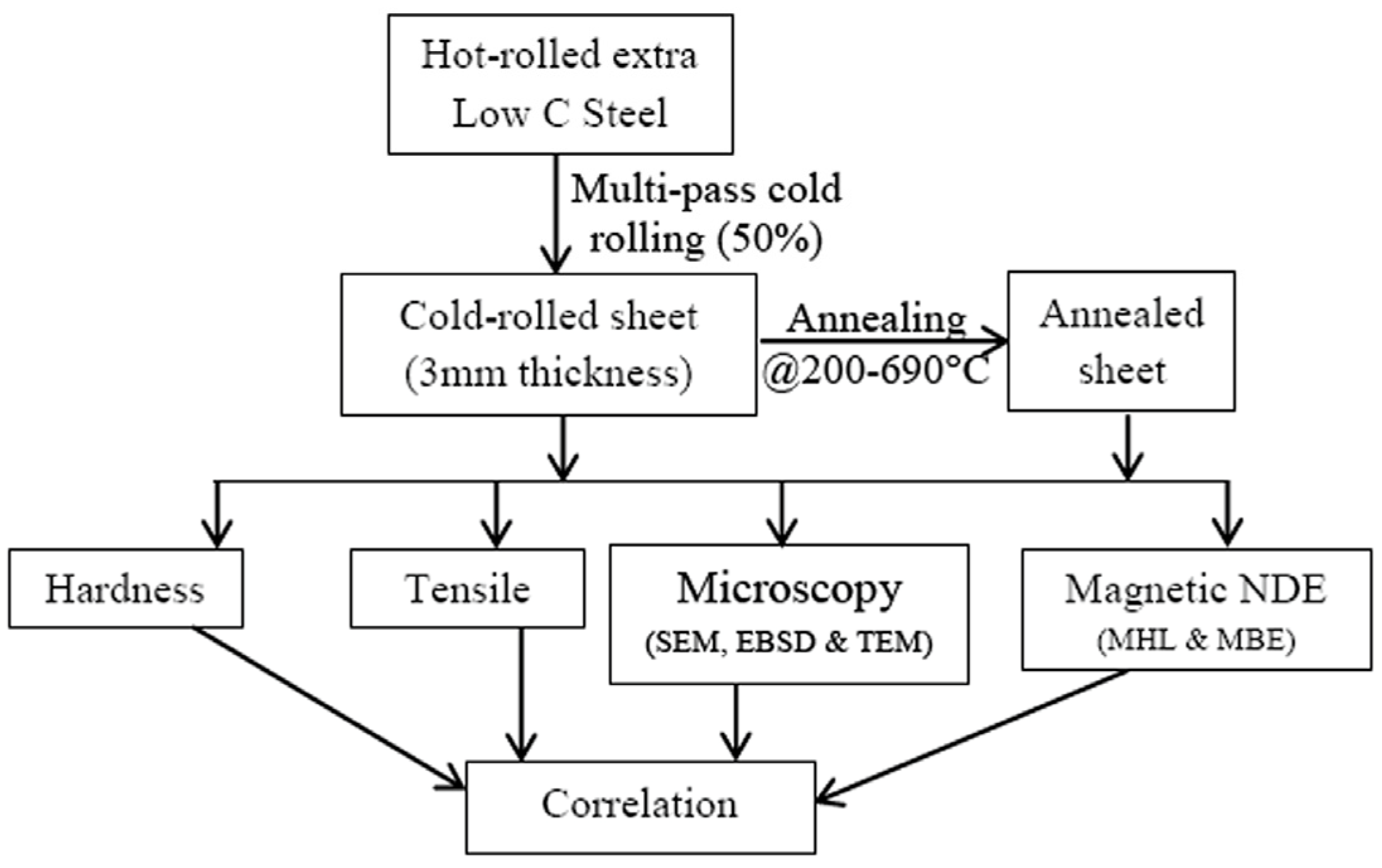

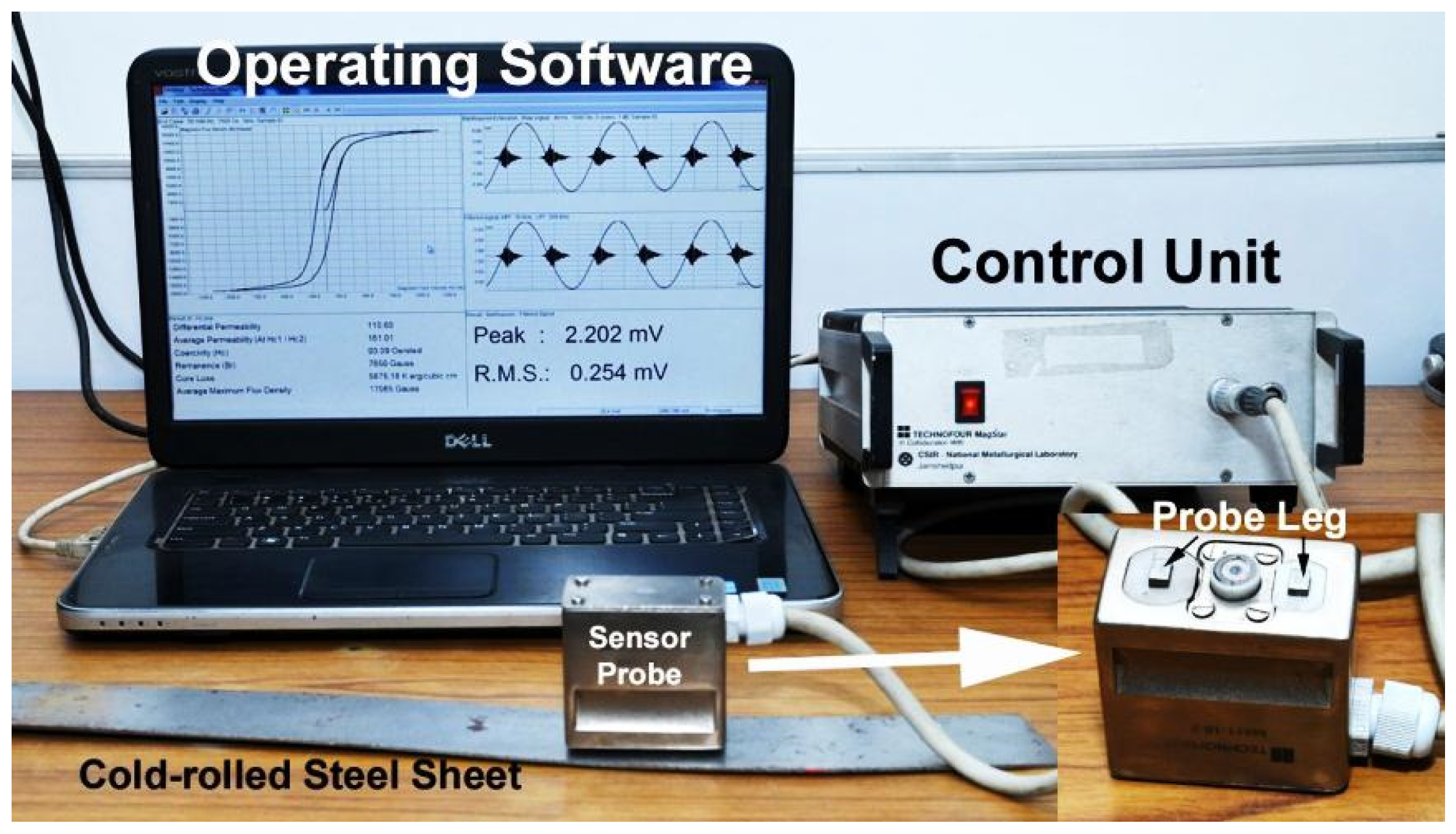

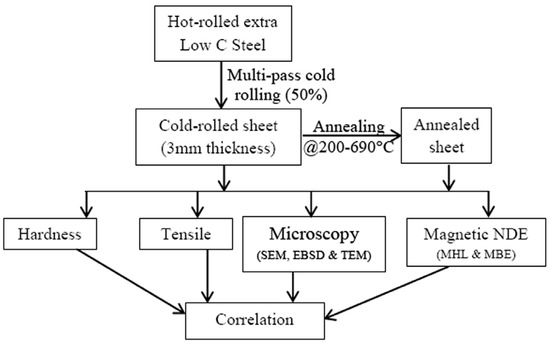

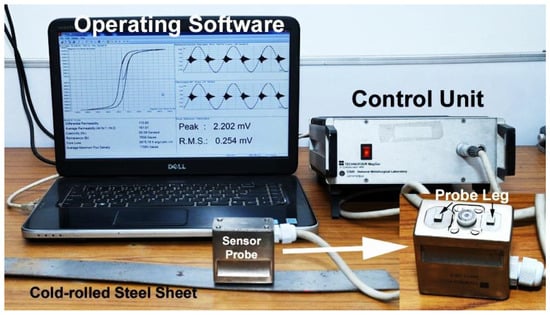

The present research is organized as a systematic investigation of destructive and non-destructive characterization techniques, and the sequences of experiments are explained through a flow sheet in Figure 1. The extra-low-carbon steel used in this study was supplied as a hot-rolled steel with a composition of (0.04C-0.18Mn-0.04Si-0.002Ti-0.01S-0.01P-restFe (wt%)). The industrially produced hot-rolled steel sheet was plastically deformed to a 50% reduction with a thickness of 3 mm by multi-pass cold rolling. The steel sheet was cut to samples with a length and width of 120 mm × 35 mm for heat treatment. The samples were isochronally annealed in a tube furnace at temperatures range of 200–690 °C with 900 s holding at each temperature under an inert atmosphere. The magnetic measurements were conducted using an electromagnetic NDE sensor (Magstar, manufactured by Technofour, Pune, India) [35] to determine the different magnetic parameters of the annealed extra-low-carbon steels. The sensor probe head consists of two probe legs which are placed on the cold-rolled sheet to apply the magnetic field (Figure 2). The applied magnetic field of 40 and 120 kA/m and frequency of 40 and 0.05 Hz are input parameters for the determinations of the magnetic hysteresis loop (MHL) and magnetic Barkhausen emission (MBE), respectively. The hardness measurement was conducted using a Vickers hardness tester (Economent VH-50MD) with a load of 30 kgf and 15 s dwelling time, and tensile properties were assessed using an Instron machine (Instron 8862) at room temperature with a cross head speed of 1 mm/min. The microstructural characterizations were carried out with a transmission electron microscope (TEM-JEM-2200FS) and scanning electron microscope (SEM, Model: FEI 430 NOVA NANO). TEM samples of 3 mm diameter disks were punched from the wafers (50 μm thickness) for steel specimens and subsequently twin-jet electro-polished in electrolyte 95% acetic acid and 5% perchloric acid at 25 V, ~40 mA. After electro-polishing, the thin samples were washed thoroughly in ethanol and investigated in TEM at 200 kV operating voltage. Additionally, the grain boundary characteristics map and kernel average misorientation (KAM) map were analyzed through an EBSD TSL–OIM analysis software version 5.3 attached to the SEM.

Figure 1.

Flow sheet representing sequence of experiments organized in the present study.

Figure 2.

Set-up arrangement of an electromagnetic sensor, Magstar, and sensor probe placed on a cold-rolled steel sheet for measuring MHL and MBE parameters.

4. Results and Discussion

4.1. Microstructural Evolution

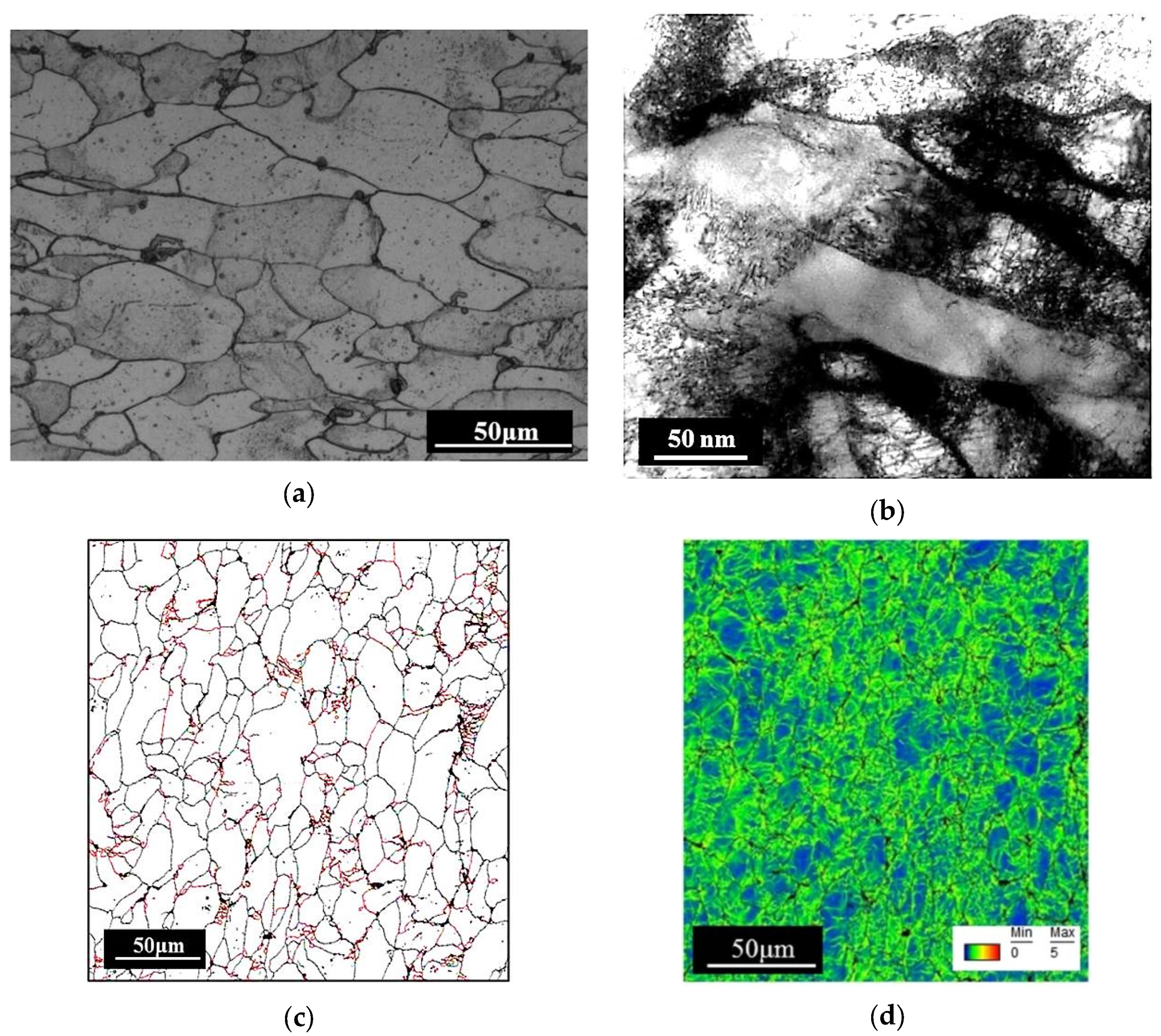

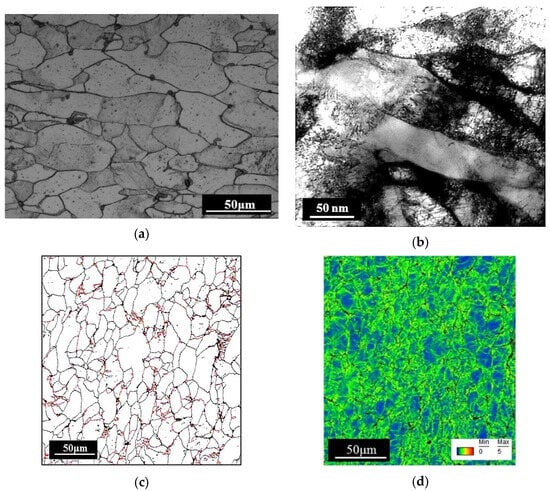

The cold-rolled steel microstructures are described by optical microscopy, transmission electron microscopy (TEM), and orientation image microscopy (OIM)-based grain boundary map (low and high angle boundaries) and Kernel average misorientation (KAM) map (Figure 3). The deformed grain structures of cold-rolled extra-low-carbon steel are revealed as elongated grains along the rolling direction with an aspect ratio of 2.5 and an average ferrite grain size of 21 μm (Figure 3a). The cold-rolled grains consist of high dislocations density, which is revealed by the bright field (BF) TEM image. The BF-TEM images, examined at the plane perpendicular to the normal direction (ND) plane of cold-rolled steel, explain the typical dislocations of cell structures within the elongated coarse grains along the rolling direction (Figure 3b). The dark and light regions represent different grains due to their varying orientation. The advantage of EBSD is the ability to scan a significantly larger area as compared to TEM, which can be used to gain relevant information for the microstructure, as well as, to a certain extent, about the sub-structures. Figure 3c shows an image quality (IQ) map overlaid with a low-angle (2–15°) boundary (LAB) represented by red and blue lines and a high-angle (15–65°) boundary (HAB) identified as a black line. The cold-rolled steel consists of high dislocation density with the modification of the sub-structure, exhibiting the presence of numerous low-angle grain boundaries (LAB) inside the grains. The presence of LABs inside the deformed grains gives a basic understanding of the deformation in the material. Several research works have reported greater formation of dislocation cell structures with an increase in cold deformations or strain rate, indicating a decrease in cell size with the increase in deformation [36,37,38]. Furthermore, the kernel average misorientation (KAM) map is evaluated to determine the local misorientation of cold-rolled steel, relating to the measurement of substantial lattice distortion at each point inside a grain [39]. The kernel size is typically designated to the nth nearest neighbor. The KAM values directly describe the local strain or stored energy in the sample matrix. The regions with high deformations or local strain dislocations density have higher KAM values (KAM > 1°), and many studies have reported that the KAM technique more conveniently supports the quantitative estimation of the local plastic deformations for cold-rolled steels [40,41,42]. The deformed grain structure is revealed by accumulated stored energy with the KAM value of 1.5° for CR steel (Figure 3d). Additionally, the green color is assigned to lattice defects with high KAM value, while the stress-free region is identified by blue grains with low KAM value.

Figure 3.

Microstructures of cold-rolled extra-low-carbon steel explaining by (a) optical image, (b) TEM bright field image, (c) grain boundaries map (red and blue lines: low-angle grain boundaries (2–15°); black line: high-angle (15–65°) boundary (HAB)) and (d) kernel average misorientation (KAM) map.

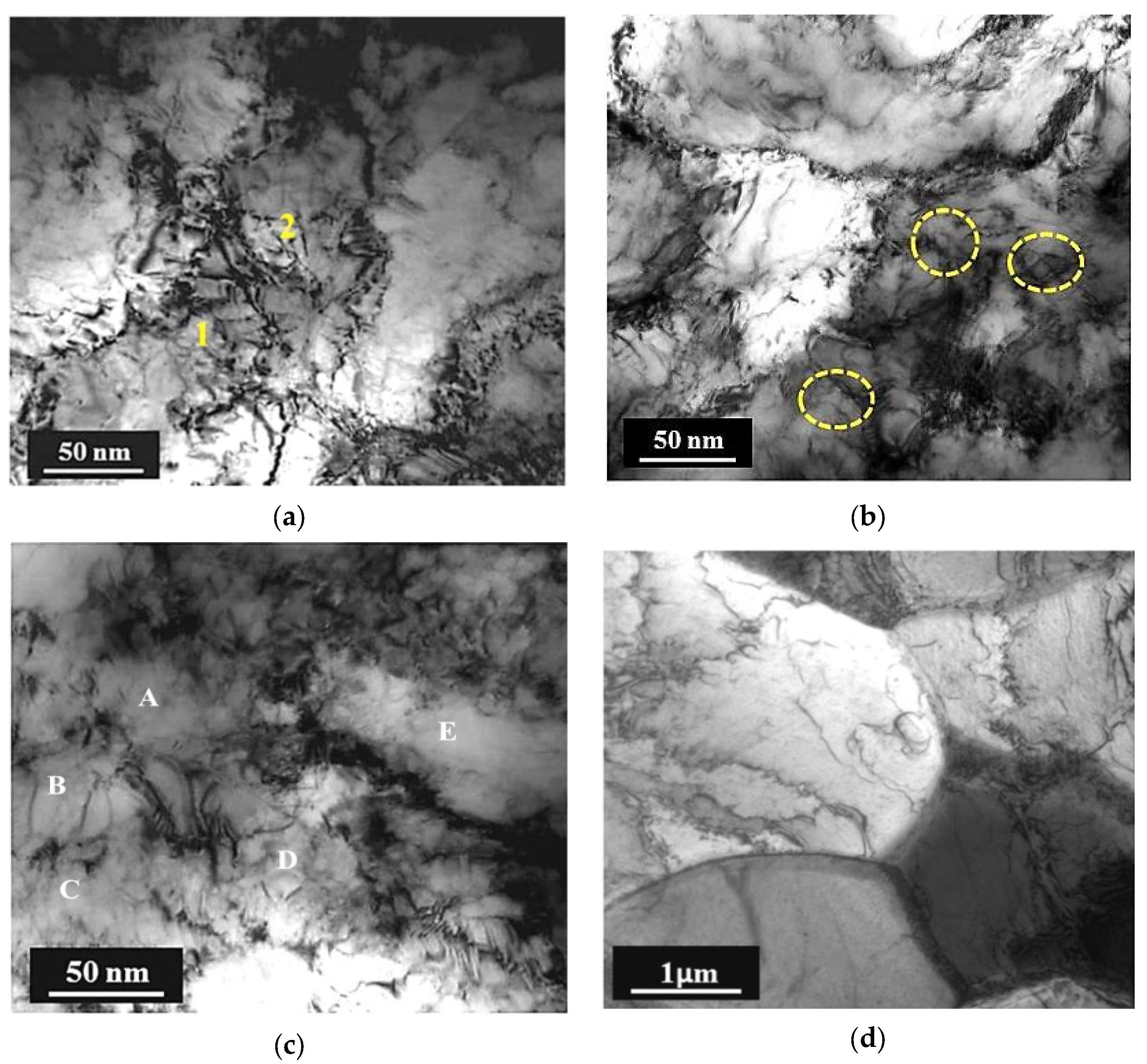

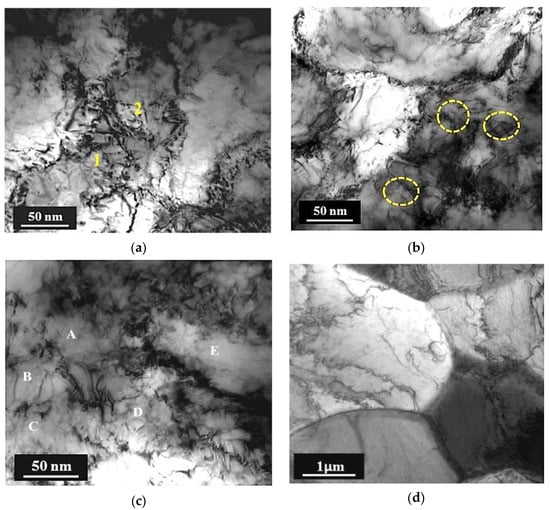

Upon the progress of annealing, the microstructural evolution of cold-rolled extra-low-carbon steel is explained in Figure 3, Figure 4 and Figure 5. At low-temperature (<450 °C) annealing, the subgrain formation (structures of low energy) is revealed inside the grains within the size ranges of ~0.3–0.5 μm by the TEM image (Figure 4a). The subgrain structure evolves low dislocation density at grain interiors, separated from one another by highly deformed cell boundaries. Generally, the misorientation of subgrain structure is dependent on the grain orientation, which is reported for cubic materials during recovery, and the comparison of existing results gives a direct indication of that phenomenon for extra-low-carbon ferrite steel [43]. As shown in Figure 4a, two different subgrains (1 and 2) are separated by grain boundaries with a high misorientation between neighboring subgrains. The recrystallization onset prevails with the nucleation of small strain-free grains (as shown by circles in Figure 4b) after annealing at 580 °C. The nuclei are poorly developed at the grain boundaries of deformed regions of higher dislocation density. With further annealing at a higher temperature of 600 °C, the decreasing dislocation density leads to the nucleation of strain-free grains, indicated by points A, B, C, D, and E, as shown in Figure 4c. After recrystallization completion at 660 °C, high-angle grain boundaries are predominant with the dispersion of low-density dislocations at grain interiors (Figure 4d).

Figure 4.

TEM-BF images of cold-rolled extra-low-carbon steel annealed at temperatures of (a) 450, (b) 580, (c) 600, and (d) 660 °C.

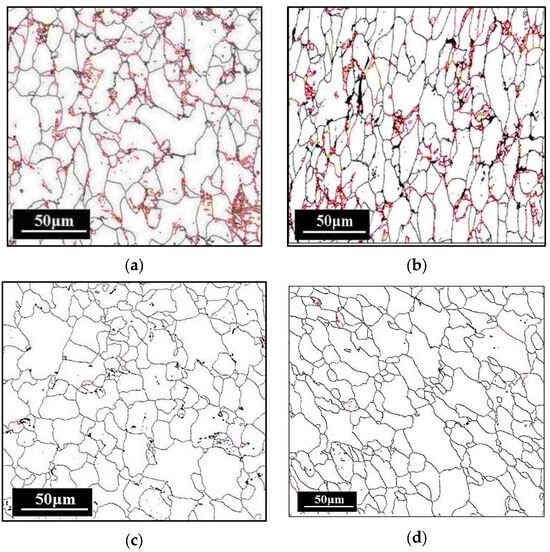

Figure 5.

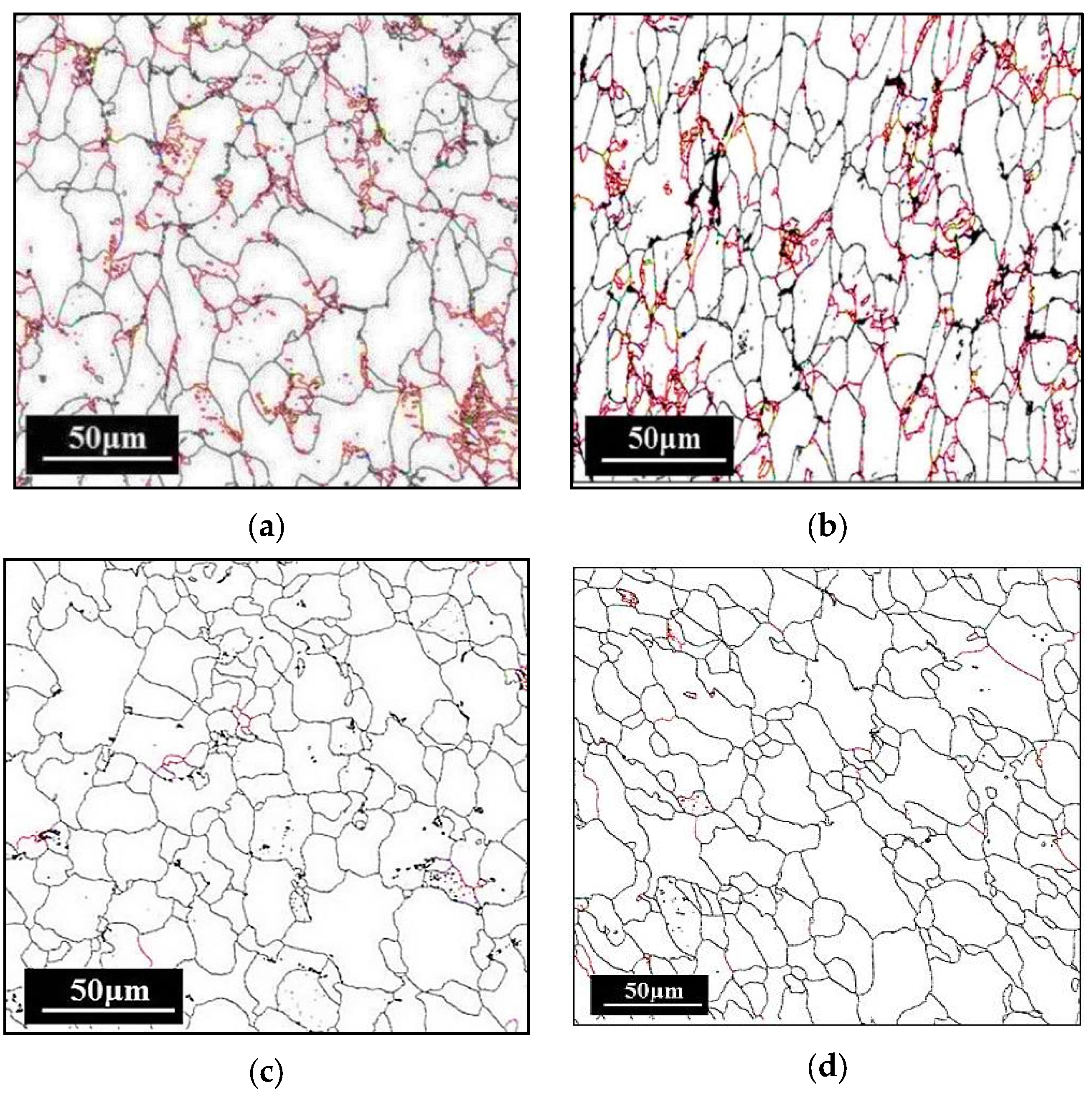

Grain boundary misorientation map of 50% CR extra-low-carbon steel after annealing at temperatures of (a) 450, (b) 580, (c) 660, and (d) 690 °C.

With the release of stresses and subsequent generation of recrystallized grains during the annealing of cold-rolled steel, the grain boundaries are distinguished as low-angle (LAB) and high-angle (HAB) in the grain boundary map of annealed steels (Figure 5). At low annealing temperatures (450 °C), due to recovery dominance, the LAB fraction increases with a decrease in the HAB fraction (Figure 5a, Table 1). This trend becomes reversed with the initiation of recrystallization after annealing at 580 °C (Figure 5b). At higher annealing temperatures, the recrystallization completion (at 660 °C) and grain growth (at 690 °C) result in HAB fractions of 89% and 94%, respectively (Figure 5c,d). The cold rolling stored energy is consumed with the progress of recrystallization, indicating the transition (low to high) of grain boundary orientation.

Table 1.

Annealing temperature effect on LAB, HAB and KAM values of cold-rolled extra-low-carbon steel.

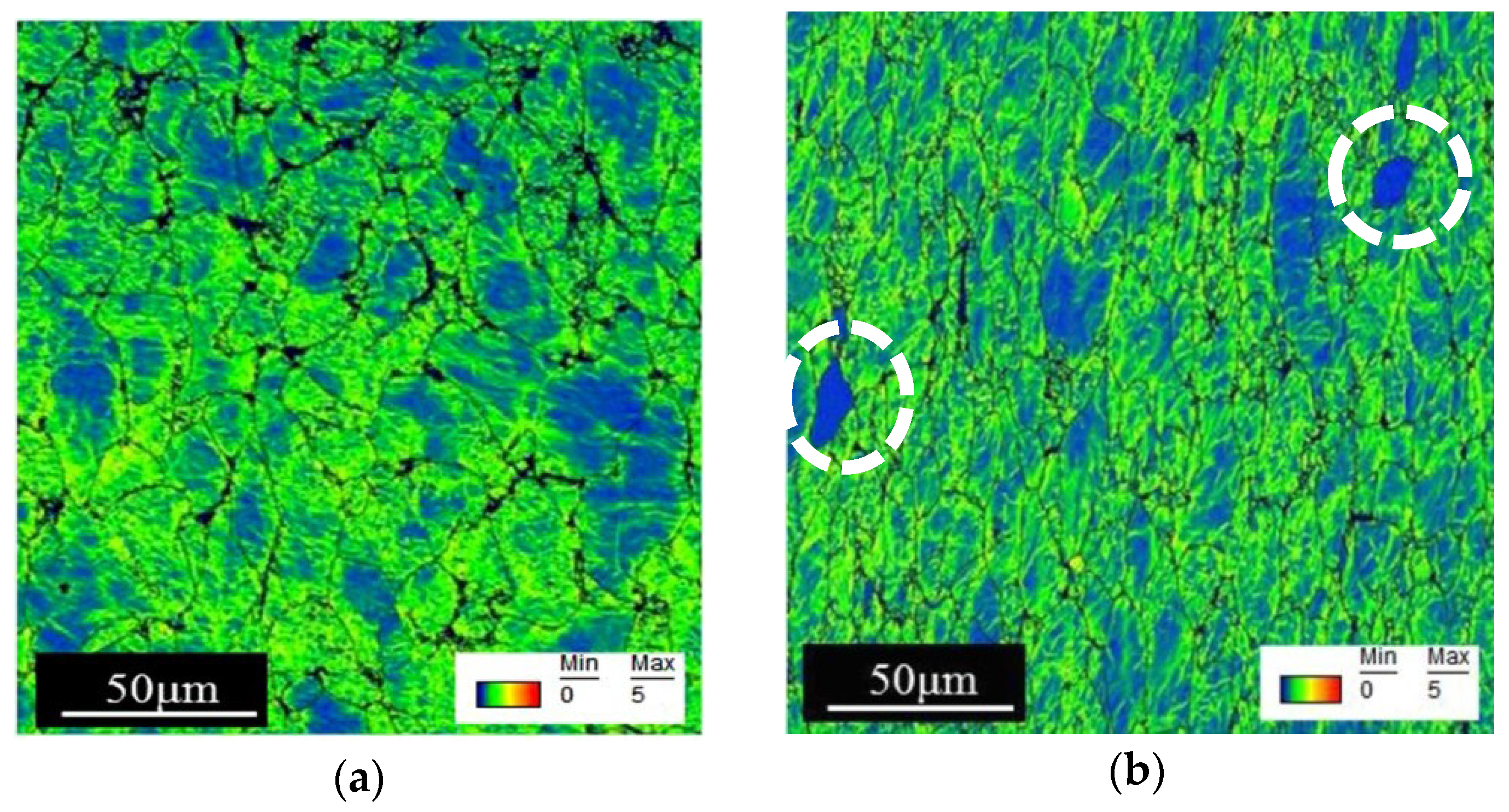

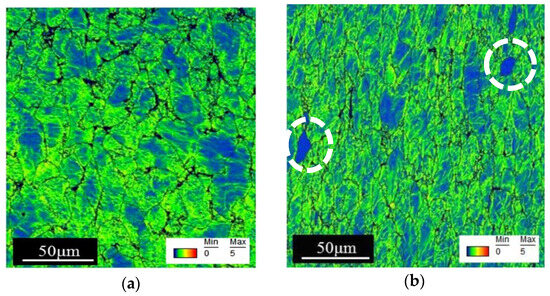

Moreover, the stored energy distribution in annealed samples is explained through kernel average misorientation (KAM) maps (Figure 6), to explain the local misorientation of microstructural grains and lattice distortion at each point inside a grain. In KAM maps, a green color is assigned to higher KAM values for more lattice defects, whereas blue-colored grains represent strain-free regions with low KAM values [30]. The stored energy released at a low temperatures (450 °C) suggests the occurrence of recovery by substructure evolution (Figure 6a). Figure 6b shows the low-strained regions grains in blue in 580 °C annealed samples, with an average KAM value of 0.62°. Further annealing at higher temperature increases strain-free grains with the progress of recrystallization, which is attributed to the decrease in the KAM value (Table 1). The equiaxed structure of the fully recrystallized (annealed at 660 °C/900 s) sample explains the mostly blue-colored grains with further decrease in the KAM value (0.58°) and a lesser orientation deviation inside the grains (Figure 6c). Annealing at 690 °C causes grain growth with dominant high-angle boundary and lesser KAM value (Figure 6d). Therefore, the KAM value fraction increases at lower ranges with increasing annealing temperature (Figure 6e). This observation is in good agreement with the investigation described by Fang et al. for Ti-bearing and Nb-bearing high-strength low-alloy steels [44]. They explained that the initial recovery and subsequent coarsening during annealing induces softening with the reduction of stored energy. Additionally, the recrystallization kinetics are reported for the surface and center layers of deformed steels using KAM maps. The kinetics at the surface are faster than in the center region. This is due to the variation in stored energy in hot bands as well as work hardening during cold rolling.

Figure 6.

Kernel average misorientation (KAM) map of cold-rolled steel annealed at (a) 450 °C, (b) 580 °C, (c) 660 °C, and (d) 690 °C and (e) distribution of KAM values for annealed extra-low-carbon steel at various temperatures. White circles in Figure (b) represent low-strain regions.

4.2. Mechanical Behavior

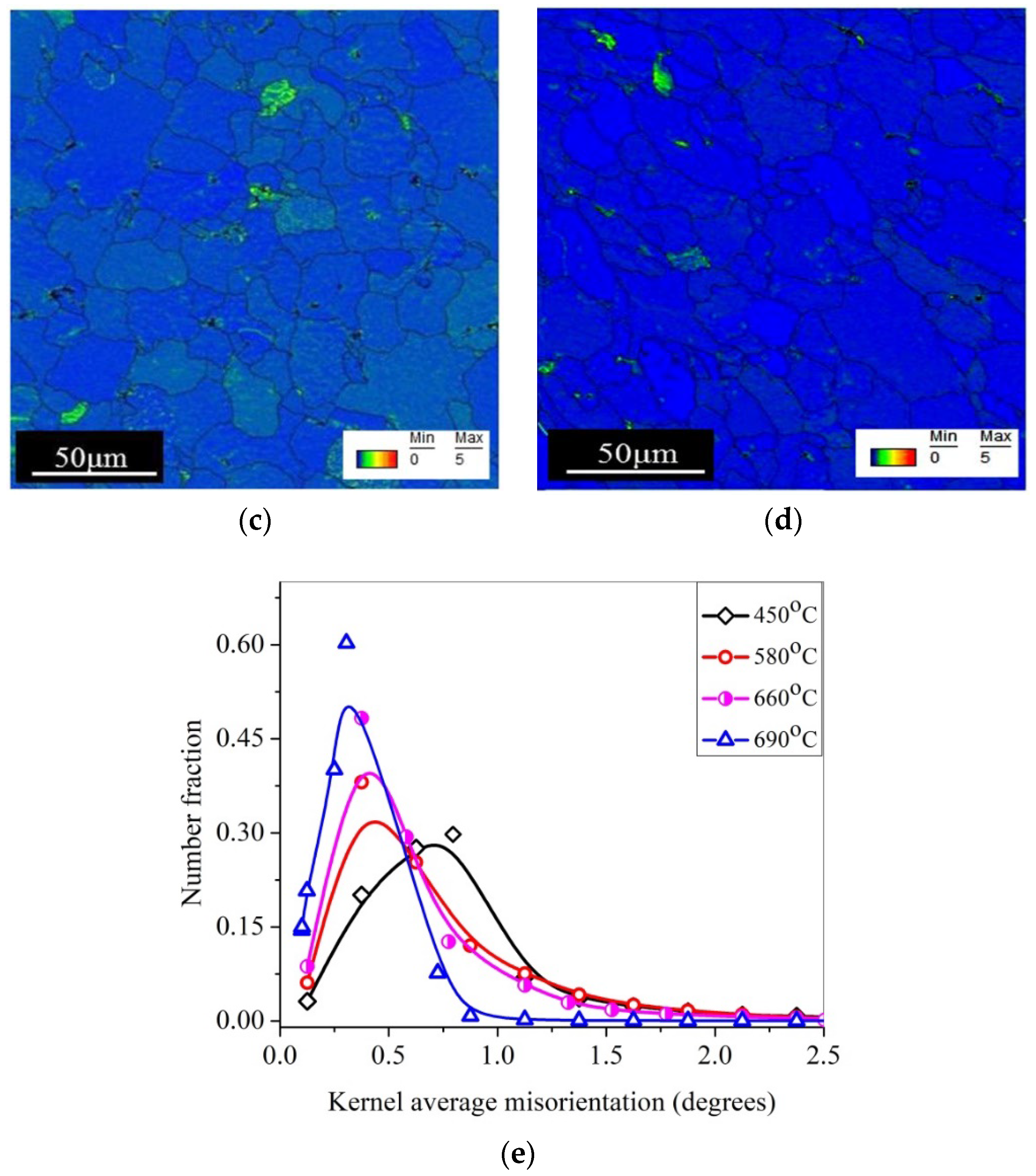

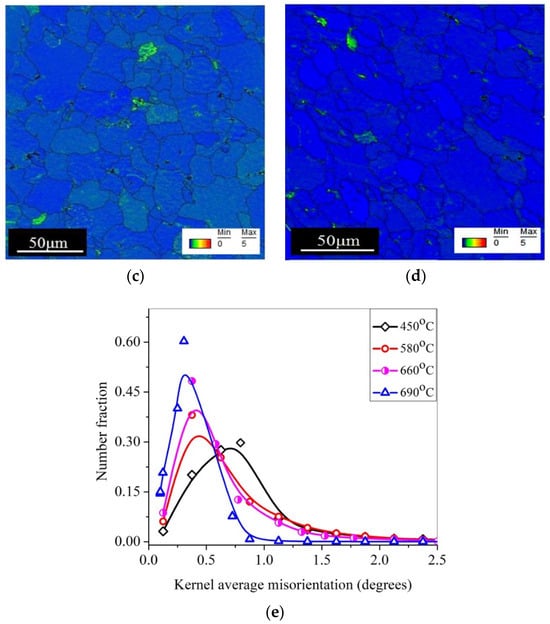

The hardness and tensile properties clearly describe the phenomena of recovery and recrystallization with the effect of annealing temperature (Figure 7). With increasing annealing temperature within 200 < T < 500 °C, the small variation in hardness (191–185 HV) and tensile strength (456–452 MPa) indicates the changing dislocation networks due to recovery. However, the elongation changes within a wide range of 1.15–15.73% at this temperature range. In the recovery region, a decrease in internally stored energy is observed due to the annihilation and rearrangement of dislocation and formation of subgrains, which is confirmed by TEM micrograph (Figure 4a). Upon further annealing to 580 °C, due to the onset of recrystallization (supported by Figure 4b), a rapid fall (indicated by a black circle) in hardness (178 HV) and tensile strength (395 MPa) is obtained. Meanwhile, the elongation increases to 18%, indicating softening, which occurs due to the process of recrystallization. Dziaszyk et al. also reported a similar hardness variation trend with isothermal annealing temperature at 780 °C for 94% cold-rolled Ti-stabilized IF steel [45]. Under partial recrystallization at 580 < T < 620 °C, the hardness continuously decreases due to mechanical softening of cold-rolled steel. Gazder et al. discussed the recrystallization behavior of IF steel and revealed that the hardness decreases as the recrystallization progresses [46]. Furthermore, the completion of recrystallization (at 660 °C) results in the stagnancy of hardness (~95 HV) and tensile strength (~309 MPa) and an increase in elongation (~31%). Above 660 °C, a negligible decrease in hardness (~94 HV) and tensile strength (~301 MPa) and an increase in elongation (~43.47%) occur due to grain coarsening. This finding has a good agreement with the results described by Purcek et al. for rolled low-carbon IF steel and its subsequent annealing behavior [47]. They found that yield strength decreases while ductility increases gradually owing to the reduced internal stresses and the start of recrystallization during annealing advancement.

Figure 7.

Variation of mechanical properties, (a) hardness and (b) tensile strength and elongation, with annealing temperature in cold-rolled extra-low-carbon steel.

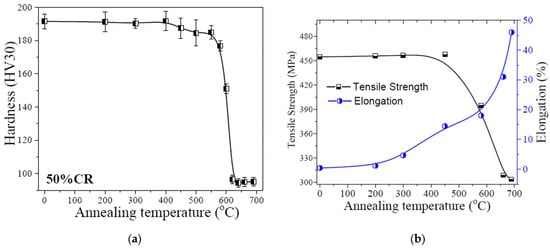

4.3. Magnetic Properties

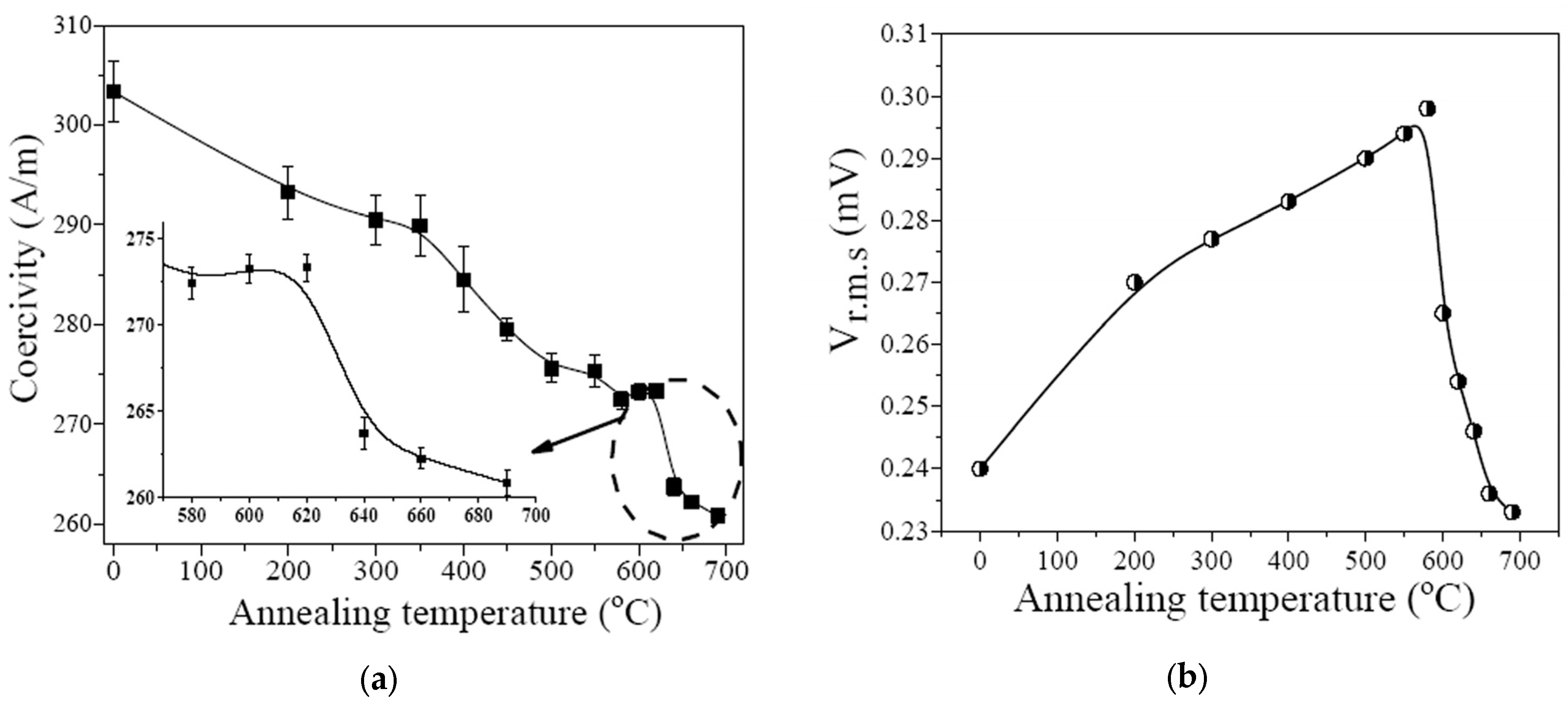

The magnetic hysteresis loop and Barkhausen emissions are measured using an electromagnetic surface probe sensor for cold-rolled and annealed extra-low-carbon steels, explaining the corresponding magnetic parameters of coercivity (Hc) and Vr.m.s. as a function of annealing temperature (Figure 8). The high dislocation density of deformed cold-rolled steel increases coercivity and the resultant magnetic hardness due to the hindrance of magnetic domain wall movement. When annealing at low temperature ranges 200 < T < 500 °C, the coercivity decreases progressively, representing the increase in magnetic softness. This occurs due to lowering dislocation density upon the recovery of cold-rolled steel, in which the dislocation density reduction reduces the pinning sites for the magnetic domain wall movement inside the matrix [48]. With the effect of recovery and subsequent annealing at the 550–620 °C temperature range, the stable dislocation structure and the onset of strain-free grains (Figure 6b) make the coercivity stagnant (shown in the inset of Figure 8a). In other words, the pinning strength of both dislocation density and grain boundaries dominate the magnetic parameter coercivity (Hc) upon annealing of cold-rolled steel. The process of annealing at T > 620 °C accelerates the recrystallization rate by increasing the volume fraction of recrystallized grains (partial recrystallization), causing the sudden drop in coercivity. It diminishes the resistance to domain wall movement, resulting in a gradual decrease in coercivity with further increasing annealing temperature. The continuous growth of strain-free grains by replacing deformed regions leads to recrystallization completion at 660 °C (Figure 6c), causing the stagnancy of coercivity beyond 660 °C.

Figure 8.

Variation of magnetic parameters with annealing temperature: (a) coercivity and (b) MBE voltage (Vr.m.s.).

Simultaneously, the MBE voltage (Vr.m.s.) also explains the recovery and recrystallization behaviors of cold-rolled extra-low-carbon steel (Figure 8b). The highly dense distribution of dislocation density in cold-rolled steel acts as pinning sites against magnetic domain wall motion, resulting in low Vr.m.s. (0.241 mV) for cold-rolled steel. With decreasing dislocation density at temperatures ranging from 200–580 °C, the mean free path of domain wall movement increases, causing the resultant enhancement of Vr.m.s. (0.272–0.298 mV). The recrystallization within an annealing temperature of 580 < T < 690 °C sharply decreases Vr.m.s. with the lowering of the mean free path of domain wall movement in a large number of strain-free grains.

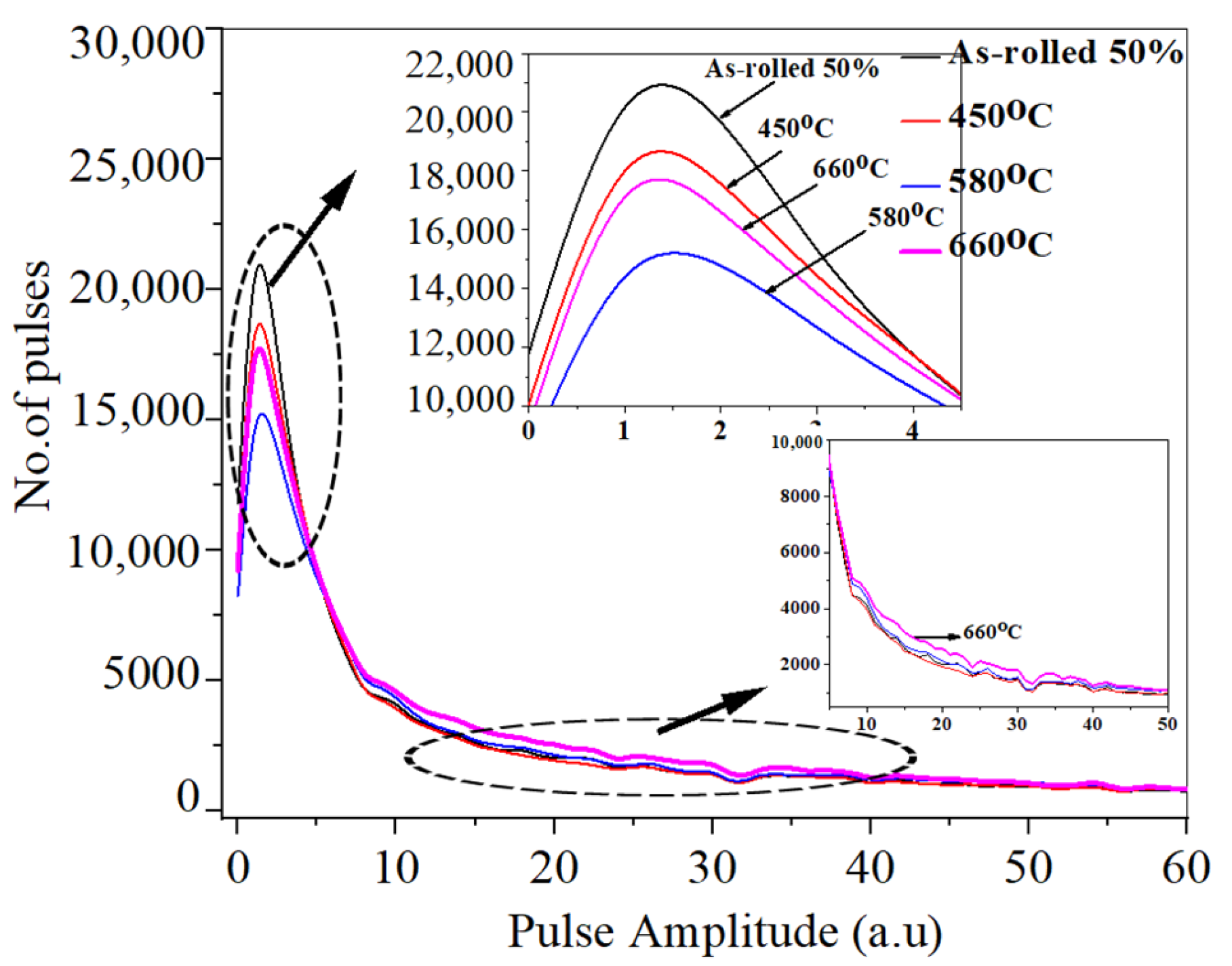

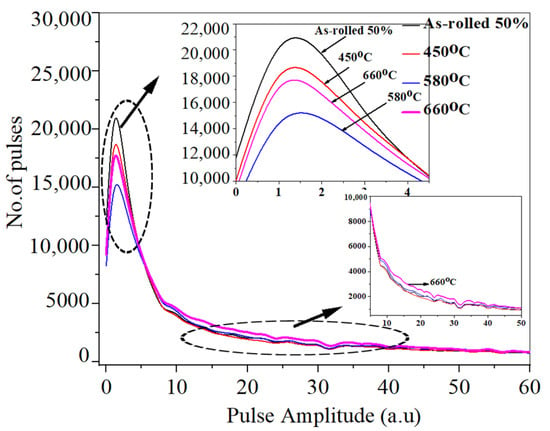

Additionally, the pinning effect on magnetic parameters can be described through the pulse height distribution derived from the MBE signals. Figure 9 shows the number of pulses for as-rolled and annealed steels as a function of pulse amplitude. The cold deformed steel with high dislocation density generates more low-amplitude pulses due to a higher number of pinning sites at scattered dislocation. At low annealing temperatures (450 °C), the subgrain formation causes a decrease in the low-amplitude pulses with easy magnetic domain movement. During the recrystallization initiation at 580 °C, the newly formed strain-free recrystallized grains decrease the mean free path and provide additional pinning sites, resulting in a lowering of the number of low-amplitude pulses. The recrystallization completion at 660 °C results in more low-amplitude pulses owing to the generation of new grain boundaries affecting the mean free path.

Figure 9.

Pulse height distribution of MBE signals of cold-rolled and annealed steels.

4.4. Correlation Between Microstructure, Mechanical and Magnetic Properties

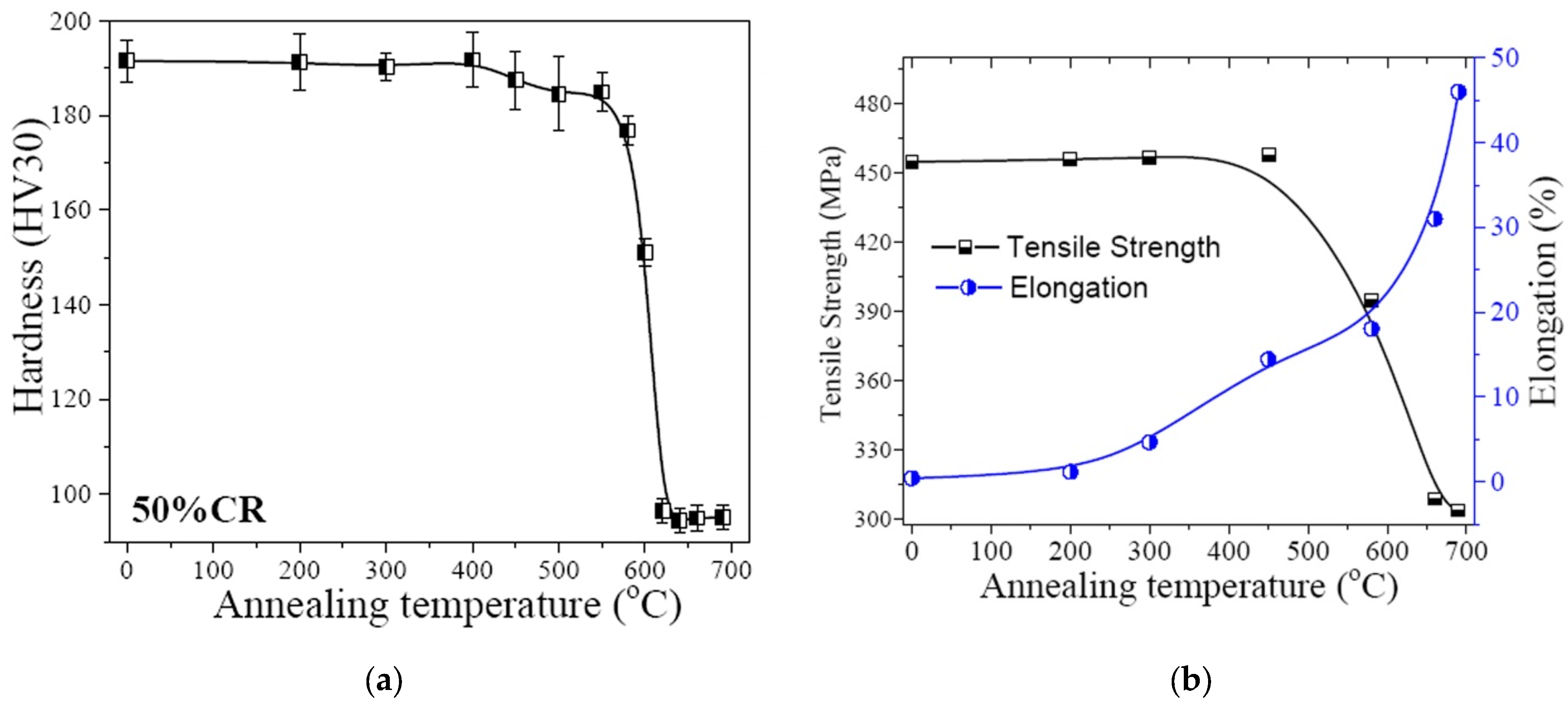

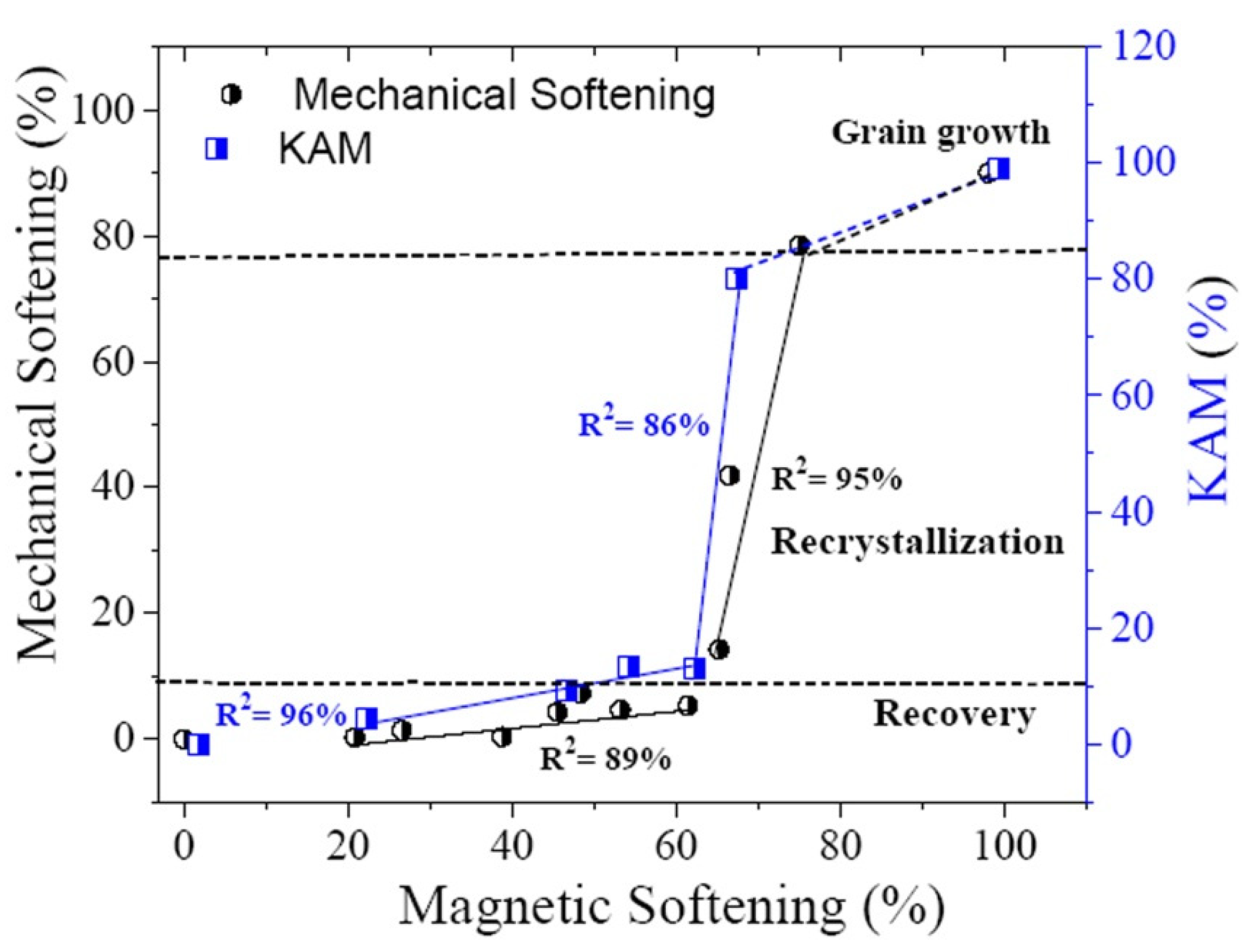

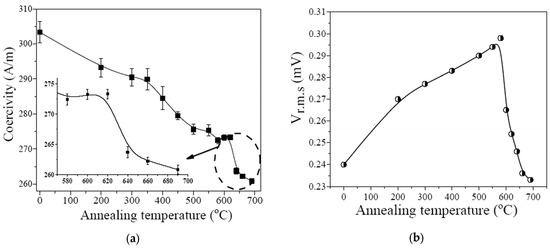

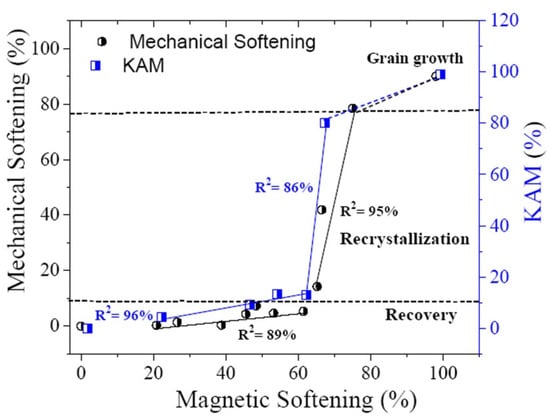

The recovery and recrystallization behaviors of cold-rolled steel can be analyzed by the decreases in coercivity and hardness as regards magnetic and mechanical softening of steel, respectively. Therefore, magnetic softening (fHc) is correlated to mechanical softening (fHv) and change in KAM values (fKAM) at each annealing temperature, evaluated by Equations (1)–(3) [29] and described in Figure 10.

where Hc,0, Hc,T, and Hc,rex are measured values of coercivity for cold-rolled, annealed at temperature T, and fully recrystallized samples, respectively.

where Hv,0, Hv,T, and Hv,rex are measured values of hardness for cold-rolled, annealed at temperature T, and fully recrystallized samples, respectively.

where k0, kT, and krex are measured values of KAM for cold-rolled, annealed at temperature T, and fully recrystallized samples, respectively.

Figure 10.

Correspondence of mechanical softening and KAM values with magnetic softening of cold-rolled extra-low-carbon steel during annealing treatment.

Three different linear relationships between mechanical and magnetic softening have been obtained for the three different steps, i.e., recovery, recrystallization, and grain growth. During recovery annealing at a temperature (<550 °C), the magnetic softening is about 40%, whereas the mechanical softening is 5%. Concurrently, no significant change is observed in the microstructure as monitored by KAM value (~5%). The low-temperature annealing causes a greater softening effect on magnetic than mechanical hardness. This is owing to the substantial impact of dislocation density on magnetic coercivity rather than hardness. Upon the progress of annealing (T > 500 °C) in recrystallization, the stable dislocation structure and new strain-free grains do not greatly affect magnetic softening, but a sharp increase in mechanical softening occurs owing to the advancement of microstructure change with the high KAM value variation (10–80%). Similarly, the linear relationship between coercive field (Hc) and a recrystallized fraction has been defined for isothermal annealed micro-alloyed steel [22]. The report suggests that the low annealing temperature, i.e., recovery region, causes a greater softening effect for magnetic than mechanical properties. Consequently, the present investigation specifies that magnetic parameter coercivity has an effective relation to recovery for cold-rolled extra-low-carbon steel, whereas mechanical hardness and microstructural KAM values have a strong relation to recrystallization.

During recrystallization, the cold-rolled microstructures are re-organized to the strain-free grains with low dislocation density. It is well established that magnetic parameters, Hc and Vr.m.s., are directly related to dislocation density (as discussed in the introduction). Therefore, the evaluation of magnetic properties is advantageous in assessing the microstructures and related mechanical properties in cold-rolled and annealed ferritic steels.

5. Conclusions and Future Research

The conclusions on the recrystallization behaviors of 50% cold-rolled extra-low-carbon steel are as follows:

- The cold-deformed steel microstructure consists of elongated ferrite grains with high dislocation density, resulting in higher coercivity (Hc), hardness, and KAM value and lower MBE voltage (Vr.m.s.).

- Low-temperature (<500 °C) annealing shows a more prominent change in coercivity (Hc) and Vr.m.s. than in hardness and microstructural variations due to rearrangement and annihilation of dislocations at the recovery regime.

- At higher temperatures (T > 500 °C), more strain-free grains affect the decrease in hardness, Hc, and Vr.m.s. with a lower KAM value.

- Stored energy is relieved during recovery and recrystallization, indicated by the advancement of softening fractions with increasing KAM fractions.

- The end of recrystallization at 660 °C causes a decrease in Hc, Vr.m.s., and KAM values and an increase in HAB fraction to 89%. Above 660 °C, the saturation of Hc and Vr.m.s. occurs due to grain growth.

- Upon annealing treatment, the cold-rolled extra-low-C steel shows a linear relation between the changes in electromagnetic NDE parameters and that in mechanical properties and microstructural parameters (KAM). This finding is compiled according to the main objectives of the present research.

- The outcomes of this research may be implied in monitoring the microstructural and mechanical behaviors of low-C structural steel upon cold rolling and following annealing treatment during industrial processing. More elaborate investigations in this area represent the research scope for the future.

Author Contributions

Conceptualization, S.D. and R.K.R.; methodology, S.D.; validation, S.D., A.K.P. and R.K.R.; formal analysis, S.D.; investigation, S.D.; resources, R.K.R.; data curation, S.D.; writing—original draft preparation, S.D.; writing—review and editing, S.D., A.K.P. and R.K.R.; visualization, S.D.; supervision, R.K.R.; project administration, R.K.R.; funding acquisition, S.D. All authors have read and agreed to the published version of the manuscript.

Funding

One of the authors (Siuli Dutta) acknowledging to Council of Scientific and Industrial Research, New Delhi, India, for financial support to accomplish this investigation.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors wish to thank the Director, CSIR-National Metallurgical Laboratory, for his kind permission to publish this paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ray, R.K.; Jonas, J.J.; Hook, R.E. Cold Rolling and Annealing Textures in Low Carbon and Extra Low Carbon Steels. Int. Mat. Rev. 1994, 39, 129–172. [Google Scholar] [CrossRef]

- Haldar, A.; Suwas, S.; Bhattacharjee, D. Microstructure and Texture in Steels; Springer: Dordrecht, The Netherlands; Berlin/Heidelberg, Germany; London, UK; New York, NY, USA, 2009. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Elsevier Science Ltd.: Oxford, UK, 2004; Volume 127. [Google Scholar]

- Mukunthan, K.; Hawbolt, E.B. Modeling recovery and recrystallization kinetics in cold-rolled Ti-Nb stabilized interstitial-free steel. Metall. Mater. Trans. A 1996, 27, 3410–3423. [Google Scholar] [CrossRef]

- Unnikrishnan, R.; Kumar, A.; Khatirkar, R.K.; Shekhawat, S.K.; Sapate, S.G. Structural developments in un-stabilized ultra low carbon steel during warm deformation and annealing. Mater. Chem. Phys. 2016, 183, 339–348. [Google Scholar] [CrossRef]

- Zaid, M.; Bhattacharjee, P.P. Electron backscatter diffraction study of deformation and recrystallization textures of individual phases in a cross-rolled duplex steel. Mater. Charact. 2014, 96, 263–272. [Google Scholar] [CrossRef]

- Zhu, K.Y.; Chaubet, D.; Bacroix, B.; Brisset, F. A study of recovery and primary recrystallization mechanisms in a Zr–2Hf alloy. Acta Mater. 2005, 53, 5131–5140. [Google Scholar] [CrossRef]

- Davis, C.L.; Strangwood, M.; Peyton, A.J. Overview of non-destructive evaluation of steel microstructures using multifrequency electromagnetic sensors. Iron Mak. Steel Mak. 2011, 38, 510–517. [Google Scholar] [CrossRef]

- Ranjan, R.; Jiles, D.C.; Rastogi, P.K. Magnetoacoustic emission, magnetization, and Barkhausen effect in decarburized steel. IEEE Trans. Magn. 1987, 22, 511–513. [Google Scholar] [CrossRef]

- Das, S.K.; Tarafder, S.; Panda, A.K.; Chatterjee, S. Magnetic and mechanical properties of Cu-strengthened aged HSLA-100 steel. Phys. Mag. 2007, 87, 5065–5078. [Google Scholar] [CrossRef]

- Roy, R.K.; Panda, A.K.; Mitra, A. Electromagnetic characterization of steels through magnetic NDE device. In Proceedings of the 2015 International Conference on Signal Processing and Communication Engineering Systems, Guntur, India, 2–3 January 2015; pp. 511–514. [Google Scholar] [CrossRef]

- Gao, L.; Zhou, Y.M.; Liu, J.L.; Shen, X.D.; Ren, Z.M. Effect of water quenching process on the microstructure and magnetic property of cold rolled dual phase steel. J. Mag. Mag. Mater. 2010, 322, 929–933. [Google Scholar] [CrossRef]

- Moorthy, V.; Vaidyanathan, S.; Raj, B.; Jayakumar, T.; Kashyap, B.P. Insight into the Microstructural Characterization of Ferritic Steels Using Micromagnetic Parameters. Mater. Trans. A 2000, 31A, 1053–1065. [Google Scholar] [CrossRef]

- Kaplan, M.; Gur, C.H.; Erdogan, M. Characterization of Dual-Phase Steels Using Magnetic Barkhausen Noise Technique. J. Nondestruct. Eval. 2007, 26, 79–87. [Google Scholar] [CrossRef]

- Liu, J.; Hao, X.J.; Zhou, L.; Strangwood, M.; Davisa, C.L.; Peyton, A.J. Measurement of microstructure changes in 9Cr–1Mo and 2.25Cr–1Mo steels using an electromagnetic sensor. Scripta Mater. 2012, 66, 367–370. [Google Scholar] [CrossRef]

- Okazaki, T.; Ueno, T.; Furuya, Y.; Spearing, M.; Hagood, N.W. Detectability of stress-induced martensite phase in ferromagnetic shape memory alloy Fe–30.2at.%Pd by Barkhausen noise method. Acta Mater. 2004, 52, 5169–5175. [Google Scholar] [CrossRef]

- Trauble, H. The influence of crystal defects on magnetization processes in ferromagnetic single crystals. In Magnetism and Metallurgy; Berkowitz, A.E., Kneller, E., Eds.; Academic Press: New York, NY, USA, 1969; Volume 2, p. 621. [Google Scholar]

- Ranjan, R.; Jiles, D.C.; Rastogi, P.K. Magnetic properties of decarburized steels: An investigation of the effects of grain size and carbon content. IEEE Trans. Magn. 1987, 23, 1869–1876. [Google Scholar] [CrossRef]

- Swartzendruber, L.J.; Hicho, G.E.; Chopra, H.D.; Leigh, S.D. Effect of plastic strain on magnetic and mechanical properties of ultralow carbon sheet steel. J. Appl. Phys. 1997, 81, 4263–4265. [Google Scholar] [CrossRef]

- Iordache, V.E.; Hug, E.; Buiron, N. Magnetic behaviour versus tensile deformation mechanisms in a non-oriented Fe–(3wt.%)Si steel. Mater. Sci. Eng. A 2003, 359, 62–74. [Google Scholar] [CrossRef]

- Fagan, P.; Ducharne, B.; Daniel, L.; Skarlatos, A.; Domenjoud, M.; Reboud, C. Effect of stress on the magnetic Barkhausen noise energy cycles: A route for stress evaluation in ferromagnetic materials. Mater. Sc. Eng. B 2022, 278, 115650. [Google Scholar] [CrossRef]

- Gurruchaga, K.; Martinez-de-Guerenu, A.; Soto, M.; Arizti, F. Magnetic Barkhausen Noise for Characterization of Recovery and Recrystallization. IEEE Trans. Magn. 2010, 46, 513–516. [Google Scholar] [CrossRef]

- Xu, B.; Zuo, Y.; Li, Y.; Li, X.; Tang, C.; Shang, C. The influence of recrystallization on magnetic Barkhausen noise in low carbon automotive sheet steels. Mater. Tod. Comm. 2025, 44, 112125. [Google Scholar] [CrossRef]

- Ghanei, S.; Alam, A.S.; Kashefi, M.; Mazinani, M. Nondestructive characterization of microstructure and mechanical properties of intercritically annealed dual-phase steel by magnetic Bakhausen noise technique. Mater. Sci. Eng. A 2014, 607, 253–260. [Google Scholar] [CrossRef]

- Sidor, J.J.; Verbeken, K.; Gomes, E.; Schneider, J.; Calvillo, P.R.; Lai, K. Through process texture evolution and magnetic properties of high Si non-oriented electrical steels. Mater. Charact. 2012, 57, 49–57. [Google Scholar] [CrossRef]

- Martinez-de-Guerenu, A.; Jorge-Badiola, D.; Gutierrez, I. Assessing the recovery and recrystallization kinetics of cold rolled microalloyed steel through coercive field measurements. Mater. Sci. Eng. A. 2017, 691, 42–50. [Google Scholar] [CrossRef]

- Oyarzabal, M.; Gurruchaga, K.; Martinez-De-Guerenu, A.; Gutierrez, I. Sensitivity of Conventional and Non-destructive Characterization Techniques to Recovery and Recrystallization. ISIJ Int. 2007, 47, 1458–1464. [Google Scholar] [CrossRef][Green Version]

- Blaow, M.; Shaw, A. Evaluation of Annealing Stages in Low Carbon Steel Using Magnetic Barkhausen Noise. ISIJ Int. 2014, 1, 1. [Google Scholar]

- Dutta, S.; Rajinikanth, V.; Panda, A.K.; Mitra, A.; Chatterjee, S.; Roy, R.K. Effect of Annealing Treatment on Mechanical and Magnetic Softening Behaviors of Cold Rolled Interstitial-Free Steel. J. Mater. Eng. Perform. 2019, 28, 2228–2236. [Google Scholar] [CrossRef]

- Gandarilla, F.C.; Bolmaro, R.E.; Leon, H.F.M.; Garrido, A.M.S.; Moreno, J.G.C. Study of recovery and first recrystallisation kinetics in CGO Fe3%Si steels using misorientation-derived parameters (EBSD). J. Microsc. 2019, 275, 133–148. [Google Scholar] [CrossRef]

- Ayad, A.; Ramoul, M.; Rollett, A.D.; Wagner, F. Quantifying primary recrystallization from EBSD maps of partially recrystallized states of an IF steel. Mater. Charact. 2021, 171, 110773. [Google Scholar] [CrossRef]

- Zhao, J.; Shen, J.; Xiao, S.; Liu, X.; Chen, Y.; Meng, Z.; Zhou, L. Study on microstructure characterization of steel using on multi-frequency electromagnetic detection and FE simulation calculation. J. Mag. Magn. Mater. 2024, 608, 172434. [Google Scholar] [CrossRef]

- Shen, J.; Xiao, S.; Dong, C.; Zhang, C.; Liu, G.; Zhou, L. Characterization on multiphase microstructures of carbon steels using multi-frequency electromagnetic measurements. Measurement 2024, 226, 114140. [Google Scholar] [CrossRef]

- Zhang, C.; Liang, D.; Shen, J.; Meng, Z.; Dong, Z. Real-time on-line characterization of steel microstructure and mechanical properties using multi-frequency electromagnetic method. Nondest. Test. Eval. 2025, 40, 1–23. [Google Scholar] [CrossRef]

- Roy, R.K.; Panda, A.K.; Mitra, A. Utilization of Electromagnetic Sensor for Structural Characterization of Steels During Processing and in-Service Components. Springer Lect. Notes Netw. Syst. 2017, 11, 247–254. [Google Scholar] [CrossRef]

- Zaefferer, S.; Kuo, J.C.; Zhao, Z.; Winning, M.; Raabe, D. On the influence of the grain boundary misorientation on the plastic deformation of aluminum bicrystals. Acta Mater. 2003, 51, 4719–4735. [Google Scholar] [CrossRef]

- Chaudhuri, A.; Sarkar, A.; Suwas, S. Investigation of stress-strain response, microstructure and texture of hot deformed pure molybdenum. Int. J. Refract. Met. Hard. Mater. 2018, 7, 168–182. [Google Scholar] [CrossRef]

- Chandrasekaran, D.; Nygards, M. A study of the surface deformation behaviour at grain boundaries in an ultra-low-carbon steel. Acta Mater. 2003, 51, 5375–5384. [Google Scholar] [CrossRef]

- Zhong, Y.; Yin, F.; Sakaguchi, T.; Nagai, K.; Yang, K. Dislocation structure evolution and characterization in the compression deformed Mn–Cu alloy. Acta Mater. 2007, 55, 2747–2756. [Google Scholar] [CrossRef]

- Torganchuk, V.; Morozova, A.; Tikhonova, M.; Kaibyshev, R.; Belyakov, A. Grain sizes and dislocation densities in fcc-metallic materials processed by warm to hot working. J. Phys. Conf. Ser. 2019, 1270, 012039. [Google Scholar] [CrossRef]

- Saeidi, N.; Ashrafizadeh, F.; Niroumand, B.; Barlat, F. EBSD Study of Damage Mechanisms in a High Strength Ferrite–Martensite Dual –Phase Steel. J. Mater. Eng. Perform. 2014, 24, 53–58. [Google Scholar] [CrossRef]

- Bollinger, C.; Billy, C.; Mussi, A.; Bouquerel, J.; Dmitri, A. Microstructural Evidence for Grain Boundary Migration and Dynamic Recrystallization in Experimentally Deformed Forsterite Aggregates. Minerals 2018, 9, 17. [Google Scholar] [CrossRef]

- Roumina, R.; Sinclair, C.W. The work hardening rate of an aged and recovered Al-Mg-Sc alloy. Metall. Trans. A 2011, 42A, 473–487. [Google Scholar] [CrossRef]

- Fang, C.; Garcia, C.I.; Choi, S.H.; Deardo, A.J. A Study of the Batch Annealing of Cold-Rolled HSLA Steels Containing Niobium or Titanium. Metall. Mater. Trans. A 2015, 46 Pt A, 3635–3645. [Google Scholar] [CrossRef]

- Dziaszyk, S.; Payton, E.J.; Friedel, F.; Marx, V.; Eggeler, G. On the characterization of recrystallized fraction using electron backscattered diffraction: A direct comparision to local hardness in an IF steel using nanoindentation. Mater. Sci. Eng. A 2010, 527, 7854–7864. [Google Scholar] [CrossRef]

- Gazder, A.A.; Cao, W.; Davies, C.H.J.; Pereloma, E.V. An EBSD investigation of interstitial –free steel subjected to equal channel angular extrusion. Mater. Sci. Eng. A 2008, 497, 341–352. [Google Scholar] [CrossRef]

- Purcek, G.; Saray, O.; Karaman, I.; Maier, H.J. High strength and high ductility of ultra fine -grained interstitial free steel produced by ECAE and annealing. Metall. Mater. Trans. A 2012, 43, 1884–1894. [Google Scholar] [CrossRef]

- Martinez-de-Guerenu, A.; Arizti, F.; Dıaz-Fuentes, M.; Gutierrez, I. Recovery during annealing in a cold rolled low carbon steel. Part I: Kinetics and microstructural characterization. Acta Mater. 2004, 52, 3657–3664. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).