1. Introduction

Ultrasonic testing is a widely used technique with applications ranging from medical diagnostics to industrial quality control [

1,

2]. In non-destructive testing, many ultrasonic techniques are based on time-of-flight measurements in contact mode. An ultrasonic transducer is coupled to a test object, a stimulation sequence is excited, and one or more backwall echoes are measured. Depending on the application, the time-of-flight provides information on material properties, material thickness, defects or stress states in the material. As the complexity of inspection systems and objects increases, so does the need to adapt ultrasonic techniques, and optimizing such systems for specific applications requires expert knowledge.

The field of material science is undergoing tremendous development, producing new complex structures, or metamaterials, to meet the demands of industry. Whereas in the past the composition and microstructure of materials were the key elements to tuning mechanical properties, metamaterials derive their properties from three-dimensional architectures [

3]. This enables the integration of completely new functions into components but also requires advances in the understanding of material physics to develop suitable characterization techniques. As materials develop, the field of non-destructive testing will need to expand.

In ultrasonic testing, several aspects can be addressed to adapt the methods to more complex testing problems. There are two distinct approaches: On the one hand, the resulting signals can be analyzed with advanced data science methods to extract information or identify false signals [

4,

5,

6]. On the other hand, the stimulation sequence can be modified into much more complex sequences, called coded excitation sequences, to maximize echo information, signal-to-noise ratio or unambiguity [

7,

8,

9,

10,

11]. However, while sequences can be selected on the basis of their auto-correlation functions, this approach has been found to have limitations and places high demands on the understanding of the interplay between ultrasound, test system and test object [

12]. All components of an ultrasonic testing system are limited in their ability to transmit signals, e.g., bandwidth or voltage range, and affect the echo deformation. For the development of ultrasonic testing methods for complex materials, all components of an ultrasonic testing system must be included in a complete system description that provides a basis for the development of tailored excitation sequences. For individual test cases, optimization can be performed manually, but this is only valid as long as all system components, including the test object, remain unchanged [

12].

Many publications have worked on the development and extension of ultrasonic transducer simulation models, covering more and more aspects and parameters [

13,

14,

15,

16,

17,

18,

19,

20,

21], but failing to cover all the components of the ultrasonic testing system, including the test object, the electrical power stage and the receiver amplifier.

The aim of this work is to develop a physically motivated modular model based on State-of-the-Art methods covering all components of an ultrasonic testing system, thus combining the description of electronic circuits [

22] with the modeling of ultrasonic transducers. The Krimholtz–Leedom–Matthaei (KLM) model is used to model the ultrasonic transducer [

15]. The KLM model is a commonly used State-of-the-Art model with physically motivated parameters [

21,

23] and the aim of this work is to implement a modular model with variable parameters that reflect a real test system. The physically motivated modeling requires a connection of all elements of the setup including the test object. After the theoretical description of the components, the implementation is adapted to the components of real ultrasonic test systems with three different configurations and evaluated with two test sequences.

Using this model, it is possible to design ultrasonic testing systems and evaluate the performance of different methods and inspection strategies. Individual components can be interchanged and their effect on system performance can be evaluated because of the modular structure. For example, before building a custom ultrasonic inspection system that allows for high quantization and bandwidth stimulation, the applicability of coded stimulation to an application can be evaluated.

2. Materials and Methods

Calculations and model implementations were performed using Matlab2020b (Mathworks Inc., Natick, MA, USA).

The specimen is designed to meet the requirements described in

Section 2.1.2. In summary, this is a specimen with boundary conditions that provide low distortion and an almost homogeneous grain structure. It is a 250 mm × 250 mm × 120 mm block machined from 1.0045/S355JR steel and heat treated at 850 °C in an inert gas atmosphere to provide a homogeneous internal structure. It should be noted the test object considered is purposefully kept simple to emphasize the description and modelling of all the system’s components. In order to generalize the model to any test object and material, the representation of the test object has to further include nonlinear effects and validated on more complex objects in the future.

The validation of the model is based on a customized ultrasonic test environment [

24].

Figure 1 shows the components of the test system. The digital system is covered by an FPGA board connected to custom-built ultrasound electronics developed at Fraunhofer IZFP. The piezoelectric transducers are also custom-built at Fraunhofer IZFP, as the matching of the model parameters to the built transducer requires knowledge of the design parameters of the transducer. They contain a 3-1 composite piezoelectric plate and a backing layer of a mixture of Al

2O

3 and araldite. The frequency range in which a piezoelectric transducer can be used for ultrasonic testing is described by the center frequency and a bandwidth. The center frequency is where the highest signal level is reached, and the bandwidth describes a frequency range around the center frequency until the signal level decreases to a certain amount—usually the 3 dB bandwidth is given in datasheets. For transducer selection, these values are determined by the material and thickness of the piezoelectric plate and are influenced by the backing layer. The parameters of the piezoelectric transducers are summarized in

Table 1. The selected components result in a center frequency of 5 MHz for Transducer 1 and 4 MHz for Transducer 2.

Note that for reasons of model complexity and applicability, we limit the scope of the paper to linear models. As such, all models and transfer functions are linear approximations. This point is further discussed in

Section 4.

2.1. Theoretical Base of Component Modeling

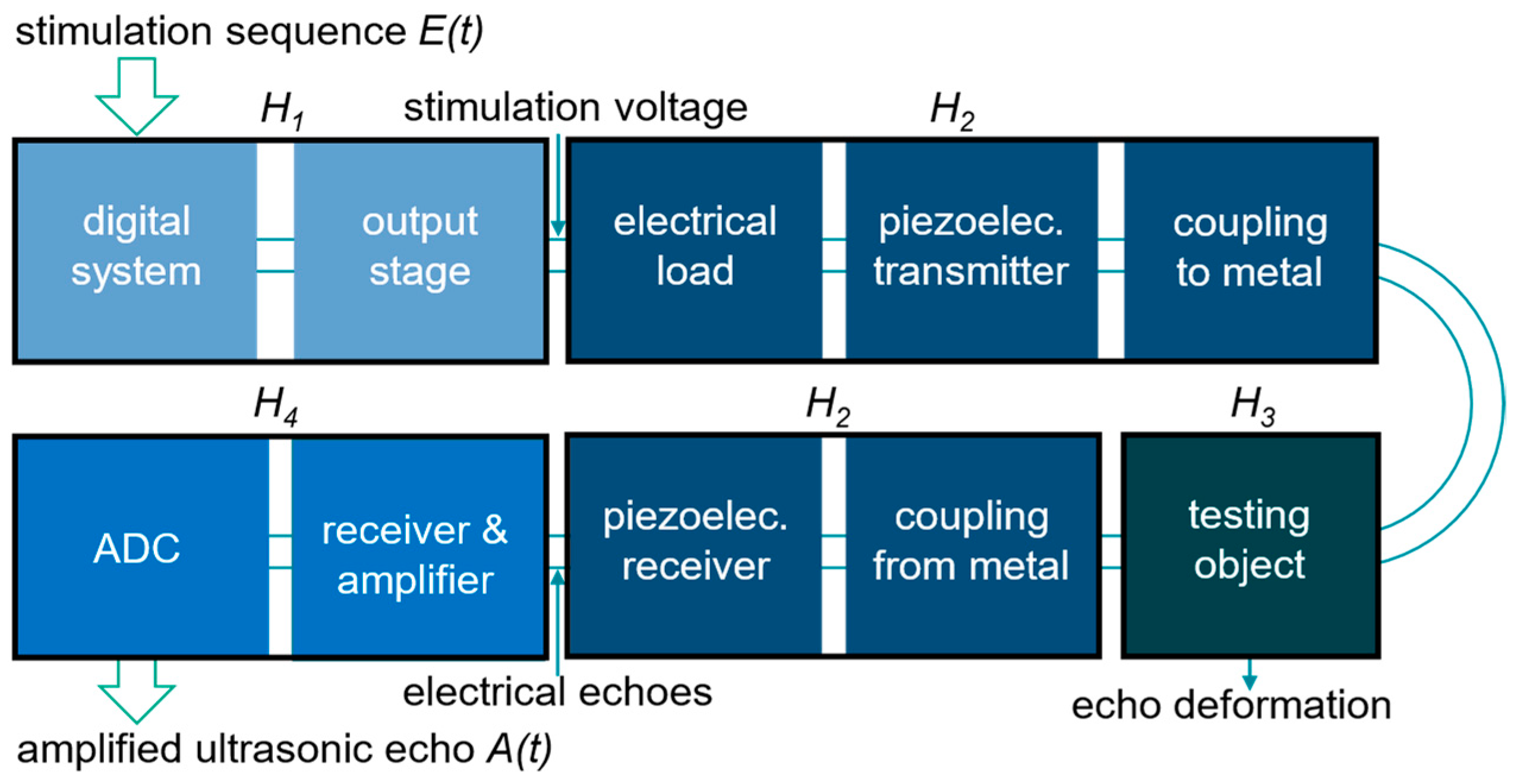

This section deals with the theoretical modeling of functions describing groups of components of an ultrasonic testing system. To develop a modular model covering several grouped components, we must first consider the structure of the system and the signal flow. A typical ultrasonic testing system can be broken down into the components shown in

Figure 2. Since the function of some components is interrelated, these components are grouped and described by a single model.

The signal flow shown in

Figure 2 shows several steps and elements in the conversion from electrical voltage to acoustic wave and back to electrical signal. Each group represents a transfer function, and to calculate the amplified ultrasonic echo (

A(

f)), all transfer functions (

H1(

f)

− H4(

f)) are applied by spectral multiplication to the input sequence (

E(

f)) as shown in (1).

E(

f) and

A(

f) are the spectral representations of the time signals

E(

t) and

A(

t). Since multiplication is a commutative operation, it does not matter which operation is performed first.

In terms of signal flow, the input to the system is an arbitrary stimulation sequence. Depending on the system components used and the test application, the sequence used to stimulate the system may change. Switching to a different transducer may change the center frequency of the sequence, and switching to complex test cases may benefit the application by using complex sequences with frequency, phase, pulse width, or amplitude modulation [

25,

26,

27].

The stimulation sequence is transmitted to the output stage where it is amplified. The output voltage is the actual stimulation voltage of the piezoelectric transducer, which is converted into a sound wave that travels through the subject. In our case, the same transducer is used to transmit and receive ultrasound. An emitted sound wave is reflected at the boundaries of the test object. These reflections travel back to the position of the transducer and are converted back into electrical signals. These signals are quite low amplitude and require amplification before evaluation can take place. After amplification, the data is digitized and made available for visualization.

The description of the groups shown in

Figure 2 and the theoretical implementation of the models representing these groups is explained in the following subsections.

2.1.1. Digital System and Output Stage

The first group of components covers the conversion from the digital stimulation sequence to the stimulation voltage. This group includes the conversion by the digital-to-analog converter (DAC) and the analog amplification by the output stage.

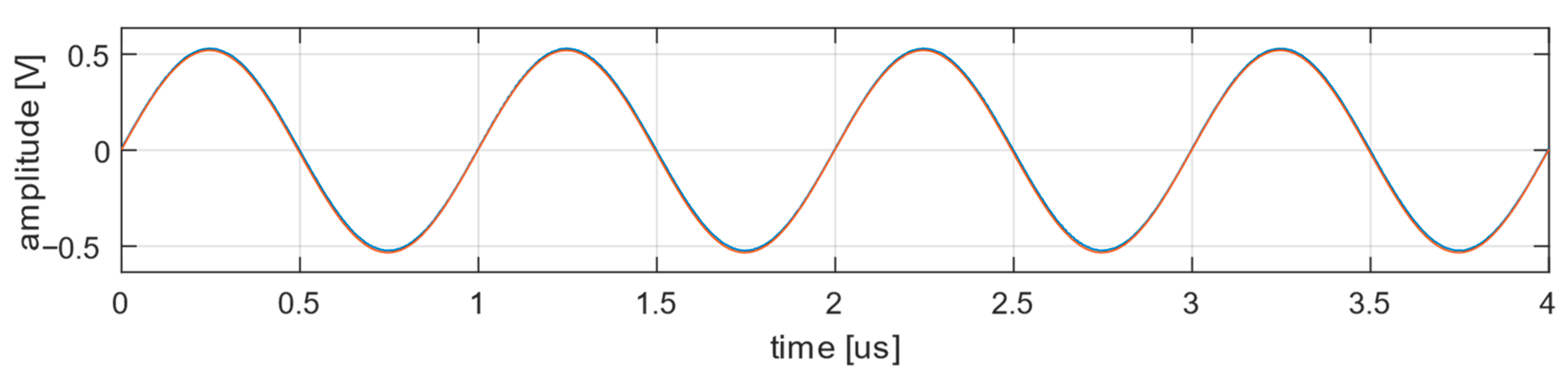

The basic function of the DAC is to convert quantized and sampled digital data into an analog signal. The integration of the DAC means a limitation of the data quantization due to the bit width of the DAC and produces a signal with a bandwidth limited to half the sampling frequency. The second element is the power stage. In a linear ultrasonic inspection system, the output stage provides an analog amplification of the stimulation sequence.

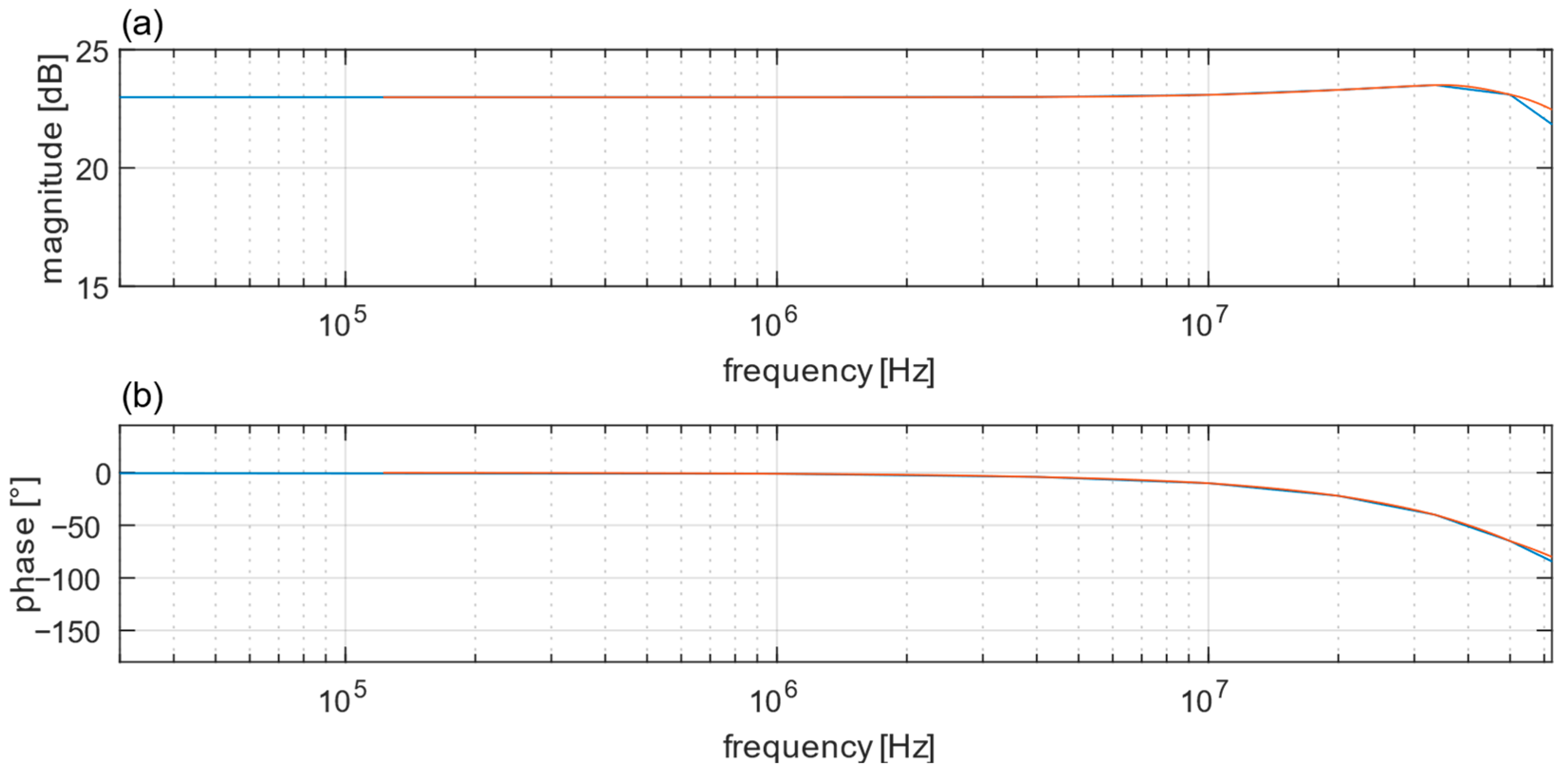

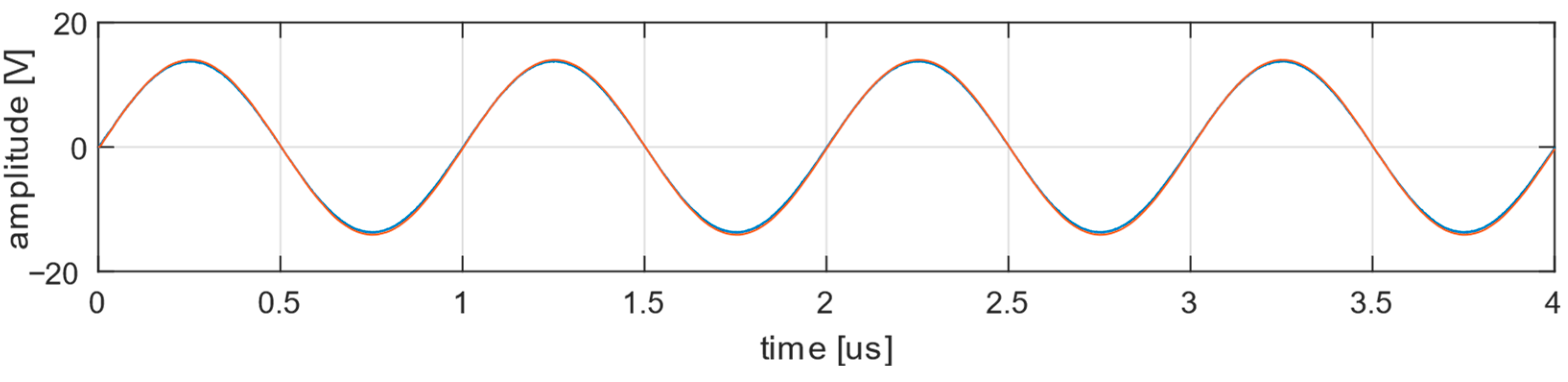

Common descriptions of analog amplifiers and filter structures are amplitude and phase responses [

22]. The transfer function for the output stage can be constructed by combining the amplitude and phase responses of the components used (op-amps, transformers, etc.) from datasheets with filter functions of discrete components. In practice, the transfer function is obtained by measuring with a network analyzer to cover the tolerances of the components.

The design of an output stage is aimed at an application. The stimulation of a piezoelectric transducer requires an output stage capable of meeting its electrical requirements. It should at least be able to transmit signals up to the center frequency of the transducer and be able to handle capacitive loads.

2.1.2. Testing Object

In the signal flow shown in

Figure 2, the test object splits the group describing the piezoelectric transducer into two parts. Since we want to calculate the transducer component as a single transfer function, and since the evaluation of the transducer necessarily involves the test object, the calculation of the test object is performed first. The basic deformation occurring in each specimen can be described by (2) [

28].

Equation (2) describes the sound pressure at a distance z from the transducer and for a frequency f. This is a simplified equation that is only valid in the far field of the ultrasonic transducer used (z > 3 N [

28]). The only effects considered here are the transducer aperture and the grain scattering caused by the material.

The beam opening is an effect based on the near field range N of the transducer, a constant based on the geometry of the transducer and the distance to the transducer z. Grain scattering is an exponential attenuation function.

Apart from the first effect, grain scattering consists of an attenuation component a, which is based only on the distance between two points, and a component b, which is influenced by the frequency and a distance. The scattering coefficients depend on the material properties and the grain structure. Measurement [

29] or experimental approximation can be used to accurately determine the appropriate values for the specimen.

In the case of ultrasonic testing of a given object, the travel distance is the parameter to be evaluated and a transfer function over a usable frequency range is required. For more complex targets, other effects such as multipath scattering need to be considered, which will be part of future work.

2.1.3. Transducer KLM Model

A piezoelectric transducer can contain different layers and materials.

Figure 3a shows a simplified diagram of a piezoelectric transducer and the basic electrical circuit model for the piezoelectric transducer.

The central component is the piezoelectric element. It is connected to the electrical port via the backing layer to the acoustic back port and via one or more matching layers to the acoustic front port. The acoustic front port is coupled to the device under test. The mathematical implementation of this structure works by converting the piezoelectric element and the other layers into an electrical circuit model [

15], as shown in

Figure 3b. The input capacitance C1, the complex impedance X1 and the transformer are based on the parameters of the piezoelectric element only. The circuit elements ZTL include the piezoelectric element and the backing layer, while ZTR is calculated from the piezoelectric elements and the matching layers. The main parameters for the model are the physical parameters of the piezoelectric element and the other layers such as thickness t, radius r, sound velocity c and density ρ. Additional parameters used within the model implementation are the electrical damping for the piezoelectric element, the mechanical damping for each layer and the coupling coefficient kt. The implementation of this model also includes the complex electrical voltage divider for transmission and reception. Therefore, the electrical impedance of the output stage and the receiver amplifier are also relevant.

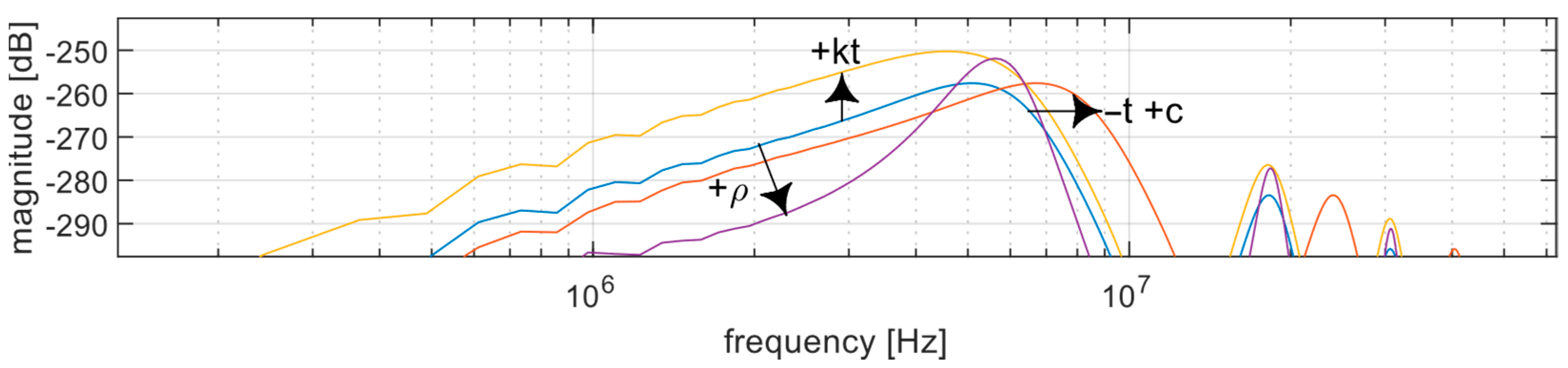

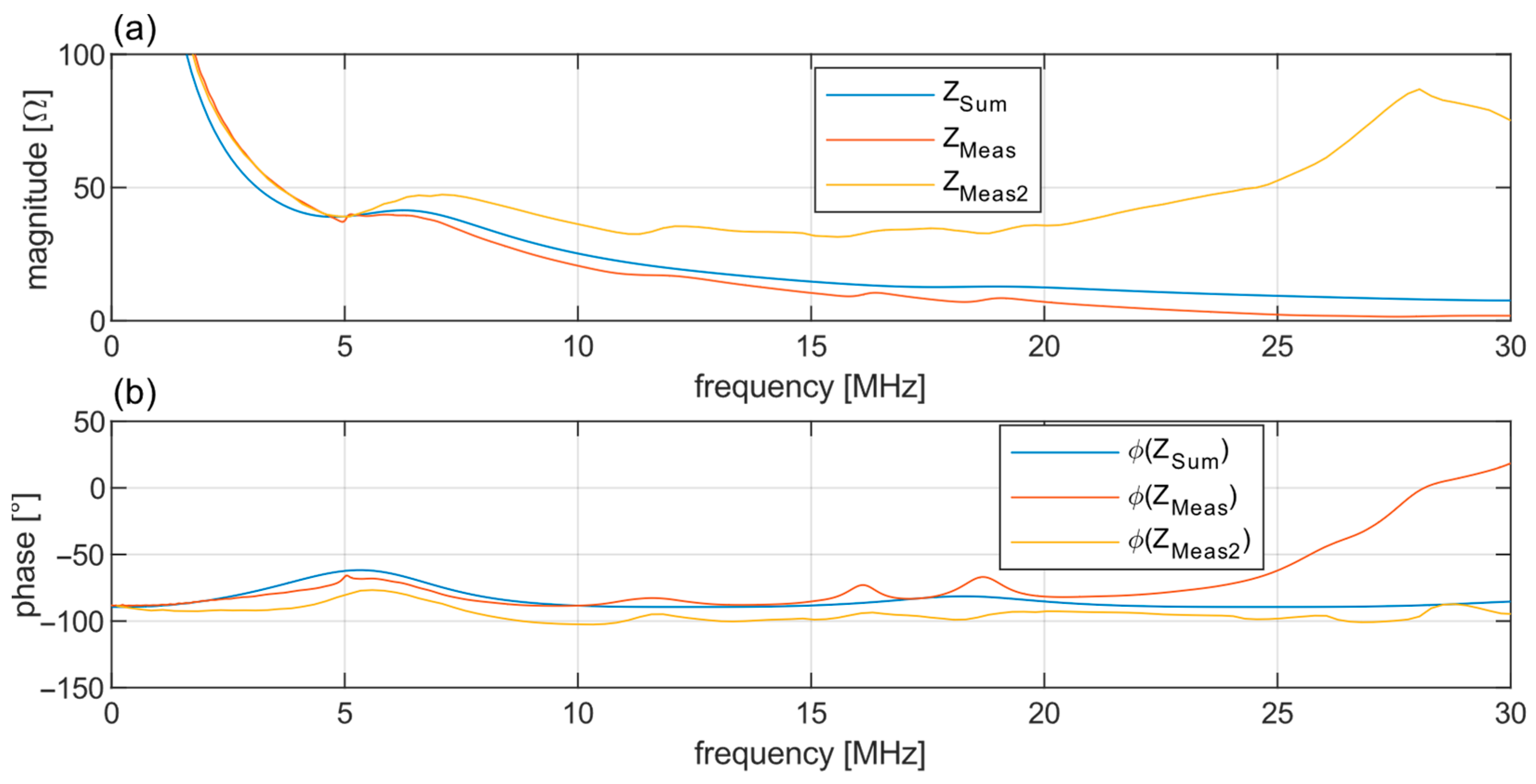

Figure 4 shows the amplitude response of the implementation of the KLM model with air coupling using the parameters presented in

Table 1, including the influence of parameter variation on the amplitude response. The two parameters t and c affect the center frequency of the transducer. The center frequency increases with increasing sound velocity and decreasing thickness. Other parameters have a different effect. Increasing kt also increases the maximum intensity, whereas increasing ρ increases the maximum intensity but reduces the bandwidth.

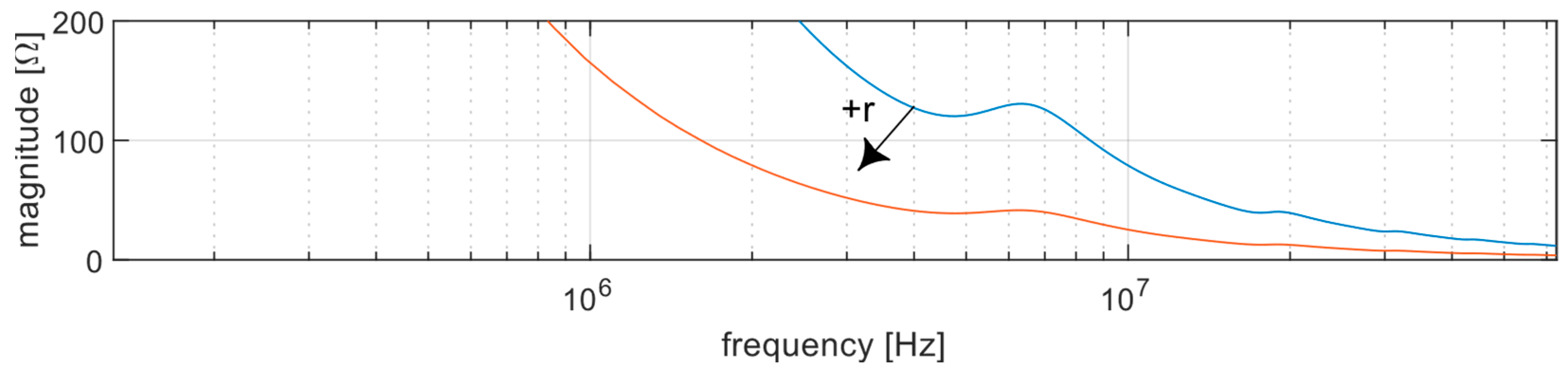

The radius of the transducer has a major influence on the impedance of the transducer.

Figure 5 shows that the impedance of the transducer decreases as the radius increases.

The impedance of the transducer is relevant to the voltage divider in transmit and receive. This effect affects the overall gain but not the center frequency or bandwidth of the transducer.

The primary objective in designing the matching layer is to find the optimum thickness and acoustic impedance to achieve either maximum power or maximum bandwidth. For the backing layer, the acoustic impedance is relevant to the maximum performance of the transducer. In addition to optimizing efficiency, the main purpose of the underlayer is to eliminate reverberation. Several studies have shown that the precise design of the matching and backing layers has a huge influence on the performance and bandwidth of the transducer [

16,

19]. These layers can be modeled using an extended model [

13,

19,

21].

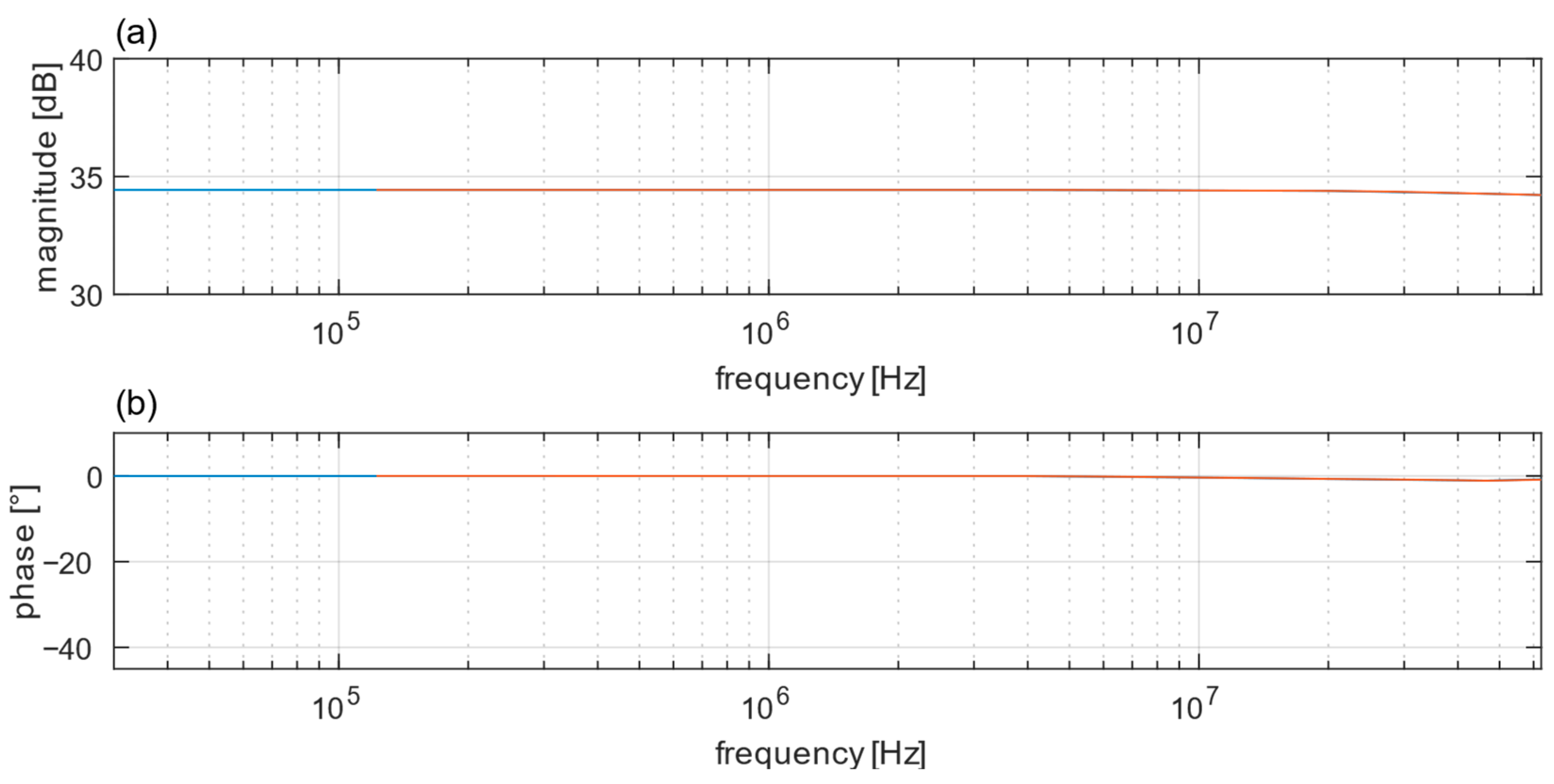

2.1.4. Amplifier and ADC

For the last component, the electrical amplifier and the analog-to-digital converter (ADC), the theoretical considerations from

Section 2.1.1 also apply to this component. The ADC does the opposite of the DAC. The analog signal at the input of the ADC is converted into digital data, depending on the quantization and sampling rate. The analog amplifier has different requirements than the output stage, but the implementation in terms of the simulation model is again an amplitude and phase response.

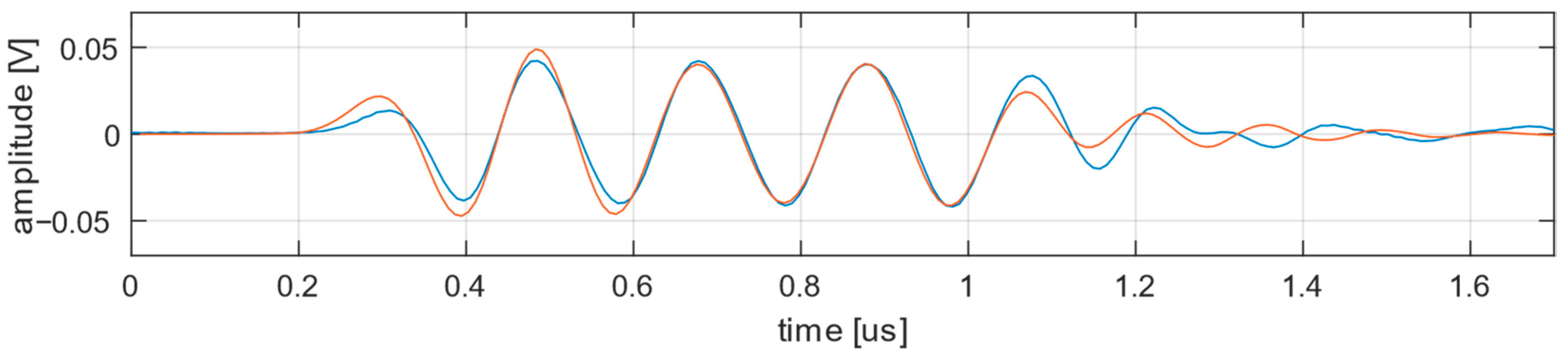

Earlier, we mentioned that in the ultrasonic testing system, the same transducer is used for transmitting and receiving ultrasound. If the same transducer is used, it is inevitable that the transmit and receive electronics will be coupled. In ultrasonic testing, the expected echoes are of very small amplitude. Peaks of less than 1 mV are common. The dynamic range of the ADC should be exploited to achieve the maximum dynamic range in data evaluation. In our test case, a gain of about 30 dB is required to amplify the echoes, but the coupling to the output stage applies the full stimulation voltage to the input of the receiver electronics. To cover both cases, the receiver electronics must be protected against overload. To give a few examples, this could be a protection circuit using depletion mode MOSFets (Metal Oxide Semiconductor Field-Effect Transistors) [

30] or the use of disengageable amplifiers at the input of the electronics. Using these technologies, or driving the analog amplifiers to overload, results in a dead time for the receiver when no valid signals are being measured. This is important for the minimum size of DUTs or the refresh rate of the test system.

Apart from these special situations, the implementation of the analog amplifier is given by an amplitude and phase response as mentioned above. In detail, several amplifier stages are implemented. The transducer can be connected either differential or single-ended. The first stage is built twice in parallel as a non-inverting amplifier with a shutdown option for overload protection during transmission. The second stage is a differential to single-ended converter. The third stage is a variable gain amplifier that allows the gain to be adjusted based on the signal strength. A non-inverting ADC driver is used before reconnecting to the ADC. A more detailed description, including a schematic, can be found in [

24]. After the amplification, the analog signal is converted by the ADC and is the data available for visualization and evaluation.

4. Discussion

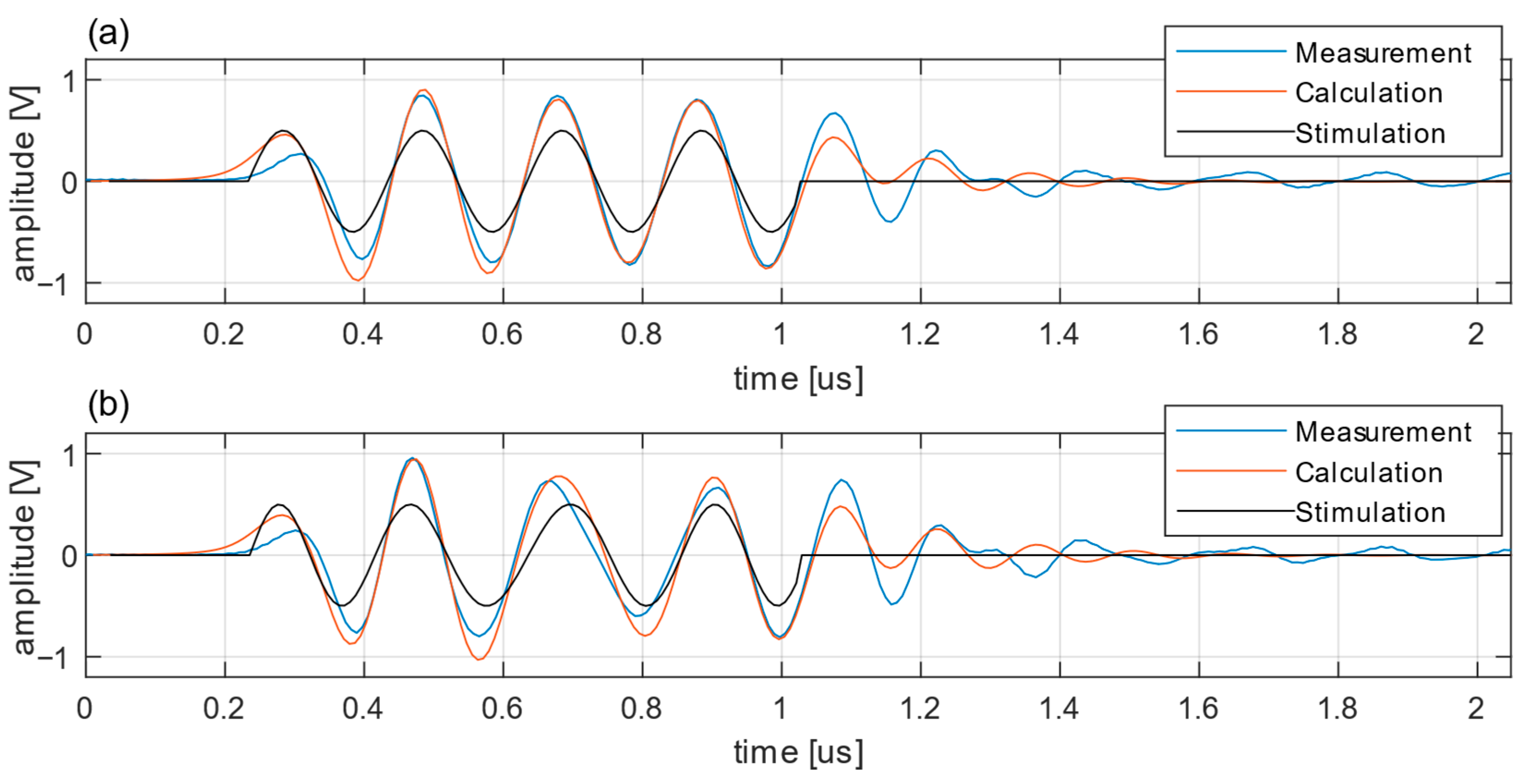

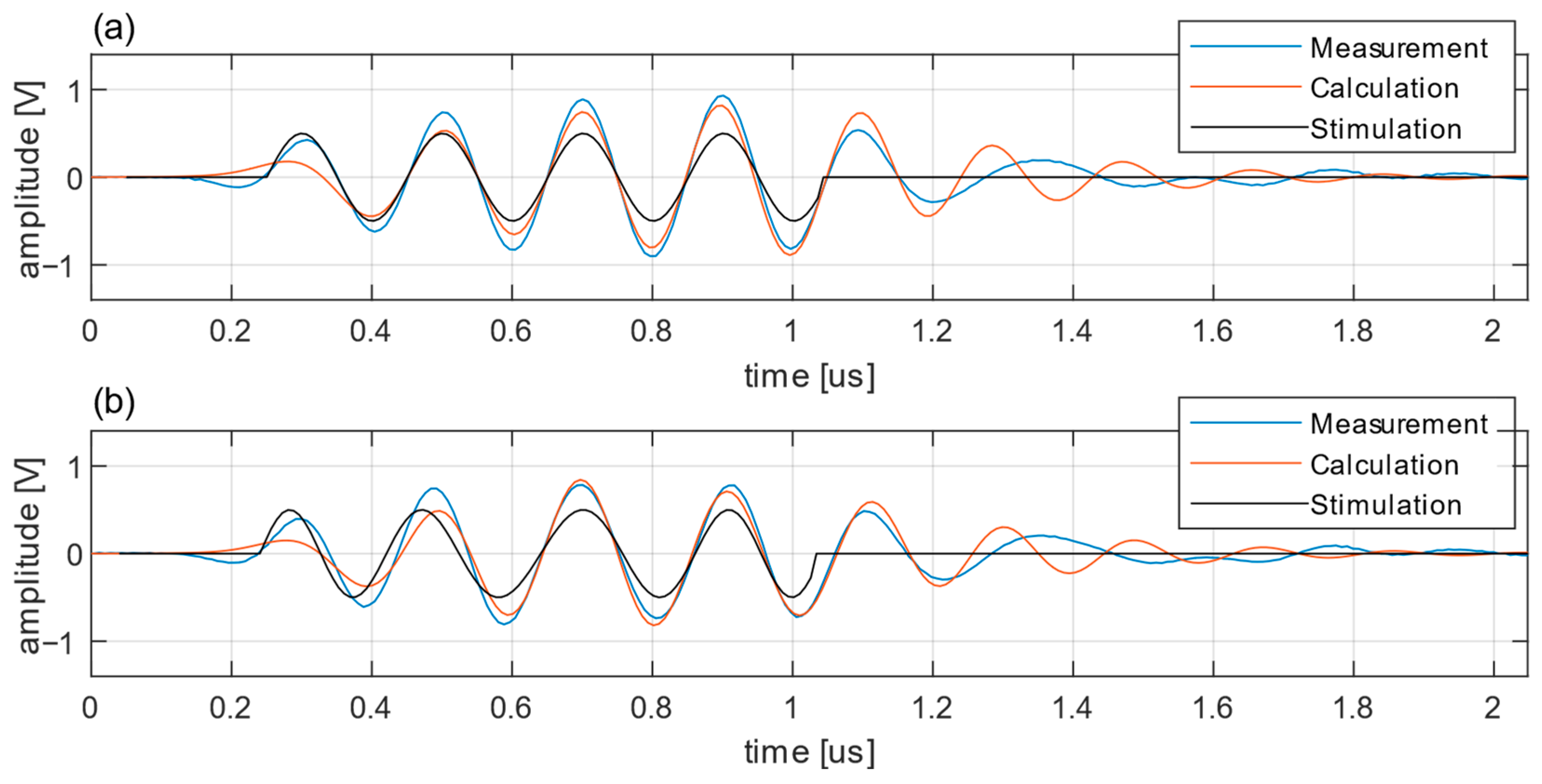

The results presented demonstrate the modular nature of the transfer function as it can be adapted to different system configurations and echo types. The approach is successfully validated with real test system configurations. We show that, although the transducer is the central component in an ultrasonic testing system, the other components are also important and can significantly affect the generation of ultrasonic echoes.

The modular structure of the system description allows one to replace single components while leaving the rest unchanged. In this work, a simple test object was used. After verification of the other components, the test object can be replaced to calculate more complex objects, such as metamaterials. Such complex objects can have multipath and edge effects, inhomogeneous grain structure, etc.

Furthermore, this work demonstrates that real test system components are subject to manufacturing tolerances. Even nominally similar components have variations that affect the accuracy of the models. To achieve an optimal match of a model to real components, many parameters must be considered, and the actual manufactured properties of the components must be accurately determined, rather than using only the specification.

The aim of this work is to implement physically motivated transfer functions and models to gain a better understanding of the system components and their influence on signal deformation. For effective use in echo computation, only one transfer function is required to cover all components. The implementation of real components using model approximations always leads to deviations, as not all effects are covered in detail and manufacturing is subject to tolerances. At the current stage of modeling, we can only implement components that have been analyzed in detail. For the ultrasonic transducers, there is often very little information available about the design.

The modeling approach can be used to design an ultrasonic testing system and evaluate the performance of different methods and testing strategies. The modular structure allows the replacement of individual components and the evaluation of their influence on system performance. For applications operating near center frequency, the presented component models perform well and show negligible deviation. For more complex applications requiring a wide bandwidth, the deviation increases, and the transducer model must be extended to cover a wider bandwidth. For example, the usability of coded stimulation can be evaluated for an application before building a custom ultrasonic inspection system that allows stimulation requiring large quantization and bandwidth. A drawback of the current State of the Art is that accurate representation of complex components requires complex models. To get an idea of the general function and usability of a method, basic models based on datasheet information are sufficient according to the principle presented in this paper. However, these models are limited in their ability to provide an accurate digital representation of the testing system under all operating conditions. If this level of accuracy and ideal representation is required, more detailed information about the actual manufactured components is needed, or even a measurement of the components must be performed, allowing a digital representation of the actual part to be integrated into the system model, limited only by the signal-to-noise ratio.

Because we limited the transfer functions and models to linear approximations, nonlinear effects cause miscalculations. For each component, such effects can occur depending on the component’s characteristics or operating conditions. For example, a misconfigured output stage may cause the voltage to reach the op-amp rail, resulting in clipping of the output signal. Other output technologies, such as switch-based, produce different impedance states. The analog electrical system has a different impedance when the positive or negative voltage is switched and when no switch is activated. These effects cannot be captured by a one-dimensional linear model.

Modeling the test object can become much more complex and many factors must be considered. As long as the sound path is linear and in the domain of linear acoustics, a linear model can cover the object description. Even multiple sound path interactions and superpositions are covered by a linear description because the acoustic signal superposition is integrated over the transducer surface. Inhomogeneous and anisotropic materials are more challenging and require more complex models [

31]. A simple model also does not cover angle-dependent effects such as mode conversion or total reflection. When using multiple transducers or high voltage, the sound pressure in the test object may exceed the linear elastic range and introduce nonlinear effects that cannot be covered by a linear description.

The ultrasonic transducer is also subject to nonlinear effects. Initially, the model is only an approximation of the transducer, providing a fit around the center frequency of the transducer. As the distance from the center frequency increases, the fit becomes worse. Furthermore, not all effects are covered by the presented KLM model, and many more effects, including multiple relationships, can improve the model’s performance. Regarding the nonlinear effects, the piezoelectric plate shows a larger perturbation with increasing voltage [

32].

The receiver amplifier will experience nonlinear effects when it reaches the amplifier rail again. Configuring too much gain can quickly lead to clipping of the recorded signals. While nonlinear effects are beyond the scope of this work, it is still possible to replace components with more complex models that include nonlinear behavior. As long as the connection between the components remains linear and one-dimensional, the structure and the other components can be retained. For example, when moving to a material model that includes a three-dimensional wave equation, the connection to the ultrasonic transducer must be extended from a one-dimensional electrical signal to a three-dimensional surface displacement of the transducer area.

An important consideration in evaluating the sensitivity and accuracy of an ultrasonic inspection system is the signal-to-noise ratio. While this topic is outside the scope of this manuscript, the modular structure of the system model provides the ability to include noise or other types of distortion functions either for the entire system or for each component separately.

For future work, the results of this work can also be used to optimize the system for the use of coded excitation functions. The bandwidth of the current transducer can be increased to allow greater variation in pulse width. Further work will also look at other ways of obtaining the transfer function of the system components and the whole system and using this to calculate echoes for more complex stimulation sequences with optimized echo characteristics. Another important goal of subsequent work is the analysis and implementation of more complex models covering test objects with complex geometry or internal structures up to metamaterials.