Abstract

Additive manufacturing (AM) technologies have witnessed remarkable advancements, offering opportunities to produce complex components across various industries. This paper explores the potential of AM for fabricating bipolar plates (BPPs) in fuel cell or electrolysis cell applications. BPPs play a critical role in the performance and efficiency of such cells, and conventional manufacturing methods often face limitations, particularly concerning the complexity and customization of geometries. The focus here lies in two specific AM methods: the laser powder bed fusion of metals (PBF-LB/M) and material extrusion of metals (MEX/M). PBF-LB/M, tailored for high-performance applications, enables the creation of highly complex geometries, albeit at increased costs. On the other hand, MEX/M excels in rapid prototyping, facilitating the swift production of diverse geometries for real-world testing. This approach can facilitate the evaluation of geometries suitable for mass production via sinter-based manufacturing processes. The geometric deviations of different BPPs were identified by evaluating 3D scans. The PBF-LB/M method is more suitable for small features, while the MEX/M method has lower deviations for geometrically less complex BPPs. Through this investigation, the limits of the capabilities of these AM methods became clear, knowledge that can potentially enhance the design and production of BPPs, revolutionizing the energy conversion and storage landscape and contributing to the design of additive manufacturing technologies.

1. Introduction

In the imminent shift towards a renewable-based economy, hydrogen is emerging as a pivotal energy carrier due to its high energy density and environmentally friendly production possibilities [1,2,3]. However, the predominant method of hydrogen production, relying on fossil fuels like petroleum and coal, raises concerns about escalating greenhouse gas emissions [4,5,6]. As an efficient and promising alternative, water electrolysis stands out, with proton exchange membrane electrolyzer/fuel cells (PEMECs/PEMFCs, hereafter referred to as PEMFCs) offering numerous advantages, such as high-purity hydrogen, the capability to produce compressed gases for direct use or storage and a swift response to current fluctuations [7,8,9]. Despite garnering significant attention, PEMFCs face several hurdles hindering their widespread commercialization, including cost, performance and durability concerns [10,11,12].

Central to PEMFCs are bipolar plates (BPPs), essential for distributing reactants and products as well as conducting the current. These plates constitute a substantial portion (from 40% to up to 51%) of the overall PEMFC cost [13]. Furthermore, the distribution of reactants and the electric contact resistance between BPPs and current distributors highly influence the cell performance [14]. Designing and manufacturing BPPs with intricate flow channels poses challenges, particularly in managing mass transport. Addressing these challenges, additive manufacturing (AM) is emerging as a transformative technology capable of rapidly producing complex structures like lattices and triply periodic minimal surface (TPMS) structures from digital 3D computer-aided design (CAD) models. AM offers significant advantages for several innovative industries like aerospace, energy and healthcare [15,16,17]. Specialized components can be created with AM that result in high-performance, lightweight and cost-effective PEMFCs for future applications [13].

Stainless steel (SS) has emerged as a viable alternative material for BPPs, offering moderate mechanical strength at a lower cost compared to titanium and graphite. However, in harsh environments, such as on the anode side of PEMFCs, SS may require corrosion-resistant coatings like Au, Au/Ni, TiN, Pt/Fe, Ti/Pt, SnO2 or CrN [14,18]. These coatings are applied through various techniques, such as the promising active screen plasma nitriding technique [19]. Conversely, the cathode side experiences less intense corrosion, making untreated SS suitable for this application [14]. Studies have been conducted on the properties and manufacturability of different BPP designs manufactured using PBF-LB/M, such as wineglass-shaped channels and vertical honeycomb geometries. However, a research gap remains regarding the investigation of more complex BPP channel geometries [20,21].

The laser powder bed fusion (PBF-LB/M) and material extrusion of metals (MEX/M) [22] are applied to manufacture BPPs and current distributors as a single AISI SS 316L part with various flow field designs. The experimental findings are especially important in the validation process of flow field simulations that can quickly identify the optimal geometry for the given operating conditions of a PEMFC.

Therefore, this paper aims to analyze the suitability of the two AM processes for the production of metallic BPPs and recognize their advantages and disadvantages. For this, BPPs with six different flow field designs were manufactured and geometrically compared to each other by microscopy and 3D scans.

2. Manufacturing Methods

2.1. MEX/M

The material extrusion of metals is an innovative AM technique revolutionizing metal component production. At its core lies screw-, plunger- or filament-based material extrusion, in which a feedstock composed of metal powder dispersed in a plastic matrix serves as the raw material. The granulate, bar or filament feedstock is extruded layer by layer, akin to in the fused deposition modeling (FDM) process, to construct the desired geometry. This additive approach allows for precise control over material deposition, facilitating the creation of intricate designs [23,24].

MEX/M follows a structured, three-step process: printing, debinding and sintering. First, the desired geometry is printed layer by layer by melting the feedstock. Following printing, the green parts formed by the deposited layers undergo debinding, where the plastic binder within is removed, leaving a porous structure of metal powder particles, also called the backbone. Subsequently, the debinded green parts, also called brown parts, are thermally debinded and sintered at high temperatures. This process involves heating the brown parts below their melting point in order to fuse the metal powder particles [23,25,26]. This results in metal parts with the desired mechanical properties and relative densities exceeding 97% [23,27].

Hot isostatic pressing (HIP) is a post-processing strategy that can significantly improve MEX/M parts by increasing their density to almost 100% and thus increasing their mechanical strength. However, due to its high price, HIP is only used when necessary. HIP and other, more conventional post-processing technologies like surface treatment, coating, subtractive machining and heat treatment allow for the fine-tuning of the material properties and surface finishes, enabling customized solutions for various industrial applications [23].

The disadvantages of the MEX/M process include a resolution that is limited by the size of the nozzle, inferior surface finishes and the high complexity of the process because of the need for debinding and sintering [23,28]. The shrinkage of MEX/M components during the sintering process can be more than 20% and makes it difficult to achieve the required dimensional accuracies [29]. Additionally, intricate components are often in need of support structures for both printing and sintering and add another layer of complexity to the MEX/M process [30].

MEX/M offers several advantages over traditional manufacturing methods. Firstly, it provides a high degree of design flexibility, enabling the fabrication of complex geometries without the restrictions of conventional machining or casting processes. Moreover, MEX/M eliminates the need for molds, which are mandatory for the metal injection molding process, which has process similarities to the MEX/M process chain, as well as reducing tooling costs and lead times. Additionally, the most common MEX/M approach (filament-based) eliminates the necessity of depowdering the final part after sintering, streamlining post-processing workflows compared to powder-based AM processes. Lastly, the widespread availability of MEX/M feedstocks made from various materials contributes to the accessibility and scalability of this AM process [31].

2.2. PBF-LB/M

The laser powder bed fusion of metals is a widely recognized AM technology that has gained prominence due to its capability to fabricate complex, dense and robust metal parts with an exceptional geometrical resolution. This technology is particularly valued for its versatility in processing a diverse array of materials, including high-strength aluminum alloys, high-melting-point elements and high-entropy alloys, which makes it suitable for various demanding applications across industries such as aerospace, automotives and healthcare [15,32,33].

One of the significant advantages of PBF-LB/M is its ability to produce intricate and lightweight components, enabling the design and manufacture of complex geometries that would be challenging or impossible to achieve with traditional manufacturing methods. However, to ensure the quality and integrity of these complex parts, the use of support structures is essential. Properly designed support structures prevent defects and warping during the build process due to thermally induced residual stresses. The development of advanced software tools for support generation and optimization has become crucial in this context [34].

Despite its strengths, PBF-LB/M has certain limitations, particularly concerning the surface quality and feature size. These challenges can be mitigated through hybrid manufacturing approaches, where PBF-LB/M is combined with subtractive techniques for post-processing. This integration enhances the overall functionality of the parts, enabling the production of components that meet stringent performance criteria [35]. Post-processing techniques such as hot isostatic pressing and solution annealing are also vital in the PBF-LB/M process. These methods are employed to improve the microstructure of the printed parts, reduce porosity and enhance the mechanical properties, ensuring that the final components meet the required specifications for critical applications [36].

Another constraint of the PBF-LB/M process is the need to get rid of semi-sintered or loose powder which is trapped in the pores of the solidified material or in the cavities of the component’s geometry after build completion. The remaining powder can be a health hazard to humans, block intricate cavities like cooling channels or fully sinter in thermal post-processes like HIP or heat treatment [37]. Typically, powder removal is achieved by loosening the powder first and then flushing it out with the help of a fluid [38]. Since these powder removal methods have their own restrictions, it is important to address this issue early in the design stage of PBF-LB/M components by avoiding closed cavities or undercuts.

In addition, the development of new materials for PBF-LB/M can be advanced through in situ alloying, where elemental powders are mixed during the printing process. While this approach opens up new possibilities for creating custom alloys, achieving a homogeneous mixture remains a challenge that requires further research and optimization [39,40].

Finally, advancements in beam-shaping techniques have shown promise in addressing challenges related to laser–material interaction. By tailoring the shape of the laser beam, it is possible to improve both the quality and efficiency of the PBF-LB/M process, paving the way for the more reliable and cost-efficient production of high-performance metal parts [41].

It is clear that both technologies have different boundary conditions, such as their minimum possible layer height and different resolution rates. The initial intention was to identify their respective potential. The PBF-LB/M process is suitable for manufacturing complex structures that cannot be produced conventionally with a density of more than 99%. The MEX/M process, on the other hand, which includes sintering and debinding steps rather than metal injection molding (MIM), can act as a complementary solution to the MIM process and enable the mass production of functional products [23].

3. Methodology

The different flow fields of the BPPs were designed in Autodesk Inventor 2023 (Autodesk, San Rafael, CA, USA) based on the state of the art [42,43]. The designs included a classic serpentine flow field structure as a starting point for further investigations; see Figure 1a. This serpentine structure was altered with various features that could positively influence the performance of a fuel cell in different ways. The dimensions of the square BPPs were 33 mm in width and length and 3 mm in thickness. For the investigation and evaluation, only the width and length were used, as it was evident that the MEX/M process would be less accurate regarding the thickness due to the greater layer heights. Unless otherwise specified, the channels of all examined geometries were 1 mm in width and height. To see all the standard tessellation language (STL) files of the BPP designs, scanning data and the measurement point locations of the scan analysis, the reader is kindly referred to the supplementary dataset of this work [44]. The bars that separated the serpentine flow channel were altered with grooves (0.3 mm high and 0.4 mm wide) that connected the neighboring channels with each other; see Figure 1b. This had a homogenizing effect on the reactant distribution at the interface and thus ensured a homogenized operating state.

Figure 1.

Flow field design of the manufactured bipolar plates; structures (a–f): serpentine, rib grooves, wave structure, triangular baffles, wavy bottom, serpentine [narrowing].

The designs in Figure 1c–e were primarily aimed at avoiding or reducing water accumulation in the channels. The wave structure in Figure 1c varied the width of the channel from 1.1 mm to 1.4 mm and prevented the accumulation of water in rectangular geometries. In Figure 1d, it can be seen that 2 mm long and 0.7 mm high pyramids were integrated into the channels, through which local turbulence was introduced into the flow of reactants, which also prevented the accumulation of water and locally increased the flow velocities. A similar, albeit homogeneous, effect was achieved by the wavy-shaped bottom of the channel, which is shown in Figure 1e. Because of this particular design, any water that formed could not accumulate. The iterative change in the channel height from 0.477 mm to 1.0 mm led to a repeatedly locally influenced flow velocity, which resulted in an overall more homogeneous flow. The serpentine [narrowing] design from Figure 1f exhibited a steady narrowing of the channel in the direction of the outlet from 1.7 mm to 0.3 mm in width. This ensured increasing pressure in the rear area of the channel and thus led to a more homogeneous pressure distribution within the BPP.

Changing a flow field design using grooves has already been investigated experimentally in [45,46]. The channel width and height were set to 1 mm, as in this work, with a groove cross-section of 0.2 mm. Compared to a simple serpentine structure, the result was an increase in the current density of 16% and an increase in the power density of 3%. Conventionally manufactured wave structures were produced from a graphite material with varying widths of 1 mm to 1.25 mm, 1 mm to 1.5 mm and 1 mm to 1.75 mm [47]. The results of the experimental investigation with different cell temperatures and air and hydrogen flow rates showed that the wave structures with a width of 1 mm to 1.25 mm had a higher performance than the other wave structures and achieved a 20.15% increase in the maximum output power with a hydrogen and air flow compared to conventional serpentine structures [47].

A simulative study of pyramid structures was conducted in [48], and the results showed that the reactant gas distribution in the gas diffusion layer could be increased compared to that of the conventional structure.

Wavy bottom channels were investigated simulatively in [49,50] and an increase in the pressure drop and an increase in the mass transfer of the reactant gas were revealed. The current density could be increased further by 21.8% with this design feature compared to a simple serpentine structure. In this case, the channel sizes were also 1 mm in the cross-sectional area, and the wave bottom structure had a height of 0.5 mm [49].

Narrower serpentine channels were simulated in [51], where the channels were continuously reduced from a width of 1.5 mm to 1.9 mm to a width of 0.5 mm to 0.1 mm. It was shown that a reduction in the channel width generally provided an advantage regarding the uneven flow distribution at high current densities compared to conventional serpentine structures. At the largest reduction in the channel width, the current density limit was 1.35 times higher than in the conventional design [51].

The BPPs were manufactured using the MEX/M and PBF-LB/M methods to compare both manufacturing processes regarding their suitability in the production of BPPs with complex geometric features and high-dimensional accuracy.

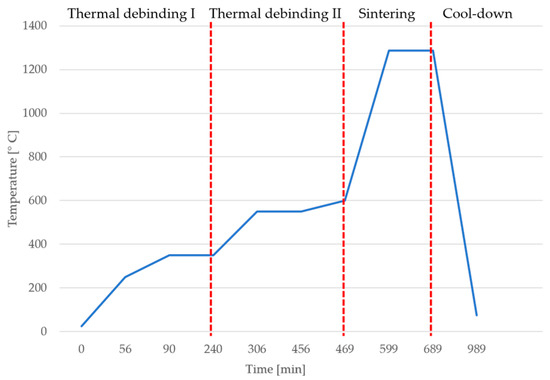

The manufacturing of the BPPs using the MEX/M process was performed on a Renkforce RF 2000 (Conrad Electronic SE, Hirschau, Germany) 3D printer with an extruder that had been optimized for constant metal filament feeding. A V6 nozzle (E3D, Chalgrove, UK), made of hardened steel and with a diameter of 0.4 mm, was used. The slicing of the CAD models was performed with Netfabb Ultimate 2023 (Autodesk, San Rafael, CA, USA) software for all PBF-LB/M models, and for the MEX/M models, a Simplify3D slicer (Cincinnati, OH, USA) was used. Available MEX/M design guidelines were adopted and are applied in this paper, including in regard to the process parameters (Table 1) and the powder composition of the 316L SS [52]. The sinter process and debinding of the BPPs was performed according to [27]. For the chemical debinding, each BPP was submerged for 12 h at 40 °C in 500 mL acetone as a solvent. The thermal debinding and sintering were performed in an Aim3D ExSO90 (New AIM3D GmbH, Rostock, Germany) sinter oven. Argon (99.9%) was used for the sintering atmosphere, and the sintering cycle used, with a maximum temperature of 1286 °C, is shown in Figure 2.

Table 1.

Parameters of the MEX/M manufacturing process.

Figure 2.

Representation of the sintering cycle for all BPPs produced in the MEX/M process.

The PBF-LB/M BPPs were produced using an MPrint 3D printer (One Click Metal GmbH, Tamm, Germany), and the process parameters shown in Table 2 were used. As in the MEX/M process, the PBF-LB/M BPPs were printed using a 316L feedstock. The spherical particle size distribution of the PBF-LB/M material was D10 = 19 μm, D50 = 29 μm and D90 = 43 μm according to ISO 13322-2, which was provided by the manufacturer, Material 4 Print GmbH & Co. KG (Löhne, Germany) [53,54].

Table 2.

Parameters of the PBF-LB/M manufacturing process.

The MEX/M filament from PT+A GmbH (Dresden, Germany) also had spherical metal particles, where the sizes were in the range of 2 μm–15 μm [27,55]. Based on a direct comparison, the MEX/M feedstock appeared to use finer metal powder than the PBF-LB/M feedstock.

For the dimensional accuracy measurement of the manufactured BPPs, a Keyence VL-500 (Keyence, Osaka, Japan) coordinate measuring machine 3D scanning system was used. It had a geometric resolution of ±10 μm. The associated scanning software, VL-500 application series (Keyence, Osaka, Japan), enabled the analysis of the scanning data by combining scans from different angles and performing 3D CAD comparisons that visualized geometric deviations between the printed BPPs and the original CAD data as false-color pictures. A VHX-S600E microscope from Keyence (Keyence, Osaka, Japan) was used to create images of small BPP features.

4. Results and Discussion

When measuring the dimensions of the MEX/M BPPs, it was observed that the channels were narrower and the ribs wider than those designed in CAD software. This was due to a combination of over-extrusion during printing and the shrinkage of the component in the sintering step. To measure these inaccuracies, three cubes with dimensions of 10 × 10 × 10 mm3 were fabricated and measured both as green parts and as sintered components in the same process chain. The shrinkage from the green body to the sintered part in the XY direction was 0.870 mm (8.70%), and in the Z direction, it was 0.896 mm (8.96%). The shrinkage was greater in the Z direction because of the higher thermal gradient, the effect of the layer direction and gravity [23,56,57]. The shrinkage of the measured cubes was below the typical MPIF 35 MIM standard, which is in the range of 12–20%, and is an indication of suitable sintering parameters [23].

This shrinkage was also reflected in the dimensions of the BPPs. By incorporating the shrinkage and over-extrusion into the component design, this effect can be compensated for in future BPPs. Therefore, in the following comparison of dimensions, the digital CAD models of the MEX/M BPPs were scaled according to the measured shrinkage values to enable a meaningful comparison. This step was not necessary for the PBF-LB/M BPPs as they did not show significant shrinkage.

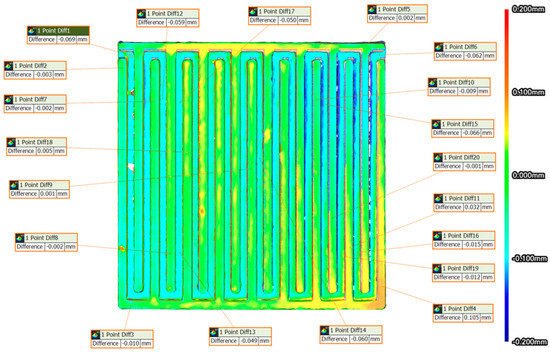

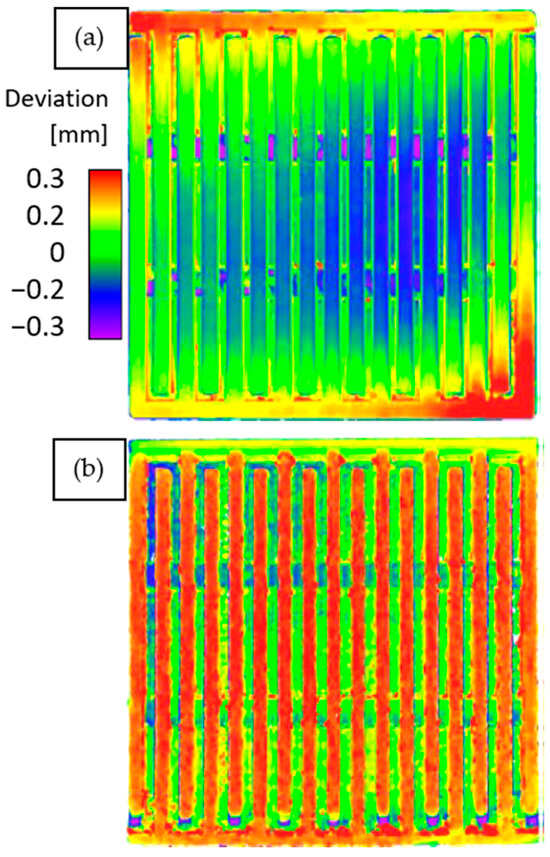

Three-dimensional scans of all the produced BPPs were generated by using the Keyence VL-500 and is shown, e.g., in Figure 3. Subsequently, the scanned data were overlaid onto the original CAD geometry to generate 3D CAD comparisons using the provided software. The color mapping of the structures represents the deviations of the scans (from +0.2 mm to −0.2 mm) from the reference geometry of the BPPs. In the color mapping, blue areas indicate deviations towards the inside and red areas indicate deviations towards the outside of the designed BPPs. Green areas represent little to no deviations. From the images, only qualitative statements regarding printing accuracy can be made. This is due to the fact that artifacts and inaccuracies arise during data processing, making precise quantitative analysis impossible.

Figure 3.

Locations of all 20 measurement points used for the geometric analysis of the scanned BPPs, shown for an example of the serpentine structure produced in the PBF-LB/M process.

To enable a comparison between the two manufacturing methods, 20 measurement points on the surface of all the scanned BPPs were created and examined. The location of these points was selected in such a way as to obtain results that were as holistic as possible, choosing geometrically interesting and highly deformed areas (the gas inlet and outlet, outer and inner walls, the bottom of the gas channel and geometric features if present in the BPP geometry). The location of all the measurement points is shown in Figure 3 using the example of the serpentine structure produced in the PBF-LB/M process.

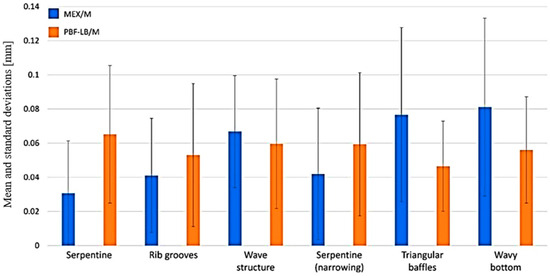

The mean deviations from the CAD geometries, as well as the standard deviations among the measurement points, were calculated and analyzed. A graph showing the mean and standard deviations of all the produced BPPs is presented in Figure 4, allowing for a comparative analysis of how the two manufacturing processes performed in terms of accuracy and consistency.

Figure 4.

Mean and standard deviations of the produced BPPs from their original CAD geometries.

The MEX/M process produced smaller mean deviations from the original CAD models for the serpentine, rib groove and serpentine (narrowing) geometries compared to the PBF-LB/M process. For instance, the serpentine geometry had the lowest mean deviation of all the MEX/M BPPs with a deviation of 0.031 mm, whereas this was more than twice as high at 0.065 mm for PBF-LB/M. Similarly, the rib groove geometry showed a lower mean deviation of 0.041 mm with MEX/M compared to 0.053 mm in the PBF-LB/M process. Notably, rib grooves exhibited the second-lowest mean deviations of all geometries in both processes. Also, the serpentine (narrowing) BPPs could be produced with higher accuracy using the MEX/M process, demonstrating a significantly lower mean deviation of 0.042 mm compared to those produced using PBF-LB/M with 0.059 mm. On the other hand, both geometries with small features (triangular baffles and wavy bottom) and the wave structure performed better in the PBF-LB/M process. The wave structure exhibited a slightly lower mean deviation in the PBF-LB/M (0.060 mm) process compared to MEX/M (0.067 mm). Triangular baffles and wavy bottom geometries followed a similar trend, with those produced using MEX/M showing significantly higher mean deviations (0.077 mm and 0.081 mm, respectively) than in the PBF-LB/M process (0.047 mm and 0.056 mm, respectively). These discrepancies likely stemmed from the small features in these two geometries. A more detailed description of this will be given further down in this section.

Notably, the triangular baffle geometry showed the lowest mean deviations in the PBF-LB/M process but the second highest in the MEX/M process. Generally, the mean deviations across all geometries were more consistent when manufactured using the PBF-LB/M process and more geometry-dependent when manufactured using MEX/M.

The standard deviations indicated the measurement consistency, and both processes exhibited varying degrees of variability across the examined geometries (see Figure 4). Serpentine, rib groove and wave structures showed standard deviations in the MEX/M process in a small range from 0.031 mm to 0.033 mm and thus less variability than in the PBF-LB/M process, with values between 0.038 mm and 0.042 mm for the same geometries. The serpentine (narrowing) geometry also exhibited a slightly lower standard deviation with MEX/M manufacturing, at 0.038 mm, compared to 0.042 mm with PBF-LB/M manufacturing. As seen in the mean deviations, MEX/M struggled with the small features in the triangular baffles and wavy bottom geometry, having standard deviations of 0.051 mm and 0.052 mm, respectively. In contrast, the PBF-LB/M process produced significantly more consistent standard deviation values of 0.026 mm and 0.031 mm, respectively. Overall, the PBF-LB/M process tended to have more consistent results for the assessed geometries with small and intricate features, as indicated by generally lower standard deviations compared to those produced using MEX/M. For all other geometries, the MEX/M process exhibited lower standard deviations and thus more consistent results.

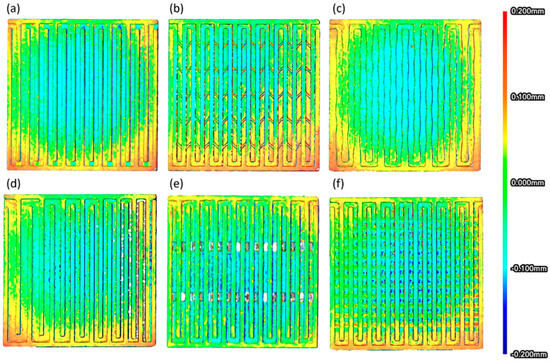

The BPPs generally exhibited high standard deviation values. For some structures, such as the narrowing serpentine structures, triangular baffles, and wavy bottom structures, the ranges fluctuated by more than 50% relative to the mean deviation. Possible reasons for this were, on the one hand, that the points were set manually in the evaluation of the structures, and therefore it was not always possible to evaluate the same point on the BPPs. Therefore, there was generally a measurement inaccuracy in the evaluation, which was unavoidable due to technical limitations. On the other hand, white areas of the BPPs with standard deviations of more than 50% can be recognized in Figure 5 and Figure 6. These areas contained the smallest design features and were not fully captured by the scanning system, meaning that there was also a fundamental source of measurement error. In order to reduce the high fluctuations in the measurements, more measuring points must be set, and the scan areas will have to be divided into several smaller segments.

Figure 5.

Three-dimensional CAD comparison of the BPPs produced in the MEX/M process; structures (a–f): serpentine, ribgrooves, wave structure, serpentine [narrowing], triangular baffles, wavy bottom.

Figure 6.

Three-dimensional CAD comparison of the BPPs produced in the PBF-LB/M process; structures (a–f): serpentine, rib grooves, wave structure, serpentine [narrowing], triangular baffles, wavy bottom.

A qualitative examination of the 3D CAD comparison images shown in Figure 5 and Figure 6 revealed that the PBF-LB/M process had a tendency to produce BPPs with corners that bent upwards, a characteristic which was less pronounced in the MEX/M BPPs.

A small study on stacked BPPs evaluated the possibility of manufacturing several BPPs in one pass and simultaneously reducing the warpage of the outer corners. Therefore, three serpentine BPPs were oriented in a standing position, connected by 2 mm wide extrusions and manufactured using MEX/M from 316L SS. Subsequently, the individual BPPs were separated with a metal saw and polished. The results were BPPs with significantly reduced warpages at the corners, of which an example is shown in Figure 7. The red areas in Figure 7b are due to inaccuracies in the separation process. A disadvantage of this procedure was the overhangs that were created by orienting the BPPs in a standing position. Further research should explore this promising approach.

Figure 7.

Three-dimensional CAD comparison of serpentine BPPs made from 316L using MEX/M. Manufactured (a) alone and horizontally and (b) stacked in a vertical, standing-up orientation.

It can be stated that the PBF-LB/M process exhibited more consistent mean deviations across all BPP geometries, whereas the mean deviations of the MEX/M process were more geometry-dependent. The BPPs with no intricate features showed a lower mean deviation when produced using MEX/M than using PBF-LB/M. In contrast, the PBF-LB/M process showed significantly lower mean and standard deviations when it came to small and complex features, as can be seen in the triangular baffles and wavy bottom geometries.

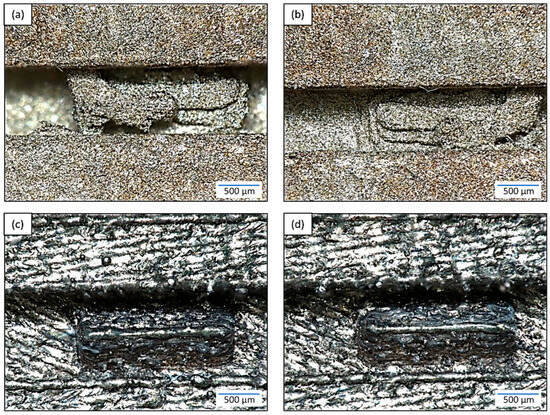

Generally, the BPPs produced using the MEX/M process became less accurate as the structures became smaller. For example, when comparing the triangular baffles manufactured using both processes (see Figure 8), the difference quickly became apparent: the pyramid-shaped structures produced using the MEX/M process, particularly at the tip, could not be manufactured true to the CAD. This was mainly due to the selection of a nozzle that was too wide, but it could also have been influenced by other process settings. Previous test series have shown that even finer structures can be produced accurately and consistently with the CAD model if the settings are adjusted and a finer nozzle is used [58]. Additionally, the tendency to produce corners bent upwards was significantly less pronounced in the MEX/M process.

Figure 8.

Comparison of (a,b) MEX/M- and (c,d) PBF-LB/M-produced pyramids inside the channels of the triangular baffle geometry.

The choice of a manufacturing process depends heavily on various parameters like the complexity of the model and the tendency of the design to warp at the outer corners. According to the findings of this paper, the MEX/M process shows great promise for the fabrication of BPPs in the near future, especially when the problems with small and complex features are overcome. For this to happen, subsequent research in this field is needed.

The economic feasibility of both manufacturing methods was assessed using the cost tool developed in [59], which contains the system and material prices used in this work and roughly estimates the costs as a function of the number of units. It should be noted that the costs are approximated based on the component volume using a simplified approach. It is assumed that the component is a cuboid fully composed of the material, thereby estimating the maximum costs. The cost tool is freely available at [60] and can be supplemented with additional -machine setups. Based on the BPP dimensions and volume, excluding post-processing, the component costs for a single BPP were EUR 121 in the MEX/M process and EUR 115 in the PBF-LB/M process. It is interesting to note that the MEX/M process chain for the production of a BPP generally assumed to be cost-effective was more expensive than the PBF-LB/M process chain. One possible reason for this is the cost of the multi-stage process chain, which requires more energy, as well as the significantly higher material costs of the filament, which were more than 4.5 times higher than the cost of the 316L powder for the PBF-LB/M process [59]. At EUR 270, the production costs for eight BPPs in the MEX/M process were exactly twice as high as the costs for production in the PBF-LB/M process. Other factors, such as several cost-intensive sintering runs, played a role due to the limited chamber volume of the sinter oven used. Furthermore, the stacking possibility was not considered in the cost estimation, meaning that the costs were overestimated and the maximum capacity of the chamber was not considered. Therefore, selecting the PBF-LB/M process for the manufacturing of more complex components appears to be both more precise and cost-effective.

5. Conclusions

In this paper, the manufacturability in the MEX/M and PBF-LB/M processes of six different bipolar plate geometries with 316L material was investigated. These technologies basically showcase the possible production methods for different bipolar plate geometries. In the MEX/M process, the limits of the technology were identified in the production of small features. For example, the pyramids in the triangular baffle structures were not produced with dimensional accuracy and shape fidelity, thereby compromising the intended function of the pyramids. One way to produce more precise features in this process is to reduce the extrusion multiplier, which has a significant influence on the extrusion process in green part production [61]. Furthermore, a smaller nozzle can also ensure a higher level of detail.

Nevertheless, the MEX/M process also had some manufacturing advantages, especially compared to the PBF-LB/M process. For example, serpentines, rib grooves and narrowing serpentines could be produced with a lower standard deviation, which was in the range of 0.03 mm to 0.04 mm. The warpage of the thin bipolar plates could be avoided by stacking several plates or by printing a complete PEMFC. The PBF-LB/M method was better suited than the MEX/M method for producing complex, irregular structures such as wavy bottom structures or wave structures, with mean deviations of 0.06 mm and 0.058 mm, respectively.

To summarize the potential of the two AM methods, it can be said that the PBF-LB/M method can be used for more complex structures with detailed geometric features. The MEX/M method offers a good trade-off between sufficient accuracy for simpler geometric bipolar plates and the necessary precision. Therefore, possible applications of the PBF-LB/M method include prototyping geometrically complex bipolar plates and performing experimental evaluations to compare with simulation results. The MEX/M process can also be used for prototype production, but here the experimental evaluation should focus on preparation for mass production using the MIM process.

Author Contributions

Conceptualization, K.A.; methodology, K.A.; software, J.H.; validation, K.A. and T.R.; formal analysis, K.A. and J.H.; investigation, K.A. and S.R.; resources, S.R. and J.H; data curation, K.A. and J.H.; writing—original draft preparation, K.A. and J.H.; writing—review and editing, K.A.; visualization, K.A. and J.H.; supervision, K.A. and C.E.; project administration, K.A.; funding acquisition, K.A. and C.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are published in: Asami, M.K.; Roth, S.; Hünting, J.; Röver, T.; Emmelmann, C. Metallic Bipolar Plate Production Through Additive Manufacturing: Contrasting MEX/M and PBF-LB/M Approaches; TUHH Universitätsbibliothek: Hamburg, Germany, 2025. https://doi.org/10.15480/882.14567 [44].

Conflicts of Interest

Author Sebastian Roth was employed by the company: Quest One GmbH. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

| 3D | Three-dimensional |

| AM | Additive manufacturing |

| BPPs | Bipolar plates |

| CAD | Computer-aided design |

| FDM | Fused deposition modeling |

| HIP | Hot isostatic pressing |

| MEX/M | Material extrusion of metals |

| MIM | Metal injection molding |

| MPIF 35 | Materials Standard 35 for MIM Parts |

| PBF-LB/M | Laser powder bed fusion of metals |

| PEMEC/PEMFC | Proton exchange membrane electrolyzer/fuel cell |

| SS | Stainless steel |

| STL | Standard tessellation language |

| TPMS | Triply periodic minimal surface |

References

- Agyekum, E.B.; Nutakor, C.; Agwa, A.M.; Kamel, S. A Critical Review of Renewable Hydrogen Production Methods: Factors Affecting Their Scale-Up and Its Role in Future Energy Generation. Membranes 2022, 12, 173. [Google Scholar] [CrossRef] [PubMed]

- Züttel, A.; Remhof, A.; Borgschulte, A.; Friedrichs, O. Hydrogen: The future energy carrier. Philos. Transact. A Math. Phys. Eng. Sci. 2010, 368, 3329–3342. [Google Scholar] [CrossRef] [PubMed]

- Sarmah, M.K.; Singh, T.P.; Kalita, P.; Dewan, A. Sustainable hydrogen generation and storage—A review. RSC Adv. 2023, 13, 25253–25275. [Google Scholar] [CrossRef]

- Budsberg, E.; Crawford, J.T.; Morgan, H.; Chin, W.S.; Bura, R.; Gustafson, R. Hydrocarbon bio-jet fuel from bioconversion of poplar biomass: Life cycle assessment. Biotechnol. Biofuels 2016, 9, 170. [Google Scholar] [CrossRef]

- Howarth, R. Methane emissions and climatic warming risk from hydraulic fracturing and shale gas development: Implications for policy. Energy Emiss. Control Technol. 2015, 2015, 45–54. [Google Scholar] [CrossRef]

- Melnyk, O.; Shumylo, O.; Onishchenko, O.; Mykhailova, I.; Obniavko, T.; Korobko, T. Concept and Prospects for the Use of Hydrogen Fuel in Maritime Transport. Collect. Sci. Works Ukr. State Univ. Railw. Transp. 2023, 203, 96–105. [Google Scholar] [CrossRef]

- Bessarabov, D.; Wang, H.; Li, H.; Zhao, N. (Eds.) PEM Electrolysis for Hydrogen Production: Principles and Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar] [CrossRef]

- Sun, X.; Xu, K.; Fleischer, C.; Liu, X.; Grandcolas, M.; Strandbakke, R.; Bjørheim, T.S.; Norby, T.; Chatzitakis, A. Earth-Abundant Electrocatalysts in Proton Exchange Membrane Electrolyzers. Catalysts 2018, 8, 657. [Google Scholar] [CrossRef]

- Esposito, D.V.; Yim, K.; Fraga Alvarez, D.V.; Cohen, L.; Jin, J.; West, A.C.; Weimer, M.S.; Moulton, S.; Dameron, A.A.; Ayers, K.E.; et al. (Invited) Proton Exchange Membrane Electrolyzers Based on Sub-Micron Thick Membranes. ECS Meet. Abstr. 2023, MA2023-01, 2028. [Google Scholar] [CrossRef]

- Kassim, Z.; Shaffee, S.N.A.; Aminuddin, F.A.; Krishnan, R.K.; Ghapar, N.A.A.; Russell, L.; Perez, V.G.; Sarawagi, A. Improving Green Hydrogen Production through Proton Exchange Membrane Electrolyzer Simulation Study. In Proceedings of the SPE Gas & Oil Technology Showcase and Conference, Dubai, United Arab Emirates, 8 May 2024; SPE: Dubai, United Arab Emirates, 2024; p. D021S018R002. [Google Scholar] [CrossRef]

- Motupally, S.; Mishra, L.; Subramanian, V.R. (Digital Presentation) Modeling Water Transport in Proton Exchange Membrane Electrolyzers through First Principles. ECS Meet. Abstr. 2023, MA2023-02, 2158. [Google Scholar] [CrossRef]

- Zeng, Z.; Bliznakov, S.; Bonville, L.J.; Maric, R. Advanced Porous Transport Layers for PEM Water Electrolyzers: Impact of the Interfacial and Bulk Properties of the PTLs on the Electrolyzers Performance. ECS Meet. Abstr. 2023, MA2023-01, 2056. [Google Scholar] [CrossRef]

- Bliznakov, S.; Zeng, Z.; Ouimet, R.; Niedzwiecki, A.; Capuano, C.; Ayers, K.E.; Bonville, L.J.; Maric, R. (Invited) Innovative Membrane Electrode Assemblies for the Next Generation Proton Exchange Membrane Water Electrolyzers. ECS Meet. Abstr. 2023, MA2023-01, 1992. [Google Scholar] [CrossRef]

- Lettenmeier, P.; Wang, R.; Abouatallah, R.; Burggraf, F.; Gago, A.S.; Friedrich, K.A. Coated Stainless Steel Bipolar Plates for Proton Exchange Membrane Electrolyzers. J. Electrochem. Soc. 2016, 163, F3119–F3124. [Google Scholar] [CrossRef]

- Sun, C.; Wang, Y.; McMurtrey, M.D.; Jerred, N.D.; Liou, F.; Li, J. Additive manufacturing for energy: A review. Appl. Energy 2021, 282, 116041. [Google Scholar] [CrossRef]

- Kamal, M.; Rizza, G. Design for metal additive manufacturing for aerospace applications. In Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 67–86. [Google Scholar] [CrossRef]

- Sheoran, A.J.; Kumar, H.; Arora, P.K.; Moona, G. Bio-Medical applications of Additive Manufacturing: A Review. Procedia Manuf. 2020, 51, 663–670. [Google Scholar] [CrossRef]

- Lin, K.; Li, X.; Dong, H.; Du, S.; Lu, Y.; Ji, X.; Gu, D. Surface modification of 316 stainless steel with platinum for the application of bipolar plates in high performance proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2017, 42, 2338–2348. [Google Scholar] [CrossRef]

- Lin, K.; Qiao, J.; Gu, D.; Wang, H.; Shi, B.; Zhang, W.; Shan, J.; Xu, Y.; Tian, L. Active screen plasma nitriding of laser powder bed fusion processed 316L stainless steel for the application of fuel cell bipolar plates. Virtual Phys. Prototyp. 2023, 18, e2225490. [Google Scholar] [CrossRef]

- Lin, K.; Xu, Y.; Gu, D.; Shan, J.; Shi, K.; Zhang, W. Laser Powder Bed Fusion of Multifunctional Bio-inspired Vertical Honeycomb Sandwich Structures: For the Application of Lightweight Bipolar Plates of Proton Exchange Membrane Fuel Cells. Chin. J. Mech. Eng. 2024, 37, 102. [Google Scholar] [CrossRef]

- Lin, K.; Qiao, J.; Shi, K.; Dong, W.; Gu, D. Laser powder bed fusion of micro-channels for the application of proton exchange membrane fuel cell bipolar plates. CIRP J. Manuf. Sci. Technol. 2023, 43, 193–204. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021; Additive Fertigung—Grundlagen—Terminologie. ISO: Geneva, Switzerland, 2022.

- Suwanpreecha, C.; Manonukul, A. A Review on Material Extrusion Additive Manufacturing of Metal and How It Compares with Metal Injection Moulding. Metals 2022, 12, 429. [Google Scholar] [CrossRef]

- Meng, F.; Beretta, M.; Selema, A.; Sergeant, P.; Vleugels, J.; Desplentere, F.; Ferraris, E. Production and characterisation of filament-based Material Extrusion (MEX) additively manufactured copper parts. Procedia CIRP 2024, 121, 234–239. [Google Scholar] [CrossRef]

- Santos, C.; Gatões, D.; Cerejo, F.; Vieira, M.T. Influence of Metallic Powder Characteristics on Extruded Feedstock Performance for Indirect Additive Manufacturing. Materials 2021, 14, 7136. [Google Scholar] [CrossRef]

- Galantucci, L.M.; Pellegrini, A.; Guerra, M.G.; Lavecchia, F. 3D Printing of parts using metal extrusion: An overview of shaping debinding and sintering technology. Adv. Technol. Mater. 2022, 47, 25–32. [Google Scholar] [CrossRef]

- Asami, K.; Crego Lozares, J.M.; Ullah, A.; Bossen, B.; Clague, L.; Emmelmann, C. Material extrusion of metals: Enabling multi-material alloys in additive manufacturing. Mater. Today Commun. 2024, 38, 107889. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Romero Gutiérrez, A.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J. Effects of fused filament fabrication parameters on the manufacturing of 316L stainless-steel components: Geometric and mechanical properties. Rapid Prototyp. J. 2022, 28, 2004–2026. [Google Scholar] [CrossRef]

- Obadimu, S.O.; Kourousis, K.I. Shrinkage behaviour of material extrusion steel 316L: Influence of primary 3D printing parameters. Rapid Prototyp. J. 2022, 28, 92–101. [Google Scholar] [CrossRef]

- Ahn, J.; Doh, J.; Kim, S.; Park, S. Knowledge-Based Design Algorithm for Support Reduction in Material Extrusion Additive Manufacturing. Micromachines 2022, 13, 1672. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef]

- Martucci, A.; Aversa, A.; Lombardi, M. Ongoing Challenges of Laser-Based Powder Bed Fusion Processing of Al Alloys and Potential Solutions from the Literature—A Review. Materials 2023, 16, 1084. [Google Scholar] [CrossRef]

- Salmi, M. Additive Manufacturing Processes in Medical Applications. Materials 2021, 14, 191. [Google Scholar] [CrossRef]

- Dimopoulos, A.; Chryssinas, G.; Mavroforaki, D.; Gan, T.-H.; Chatzakos, P. An Interactive Web-Based Platform for Support Generation and Optimisation for Metal Laser Powder Bed Fusion. Materials 2024, 17, 1639. [Google Scholar] [CrossRef]

- Holder, D.; Henn, M.; Buser, M.; Hagenlocher, C.; Onuseit, V.; Graf, T. Bridging additive and subtractive manufacturing: Exceeding the limits of conventional manufacturing with combined continuous-wave and ultrafast lasers. PhotonicsViews 2024, 21, 50–53. [Google Scholar] [CrossRef]

- Kimm, J.; Hanke, S.; Weber, S.; Lentz, J. Processing of High Interstitial Austenitic Steel with Powder Bed Fusion-Laser Beam/Metal: Evolution of Chemical Inhomogeneity and Microstructural Features during Postprocessing. Adv. Eng. Mater. 2024, 26, 2301902. [Google Scholar] [CrossRef]

- Hunter, L.W.; Brackett, D.; Brierley, N.; Yang, J.; Attallah, M.M. Assessment of trapped powder removal and inspection strategies for powder bed fusion techniques. Int. J. Adv. Manuf. Technol. 2020, 106, 4521–4532. [Google Scholar] [CrossRef]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. J. Orthop. Res. 2016, 34, 369–385. [Google Scholar] [CrossRef]

- Huber, F.; Rasch, M.; Schmidt, M. Laser Powder Bed Fusion (PBF-LB/M) Process Strategies for In-Situ Alloy Formation with High-Melting Elements. Metals 2021, 11, 336. [Google Scholar] [CrossRef]

- Venkatesh Kumaran, S.; Torralba, J.M. Laser Powder Bed Fusion Processing of Low Cost CoCrFeNiMoxNby High Entropy Alloys with Promising High-Temperature Properties via In Situ Alloying Commercial Powders. Metals 2024, 14, 500. [Google Scholar] [CrossRef]

- Paillier, G.; Prätzsch, N. Beam shaping to tackle laser powder bed fusion challenges: Multi-plane light conversion to increase the printing speed and reduce hot-cracking. PhotonicsViews 2024, 21, 30–35. [Google Scholar] [CrossRef]

- Yin, W.; Guo, P.; Wei, J.; Peng, J.; Bian, N.; Xing, H. Development Status of Flow Field Design for Bipolar Plates in Hydrogen Fuel Cells. J. Eng. Res. Rep. 2024, 26, 250–261. [Google Scholar] [CrossRef]

- Balamurugan, C.; Jeno, S.; Adhikesavan, C.; Praveen, A. Design and Analysis of Bipolar Plates in Proton Exchange Membrane Fuel Cells Using Computational Fluid Dynamics Analysis; SAE International: Columbus, OH, USA, 2024; p. 2024-01-4324. [Google Scholar] [CrossRef]

- Asami, M.K.; Roth, S.; Hünting, J.; Röver, T.; Emmelmann, C. Metallic Bipolar Plate Production Through Additive Manufacturing: Contrasting MEX/M and PBF-LB/M Approaches; TUHH Universitätsbibliothek: Hamburg, Germany, 2025. [Google Scholar] [CrossRef]

- Marappan, M.; Palaniswamy, K.; Velumani, T.; Chul, K.B.; Velayutham, R.; Shivakumar, P.; Sundaram, S. Performance Studies of Proton Exchange Membrane Fuel Cells with Different Flow Field Designs—Review. Chem. Rec. 2021, 21, 663–714. [Google Scholar] [CrossRef]

- Koresawa, R.; Utaka, Y. Water control by employing microgrooves inside gas channel for performance improvement in polymer electrolyte fuel cells. Int. J. Hydrogen Energy 2015, 40, 8172–8181. [Google Scholar] [CrossRef]

- Seyhan, M.; Akansu, Y.E.; Murat, M.; Korkmaz, Y.; Akansu, S.O. Performance prediction of PEM fuel cell with wavy serpentine flow channel by using artificial neural network. Int. J. Hydrogen Energy 2017, 42, 25619–25629. [Google Scholar] [CrossRef]

- Barati, S.; Khoshandam, B.; Ghazi, M.M. An investigation of channel blockage effects on hydrogen mass transfer in a proton exchange membrane fuel cell with various geometries and optimization by response surface methodology. Int. J. Hydrogen Energy 2018, 43, 21928–21939. [Google Scholar] [CrossRef]

- Sun, F.; Su, D.; Yin, Y.; Pang, B.; Guo, J. Effects of Combined Baffles on the Proton Exchange Membrane Fuel Cell Performance. Int. J. Electrochem. Sci. 2022, 17, 221134. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, P.; Ren, J.; Jin, Z.; Han, X. Effect of flow channel shapes of proton exchange membrane fuel Cell on its performances. Int. J. Electrochem. Sci. 2022, 17, 220319. [Google Scholar] [CrossRef]

- Wang, C.-T.; Ou, Y.-T.; Wu, B.-X.; Thangavel, S.; Hong, S.-W.; Chung, W.-T.; Yan, W.-M. A modified serpentine flow slab for in Proton Exchange Membrane Fuel Cells (PEMFCs). Energy Procedia 2017, 142, 667–673. [Google Scholar] [CrossRef]

- Asami, K.; Herzog, D.; Bossen, B.; Klemp, C.; Geyer, L.; Emmelmann, C. Design Guidelines For Green Parts Manufactured From Stainless Steel In The Filament Based Material Extrusion Process For Metals (MEX|M). In World PM2022 Proceedings; EPMA: Lyon, France, 2022. [Google Scholar] [CrossRef]

- Asami, K.; Roth, S.; Krukenberg, M.; Röver, T.; Herzog, D.; Emmelmann, C. Predictive modeling of lattice structure design for 316L stainless steel using machine learning in the L-PBF process. J. Laser Appl. 2023, 35, 042046. [Google Scholar] [CrossRef]

- Technical Data Sheet m4pTM 316 l. Feistritz i.R. Available online: https://www.metals4printing.com/path/app/?qs_page=F2E685075C7378F5FE3FA2BE952763874D72F446&qs_productId=31D00E5751FA4C775C33275302EACA5B918A58C5# (accessed on 5 February 2025).

- Metall Filamente für FFF/FDM. Available online: http://www.pt-a.de/filament%20en.htm (accessed on 5 February 2025).

- Quarto, M.; Carminati, M.; D’Urso, G. Density and shrinkage evaluation of AISI 316L parts printed via FDM process. Mater. Manuf. Process. 2021, 36, 1535–1543. [Google Scholar] [CrossRef]

- Shaikh, M.Q.; Singh, P.; Kate, K.H.; Freese, M.; Atre, S.V. Finite Element-Based Simulation of Metal Fused Filament Fabrication Process: Distortion Prediction and Experimental Verification. J. Mater. Eng. Perform. 2021, 30, 5135–5149. [Google Scholar] [CrossRef]

- Singh, P.; Balla, V.K.; Atre, S.V.; German, R.M.; Kate, K.H. Factors affecting properties of Ti-6Al-4V alloy additive manufactured by metal fused filament fabrication. Powder Technol. 2021, 386, 9–19. [Google Scholar] [CrossRef]

- Asami, K.; Herzog, D.; Deutschmann, T.; Röver, T.; Kelbassa, I.; Emmelmann, C. Methodology for Cost Estimation Using Characteristic Factors in Additive Manufacturing. J. Jpn. Soc. Powder Powder Metall. 2025, 72, S75–S82. [Google Scholar] [CrossRef]

- Asami, M.K.; Herzog, D.; Deutschmann, T.; Röver, T.; Kelbassa, I.; Emmelmann, C. Cost Application for the Publication: Methodology for Cost Estimation Using Characteristic Factors in Additive Manufacturing; TUHH Universitätsbibliothek: Hamburg, Germany, 2024. [Google Scholar] [CrossRef]

- Ghorbani, J.; Koirala, P.; Shen, Y.-L.; Tehrani, M. Eliminating voids and reducing mechanical anisotropy in fused filament fabrication parts by adjusting the filament extrusion rate. J. Manuf. Process. 2022, 80, 651–658. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).